Page 1

Page 2

DAXOM boilers provide following sufficiency

Gas Appliances Directive 2009/142/EEC

Boiler Efficiency Directive 92/42/ECC

Electromagnetic Compability Directive 2004/108/CE

Low Voltage Directive 2006/95/CE

Page 3

CONTENTS

1.SECURITY INFORMATIONS AND WARNINGS .......................................................................................... 4

1.1 Warnings ......................................................................................................................................... 4

1.2 Warnings .......................................................................................................................................... 4

2 GENERAL INFORMATIONS ...................................................................................................................... 5

2.1 General Information ................................................................. Hata! Yer işareti tanımlanmamış.

2.2 Giving Information to Customer While Deliver the Device ............................................................ 5

2.3 Description ...................................................................................................................................... 5

2.4 Device Dimensions .......................................................................................................................... 6

2.5 Boiler Installation Distances ............................................................................................................ 8

2.6 Inside Structure Of the Device ........................................................................................................ 9

2.7 Technical Specificitions .................................................................................................................. 10

3 INSTALLATION....................................................................................................................................... 12

3.1 Installation ..................................................................................................................................... 12

3.2 Plumbing ........................................................................................................................................ 12

3.3 Natural Gas Line ............................................................................................................................ 12

3.4 Electrical Installation ..................................................................................................................... 13

3.5 Pipe Line ........................................................................................................................................ 13

4 SAMPLE INSTALLATION DIAGRAMS...................................................................................................... 15

4.1 Heating System with Boiler ........................................................................................................... 15

4.2 Cascade Heating System Diagram with Solar System ................................................................... 16

5 PIPE IMPLEMENTATIONS ...................................................................................................................... 17

6 ELECTRICAL PROJECT ............................................................................................................................ 18

7. ACCESORIES ......................................................................................................................................... 21

8 FIRST OPERATION ................................................................................................................................. 23

8.1 Heating Mode Selection ................................................................................................................ 23

8.2 Setting Time Programme ............................................................................................................... 23

8.3 Setting Room Temperature ........................................................................................................... 23

8.4 Mannual Using ............................................................................................................................... 23

8.5 Reset .............................................................................................................................................. 23

9 MAINTENANCE ..................................................................................................................................... 23

9.1 Periodic Controls that Users Must Be Made ................................................................................. 24

9.2 Service Maintenance Prosedures .................................................................................................. 24

9.3 Maintenance Warning Codes ........................................................................................................ 25

Page 4

1. SECURITY INFORMATION AND WARNINGS

1.1WARNINGS

- This user manual is inseparable piece of your

device Please keep it in a place near the device

that is immediately got. In case of any lost or

damage, please supply new one with Isı Cihazları

Company.

- DAXOM / Naviels wall hung condensing boiler

must be installed by authorized person according

to the closing rules.

- Boiler must not be used except production

purpose. Manufacturer Company rejects

responsibilities of injuries and economic damages

cause from wrong installation of boiler, wrong

setting or not maintenance timely.

- When you open the packet box of the device,

firstly control if any damage at the device or not. In

case of any problem contact with the seller

company.

- Before making the installation of the device,

firstly be sure that plumbing is cleaned. Dirtiness

that is occurring inside the heating cycle causes

low efficiency and noise operation.

- Please careful about leaving min space while

making installation for interfere the system.

- Control the water level periodically from water

level indicator occurs at the boiler. Indicator must

be over 1 bar.

- If you observe water leakage at the boiler, close

the water valve immediately and contact with

authorized service.

- If the boiler will not be used for a long time, cut

off the electric supply and gas inlet of the boiler. If

there is freezing risk at water installation or boiler

system, you need to discharge water inside the

plumbing.

- Control the operation of the air conditioner of the

place that the boiler is placed at regular intervals.

-Boiler is designed for using at interior place. It is

not suitable for using at open environment places.

- Because of boiler is condensing type, be careful

that the condensing discharge line is connected

and not blocked.

- Make the authorized service maintenance your

boiler at least once a year.

1.2 Warnings

- If gas or smoke smell are sensed, do not operate

any electrical devices in case of gas leakage,

ventilate environment by closing gas valve and

contact with authorized people. Do not smoke at

the environment in no sense.

- Do not touch cover of boiler with wet hands or

bare foot?

- Do not certainly pull and twist or force cables

connected to boiler even it is no energy.

