Daytona AC-400 User Manual

PROTEC AC-400 USER MANUAL V2.20

AC-400

A/C SERVICE STATION

1/24

PROTEC AC-400 USER MANUAL V2.20

INDEX

SPECIFICATIONS----------------------------------------------------------------------------------------------------------------2

FUNCTION TABLE--------------------------------------------------------------------------------------------------------------3

PART DESCRIPTION------------------------------------------------------------------------------------------------------------4

FIRST OPERATION--------------------------------------------------------------------------------------------------------------5

EQUIPMENT CONNECTION (For recovery/vacuum/oil injection/charge/Auto mode)-------------------------------7

RECOVERY------------------------------------------------------------------------------------------------------------------------8

VACUUM---------------------------------------------------------------------------------------------------------------------------9

OIL INJECTION-----------------------------------------------------------------------------------------------------------------10

CHARGE--------------------------------------------------------------------------------------------------------------------------11

AUTO. MODE--------------------------------------------------------------------------------------------------------------------12

HP LEAK TEST------------------------------------------------------------------------------------------------------------------14

SYSTEM SETTING-------------------------------------------------------------------------------------------------------------16

UPDATE---------------------------------------------------------------------------------------------------------------------------20

MAINTENANCE REMINDING----------------------------------------------------------------------------------------------21

MAIN TROUBLESHOOTING------------------------------------------------------------------------------------------------22

1/24

PROTEC AC-400 USER MANUAL V2.20

Specifications:

Dimension:Package 700*630*1230mm; Unpacked machine 635*585*1075mm

Input power:AC220V±10%~50/60Hz,or AC110V±10%~60Hz

Compressor power:3/8HP

Average gas state refrigerant recovery speed (through charge/suction port):0.25Kg/min.

Hand valves free.

Recovery rate: 99%, recovery to -0.5BAR.

Pressurization to speed up old oil discharge.

Vacuum pump capacity:60L/min.

TEKTINO individualized drier-filter capacity: 600ml

Accuracy of gas cylinder load cell:±10g

Accuracy of oil bottle load cell:±5g

Gas cylinder capacity: 10KG Max.

New/old oil bottle capacity:330ml

System Max. Pressure:20bar

Charge speed:2Kg/Min(max.)

LCD display:105.5*67.2mm, 480RGB x 272 Dots ,TFT full color

High pressure gauge range:-1bar~3.5MPa

Low pressure gauge range:-1bar~3.5MPa

A/C database included, update through USB port.

Automatic service reminding. The equipment provides 1200 operations totally (each recovery or

vacuum counts for one operation) between regular maintenances. When 1200 operations have been

made the machine automatically reminds to call distributor for service.

Thermal printer

Optional: Refrigerant adding port for external gas cylinder. The recovery speed of liquid state refrigerant

through this port: 0.35KG/min.

Optional: Condenser and cooling fan.

Optional: Vacuum leak test.

Optional: Heater band

Optional: Large capacity vacuum pump 120L/mn.

Optional: HP leak test at 2.0MPa.

