Page 1

WT3

is produced by:

Dayton Audio

725 Pleasant Valley Drive

Springboro, Ohio 45066 USA

http://www.daytonaudio.com

Online User’s Guide

Revised: May 11, 2008

Copyright © 2007-2008 by John L. Murphy, Andersonville, TN USA All Rights Reserved.

No part of this publication may be reproduced without prior express written permission.

Page 2

Minimum Requirements for the PC

The minimum requirements to run WT3 are:

•

A PC with a processor running at no less than 500 MHz with 64 MB RAM

•

One available USB port

•

A display with resolution of at least 800 x 600 pixels

WT3 runs under Microsoft Windows 98, Me, 2000, XP and VISTA operating systems.

Page 3

*** VERY IMPORTANT SAFETY NOTE ***

Quick Start for the WT3 Woofer Tester

NEVER connect the test leads of the WT3 to a speaker that

is connected to any other equipment or to an equipment

ground! Severe damage could occur to the WT3 unit or to

the other equipment. Only connect the WT3 to an

unconnected loudspeaker.

Naturally, you will want to test your first woofer as soon as you get your WT3. Here are step-by-step

instructions to get you going quickly.

1) Install the WT3 software.

•

Insert the WT3 CD and allow the file named "WT3_setup.exe" to auto-run.

(Alternately you can double-click on the "WT3_setup.exe" file to start the installation

process.)

•

Follow the on-screen instructions to complete the software installation

•

Check for available upgrades at: http://www.daytonaudio.com/wt3updates.html

2) Connect the WT3 hardware unit to any convenient USB port on your computer.

After a few seconds the PC will recognize the new hardware. However, on initial power up the unit

requires a full 90 seconds to stabilize before measurements can be made. After this initial plug-in

delay, impedance measurements take only a few seconds to complete. This settling time is due to the

extremely wide low frequency bandwidth required for high precision measurements down to 1 Hz.

3) Set the Windows Volume Controls to Maximum.

From the task bar, double-click on Volume Control to open the mixer and Raise both the "Master" and

the "Wave" sliders to maximum. Make sure the Wave signal is panned to center. Although drivers can

be tested at lower signal levels, WT3 was designed to normally be used with the Windows Volume

control set at maximum.

4) Launch the WT3 application software.

From the Windows "Start" button select "All Programs" then select "WT3". The WT3 software will

launch.

5) Connect the alligator clips from the WT3 unit to the 1k Ohm calibration resistor.

Page 4

6) Select “Impedance Calibration” under the “Impedance Analyzer” menu.

The software will sweep the resistor and plot the results. The uncalibrated impedance is

displayed and the calibration is complete. You should also calibrate the test leads at this time

by selecting the appropriate command under the "Impedance Analyzer" menu and following

the on-screen instructions.

7) Connect the alligator clips from the WT3 unit to the terminals of the driver under

test.

The driver MUST NOT BE CONNECTED to an amplifier or other equipment. The connection

polarity does not matter. For the best results the driver should be clamped in place during testing. It

may be necessary to elevate drivers with vented pole pieces in order to make sure the vent is not

blocked during testing.

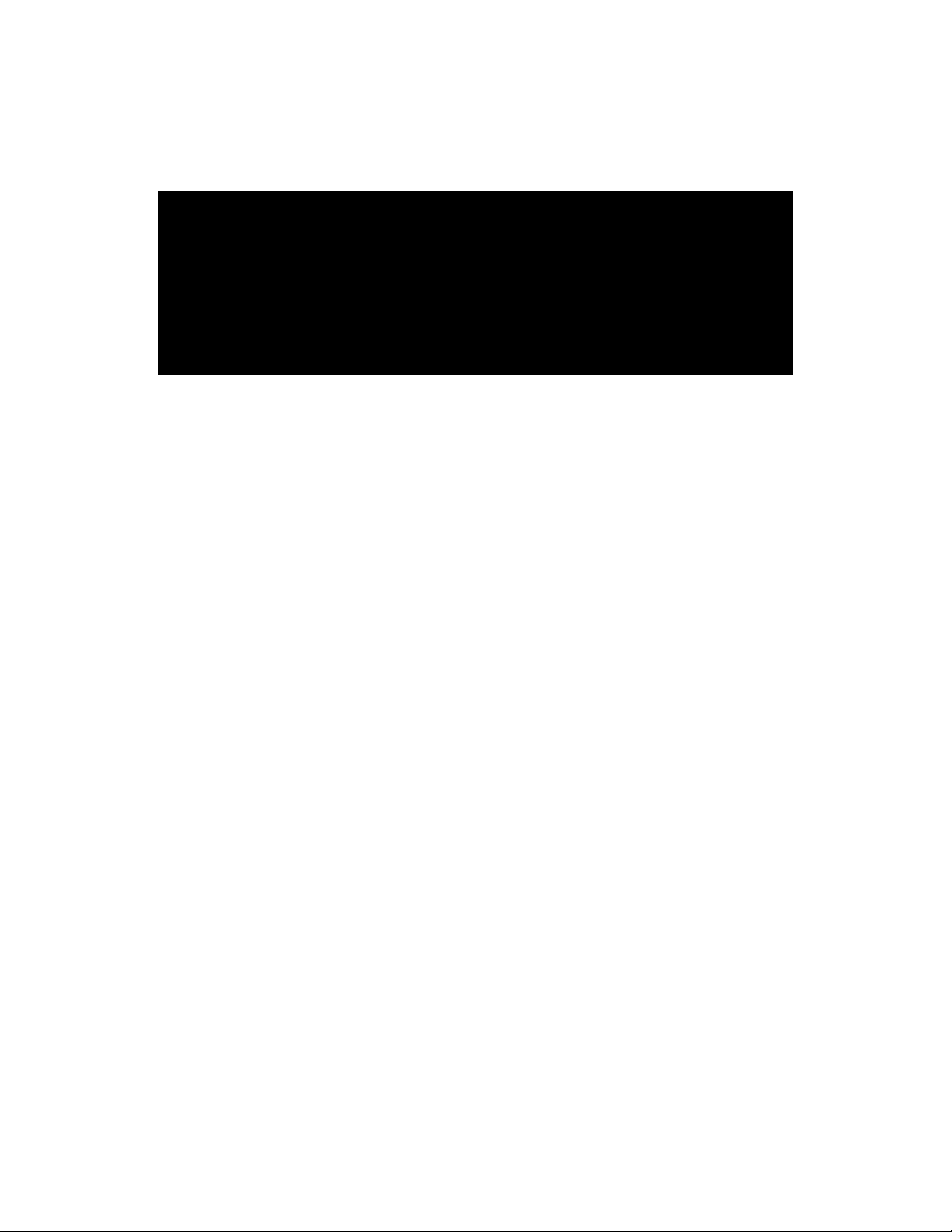

8) Click on the "Measure Free Air Parameters" button at the left of the WT3 window.

You should hear the sweep and then see the impedance response of the driver appear on the screen

similar to the figure below. Note that the driver's measured parameters are displayed in the Parameters

Bar at the right side of the screen. The Impedance Bar at the left side of the screen is where you can set

the upper impedance limit as well as the high and low frequency limits of the display.

Page 5

9) Measure the driver's V(as).

Once you have measured the driver's free air parameters the "Measure V(as)" button becomes enabled.

Select one of the three methods to measure the V(as). Then press the “Measure V(as)” button to start

the measurement procedure. The three V(as) measurement methods are:

Test Box Method

Added Mass Method

Specified SPL Method

10) After measuring the driver you can:

•

Save the data to one of 20 project memories.

•

Save your work to a WT3 test project file (file type .wt3) which includes your test setup

and all 20 memories.

•

Export the impedance and phase data in either .txt or .zma formats. Parameters are

included in the text notes.

•

Overlay plots of various measured impedances from the 20 memories for detailed

comparison.

•

Print a report showing the impedance plots and parameters of the displayed memories

(see below).

Page 6

Windows Vista - Additional Setup Requirements

PLEASE NOTE: STEP 2 IS CRITICAL FOR WINDOWS VISTA USERS!