- Freezing prevention system occurs at the boiler

Because of this, do not cut off electric and close

the gas valve of boiler when the external

environment is cold.

- Do not absolutely start boiler cleaning before cut

off main electric supply.

- Do not keep flammable or explosive materials at

the boiler room.

- Do not certainly interfere safety device occurred

on the boiler. Do not deactivate for short term or

continuously.

-Be sure that pipe fitting is made correctly and not

leak gas to the environment.

-Do not certainly operate heater without water

inside plumbing.

Page 5

2 GENERAL INFORMATION

2.1 General Information

-The user manual which is given with condensing

boiler is inseparable piece of the device. Because

of this, it must be kept carefully and it must be

kept in a place near the device that is immediately

got. In case of any lost or damage, it must be

supplied from DAXOM Company.

Any person except authorized person or person

who had education from authorized service must

not interfere to device.

Considering warnings inside the manual is

important for both your safety and safe operation

of the device.

Device must be operated by installing stated inside

the manual under necessary conditions of safety

and operating. Under these conditions DAXOM

trade mark boiler is less than 2 years warranty

cover by Manufacturer Company.

Using the device out of its purpose, using different

from conditions stated inside the manual, interfere

by unauthorized person and problems which cause

because of external factors such as (gas, electric

and etc) are evaluated as out of warranty.

The lifetime of the device determined by Ministry

of Customs and Trade is 10 years in case of obey to

user instructions. In the meantime manufacturer

and Seller Company obliged to meet service and

spare parts of user.

The first operation and controls of boiler must be

done by authorized service and product guarantee

must be done. Devices which are using before

doing warranty start by authorized service will be

no warrantable.

2.2 Giving Information to

Customer While Deliver the Device

Tell consumer about operation of the device,

significant points that must be careful before

operation of the system or during operation of

system, importance of periodic maintenance in

terms of performance and efficiency of device and

inform about maintenance agreement.

Explain user that necessary services contact

information is found inside user manual.

Deliver the user manual to consumer and tell him /

her that are needed to keep near the boiler.

2.3 Description

DAXOM Navidens boilers are condensing boilers

that are used by installing wall are designed as

heating water inside heating system with NG or

LPG and also meet the need heat demand of a

boiler through this water.

DAXOM Navidens condensing boilers are also

enable for coupled solar energy to boiler system.

On the other hand, they have necessary

substructure for heating swimming pools.

There is burner inside the boiler which provides

Combustion with aluminum casting hot bulb and

premix technology.

There is flow meter gas valve on the boiler which

determines and stops quantity of gas that obtains

necessary energy for heating. There are sensors at

the system for following inlet and outlet water

temperatures for the aim of determination of

boiler operation capacity.

On the other hand, for the aim of security control

of the system there are bottom water pressure

control wind pressure switch, drain valve, safety

thermostat and pipe gas temperature sensor.

Boilers’ ignition, flame monitoring, capacity

control, safety device and operation functions

occur by electronic control card.

It can be operated as connected external room

thermostat.

By the LCD panel on the boiler information can be

followed concerning to operation of the system.

(Instant operation capacity, boiler inlet, outlet

temperatures, etc)

