Davis Instruments EnvrioMonitor, GroWeather, GroWeather 7450, EnvrioMonitor 7460, EnvrioMonitor 7470 Install Manual

Page 1

For 7450 (GroWeather), 7460 (Energy EM), and 7470 (Health EM)

S

YSTEM INSTALLATION

F

OR STANDARD GROWEATHER

™

AND ENVIROMONITOR

™ S

YSTEMS

I

NTRODUCTION

This manual covers basic GroWeather/EnviroMonitor installation, including

how to connect your sensors to the sensor interface module (SIM) and how to

power your unit. Instructions on installing/mounting sensors and other system components (such as the Alarm Output Module) are contained in the manuals for those products. This manual does include several installation drawings

which depict typical GroWeather/EnviroMonitor installations and should help

you connect all of your components correctly.

S

YSTEM

C

OMPONENTS

The system includes the following components. Please make sure you have all

listed components before continuing.

✦

Console with Mounting Base attached

✦

Sensor Interface Module

✦

8-foot (2.4-m) 8-Conductor Cable

✦

AC-Power Adapter

✦

Two #8 X 3/4" Pan Head Self-Threading Screws

✦

16.5-foot (5 m) Ground Wire (12 AWG)

✦

Three #6 x 1" (25 mm long) Self-Threading Screws

Page 2

System Installation

Page 2 Standard System Installation Manual

✦

Two Cable Ties

✦

Four Adhesive Pads

✦

Two Cable Label Sheets

T

OOLS

AND

M

ATERIALS

N

EEDED

In addition to the components listed above, you may need some of the following tools and materials. Please be sure you have everything you need before

beginning the installation.

✦

Medium-sized Phillips Screwdriver

✦

9-volt Alkaline Battery

✦

Drill with #36 (.106" or 2.5 mm) and #29 (.136" or 3.5 mm) drill bits

✦

Standard Switch Box (if you wish to mount the console on a wall with the wires

running inside the wall)

U

SING

THE

L

ABEL

S

HEET

We have provided two sheets of labels which should aid you in your installation. The majority of the labels on the sheets are cable labels for marking the

ends of each cable. These labels contain connector codes which will help you

attach the correct cable to the correct connector. We have included two label

sheets so you can label both ends of each cable with the same label.

Note: Also included on the label sheet are circuit board labels which are for use only with industrial

versions of the stations.

Cable Connector Codes

To simplify installation, we have coded each connector and included the code

on the cable label and on the circuit board or enclosure next to the appropriate

connector. Most connector codes includes a letter and a number. The letter

identifies the module or unit on which the connector is located while the number identifies the specific connector. The following letter codes identify the

module/unit on which a connector is located.

