Page 1

A

Klippel Non-Linear Test

Results

LSI (Large Signal

Identification)

Driver Name: ND90-4

Introduction

Large Signal Modeling

t higher amplitudes, loudspeakers produce substantial distortion in the output signal, generated by

nonlinear ties inherent in the transducer. The dominant nonlinear distortions are predictable and are

closely related with the general principle, particular design, material properties and assembling

techniques of the loudspeaker. The Klippel Distortion Analyzer combines nonlinear measurement

techniques with computer simulation to explain the generation of the nonlinear distortions, to identify

their physical causes and to give suggestion for constructional improvements. Better insight into the

nonlinear mechanisms makes it possible to further optimize the transducer in respect with sound

quality, weight, size and cost.

Nonlinear Characteristics

The dominant nonlinearities are modelled by variable parameters such as

Bl(x) instantaneous electro-dynamic coupling factor (force factor of the

motor) defined by the integral of the magnetic flux density B over

voice coil length l as a function of displacement

KMS(x) mechanical stiffness of driver suspension a function of

displacement

LE(i) voice coil inductance as a function of input current (describes

nonlinear permeability of the iron path)

LE(x) voice coil inductance as a function of displacement

More information about these parameters can be found in the article “

Displacement limits”

Nonlinear Parameters

Page 2

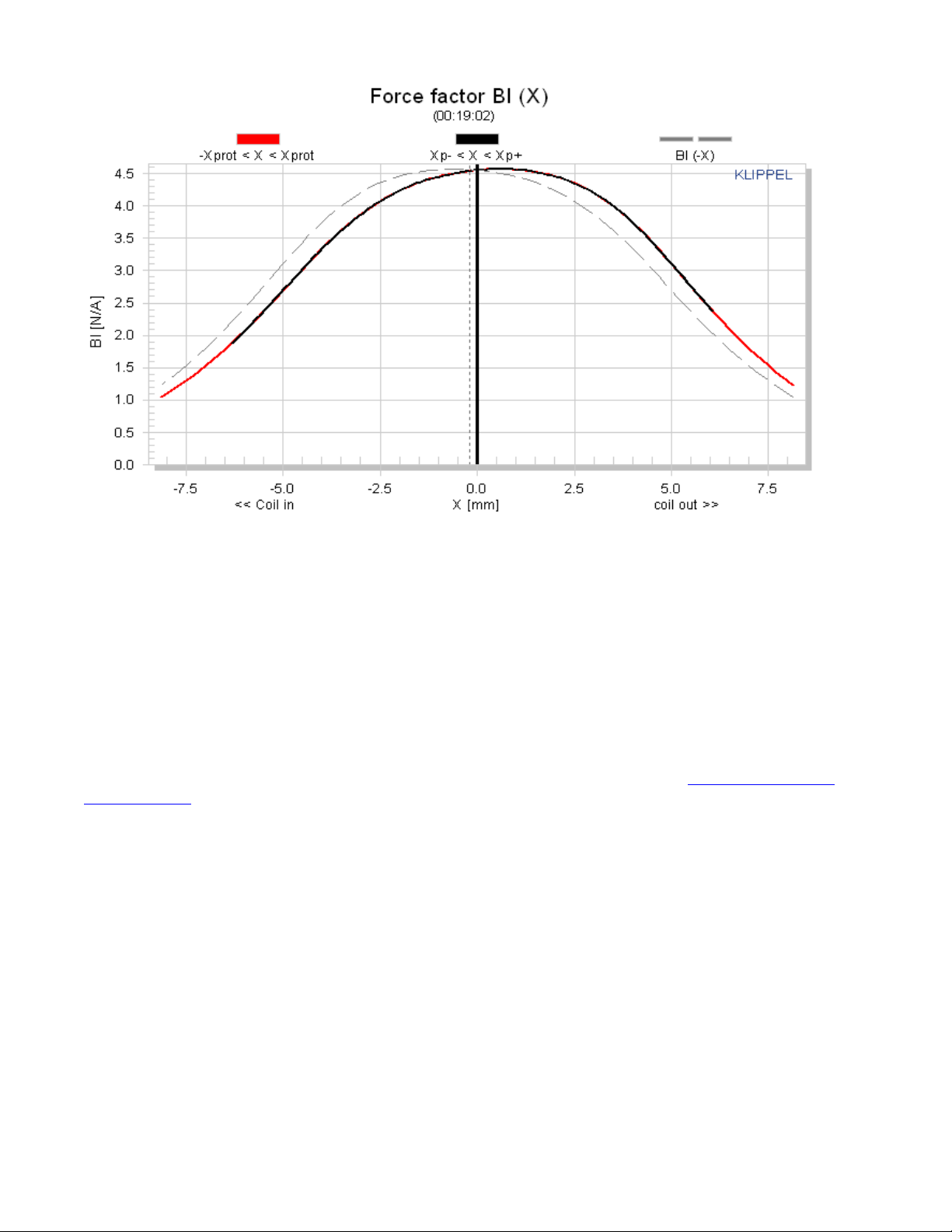

The electrodynamic coupling factor, also called Bl-product or force factor Bl(x), is defined by the

integral of the magnetic flux density B over voice coil length l, and translates current into force. In

traditional modeling this parameter is assumed to be constant. The force factor Bl(0) at the rest

position corresponds with the Bl-product used in linear modeling. The red curve displays Bl over the

entire displacement range covered during the measurement. You see the typical decay of Bl when the

voice coil moves out of the gap.At the end of the measurement, the black curve shows the confidential

range (interval where the voice coil displacement in this range occurred 99% of the measurement

time). During the measurement, the black curve shows the current working range. The dashed curve

displays Bl(x) mirrored at the rest position of the voice coil – this way, asymmetries can be quickly

identified. Since a laser was connected during the measurement, a "coil in / coil out" marker is

displayed on the bottom left / bottom right.

More information regarding Bl(x) and its optimization can be found in the article “

Rest Position”