Page 6

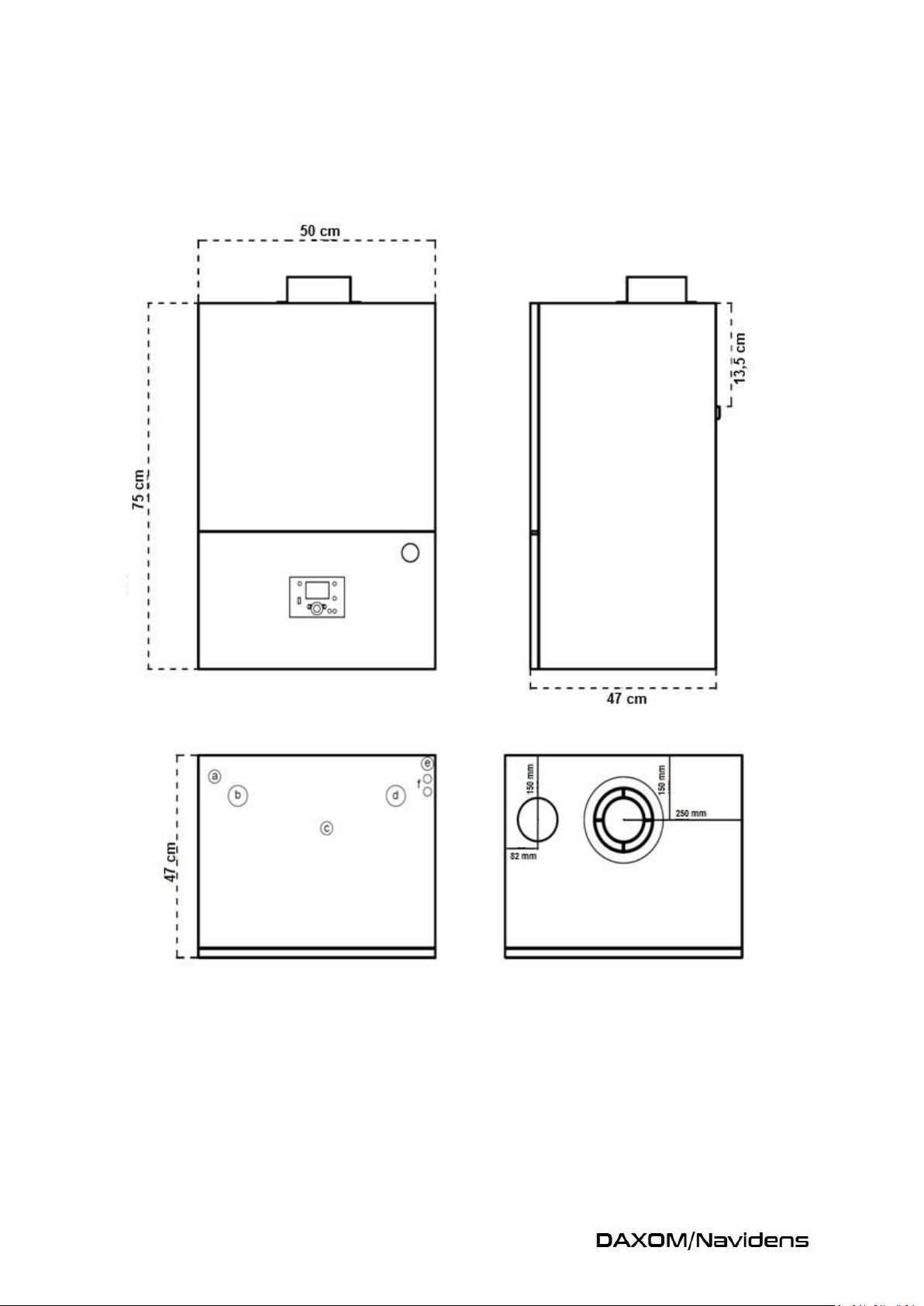

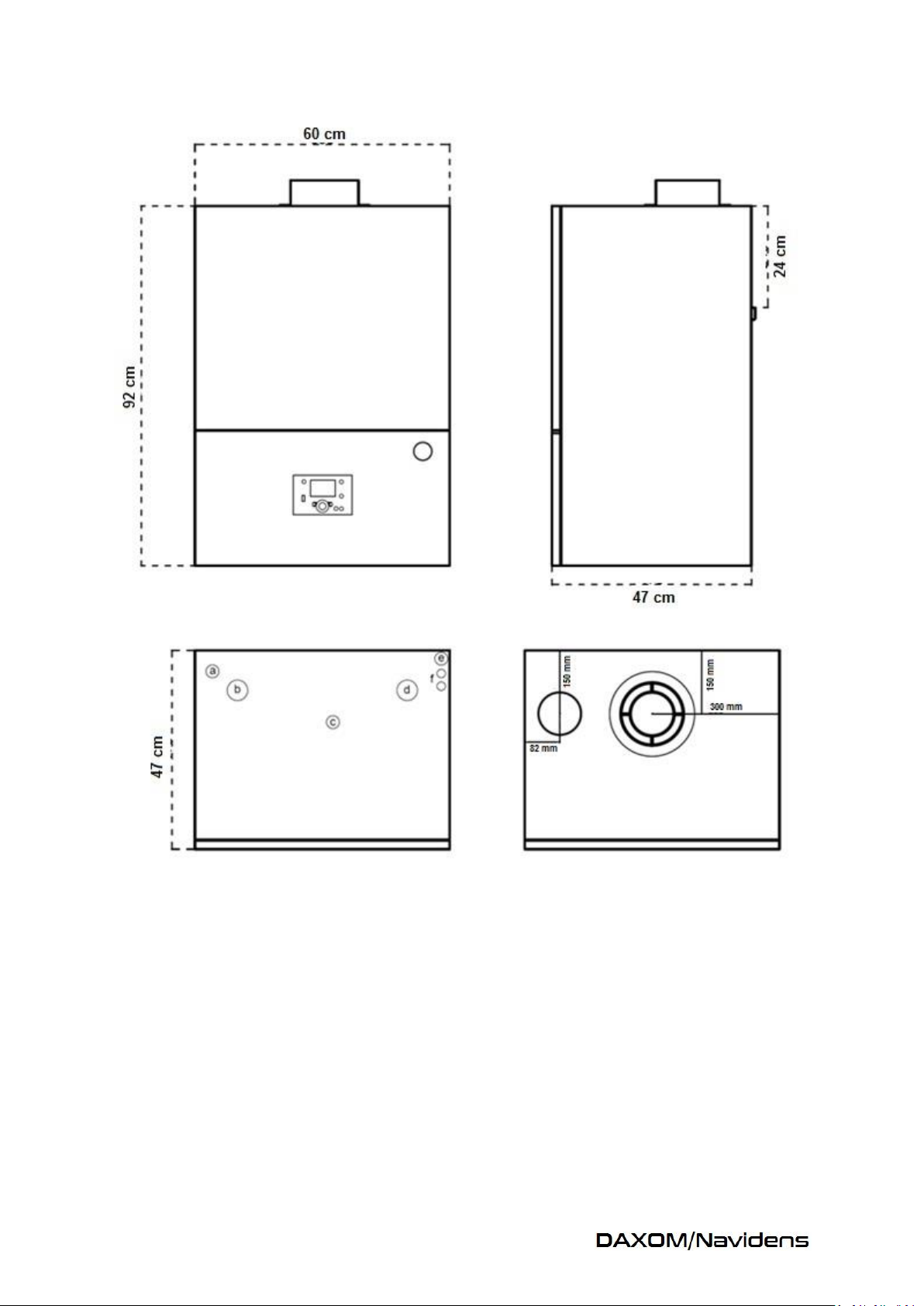

2.4 Dimension of Device

Navidens 50-70

Page 7

Navidens 125-145

a: Safety Valve Outlet

b: Plumbing Return

c: Gas Inlet

d: Plumbing Exit

e: Condensing Outlet

f: Cable Entry

Page 8

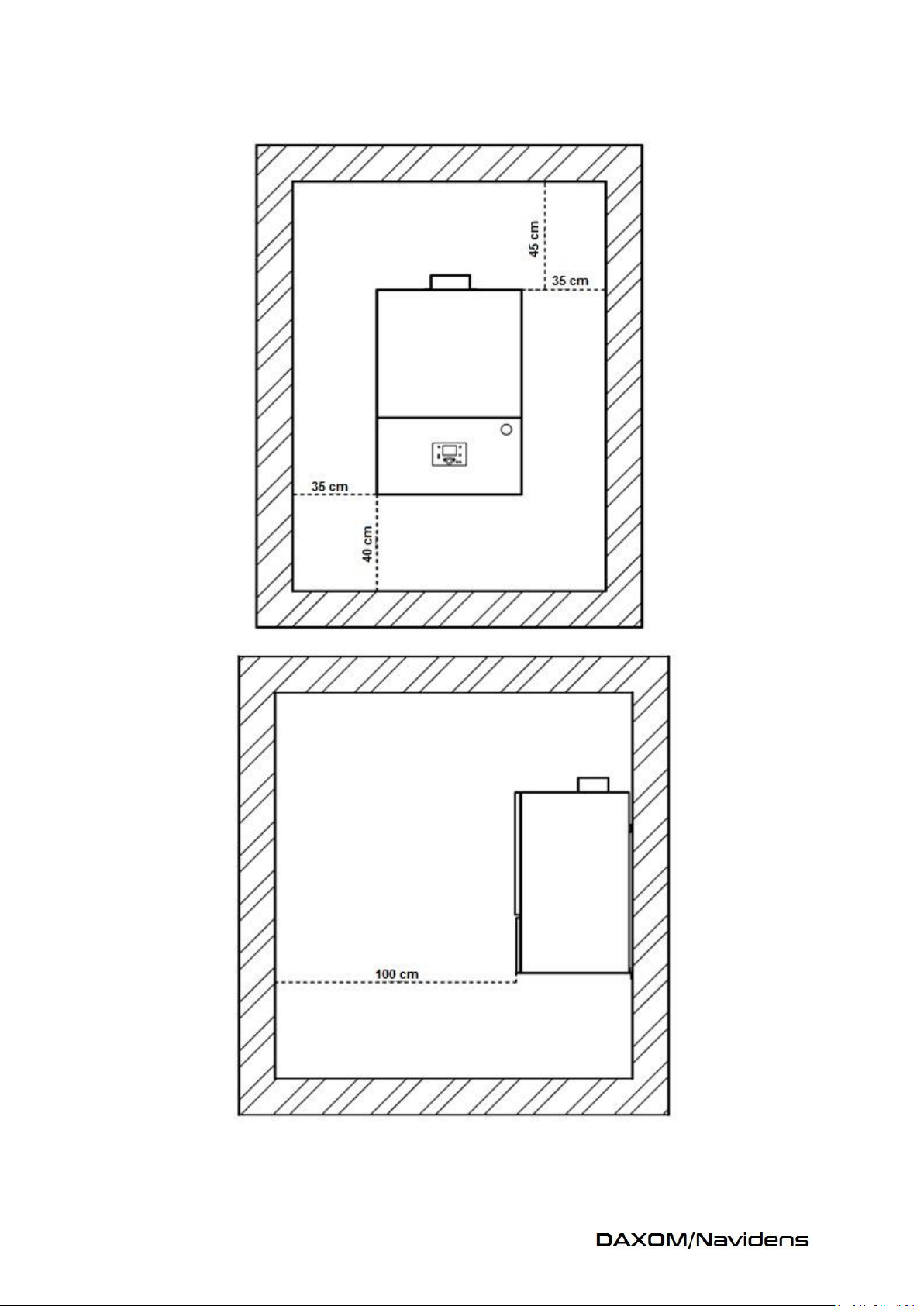

2.5 Boiler Installation Distances

Page 9

2.6 Inside Structure of the Device

1- Automatic Air Relief Cock

2- Safety Thermostat

3- Manual Air Relief Cock

4- Outlet Water Temperature Sensor

5- Ionization Electrode

6- Ignition Electrode

7- Sight Glass

8- Combustion Space

9- Pipe Gas Temperature Sensor

10- Condensation Tank

