Page 1

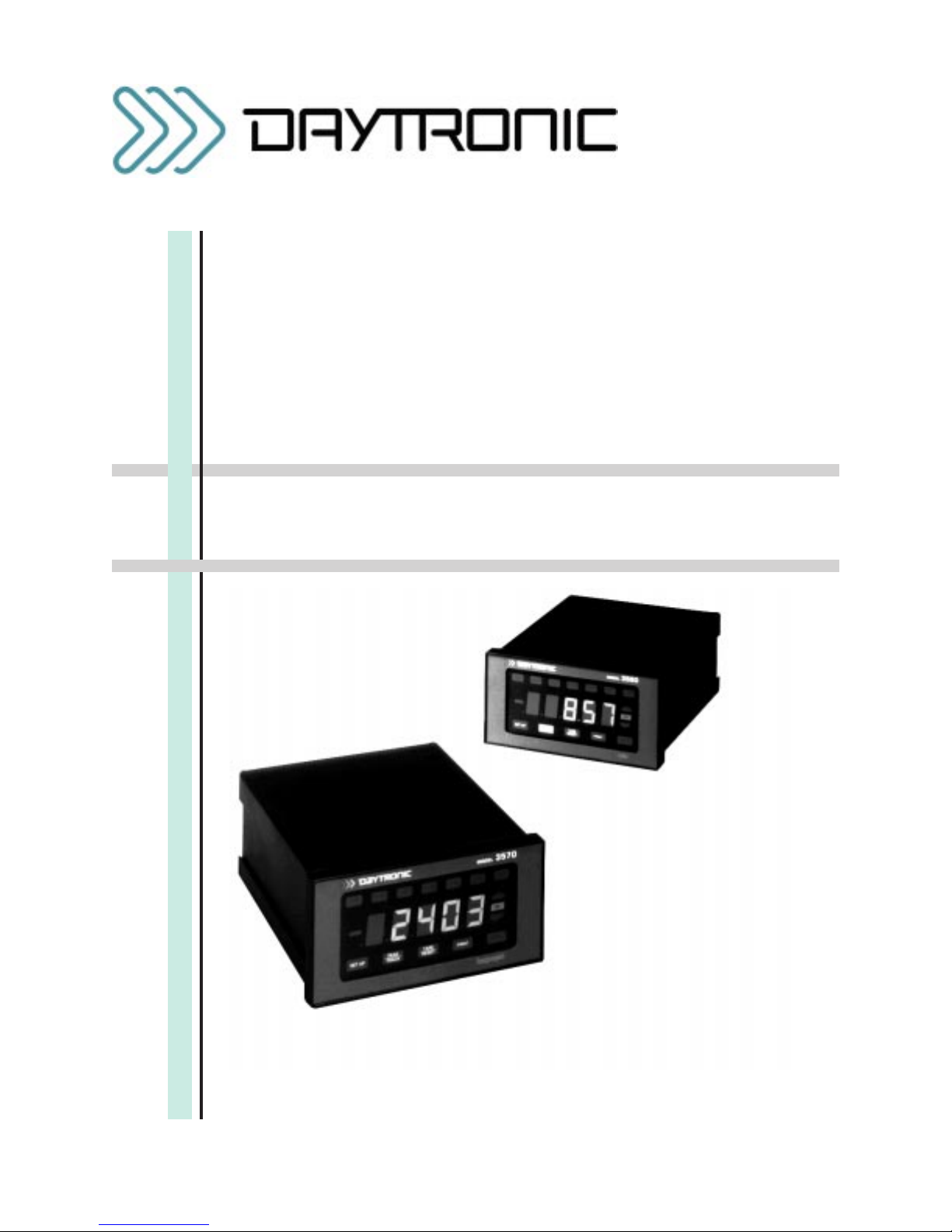

3500

INSTRUMENT SERIES

SB.3

INSTRUCTION MANUAL

Page 2

Copyright © 1997, Daytronic Corporation. All rights reserved.

No part of this document may be reprinted, reproduced, or used in any form or by

any electronic, mechanical, or other means, including photocopying and recording,

or in any information storage and retrieval system, without permission in writing from

Daytronic Corporation. All specifications are subject to change without notice.

Page 3

3500 Series Instruction Manual, v. SB.3

Pub. No. 3500M.3, Issued 1/97

3500

INSTRUMENT

SERIES

Part No. 91668

INSTRUCTION MANUAL

Daytronic Corporation

2211 Arbor Blvd. • Dayton, OH 45439-1521 • Tel (937) 293-2566 • Fax (937) 293-2586

www.daytronic.com

Page 4

C

ONTENTS

1INTRODUCTION

a. Using This Manual ........................................................................................................ 1.1

b. General Instrument Descriptions

1. Introduction ....................................................................................................................... 1.1

2. The Model 3510 Thermocouple Conditioner ....................................................... 1.2

3. The Model 3530 LVDT Conditioner .......................................................................... 1.2

4. The Model 3540 Frequency Input Conditioner .................................................... 1.2

5. The Model 3560 Voltage Conditioner ..................................................................... 1.3

6. The Model 3570 DC Strain Gage Conditioner ...................................................... 1.3

7. The Model 3578 AC Strain Gage Conditioner ...................................................... 1.3

c. Physical Layout .............................................................................................................. 1.4

d. Panel Mounting ...............................................................................................................1.6

e. Summary of Setup Button Functions ............................................................ 1.7

f. Summary of Logic I/O Functions ..................................................................... 1.8

g. Mnemonic Commands ............................................................................................. 1.9

2SETUP: CONNECTIONS AND POWER

a. Transducer Connections

1. The “Standard” Analog Input Connector ............................................................... 2.1

2. Connecting a Thermocouple to the Model 3510 ................................................ 2.1

3. Connecting an LVDT or Variable Reluctance Transducer

to the Model 3530 .......................................................................................................... 2.2

4. Connecting a Frequency Source to the Model 3540 ........................................ 2.4

5. Connecting a Voltage Source to the Model 3560 .............................................. 2.6

6. Connecting a DC Strain Gage Transducer to the Model 3570 ...................... 2.7

7. Connecting an AC Strain Gage Transducer to the Model 3578 .................... 2.8

b. RS-232 (“Single-Node”) Connections .......................................................... 2.10

c. RS-485 (“Multinode Network”) Connections ......................................... 2.12

d. Analog Output Connections .............................................................................. 2.15

e. Logic Input/Output Connections ................................................................... 2.16

f. Powerup ............................................................................................................................ 2.18

3SETUP: INSTRUMENT CONFIGURATION

a. Configuring Through the Front Panel

1. Entering and Exiting SETUP MODE .......................................................................... 3.1

2. Security Code .................................................................................................................. 3.2

3. RS-232 Communications Parameters: COM Key .............................................. 3.3

4. RS-485 Communications Parameters: COM Key .............................................. 3.7

5. Input Range: RANGE Key ........................................................................................... 3.8

a. Setting the Model 3510’s TC Type and Scale ................................................ 3.8

b. Setting the Model 3530’s LVDT Input Range .................................................. 3.9

c. Setting the Model 3540’s Frequency Input Range and Sensitivity ...... 3.10

d. Setting the Model 3560’s Voltage Input Range .......................................... 3.10

e. Setting the Model 3570’s DC Strain Gage Input Range

and Excitation .......................................................................................................... 3.11

f. Setting the Model 3578’s AC Strain Gage Input Range ........................... 3.11

iv

Page 5

C

ONTENTS

6. Filter: FILTER Key ......................................................................................................... 3.12

7. Analog Output: ANO Key .......................................................................................... 3.13

8. Limits: LIMIT Key .......................................................................................................... 3.14

9. Tare Offset: TARE Key ................................................................................................ 3.17

10. Print and Output Parameters: PRINT Key ........................................................... 3.18

b. Configuring Through the RS-232/485 Interface .................................. 3.20

1. Security Code ............................................................................................................... 3.20

2. Communications Parameters ................................................................................. 3.20

3. Thermocouple Type (Model 3510 ONLY) ........................................................... 3.21

4. Input Range or Scale .................................................................................................. 3.21

5. Excitation (Models 3570 and 3578 ONLY) .......................................................... 3.22

6. Sensitivity (Model 3540 ONLY) ............................................................................... 3.22

7. Filter .................................................................................................................................. 3.22

8. Analog Output .............................................................................................................. 3.23

9. Limits ................................................................................................................................ 3.23

10. Tare Offset ...................................................................................................................... 3.23

11. Print and Output Parameters ................................................................................... 3.23

4SETUP: INSTRUMENT CALIBRATION

a. Introduction: Calibration Techniques ............................................................ 4.1

1. Absolute Calibration ...................................................................................................... 4.1

2. “Actual” Two-Point (Deadweight) Calibration ....................................................... 4.2

3. “Simulated” Two-Point (Deadweight) Calibration ............................................... 4.2

4. Internal 15-Segment Linearization ........................................................................... 4.3

5. Calculated Calibration .................................................................................................. 4.3

6. Calculated Calibration Via Mnemonic Command .............................................. 4.3

b. Phase and Symmetry Adjustment of the

Model 3578 AC Strain Gage Conditioner .................................................... 4.4

c. Calibrating Through the Front Panel

1. Using the CAL Key ......................................................................................................... 4.8

2. “Actual” Two-Point (Deadweight) Calibration ....................................................... 4.8

3. “Simulated” (Shunt) Calibration for a Strain Gage Conditioner

(Model 3570 or 3578) ................................................................................................. 4.10

4. 15-Segment Linearization

a. Introduction .............................................................................................................. 4.12

b. By “TABLE” ............................................................................................................... 4.13

c. By “FORCE” .............................................................................................................. 4.15

5. “Calculated” Calibration

a. For the Models 3510, 3530, 3540, and 3560 ............................................... 4.16

b. For the Model 3570 (ONLY) ............................................................................... 4.17

d. Calibrating Through the RS-232/485 Interface .................................... 4.18

1. Setting the Active Calibration Method .................................................................. 4.18

2. “Two-Point” Calibration .............................................................................................. 4.19

3. 15-Segment Linearization ........................................................................................ 4.19

4. “Calculated” Calibration ............................................................................................ 4.20

v

Page 6

C

ONTENTS

5RUN-TIME OPERATION

a. RS-232/485 Communications

1. RS-232/485 Outputs: CHN and DMP Commands ............................................ 5.1

2. Data-Transmission Format ......................................................................................... 5.1

3. “Opening” a Node to Receive Commands from the Computer ................... 5.2

b. Peak Capture ................................................................................................................... 5.3

c. Tare and Reset ................................................................................................................ 5.5

d. Initiating Hard-Copy Printouts ............................................................................. 5.6

e. Track/Hold Function .................................................................................................. 5.7

Appendix A 3500 SERIES SPECIFICATIONS

1. General Specifications ........................................................................................... A.1

2. Individual Conditioner Specifications

a. Model 3510 Thermocouple Conditioner .............................................................. A.2

b. Model 3530 LVDT Conditioner ................................................................................. A.3

c. Model 3540 Frequency Input Conditioner ........................................................... A.4

d. Model 3560 Voltage Conditioner ............................................................................. A.5

e. Model 3570 DC Strain Gage Conditioner ............................................................. A.6

f. Model 3578 AC Strain Gage Conditioner ............................................................. A.7

Appendix B COMMAND AND RESPONSE SYNTAX

1. Introduction: RS-232 and RS-485 Modes .................................................... B.1

2. The OPEN (OPN) Command ................................................................................ B.1

3. Response to “Invalid” Commands ................................................................. B.1

4. Setup Commands ....................................................................................................... B.2

5. Interrogation Commands ...................................................................................... B.2

6. Imperative Commands ............................................................................................ B.2

7. Commands That Initiate Data Transmissions ....................................... B.3

8. Table of Mnemonic Commands ....................................................................... B.3

Appendix C TABLE OF ERROR NUMBERS ...................................... C.1

Appendix D NETWORKING GUIDELINES ........................................... D.1

Appendix E RUN-TIME BUTTON FUNCTIONS ............................. E.1

Appendix F STANDARD LOGIC CONFIGURATION ................... F.1

vi

Page 7

C

ONTENTS

Illustrations

1(a) Typical “Run-Time” Display ........................................................................................... 1.4

1(b) Typical “Setup” Display .................................................................................................. 1.4

2(a) Rear Panel for the Model 3510 Thermocouple Conditioner

and the Model 3578 AC Strain Gage Conditioner ................................................ 1.5

2(b) Rear Panel for All Other 3500 Models ...................................................................... 1.6

3 Panel Mounting ................................................................................................................. 1.6

4 Use of NUMERIC BUTTONS in SETUP MODE ...................................................... 1.8

5(a) Standard Logic INputs and Outputs ......................................................................... 1.8

5(b) Shunt-Control Logic Inputs for the Model 3570 DC Strain Gage

Conditioner (ONLY) ..........................................................................................................1.9

6 Model 3510 Transducer Cabling ............................................................................... 2.2

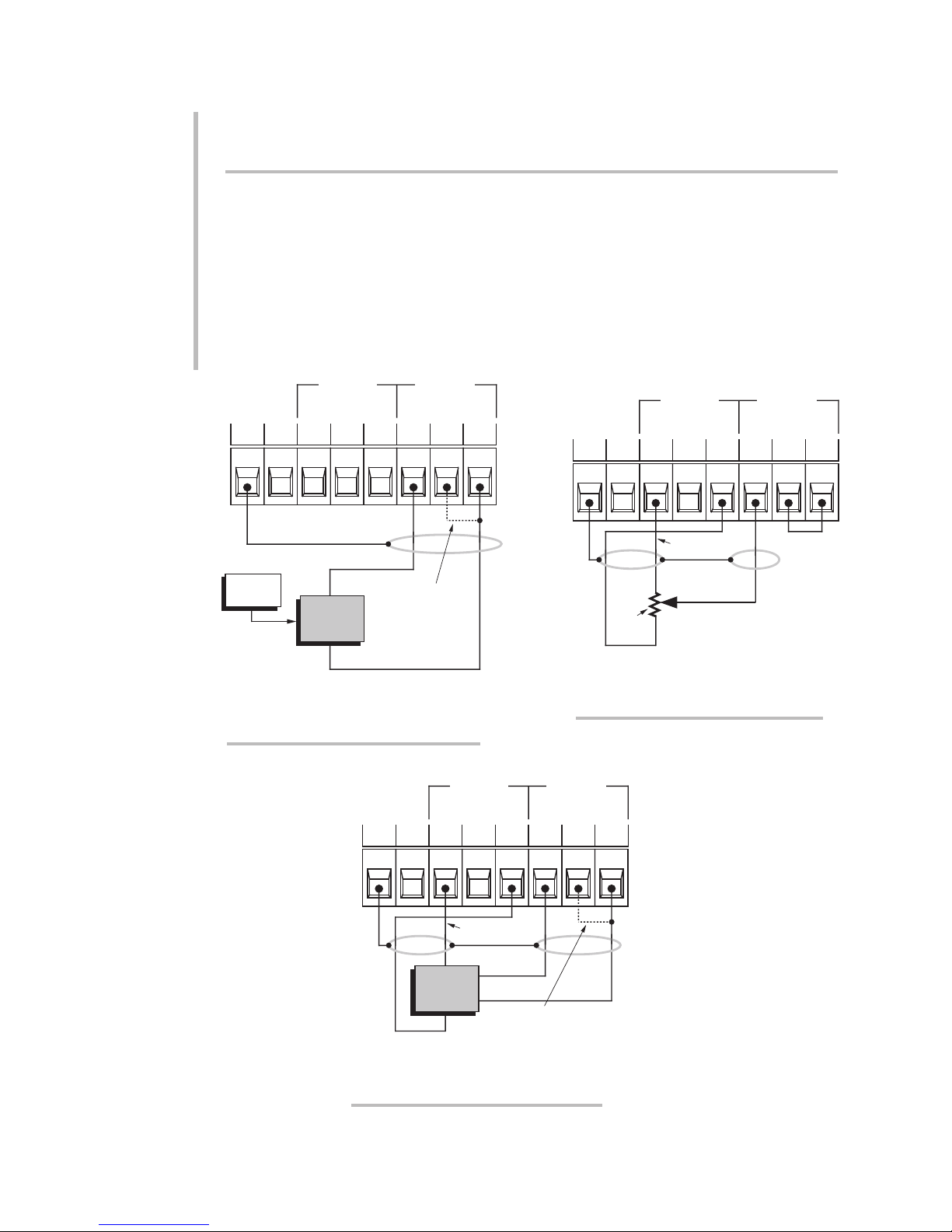

7(a) Model 3530 Transducer Cabling: 5-Wire LVDT Cabling

(under 20 ft. in length) .................................................................................................... 2.3