2/24

PROTEC

AC-400 USER MANUAL V2.20

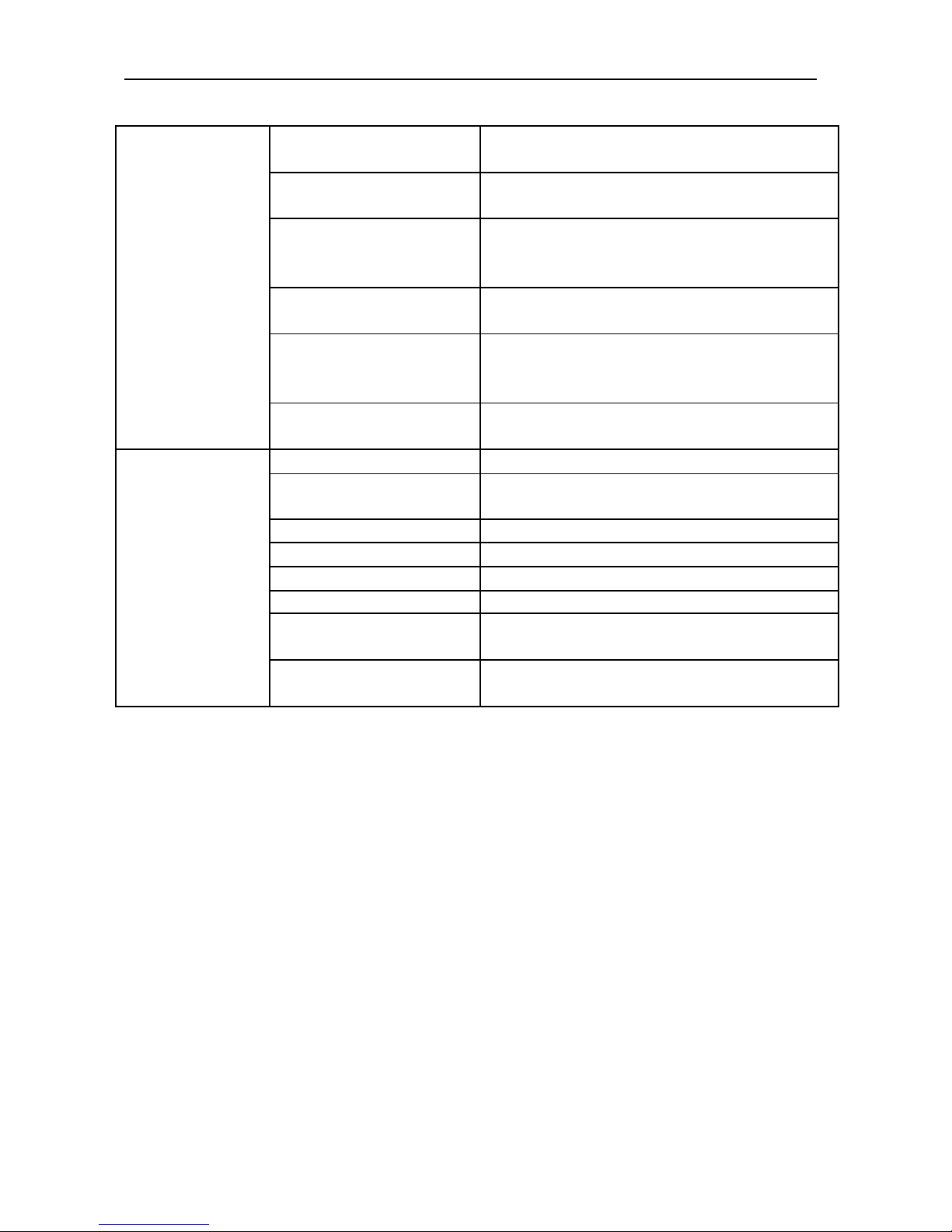

Function Table

Recovery

Recovers and purifies refrigerant from automotive A/C

to equipment tank.

Vacuum

Evacuates air and moisture from the A/C system.

Automatic vacuum leak test (optional).

Oil injection

Inject refrigeration oil to automotive A/C system.

Can inject oil by setting volume manually, or

Main function

automatically.

Charge

Charge refrigerant from equipment gas cylinder to

automotive A/C system

Auto. mode

Performs the selected functions in a fully automatic

sequence. The machine will stop automatically once all

the selected functions have been completed

HP leak test

Inject high pressure compressed N2 to auto A/C

system, to detect leak location in auto A/C system.

Language

Select operation language

Calibration

Calibration refrigerant gas cylinder load cell and/or oil

bottle load cell.

Air purge

Purge non-condensable in equipment gas cylinder.

Database

Enter automotive A/C database

Sys. setting

Printer

Test printer

Unit set

Select metric or imperial units

Empty container weight set

Set empty refrigerant gas cylinder or refrigeration oil

containers weight.

Component test

Test work status of solenoids, vacuum pump and

compressor.