11- Siphon

12- Electronic Control Card

13- Circulation Pump

14- Safety Valve

15- Return Water Temperature Sensor

16- Manometer Hour Connection

17- Pressure Switch

18- Pulse Ignition System

19- Gas Valve

20- Air Suction Inlet

21- Air Fan

Page 10

UNIT

NAVİDENS50

NAVİDENS70

NAVİDENS125

NAVİDENS145

Fuel Type

G20/G30

Pipe Type

B23,C13,C33,C43,C83

Max Operation Pressure

bar 6 6 6 6

Maximum Operation

Temperature

⁰C

85

85

85

85

Fuel Consumption

max

lt/min

89,5

114,5

203

237

min

lt/min

18,3

20,9

29,5

38,3

Heat Input

max

kW/h

50

66

117

136,7

min

kW/h

10

12

17

22

Heat Power

Nominal Heat Load

30-50 ⁰C

kW/h

52,5

68

125

145

Nominal Heat Load

80-60 ⁰C

kW/h

48,5

64

112,5

131,15

Efficiency

Min Heat Load

30-50 ⁰C

%

107,6

108

106,4

106,7

Nominal Heat Load

30-50 ⁰C

%

105

104

103,7

102,8

Partial Load

30 ⁰C % 108

107

106,85

106,08

Nominal Heat Load

80-60 ⁰C

%

97

97

96,12

95,94

Min Heat Load

80-60 ⁰C

%

95

96

94

95

Efficiency Class

☆☆☆☆

Pipe Dates

Pipe Pressure

Pa

150

135

240

210

Exhaust Gas Flow Rate

Max

g/sec

22

29

51,5

60

Min

g/sec

4,5

5,4

7,5

9,7

Combustion Values

CO2 Emission ( G20 )

Max Load

%

9,3

9,9

9,4

9,5

Min Load

%

9,8

9,6

9,7

9,6

CO2 Emission ( G30 )