7(b) Model 3530 Transducer Cabling: 7-Wire LVDT Cabling (20 ft. or longer) ... 2.3

7(c) Model 3530 Transducer Cabling: 3-Wire Variable Reluctance Cabling

(under 20 ft. in length) .................................................................................................... 2.3

7(d) Model 3530 Transducer Cabling: 5-Wire Variable Reluctance Cabling

(20 ft. or longer) ................................................................................................................ 2.4

8(a) Model 3540 Transducer Cabling: Differential (Floating) Frequency Input .. 2.5

8(b) Model 3540 Transducer Cabling: Single-Ended (Grounded) Frequency

Input ...................................................................................................................................... 2.5

8(c) Model 3540 Transducer Cabling: Input from a Zero-Velocity Sensor .......... 2.5

8(d) Model 3540 Transducer Cabling for Elimination of DC Offset ........................ 2.5

8(e) Model 3540 Transducer Cabling for Suppression of High-Frequency

Noise .................................................................................................................................... 2.5

9(a) Model 3560 Transducer Cabling: General Voltage Source ............................. 2.6

9(b) Model 3560 Transducer Cabling: External Potentiometer ............................... 2.6

9(c) Model 3560 Transducer Cabling: External DC-to-DC LVDT ............................. 2.6

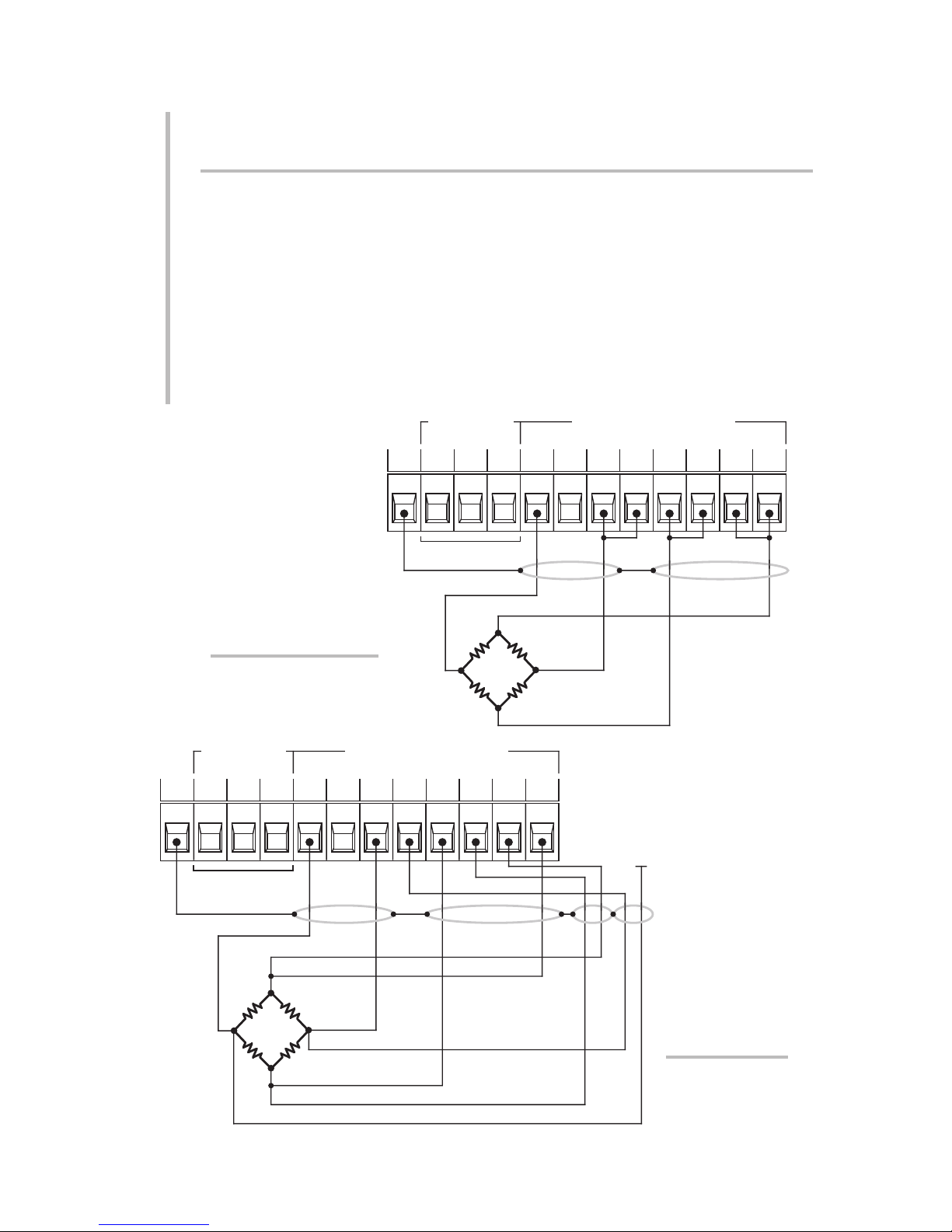

10(a) Model 3570 Transducer Cabling: 4-Wire Cabling (under 20 ft. in length) ... 2.7

10(b) Model 3570 Transducer Cabling: 8-Wire Cabling (20 ft. or longer) .............. 2.7

11(a) Model 3578 Transducer Cabling: 4-Wire Cabling (under 20 ft. in length) ... 2.8

11(b) Model 3578 Transducer Cabling: 8-Wire Cabling (20 ft. or longer) .............. 2.8

11(c) Model 3578 Transducer Cabling: Installation of User’s External Shunt

Calibration Resistor ......................................................................................................... 2.9

11(d) Model 3578 Transducer Cabling: 8-Wire Cabling to LEBOW 1600

SERIES TRANSDUCER (ONLY) ................................................................................... 2.9

12 Suggested RS-232-C Interface Connections (to 25-Pin RS-232-C

Connector) ....................................................................................................................... 2.11

13 Suggested RS-232-C Interface Connections (to 9-Pin RS-232-C

Connector) ....................................................................................................................... 2.12

14(a) Connections for a Network of Three Instrument Nodes

(where the first is a 3500 Series Instrument) ...................................................... 2.13

14(b) RS-485 Cabling Between the Model 5E485 and the FIRST Network

Node (if it is a 3500 Series Instrument) ................................................................. 2.14

14(c) RS-485 Cabling Between Successive 3500 or 4000 Instrument Nodes .. 2.14

14(d) RS-485 Cabling Between a 3500 or 4000 Instrument Node and a

5000 Instrument Node ................................................................................................ 2.14

15 Analog Output Programming Pins .......................................................................... 2.15

16 Analog Output Connections (ALL Conditioners) ............................................... 2.16

(cont’d)

vii

Page 8

C

ONTENTS

17(a) Logic I/O Connections: Input from External Switch .......................................... 2.17

17(b) Logic I/O Connections: External TTL Logic ......................................................... 2.17

17(c) Logic I/O Connections: External Controller ......................................................... 2.17

17(d) Logic I/O Connections: Output to External Relay .............................................. 2.18

18 Limit Zones ...................................................................................................................... 3.15

19 High and Low Hysteresis Windows ........................................................................ 3.16

20 Symmetry and Phase Adjustment Controls for the Model 3578 ................... 4.4

21 Typical Linearization Curve with Seven Segments .......................................... 4.12

22 Capture and Hold of Successively Higher-Valued Maxima ............................ 5.4

23 Capture and Hold of Successively Lower-Valued Maxima Using

Peak Reset ......................................................................................................................... 5.4

24 Tare Offset Operation .................................................................................................... 5.5

25 3500 Physical Dimensions .......................................................................................... A.1

viii

Page 9

INTRODUCTION

1.a USING THIS MANUAL

THIS MANUAL TREATS ALL SIX STANDARD MODELS BELONGING TO THE

DAYTRONIC 3500 INSTRUMENT SERIES. THESE MODELS ARE AS FOLLOWS:

• the Model 3510 Thermocouple Conditioner

• the Model 3530 AC LVDT Conditioner

• the Model 3540 Frequency Input Conditioner

• the Model 3560 Voltage Conditioner

• the Model 3570 DC Strain Gage Conditioner

• the Model 3578 AC Strain Gage Conditioner

EXCEPT WHERE OTHERWISE STATED, THE INFORMATION IN THIS MANUAL

APPLIES EQUALLY TO ALL SIX MODELS.

DESCRIPTIONS, PROCEDURES, AND OPERATIONS SPECIFIC TO A GIVEN

MODEL OR MODELS WILL BE CLEARLY IDENTIFIED AS SUCH.

1.b GENERAL INSTRUMENT DESCRIPTIONS

1

1.b.1 INTRODUCTION

Every 3500 Series instrument can be completely set up and operated either

through the front-panel keypad or via simple mnemonic commands received

from an external computer or terminal through its RS-232/485 Interface Port.

The instrument can transmit data from this port in response to an interrogation

from an external computer, or can send it to an RS-232 serial printer when the

PRINT button is pressed (assuming that it is set to RS-232 mode). When in RS485 mode, a given 3500 instrument can represent one of up to 99 data-collection

"nodes" of a high-speed multidrop network.

Features common to all models include

• continuous dual-limit monitoring with front-panel annunciation, programmable

hysteresis windows, and TTL-level logic control outputs

• front-panel security code

• real-time positive peak capture or track/hold operation

• user-settable automatic tare offset

• internal 15-segment linearization for calibration of nonlinear inputs (except for

the Model 3510 Thermocouple Conditioner)

• selectable digital filtering

• selectable analog filtering (except for the Model 3510 Thermocouple Condi-

tioner)

• scalable analog output to drive strip-chart recorders or other devices (it may

also be used as feedback for a PID control loop)

• data-transmission formatting options, including "header" and "tailer" character

strings, node-number "echo," and limit-status indication

1.a USING THIS MANUAL 1.b GENERAL INSTRUMENT DESCRIPTIONS

1.1

Page 10

1

INTRODUCTION

• logic-input control of peak capture, unlatching of latched limit conditions,

application of tare offset, and initiation of hard-copy printout

For complete specifications, see Appendix A.

1.b.2 THE MODEL 3510 THERMOCOUPLE CONDITIONER

This instrument accepts a temperature signal from a Type B, E, J, K, R, S, or T

Thermocouple. The sensor may be grounded or ungrounded. The conditioner

employs "absolute" calibration, which means that no calibration is required by the

user, once the proper "TC Type" is entered. During operation, appropriate reference-junction compensation, digital linearization, and engineering-unit scaling are

automatically applied. Detection of "open" thermocouples is also provided.

The 3510’s special rear connector assembly contains a thermistor for precise

measurement of the reference-junction temperature. Therefore, no external cold

junction is required—although the user may supply his own Controlled Ambient

Temperature Zone for reference-junction purposes, if desired.

1.b.3 THE MODEL 3530 LVDT CONDITIONER

This instrument measures displacement, force, pressure, and other parameters

obtained with a 5- or 7-wire linear variable differential transformer (LVDT)

capable of 3280-Hz operation and having primary impedance of 80 Ω or greater.

It can also be used with a 3- or 5-wire variable reluctance transducer. The

"normal" input range can be 0-150, 0-300, or 0-600 mV/V, full scale. Input provisions also exist for "long-stroke" LVDT's (0-1, 0-2, or 0-4 V/V, full scale). Nominal 3

V-AC (rms) excitation is supplied.

1.b.4 THE MODEL 3540 FREQUENCY INPUT CONDITIONER

This instrument is used for measurement of flow, rpm, and other phenomena that

can be sensed by pulse transformer transducers with two-wire isolated windings

(tachometer pickups, turbine flowmeters, etc.), transistor or logic-circuit drivers,

"zero-velocity" (true digital output) sensors, and similar frequency-generating

transducers. It will accept any AC or unipolar pulse signal, floating or grounded,

irrespective of waveform. Input range is from 10% to 100% of 250, 500, 1000,

2000, 4000, 8000, 16000, or 32000 Hz.

The 3540’s analog-input threshold level is selectable to accommodate signals

from 100 mV to 100 V, thus guaranteeing reliable triggering when the input is at

the low end of the frequency range. Capacitive coupling of 0.1 µF is provided for

low-frequency inputs, to eliminate false triggering by signal noise or any DC offset

that exists for the frequency signal. For "zero-velocity" sensors, an excitation of

nominal ±5 V-DC ± 5% is supplied.

When you know the manufacturer-supplied full-scale rating of the frequency

source (or the highest frequency expected to be measured), the Model 3540’s

measurement channel can be quickly calibrated by issuing an "FRQ" command

through the RS-232/485 Interface Port.

1.2

1.b GENERAL INSTRUMENT DESCRIPTIONS

Page 11

INTRODUCTION

1.b.5 THE MODEL 3560 VOLTAGE CONDITIONER

This is a general-purpose instrument for conditioning, displaying, and monitoring

the signal received from a DC-to-DC LVDT, potentiometer-type sensor, or other

external two-wire voltage source, either floating (differential) or grounded (single-ended). The input signal may also represent output from some other instrument system. Allowable full-scale voltage ranges are ±0.5, ±1.0, ±2.0, ±5.0, ±10.0,

and ±20.0 V-DC (up to ±100 V without damage). A ±12-V excitation is supplied for

sources that require it.

1.b.6 THE MODEL 3570 DC STRAIN GAGE CONDITIONER

This is a general-purpose instrument for input of pressure, force, torque, weight,

and other variables measured by conventional DC-excited strain gage trans-

ducers. It accepts a single input from any conventional 4-arm strain gage bridge,

nominal 120 ohms or higher, with a full-scale range of 0.75, 1.5, or 3.0 mV/V.

(User-supplied bridge-completion circuitry allows input from a 2-wire 1/4-bridge,

3-wire 1/4-bridge, or 1/2-bridge gage configuration.) The user may select a nominal excitation level of 2, 5, or 10 V-DC. Remote sensing of bridge voltage yields

consistently stable ratiometric measurement, unaffected by possible power-supply drift.

1

Simple two-point "zero and span" calibration is provided for the 3570’s input

channel. In addition, a 100-kΩ, 0.1% shunt resistor is supplied. You can use this

resistor—or one of your own—to apply an "equivalent input" for calibration purposes, when the transducer's full-scale mV/V sensitivity is accurately known. The calibration shunt may be switched in and out for either a positive or negative

up-scale reading via simple commands issued to the RS-232/485 port or by

means of logic-level command signals through the rear Analog Input Connector.

A third calibration technique for the Model 3570 involves application of an "MVV"

command through the RS-232/485 Interface Port when both "mV/V" sensitivity

and corresponding full-scale rating of the transducer are known.

1.b.7 THE MODEL 3578 AC STRAIN GAGE CONDITIONER

This instrument is similar to the Model 3570 DC Strain Gage Conditioner, above,

but is of phase-sensitive carrier-amplifier design. Intended for applications involv-

ing transformer-coupling to the transducer bridge (as with rotary-transformer

torque sensors), it can also be used when high sensitivity is required or where

the electrical environment is especially noisy. Responding only to the modulated

carrier frequency, the 3578 rejects extraneous voltages that can cause errors in

DC systems, particularly when there is a need to "blow up" a portion of the transducer range.

The Model 3578 accepts input from a 4-arm bridge of nominal 90 ohms or higher,

and a full-scale range of 0.75, 1.50, or 3.00 mV/V. Excitation is fixed at 3 V-AC

(rms) at 3280 Hz. There are user-settable phase and symmetry controls. This

conditioner also offers the same shunt calibration provisions as the 3570, except

that shunt calibration of the AC Strain Gage Conditioner cannot be controlled via

logic-input commands.

