Page 1

INNOVATIVE

PILING

EQUIPMENT

HYDRAULIC PILING HAMMERS

HPH 1200

HYDRAULIC HAMMER

EXCAVATOR MOUNTED

EXCAVATOR MOUNTED DRILLS

QUIET, VIBRATIONLESS

SHEET PILE GUIDE FRAMES

CAPPING SYSTEMS

HANDLING / LIFTING

VIBRATORS

PUSH-PULL PILING

PILE EXTRACTION

SHEET PILE

CFA CLEANERS

PILE POINTS

& SPLICERS

www.dcpuk.com

www.dcpuk.com

Page 2

DAWSON

CONSTRUCTION PLANT LIMITED

HPH 1200 HYDRAULIC

HAMMER AND POWER PACK

- USER'S MANUAL

HAMMER SERIAL NO: ..............................................

HAMMER COMMISSION DATE: .............................

POWER PACK SERIAL NO: ......................................

POWER PACK COMMISSION DATE: ......................

ENGINE TYPE: ...........................................................

ENGINE SERIAL NO: ................................................

POWER PACK TYPE: .................................................

V8 05/06/06

Page 3

C O N T E N T S

0.0 EC Declaration of Conformity

1.0 Introduction

1.1 Basic Safety Points

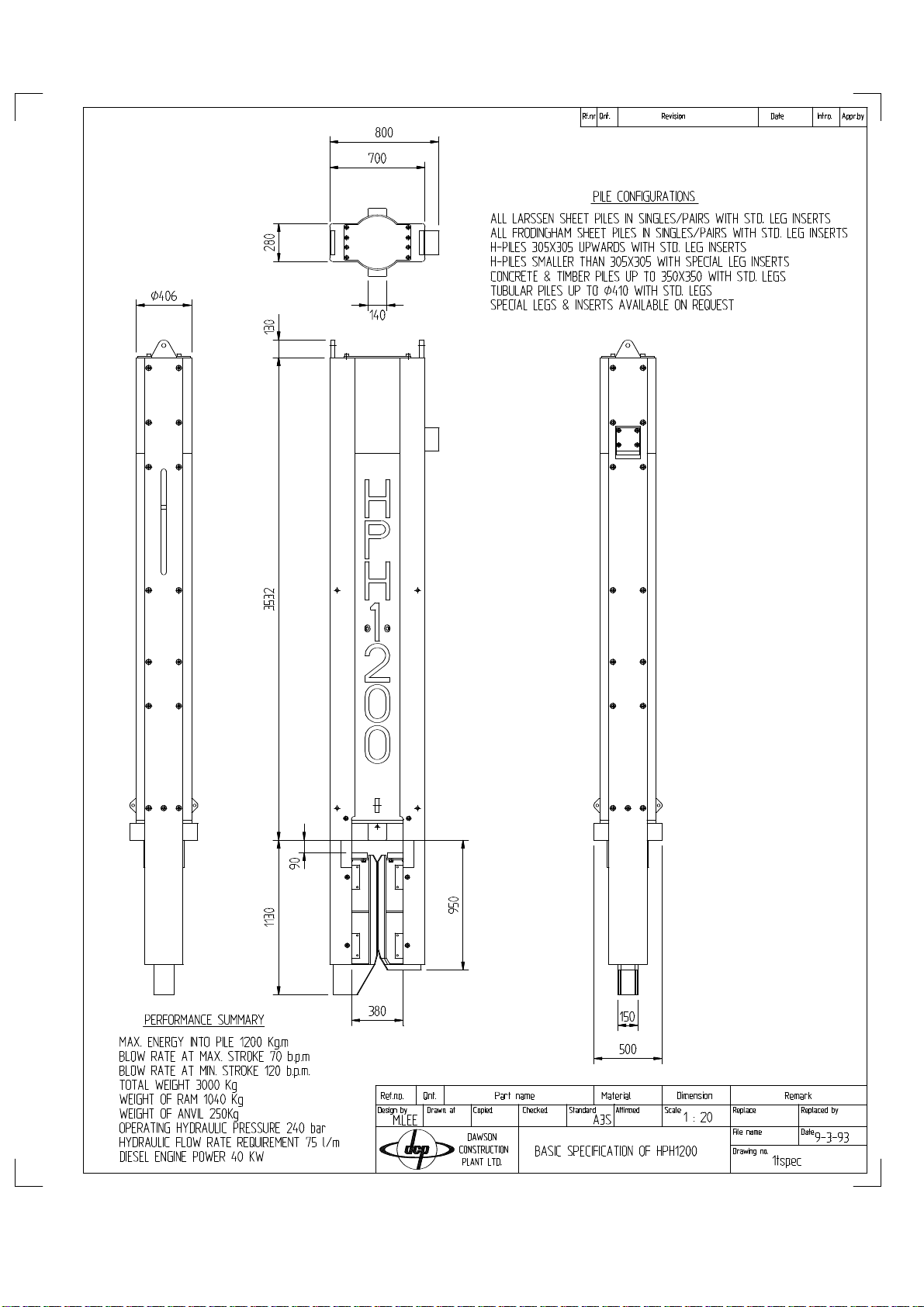

- Basic Specification of HPH 1200 - Drawing

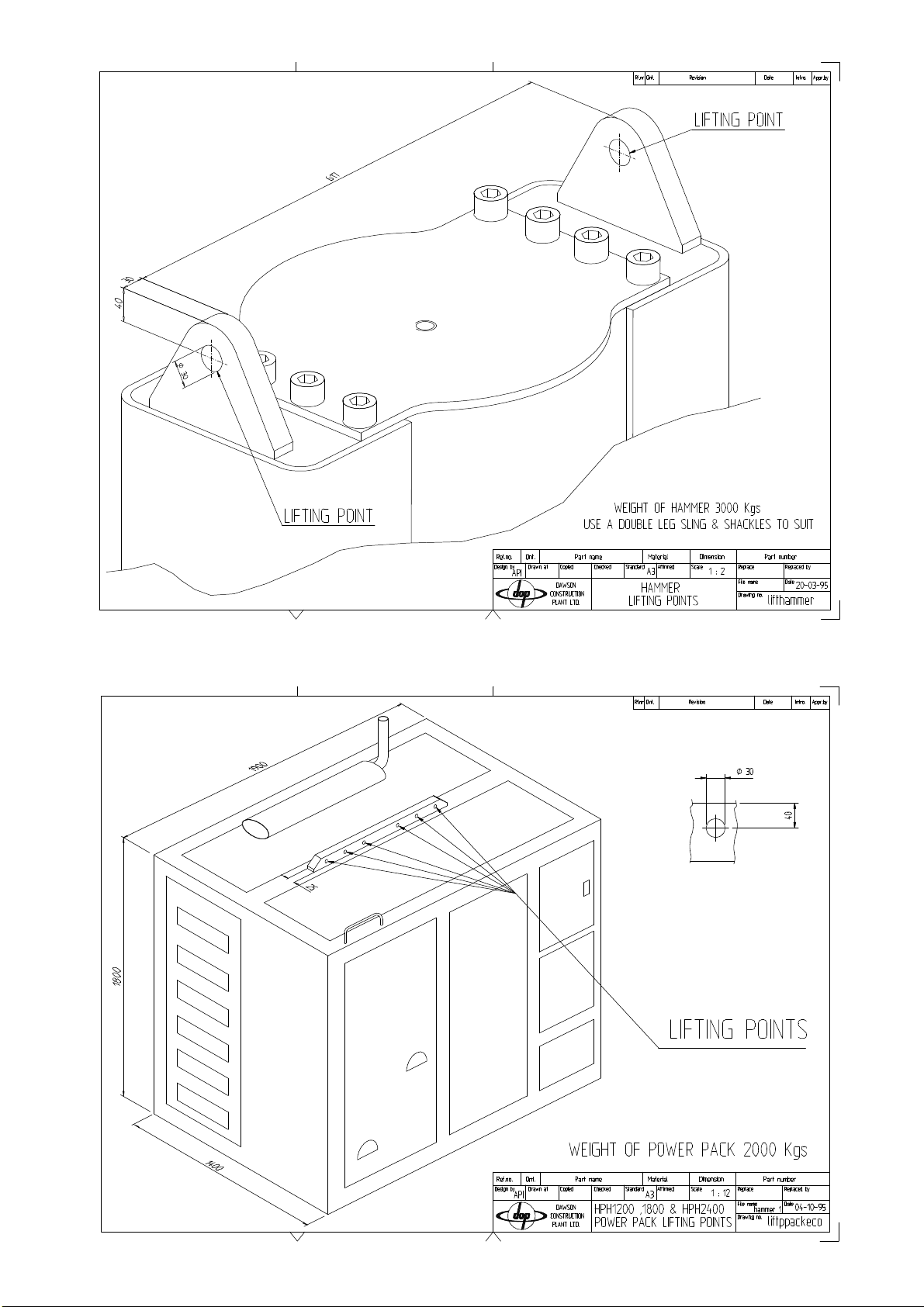

- Lifting the HPH 1200 & Power Pack -

Drawing

1.2 Transportation and laying hammer down

2.0 How does the Hammer Work?

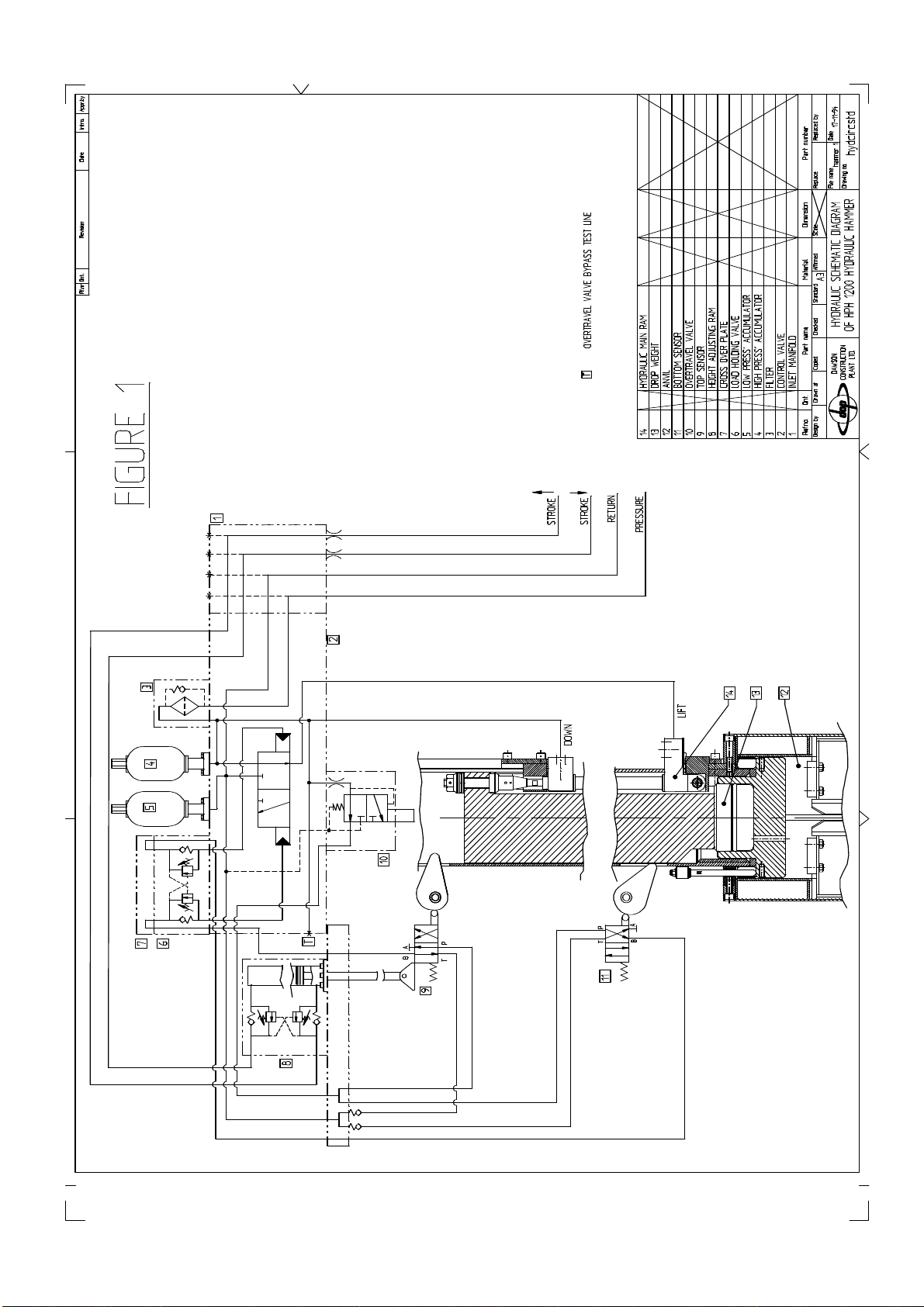

Figure 1

3.0 Power Pack and Hammer Operation

3.1 Connecting the hydraulic hoses and

control pendant