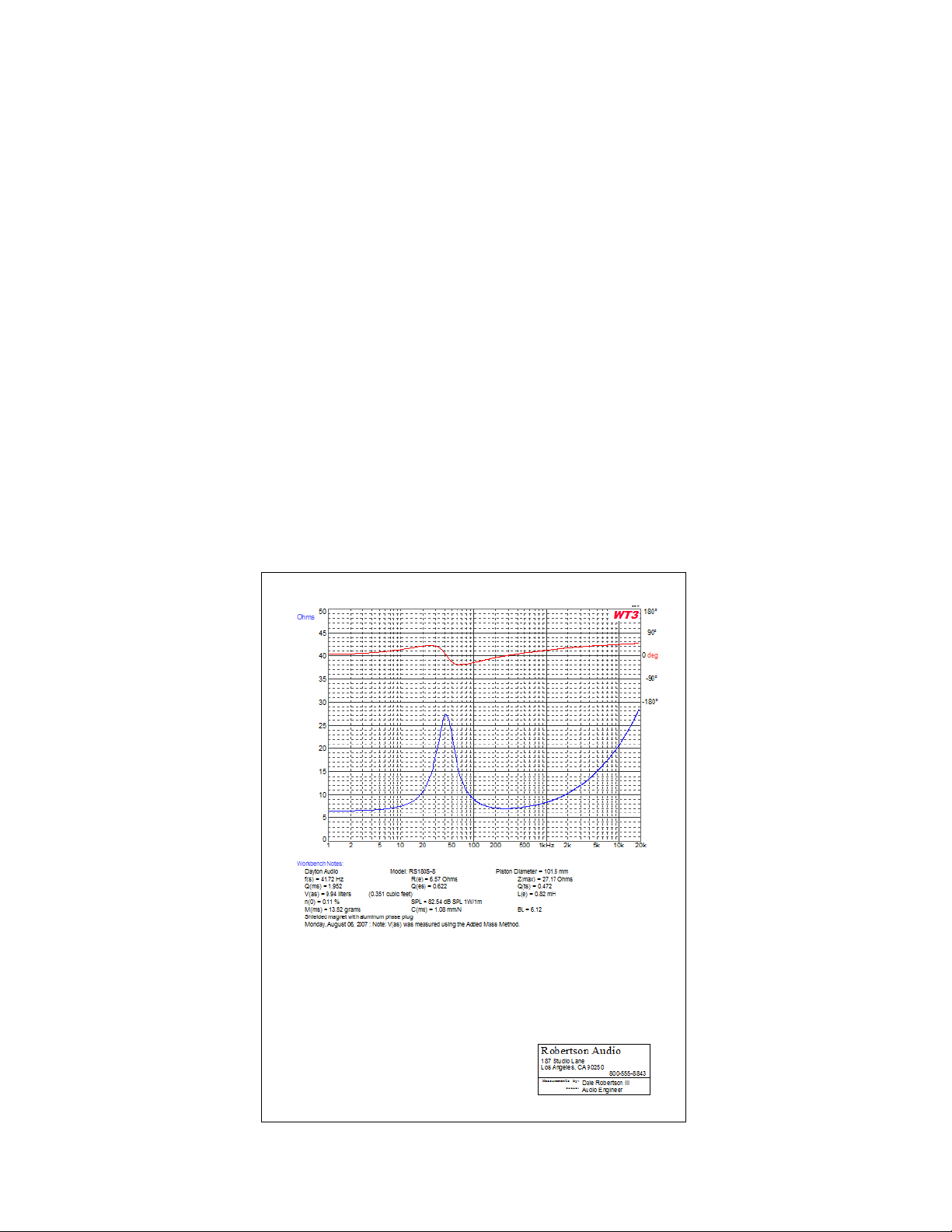

1. Go to the Windows Control Panel and open the “Sound” control panel. At the "Playback" tab make

sure that "USB Audio Codec" is selected as the default sound system for playback. (the icon should

appear with a green check mark as shown). If not, click on the "USB Audio Codec" and then click the

"Set Default" button below.

2. Change to the "Recording" tab at the top of the Sound control panel. As above, make sure that "USB

Audio Codec" is selected as the default sound system for recording (the icon should appear with a

green check mark as shown). If not, click on the "USB Audio Codec" selection and then click the "Set

Default" button below. The "USB Audio Codec" should now appear as the default selection. While at

the "Recording" tab click on the "Properties" button and switch to the "Advanced" tab (shown below).

If not already selected, then select "2 channel, 16 bit, 44100 Hz (CD Quality)" from the list. Click

OK to set the recording format and close the dialog.

Page 7

3. Click OK to close the "Sound" control panel.

Note that this setup must be performed once for each USB port with which the WT3 unit will be used.

Also, when starting WT3, always click on the Speaker icon in the task bar and make sure the Windows

Volume Control is set at maximum.

Page 8

Introducing WT3

No other loudspeaker parameter measurement system is as fast or as easy to use as Dayton Audio’s

WT3. WT3 employs powerful new DSP measurement techniques to provide highly accurate

parameters in seconds. While previous generation woofer testers took around 6 minutes to measure 30

impedance points, the new WT3 measures over 30,000 data points in only a few seconds! Using a new

swept sine technique that is only available in WT3 the system achieves very accurate, high resolution

impedance measurements that allow the extraction of high quality driver parameters suitable for the

most critical loudspeaker design work. WT3 is designed to measure impedances in the range from

about 1 Ohm up to 5k Ohms; it operates over a frequency range from 1 Hz to 20k Hz. Within this

range of operation, and with proper calibration, the accuracy of WT3's impedance measurements is

typically within 1%.

The WT3 software is supplied on a CD. The software runs under Windows and provides an easy to use

interface that allows users to be up and running quickly. When the software is launched it opens with

an Untitled Project file. You can save as many as 20 impedance measurements per project and overlay

any or all of the measurements to create a custom report. Your personal notes are included with each

measurement. Operation of WT3 is very simple. Free air parameters are measured first, then V(as) can

be measured by one of three methods:

•

Test Box Method

•

Added Mass Method

•

Specified SPL Method

While the primary application for WT3 will be testing raw drivers in order to gather the speaker

parameters required for speaker design, loudspeaker designers can also use WT3 as follows:

•

Measure a Woofer's Parameters

•

Measure a Tweeter's Parameters

•

Measure a Resistor

•

Measure an Inductor

•

Evaluate a Closed Box Loudspeaker

•

Evaluate a Vented Box Loudspeaker

•

Evaluate a Complete Speaker System

•

Diagnose Loudspeaker Fault Conditions

•

Design a Zobel Network

The WT3 hardware consists of a compact USB interface unit with attached USB cable and alligator

clip leads. A precision resistor (1k Ohm 1%) is included for calibrating the unit.