1.b GENERAL INSTRUMENT DESCRIPTIONS

1.3

Page 12

1

INTRODUCTION

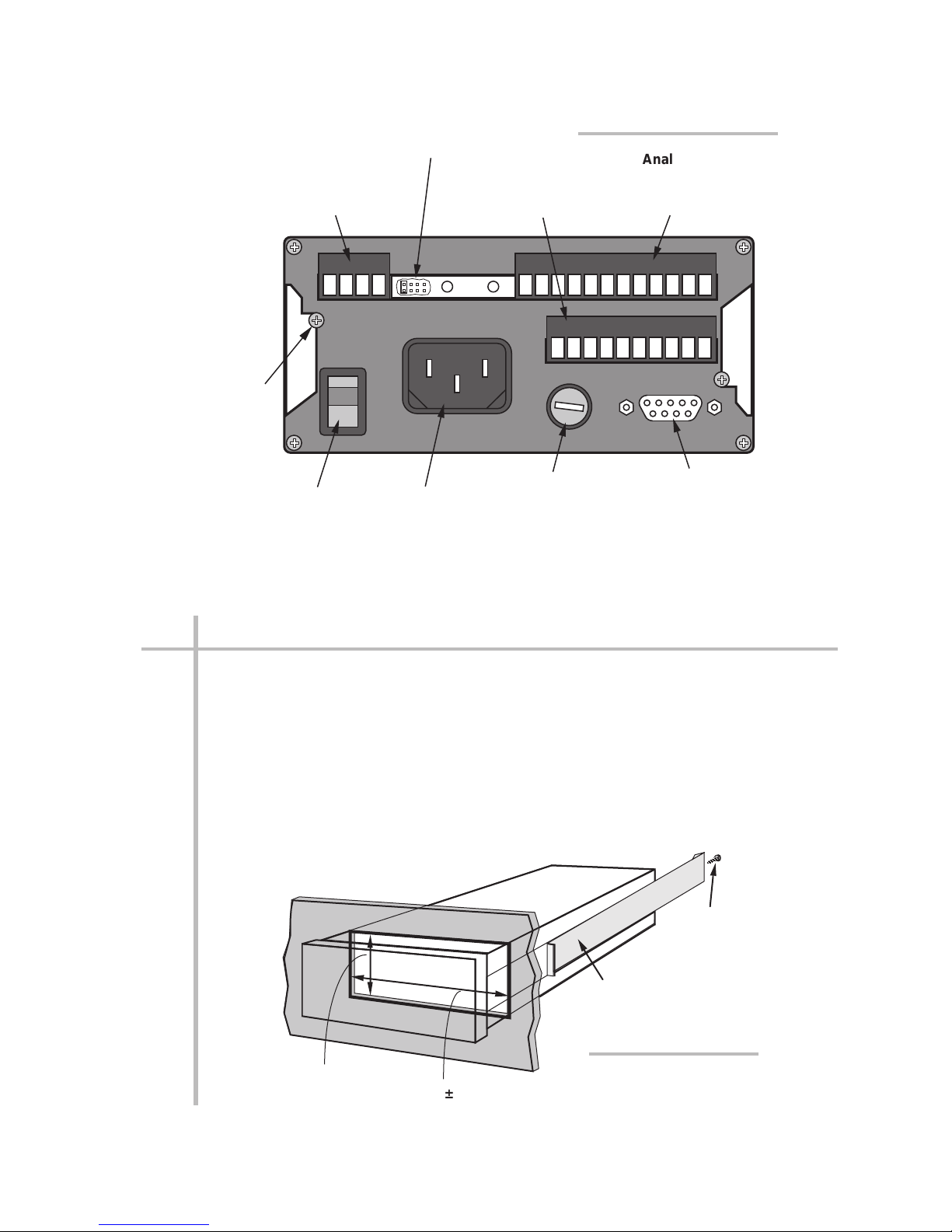

1.c PHYSICAL LAYOUT

Study the following diagrams to acquaint yourself with the most important front

and rear elements.

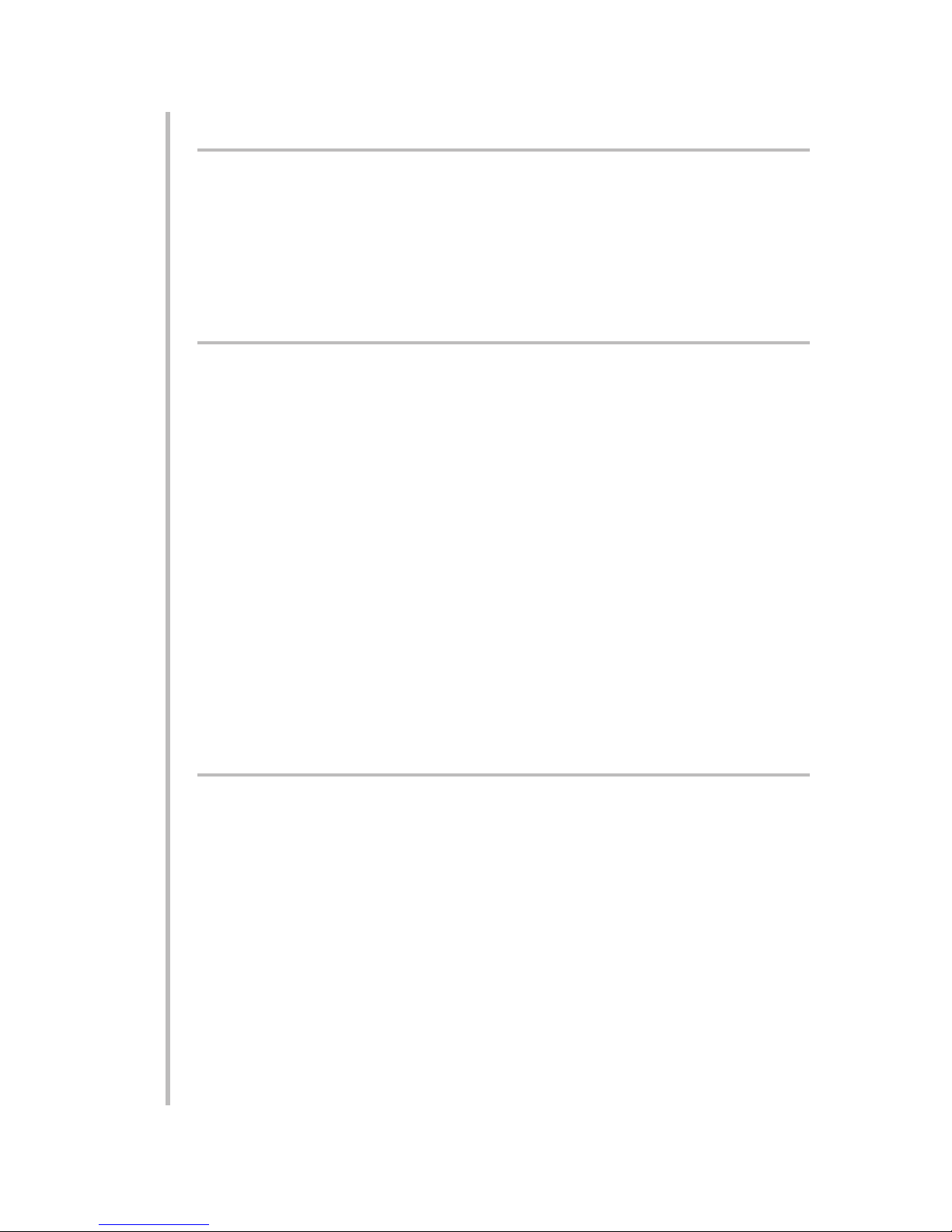

Fig. 1(a) shows a typical "RUN-TIME" display, with "live" data and limit-status

annunciation. Note the four front-panel buttons that are active (but not necessarily lit) during normal run-time operation. For a full description of run-time button

functions, see Appendix E.

Fig. 1(b) shows a typical SETUP display—specifically, the display that appears

after the security code has been entered and the unit is ready for any of the frontpanel setup procedures given in Sections 3.a and 4.a.

Fig. 1(a) Typical “Run-Time” Display

RANGE

COM

CAL FILTER ANO

Active Run-Time Buttons

Active Setup

Buttons are lit

Setup message or

parameter value

"Live" Data

Display

"Live" Limit

Status Indicators

DEC

LIMIT

HI

OK

LO

ENTER

"DEC" button lights when

decimal-point location of

setup parameter can be

changed

Fig. 1(b) Typical “Setup” Display

1.4

1.c PHYSICAL LAYOUT

COM

SET UP

RANGE

CAL FILTER ANO

PEAK

TRACK

TARE

RESET

DEC

PRINT ENTER

LIMIT

HI

OK

LO

Limit Status Indicators

updated with every change

of the display

Page 13

INTRODUCTION

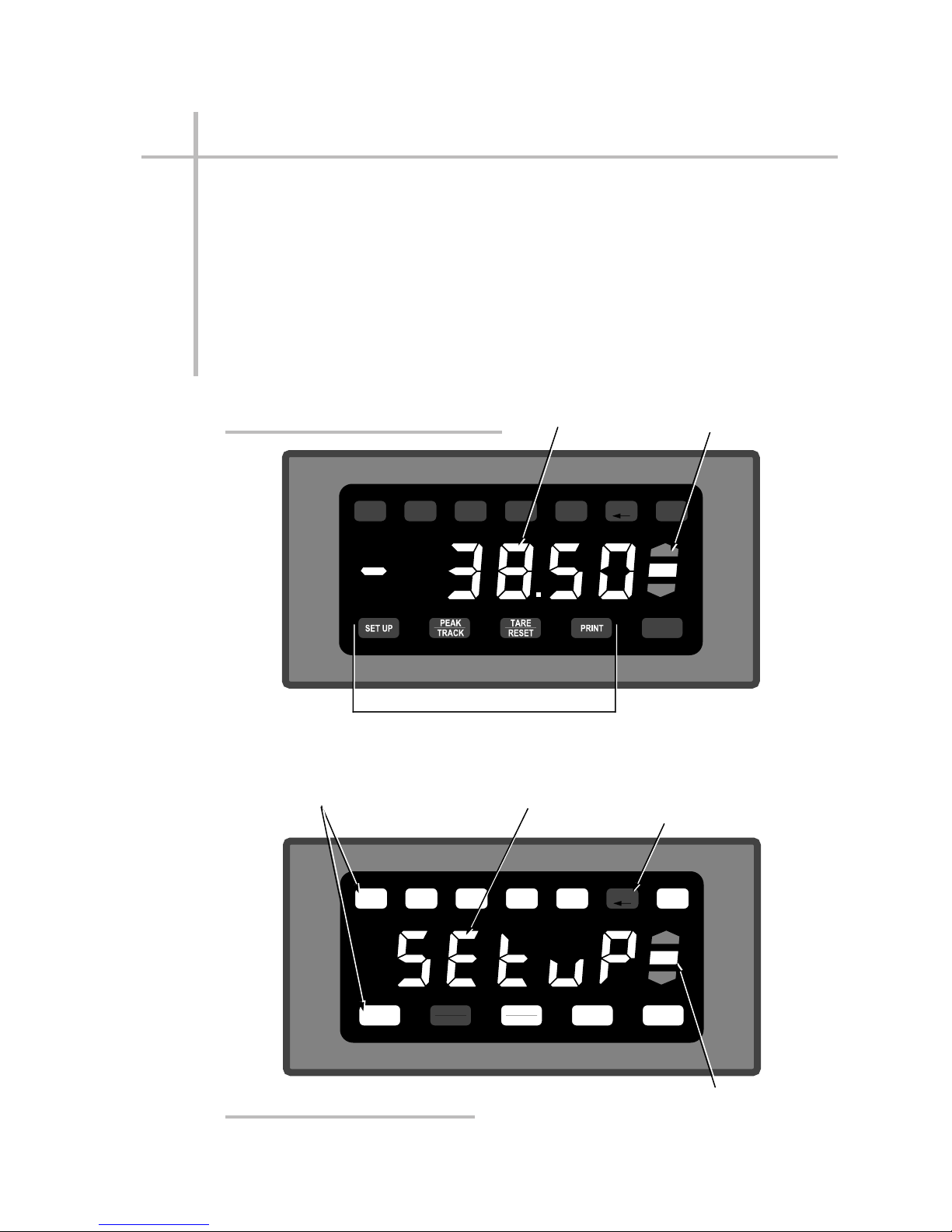

Analog Output

Connector

(see Fig. 16)

Conditioner Connector

—attaches to Analog

Input Board

(see Fig. 6 or 11)

Logic I/O

Connector

(see Figs. 5, 17)

Fuse

(0.5-amp SLO-

BLO)

ON-OFF

Switch

AC Power

Connector

RS-232/485 Inter-

face Connector

(see Figs. 12 - 14)

PanelMount

Clamp

Screw

ON

OFF

+

+

Analog Output

Programming Pins*

(behind cover plate—see Fig. 15)

Symmetry and

Phase Controls*

(see Fig. 20)

* Not present on the Thermocouple Conditioner.

NOTE: Your instrument is supplied with a large assortment of standard engineering unit legends on a 4" x 5 1/2" dry transfer sheet. The selected legend may be

rubbed directly onto the instrument's front-panel frame using the tip of a ball-point

pen or the blunt end of a stylus or other burnishing tool. DO NOT PRESS TOO

HARD. You can easily make up your own legends, since the sheet includes individual numerals, upper- and lower-case letters, ampersand ("&"), and Greek "∆,"

"ø," "µ," and "π."

The two rear panel types are shown below. The Model 3510 Thermocouple

Conditioner and the Model 3578 AC Strain Gage Conditioner have the rear

panel illustrated in Fig. 2(a). Each of these instruments employs a special CONDITIONER CONNECTOR that attaches directly to the rear edge of the unit's internal

Analog Input Board. In addition, the 3578 (only) has rear-panel Symmetry and

Phase Controls. All other models use a standard "clip-on" Analog Input Connector like that shown in Fig. 2(b).

1

Fig. 2(a) Rear Panel for the Model 3510 Thermocouple

Conditioner and the Model 3578 AC Strain Gage Conditioner

1.c PHYSICAL LAYOUT

1.5

Page 14

1

Analog Output

Connector

(see Fig. 16)

Analog Input

Connector**

(see Fig. 7, 8, 9,

or 10)

Logic I/O

Connector

(see Figs. 5, 17)

Fuse

(0.5-amp SLO-

BLO)

ON-OFF

Switch

AC Power

Connector

RS-232/485 Inter-

face Connector

(see Figs. 12 - 14)

PanelMount

Clamp

Screw

ON

OFF

+

+

Analog Output

Programming Pins*

(behind cover plate—see Fig. 15)

+

Not present on the Frequency Conditioner.

The number of connector terminals will vary with the conditioner type.

*

**

138 ± 1.0 mm

(5.43 ± 0.04 in)

68 ± 0.7 mm

(2.68 ± 0.03 in)

CLAMP SLIDE

CLAMP

SCREW

INTRODUCTION

Fig. 2(b) Rear Panel for All

Other 3500 Series Models

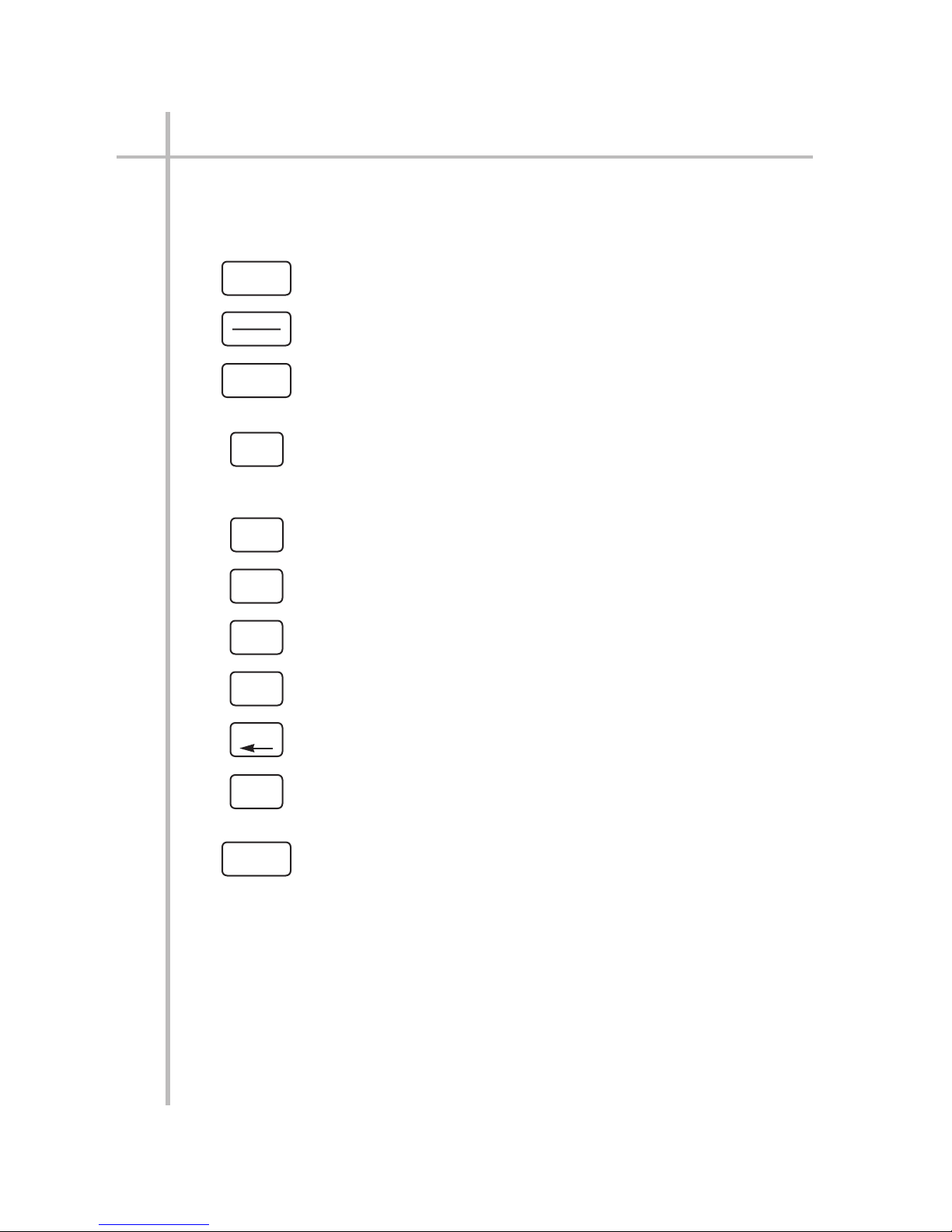

1.d PANEL MOUNTING

You can easily mount the instrument in your own precut panel. Cutout dimensions for a panel-mounted unit are standard DIN (see Fig. 3); panel thickness

should not exceed 6 mm (0.24 in).