3.2 Checking the power pack

3.3 Starting the power pack

3.3.1 Hydraulic oil warm-up procedure

3.4 Using the hammer

3.4.1 Installing hammer on the pile

3.4.2 Bleeding air from the hammer

hydraulic system

3.4.3 Pile driving with the hammer

3.4.4 Cold running/overtravel

3.4.5 Refusal

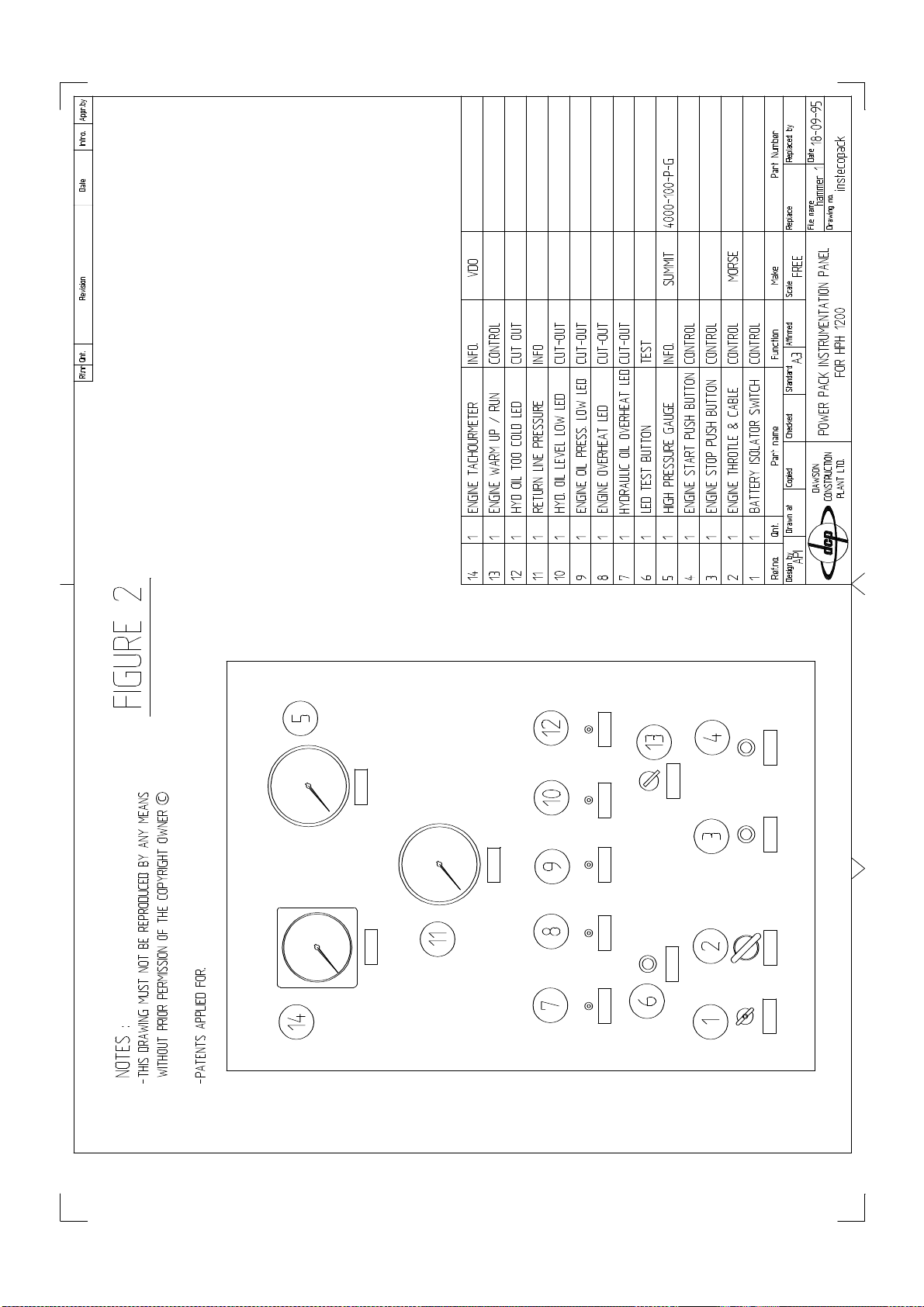

Figure 2

3.5 Using the hammer underwater

3.6 Wider or special pile sections

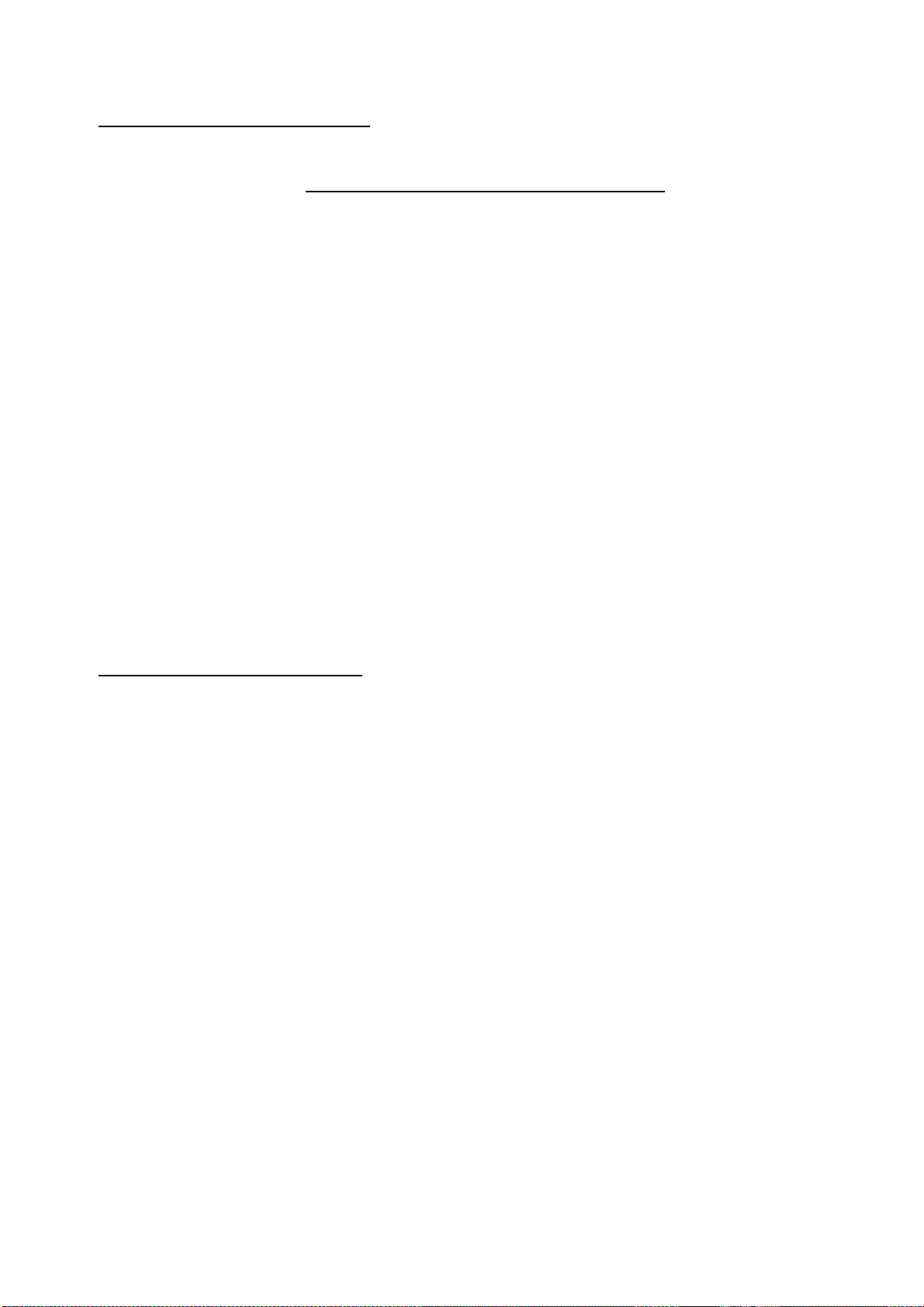

Figure 3

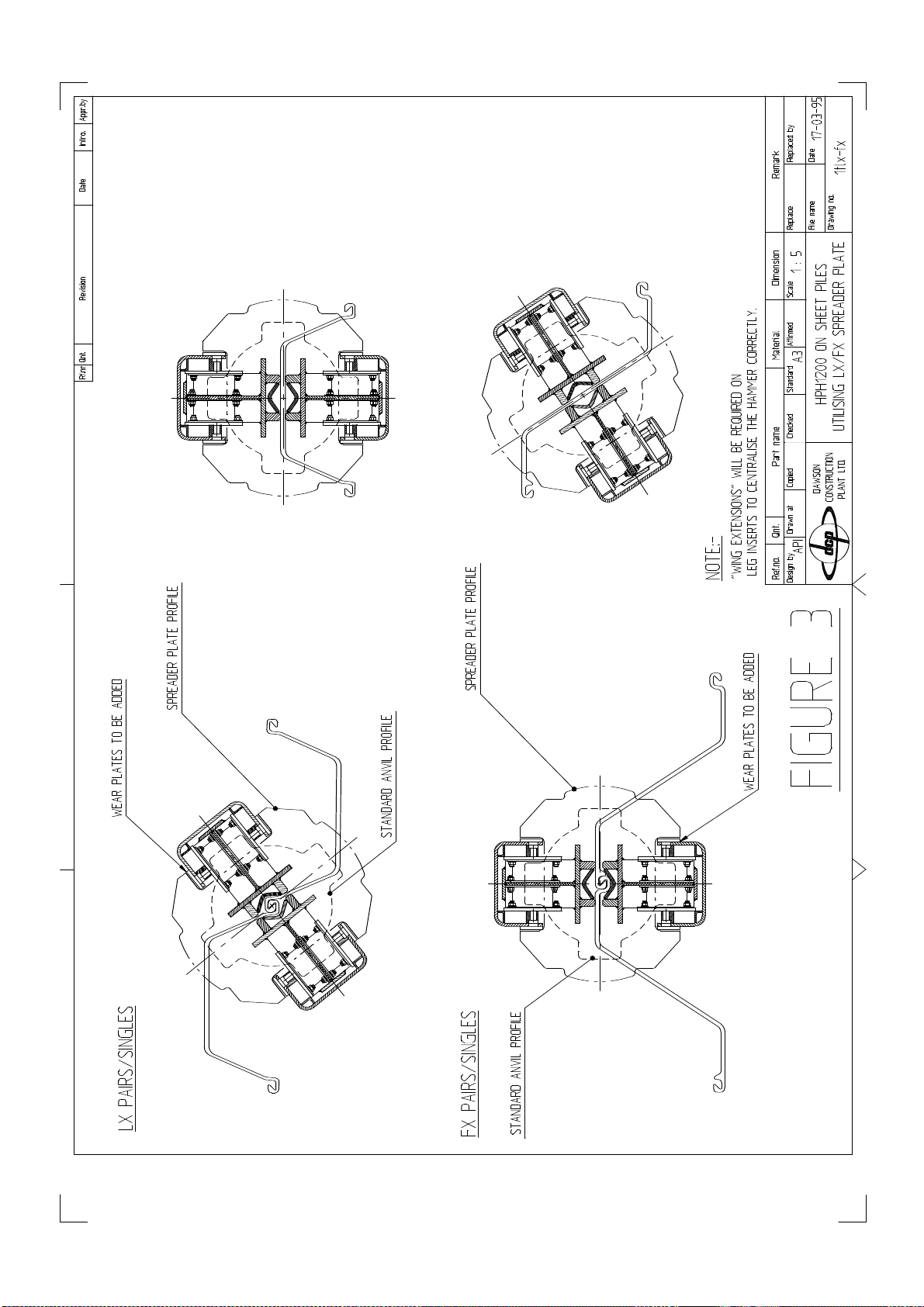

Figure 4

3.7 Preventive Maintenance Guideline Chart

4.0 Hammer Maintenance

4.1 Daily maintenance

4.2 Planned 125 hour maintenance checks

4.3 Planned 250 hour maintenance checks

4.4 Planned 500 hour maintenance checks

4.4.1 Changing Resilient Washers

4.4.2 Other items

Figure 5

4.5 Planned 1000 hour maintenance checks

5.0 Power Pack Maintenance

5.1 Power pack specifications

5.1.1 Basic specification

5.1.2 Lubrication specification

5.2 Daily maintenance checks

Figure 6 Dolly wear

5.3 Planned maintenance checks

5.3.1 Every 125 hours

5.3.2 Every 250 hours

5.3.3 Every 500 hours

5.3.4 Every 1000 hours

5.4 Maintenance procedures

5.5 Setting procedures

6.0 Troubleshooting

6.1 Power pack engine will not start

6.2 Engine cuts out during running

6.3 Power pack does not generate any pressure

6.4 Power pack generates pressure but hammer

does not run

6.5 Hammer will lift but not drop