Page 9

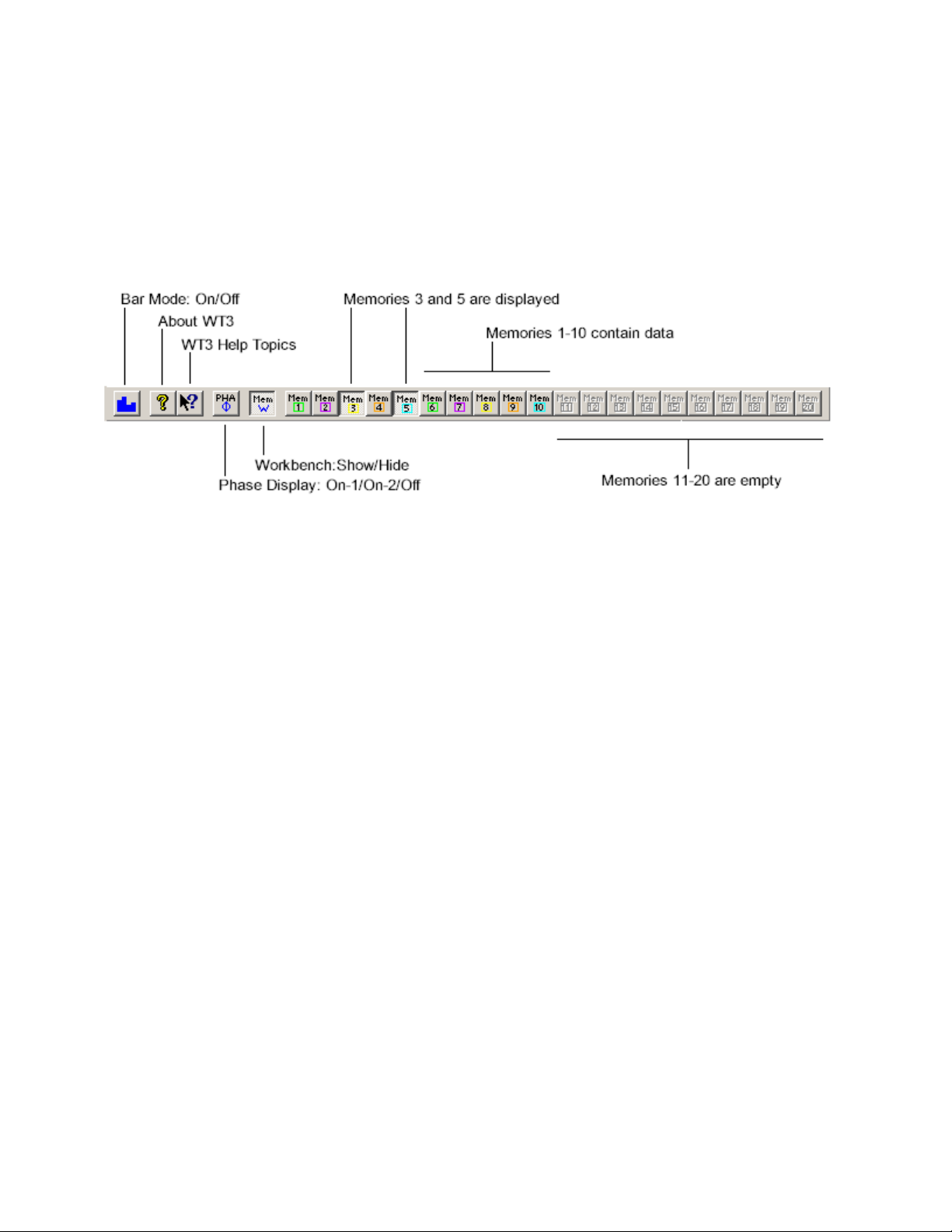

The WT3 Toolbar

The WT3 Toolbar provides easy access for many frequently used commands. Memory show and hide

operations are especially convenient with the toolbar. Note that empty memories are grayed out until

data is saved to them. Once they contain data they become enabled to switch between show and hide

modes.

Page 10

Using the WT3 Memories

The WT3 software features 20 user memories for saving your detailed measurements along with much

other user entered information about the driver. Each memory consists of the impedance and phase

plots, the test setup information (test box volume, added mass etc.) along with the three pages of

parameters, ,specifications and comments that are seen at the Driver Editor. When you save a WT3 file

(type ".wt3") to disc this measurement project file contains all the measurements in the projects 20

memories as well as the data currently on the Workbench.

Note: The most recently measured impedance plot is said to reside on the WT3 “Workbench.” This

measurement is overwritten each time the analyzer is run. The Workbench is also overwritten when a memory is

recalled or when data is imported. Once you have measured data you want to keep (even temporarily) save it to

one of the 20 memories before proceeding with another measurement. All data in the 20 memories is saved with

the WT3 project file. Multiple memories can be overlaid to allow for easy comparison of various measurements.

Use the memory buttons in the Toolbar to show or hide various memories. After a memory has been recalled it

can then be saved to a different memory. After a memory is recalled it is available to be exported to a .txt file.

All the commands related to memory operations can be found under the "View" menu. Here are the

details of the memory commands. Note that each command has a keyboard shortcut that you may find

more convenient than the menu command after you become familiar with the software.

View Menu: Save to Memory

These commands cause the plot on the Workbench to be saved to the selected Memory along with all

the driver parameters.

From the keyboard, use Alt+1, Alt+2 etc. through Alt+0 to save to memories 1 through 10. Use

Alt+Shift+1, 2 etc. through 0 to save to memories 10 through 20. For example, to save the current

response to Memory 5 you would press and hold the Alt key and then press the 5 key.

View Menu: Show/Hide Memory

These commands alternately show and hide the selected memory.

•

From the keyboard, use Ctrl+1, Ctrl+2 etc. through Ctrl+0 to show or hide memories

1 through 10

•

Use Ctrl+Shift+1, 2 etc. through Ctrl+Shift+0 to show or hide memories 10 through

20

For example, to toggle the display of the response in Memory 5 you would press and hold the Ctrl key

and then press the 5 key. Use Ctrl+W to toggle the display of the Workbench response. In addition to

the menu and keyboard commands, you can also toggle each memory on or off at the Memory

Toolbar.

Page 11

View Menu: Clear Memory

These commands erase the contents of the specified memory.

•

From the keyboard, use Ctrl+Alt+1, Ctrl+Alt+2 etc. through Ctrl+Alt+0 to clear the

contents of memories 1 through 10

•

Use Ctrl+Alt+Shift+1, 2 etc. through Ctrl+Alt+Shift+0 to clear the contents of

memories 10 through 20

For example, to erase the response in Memory 5 you would press and hold the Ctrl and Alt keys and

then press the 5 key. Should you need to clear all of the memories it is usually easier to just create a

new project file by selecting "New" under the "File" menu.

View Menu: Hide All Memories (Ctrl+E)

This command turns off the display of all memories without affecting the contents of the memories.