Max Load

%

10,9

11,1

11

11,2

Min Load

%

10,3

10,5

10,5

10,6

NO Emission ( G20 )

Max Load

ppm

14

19

15

15

Min Load

ppm 9 10 9 10

NO Emission ( G30 )

Max Load

ppm

14

19

13

14

Min Load

ppm

10

12 9 9

Pipe Gas Temperature ( G20

)

Max Load

⁰C

66

68

81

83

Min Load

⁰C

33

34

38

41

Pipe Gas Temperature ( G30

)

Max Load

⁰C

68

71

83

85

MinLoad

⁰C

35

37

40

44

Electric

Electric Supply

V/Hz

230/50

Fuse

A

2

6

Power Consumption

W

275

550

2.7 Technical Specifications

Page 11

Plumbing Connections

Heating Cycle Exit

inch

1 1/4"

1 1/4"

1 1/2"

1 1/2"

Heating Cycle Circulation

inch

1 1/4"

1 1/4"

1 1/2"

1 1/2"

Gas Line

inch

3/4"

3/4"

1"

1"

Condensing Outlet

mm

30

30

30

30

Safety Discharge Outlet

mm

30

30

30

30

Fresh Air Inlet

mm

125

125

150

150

Exhaust Gas Outlet

mm

80

80

100

100

Specifications

Cascade Connections

256

Freezing Prevention

CURRENT

Hour

CURRENT

Holiday Programmer

CURRENT

Ip Class

IP44

Dimensions 500X750X450

600X920X470

Weight

45

84

Page 12

3 INSTALLATION

3.1 Installation

- Installation of the device must be done

concerning installation distance determined

inside user manual.

- While installs the device; obey installation

distances determined above for making necessary

interferences easily in the future.

- The installation surface of the device must be

durable for carrying weight of device with water.

- Do not keep materials having risk such as

inflammable, explosive at the same place with

the device.

- In case of device installation wall is made of low

heat durable material (wood, etc), wall isolation

must be made suitable.

3.2 Plumbing

- Plumbing water hardness scale must not be

higher than 20F. In case of higher hardness scale

must be reduced. Damages that occur because of

hardness scale will make device out of warranty.

- Condensing outlet of boiler is located lower left

corner of the boiler. Condensing siphon must be

absolutely filled water before operation of the

boiler. Otherwise, exhaust gas that is formed

while combustion will leak to environment.

- Condensing outlet must be connected to

discharge line. Metal material must not be used

for discharge line. It must completely make of

from plastic materials. It can be followed by eye

that water inside the condensing line flows from

discharge. Any blockage inside condensing line

causes breakdown by failure of boiler. Do not

forget that this condition will be evaluated as out

of warranty.

- Be sure that plumbing is completely cleaned

before making plumbing connections.

- Installing valve to heating inlet and outlet of

boiler will provide convenience for processes that

will be made in the future.

- Your boiler’s operation pressure can be set max

6 bars. Be sure that plumbing pressure is at the

necessary range before operation.

- Internal circulation pump is located inside

boiler.

- In case of plumbing pressure is higher, it is

needed to put hydraulic separator between

plumbing and boiler.

- It must be expansion tank on the plumbing that

is chosen suitable to line. It must have automatic

air relief cock on the hydraulic separator and

discharge valve at bottom of hydraulic separator.

3.3 NATURAL GAS LINE

- Your device is compatible with NG and LPG

operation. At the product label it is written

about which gas it is needed to operate. Control

the correction of the gas type.

- Be sure that gas line pressure is at allowable

range.

- Be sure that gas pressure coming from plumbing

is at allowable range. In case of it is high, you

need to use pressure reduce regulator for

plumbing.

- There must be 1 pcs filter on the line for

protecting from dirt that may be come from line.

- Before first operation of the boiler, air of the

line must absolutely be taken.

Page 13

3.4 Electrical Installation

Your device operates with 220V 50 Hz electric

supply.

Prefer 3*1,5mm2 cable for electrical installation.

On the other hand, 2A fuse is needed on electric

wiring that is control the boiler electric supply.

You must be sure correction of phase and neural

connection ways.

Ground connection absolutely has to be

connected to boiler.

Do not definitely use water or natural gas line for

grounding. In case of using, do not forget that

your device will be out of warranty for damages

that can occur.

3.5 Pipe Line

- Pipe line must be made suitably to legal

regulations.