6.6 Hammer runs erratically

6.7 Excessive hose 'jumping'

6.8 Hammer 'jumping' excessively on pile top

6.9 Stroke height indicator will not move

6.10 Smoke from bottom end of hammer

7.0 Appendices

7.1 Hammer parts list

7.2 Accumulator parts list and instructions

7.3 See Cummins service manual

7.4 Power pack parts list

7.4.1 Hydraulic circuit schematic

7.4.2 Electrical circuit schematic

7.4.3 General assembly drawing - 3 off

7.5 Tool kit parts list

Page 4

DAWSON

The responsible person:-

DAWSON CONSTRUCTION PLANT LIMITED

CHESNEY WOLD, BLEAK HALL

MILTON KEYNES MK6 1NE

ENGLAND

EC DECLARATION OF CONFORMITY

Description:

Type:

Serial Number:

1. Hydraulic Piling Hammer

2. Power Pack - 93kW

1. Hyd Piling Hammer - HPH 1200

2. Power Pack - 1800/2400 Diesel Engine

Hydraulic

1. HPH1200 –

2. Power Pack -

The above mentioned equipment conforms to the Machinery Directive 89/392/EEC(a)

as amended by Council Directive 91/368/EEC(b), Council Directive 93/44/EEC(c)

and Article 6 of Council Directive 93/68/EEC(d).

Signed for and on behalf of

Dawson Construction Plant Limited: .............................................................................

Name: .............................................................................

Position: .............................................................................

Date: ............./............./.............