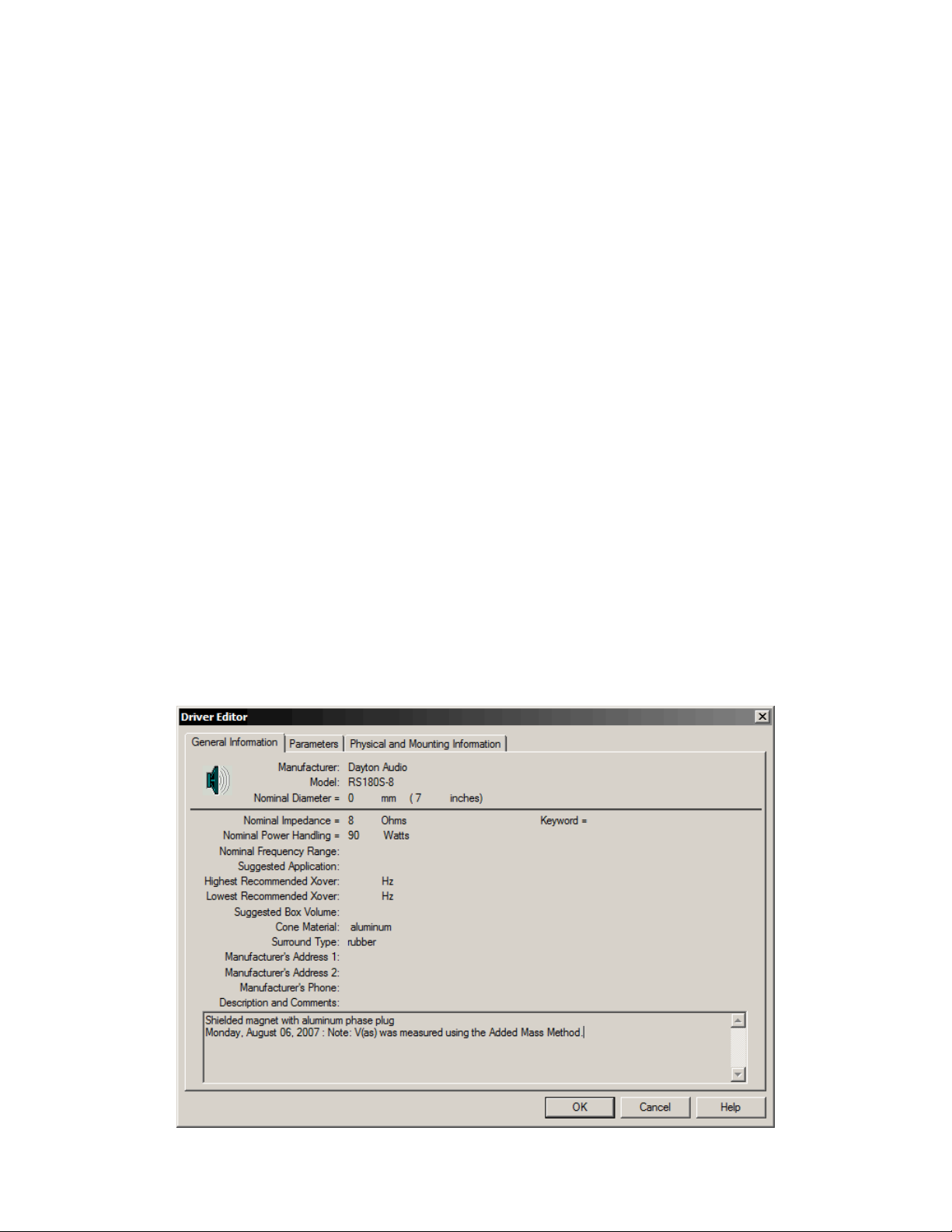

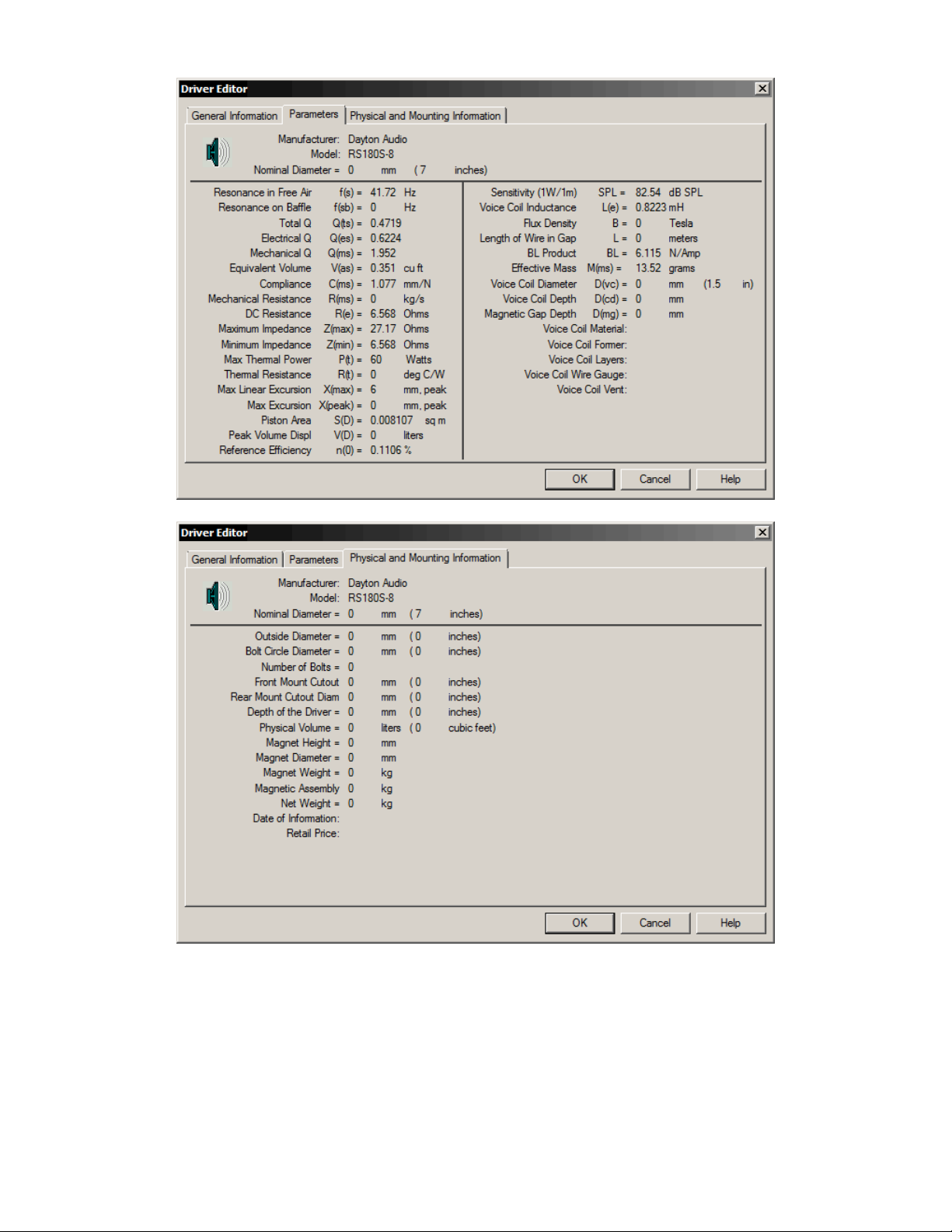

Below are sample screen shots of the three Driver Editor pages. While the WT3 system measures

many of the parameters detailed on the second page the remainder of the data, such as the driver's

manufacturer and model number, may be entered by the user to create a more complete record on the

driver under test. You can add any notes you wish at the Comments field and your notes will be saved

when you save the Workbench to a memory. When you recall a memory to the Workbench your notes

will be displayed at both the driver editor General Information page and in the Notes field below the

plot window. Entering a line or two of descriptive information before saving data to one of the 20

memories makes it easy to keep track of the multiple measurements that make up each WT3 project

file.

Page 12

Page 13

Frequently Asked Questions about WT3

Q: Why do I have to wait 90 seconds for the WT3 hardware to warm up?

A: The initial 90 second waiting period delay is required in order for the hardware power supplies to

ramp up and stabilize. To perform precision measurements down to 1 Hz very wide low frequency

bandwidth is required.

Q: My WT3 was working fine but it seems to have stopped working correctly. What might have

happened?

A: The Windows Volume control settings may have been changed (reduced) when the hardware unit

was connected or disconnected. Open the Windows audio mixer by double-clicking on the speaker

icon in the task bar. Make sure that both the "Master" volume and the "Wave" signal are set to

maximum. The "Wave" signal must be panned to center and the audio must not be muted.

Note that it is possible to upset the DC balance of the unit momentarily should a test lead be

accidentally grounded or come in contact with any stray electrical charge. This may result in erratic

measurements until the system stabilizes again (this can take up to 90 seconds). Remember, never

connect the WT3 to a speaker that is connected to any other equipment or damage to the WT3 unit

could result.

Q: The title block is empty on my printed reports. How do I enter my info?

A: Go to Help > User Information to open the User Information dialog. The information you enter here

will appear in the title block of your printed reports.

Q: How accurate is WT3?

A: Because the speaker parameters are extracted from the impedance data they can only be as accurate

as the impedance measurement itself. When calibrated WT3 provides measurements below 1000 Ohms

and above 1 Ohm that are typically accurate to better than ± 1 %.

Page 14

Removing WT3 from your Computer

You can easily remove WT3 from your computer’s hard drive if needed.

•

Go to the control panel and double click on the “Add/Remove Programs” icon

•

When the Add/Remove dialog appears, locate WT3 in the list

•

Select WT3 and then click on the Add/Remove button

•

When you are asked “Are you sure you want to completely remove the selected application and

all of its components?” select “Yes”

WT3 will be removed from your computer.

Page 15

File Menu

The commands under the File menu are as follows:

ew (Ctrl+)

Clears all current data to create a new empty WT3 project file. Each project file holds up to 20

measurements in individual memories. The memories can be displayed or hidden by clicking the

corresponding memory buttons on the toolbar.

Open… (Ctrl+O)

Opens a WT3 project file (.wt3) which you have previously saved to disc. Note that WT3 can be

launched and a project .wt3 file opened from the desktop by double-clicking on the file icon. Project

files can also be opened by dragging and dropping them onto the open application window.

Save (Ctrl+S)

Saves a WT3 project file to disc with the .wt3 filename extension. A single .wt3 file can contain up to

20 memories of data and notes in addition to the immediate data and notes on the Workbench. Project

files also contain complete test setup information so that opening a saved project file restores the test

setup that was in place when the project file was saved. This includes such settings as the Impedance

and Frequency plot limits. In addition, a large number of measurement setup variables are saved within

each project file.

Save As…

Brings up a save as file dialog which allows you to save the current project file under a different name

or to a different location on your system.

Page 16

Import Impedance Data…

Opens a file dialog to select a .txt (or .zma) file containing data to be imported to the Workbench.

Within the .txt file each data point must be on a single line in the format: “Frequency Impedance

Phase” with the frequency, impedance and phase data separated by a tab or spaces. When the file is

opened the data is imported to the WT3 Workbench, interpolated via a powerful cubic spline routine

and then plotted on the screen. Note that imported phase data must be in degrees. A minimum of two

data points are required. Data below 1 Hz will be ignored.