Simply unscrew the two rear-panel CLAMP SCREWS and slide the CLAMP

SLIDES rearwards out of their grooves (THE FRONT BEZEL NEED NOT BE

REMOVED). Insert the unit through the panel cutout, from the front of the panel (if

the unit has rubber feet, these will have to be removed). Then reinstall the

CLAMP SLIDES, and tighten the CLAMP SCREWS until the instrument is securely

mounted.

Fig. 3 Panel Mounting

1.6

1.d PANEL MOUNTING

Page 15

INTRODUCTION

1.e SUMMARY OF SETUP BUTTON FUNCTIONS

The use of the SETUP buttons is explained in detail in Sections 3.a and 4.a. The

following table summarizes the relevant functions:

Button Button Function (in SETUP MODE):

1

SET UP

TARE

RESET

PRINT

COM

RANGE

CAL

FILTER

ANO

Used to exit current setup procedure ("COM," "RANGE," "CAL,"

etc.) or to exit SETUP MODE.

Used to enter a value into the TARE REGISTER.

Used to enter desired PRINT AND OUTPUT PARAMETERS:

printing interval; node-number "echo" (ON/OFF); and limit-status indication (ON/OFF).

Used to enter desired COMMUNICATIONS PARAMETERS:

baud rate; number of data bits; number of stop bits; parity;

node number; INPUT TERMINATOR character; and OUTPUT

TERMINATOR character(s).

Used to enter desired INPUT RANGE or SCALE, plus other

parameters, where applicable (EXCITATION, SENSITIVITY, etc.)

Used for CALIBRATION of the analog input ("Two-Point," "Linearization," or "Calculated").

Used to set the ANALOG and DIGITAL FILTERS.

Used to scale the ANALOG OUTPUT.

DEC

LIMIT

ENTER

In addition to the above SETUP buttons, the instrument provides two NUMERIC

BUTTONS for each displayed character of the LCD display, plus a polarity "sign"

button. These buttons let you change the value of a displayed number or step

forwards or backwards through a displayed series of allowed setup values. In

general, to increase by "1" the numeric value of a displayed digit (up to a maximum of "9"), press the TOP LCD SEGMENT of that digit, whether or not it is lit. To

decrease by "1" the numeric value of a displayed digit (down to a minimum of "0"),

press the BOTTOM LCD SEGMENT of that digit, whether or not it is lit. To change

the polarity of the displayed number, press the "minus-sign" segment at the

extreme left of the display (whether or not it is lit). The NUMERIC BUTTONS are

only active when the instrument is in SETUP MODE.

Used to change DECIMAL-POINT LOCATION for certain setup

values.

Used to enter LIMIT PARAMETERS: high limit; high hysteresis;

high latch (ON/OFF); low limit; low hysteresis; low latch

(ON/OFF).

Used to display the "existing value" of a setup parameter and

to finalize entry of a modified value.

1.e SUMMARY OF SETUP BUTTON FUNCTIONS

1.7

Page 16

1

SET UP

TARE

RESET

PRINT ENTER

HI

OK

LO

COM

RAN

FILTER ANO

DEC

LIMIT

Press top segment to

increment digit (up to "9")

Press bottom segment to

decrement digit (down to "0")

Press "–"

segment to

change polarity

INTRODUCTION

Fig. 4 Use of

NUMERIC

BUTTONS in

SETUP MODE

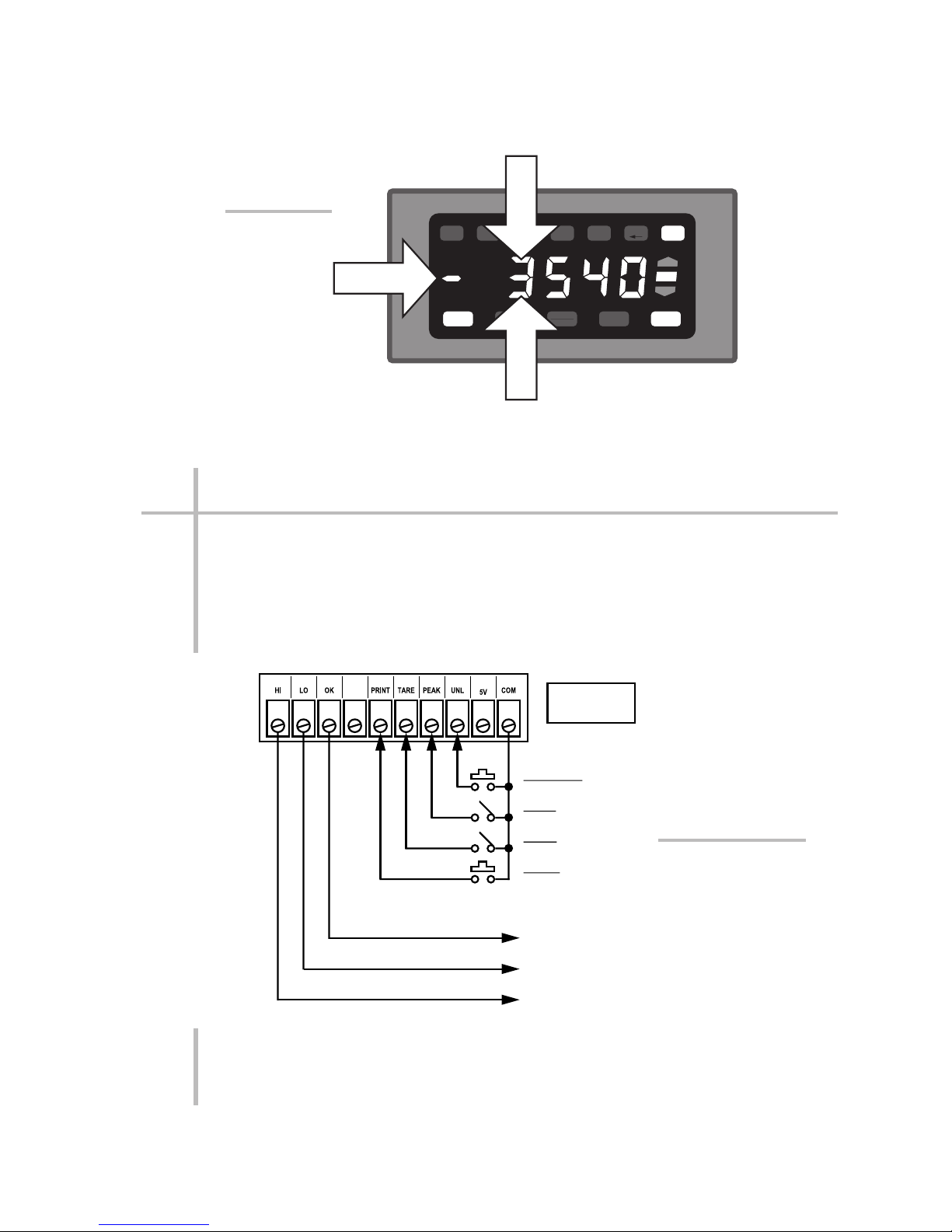

1.f SUMMARY OF LOGIC I/O FUNCTIONS

The rear-panel LOGIC I/O CONNECTOR provides seven active logic input/output

bits in open-collector, negative-true form, where the "Logic 1" state is defined as

nominal 0 V-DC and "Logic 0" as nominal +5 V-DC. The standard logic I/O configuration is shown in Fig. 5(a), below, with reference to the 10-terminal Logic I/O

Connector on the rear of the unit. For recommended logic interconnections, see

Section 2.e. Each I/O function is fully described in Appendix F.

+

*

PLEASE NOTE: THE MINIMUM TIME ALLOWED BETWEEN ACTIVATION AND

REACTIVATION OF ANY OF THE FOUR LOGIC CONTROL INPUTS IS 100 MILLISECONDS.

*

Ground connections to

be provided by user.

See also Fig. 17(a).

LOGIC LOW

TO ENABLE

Logic Inputs:

UNLATCH

PEAK

TARE

PRINT

Logic Outputs:

"LIVE" DATA IN

"OK" ZONE

"LIVE" DATA IN

"LESS THAN" ZONE

"LIVE" DATA IN

"GREATER THAN" ZONE

Fig. 5(a)

Standard Logic

Inputs and Outputs

1.8

1.f SUMMARY OF LOGIC I/O FUNCTIONS

Page 17

INTRODUCTION

ANALOG INPUT CONNECTOR

–

SHLD

SHUNT CAL

CONTROL

COM

SIG

+

–

SIGCOM

PWR

*

Ground

connections to

be provided by

user. See also

Fig. 17(a).

*

LOGIC LOW

TO ENABLE

Logic Inputs:

+ CALIBRATE

– CALIBRATE

You can use the three logic control outputs to actuate solenoid valves, illuminate

panel displays, sound alarms, start and stop motors or pumps, initiate and control

safety shut-down sequences, and perform many other automation tasks that

require "intelligent" switching, even of substantial amounts of power.

In addition to the standard logic inputs and outputs provided by the LOGIC I/O

CONNECTOR, the Model 3570 DC Strain Gage Conditioner (ONLY) also

accepts two negative-true logic inputs at its rear-panel ANALOG INPUT CONNECTOR. These two inputs, shown in Fig. 5(b), let the operator directly control the

SHUNT CALIBRATION process, which is explained in detail in Section 4. Again,

see Appendix F for a full description of these logic functions.

Fig. 5(b)

Shunt-Control Logic

Inputs for the Model

3570 DC Strain Gage

Conditioner (ONLY)

1

1.g MNEMONIC COMMANDS

There are two ways to issue commands to a 3500 Series instrument. One way is

through the front-panel push buttons. These buttons allow you

• to enter all necessary SETUP COMMANDS, as explained in Sections 3.a and

4.a*; and also

• to enter RUN-TIME COMMANDS for control of positive peak capture, application of tare offset, and initiation and halting of hard-copy transmissions (see

Sections 5.b, 5.c, and 5.d).

The second way to issue commands to the instrument is via the RS-232/485

Computer/Network Communications Interface. When set to the RS-232 (SINGLENODE) mode, this interface will accept commands from a connected computer,

terminal, or other RS-232-C device. When the unit is used in the RS-485 (MULTINODE) mode, commands will normally originate from an application program in the

network's supervisory computer.

In either RS-232 or RS-485 mode, commands to the instrument must be transmitted in a standard ASCII Command Syntax. This syntax uses simple three-letter

* As explained in Section 3.a.2, if a nonzero SECURITY CODE has been specified, the operator will

have to enter that code before any SETUP COMMANDS can be applied via the front-panel buttons.

1.g MNEMONIC COMMANDS

1.9

Page 18

1

INTRODUCTION

English mnemonics, and includes SETUP ("WRITE"), INTERROGATION ("READ"),

and TRANSMISSION-INITIATING commands. In RS-485 (MULTINODE) operation,

every command received at the RS-232/485 Interface Port will evoke a response

from that port (either "ACKNOWLEDGED," "NOT ACKNOWLEDGED," or the requested PARAMETER or DATA VALUE(S)). For a complete listing of mnemonic

commands and responses, see Appendix B.

1.10

1.g MNEMONIC COMMANDS

Page 19

SETUP: CONNECTIONS AND POWERUP

2.a TRANSDUCER CONNECTIONS

2.a.1 THE “STANDARD” ANALOG INPUT CONNECTOR

All 3500 Series instruments except the Model 3510 Thermocouple Conditioner

and the Model 3578 AC Strain Gage Conditioner use the "standard" Analog

Input Connector. Shown in Fig. 2(b), this connector is located on the rear of the

unit. The number of terminals and the specific terminal assignments will depend

on the model itself.

Referring to the appropriate cabling diagram below, connect the wires of your

transducer cable to the corresponding screw terminals of the Analog Input Connector. To facilitate cable connection, the front (screw-terminal) portion of the

connector may be removed from the rear (pin) portion, which is mounted on the

internal Analog Input Board. Press hard when reinserting the front portion, to

make sure it is fully engaged (the small clips should snap into place on the rear

portion).

The special CONDITIONER CONNECTORS used by the Model 3510 Thermocouple Conditioner and the Model 3578 AC Strain Gage Conditioner are described in

the respective sections below.

2

PLEASE NOTE: CABLE SIGNAL WIRES OR TWISTED WIRE PAIRS SHOULD

ALWAYS BE PROPERLY SHIELDED, AS INDICATED IN THE CABLING DIAGRAMS.

THIS WILL MINIMIZE THE PRODUCTION OF UNWANTED ELECTRICAL NOISE

FROM CAPACITIVE AND INDUCTIVE EFFECTS.

2.a.2 CONNECTING A THERMOCOUPLE TO THE MODEL 3510

The Model 3510 Thermocouple Conditioner's rear Analog Input Board mates

with a special CONDITIONER CONNECTOR (shown in Fig. 2(a) and in Fig. 6,

below), which provides a precision thermistor for reference-junction compensation. This connector contains a screw-terminal pair labelled "+" and "–." The other

two terminals are not used.

Each TC lead should be directly attached to its corresponding screw terminal (it

should never be soldered). The connector itself is "keyed" by a small plastic

insert embedded between a certain terminal-pin pair, which matches a slot in the

rear Analog Input Board. This prevents the connector from being inadvertently

attached upside-down.

Open the connector housing by removing the four screws that hold it together

(two on each side). Be sure to put back the insulating foam block before

reassembling the connector. It's also a good idea to wrap each cable wire

around the respective strain-relief post.

The "shield" wire of the transducer cable should be soldered to the exposed terminal of the L-shaped GROUND LUG located under the head of one of the connector's two captive screws. This will ensure direct shield contact with the 3510’s

metal case.

Open Thermocouple Detection—In the event of a broken thermocouple wire or

other "open TC" condition, the 3510 will automatically report an indeterminate off-

scale reading—that is, a value well outside the normal range of the TC type for

which it has been set.

2.a TRANSDUCER CONNECTIONS: MODEL 3510

2.1

Page 20

2

+–

To

Thermocouple

Conditioner

Analog Input

Board

– SIGNAL

+ SIGNAL

SHIELD

Ground

Lug

LOW HI

Strain

Relief

Post

Open TC Detection

Programming Jumpers

This terminal

NOT USED

This terminal

NOT USED

+ +

+ +

SETUP: CONNECTIONS AND POWERUP

Fig. 6 Model 3510

Transducer Cabling

The Model 3510 is normally preset at the factory for positive off-scale "open TC"

indication. However, you may easily reset it for negative indication. Open the

connector housing and locate the "Open TC Detection Programming Jumpers"

(see Fig. 6). You will have to remove the solder drop connecting the middle terminal pad to the "HI" (positive) pad, and to place a solder drop between the middle

pad and the "LOW" (negative) pad. Use a fine-point solder gun to heat the solder

drop to be removed, until it has melted sufficiently for you to wipe it off with a

clean rag. Make sure you remove all traces of solder from the jumper pads you

wish to disconnect.

