Dayton RS621MK User Manual

6. Install Grill

The grill has four neodymium magnets which are embedded in the

frame. These magnets are arranged to align with the screws that hold the

bafe in place. Simply place the grill on the bafe and align as necessary.

7. Test the speaker

Connect the speakers to your stereo system and play music through

the speakers to verify that the overall sound is full and smooth. If a

driver is not working or the sound is intermittent or distorted, please

see the troubleshooting section for possible remedies. In most cases

the cause of a problem will be traced back to improper wiring of the

crossover and not faulty drivers.

Break-In: Please allow a full two weeks of playing time at moderate

volumes before playing the system at high energy levels. This will allow

the drivers suspensions to properly break in before being subjected to

large excursions.

Troubleshooting

Again, in most cases the cause of a problem will be traced back to the improper wiring of the crossover and not a faulty driver. Common mistakes:

using the wrong harness, improper polarity, bad or loose connections.

Care and cleaning

To protect the Dayton speaker system’s nish, use some care when

cleaning it. To remove dust from drivers, grills, or the cabinet tops, a

synthetic “feather duster” works well. For more stubborn dust on the

grills or woofers, a vacuum cleaner with gentle brush attachment may

be used. It is not recommended to use any type of cleaning apparatus

on tweeter domes; dust will not affect the sound, and the chance of

damaging the dome is high.

For cleaning streaks or ngerprints on the cabinet nishes, an

ammonia-based window cleaner is recommended. It will not affect the

nish and will leave a streak-free shine. It is important to use only very

soft, clean cloths, and to wipe gently at the surface. Intense scrubbing

or using cloths with debris on them may cause small swirl marks or

scratches. Of course, the best way to maintain the nish on the cabinet

is to prevent soiling it in the rst place. Never place drinks or abrasive

objects on the top of the speaker.

Problem: No output from speaker system.

Cause: Bad connection.

Solution: Check connections from the stereo to the input of the

speaker system. If OK, check the connection from the binding post

to tweeter and woofer input terminals. If this is OK, Test speaker on

another system. If sound comes out check initial stereo settings and

connections (speakers on/off). If there is no sound at all, please contact

your place of purchase immediately.

Problem: No output from woofer in individual speaker.

Cause: Bad connection or defective woofer.

Solution: Check connections from crossover board to woofer. If this

is OK, directly test the woofer by hooking it up to stereo system at

low volume setting. If sound comes out of the woofer, then go back

and check connections. If there is no sound at all, then woofer is likely

defective. Please contact your place of purchase immediately.

Problem: No output from tweeter in individual speaker.

Cause: Bad connection or defective tweeter.

Solution: Check connections from crossover board to tweeter. If OK, it

is possible to carefully test the tweeter by directly connecting it to your

stereo. Test at a very low volume for a brief period of time, at the level

of a loud whisper. If there is high-frequency sound, then go back and

check connections. If no sound at all, then tweeter is likely defective.

Please contact your place of purchase immediately.

Problem: There is sound from the speaker, but it is very quiet and

seems to be mostly treble or midrange.

Cause: Woofer and tweeter are wired backwards.

Solution: Immediately cease testing to prevent damage to the tweeter.

Check connections from crossover board to woofer and tweeter, making sure the high pass lter denoted with a “T” on the output terminal

is connected to the tweeter and the low pass lter denoted as “W” is

connected to the woofer.

Problem: Intermittent output of entire speaker, woofer, or tweeter.

Cause: Bad connection in wires or crossover board.

Solution: If entire speaker is intermittent, then check connections

between the input terminals and the crossover board. If just woofer or

tweeter is intermittent, check the wires going to the drivers. If these are

OK, check the connections of the components within the appropriate

section of the crossover.

Problem: In stereo, speakers lack bass or image is unfocused.

Cause: Speakers are out of phase.

Solution: Check connections from amplier to the speakers. Make

sure polarity is the same on both speakers. If correct, check the polarity

of connections going from binding posts to input on crossovers. If this

does not correct the problem, check polarity throughout the rest of the

system, looking for one driver that is wired incorrectly.

Problem: One speaker appears louder than the other.

Cause: Amplier settings, environmental factors, psychoacoustics,

poor connection in crossover.

Solution: Check your amplier to ensure that the balance is set even.

Next, check that one speaker isn’t closer to a wall, window, couch, or

other acoustically important object. This may affect perceived loudness

due to the addition or reduction of extra sound reections. If this is the

case, physically switch the left and right speakers, and re-observe. If the

same location still sounds quieter, then it is the environment. If the quiet

speaker moves, then you may have a problem within the speaker. Often,

if you think one speaker is louder than the other, it will appear so. Have

someone help you do a blind test or take a break and allow time for your

brain to relax. The next day, if one still seems louder, investigate all connections within the crossover.