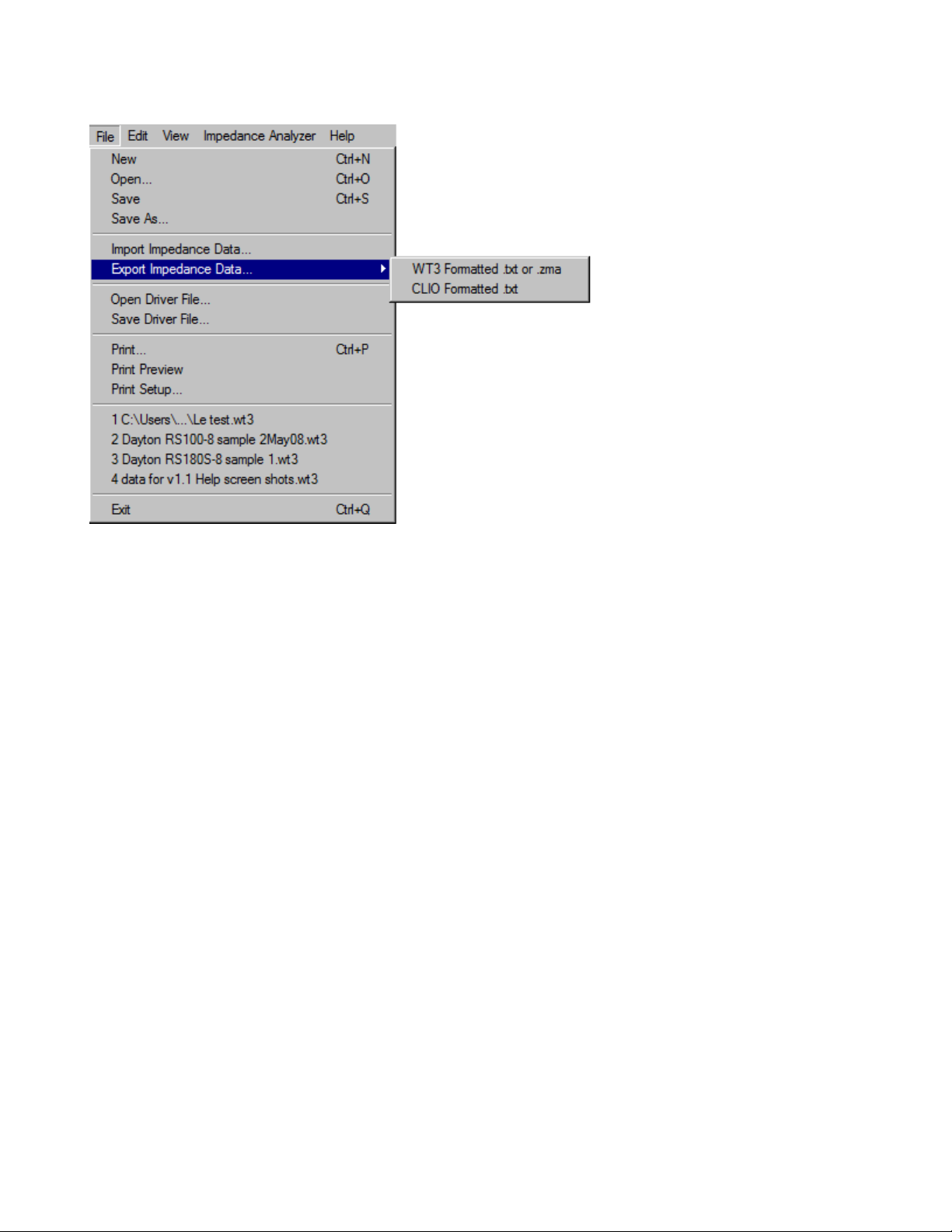

Export Impedance Data…

Exports the response on the workbench to a .txt (or .zma) file for use with other applications. Each

frequency and its impedance magnitude and phase are listed on a single line separated by tabs. The full

frequency range from 1 Hz up to F(s)/2 is exported. Note that exported phase data is in degrees. A text

header is included which contains details on the extracted driver parameters. Data can also be exported

in a format similar to data exported from CLIO. This allows importing driver parameters into

loudspeaker simulation software such as Bass Box .

Open Driver File…

This opens a file dialog which allows you to select a WinSpeakerz individual driver file (.dvr) to open

to the WT3 Workbench. This is useful for exchanging data with WinSpeakerz (loudspeaker simulation

software available separately from True Audio). Driver files contain only the Driver Editor data, no

impedance plot data is contained in these files.

Save Driver File …

Brings up a "save file" dialog which allows you to save the data and notes currently on the Workbench

to a WinSpeakerz individual driver (.dvr) file. Driver files are saved with the .dvr filename extension.

You can use individual driver files to exchange data with WinSpeakerz (available separately from True

Audio).

Print… (Ctrl+P)

Brings up a print dialog box and prints a report based on the currently displayed memories. The report

shows all of the currently displayed memories. You can print in either Portrait or Landscape mode and

the report will adapt to the shape. The use of color and other preferences can be set at the menu: Edit/

Preferences.

Print Preview

Shows an on-screen preview of what the printed page will look like..

Print Setup…

This command displays the printer setup dialog to allow you to select the printer, paper and page

orientation. Printing in portrait orientation provides space for the most printed notes, while printing in

landscape orientation provides a larger printed plot with less space for notes.

Page 17

Recent Files...

A list of recently used files is displayed for easy access.

Exit (Ctrl+Q)

Exits the application. The keyboard shortcut is very convenient.

Page 18

Edit Menu

The commands under the Edit menu are as follows:

Undo (Ctrl+Z)

Undo is not implemented

Cut (Ctrl+X)

Cut is implemented for various text fields. Text is cut and placed on the clipboard for pasting to

another location if desired

Copy (Ctrl+C)

Copy is implemented for various text fields. Copied text is placed on the clipboard for pasting to

another location

Paste (Ctrl+V)

Paste is implemented for various text fields. Use this command to paste text that has been placed on

the clipboard

Open the Driver Editor (Ctrl+D)

Opens the Driver Editor for access to a fully detailed set of driver data. Besides the measured driver

parameters there are fields for you to enter as much additional data as you wish. Each of the 20

memories in a project file holds its own complete set of driver data. When you save a driver file the

complete set of data is saved to a .dvr file which can be opened by the popular loudspeaker design

program WinSpeakerz. Similarly, individual driver files saved by WinSpeakerz can be opened in WT3.

Page 19

Preferences

This command opens the Preferences Dialog (shown below) where you can change various printing,

measurement and display settings

Plots can be switched between fine and bold lines separately for display and printing. You can select

metric units separately for Volumes and other units. Auto Ranging is normally on but can be switched

off for those occasions where you need a different fixed scale for repeat measurements. An initial

"connect the driver" dialog can be enabled for production testing. A preference can be set to measure

L(e) at either 1 kHz or 10 kHz. Measurement at 1 kHz is recommended for general use except when

measuring inductors less than 0.5 mH or drivers smaller than 6 inches in diameter where measurement

at 10 kHz is likely to be more representative.

Page 20

View Menu

The commands under the View menu are as follows:

Toolbar

Select the Toolbar command to alternately hide or show the toolbar.

Status Bar

Select the Status Bar command to alternately hide or show the status bar at the bottom of the main

page. The Status Bar displays information for menu items and buttons. The Status Bar also shows

who's parameters are currently displayed.

Show Phase Response

The Phase Response has three different display modes: Off, On (located center screen) and On (located

at top half). The display rotates through these three states as the menu (or tool bar) command is

selected. The phase range is always +180 degrees to -180 degrees but the scale division varies with the

selected impedance range (in order to use the same grid lines as impedance).

Grid in Front

Displays the grid in front of data on the main screen in order to facilitate reading precise signal levels.

Normally the grid is displayed behind the data.

Background Color

Selects the background color for the main screen. The trace and grid colors also change with each

background color. Choices are: Black, White, Green, Light Gray and Dark Gray.

Save to Memory

These commands cause the plot on the Workbench to be saved to the selected Memory along with all

the driver parameters.