2.2

2.a.3 CONNECTING AN LVDT OR VARIABLE

RELUCTANCE TRANSDUCER TO THE MODEL 3530

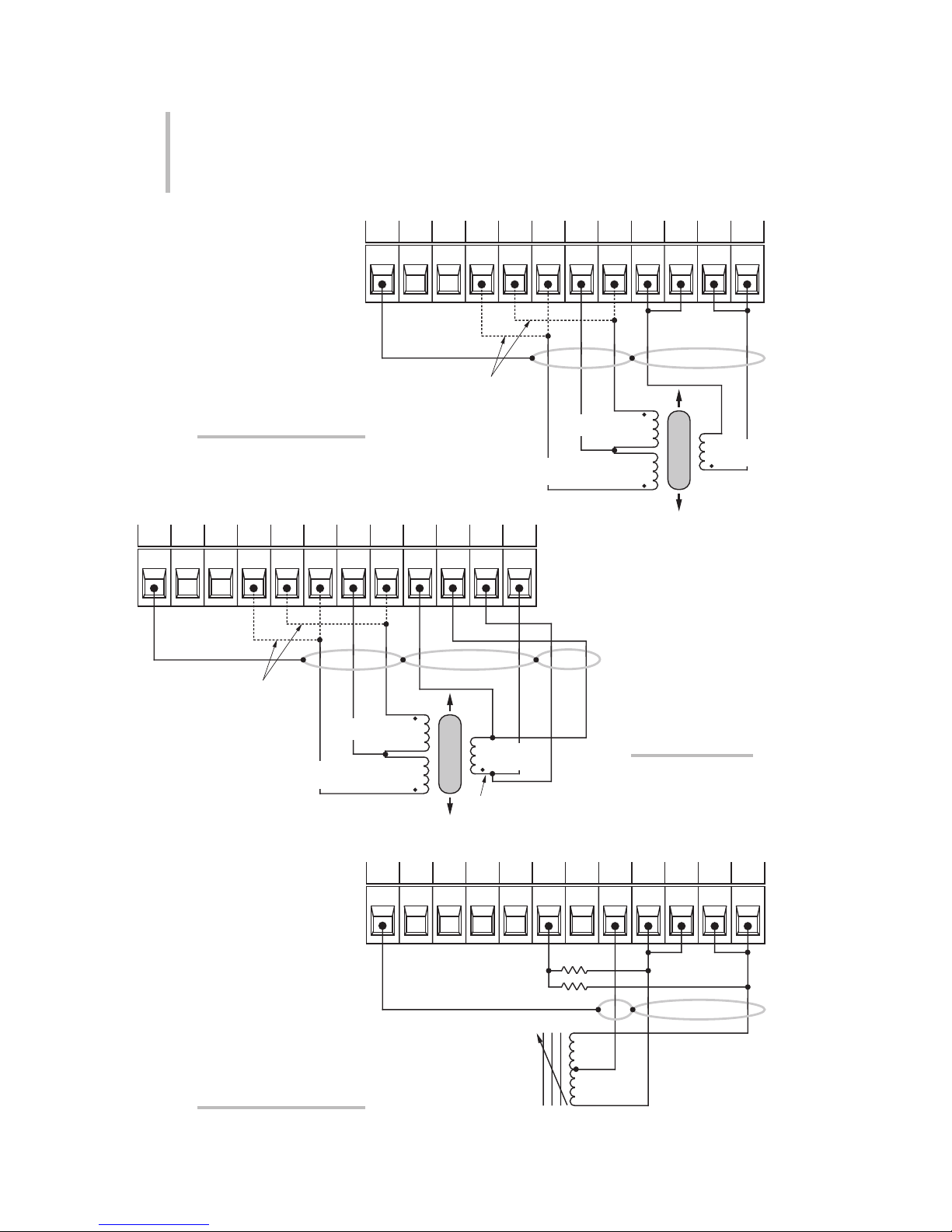

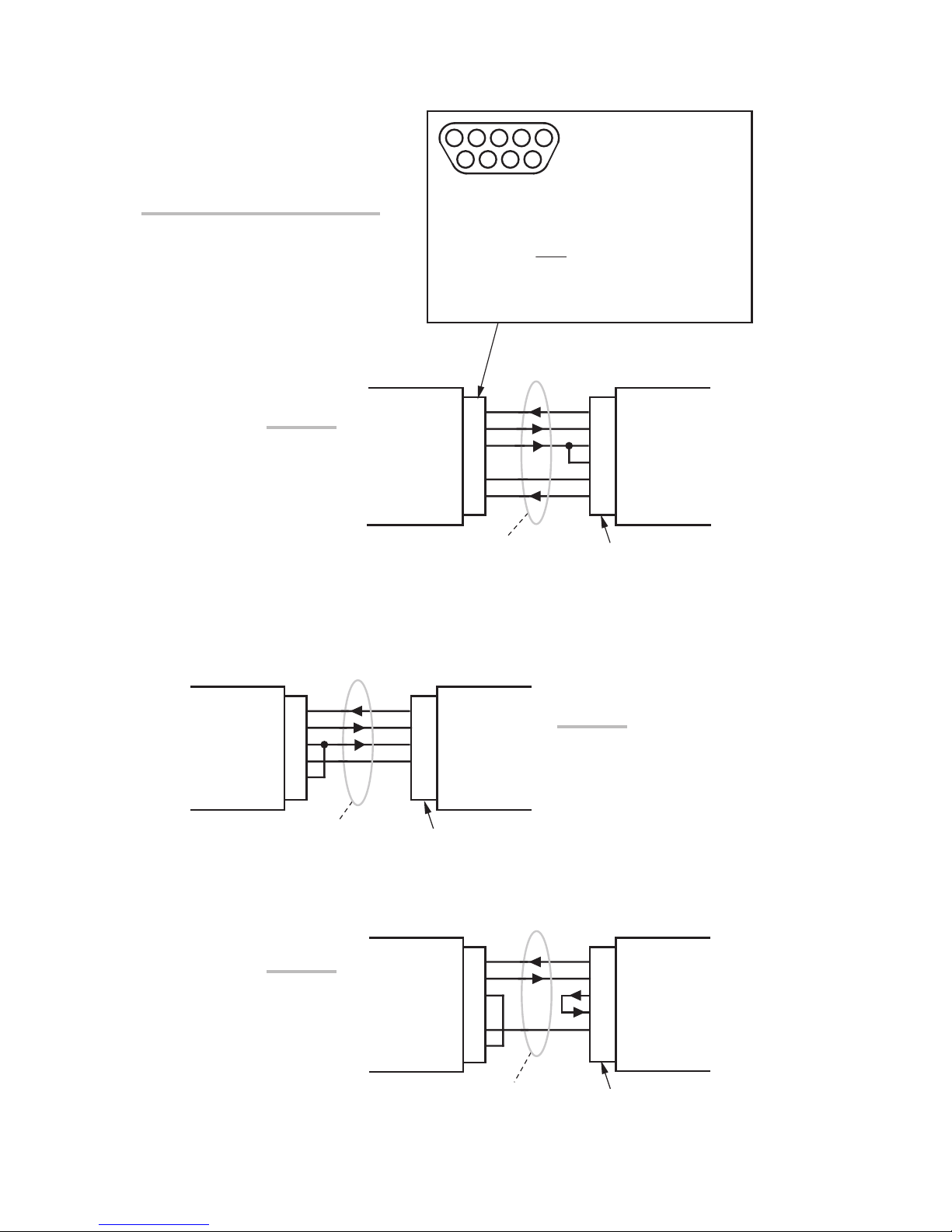

With regard to transducer cabling for the Model 3530 LVDT Conditioner, please

note the following:

a. 5-wire LVDT cabling (Fig. 7(a)) or 3-wire variable reluctance transducer

cabling (Fig. 7(c)) is to be used when the cable is under 20 feet in length. In

this case, the +SENSE and –SENSE lines are tied to the corresponding EXCITATION lines at the CONDITIONER CONNECTOR.

7-wire LVDT cabling (Fig. 7(b)) or 5-wire variable reluctance transducer

cabling (Fig. 7(d)) is to be used when the cable is 20 feet or longer. In this

case, the +SENSE and –SENSE lines are tied to the corresponding EXCITATION lines at the transducer.

b. When wiring an LVDT transducer to the 3530, you should connect both series-

opposed secondary coils to the terminal labelled "CENTER WIRE," as shown

in Figs. 7(a) and 7(b).

c. NOTE THAT THERE ARE SPECIAL +SIGNAL AND –SIGNAL CONNECTIONS

FOR USE WITH LONG-STROKE LVDT'S (FULL-SCALE INPUT OF 0-1, 0-2, OR

0-4 VOLTS/VOLT).

Thus, to allow for the larger input voltages produced by such a sensor, you

would connect its +SIGNAL line to the terminal labelled "HI +SIG," instead of to

the "+SIG" terminal. Similarly, you would connect the –SIGNAL line to the terminal labelled "HI –SIG" instead of to the "–SIG" terminal.

2.a TRANSDUCER CONNECTIONS: MODEL 3530

Page 21

SETUP: CONNECTIONS AND POWERUP

–

SIG

+

SIG

CNTR

WIRE

+

SENS+EX

LVDT INPUT

–EX–

SENS

HI –

SIG

HI +

SIG

–SENSE

+SENSE

+EXCITATION

+SIGNAL

–EXCITATION

–SIGNAL

10K

10K

N/C

SHIELD

SHLD N/C

–

SIG

+

SIG

CNTR

WIRE

+

SENS+EX

LVDT INPUT

–EX–

SENS

HI +

SIG

–SENSE

+SENSE

–EXCITATION

+EXCITATION

+SIGNAL

–SIGNAL

PRIMARY

COIL

SECONDARY

COILS

Sec. 1

Sec. 2

CENTER

WIRE

HI –

SIG

N/C

SHIELD

SHLD N/C

For

Long-Stroke

LVDT's

–

SIG

+

SIG

CNTR

WIRE

+

SENS+EX

LVDT INPUT

–EX–

SENS

HI –

SIG

HI +

SIG

–SENSE

+SENSE

–EXCITATION

+EXCITATION

–SIGNAL

PRIMARY

COIL

Sec. 1

Sec. 2

CENTER

WIRE

For

Long-Stroke

LVDT's

SECONDARY

COILS

+SIGNAL

N/C

SHIELD

SHLD N/C

d. When wiring a variable reluctance transducer to the 3530, you must install a

10-kilohm "half-bridge completion" resistor between the –SIGNAL line and

each of the two EXCITATION lines, as shown in Figs. 7(c) and 7(d).

Fig. 7(a) Model 3530

Transducer Cabling:

5-Wire LVDT Cabling

(under 20 ft. in length)

2

Fig. 7(c) Model 3530

Transducer Cabling:

3-Wire Variable

Reluctance Cabling

(under 20 ft. in length)

Fig. 7(b) Model 3530

Transducer Cabling:

7-Wire LVDT Cabling

(20 ft. or longer)

2.a TRANSDUCER CONNECTIONS: MODEL 3530

2.3

Page 22

2

–

SIG

+

SIG

CNTR

WIRE

+

SENS+EX

LVDT INPUT

–EX–

SENS

HI –

SIG

HI +

SIG

–SENSE

+SENSE

+EXCITATION

+SIGNAL

–EXCITATION

SHIELD

–SIGNAL

10K

10K

N/CSHLD N/C

SETUP: CONNECTIONS AND POWERUP

Fig. 7(d) Model 3530

Transducer Cabling: 5-Wire Variable

Reluctance Cabling (20 ft. or longer)

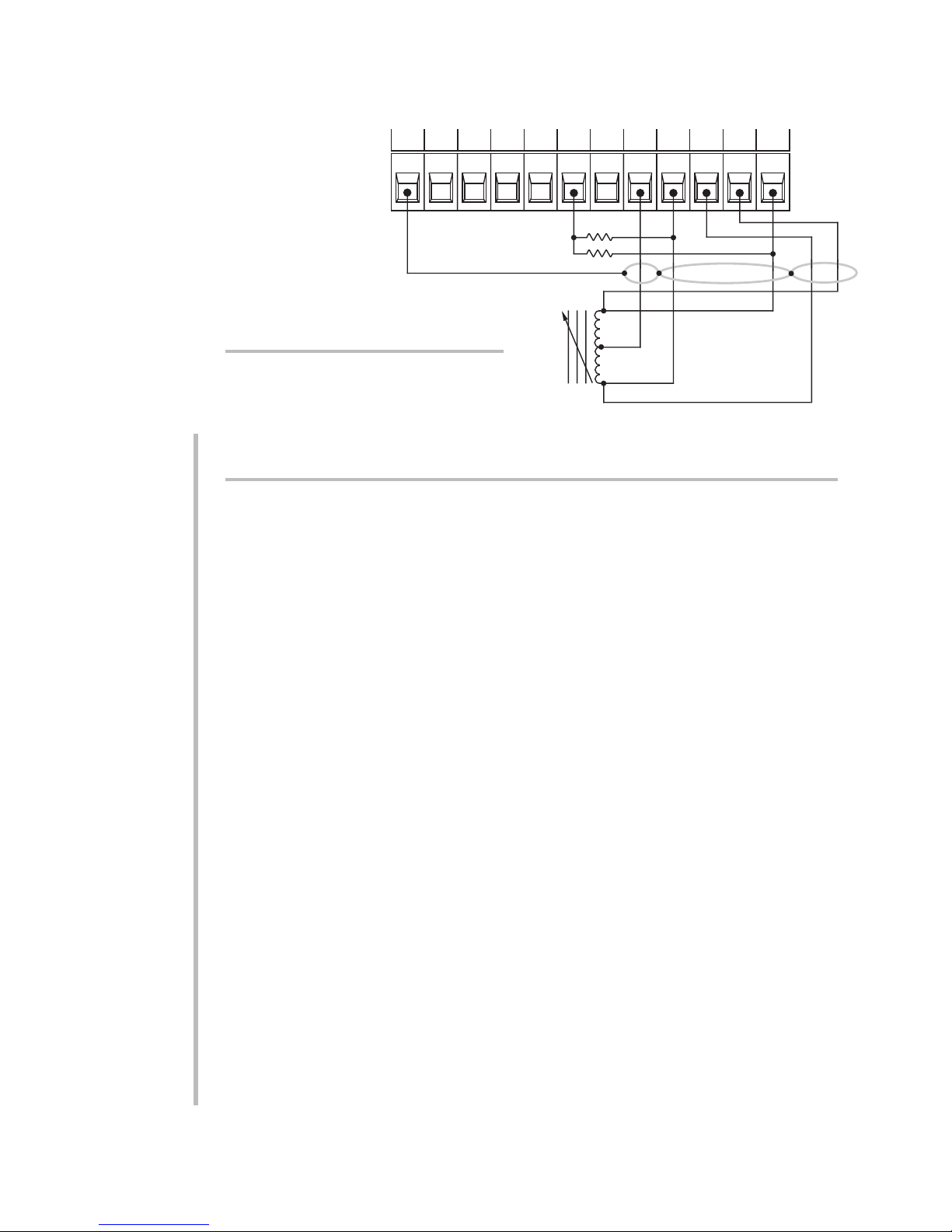

2.a.4 CONNECTING A FREQUENCY

SOURCE TO THE MODEL 3540

Fig. 8(a) shows recommended cabling for connecting the Model 3540 Frequency Conditioner to a pulse transformer transducer with two-wire isolated wind-

ings (tachometer, turbine flowmeter, etc.). Fig. 8(b) shows the connection to a

transistor or logic-circuit driver, while Fig. 8(c) shows the connection to a "zero-

velocity" (i.e., true digital output) sensor. For a single-ended input, note that the

–SIG terminal should be tied to the SIG COM terminal, as shown in Fig. 8(b).

Note too that, when used with an open-collector type sensor—such as a zerovelocity sensor—a pull-up resistor of typically 10 kilohms is required between the

terminal to which the +SIGNAL line is tied and the +5V terminal, as shown in Fig.

8(c). For a zero-velocity sensor, the +SIGNAL line is to be tied to the +SIGA terminal to eliminate any DC offset (see below).

The Model 3540’s input channel is equipped with a capacitive-coupled input (0.1

µF). This special input may be used with either floating or grounded configurations if you require elimination of DC offset or suppression of high-frequency

noise. Figs. 8(d) and 8(e) show how these effects can be achieved.