Page 5

1.0 INTRODUCTION

The D.C.P. Hydraulic Hammer has been designed and manufactured to meet the demands of today's

contractor. The hammer has many advantages over traditional piling hammers, including other

hydraulic hammers:-

- The hammer fits all British and most foreign single sheet piles as well as numerous 'H' piles using

one set of legs and inserts. It will also fit pairs of sheet piles and open bent corners with the same

configuration. This significantly improves productivity and reduces costs.

- The hammer does not have a single electrical component on it. This means no vulnerable

electrical cable running across the site and no delicate electronics on the hammer. All competent

fitters can understand this hammer.

- Hydraulic hammers are inherently efficient, typically 80-90% of the potential driving energy

being transferred into the pile as opposed to 25-35% for diesel hammers.

- Rapid blow rate. The hammer is double acting, not only giving high energy output, but

increasing the speed of operation. This inevitably increases production and keeps the pile on the

move.

- Infinitely variable stroke controlled, between limits, at the touch of a button. This enables precise

energy control which is very important when commencing piling or when coping with delicate

operations.

- Robust construction. The hammer has been designed with full knowledge of what is required of

piling equipment. A quick look at the hammer sitting on a pile will confirm this.

- With the hammer weighing only 3 tonnes, it lends itself to being used on long reach jobs where

there are few economic alternatives.

- Noise levels are considerably lower than that of diesel or air hammers.

- Transmitted ground vibrations have been measured lower than that of a vibrator.

1.1 Basic Safety Points

- Ear protection should be worn when in close proximity of the hammer.

- Keep clear of the hammer and/or power pack when they are being lifted.

- Avoid standing directly below the hammer when it is piling.

- Adhere to maintenance requirements set out in this manual.

- Lift equipment using lifting points specified only (see figures over).

1.2 Transportation and laying down hammer

- BEFORE operating hammer first time AND after each lay-down use inspection holes to ensure

dolly is seated correctly in anvil before striking.

- WHEN LAYING DOWN HAMMER, support top of hammer at higher level than bottom of

hammer.

- TRANSPORTATION, support top of hammer at higher level than bottom of hammer.

Page 6

Page 7

Page 8

2.0 HOW DOES THE HAMMER WORK? (See fig. 1)

The D.C.P. Hydraulic Hammer consists of a 'drop weight' driven up and down by a 'hydraulic ram'

inside a 'casing.' The hydraulic ram is double acting which means the drop weight is accelerated

both on the upstroke and on the downstroke. This gives the hammer its very efficient energy output

and high blow rate.

The oil supplied to the hydraulic ram comes from the power pack via a 'control valve' mounted

inside the top of the hammer. This control valve switches the oil supply on or off at the upstroke

side of the hydraulic ram i.e. oil supply 'on' lifts the drop weight and oil supply 'off' drops it.

The control valve itself has to be switched from one position to another at precisely the right times

for optimum performance. The control valve is switched by hydraulic pilot signals from two

mechanically actuated sensors mounted on the hammer casing. The 'bottom sensor,' when actuated

by the drop weight, switches the control valve to the on (lift) position and the 'top sensor' switches

the control valve to the off (drop) position. The stroke of the drop weight is adjusted by moving the

position of the top sensor e.g. moving the sensor down reduces the stroke or vice versa.

The position of the top sensor is altered by a small 'height adjusting ram' mounted inside the top of

the hammer. This is adjusted as required by the operator who can view an indicator on the side of

the hammer.

The hammer is fully controlled using a hand-held control pendant. This unit enables the hammer to

be started/stopped, run on single/automatic blows and have its stroke varied. The controller may be

used from a remote position.

Page 9

Page 10

3.0 POWER PACK AND HAMMER OPERATION

3.1 Connecting the hydraulic hoses and control pendant

(The power pack must be turned off at this time to enable correct installation of the hoses)

There are four hydraulic hoses running between the power pack and the hammer, viz:

1. Pressure line (1" BSP) carries the main high pressure oil supply to the hammer.

2. Return line (1¼" BSP) returns low pressure oil from the hammer to the power

pack.

3.} Height adjusting lines (3/8" BSP) used to deliver

4.} Oil to the height adjusting ram, as required.

The pressure/return hoses have the same specification. However, the return hose ends have larger

fittings than the pressure hose to avoid possible confusion. Similarly, the height adjusting hoses

have different end types. The hoses should be left connected to the hammer at all times - this

reduces the likelihood of oil contamination and reduces leakage problems. The hoses should be

connected/ disconnected at the outlets of the power pack. All these connectors are of the

'quick-release' type. The hoses should be disconnected from the power pack when moving the

power pack around to avoid straining the connectors.

Make sure that the connectors are thoroughly cleaned when making a connection

Having connected the hoses, next fit the hand control pendant connector block to the multi-pin

outlet from the power pack. This is positioned below the instrumentation panel of the unit. Check

that a clean connection is made and that no water is present in either half of the connection. The

'power' switch on the controller should be turned off.

3.2 Checking the power pack before starting

Having connected the hydraulic hoses and hand control pendant, as described in section 3.1, next

check fluid levels on the power pack. Check:

a. engine oil level

b. diesel fuel level

c. hydraulic oil level, and fill if required

Notes:-

1. The diesel fuel and hydraulic oil tanks have sight gauges on the side of the tanks.

2. The power pack will not run if the hydraulic oil level is too low.

3. The hammer will not run if the hydraulic oil temperature is too low. The auto warm-up routine

must be used to pre-warm the oil. See section 3.3.1.

Page 11

3.3 Starting the power pack (see fig. 2)

Prior to starting the power pack, check that the hand control pendant is turned 'off.' Set the throttle

control lever to half of full throttle (2). Turn 'on' the battery isolator (1). Push the engine start push

button (4) until the engine starts.

Allow the engine to reach working temperature by running it at 1500 r.p.m. under zero load for

10-15 minutes. Check all gauges and diagnostic lights for correct function of unit (diagnostic lights

should be off.)

Notes:-

1. If any of the following L.E.D.'s (7, 8, 9 or 10) are 'on' when the isolator switch (1) is turned 'on,'

the power pack will not start. Rectify problem immediately.

2. If L.E.D. (12) is on, the power pack will start but the pendant will be ‘dead’ until the hydraulic

oil warm up procedure is carried out.

3.3.1 Hydraulic Oil Warm-up Procedure

If the hydraulic oil temperature is less than +25ºC, L.E.D. (12) will be on and the oil will require

warming prior to using the hammer.

The hand control pendant will be ‘dead’ for as long as L.E.D. (12) is on.

To warm the oil:-

a) Run the engine at 1800 r.p.m.

b) Turn the ‘warm-up/run’ selector switch (13) to ‘warm-up’. (The engine should go under load

and the high pressure gauge (5) should read approx. 200 bar).

c) Leave the pack in this condition until the L.E.D. (12) goes off. (The engine should come off

load at the same time the L.E.D. goes out and gauge (5) return to zero bar).

d) Turn the ‘warm-up/run’ selector switch (13) to ‘run’. The power pack is now ready for use.

3.4 Using the hammer

3.4.1 Installing hammer on the pile

The hammer must be sat correctly on the pile to avoid hammer or pile damage. The pile tops should

be as level and square cut as possible. The hammer anvil must be in good condition.

Lift the hammer onto the pile(s) to be driven. Lower the hammer down until the handling slings

lose their tension. At this point, the anvil should be seated correctly i.e. the rubber ring around the

anvil should be compressed between the casing and the anvil. If it is not and there is a gap here,

re-site the hammer.

Note: Before using the hammer (and particularly after transportation) check

that the dolly is fitted correctly in the anvil.

Page 12

3.4.2. Bleeding air from the hammer hydraulic system - only required

when running hammer after initial connection or following a repair

When running the hammer for the first time after initial connection to the power pack, there will be

air in the hydraulic system. The hammer will 'bleed' this air automatically but the following

procedure must be applied:-

a. Run the power pack at 2300 r.p.m.

b. Turn on the control pendant 'power' button.

c. Adjust the stroke height indicator to minimum using the '↓' push button.

d. Set the 'Auto/Man' turn button to 'Man.'

e. Hold the 'start' push button down for 2-3 seconds.

f. Repeat (e) three or four times until the hammer consistently gives one or two small blows each

time. Providing the hammer does not 'jump' on the pile, hold the 'start' push button down, so

that the hammer gives several consistent blows, on the next operation. (Approximately 120

blows per minute.) If the hammer 'jumps' on the pile, because the drop weight is hitting the top

of the hammer casing, the hammer will stop automatically. To reset see section 3.4.4.

g. Commence the piling operation using the hammer as required.

3.4.3 Pile driving with the hammer

Having the hammer sited on the pile and removed air from the hydraulic system (if necessary) as

described above, the hammer is ready for pile driving:-

a. Increase the power pack engine speed to 2300 r.p.m. (having followed - "Starting the power

pack" section 3.3)

b. Turn the hand control pendant 'power' button on.

c. Adjust the 'stroke height indicator' on the side of the hammer to minimum stroke by pressing the

'↓' push button.

d. Set the 'Auto/Man' selector button to the required position:

'Auto' - hammer will continue running automatically when the 'start' push button is pressed once.