Problem: Speakers play well, but amplier shuts down.

Cause: Amplier does not have enough power or cannot handle

speaker impedance.

Solution: If using 4 ohm speakers, check receiver/amplier manual to

see if it can handle 4 ohm speakers or if it has a low impedance setting.

If not, upgrade your amplier. If the receiver/amplier can safely handle

the speaker load, then it may simply not have enough power.

Loudspeaker Kit

Assembly Instructions

Dayton Audio RS621 Speaker Kit

P.O. Box 52 • Springboro, OH • 45066-052 • Phone: (937) 743-8248

© Dayton Audio®Last Revised: 3/29/2011

IMRS62109A

www.daytonaudio.com

Introduction

The Dayton Audio RS150-8 6" woofer and Dayton Audio RS28A-4 1-1/8" tweeter have been sonically matched and integrated in this system. Great

drivers, superbly constructed enclosures, and optimized crossovers are combined to provide impressive music playback performance. The net crossover

point between the woofer and tweeter is at about 2,300 Hz. A fourth-order acoustic slope was used for the low pass lter and the tweeter utilizes a simple

third-order electrical lter.

The overall output capability and impressive bass response of this compact loudspeaker is second to none—supplemented with a subwoofer, this system really rocks! It is very accurate, yet not harsh or overly clinical. When used properly, the RS621 can handle a healthy amount of power and produce

sound pressure levels that will ll any average-sized room. Overall, these great all-around compact speakers will excel in a myriad of applications.