Elimination of DC Offset—The 0.1-µF capacitive coupling can be used to eliminate any positive or negative DC offset that exists for the frequency signal. Simply connect the +SIGNAL line from the frequency source to the +SIGA terminal,

instead of to the normal +SIG terminal (see Fig. 8(d)). The capacitor is here in

series with the +SIGNAL input and allows only AC to pass.

Suppression of High-Frequency Noise—False triggering can sometimes occur,

especially at the low-frequency input range, because of stray pickup of frequencies outside the common-mode range. Capacitive coupling of the frequency

input to ground can in such cases serve to suppress unwanted signal noise.

Thus, if you find your frequency reading to be unacceptably unstable or "noisy,"

you should tie the +SIGA terminal to the SIG COM terminal, while maintaining the

normal +SIGNAL connection to the +SIG terminal (see Fig. 8(e)). With reference to

the suppression of high-frequency noise by grounding +SIGA, note that

• it is always recommended for magnetic-pickup sensors; and

• in general, it is NOT to be used with transducers that produce

active output (e.g., TTL logic drivers).

2.4

2.a TRANSDUCER CONNECTIONS: MODEL 3540

Page 23

SETUP: CONNECTIONS AND POWERUP

SHIELD

SHLD

–SIGNAL

+SIGNAL

–

+

EXCITATION

COM

SIG

SIG

–

SIG

+

FREQUENCY

SOURCE

SIGNAL INPUTS

SIGA

+

5V

–

COM

PWR

5V

+

SHIELD

SHLD

–SIGNAL

+SIGNAL

–

+

EXCITATION

COM

SIG

SIG

–

SIG

+

FREQUENCY

SOURCE

SIGNAL INPUTS

SIGA

+

5V

–

COM

PWR

5V

+

SHLD

EXCITATION

COM

SIG

SIG

–

SIG

+

SIGNAL INPUTS

SIGA

+

5V

–

COM

PWR

5V

+

+SIGNAL

SHLD

EXCITATION

COM

SIG

SIG

–

SIG

+

SIGNAL INPUTS

SIGA

+

5V

–

COM

PWR

5V

+

ZERO-VELOCITY SENSOR

+EXCITATION

+SIGNAL

–EXCITATION

SHIELD

10K

10K Pull-up Resistor (for

use with open-collector

sensor)

SHLD

EXCITATION

COM

SIG

SIG

–

SIG

+

SIGNAL INPUTS

SIGA

+

5V

–

COM

PWR

5V

+

+SIGNAL

2

Fig. 8(a) Model 3540 Transducer

Cabling: Differential (Floating)

Frequency Input

Fig. 8(b) Model 3540 Transducer

Cabling: Single-Ended (Grounded)

Frequency Input

Fig. 8(c) Model 3540

Transducer Cabling:

Input from a ZeroVelocity Sensor

Fig. 8(d) Model 3540 Transducer

Cabling for Elimination of DC Offset

Fig. 8(e) Model 3540 Transducer

Cabling for Suppression of HighFrequency Noise

2.a TRANSDUCER CONNECTIONS: MODEL 3540

2.5

Page 24

2

SHIELD

N/CSHLD

–SIGNAL

+SIGNAL

Reg. Power

Supply

(if required)

–

+

ANALOG

SIGNAL

SOURCE

Add wire for

floating input

POWER

OUT

SIGNAL

INPUT

± 40 MA MAX

COM

SIG

SIG

–

SIG

+

–12VCOM+12V

N/CSHLD

POWER

OUT

SIGNAL

INPUT

± 40 MA MAX

COM

SIG

SIG

–

SIG

+

–12VCOM+12V

SHIELD

+SIGNAL

–EXCITATION

2K to

10K

+EXCITATION

N/CSHLD

POWER

OUT

SIGNAL

INPUT

± 40 MA MAX

COM

SIG

SIG

–

SIG

+

–12VCOM+12V

SHIELD

+SIGNAL

–EXCITATION

+EXCITATION

DC-to-DC

LVDT

–SIGNAL

Tie the –SIG and SIG COM

terminals if a –SIGNAL wire from

the transducer is not available

SETUP: CONNECTIONS AND POWERUP

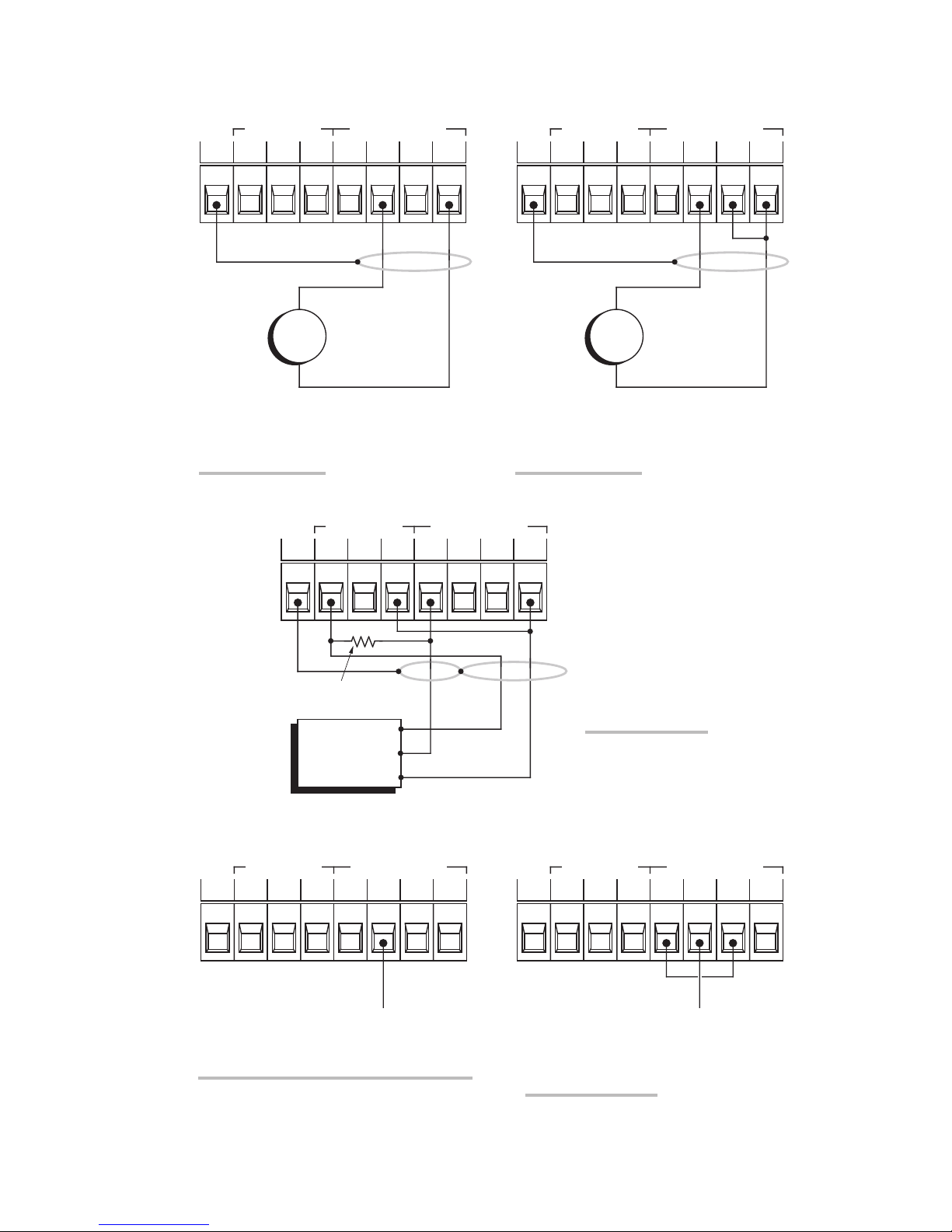

2.a.5 CONNECTING A VOLTAGE

SOURCE TO THE MODEL 3560

Fig. 9(a) gives standard cabling for connecting to the Model 3560 Voltage Conditioner a general ANALOG SIGNAL SOURCE, floating or grounded, with its own

power supply (if required); Fig. 9(b), for connecting an EXTERNAL ZERO-TO-FULLSCALE POTENTIOMETER with a resistance from 2 to 10 kilohms, using the instru-

ment's ±12-V excitation; and Fig. 9(c), for connecting an EXTERNAL DC-TO-DC

LVDT, again using the ±12-V excitation. As shown in Fig. 9(a), a floating input is to

be grounded by tying the transducer's –SIGNAL line to the SIG COM terminal.

When a –SIGNAL line from the transducer is not available, the –SIG and SIG COM

terminals should be connected by a jumper wire (as in Figs. 9(b) and 9(c)).

Fig. 9(a) Model 3560 Transducer

Cabling: General Voltage Source

2.6

2.a TRANSDUCER CONNECTIONS:MODEL 3560

Fig. 9(b) Model 3560 Transducer

Cabling: External Potentiometer

Fig. 9(c) Model 3560 Transducer

Cabling: External DC-to-DC LVDT

Page 25

SETUP: CONNECTIONS AND POWERUP

See Fig. 5(b)

–

SHLD

SHUNT CAL

CONTROL

STRAIN GAGE INPUT

SIG

+–

COM

SIG

+

EX

+

SENS

+

SENS

–

EXSENS

CAL–

SIGCOM

PWR

SHIELD

+SENSE

+EXCITATION

–EXCITATION

–SIGNAL

+SIGNAL

–SENSE

CAL

SENSE

See Fig. 5(b)

–

SHLD

SHUNT CAL

CONTROL

STRAIN GAGE INPUT

SIG

+–

COM

SIG

+

EX

+

SENS

+

SENS

–

EXSENS

CAL–

SIGCOM

PWR

SHIELD

+SENSE

+EXCITATION

–EXCITATION

–SIGNAL

+SIGNAL

–SENSE

CAL SENSE

UNCONNECTED WIRE

(PAIRED WITH "CAL SENSE")

2.a.6 CONNECTING A DC STRAIN GAGE

TRANSDUCER TO THE MODEL 3570

Four-wire strain gage cabling (Fig. 10(a)) is to be used with the Model 3570 DC

Strain Gage Conditioner when the cable is under 20 feet in length. In this case,

the +SENSE and –SENSE lines are tied to the corresponding EXCITATION lines,

and also the CALIBRATION SENSE line to the +SIGNAL line, at the CONDITIONER

CONNECTOR.

Eight-wire strain gage cabling (Fig. 10(b)) is to used when the cable is 20 feet or

longer. In this case, the +SENSE and –SENSE lines are tied to the corresponding

EXCITATION lines, and the CALIBRATION SENSE line to the +SIGNAL line, at the

transducer. Note also the wire connected to the –SIGNAL line at the transducer,

but left unconnected at the instrument. This wire is to be paired with the CAL

SENSE line, as shown, for shielding purposes.

2

Fig. 10(a) Model 3570

Transducer Cabling:

4-Wire Cabling

(under 20 ft. in length)

Fig. 10(b) Model 3570

Transducer Cabling:

8-Wire Cabling

(20 ft. or longer)

2.a TRANSDUCER CONNECTIONS: MODEL 3570

2.7

Page 26

2

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

+SIGNAL

CONDITIONER CONNECTOR

–EXCITATION

+EXCITATION

–SIGNAL

–SENSE

+SENSE

CAL SENSE

SHIELD

Connector pins shown as viewed

from rear (cable) side of

connector.

Ground Lug

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

CONDITIONER CONNECTOR

+EXCITATION

+SENSE

SHIELD

Connector pins shown as viewed

from rear (cable) side of

connector.

Ground Lug

+SIGNAL

–EXCITATION

–SIGNAL

–SENSE

CAL SENSE

Unconnected wire

(Paired with "CAL SENSE")

SETUP: CONNECTIONS AND POWERUP

2.a.7 CONNECTING AN AC STRAIN GAGE

TRANSDUCER TO THE MODEL 3578

As shown in Fig. 2(a), the Model 3578 AC Strain Gage Conditioner's Analog

Input Board mates with a special CONDITIONER CONNECTOR. This connector

allows direct solder-terminal attachment of cable leads. The connector's internal

solder terminals are labelled 1 through 10 and A through L. The connector is

"keyed" by small plastic inserts embedded between certain terminal-pin pairs,

each of which matches a slot in the conditioner's Analog Input Board. This prevents the connector from being inadvertently attached upside-down.

Open the connector housing by removing the four screws that hold it together.

Secure the cable by means of one of the internal clamp bars.

The "shield" wire of the transducer cable should be soldered to the exposed terminal of the L-shaped GROUND LUG located under the head of one of the connector's two captive screws. This will ensure direct shield contact with the 3578’s

metal case.

Fig. 11(a) Model 3578

Transducer Cabling: 4-Wire

Cabling (under 20 ft. in length)

2.8

2.a TRANSDUCER CONNECTIONS: MODEL 3578

Fig. 11(b) Model 3578

Transducer Cabling: 8-Wire

Cabling (20 ft. or longer)

Page 27

SETUP: CONNECTIONS AND POWERUP

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

CONDITIONER CONNECTOR

–SENSE

+SENSE

SHIELD

External

SHUNT

CALIBRATION

RESISTOR

(UserSupplied)

+SIGNAL

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

CONDITIONER CONNECTOR

+EXCITATION

+SENSE

SHIELD

Connector pins shown as viewed

from rear (cable) side of

connector.

Ground Lug

+SIGNAL

–EXCITATION

–SIGNAL

–SENSE

A

D

C

B

CAL

(E)

Unconnected wire

(Paired with "LEBOW CAL")

LEBOW CAL

Fig. 11(c) Model 3578

Transducer Cabling:

Installation of User’s

External Shunt

Calibration Resistor

Fig. 11(d) Model 3578

Transducer Cabling: 8-Wire

Cabling to LEBOW 1600 SERIES

TRANSDUCER (ONLY)

2

Four-wire strain gage cabling (Fig. 11(a)) is to be used when the cable is under 20

feet in length.

The Model 3578 is equipped with an internal 59-KΩ, 0.1% calibration resistor for

the standard "shunt" calibration technique described in Section 4. If you wish to

use your own external shunt resistor, it should be tied between Pin 5 of the CONDITIONER CONNECTOR and the transducer's +SIGNAL line, as shown in Fig.

11(c). In this case, "CAL SENSE" (Pin 4) is not used.

With cabling under 20 feet in length, the +SENSE and –SENSE lines are tied to the

corresponding EXCITATION lines at the CONDITIONER CONNECTOR. Also, the

CALIBRATION SENSE line from Pin 4—or the optional external SHUNT RESISTOR

line from Pin 5—is tied to the +SIGNAL line at the CONDITIONER CONNECTOR.

Eight-wire strain gage cabling (Fig. 11(b)) is to used when the cable is 20 feet or

longer.* As before, you can install your own shunt calibration resistor between

Pin 5 and the +SIGNAL line, in which case Pin 4 is not used.

With cabling of 20 feet or over, the +SENSE and –SENSE lines are tied to the corresponding EXCITATION lines at the transducer. Also, the CALIBRATION SENSE

* NOTE: This cabling is to be used when connecting the Model 3578 to a Lebow 1800 Series

Transducer, regardless of cable length.

2.a TRANSDUCER CONNECTIONS: MODEL 3578

2.9

Page 28

2

SETUP: CONNECTIONS AND POWERUP

line from Pin 4—or the optional external SHUNT RESISTOR line from Pin 5—is tied

to the +SIGNAL line at the transducer. Note the wire connected to the –SIGNAL

line at the transducer, but left unconnected at the instrument. This wire is to be

paired with the CAL SENSE or SHUNT RESISTOR line for shielding purposes.