Optimal Voice Coil

Page 3

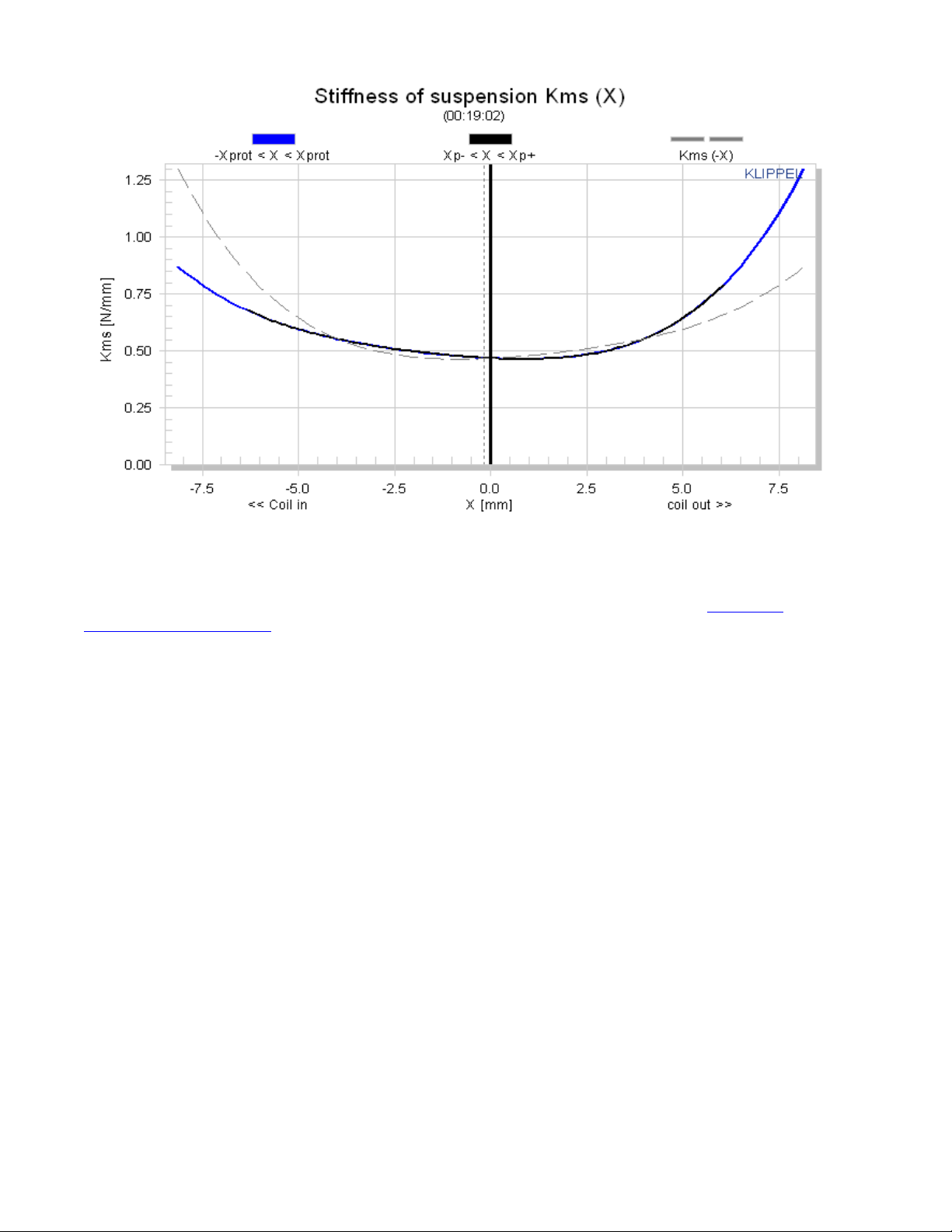

The stiffness KMS(x) describes the mechanical properties of the suspension. It's inverse is the

compliance CMS(x)

More information regarding Kms(x) and its