'Man' - hammer will only run whilst the 'start' push button is held down.

e. Depress the 'start' push button as required by 'Auto/Man.'

f. During operation the hammer stroke may be altered using the '↑' or '↓' push buttons to adjust the

stroke height indicator.

g. To stop the hammer whilst it is running on 'Auto,' turn the 'Auto/Man' selector to 'Man' or turn

the 'power' selector off.

Page 13

It is good practice to start piling with the hammer set on minimum stroke, this limits unnecessary

damage to both the hammer and the pile when the pile can be driven easily. The stroke may then be

adjusted to suit the changing driving resistance.

On certain piling jobs, it may be possible to start driving on pairs of sheet piles, changing over onto

a single sheet pile as the driving resistance increases (this will give maximum productivity.)

3.4.4 Cold running/overtravel

The hammer 'jumps' on the pile top when trying to achieve full stroke if the hydraulic system is

'cold.' If this happens, the hammer will stop automatically. (Thus preventing internal damage to

the unit.) The power pack will continue to run and the 'pressure' gauge will read approximately 240

bar.

In order to reset the hammer, turn off the 'power' selector on the hand control pendant and stop the

power pack. Allow the engine to stop for approximately 10 seconds then restart the unit. Reduce

the stroke of the hammer to minimum. Run the hammer at this lower setting until the oil is warm

enough to allow correct full stroke setting. If reducing the stroke does not cure the problem, warm

the hydraulic oil as described in section 3.3.1.

If the hammer overtravels again, refer to the Troubleshooting section 6.0.

THE HAMMER WILL NOT RUN IF IT IS NOT ALLOWED TO RESET CORRECTLY

3.4.5 Refusal

Piling must stop with this hammer when the rate of driving reaches 10 blows per 25mm.

Continued use will result in hammer and/or pile damage

Page 14

Page 15

3.5 Using the hammer underwater

It is possible to drive piles with this hammer underwater. However, the hammer must be prepared

correctly in order to do so - it can not be used underwater in standard format.

The work involved is briefly as follows:-

a) The stroke adjuster ‘slot’ in the leg guide must be sealed with a cover.

b) The insides of the hammer should be suitably greased to minimise the effects of corrosion.

c) The gaps between hammer casing, leg guides and top cover must be sealed with silicone mastic.

d) The inspection holes near the bottom of the hammer casing must be plugged.

e) A threaded compressed airline port must be added in the bottom end of the hammer casing or leg

guide.

f) The hammer must be run in conjunction with a 35/70 c.f.m. (100 psi) air compressor.

g) The hammer grease nipples must be greased after every pile drive to ensure ample lubrication.

NOTE: FOR DETAILED ASSISTANCE WITH THIS TYPE OF WORK PLEASE CONTACT

THE MANUFACTURER.

3.6 Wider or special pile sections.

The HPH 1200 hammer in standard format will drive a considerable range of steel piles. In some

applications, however, where sheet piles are particularly wide or perhaps boxed together it is

possible to use simple leg insert modifications and/or spreader plates to give improved pile coverage

reducing pile head stress and improving productivity rates.

A good example of this is with B.S.C. LX or Arbed PU type sheet piles. The standard leg inserts

can have “wing extensions” bolted on to correctly centralise the hammer on a single sheet pile.

Then either a special anvil can be used to give wider coverage, or, by dropping the inserts to a lower

set of location holes, a ‘spreader plate’ can be added below the standard anvil to give improved pile

coverage. This is a tried and tested technique (see figure 3).

With tubular piles, for example, the standard inserts can be removed and in place some simple bolt

on plates added to centralise the hammer on the tube (see figure 4). A further refinement, if

necessary, is to weld a ring onto the underside of the anvil to give correct location on the tube.

PLEASE CONTACT THE MANUFACTURER IF YOU HAVE A SPECIFIC PILE DRIVING

PROBLEM - IT MAY HAVE BEEN DONE BEFORE!

Page 16

Page 17

Page 18

3.7 PREVENTATIVE MAINTENANCE GUIDELINES FOR HPH 1200 & 2400 HYDRAULIC HAMMERS, AND DIESEL ENGINED POWER PACKS

DAILY OR REFUELLING EVERY 125 HOURS EVERY 250 HOURS EVERY 500 HOURS EVERY 1000 HOURS EVERY 2000 HOURS

CHECK

:

•

OIL LEVEL

•

COOLANT LEVEL

•

FAN - INSPECTION

•

DRIVE BELT - INSPECT

•

FUEL WATER TRAP - DRAIN

CHECK

:

•

HYDRAULIC OIL LEVEL

•

AIR INLET/OUTLETS FREE

FROM OBSTRUCTION

•

CONDITION OF LIFTING POINTS

&

SLINGS/SHACKLES

•

TEST DIAGNOSTIC LEDS

•

INSPECT GAUGES

•

CONDITION OF QUICK RELEASE

COUPLINGS

CHECK

•

ALL EXTERNAL FASTENERS

FOR TIGHTNESS

•

DOLLY CONDITION

•

SUSPENSION BLOCK

SUSPENSION RING CONDITION

•

LIFTING POINT CONDITION

•

SERVICEABILITY OF

SLINGS/SHACKLES

&

CHECK

:

•

FOR HYDRAULIC OIL LEAKS

&

RECTIFY

•

CONDITION OF HOSES

•

TIGHTNESS OF FASTENERS

•

CONDITION OF PAINTWORK

•

BATTERY WATER LEVEL

•

FUNCTION OF PENDANT

CONDITION OF CABLE

CHECK

:

•

TIGHTNESS OF ALL HOSES

FITTINGS AND FASTENERS

INSIDE HAMMER

•

CONDITION OF BOTH

SENSORS

•

WEAR LEVEL ON LEG INSERTS

&

MUST

:

•

GREASE HAMMER

FREQUENTLY

CHANGE

:

•

LUBE OIL

•

LUBE FILTER

CHECK

:

•

AIR CLEANER

•

INTAKE SYSTEM

•

CHARGE AIR COOLER

CHANGE

•

FUEL FILTER

CHECK

•

ANTI FREEZE

:

:

ADJUST

:

•

VALVE LASH CLEARANCE

CHECK

:

•

FAN HUB

•

BELT TENSIONER BEARING

•

BELT TENSION

CHANGE

:

•

ANTI FREEZE

CHECK

:

•

DAMPER

CHECK

:

•

BATTERY CHARGING

CHANGE

:

•

,

HYDRAULIC OIL/FUEL

FILLER FILTERS

CHECK

:

•

ACCUMULATOR NITROGEN

PRECHARGE PRESSURES

•

HAMMER FILTER

•

FUNCTION OF OVERTRAVEL

VALVE

•

FUNCTION/CONDITION OF

PROBE ASSEMBLY AND

BOTTOM TRIP DEVICE

CHANGE

:

•

RESILIENT WASHERS

BETWEEN DROP WEIGHT

HYDRAULIC RAM ON HPH

2400

ONLY

CHECK

:

•

PRESSURE OUTPUT OF PUMP

•

FLOW OUTPUT OF PUMP

CHANGE

:

•

PRESSURE/RETURN

HYDRAULIC FILTERS

CHECK

:

•

CONDITION OF HEIGHT

ADJUSTING RAM

•

TIGHTNESS OF

ACCUMULATORS

•

CONDITION OF MAIN FEED

HOSES TO HAMMER

CHECK

:

•

CONDITION OF WIRING

•

DRIVE COUPLING FOR WEAR

•

CONDITION OF EXHAUST

CHANGE

:

•

HYDRAULIC OIL AND CLEAN

OUT SYSTEM

CHECK

:

•

PLAY IN MAIN RAM

ANCHORAGE ASSEMBLY

•

CONDITION OF ANVIL

•

PLAY BETWEEN DROP WEIGHT

AND CASING BORE

CHANGE

:

•

RESILIENT WASHERS BETWEEN

DROP WEIGHT AND

HYDRAULIC RAM

&

-

TEST RUN ON PILE

BEFORE AND AFTER CHECKING

15

MINUTES

TEST RUN ON PILE

BEFORE AND AFTER CHECKING

15

MINUTES

TEST RUN ON PILE

BEFORE AND AFTER CHECKING

30

INUTES

(FOR FULL DETAILS SEE SECTIONS 4 AND 5 IN THE HAMMER MANUAL AND THE CUMMINS SERVICE MANUAL)

TEST RUN ON PILE

BEFORE AND AFTER CHECKING

30

MINUTES

TEST RUN ON PILE

BEFORE AND AFTER CHECKING

30

MINUTES

Page 19

4.0 HAMMER MAINTENANCE (SEE APPENDIX 7.1)

4.1 Daily maintenance checks (or every 10 hours)

a. Apply Lithium based general purpose grease to hammer through each one of five grease points

(part 1-057-00-01). Ten operations of a grease gun on each grease point every shift will be

adequate. If the hammer is working particularly hard grease more frequently.

b. Check all external fasteners for tightness and re-tighten where necessary.

c. Check that the dolly (part 1-006-00-06) has not been damaged or worn beyond its

serviceable limit. If the dolly is replaced, ensure that the O' ring is replaced with it (part

1-067-00-01.)