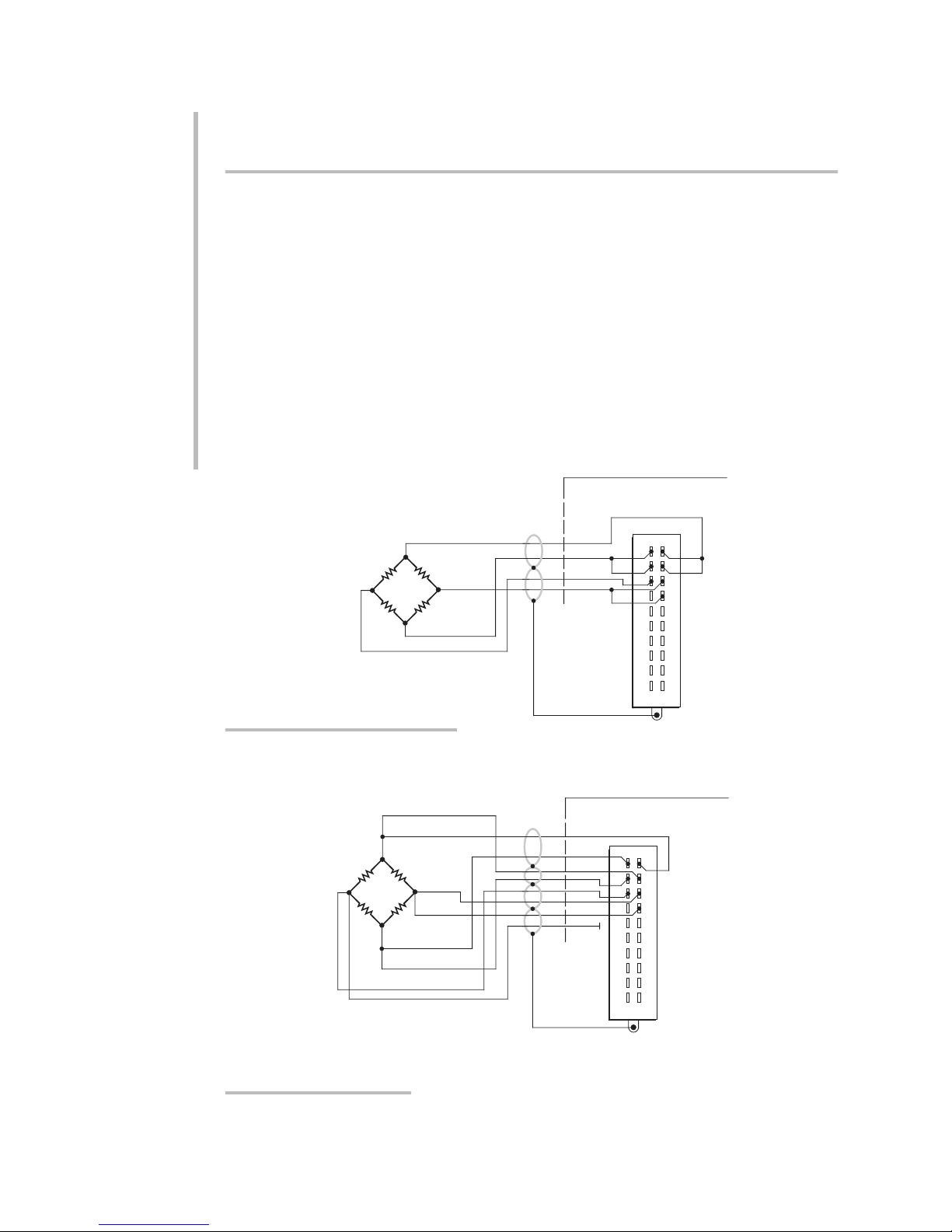

Special 8-wire cabling (shown in Fig. 11(d)) is required for connecting the 3578 to

a Lebow 1600 Series Transducer. The cable should be shielded in four pairs,

as shown in the figure, with the shield open at the transducer end. Also note that

• SENSE and EXCITATION lines should be tied at the transducer.

• The conditioner's Pin 5 ("LEBOW CAL") is to be connected to the "CAL" pin on

the Lebow sensor (Pin 4 is not used in this case).

• You should leave the last (extra) wire unconnected at both ends, and pair it

with the "LEBOW CAL" line for the fourth shield.

• THE MODEL 3578 MUST BE INTERNALLY SET TO "SIGNAL COMMON"

MODE. CONTACT THE FACTORY FOR PRECISE INSTRUCTIONS.

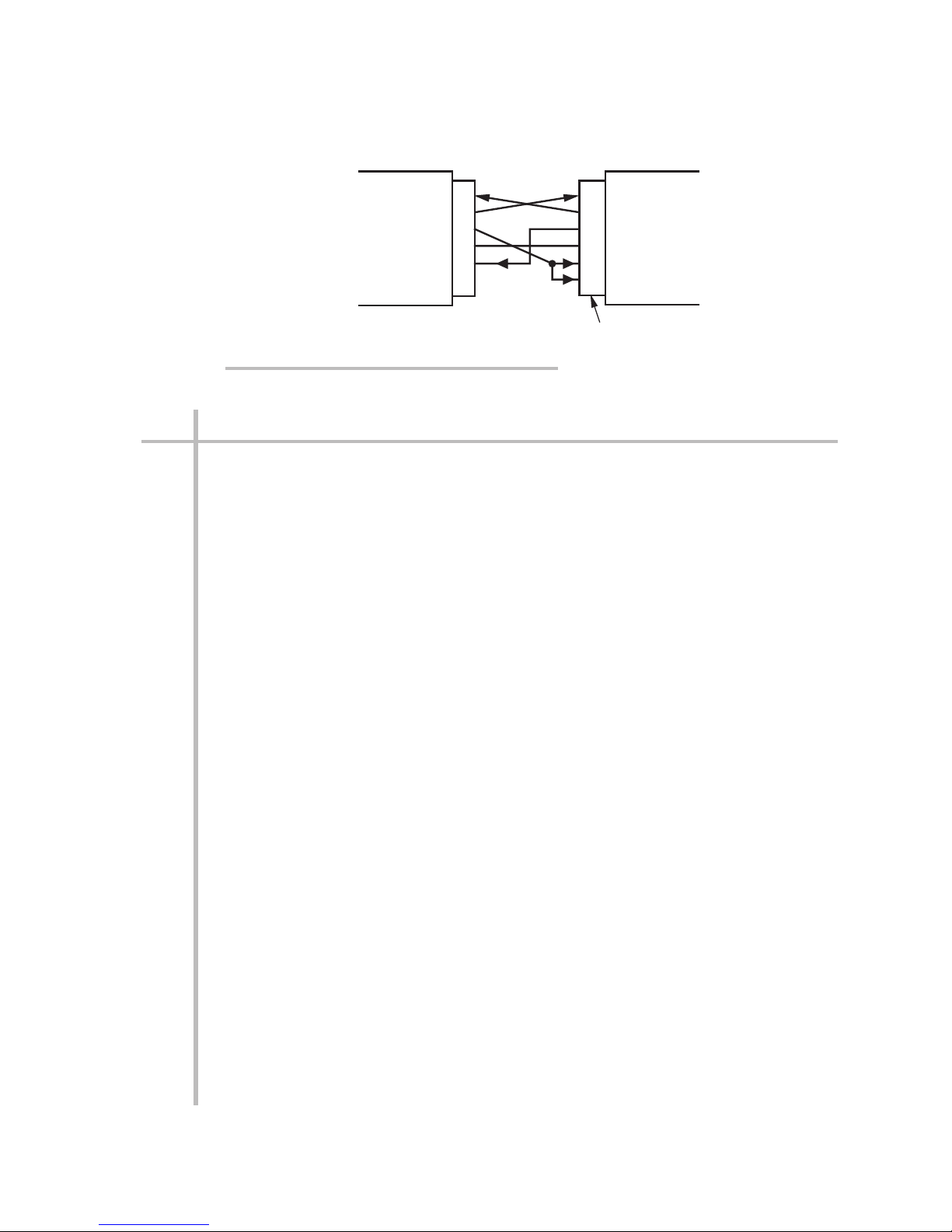

2.b RS-232 (“SINGLE-NODE”) CONNECTIONS

You should set the RS-232/485 Interface Port for RS-232 operation when you

want your 3500 Series instrument to communicate with a single computer, terminal, buffered printer, or other RS-232-C device. To do so, you need only MAKE

SURE THAT THE INSTRUMENT'S CURRENT NODE NUMBER IS "0" (ZERO). You

will be shown in Section 3.a.3 how to set the node number and other necessary

RS-232 communications parameters via the front-panel buttons.

If you did not order a specific RS-232-C Interface Cable with your 3500 Series

instrument, you will have to provide your own connection. Fig. 12 shows suggested cabling between the instrument and a computer, terminal, printer, etc., that

uses a 25-Pin RS-232-C Connector. FOR MAXIMUM DATA-TRANSFER SPEED

AND ACCURACY, A "FULL HANDSHAKE" INTERCONNECTION IS GENERALLY

RECOMMENDED (Fig. 12(a)). However, cabling is also given for "INCOMING

HANDSHAKE ONLY" and "NO HANDSHAKE" situations (Figs. 12(b) and 12(c),

respectively). Following RS-232-C conventions, the device at each end of the

interface is seen as "DATA TERMINAL EQUIPMENT (DTE)."

Fig. 13 shows suggested cabling between a 3500 Series instrument and a computer, terminal, printer, etc., that uses a 9-Pin D-Subminiature Connector for its RS232-C interface (such as an IBM PC/AT).

Please note that the cabling in Figs. 12 and 13 is by no means definitive. In all

cases, you should carefully study the literature accompanying the specific RS232-C device you wish to connect to your instrument, to determine the cable

arrangement that will create the "handshake" you need (if any). On some devices,

for example, the DATA TERMINAL READY (DTR) signal may have a different

name (such as NOT BUSY) and may even appear on a pin other than No. 20 or

No. 4.

2.10

2.b RS-232 (“SINGLE-NODE”) CONNECTIONS

Page 29

SETUP: CONNECTIONS AND POWERUP

Computer

or other RS-232-C Device

25-Pin RS-232-C

Connector

2

3

4

5

8

2

3

5

6

7

20

RECEIVE

TRANSMIT

DTR

COMMON

CTS

TRANSMIT

RECEIVE

CTS

DSR

COMMON

DTR

FULL HANDSHAKE

(RECOMMENDED)

*

* Required for IBM and IBM-compatible computers.

DATA (RS-485)

RECEIVE (RS-232)

TRANSMIT (RS-232)

DATA TERMINAL READY (RS-232)

COMMON

DATA (RS-485)

+12 V (RS-485)

CLEAR TO SEND (RS-232)

SHIELD

RS-232/485 Interface

Connector—Male

(see Fig. 2)

1

2345

6

789

1

2

3

4

5

6

7

8

9

Pin No. Function

3500 Series

Instrument

25-Pin RS-232-C

Connector

2

3

4

5

8

2

3

5

7

20

RECEIVE

TRANSMIT

DTR

COMMON

CTS

TRANSMIT

RECEIVE

CTS

COMMON

DTR

INCOMING HAND-

SHAKE ONLY

Computer

or other RS-232-C Device

3500 Series

Instrument

25-Pin RS-232-C

Connector

2

3

4

5

8

2

3

4

5

7

20

RECEIVE

TRANSMIT

DTR

COMMON

CTS

TRANSMIT

RECEIVE

RTS

CTS

COMMON

DTR

NO HANDSHAKE

Computer

or other RS-232-C Device

3500 Series

Instrument

Fig. 12 Suggested RS-232-C

Interface Connections

(to 25-Pin RS-232-C Connector)

Fig. 12(a)

2

Fig. 12(c)

Fig. 12(b)

2.b RS-232 (“SINGLE-NODE”) CONNECTIONS

2.11

Page 30

2

9-Pin RS-232-C

Connector

2

3

4

5

8

2

3

4

5

6

8

RECEIVE

TRANSMIT

DTR

COMMON

CTS

RECEIVE

TRANSMIT

DTR

COMMON

DSR

CTS

Computer

or other RS-232-C Device

SETUP: CONNECTIONS AND POWERUP

Fig. 13 Suggested RS-232-C Interface

Connections (to 9-Pin RS-232-C Connector)

2.c RS-485 (“MULTINODE NETWORK”) CONNECTIONS

You can also set a 3500 Series instrument's RS-232/485 Interface Port for RS-485

intercommunications with a multidrop network of up to 99 independent Daytronic

signal conditioning instruments (3500 Series, 4000 Series with “N” Option, and/or

5000 Series)—all controlled by a supervisory computer with RS-232-C I/O. To do

so, YOU MUST ASSIGN THE 3500 INSTRUMENT A UNIQUE NONZERO NODE

NUMBER. You will be shown in Section 3.a.4 how to set the node number and

other necessary RS-485 communications parameters via the front-panel buttons.

IMPORTANT: BEFORE NETWORK INTERCONNECTIONS ARE ESTABLISHED,

YOU SHOULD SET UP EACH 3500 SERIES NETWORK "NODE" INDIVIDUALLY, BY

MEANS OF THE SETUP PROCEDURES GIVEN IN SECTIONS 3 AND 4.

While it is possible to make separate network "branches" issue from a single

node, such an arrangement can lead to less than optimum signal-to-noise ratio

because of unwanted reflections over interface lines. A strictly linear configuration like that shown in Fig. 14(a) is therefore highly recommended.

For proper conversion of interface levels, you must attach a Model 5E485

RS232-to-RS485 Adaptor to the computer's RS-232-C port, via the Model 5E25

DB25 Male-to-Female Converter, as shown in Fig. 14(a).* The adaptor’s RS-

485 Interface Port should then connect directly to the RS-232/485 Interface Port

of the first network node—which should be a 3500 Series instrument—via the

cabling given in Fig. 14(b). Note that the +12-V supply of the first node (when it is

a 3500 instrument) is used to power the Model 5E485, as shown in Fig. 14(b).**

Fig. 14(c) shows the pin-to-pin cabling to be used between each pair of adjacent

3500 instrument nodes, or between a 3500 node and an adjacent 4000 Series

node. Interconnections between a 3500 or 4000 node and a separately powered

5000 node are shown in Fig. 14(d).

* The Model 5E25 is not necessary when the computer is equipped with a Model PC-HSICA

High-Speed Serial Interface Card. Also, you may use your own RS-232-to-RS-485 converter

in place of the Model 5E485, if desired. Converter connections will depend on whether there

are separate "XMIT" and "RCV" pairs or a single "485 DATA" pair. Contact the factory for

instructions.

** If the network contains one or more 5000 Series instrument nodes, a separate power source

of 10 to 40 V-DC (nominal 24 V-DC recommended) is required to power both the 5E485 and

the 5000 nodes—in which case the +12-V pin on every 3500 node should not be used. See any

5000 instrument instruction manual for details.

2.12

2.c RS-485 (“MULTINODE NETWORK”) CONNECTIONS

Page 31

SETUP: CONNECTIONS AND POWERUP

100 Ω

0.0047 µf

RS-485 Terminator

(for chains over 500 ft.)

Computer 25-Pin

RS-232-C Port

Model 5E485

RS232-to-RS485

Adaptor

Model 5E25

Male-to-Female

Converter*

Not required with

Model PC-HSICA

High-Speed Serial

Interface Card.

Node 1

COMMON

485 DATA

485 DATA

SHIELD

4-pin RS-485 Interface

& DC Power Port

Node RS-485 Interface

Port or Computer

Interface Port in RS-485

Communications Mode

For cabling,

see Fig. 14(b)

For cabling,

see Fig. 14(c)

Node 2

Node 3

*

3500 Series

Instrument

2

Fig. 14(a) Connections for a Network of Three Instrument Nodes (where the first is a 3500 Series instrument)

For RS-485 communications, the relevant pins of the RS-232/485 Interface Port

are as follows:

Pin No. Function

1 485 DATA

5 COMMON (GND)

6 485 DATA

7 +12 V

9 SHIELD

RS-485 interconnections require Belden 8162 Datalene 100-Ω shielded cable (or

equivalent). THE INDICATED SHIELDING IS VERY IMPORTANT AND SHOULD BE

FOLLOWED CLOSELY.

For network chains of over 500 feet, the RS-232/485 Interface Port of the last

node in the sequence should be "terminated" by means of a 0.0047-µf capacitor

and a 100-Ω resistor across the two "DATA" terminals (again, see Fig. 14(a)).