optimization can be found in the article “

Mechanical Suspension”

Adjusting

Page 4

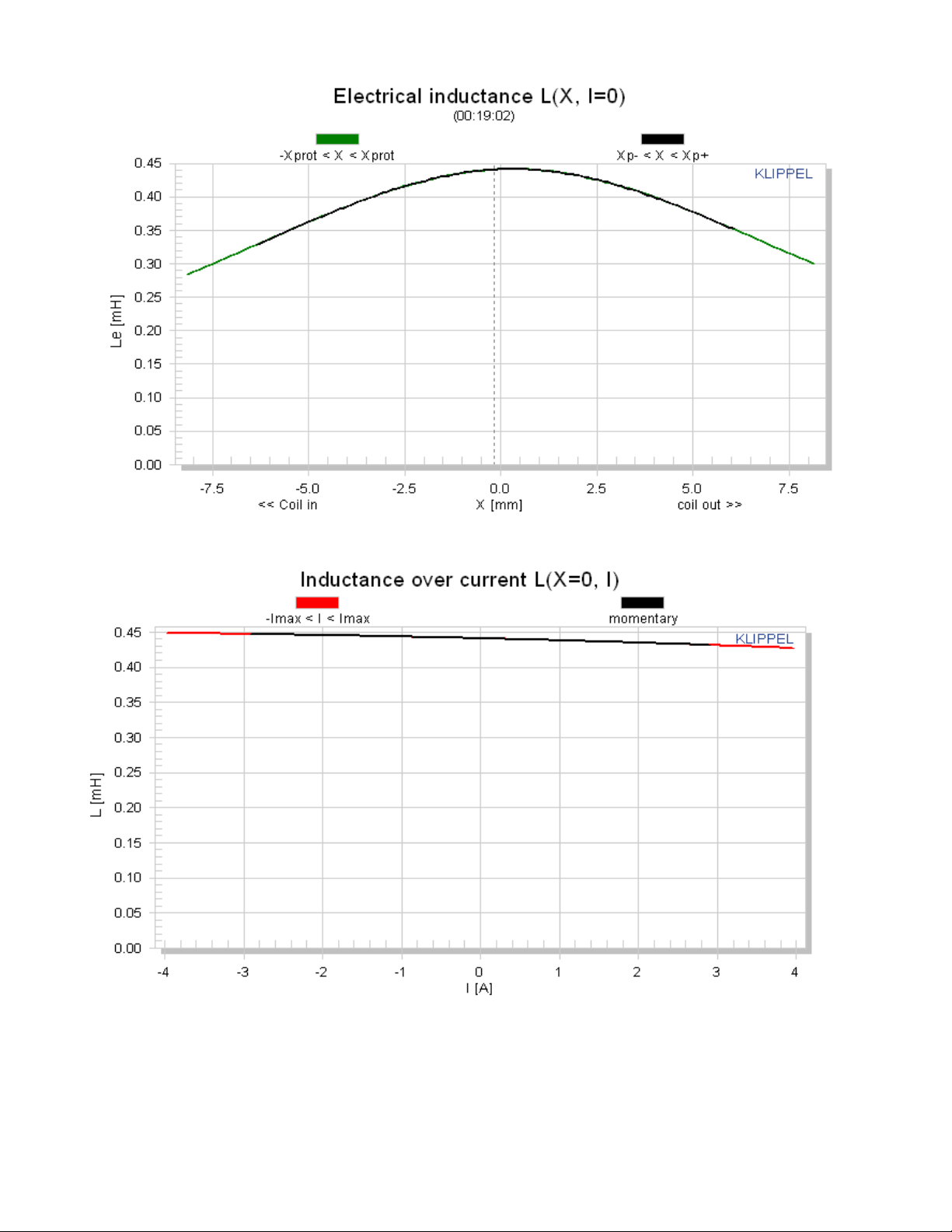

The inductance components Le (x) and Bl(i) of most drivers have a strong asymmetric characteristic. If