To inspect the dolly, remove eight screws (part 1-034-00-01) and drop the leg inserts

(1-019-00-01 and 1-020-00-01) down far enough to view the dolly. If the dolly is compressed

past it's serviceable limit i.e. 30mm of wear, or if the dolly is cracked or melted replace it.

To replace the dolly insert a steel bar through one of the holes in the bottom of the anvil (part

1-005-00-01) and drive the old dolly out using a hammer. Insert a new dolly (complete with O'

ring) ensuring that it is pushed fully home.

d. Check the suspension blocks (part 1-025-00-01) and suspension ring (part 1-024-00-05) for

wear/damage and replace if necessary. These must be in good condition at all times. These

items act as the hammers 'suspension system' reducing the shock transmitted from the blow to

the hammer and its components - very important for keeping the hammer functioning correctly.

e. Check the condition of lifting tackle and lifting points prior to being taken into service.

4.2 Planned 125 hour maintenance checks (run the hammer for 15 minutes before and after

this maintenance work)

Every 125 hours the following work should be carried out in addition to that described in 4.1

above:-

a. Remove each hammer leg guide in turn and check the condition and tightness of: all hydraulic

hoses and fittings; bolts; locking rings, and visually check all components for condition.

b. Check the condition of each sensor assembly paying particular attention to cam wear, roller

operated valve travel and tightness of fixing bolts. Each roller valve should have a travel of

4mm through full actuation of its associated cam. This measurement is critical and if it is not

achieved the hammer will not run correctly (as with the ignition timing on a motor car). Travel

can be lost through excessive cam wear or with wear on the roller or roller pin at the end of the

valve.

c. Check the condition of leg inserts to ensure correct fitting on pile sections. The inner faces of

each insert should touch the opposite insert. If not, the wear faces may require building up with

hard facing.

Page 20

4.3 Planned 250 hour maintenance checks (run the hammer for 15 minutes before and after

this maintenance work)

Every 250 hours the following work should be carried out in addition to the work described in 4.1

and 4.2 above:

a. Check the accumulator (part 1-048-00-04) precharge pressures using the gas pressure checking

kit and a bottle of nitrogen gas. The high pressure accumulator is situated on the side of the

hammer that the supply hoses come in.

The precharge pressures are:-

High pressure -100 bar

Low pressure - 3 bar

To gain access to the accumulators it is necessary to remove the top cover (part 1-017-00-02.)

To check the precharge pressures see appendix 7.2 in this manual.

b. Check the hammer filter (part 1-079-00-02) for cleanliness. First remove the top cover (part

1-017-00-02.) Then unscrew the filter bowl and remove the filter element. Check the filter for

damage and any unusual debris. Wash the filter with clean diesel and blast through from inside

the filter with compressed air. Alternatively throw the element away if it is a non-metallic filter.

PAY EXTRA CARE NOT TO ALLOW DIRT INTO THE FILTER ASSEMBLY ON

RE-FITTING

c. Check the function and condition of the bottom trip device.

d. Check the function of the hammer’s overtravel valve by intentionally overstroking the hammer

when cold.

4.4 Planned 500 hour maintenance checks (run the hammer for 30 minutes before and after

this maintenance work)

Besides work mentioned in 4.1, 4.2 and 4.3 above the following work should be carried out:-

4.4.1 Change the Resilient Washers

The flexible coupling between the main hydraulic ram and the drop weight must be changed. The

procedure is quite straightforward (see figure 5). Failure to do this will result in an expensive repair.

a. Lay the hammer on stable level ground on its Front Leg Guide packed on timbers. Remove the

Rear Leg Guide (part 1-002-00-02).

b. Remove the 3 no. Nyloc Nuts, Dog Point Grub Screws and Anti-Vibration Washers (parts

1-334-00-01, 1-349-00-01 and 2-089-00-01) from the Connector Nut (part 1-011-00-02). It may

require a little

c. Unscrew the Connector Nut from the Ram Connector (part 1-009-00-02) and remove the Nut

together with 2 no. Buffer Spacers (part 1-012-00-02) and the Resilient Washer 2 (part

1-016-00-02).

heat to melt the Loctite on the grub screws.

Page 21

d. Retract the piston rod of the Hydraulic Ram from the Drop Weight by hand and remove the

other Resilient Washer (part 1-016-00-01), Buffer Washer (part 1-010-00-01).

e. Inspect the removed steel components for wear and replace those with signs of fretting or

bruising. Dispose of the old Resilient Washers irrespective of their condition - do not reuse

them!

f. Ensure the Connector Nut threads are clean and fully degreased. Pay particular attention to de-

greasing the Grub Screws threads and the Grub Screws as this will ensure the Loctite adhesive

works correctly. Failure to do this correctly may result in the assembly working loose!

g. Re-assemble the connection as in figure 5 ensuring the new Resilient Washers are installed in

their correct positions. Tighten the Connector Nut until it is hand tight (there should be no free

play on any component). Tighten the Connector Nut further using a socket until the nut bottoms

out. Align a Dog Point Grub Screw hole in the Connector Nut with one of the axial slots in the

Ram Connector thread. This may require the Nut to be slightly backed off.

h. Install the 3 no. Dog Point Grub Screws using some Loctite 270 Studlock thread adhesive, and

fully tighten each in turn to the torque quoted on Figure 5. Next install the pairs of antivibration washers onto each grub screw and lock the grub screws using new Nyloc nuts.

i. Re-assembly the Rear Leg Guide on the hammer. The unit is now ready for running.

4.4.2 Other items

Check the following:-

a. Condition and function of the Height Adjusting Ram.

b. Tightness of the Accumulator assemblies.

c. Condition of the main feed hoses between the hammer and power pack. Hoses with excessive

amount of “braiding” exposed or damaged should be replaced.

4.5 Planned 1000 hour maintenance checks (run the hammer for 30 minutes before and after

this maintenance work

Check the following:-

a. Play in the main ram anchorage assembly.

b. Condition of the Anvil.

c. Play between the Drop Weight and Casing bore.

Note: It is strongly recommeded that in order to achieve thorough and correct maintenance of

this equipment that customer’s service personnel should be fully trained by the manufacturer.

Page 22

Page 23

5.0 POWER PACK MAINTENANCE

5.1 Power pack specification

5.1.1 Basic specification

Engine power output - 55 kW (74 hp) @ 2300 rpm

Engine maximum r.p.m. - 2300

Hydraulic flow output - 75 l/min

Max hydraulic pressure output - 240 Bar

Dimensions (l x w x h) - 1900 x 1400 x 1800mm

Weight - 2000 kg

5.1.2 Lubrication specification

Hydraulic oil type - Fina Hydran LZ 32 or equivalent

Hydraulic oil capacity - 465 litres

Diesel engine oil type - API-CD-DE

Diesel engine oil capacity - 9.5 litres (incl. filter)

Diesel fuel type - DIN 51601-DK

Diesel fuel capacity - 235 litres

5.2 Daily maintenance checks (for full details of diesel engine maintenance see Cummins

service manual)

a. Check hydraulic oil level - must be visible in sight glass, but not over half way in sight.

b. Check diesel lubrication oil level.

c. Ensure pump isolator valve is fully open.

d. Ensure air inlet/outlet panels are free from obstruction.

e. Drain water from diesel water trap.

f. Inspect lifting tackle and lifting points before being put into service.

g. Check function of diagnostic L.E.D.’s by pressing test button.

h. Check function of gauges.

i. Check condition of quick release couplings.

j. Check engine coolant level.

k. Check condition of fan and drive belt.

Page 24

FIGURE 6 Hammer Dolly photographs

dy

Debris embedded in dolly, remove debris

and continue.

Overworked 6500 dolly stuck in anvil body

must be replaced or it can cause the anvil bo

to break.

4500 dolly starting to show signs of cracks after

150 hrs of piling. O.K. but if cracks extend to

the outer edge or the underside of the dolly, it

must be changed.

Severely cracked 6500 dolly should be

replaced.

If dolly is not replaced when it has been

overworked, the anvil body can break due to

expansion of dolly material.

View showing underside of 4500 dolly after 150

hrs of work. No signs of cracking. O.K.

Page 25

5.3 Planned maintenance checks

For full details of diesel engine maintenance see Cummins service manual and for power pack

maintenance procedures see section 5.4.

Page 26

5.3.1 Every 125 hours

Check the following:-

a. Hoses, pipework and fittings for any hydraulic oil leaks and rectify as required.

b. Tightness of all fasteners.

c. Condition of body panels and paintwork. Touch-up where necessary.

d. Battery water level.

e. Condition and function of hand control pendant.

5.3.2 Every 250 hours

Check the following:-

a. Engine air cleaner.

b. Engine intake system

c. Engine charge air cooler.

d. Battery charging rate.

Change the following:-

e. Engine oil.

f. Engine oil filter.

g. Hydrauic oil filling filter.

h. Diesel fuel filling filter.

5.3.3 Every 500 hours

Check the following:-

a. Anti freeze in engine coolant.

b. Pump output flow rate and working pressure.

Change the following:-

c. Fuel filter.

d. Hydraulic oil pressure and return filters.

Page 27

5.3.4 Every 1000 hours

Check the following:-

a. Engine fan hub.

b. Engine belt tensioner bearing.

c. Engine belt tension.

d. Adjust valve lash clearance on engine.

e. Condition of all wiring and tightness of electrical connectors.

f. Wear on hydraulic pump flexible coupling.

g. Condition of exhaust.