3/24

PROTEC

AC-400 USER MANUAL V2.20

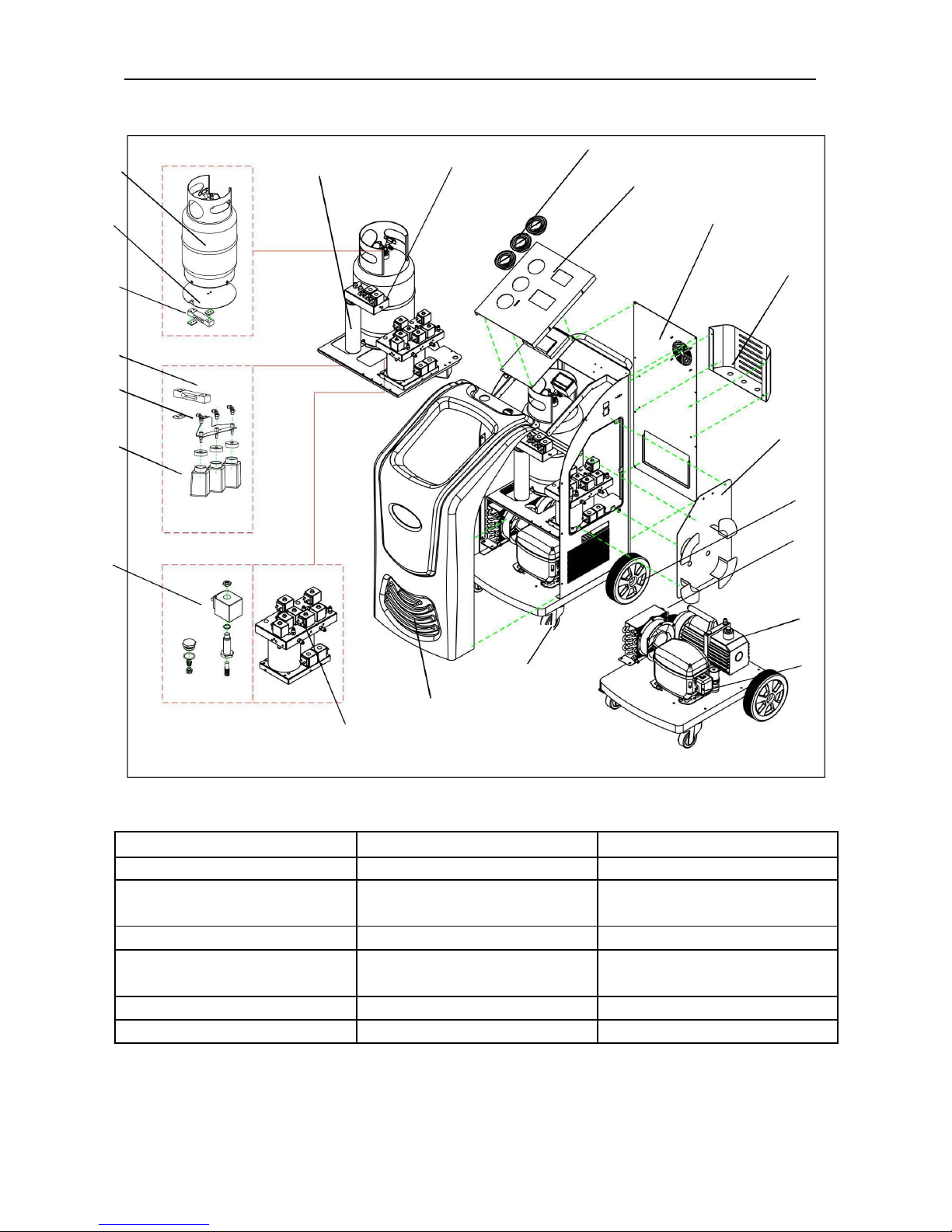

Part description

19

1

21

20

18

2

17

3

4

5

16

6

15

14

13

7

12

10 11

9

8

1)Refrigerant gas cylinder

2)Gas cylinder support plate

3) Gas cylinder load cell

4)Oil bottle load cell

5)Oil bottle support

6)Oil bottles

7)Assembly of solenoid valve and

8)Manifold assembly 1

9)front cover (plastic)

check valve

10) Front wheel

11)Compressor

12)Vacuum pump

13)Condenser and cooling fan

14)Rear wheel

15)Side cover

(optional)