- You must be sure that all connection points of

pipeline are leak proof.

- Pipe line must be durable to heat, condensing

water and mechanical stress.

- Pipe installation must be made as 1⁰ inclined

through the boiler.

- In case of combustion air is taken from

environment, maximum pipe length is 20m.

90⁰bend correspond with 2 meter pipe and

45⁰bend correspond with 1,5m pipe.

- Do not forget that extra connection accessories

that will be used for line will also create

resistance and will reduce allowed total pipe

length distance.

- Your boiler must be together with an internal

pipe gas temperature sensor. In case of any

temperature exceed, it stops the system for

security.

- In case of combustion air is taken from

environment, necessary environment ventilation

must be suitable to boiler capacity.

- The operating temperature of boiler is between

-15, and + 60 ⁰C. Environment temperature must

be between these values.

- There is freezing prevention function in your

boiler. When environment temperature

decreases less than 5 degree, this function start

to operate separately from operating

programme. Boiler heating function becomes

active and operates until boiler return water

temperature reaches to set temperature then it

stops.

- Your device is produced as concentric pipe but

according to demand it can be supplied with

double pipe or later it can be converted to double

pipe with necessary accessories.

Page 14

Concentric Pipe System

Double Pipe System

Page 15

4 Sample Installation Diagram

4.1 Heating System with Boiler

Page 16

4.2 Cascade Heating Diagram with Solar Energy

Page 17

5 Pipe Implementation

B23 When combustion air is taken from environment, exhaust gas transfer to outside with pipe.

C13 Combustion air and exhaust gas transfer to outside by pipes which their outlets are

interwoven or it can be transferred by separate pipes as maximum 50 cm distance between them.

C33 Vertical exit is made from roof by interwoven pipes

C43 Connection to common pipe outlet by interwoven pipes.

C53 Exit from wall or roof with separate pipes outlets at areas that have different pressure values.

While exiting from wall, it must not be exit from opposite walls.

C83 While fresh –air intake is being made from external environment by wall passing, exhaust gas

pipe can be directly taken out to outside or can be connected to common pipe system.

Page 18

6 ELECTRIC PROJECT

Navidens 50/70

Page 19

Navidens 125/145

Page 20

INTERIOR CONNECTION

DESCRIPTIONS

IS

Boiler Return Sensor

OS

Boiler Exit Sensor

PS

Pressure Switch

CS

Pipe Gas Sensor

TL

Safety Thermostat

M

Fan Motor

P

Circulation Pump

CLEMENS DESCRIPTION

QX2

Boiler Cycle Pump

QX3

Heating Cycle Pump

H5

Room Thermostat

B9

Outside Environment Sensor

B3/38

Optional Sensor Inlet

BX3

Optional Sensor Inlet

BX2

Optional Sensor Inlet

Page 21

7. ACESSORIES

PRODUCT DESCRIPTION

PHOTO

Cascade Communication Module

Three Way Valve Connection Module

Outlet Air Sensor

Room Thermostat

Cascade Sensor

Page 22

PRODUCT DESCRIPTION

PHOTO

Pipe Set

Ø 80/125 mm

Ø 100/150 mm

45-90 Degree Bends

Ø 80/125 mm

Ø 100/125 mm

Exhaust Gas Pipe

Ø 80 mm

Ø 100 mm

Additional Pipe

Ø 80/125 mm

Ø 100/125 mm

Fresh Air Inlet Accessory

Ø80mm

Ø 100mm

( For double pipes system)

Exhaust Gas Outlet Accessory

Ø 80mm

Ø 100mm

( For Double Pipes Systems)

Page 23

8 FIRST OPERATION

1

Boiler Selection Knob

2

Computer Connection Inlet

3

Exit 4 Reset

5

Manual Control Knob

6

Pipe Function Knob

7

Confirm Button

8

Set Button

9

Information Button

10

Operation Mode Selection

Button

11

LCD Display

OFF Concort Mode

Night Mode

Automatic Mode

8.1 Heating Mode Selection

When you press operation mode selection

(number 10) knob, you can make passing

between modes that are explained in the

following.

Modes are;

1- It is entered to submenu by pressing

confirm button (number 7) while it is in

home screen of device.

2- It is entered to “Time program of heating

cycle 1” menu by pressing OK button.

3- Firstly, it is chosen for which day’s

program will make. You can make

passing between options with Set Button

(number 8). When you come to your

demanded days, make your choosing

with OK button.