Change the following:-

h. System hydraulic fluid.

5.4 Maintenance procedures

NOTE: Before any of the following procedures are undertaken, the battery

isolator switch must be switched off.

a. Changing fuel/hydraulic oil inlet filler elements.

(i) Replacement element

(ii) Remove filter bowl

(iii) Remove and discard filter element (do not clean)

(iv) Wash bowl thoroughly

(v) Fit replacement element into bowl

(vi) Re-assemble filter

(vii) Prime hand pump

b. Changing hydraulic pressure filter element.

(i) Replacement element

(ii) Remove filter bowl

(iii) Remove and discard filter element (do not clean)

(iv) Wash bowl thoroughly

(v) Fit replacement element onto spigot

(vi) Fill filter bowl with clean hydraulic oil

(vii) Replace bowl O' ring if necessary

(viii) Re-assemble filter

Page 28

c. Change hydraulic return filter element.

(i) Replacement element

(ii) Remove filter bowl

(iii) Remove and discard filter element (do not clean)

(iv) Wash bowl thoroughly

(v) Fit replacement element onto spigot

(vi) Fill filter bowl with clean hydraulic oil

(vii) Replace bowl O' ring if necessary

(viii) Re-assemble filter

d. Pump removal/re-fitting.

(i) IMPORTANT NOTE - the hydraulic pump should be returned to the

manufacturer for repair/overhaul. This item

must not be stripped or tampered with.

(ii) Isolate pump from hydraulic oil reservoir using pump isolator valve

(iii) Remove hoses (3 off) from pump body

(iv) Remove 2 off mounting screws from front flange of pump

(v) Withdraw pump from coupling towards oil reservoir

(vi) Remove bellhousing from engine mounting flange

(vii) Reverse procedure for re-assembly

(viii) Fill case drain of pump with clean hydraulic oil prior to start up following removal

from the system (port located on the top of the pump with adaptor fitted)

e. Cooler removal/re-fitting.

(i) Close pump isolator valve to prevent system syphoning

(ii) Remove 2 off flexible hoses from cooler

(iii) Remove mounting bolts from cooler

(iv) To remove matrix, remove top and bottom retaining strips from front of

cooler and withdraw matrix from front of cooler assembly

(v) To remove fan remove matrix and withdraw fan from motor shaft

(vi) To remove motor remove matrix and fan, unbolt motor from back of cooler

f. Control valve assembly.

(i) Close pump isolator valve to prevent system syphoning

(ii) To replace solenoid coils remove plastic retainer from end of coil and

withdraw coil from retaining tube

(iii) To replace valve assemblies remove 4 off retaining screws from top of valve and

replace component as necessary

Page 29

g. Pipework.

(i) For details of hose assemblies see hydraulic schematic drawing Appendix

7.4.1

(ii) In the event of steel pipe failure, 25mm 3 series fittings should be utilised in

conjunction with 25mm bore x 3mm wall thickness tube

(iii) Welded pipe ends are currently utilised and should it become necessary to

disturb these fittings a replacement 'O' ring should be used

h. Changing system hydraulic fluid

(i) Change hydraulic fluid

(ii) Remove cleanout cover and clean reservoir

(iii) Replace fuel inlet and hydraulic fluid inlet filter elements

(iv) Replace hydraulic pressure line filter element

(v) Replace hydraulic return line filter element

(vi) Blow through cooler matrix to clear

(vii) Replace solid pipe fitting 'O' rings as necessary

(viii) Replace tank cover gasket

(ix) Check all electrical connections for tightness

(x) Check drive coupling for wear and replace or adjust if necessary

5.5 Setting procedures

a. Re-setting pressure

The pressure regulating adjuster is situated on the main control valve assembly.

To adjust:

(i) Loosen the lock nut and wind the centre spigot counter clockwise to reduce pressure

(ii) Press the test button on the control panel to load the system

(iii) Turn the centre spigot clockwise to raise the system pressure

(iv) When the required pressure has been achieved (max 240 bar) tighten the lock nut

NOTE: Should the required pressure be exceeded, wind the adjuster back

and increase again. Never wind the pressure downwards to set

b. Engine gauges replacement.

(i) There is a resistor fitted to all gauge power lines. This must be replaced after

maintenance to prevent damage to the gauges.

Page 30

6.0 TROUBLESHOOTING

6.1 Power pack engine will not start

a. Check battery condition.

b. Check diagnostics panel for fault LED showing (see fig. 2.)

6.2. Engine cuts out during running

a. Check diagnostics panel for fault LED showing and rectify (see fig. 2.)

6.3. Power pack does not generate any pressure

a. Check L.E.D. (12) to see if hydraulic oil is up to temperature (see figure 2). If not perform

warm-up operation described in section 3.3.1.

b. Check operation of main valve in power pack by turning selector switch (13) to ‘warm-up’ on

the instrumentation panel (fig. 2.) This gives 200 bar reading on pressure gauge.

c. Check fuses or electrical connections to valve block if no reading from (b).

d. Check operation of relief valve if no reading from (b).

e. Check operation of hand control pendant and fuses in electrical box if reading is

O.K. in (b).

6.4. Power pack generates pressure but hammer does not run

a. Anvil not pushed fully up into hammer casing (see section 3.4.1.) or the dolly is not sitting

correctly in the anvil (especially after transportation or laying on its side - see also section 1.2).

b. Check oil flow rate gauge reading - 75 l/min minimum. (Note: this figure will be much higher

whilst the hydraulic oil is cold).

c. Air in hammer hydraulic system - see section 3.4.2.

d. Hammer has been allowed to overtravel - see section 3.4.4. to reset.

e. Damaged hose on control side of hammer - check by removing front leg guide for inspection.

f. Faulty bottom sensor assembly - lay the hammer on timber blocks on level stable ground on its

rear leg guide then remove front leg guide and check bottom sensor as follows:-

(i) Cam/spring operation - does the cam rotate/return freely and is the spring in good order.

(ii) Check for correct lift on valve roller (4mm)

(iii) Check 'trip' arrangement for correct function (part 1-083-00-05 & 1-36-00-05)

Page 31

(iv) It is possible to work the hammer for diagnostic purposes whilst it is laying on the

ground. However, extreme caution must be exercised when doing so as incorrect

operation will cause hammer damage. Always ensure the pendant is in MANUAL mode

and NOT automatic mode. The anvil must be in the ‘up’ position so as to ensure the

trip device is ‘off’. The hammer can be pressurised by ‘tapping’ the ‘start’ push button

on the pendant (power pack running) very gradually building up enough pressure to

move the drop weight. If the button is held for too long the drop weight will possibly

impact the inside top of the hammer - not a good idea!

However, by careful application of this method it is possible to check pressure is

reaching the relevant sensor. If it is not, then the problem may be with the overtravel

valve (part 1-084-00-02) not allowing oil flow to the control side of the hammer. This

can be confirmed by removing the main pressure feed to either sensor - no oil flow

when pressurising the system indicates overtravel valve problems and this item should

be removed for inspection. (The overtravel valve can be removed through the wide slot

in the side of the hammer encased by the rear leg guide and the hammer will require

turning over to do this). Turn the power pack off before removal.

When checking the overtravel valve first check the small restrictor/dowel on its top face

for any blockage. The valve is unlikely to be faulty inside and if this is suspected the

unit should be returned to the manufacturer for checking.

If pressure is reaching the sensor check that the pilot signal from the sensor is reaching

the main control valve block at the top of the hammer when the roller valve is operated.

If not, remove and inspect the roller valve.

g. If this all appears to be in order check the top sensor mechanism in a similar manner to that

described in f. (i) and (ii) above as it may be that the top sensor is jammed on.

Note: The spool inside the roller valve and the roller shaft are not connected so even though

the roller returns when operated it does not follow that the spool has returned. Check

the tension on the roller shaft, if there is none the spool may be stuck open.

h. If all appears well the problem may be with the load holding valve (part 1-073-00-02) or the

main control valve spool. Contact the manufacturer for further details.

6.5 Hammer will lift but not drop

a. Has the hammer been allowed to overtravel. Check reset - see section 3.4.4.

b. Air in hammer hydraulic system - see section 3.4.2.

c. Damaged 'looped' hose from sensor assembly - check by removing front leg guide for inspection.

d. Faulty top sensor assembly - see 6.4.e. as diagnosis is similar to faulty bottom sensor assembly.

e. Faulty bottom sensor assembly i.e. valve is staying on (see section 6.4.f. for similar diagnosis)

Page 32

6.6 Hammer runs erratically

a. Air in hydraulic system - see section 3.4.2.

b. 'Cold' hydraulic oil - see section 3.4.4.

c. Accumulator pressures incorrect or bladders damaged.

See Appendix 7.2.High pressure accumulator - 100 bar (2 off)

Low pressure accumulator - 3 bar (2 off)

d. Blocked filter on hammer - see section 4.2.b.

e. Not enough hydraulic flow/pressure from power pack - check flow rate gauge and pressure

gauge.

f. One or both sensors damaged/contaminated - see sections 6.4 and 6.5,

6.7 Excessive hose 'jumping'

Check accumulator pressures/condition - see Appendix 7.2.