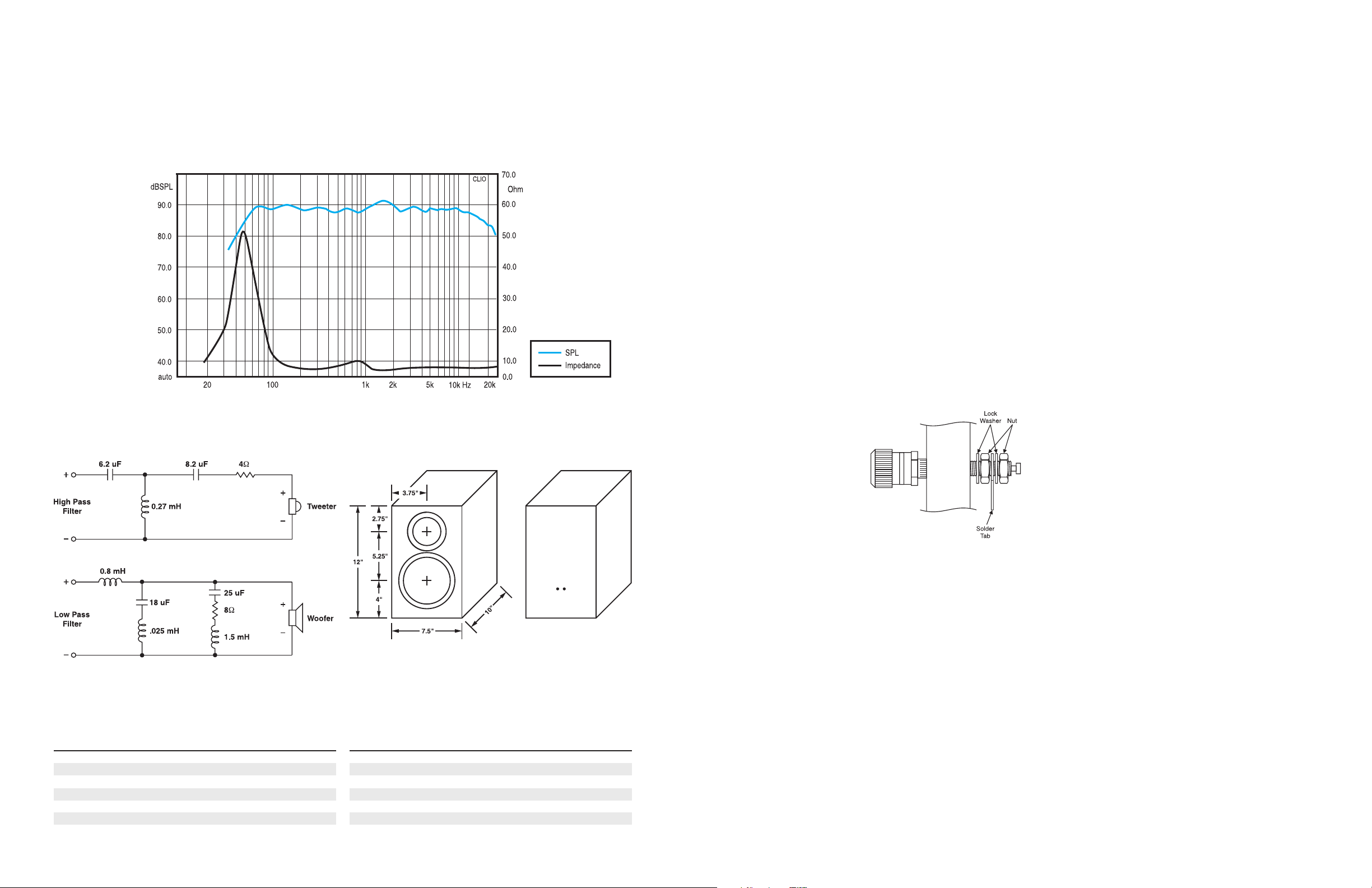

Frequency Graph

Specifications: • Impedance: 8 ohms • Frequency response: 60 - 20,000 Hz • SPL: 88 dB 2.83V/1m • Power Handling: 65 watts RMS

• Cabinet dimensions (straight-sided): 12" H x 7.5" W x 10" D • Cabinet dimensions (curved sided): 12" H x (7.5" front, 4.5" back) W x 10.5" D.

Front Back

Crossover Diagram

Parts Inventory

Before beginning the assembly process, please read this manual in its entirety and conrm that you have all necessary components listed below.

If anything appears to be missing, please contact your place of purchase immediately

Qty Description

1 Dayton Audio custom .25 ft³ cabinet pair

2 Dayton Audio RS28A-4 1-1/8" aluminum dome tweeter

2 Dayton Audio RS150-8 6" aluminum cone woofer

2 Dayton Audio Optimized high pass lter

2 Dayton Audio Optimized low pass lter

2 Input wiring harness (12" w/ .250" terminals)

2 Woofer wiring harness (12" w/ .250" terminals)

Qty Description

2 Tweeter wiring harness (12" w/ .250" terminals)

2 Dayton Audio heavy duty binding post pair

1 Acoustic foam 24" x 18" x 1-1/2" UL 94

24 #6 x 3/4" Pan head screws

12 #8 x 3/4" Pan head screws

2 36" Speaker sealing caulk

1 Assembly instruction manual

Dimensions based on traditional cabinet design.

Loudspeaker Kit Assembly Instructions

By following these instructions and assembling the speaker in a conscientious manner, you will be able to enjoy your investment for many

years to come. If there are any questions during the assembly process,

please contact your place of purchase.

Gather the Necessary Tools

The assembly of your speaker kit requires several basic tools and

supplies, though more advanced tools can be used if desired. The following list represents the basic tools that are required:

Hammer

#2 Phillips head screwdriver or power driver

Small wrench or pliers

Silicone adhesive or hot-melt glue gun

Scissors or utility knife (for cutting foam)

Workspace Considerations

As with any type of kit assembly, it is best to have a well-lit, large, clean

work area. This will save time by eliminating lost parts and preventing

assembly errors. When working with the cabinets, it is important to

cover the work surface with a cloth or foam layer to protect the speaker

nish. The foam wrap that is around the speaker cabinets will work well

for this, but make sure it is free from dust or other debris.

Getting Organized

To prepare for the kit assembly, begin with some basic unpacking

and organizing. Open the large speaker cabinet box and remove the

cabinet from the packaging. You will need to unwrap the cabinet itself,

saving the wrap to protect your work surface. Remove the bafe from

the cabinet and place the bafe screws somewhere safe. Unpack the

binding posts and other packaged items.

Assembly

1. Install Binding Posts

The posts will need to be

“knocked” into place with

a hammer and secured

from the inside of the cabinet. Start by placing the

cabinet face-down onto

the work surface, being

sure that the cabinet is

rmly supported.

Remove the binding posts

from their package, and

unscrew all washers and

nuts from the shaft. Next,

remove the main nut that

is used to hold the speaker wire onto the terminals—this will prevent

them from getting damaged while the posts are being inserted.

Insert one of the post shafts into the hole and align it, ensuring the

wire through-hole is running vertically. Gently tap into place until the

shoulder is even with the rear of the cabinet.

Note: Excessive hammering is not necessary and may cause damage

to the nish of the cabinet around posts. Repeat the same process with

the second post.