the voice coil moves towards the back plate the inductance usually increases since the magnetic field

generated by the current in the voice coil has a lower magnetic resistance due to the shorter air path.

The nonlinear inductance Le(x) has two nonlinear effects. First the variation of the electrical impedance

Page 5

with voice coil displacement x affects the input current of the driver. Here the nonlinear source of

distortion is the multiplication of displacement and current. The second effect is the generation of a

reluctance force which may be interpreted as an electromagnetic motor force proportional to the

squared input current.

The flux modulation Bl(i) has two effects too. On the electrical side the back EMF Bl(i)*v produces

nonlinear distortion due to the multiplication of current i and velocity v. On the mechanical side the

driving force F = Bl(i)*i comprises a nonlinear term due to the squared current i. This force produces

similar effects as the variable term Le(x).

Nonlinear Parameters

The displacement limits XBL, XC, XL and Xd describe the limiting effect for the force factor Bl(x),

compliance Cms(x), inductance Le(x) and Doppler effect, respectively, according to the threshold

values Blmin, Cmin, Zmax and d2 used. The thresholds Blmin= 82 %, Cmin=75 %, Zmax=10 % and

d2=10% generate for a two-tone-signal (f1=fs, f2=8.5fs) 10 % total harmonic distortion and 10 %

intermodulation distortion. The thresholds Blmin= 70 %, Cmin=50 %, Z

harmonic distortion which is becoming the standard for acceptable subwoofer distortion thresholds.

Traditionally, Xmax has been defined as the physical overhang of the voice coil, 15% times the

physical overhang, or the point where BL has dropped 70% from its X=0 value (same as X Bl). The

additional nonlinear limits allow us to quantify the other factors that limit a loudspeaker’s performance.

max=17 % create 20 % total

These parameters are defined in more detail in the papers: “AN04

Displacement Xmax”, “AN05 - Displacement Limits due to Driver Nonlinearities.”, “AN17 - Credibility of

Nonlinear Parameters”, “Prediction of Speaker Performance at High Amplitudes”, “Assessment of

Voice Coil Peak Displacement Xmax”, and “Assessing Large Signal Performance of Loudspeakers”

Symbol Number Unit Comment

Displacement

Limits

X Bl @ Bl

min=82%

X C @ C min=75% 4.8 mm Displacement limit due to compliance variation

X L @ Z max=10

%

X d @ d2=10% 19.7 mm Displacement limit due to IM distortion (Doppler)

alpha Heating of voice coil by eddy currents

alphaOrg Heating of voice coil by eddy currents (without limits)

Rtv K/W thermal resistance coil ==> pole tips

rv Ws/Km air convection cooling depending on velocity

Rtm K/W thermal resistance magnet ==> environment

tau m min thermal time constamt of magnet

Ctm Ws/K thermal capacity of the magnet

thresholds can be changed in Processing property page

3.3 mm Displacement limit due to force factor variation

>6.0 mm Displacement limit due to inductance variation

– Measurement of Peak

Page 6

tau v s thermal time constant of voice coil

Ctv Ws/K thermal capacity of the voice coil

delta Tw K Temperature increase in Warm Resistance Mode

delta Tc K Temperature increase in Convection Mode

delta Te K Temperature increase in Eddy Mode

Pcoil(warm) W Pcoil in warm mode

Pcoil(conv) W Pcoil in convection mode

Ptv(mag.beg) W power heating the coil at beginning of magnet mode

Ptv(mag.mid) W

power heating the coil sampled in the middle of magnet

mode

Ptv(mag.end) W power heating the coil at end of magnet mode

Ptm(mag.beg) W power heating the magnet at beginning of magnet mode

Ptm(mag.mid) W

power heating the magnet sampled in the middle of magnet

mode

Ptm(mag.end) W power heating the magnet at end of magnet mode

f1 -0.006115 1/A coefficient (1) of Inductance over current (flux modulation)

f2 -0.000457 1/A^2 coefficient (2) of Inductance over current (flux modulation)