16)Accessory holder

17)Back cover

18)Upper cover

19)Pressure gauges

20)Manifold 2

21) Drier-filter

4/24

PROTEC AC-400 USER MANUAL V2.20

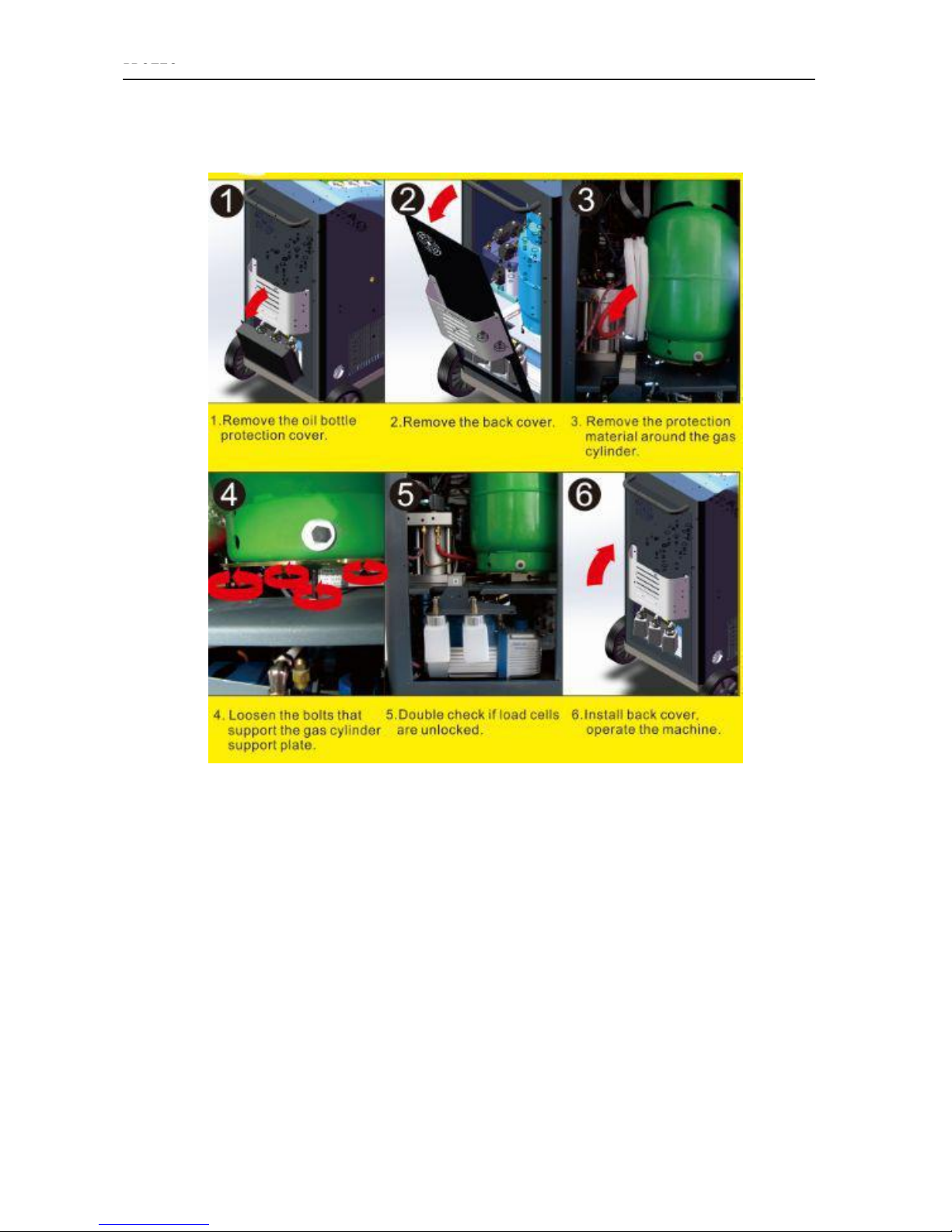

FIRST OPERATION

Unlock load cells (Remove the protection materials for transportation, in equipment side

you can find same sticker).

Fill equipment with refrigerant (New equipment is empty, you need to fill the equipment

with refrigerant and refrigeration oil)

5/24

PROTEC AC-400 USER MANUAL V2.20

2. Open external tank valve. Run recovery.

1.Connect equipment either CHARGE or

SUCTION port to an external tank with

refrigerant, block other port of the equipment.

You can also put the external upside down.

3. When total refrigerant in equipment reaches

2-9KG, close the external tank valve, wait for the

equipment to stop recovering automatically.