Once the posts have been knocked into place you will need to secure

them from the inside of the cabinet. A lock washer followed by a nut

should be installed to secure the posts to the cabinet. Next, install the

wire terminal tab, the second lock washer, the second nut, and then

tighten into place.

Now that the posts are fully secured, reinstall the colored knobs on the

outside of the cabinet. When viewed from the rear of the cabinet (terminals should be closer to the “bottom” of the cabinet), the “red” terminal

is normally positioned on the right-hand side.

2. Wiring and installing the crossovers

The crossover is composed of two sections (two boards): a low pass

lter for the woofer and a high pass lter for the tweeter. There is an

indicator on the printed circuit board near the output terminals of each

lter, “W” denotes the low pass lter and is for connection to the woofer

and “T” denotes the high pass lter and is for connection to the tweeter.

The input terminal for each board is indicated using “IN”.

Note: In most cases the cause of a problem will be traced back to improper wiring of the crossover so please double check your connections.

Wiring: Each kit includes input, woofer(s) and tweeter wiring harness

with the crossover boards.

Using the parts list, identify the correct harnesses and attach to the appropriate terminals on the crossover boards. The crossover board side

of the harness will always use the larger .250" connectors. Connect the

input wiring harness from both crossover boards to the binding posts

wire terminal tabs while paying close attention to polarity. The red wires

will connect to the terminals that are marked with a + sign.

Location: With the crossover boards in the cabinet and connected to

the input binding posts, identify a suitable mounting location making

sure both the woofer(s) and tweeter wiring harness will reach their

respective drivers. The best location for the high pass lter is on the

bottom front half of the cabinet and the best location for the low pass

lter is across the center of the internal brace.

Mounting: Secure the crossovers to the inside of the cabinet with the

included #6 screws or with silicone or hot-melt glue. If using hot-melt

glue, it is recommended to place the glue on the surface of the cabinet

and then press the board into it. This prevents the glue from cooling too

rapidly or dripping onto the cabinet. For curved-sided cabinets, we recommend using the screws to secure the crossover boards. If you are

using silicone, it is easier to apply the glue to the back of the PC board.

Make sure the mounting location is horizontal, and place the board

into its location. Allow the silicone to cure for an hour or so before you

change the orientation of the cabinet.

3. Install damping material

Fully line the cabinet using the included 1-1/2" acoustic foam. One

sheet should be allocated for each cabinet—cut the foam to size and

then secure to the cabinet interior walls using a spray adhesive such

as 3M’s Super 77 or with hot-melt glue. Cut and piece the foam around

crossover boards and bracing. When using spray adhesive, please

follow the manufacturer’s instructions. It is best to apply the spray to the

foam itself, being sure to spray away from the cabinet to prevent getting

adhesive on the cabinet exterior. When using hot-melt glue, simply

place a few drops of glue at various locations on the rear of the foam

and press into place.

Note: Do not place foam directly on top of or underneath the

crossover boards.

4. Install the baffle

Press the bafe into the cabinet, working carefully to ensure that no

wires are trapped between the bafe and the cabinet. Rout the driver

wiring to their proper driver hole location. Once the bafe is fully

installed, it can be secured via the included machine screws and glued

into place if desired.

Note: Once the bafe is glued into place, making any changes to the

speaker becomes very difcult. Using the four machine screws by

themselves will have adequate holding power to prevent leaks and

vibrations of the bafe. However, for the utmost cabinet strength, the

bafe should be glued into place with polyurethane glue.

5. Install drivers in baffle

When mounting the drivers, start with the tweeter. This will leave the

large woofer opening to help the wiring and placement of the more

delicate tweeter. Identify the tweeter wiring harness and gently pull it

through the tweeter opening and attached the terminals while paying

close attention to the polarity of the connections. The red wires will

connect to the terminals that are marked with a “red” dot or “+” sign.

Repeat this step for the woofer(s).

All drivers should be lowered carefully into place on the bafe. Facing

the terminals towards the bottom of the cabinet is the generally accepted

orientation, though it is not a critical. Using the included screws and predrilled pilot holes carefully tighten the drivers down onto the bafe. Pay

particular attention to not over-tighten screws on drivers with stamped

steel or polymer frames, which can cause deformation of the ange.

Secure the drivers to the bafes with the included screws. All screw

holes are pre-drilled so be sure to properly align the drivers with these

holes during installation. For all driver installations, some form of gasket material should be used between the driver frames and the bafe to

prevent air leaks and vibrations.

Loading...

Loading...