6.8 Hammer 'jumping' excessively on pile top - reduce stroke immediately

and/or stop piling

a. Too much hydraulic oil input - set to 75 l/min.

b. 'Cold' hydraulic oil - see section 3.4.4 and reduce stroke. To warm the oil see section 3.3.1.

c. Stroke adjuster set too high - reduce immediately to continue working.

d. Suspension blocks (1-025-00-01) and ring (1-025-00-05) damaged. Inspect and replace

immediately, if necessary.

e. Incorrect operation of top sensor assembly i.e. cam wear and/or incorrect roller travel.

6.9 Stroke height indicator will not move

a. With the power pack running and control pendant connected, check pressure gauges when '↑'

and '↓' are pressed. If no readings, check relevant valve and wiring/fuses in power pack.

b. If readings are O.K., check hoses to hammer. If these are O.K., check restrictor orifices for

blockages - these are the male/male adaptors located on the inlet manifold

c. If these are clear remove front leg guide and check height adjusting ram (1-026-00-01) and top

sensor assembly.

Page 33

6.10 Smoke from bottom end of hammer

a. Most likely to be a worn or partially damaged plastic dolly. This does not mean the dolly has to

be thrown away!

Inspect the dolly as described in section 4.1. The dolly may only require dressing up and

rotation prior to being re-used.

b. Early signs of hydraulic oil leak. Investigate further.

Page 34

APPENDIX 7.1 -

HPH 1200 HYDRAULIC HAMMER

PARTS LIST

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

HYDRAULIC HOSE DETAILS FOR HPH 1200

Control Side of Hammer (Sensor Side) - Assy Number 1.110.00.02

Qty Description (Hose Length = Cut Length) Part No.

3 off Hose Assy 900mm

4 off Hose Assy 814mm

3/8

" R2T c/w 20 x 1.5 heavy 12s fem E/E 1.110.05.02

3/8

" R2T c/w 20 x 1.5 heavy 12s fem E/E 1.110.01.02

3 off Hose Assy 990mm ¼" R2T c/w 16 x 1.5 heavy 8s fem E/E 1.110.04.01

2 off Hose Assy 790mm

6 off GE8 PSR ED 8s x

3/8

" R2T 20 x 1.5 heavy 12s fem E/E 1.110.03.02

3/8

" BSP Stud 1.110.02.02

24 off GE12 PSR ED 12s x

3/8"

BSP Stud 1.111.14.02

2 off RHZ 12 PSR ED 12s x

4 off Hose Assy 665mm

3/8

" BSP Stud 1.100.03.02

3/8

" R2T c/w 20 x 1.5 heavy 12s fem E/E 1.110.06.01

Height Adjusting Ram Hoses

2 off Hose Assy 430mm ¼" R2T c/w 16 x 1.5 heavy 8s fem

to 16 x 1.5 heavy 8s 90

4 off GE8 PSR ED 8s x ¼

° swept fem 1.111.11.02

" BSP Stud 1.111.12.01

Power Side of Hammer (Supply Side) - Assy Number 1.111.00.05

1 off Hose Assy 1335mm (Flange to Cone) 1" R13 c/w 42 x 2

heavy 30s fem to 1" SAE 6000 Straight Flange - Interlock type 1.111.07.02

1 off Hose Assy 2320mm (Flange to Flange) 1¼" R13 c/w 1¼"

SAE 6000 Straight Flange each end - Interlock type 1.111.08.05

1 off Voss Flanged Elbow 195241 1.111.17.01

2 off 1" SAE 6000 Split Flange Clamp Halves - metric bolt holes 1.111.20.01

4 off 1¼" SAE 6000 Split Flange Clamp Halves - metric bolt holes 1.111.21.01

8 off M14 x 50 Socket Head Cap Screw 1.111.22.01

8 off M14 Spring Washer 1.111.23.01

4 off M12 x 45 Socket Head Cap Screw 1.111.24.01

4 off M12 Spring Washer 1.094.00.01

Fittings for underside of Inlet Manifold

2 off

3/8

" BSP M/M Adaptor (restricted 0.79mm bore)

1.100.02.02

1 off 1" BSP M/M Adaptor 1.101.05.01

1 off 1¼" BSP M/M Adaptor 1.101.08.01

Page 46

Appendix 7.2 – Accumulator Parts List and Instructions

Page 47

Important Safety Notes for Bladder Accumulators

1. Use nitrogen gas only

2. All accumulators are supplied precharged to 100bar (1450 psi) unless sent via air-freight – in which case

they will be shipped unprecharged

3. Always use the gas filling apparatus supplied by Dawson. This equipment includes a regulator valve

specifically designed for use with hammer accumulators where the precharge pressure is less than the

supply cylinder pressure.

4. Read the instructions below fully before attempting to adjust the precharge in any accumulator

5. Routine maintenance on the accumulator in-situ or removal of the accumulator must only be carried out

when the hydraulic system pressure has been completely removed.

Accumulator Precharge Pressure

High pressure accumulator – 100 bar Low Pressure Accumulator – 3 bar

Pre-charge Procedure

1. Remove protective cap (1) and sealing cap (2) – see figure 1.

2. Attach the Regulator Valve to the nitrogen cylinder – see figure 2.

3. Attach the charging set (5) to the accumulator gas valve assembly (6) and connect

charging hose (7) between the regulator and the charging set connection.

4. Back off handle (8) anticlockwise until loose. Check gas bleed valve (9) on

charging set is closed and screw hand wheel (10) clockwise to open gas valve.

5. Open nitrogen cylinder valve by turning key (11), cylinder pressure will register on

right hand gauge (12). This pressure should be checked against the required

precharge pressure.

6. Turn handle (8) clockwise until outlet pressure on left hand gauge (13) registers

10% higher than required precharge pressure (110 bar or 3.5 bar). When pressure

on the charging set and outlet gauges are equal, close nitrogen cylinder valve.

7. Turn hand wheel (10) anticlockwise to seal gas valve.

8. Crack bleed valve (9) to exhaust gas from charging hose and remove hose from charging set and replace

hose connection sealing cap.

9. Close bleed valve, turn hand wheel (10) clockwise to open gas valve and crack bleed valve (9) to vent

down to required precharge pressure. Close bleed valve.

10. Turn hand wheel (10) anticlockwise to reseal gas valve, crack bleed valve and remove charging set from

the accumulator.

11. Test accumulator gas valve for leaks using soapy water or similar.

12. Replace sealing cap (2) and tighten with pliers. Replace protective cap using a wrench.

Figure 1

Page 48

Inspection and repair of Accumulators

Due to the nature of the design and specific assembly procedures it is recommended that the accumulators should

only be inspected and repaired by a competent person. Dawson Construction Plant Limited or their approved

dealers will be happy to undertake this work as required. Please note the Important Safety Notes at the beginning

of this section.

Page 49

Page 50

Page 51

Page 52

Page 53

APPENDIX 7.5 -

HPH 1200 TOOL KIT

(S/NO 1011 ONWARDS)

(PART NO. 1.150.00.02)

PART NO. QTY. DESCRIPTION

066 1 off 4mm Allen Key

067 1 off 5mm Allen Key

069 1 off 10mm Allen Key

070 1 off 17mm Allen Key

1.150.31.01 1 off 6mm Allen Key - long series

1.150.01.01 1 off 8mm Allen Key - long series

1.150.33.01 1 off 12mm Allen Key - long series

1.150.02.01 1 off 19mm Allen Key - long series

1.150.07.01 1 off 46 x 50 Open End Spanner

1.150.09.01 1 off 18" Adjustable Spanner

1.150.12.01 1 off 19mm Combination Spanner

1.150.27.01 1 off 22mm Combination Spanner

1.150.28.01 1 off 24mm Combination Spanner

1.150.29.01 1 off 27mm Combination Spanner

1.150.30.01 1 off 30mm Combination Spanner

1.150.26.01 1 off 10mm Socket - 1/2" drive

1.150.13.01 1 off 19mm Socket - 1/2" drive

1.150.14.01 1 off 60mm Socket - 3/4" drive

1.150.15.01 1 off Sliding T Bar - 1/2" drive

1.150.16.01 1 off Sliding T Bar - 3/4" drive

1.150.17.01 2 off M20 Lifting Eye

1.150.18.01 2 off M24 Lifting Eye

1.150.20.01 1 off 5/16" Parallel Pin Punch

1.150.21.01 1 off External/Internal Circlip Pliers

1.150.23.01 1 off 200mm Extension - 3/4" drive

1.150.24.01 1 off Soft Faced Hammer

1.150.25.01 1 off Grease Gun

1.070.00.01 1 off Gas Filling Apparatus

Page 54

HPH 1200

HYDRAULIC HAMMER

Dawson Construction Plant Ltd

Chesney Wold.

Bleak Hall,

Milton Keynes,

MK6 1NE, England

Tel: +44 (0) 1908 240300

Fax: +44 (0) 1908 240222

D.C.P. RESERVES THE RIGHT TO DISCONTINUE EQUIPMENT AT ANY TIME, OR CHANGE

SPECIFICATIONS OR DESIGNS WITHOUT NOTICE OR INCURRING OBLIGATIONS

Loading...

Loading...