2.c RS-485 (“MULTINODE NETWORK”) CONNECTIONS

2.13

Page 32

2

+10 to 40 V

PWR COM

485 DATA

485 DATA

COMMON

485 DATA

485 DATA

Shield

For RS-485, use Belden 8162 Datalene

100- Shielded Twisted Pairs or other

cable intended for EIA RS-422/485

SHIELD

RS-485 Interface Port

(Model 5E485)

RS-232/485 Interface Port

(3500 Series Instrument)

+12 V

COMMON

485 DATA

485 DATA

COMMON

485 DATA

485 DATA

Shield

For RS-485, use Belden 8162 Datalene

100- Shielded Twisted Pairs or other

cable intended for EIA RS-422/485

SHIELD SHIELD

RS-232/485 Interface Port

(3500 or 4000 Series Instrument)

RS-232/485 Interface Port

(3500 or 4000 Series Instrument)

COMMON

485 DATA

485 DATA

+10 to 40 V

PWR COM

485 DATA

485 DATA

Shield

For RS-485, use Belden 8162

Datalene 100- Shielded

Twisted Pairs or other cable

intended for EIA RS-422/485

SHIELD

+

–

Power

Supply

See 5000 Instrument

Instruction Manual

RS-232/485 Interface Port

(3500 or 4000 Series Instrument)

RS-485 Interface Port

(5000 Series Instrument)

SETUP: CONNECTIONS AND POWERUP

Fig. 14(b) RS-485 Cabling Between the Model 5E485 and

the FIRST Network Node (if it is a 3500 Series instrument)

Fig. 14(c) RS-485 Cabling Between

Successive 3500 or 4000 Instrument Nodes

2.14

2.c RS-485 (“MULTINODE NETWORK”) CONNECTIONS

Fig. 14(d) RS-485 Cabling Between a 3500 or

4000 Instrument Node and a 5000 Instrument Node

Page 33

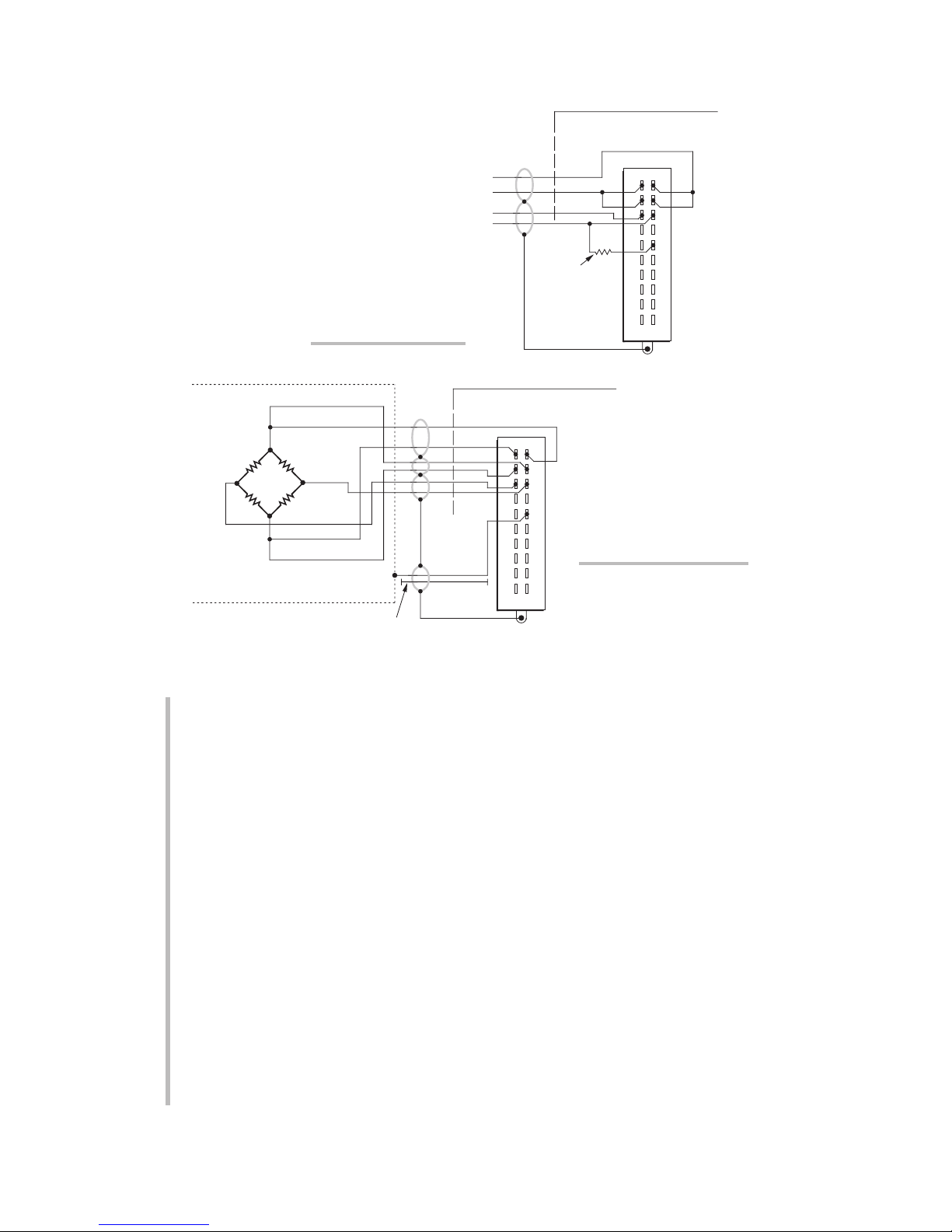

SETUP: CONNECTIONS AND POWERUP

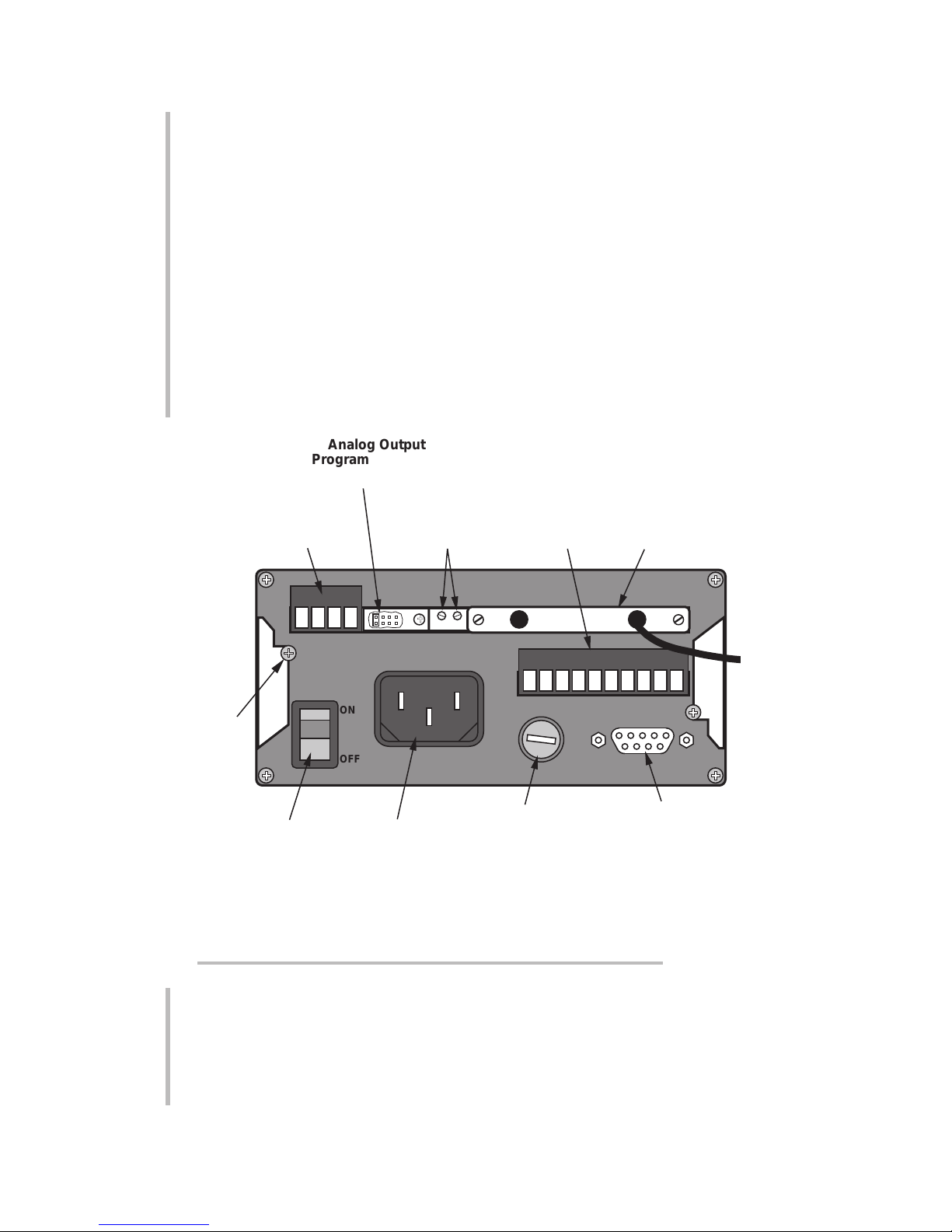

Analog Output

Analog Input

+PEAK A/D

Analog Output

Programming Pins

(see Fig. 2)

A

Berg-Pin Jumper

(connect one pair only)

BCD

ABC

Fixed Analog Filter:

Model 3530 LVDT Conditioner: 100 Hz

Model 3560 Voltage Conditioner: 2000 Hz

Model 3570 DC Strain Gage Conditioner: 2000 Hz

Model 3578 AC Strain Gage Conditioner: 20 Hz

Selectable Analog Filter:

5/10/20 Hz

This diagram does not apply to the Models

3510 and 3540, which do not have Analog

Output Programming Pins.

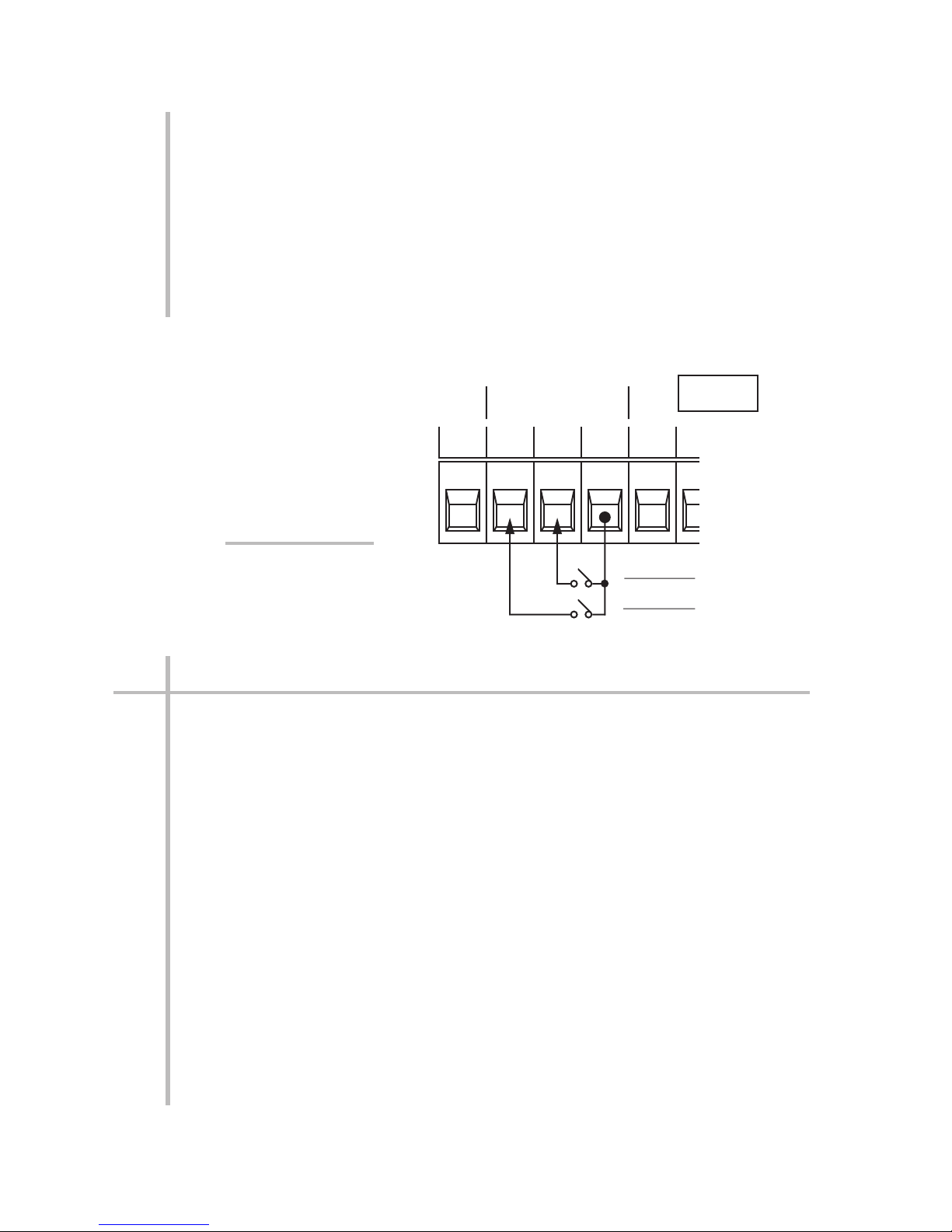

2.d ANALOG OUTPUT CONNECTIONS

As indicated in Fig. 15, the ±5-V analog output signal of the Model 3530 LVDT

Conditioner, Model 3560 Voltage Conditioner, Model 3570 DC Strain Gage

Conditioner, or Model 3578 AC Strain Gage Conditioner may represent the

state of the conditioned input (A) after the FIXED ANALOG FILTER; (B) after analog

peak capture; or (C) after the SELECTABLE ANALOG FILTER (5/10/20 Hz for each

of these conditioners).* Each unit is initially set at the factory to source the analog

output after the FIXED ANALOG FILTER (Point A). To select a different source

point for any of these conditioners, you should

1. First turn OFF the unit and disconnect the power cord.

2. Remove the screw(s) holding the rear plate that covers the ANALOG OUTPUT

PROGRAMMING PINS (see Fig. 2(a) or 2(b)).**

3. Using needle-nose pliers, pull out the single Berg-Pin jumper and reposition it

on the pair of pins corresponding to the desired source (A, B, or C—again, see

Fig. 15). The pins labelled D are not currently used.

4. Replace the cover and reactivate the unit.

2

Fig. 15 Analog Output Programming Pins

* For the Model 3540 Frequency Conditioner, the SELECTABLE ANALOG FILTER is 2.5/5/10 Hz;

for the Model 3510 Thermocouple Conditioner, there is no SELECTABLE ANALOG FILTER. The

3510’s ANALOG OUTPUT is taken directly from the DIGITAL/ANALOG CONVERTER; the 3540’s

ANALOG OUTPUT is always taken from souce "C" in the figure.

** The Model 3578 AC Strain Gage Conditioner has only one screw; the others have two.

2.d ANALOG OUTPUT CONNECTIONS

2.15

Page 34

2

EXTERNAL

DEVICE

+

–

Signal

Common

Signal

Shield

GND OUT

ANALOG

+5V

PWR

COM

This terminal not

currently used

SETUP: CONNECTIONS AND POWERUP

Fig. 16 shows how an external device connects to the ANALOG OUTPUT CONNECTOR on the rear of the conditioner, including the Models 3510 and 3540. The

output is single-ended, and returns to "SIGNAL COMMON" (i.e., GROUND).

For offsetting and scaling of the ANALOG OUTPUT, see Section 3.a.7. The fre-

quency characteristics and step-response settling time of the output will depend

on which pair of programming pins are jumpered. For details, see Appendix A.

Fig. 16 Analog Output

Connections

(ALL Conditioners)

2.e LOGIC INPUT/OUTPUT CONNECTIONS

The rear LOGIC I/O CONNECTOR is shown in Figs. 2 and 5(a). It has eight

labelled TTL/CMOS-compatible I/O terminals (one of which is normally unused),

plus a LOGIC REFERENCE terminal (+5 V) and a GROUND terminal (COM). In the

standard logic configuration described in Section 1.f and Appendix F, the first

three I/O terminals (left to right) are logic outputs, while the last four are logic

inputs. For the Model 3570 DC Strain Gage Conditioner (only), two logic inputs

("+" and "–") are also provided on the Analog Input Connector, for control of shunt

calibration—see Fig. 5(b). For complete logic-signal specifications, see Appendix

A.

Fig. 17 shows how to wire

a. negative-true logic INPUT to a given terminal from external switch contacts;

b. negative-true logic INPUT to a given terminal from an active TTL logic system

and open-collector logic OUTPUT from a given terminal to an active TTL logic

system;

c. negative-true logic INPUT to a given terminal from an INPUT CONTROL

BLOCK and open-collector logic OUTPUT from a given terminal to an isolated

POWER CONTROL BLOCK.

d. open-collector logic OUTPUT from a given terminal to drive an external relay

or TRIAC controller.

2.16

2.e LOGIC INPUT/OUTPUT CONNECTIONS

Page 35

SETUP: CONNECTIONS AND POWERUP

Logic I/O Connector

COM

+5 V

Logic Input*

. . .

. . .

OPEN = LOGIC 0

CLOSED = LOGIC 1

Also includes "+" and "–" Calibration

Inputs for the Model 3570 DC Strain Gage