4- Set the operation start hour and press

the OK button.

5- Then set operation finish hour and press

OK button.

6- Return to home screen by ESC button

after you chose AUTO, your device will

start to operate according to set

operation hour.

8.3 Room Temperature Setting

While the device is in home screen, turn the

number 8 button. Temperature values will be

appearing at the display. Exit from menu with OK

button after you bring your demanded value.

8.4 Manual Using

It is used for operating device independent from

auto operation mode. Manual control can be

activated or passivity with number 5 knob.

Intended boiler temperature can be set from info

menu.

8.5 Reset

When your device goes out of order, error

description is written on the display and passes to

standby mode. Do not forget that, this device can

be gone out of order at gas leakage and

installation failures. After making control of

these, try restart again by pressing number 4

reset knob. After trying 3 times if the device has

still not operated, contact with authorized

service.

OFF: Device waits in standby mode. Except

freezing prevention it does not operate any

function.

Comfort Mode: Operates according to set

temperature.

Night Mode: Operates according to set

temperature.

Automatic Mode: Enables to operate depending

hour time. General operation mode of the system

will be this.

8.2 Setting Time Hour

9. MAINTENANCE

As well as it changes using place and using

conditions, it is preferred to have your device

maintenance done once a year.

It is importantly preferred, have your boiler

maintenance done by authorized service agency

and using original parts while changing necessary

parts. Do not forget that your device will be out

of warranty in case of intervention of authorized

personnel or using parts which are not original.

It is needed to have your installation control

made together with boiler maintenance for

unproblematic operation of the system.

Page 24

9.1Periodic Controls That User

Must Be Made

Installation pressure must be made within year.

Operation pressure must be between 1-5 bars. If

installation pressure reduces frequently, it can be

leakage at your installation or breakdown occurs

at expansion tank. It must be controlled that if

any block at air-suction outlet / inlet of boiler.

There must not be loosening or leakage at the

pipeline which is used for discharge of exhaust

gas. Please control if there is blockage at the

point of the pipe that opens the external

environment.

9.2 Service Maintenance

Procedure

*Close device electric supply, gas line and heating

system inlet and outlet valves.

* If it is needed, discharge water inside the boiler.

* It must be controlled that if there is loosening,

leakage or blockage at boiler pipes or not.

* It must be controlled that if any intervention to

gas installation or not.

* It must be controlled that if any blockage or

removing from its place at condensing outlet

under the heat exchanger.

* By removing fan motor, it must be controlled

that if any dirt or residual occurred at the fan

steering fin or not. Then it must be cleaned

sensitively.

* By opening hot bulb, seal between burner and

heat exchanger must be controlled and if it is

needed it must be changed.

* Ignition and ionization electrodes must be

cleaned by emery. If it is needed it must be

changed with new one.

*It must be checked if any dirt or residue inside

heat exchanger which causes blockage. If it is

needed it must be cleaned by pressure water by

removing from its place.

* Combustion setting of the device must be made

after maintenances of device are finished and

install parts to their places.

* Because of fan cycle of device is load according

to capacity at the factory, after fan cleaning is

made, you will not need to make any air setting.

According to air quantity, necessary gas quantity

will be pulled from gas valve by venturi.

Capacity control from meter according to capacity

information inside product label.

After that, make control of calorific values with

pipe gas analyze device.

At the result of analyze CO2 value must be

between 9, 3 and 9, 8.

* Information about faults that are seen in the

system but irrelevant with boiler must be given to

customer.

** After maintenance is finished, write processes

that are done to service form and deliver analyze

result to customer by printing out.

** Faults that are seen related to system and

notified to customer must also noted to service

form.

Page 25

Maintenance

Code

Description

Priority

1

Burner operation hour is exceeded.

6

2

Burner starting quantity is exceeded.

6

3

Maintenance interval is exceeded.

6

5

Heating cycle water pressure is too low.

9

Bottom water pressure limit is reduced

under1.

10

Change battery of outside air sensor.

6

18

Heating cycle water pressure 2 is too

low.

9

Bottom water pressure limit is reduced

fewer than 2.

22

Heating cycle water pressure 3 is too

low.

9

25

bottom water pressure limit is reduced

under 3

3

Automatic water filling is activated.

9.3 MAINTENANCE WARNING CODES

Loading...

Loading...