Bl0 = Bl (X=0) 4.6298 N/A constant part in force factor

Bl1 0.065773 N/Amm 1st order coefficient in force factor expansion

Bl2 -0.077099 N/Amm^2 2nd order coefficient in force factor expansion

Bl3 -0.00098838 N/Amm^3 3rd order coefficient in force factor expansion

Bl4 0.00034136 N/Amm^4 4th order coefficient in force factor expansion

Bl5 N/Amm^5 5th order coefficient in force factor expansion

Bl6 N/Amm^6 6th order coefficient in force factor expansion

Bl7 N/Amm^7 7th order coefficient in force factor expansion

Bl8 N/Amm^8 8th order coefficient in force factor expansion

L0 = Le (X=0) 0.44012 mH constant part in inductance

L1 0.0019246 mH/mm 1st order coefficient in inductance expansion

L2 -0.0031499 mH/mm^2 2nd order coefficient in inductance expansion

L3

-1.4492e005

mH/mm^3 3rd order coefficient in inductance expansion

L4 1.4141e-005 mH/mm^4 4th order coefficient in inductance expansion

L5 mH/mm^5 5th order coefficient in inductance expansion

L6 mH/mm^6 6th order coefficient in inductance expansion

L7 mH/mm^7 7th order coefficient in inductance expansion

L8 mH/mm^8 8th order coefficient in inductance expansion

C0 = Cms (X=0) 2.1454 mm/N constant part in compliance

C1 0.010852 1/N 1st order coefficient in compliance expansion

C2 -0.021891 1/Nmm 2nd order coefficient in compliance expansion

Page 7

C3 -0.00071187 1/Nmm^2 3rd order coefficient in compliance expansion

0

(

C4 4.2192e-005 1/Nmm^3 4th order coefficient in compliance expansion

C5 1/Nmm^4 5th order coefficient in compliance expansion

C6 1/Nmm^5 6th order coefficient in compliance expansion

C7 1/Nmm^6 7th order coefficient in compliance expansion

C8 1/Nmm^7 8th order coefficient in compliance expansion

K0 = Kms (X=0) N/mm constant part in stiffness

K1 -0.0083501 N/mm^2 1st order coefficient in stiffness expansion

K2 0.0042013 N/mm^3 2nd order coefficient in stiffness expansion

K3 0.00052573 N/mm^4 3rd order coefficient in stiffness expansion

K4 7.7367e-005 N/mm^5 4th order coefficient in stiffness expansion

Xpse 8.1 mm -Xpse < X < Xpse, range where power series is fitted

Parameters at the Rest Position

The value of the nonlinear parameters at the rest position (x=0) may be used as input for the traditional

linear modelling and may be referred as “linear parameters”. Please note that these parameters

depend on the instantaneous state of the driver (voice coil temperature, peak value of displacement)

and are presented for three different modes of operation:

Mode Properties

LARGE+WARM the transducer is operated in the large signal domain, the peak value of the

displacement is high (|x| < xmax), the variation of the parameters is not

negligible, the voice coil temperature is increased (D TV >

LARGE+COLD the transducer is operated in the large signal domain, the peak value of the

displacement is high (|x| < xmax), the variation of the parameters is not

negligible, the effect of heating is compensated while considering the cold voice

coil resistance Re

SMALL SIGNAL the transducer is operated in the small signal domain, the amplitude of the

excitation signal is sufficiently small, the displacement is small in comparison to

the allowed maximal displacement (|x| << xmax ), the variations of the nonlinear

parameters are negligible, the increase of voice coil temperature is negligible (D

TV » 0), the effects of the nonlinear, thermal and time-varying mechanisms are

negligible, the transducer behaves almost linear.

D TV =0).

) due to heating.