Page 21

From the keyboard, use Alt+1, Alt+2 etc. through Alt+0 to save to memories 1 through 10. Use

Alt+Shift+1, 2 etc. through 0 to save to memories 10 through 20. For example, to save the current

response to Memory 5 you would press and hold the Alt key and then press the 5 key.

Note: The most recently measured impedance plot is said to reside on the WT3 “Workbench.” This

measurement is overwritten each time the analyzer is run. The Workbench is also overwritten when a memory is

recalled or when data is imported. Once you have measured data you want to keep (even temporarily) save it to

one of the 20 memories before proceeding with another measurement. All data in the 20 memories is saved with

the WT3 project file. Multiple memories can be overlaid to allow for easy comparison of various measurements.

Use the memory buttons in the Toolbar to show or hide various memories. After a memory has been recalled it

can then be saved to a different memory. After a memory is recalled it is available to be exported to a .txt file.

Show/Hide Memory

These commands alternately show and hide the selected memory.

•

From the keyboard, use Ctrl+1, Ctrl+2 etc. through Ctrl+0 to show or hide memories

1 through 10

•

Use Ctrl+Shift+1, 2 etc. through Ctrl+Shift+0 to show or hide memories 10 through

20

For example, to toggle the display of the response in Memory 5 you would press and hold the Ctrl key

and then press the 5 key. Use Ctrl+W to toggle the display of the Workbench response. In addition to

the menu and keyboard commands, you can also toggle each memory on or off at the Memory

Toolbar.

Clear Memory

These commands erase the contents of the specified memory.

•

From the keyboard, use Ctrl+Alt+1, Ctrl+Alt+2 etc. through Ctrl+Alt+0 to clear the

contents of memories 1 through 10

•

Use Ctrl+Alt+Shift+1, 2 etc. through Ctrl+Alt+Shift+0 to clear the contents of

memories 10 through 20

For example, to erase the response in Memory 5 you would press and hold the Ctrl and Alt keys and

then press the 5 key. Should you need to clear all of the memories it is usually easier to just create a

new project file by selecting "New" under the "File" menu.

Hide All Memories (Ctrl+E)

This command turns off the display of all memories without affecting the contents of the memories.

Page 22

Impedance Analyzer Menu

The Impedance Analyzer Menu contains commands for running measurements and for performing

calibration of the test lead resistance and master calibration as follows:

Measure Free Air Parameters

This command causes WT3 to run an impedance sweep and then extract the driver's free air

parameters. You can also use this command to measure resistor and inductor values. Measuring a

resistor should result in a flat impedance plot indicating the resistance is the same across the audio

frequency band. R(e) is the measured resistance value. The measured resistance can also be read

directly from the plot. When measuring an inductor, the plot will rise at high frequencies and L(e)

indicates the measured inductance value. You can also execute the Free Air Parameters command by

clicking the same named button at the Impedance Bar at the left side of the main window.

Measure V(as) by the Selected Method

Before any measurements are made this command is disabled (grayed out). After making a free air

measurement this command becomes enabled and can be used to measure the V(as) of a driver by any

of three methods. The V(as) test method is selected at the Parameters Bar at the right side of the main

window. You can also Measure V(as) by clicking the same named button at the Impedance Bar at the

left side of the main window. The three methods are: Test Box, Added Mass and Specified SPL.

•

Test Box: This method is probably the most widely used and trusted. For this method

you will need a test speaker enclosure of suitable size for the driver being tested

•

Added Mass: Although the added mass method can employ added mass in the simple

form of coins added to the cone it is best to make sure the added mass actually adheres

to the cone so that it moves with the cone at all times. If the mass "decouples" as the

cone moves then accuracy will be compromised. Use an added mass that will shift the

F(s) lower by about 25-50%. An added mass equal to the driver's Mms is just about

right. WT3 will warn you if the shift in the measured F(s) is not within the above

recommended range.

Some items used for added mass include: coins, modeling clay, carpenters putty, rope caulk, tape rolls.

In general you should measure the weight of the added mass accurate to 1/10th of a gram. In a pinch,

US coins can provide an easy source of standard weights. One US nickel ($.05) weighs 5.0 grams.

•

Specified SPL: This is the simplest V(as) method as it requires no test box or added

masses. It is also probably the least accurate as it depends strongly on the accuracy of

the SPL you specify.

Page 23

Impedance Sweep

Use this command to perform a simple impedance sweep without the extraction of any parameters.

Driver parameters will be cleared to prevent any confusion.

Impedance Calibration...

When first installed, WT3 is calibrated to within about 2% for the impedance range under 100 Ohms.

This is adequate for measuring driver parameters. For even finer calibration you can use this command

to custom calibrate the system for your particular WT3 hardware unit. When you select this command

the impedance calibration dialog (shown below) will open.

Enter the actual value of the calibration resistor you are using (if different from the recommended 1k

Ohms). Then, connect the calibration resistor to the WT3 test leads and click OK. The software will

measure the calibration resistor and adjust its internal calibration accordingly. After calibration, you

might want to make another measurement of the calibration resistor to confirm the new calibration. By

design, WT3 is most accurate in the lower impedance range with accuracy decreasing at higher

impedances (above 1k Ohms). Calibration in the lower impedance range will typically be improved to

within 1% following calibration at 1k Ohms with the 1% resistor included with the unit. You can

actually calibrate the unit with any convenient resistor in the range from about 500 to 2k Ohms. It is

important that the actual value of the resistor be known to within 1%. High quality digital multi-meters

will often be able to measure any resistor to within 1%.

When you exit the application the new calibration will be remembered for your next session.

Impedance calibration only needs to be performed one time after the software is installed on a PC.

Page 24

Test Leads Calibration...

When the software is first installed the default test lead impedance is 0.3 Ohms which is typical of the

units. Use this command to refine the test lead calibration for your WT3 unit. Shown below is the test

leads calibration dialog. Just short the test leads and click OK. The software will measure the test lead

resistance and adjust the internal calibration. When you exit the application the new test lead

calibration will be remembered for your next session.

Page 25

Help Menu

The commands under the Help menu are as follows:

Help Topics

The complete WT3 User’s Guide can be found under the Help menu > Help Topics.

User Information

Enter your personal information in this window. This is the information that will display at the Splash

Screen and in the title block of your printed reports.

About WT3

Displays the WT3 version number, copyright and user information.

Page 26

Using WT3 to Measure a Woofer's Parameters

The basic steps to measure a driver's parameters are as follows. Before starting, be sure the unit has

been calibrated.

•

Start by connecting the WT3 hardware unit to a USB port on your PC.

•

Next, launch the WT3 software.

•

Make sure that the woofer is not connected to any other equipment and then connect the test

leads of the WT3 unit to the terminals of the speaker under test.

•

Raise the Windows volume control to maximum.

•

Click the "Measure Free Air Parameters" button at the left side of the WT3 screen.

•

You should hear the sweep from the speaker, the impedance is plotted and the parameters are

displayed.

•

Select a method to measure V(as), enter the required data and click on the "Measure V(as)"

button.

After measuring a speaker you may want to enter additional information (say, the manufacturer and

model of the speaker) at the Driver Editor. Then save the measurement to an empty memory. As an

example, the keyboard sequence "Alt + 1" saves new data to memory 1.

Here is a typical measurement result:

Page 27

Using WT3 to Measure a Tweeter's Parameters

A typical sealed back moving coil tweeter operates as a very small closed box system and therefore

can be characterized by it's closed box resonance and Q, F(sc) and Q(tc). You can use WT3 to measure

both of these parameters for tweeters as well as woofers and midranges. The frequency response of a

tweeter is the same as that of a purely electrical second order high-pass filter with the same electrical

resonance frequency and Q as the tweeter's electro-acoustic resonance and Q. While the resonance

frequency determines the low frequency bandwidth of the tweeter, the Q(tc) determines the shape of

the response in the corner region with Q = .707 corresponding to a maximally flat Butterworth

response.

The impedance response of a tweeter operating as a closed box loudspeaker has a single well defined

peak at the tweeter's primary resonance frequency at the low end of the tweeter's operating range.

Before starting, make sure the WT3 unit has been calibrated and has stabilized for at least 90 seconds.

Measure the tweeter's impedance as follows:

•

Launch the WT3 software and make sure the volume is at maximum.

•

Under the Edit menu select Preferences and set the L(e) Measurement Frequency to 10 kHz.