6/24

PROTEC AC-400 USER MANUAL V2.20

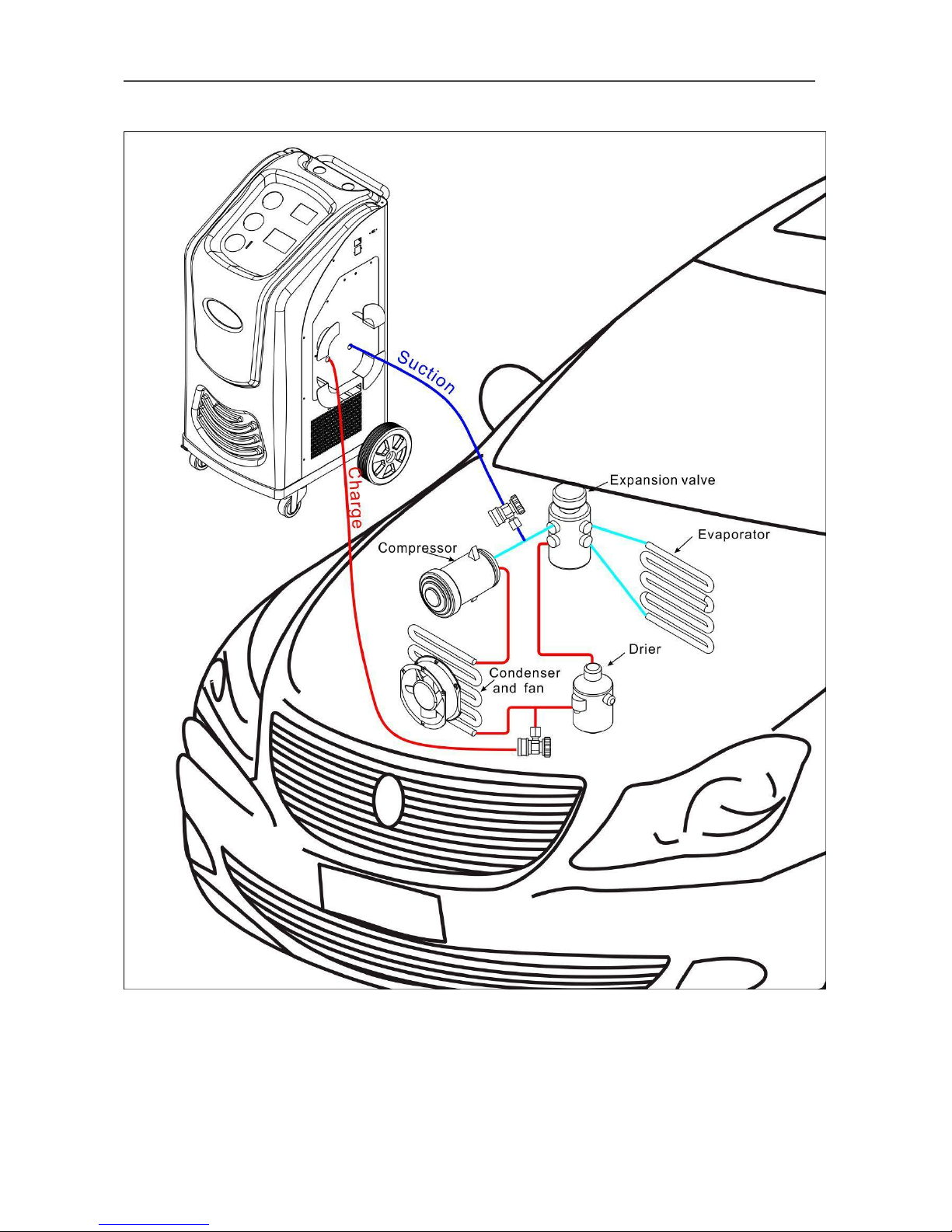

Equipment Connection (For recovery/vacuum/oil injection/charge/Auto. Mode)

Warning: Except the situations clearly stated in the manual, during all equipment operations, please maintain

the vehicle engine and A/Cswithed off, otherwise unexpected damages may be caused.

Remarks: HP leak test equipment connection is different, please refer to “HP leak test” chapter in this manual.

7/24

Loading...

Loading...