Linear Parameters

Symbol

Note:

Large +

Warm

Large +

Cold

Small

Signal

Unit Comment

for accurate small signal parameters, use LPM

module

Delta Tv =

29 0 0 K

increase of voice coil temperature during the

Page 8

Tv-Ta measurement

Xprot 8.1 8.1 4.1 mm

Re (Tv) 4.52 4.07 4.07 Ohm

Le (X=0) 0.44 0.44 0.38 mH

L2 (X=0) 1.21 1.21 0.46 mH

R2 (X=0) 1.62 1.62 1.77 Ohm resistance at the rest position due to eddy currents

Cmes (X=0) 305 305 303 µF electrical capacitance representing moving mass

Lces (X=0) 39.37 39.37 20.80 mH

Res (X=0) 52.47 52.47 25.33 Ohm

Qms (X=0,

Tv)

Qes (Tv) 0.35 0.32 0.44 electrical Q-factor considering Re (Tv) only

Qts (X=0,

Tv)

fs 46.0 46.0 63.4 Hz driver resonance frequency

Mms 5.600 5.600 5.600 g

Rms (X=0) 0.350 0.350 0.729 kg/s mechanical resistance of total-driver losses

Cms (X=0) 2.14 2.14 1.13 mm/N

Bl (X=0) 4.55 4.55 4.55 N/A

Vas 2.7958 2.7958 1.4702 l equivalent air volume of suspension

N0 0.074 0.082 0.082 % reference efficiency (2Pi-sr radiation using Re)

Lm 80.8 81.3 81.3 dB characteristic sound pressure level

Sd 30.43 30.43 30.43 cm² diaphragm area

4.62 4.62 3.06 mechanical Q-factor considering Rms only

0.33 0.30 0.38 total Q-factor considering Re (Tv) and Rms only

maximal voice coil excursion (limited by

protection system)

(imported) voice coil resistance considering

increase of voice coil temperature Tv

voice coil inductance at the rest position of the

voice coil

para-inductance at the rest position due to the

effect of eddy current

electrical inductance at the rest position

representing driver compliance

resistance at the rest position due to mechanical

losses

(imported) mechanical mass of driver diaphragm

assembly including voice-coil and air load

mechanical compliance of driver suspension at the

rest position

(imported) force factor at the rest position (Bl

product)

For accurate system modelling

parameters because they more closely reflect the parameters in their typical operating range.

“Large + Cold” parameters are preferable to “Small Signal”

Asymmetrical Nonlinearities

Page 9

A

symmetrical nonlinearities produce not only second- and higher-order distortions but also a dc-part in

the displacement by rectifying low frequency components.

For an asymmetric stiffness characteristic the dc-components moves the voice coil for any excitation

signal in the direction of the stiffness minimum.

For an asymmetric force factor characteristic the dc-component depends on the frequency of the

excitation signal. A sinusoidal tone below resonance (f<fS) would generate or force moving the voice

coil always in the force factor maximum. This effect is most welcome for stabilizing voice coil position.

However, above the resonance frequency (f>fS) would generate a dc-component moving the voice coil

in the force factor minimum and may cause severe stability problems.

For an asymmetric inductance characteristic the dc-component moves the voice coil for any excitation

signal in the direction of the inductance maximum.

Please note that the dynamically generated DC-components cause interactions between the driver

nonlinearities. An optimal rest position of the coil in the gap may be destroyed by an asymmetric

compliance or inductance characteristic at higher amplitudes. The module "Large Signal Simulation

(SIM)" allows systematic investigation of the complicated behaviour.

Bl Symmetry xb(x)

This curve shows the symmetry point in the nonlinear Bl-curve where a negative and positive

displacement x=xpeak will produce the same force factor

Bl(xb(x) + x) = Bl(xb(x) – x).

If the shift xb(x) is independent on the displacement amplitude x then the force factor asymmetry is

caused by an offset of the voice coil position and can be simply compensated.

If the optimal shift xb(x) varies with the displacement amplitude x then the force factor asymmetry is

caused by an asymmetrical geometry of the magnetic field and can not completely be compensated by

coil shifting.

Page 10

A

Kms Symmetry xc(x)

This curve shows the symmetry point in the nonlinear compliance curve where a negative and positive

displacement x=xpeak will produce the same compliance value

kms(xc(x) + x) = kms(xc(x) – x).

high value of the symmetry point xc(x) at small displacement amplitudes x » 0 indicates that the rest

position does not agree with the minimum of the stiffness characteristic. This may be caused by an

asymmetry in the geometry of the spider (cup form) or surround (half wave). A high value of the

symmetry point xc(x) at maximal displacement x» xmax may be caused by asymmetric limiting of the

surround.

Page 11

You can find a detailed description of these non-linearities and their remedies in the papers

“Loudspeaker Nonlinearities

Loudspeakers, and “Diagnosis and Remedy of Nonlinearities

Testing performed by Redrock Acoustics – www.redrockacoustics.com

- Causes and Symptoms, Assessing Large Signal Performance of

Loading...

Loading...