•

Make sure that the tweeter is not connected to any other equipment and then connect the test

leads of the WT3 unit to the tweeter under test.

•

Click the "Measure Free Air Parameters" button at the left side of the WT3 screen.

•

You should hear the sweep from the tweeter, the impedance is plotted and the parameters are

displayed.

•

The tweeter's equivalent closed box resonance frequency, F(sc) is displayed in the F(s) data

field.

•

The tweeter's equivalent closed box total Q, Q(tc) is displayed in the Q(ts) field.

•

Save the equivalent closed box data to a memory for future reference.

•

The DC resistance of the tweeter is displayed in the R(e) field. Ignore all other parameters.

•

Repeat the measurement to confirm the result. Repeated measurements should be in good

agreement.

Page 28

Here is a typical result when measuring a tweeter:

We can read the tweeter's resonance frequency, F(s) (or, more strictly F(sc)), directly from the

impedance plot or note the value at the Measured Parameters F(s) field. Just as with a closed box, the

system's Q(tc) is read from the Q(ts) field. Similarly for the electrical and mechanical Q's. The above

tweeter is seen to have a resonance of 1.848 kHz and Q(tc) of .5067.

Page 29

Using WT3 to Measure a Resistor

Before starting, make sure the WT3 unit has been calibrated and has stabilized for at least 90 seconds.

Measure the value of a resistor as follows:

•

Launch the WT3 software and make sure the volume is set at maximum.

•

Make sure that the resistor is not connected to any other equipment and then connect the test

leads of the WT3 unit to the resistor under test.

•

Click the "Measure Free-Air Parameters" button at the left side of the WT3 screen.

•

The sweep is silent, then the impedance is plotted and the parameters are displayed.

•

Read the value of the resistor in the R(e) field at the right side of the screen. Ignore the other

parameter fields.

•

Repeat the measurement to confirm the result. Repeat measurements should be in good

agreement.

Here is a typical result when measuring a 10 Ohm resistor:

An ideal resistor would have a perfectly flat impedance response at exactly the rated value of the

resistor. Notice that the measured impedance (shown above in blue) of this 10 Ohm precision resistor

is almost perfectly flat over the audio frequency range. This is not unusual for a resistor because real

resistors typically do behave largely as ideal resistors. The impedance phase response is essentially flat

Page 30

at 0 degrees except for a slight rise at the high frequency limit. Here the measured value of 9.998

Ohms is seen to closely match the resistor's specified value of 10 Ohms +/- 0.1%.

At full playback volume the "noise" on the measurement is usually only one or two pixels as seen

above. Higher noise levels can indicate that the test signal level was low and should be raised.

Page 31

Using WT3 to Measure an Inductor

Before starting, make sure the WT3 unit has been calibrated and has stabilized for at least 90 seconds.

Measure the value of an inductor as follows:

•

Launch the WT3 software and make sure the volume is set at maximum.

•

Make sure that the inductor is not connected to any other equipment and then connect the test

leads of the WT3 unit to the inductor under test.

•

Click the "Measure Free-Air Parameters" button at the left side of the WT3 screen.

•

The sweep is silent, then the impedance is plotted and the parameters are displayed.

•

Read the value of the inductor in the L(e) field at the right side of the screen. The DC resistance

of the inductor is displayed in the R(e) field. Ignore all other parameters.

•

Repeat the measurement to confirm the result. Repeat measurements should be in good

agreement.

Here is a typical result when measuring a 1.0 mH inductor:

An ideal inductor would have an impedance of zero Ohms at the lowest frequencies and then the

impedance would rise with increasing frequency. The phase response of the inductance depends on the

exact circuit in which the inductor finds itself. At very low frequencies (1 Hz) the impedance

measurement reveals the DC resistance of the inductor. Notice that the impedance (blue) of the real

inductor measured above is near zero at low frequencies and rises at high frequencies as expected. The

Page 32

phase response (red) is seen to be near zero degrees at low frequencies and increases to 90 degrees at

high frequencies as expected for the simple (R-L) test circuit. The measured value of 0.9893 mH is in

good agreement with the inductor's nominal 1.0 mH rating. At 0.2422 Ohms the inductor's DC

resistance is nicely low as required for use in a passive crossover. Note that WT3 can measure

inductance at either 1kHz or 10 kHz based on the selection at the Preferences dialog. Measurement at

1 kHz is recommended for general use except when measuring inductors less than 0.5 mH or drivers

smaller than 6 inches in diameter where measurement at 10 kHz is likely to be more representative.

Page 33

Using WT3 to Evaluate a Closed Box Loudspeaker

A closed box type of loudspeaker system is characterized by a resonance frequency F(sc), an electrical

Q value Q(ec), a mechanical Q value Q(mc) and a total Q value Q(tc). Just as you can use WT3 to

measure a driver's parameters you can also use WT3 to measure the corresponding parameters of a

closed box loudspeaker system. The frequency response of a closed box speaker is the same as that of

a purely electrical second order high-pass filter with the same electrical resonance frequency and Q as

the loudspeaker's electro-acoustic resonance and Q. While the resonance frequency determines the low

frequency bandwidth of the system, the Q(tc) determines the shape of the high-pass response in the

corner region with Q = .707 corresponding to a maximally flat Butterworth response.

The impedance response of a closed box loudspeaker has a single well defined peak at the system's

primary resonance frequency. Compared to the same driver in free air, the resonance frequency will

always be seen to increase when a driver is mounted on a closed box enclosure. The larger the

enclosure the less the resonance frequency is increased. The same is also true for the driver's Q(ts)

parameter versus the closed box system's Q(tc). The Q(tc) for the driver in an infinitely large enclosure

would equal the Q(ts) of the driver. As the enclosure size is reduced the Q(tc) of the closed box system

increases. So a given closed box speaker will always have F(sc) and Q(tc) values somewhat higher

than the driver's corresponding free air parameters F(s) and Q(ts).

Before starting, make sure the WT3 unit has been calibrated and has stabilized for at least 90 seconds.

Measure the system impedance as follows:

•

Launch the WT3 software and make sure the volume is at maximum.

•

Make sure that the speaker system is not connected to any other equipment and then connect

the test leads of the WT3 unit to the speaker under test.

•

Click the "Measure Free Air Parameters" button at the left side of the WT3 screen.

•

You should hear the sweep from the speaker, the impedance is plotted and the parameters are

displayed.

•

The system's closed box resonance frequency, (F(sc) is displayed in the F(s) data field.

•

The system's closed box total Q, Q(tc) is displayed in the Q(ts) field.

•

The system's closed box mechanical Q, Q(mc) is displayed in the Q(ms) field.

•

The system's closed box electrical Q, Q(ec) is displayed in the Q(es) field.

•

The DC resistance of the system is displayed in the R(e) field. Ignore all other parameters.

•

Repeat the measurement to confirm the result. Repeated measurements should be in good

agreement.

Page 34

Here is a typical result when measuring a single full range driver in a closed box type enclosure:

By inspecting the impedance plot we can determine that this is a closed box type of loudspeaker

system from the presence of the single impedance peak in the low frequency range. From the

impedance plot alone we can identify the closed box resonance frequency F(sc) = 95 Hz by reading the

center frequency of the impedance peak from the frequency scale below. The impedance rise at higher

frequencies is due to the inductance of the voice coil. At very low frequencies (1 Hz) the system's DC

resistance is seen to be about 3 Ohms. The height of the impedance peak is largely dependent of the

mechanical Q of the driver or system. The Measured Parameters bar at the right side of the screen

show that this closed box system's resonance is at 95.55 Hz with a system Q(tc) of 0.6232 (displayed in

the Q(ts) field). The system's Q(ec) and Q(mc) appear in the Q(es) and Q(ms) fields respectively, for a

closed box measurement. The R(e) field gives the DC resistance of the system.

Page 35

Using WT3 to Evaluate a Vented Box Loudspeaker

A vented box type of loudspeaker system can be characterized by it's equivalent closed box Q(tc) and

the vented enclosure's Helmholtz tuning frequency F(b). You can use WT3 to measure both of these

parameters for any vented box loudspeaker system. The frequency response of a vented box speaker is

more complex than that of a closed box being equal to the frequency response of a fourth order highpass filter. The characteristics of the fourth order high-pass response depend on both the equivalent

closed box response and the vent tuning frequency.

The impedance response of a typical vented box speaker is characterized by two impedance peaks in

the low frequency region. The enclosure's tuning frequency is indicated by the frequency where the

impedance is a minimum between the resonance two peaks.

Before starting, make sure the WT3 unit has been calibrated and has stabilized for at least 90 seconds.

Measure the system impedance as follows:

•

Launch the WT3 software and make sure the volume is at maximum.

•

Make sure that the speaker system is not connected to any other equipment and then connect

the test leads of the WT3 unit to the speaker under test.

•

Temporarily block the speaker's vent using an airtight plug to convert the speaker to the

equivalent closed box system.

•

Click the "Measure Free Air Parameters" button at the left side of the WT3 screen.

•

You should hear the sweep from the speaker, the impedance is plotted and the parameters are

displayed.

•

The system's equivalent closed box resonance frequency, F(sc) is displayed in the F(s) data

field.

•

The system's equivalent closed box total Q, Q(tc) is displayed in the Q(ts) field.

•

Save the equivalent closed box data to a memory for future reference.

•

Unplug the vent and click the "Measure Free Air Parameters" button again.

•

You should hear the sweep from the speaker, the impedance is plotted.

•

Identify the two resonance peaks in the low frequency range.

•

Read the system's box tuning frequency, F(b) as the frequency at the minimum between the two

peaks.

•

The DC resistance of the system is displayed in the R(e) field. Ignore all other parameters.

•

Repeat the measurement to confirm the result. Repeated measurements should be in good

agreement.

Page 36

Here is a typical result when measuring a single full range driver in a vented box type enclosure:

Page 37

In order to read the vent tuning frequency, F(b), more precisely we can adjust the frequency display

limits to zoom in on the frequency range containing the two impedance peaks as shown below:

At this screen we can determine that F(b), the tuning frequency of the vented box, is approximately 40

Hz by locating the impedance minimum between the two peaks and reading the frequency where the

minimum occurs. The closely zoomed view makes it easier to read the frequency from the scale below.

Page 38

Using WT3 to Evaluate a Complete Speaker System

You can use WT3 to measure the impedance of complete multi-way loudspeaker systems. Based on

this impedance curve we can tell a number of things about the system, such as whether the woofer uses

a closed or vented enclosure. While a single peak in the low frequency range suggests a closed box, a

single peak would also be seen for a driver operating as a dipole on a large baffle. Twin resonance

peaks typically indicate a vented enclosure. The enclosure tuning frequency is the frequency between

the two peaks where the impedance is a minimum.

Before starting, make sure the WT3 unit has been calibrated and has stabilized for at least 90 seconds.

Measure the speaker system impedance as follows:

•

Launch the WT3 software and make sure the volume is at maximum.

•

Make sure that the speaker system is not connected to any other equipment and then connect

the test leads of the WT3 unit to the speaker under test.

•

Click the "Measure Free Air Parameters" button at the left side of the WT3 screen.

•

You should hear the sweep from the speaker, the impedance is plotted and the parameters are

displayed.

•

Save the system's impedance response to a memory for future reference.

•

The DC resistance of the system is displayed in the R(e) field. Ignore all other parameters.

•

Repeat the measurement to confirm the result. Repeated measurements should be in good

agreement.

Page 39

Here is a typical result when measuring a complete 2-way speaker system:

We can see that this system employs a vented woofer system with the vented enclosure tuned to about

40 Hz. Even with a minimum impedance of just over 6 Ohms this would often be considered to be a

nominal 8 Ohm loudspeaker system.

Page 40

Using WT3 to Diagnose Loudspeaker Fault Conditions

When carefully applied WT3 can be used to spot common problems with a speaker system. For

example, the screen below shows two impedance measurements of the same two-way speaker system.

The green (lower) plot shows the normal impedance response of this system. The purple (upper) plot

shows the system with the tweeter in an open circuit fault condition. The missing tweeter load causes

the impedance response to rise above 2 kHz suggesting that the tweeter has faulted to an "open

circuit". If only the faulty system is available for testing it may be less apparent that there is a problem.

But if a suspect speaker is compared to a good speaker the fault condition is easy to see.

Page 41

In the screen below you see the same system as above but this time with a shorted tweeter. The green

(upper) plot again shows the normal impedance response of this system. The yellow (lower) plot shows

the system with a shorted tweeter. The system with the shorted tweeter appears to have a suspiciously

low impedance above 4 kHz or so but when compared to the normal response (green) it is easy to see

there is a problem.

Page 42

Now let's examine similar fault conditions for the woofer. The screen below shows the same 2-way

system as above with the green plot representing the normal system and the orange plot showing the

system in a fault mode with an open circuit woofer. The system is seen to be unloaded (high

impedance) over most of the woofer's frequency range. (not that a dead woofer is very hard to detect!)

Page 43

Finally, here is a screen shot showing the same system with the woofer in a short circuit fault condition

(lower blue trace). As we see in these examples often a system fault is most easily detected by

comparing the suspect system to a known good system.

Page 44

Using WT3 to Design a Zobel Network

Zobel networks are used to control the impedance of a loudspeaker driver in the upper frequency range

where voice coil inductance normally causes the impedance to rise with increasing frequency. Zobel

networks are used to help crossovers do a better job of keeping the highs from passing to the woofer.

A Zobel consists of a resistor and capacitor connected in series and attached between the terminals of

the driver. The resistor is normally selected to match the nominal impedance of the system. The

capacitor value can then be calculated or, in this case, determined empirically. Because WT3 is able to

perform impedance sweeps in just a few seconds it can be used for any type of repetitive adjust and

measure process...such as designing a Zobel network to neutralize the inductance of a driver. Yes, you

can calculate the component values for a Zobel network but sometimes it is easier to just clip a

resistor/capacitor network across the driver and see what you get for the impedance.

Below is the impedance response of a small woofer with no other components connected. Notice the

rising impedance above 500 Hz. We would like to design a Zobel network to compensate the woofer

and restore the impedance to some nominal value above 500 Hz.

With a DC resistance of 5.5 Ohms this would most likely be considered to be an 8 Ohm driver. So let's

set the resistor value to about 8 Ohms. Looking in my parts bin I see the closest values on hand are 5

and 10 Ohms. Let's use 10 Ohms so that we tend to under compensate. We'll select the capacitor value

by starting too low and stepping up the capacitor until the impedance response looks about as flat as

Page 45

we can get it in the upper frequency range. Let's start with around 1 uF for the capacitor and see what

we get for a new impedance response. The screen below shows the new impedance response in purple

with the original (uncompensated) response in blue. Notice that the impedance has only been reduced

above 5 kHz. This is because our capacitor value is too low. Let's increase the capacitor and see what

happens.

Page 46

Below is the impedance with the capacitor increased to 2 uF (blue trace). The original

(uncompensated) impedance is shown in green. The 2 uF capacitor has flattened out the impedance so

that it rises only slightly above 8 Ohms. Since it is easy to do let's continue to increase the capacitor

value and see if we can get a further improvement. Ideally we would like the impedance to be as flat as

possible...at least above the resonance peak.

Page 47

The screen below shows the effect of increasing the capacitor to 3 uF (blue trace). The increase from 2

to 3 uF gave even further improvement as the impedance above resonance is now quite flat. Just to see

what happens, let's increase the capacitor further to 5 uF.

Page 48

Below we see the effect of increasing the capacitor to 5 uF in the lowest (blue) trace. It seems we have

gone too far with the increase to 5 uF. The impedance in the 2 to 3 kHz range has been reduced to the

DC resistance value and is now rising above the previous measurement with the 3 uF capacitor. This

rise may be due to an interaction with the voice coil inductance. It looks like the 3 uF capacitor will be

the best overall choice to tame the driver's high frequency impedance.

The point of the exercise was to demonstrate how an inductance compensating network, or Zobel

network could be designed experimentally by "trial and error". Even if you choose to calculate the

values for the Zobel network you still might want to verify the resulting impedance response of the

driver with the Zobel connected. In general you could take the same approach to verify other networks

such as the resonance compensation network (R-L-C) sometimes used to neutralize the impedance

peak of a tweeter. As an impedance measurement system the additional applications for WT3 are

limited only by the user's imagination.

Loading...

Loading...