✦

S = Sensor Interface Module

✦

P = Power

✦

C = Console

✦

L = WeatherLink

✦

B = Battery and Solar Power

✦

A = Alarm Output Module

✦

PC = Computer

Page 3

Using the Label Sheet

Standard System Installation Manual Page 3

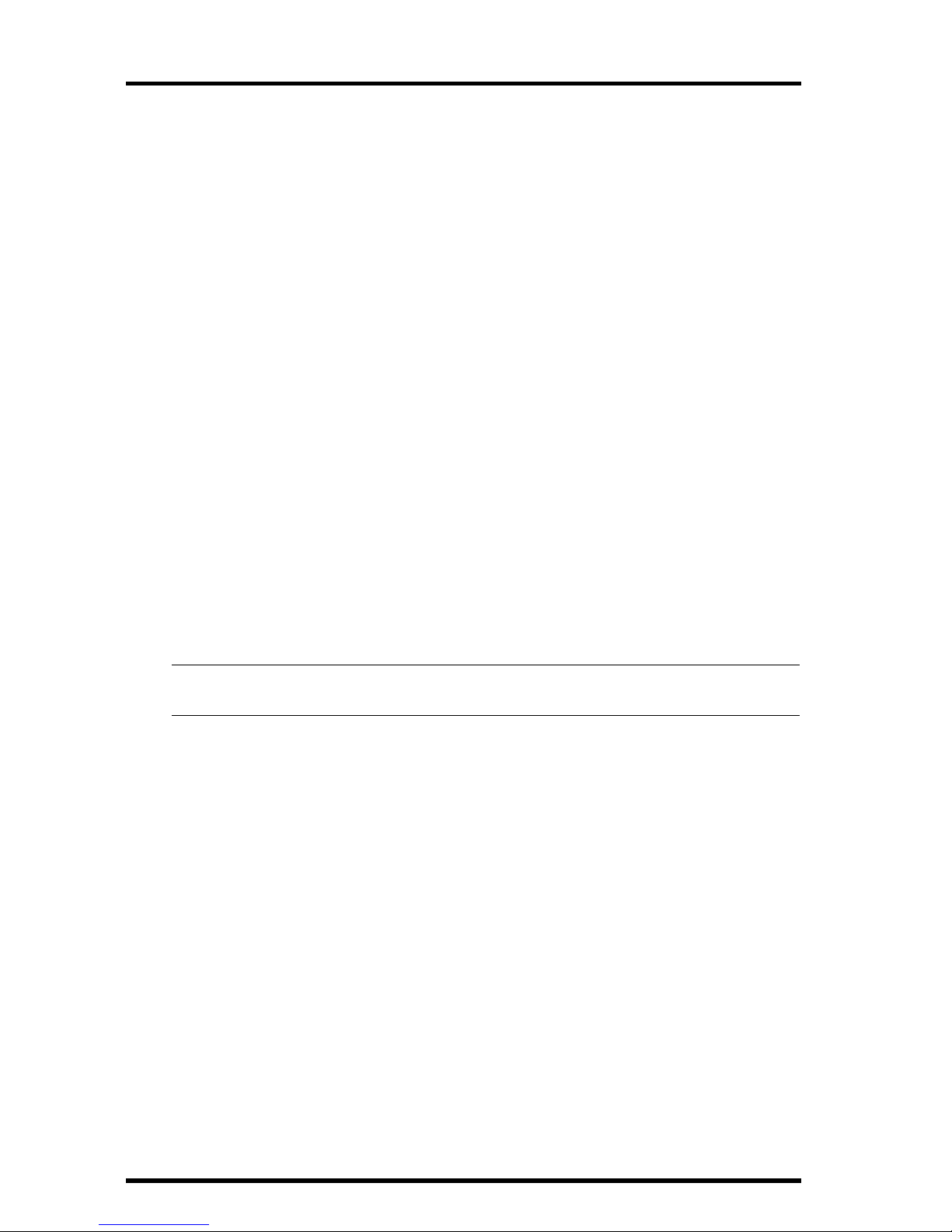

Labeling Cables

Any installation is going to include a number of cables running from various

sensors and components to other components. To alleviate confusion, we have

included label sheets which you should use to mark your cables (see “Cable

Connector Codes” on page 2).Before you begin installation, lay out all of your

cables and attach the appropriate label to each end of each cable. Make sure

you label every cable end, including extension cables. Doing this now will help

prevent confusion during the installation and if you ever need to disconnect a

sensor/component at a later date.

When labeling cables, orient the label so the connector code nearest the end of

the cable matches the connector to which that end of the cable will be attached.

For example, place one C2/SENSOR I’FACE/S7 label onto the 8-conductor

cable (which will be running between the sensor interface module (SIM) and

the console) so the C2 side of the label is nearest the end of the cable which will

be connected to the console. Place the second C2/SENSOR I’FACE/S7 label

onto the other end of the cable so the S7 side of the label is closest to the SIM

end of the cable.

L

ABELING

Y

OUR

C

ABLES

Temperature Sensor/Probe Labels

There are two labels (TEMP/S2 and TEMP2/S3) for the external temperature

sensor/stainless steel temperature probe because you may connect this sensor

in one of two locations (connector S2 or S3). Consult the guidelines below to

decide which label to use on your external temperature sensor/stainless steel

temperature probe. Note that you should always use the T-HUM/S2 label on

your external temperature/humidity sensor.

✦

If you have a temperature/humidity sensor connected to the system, and want to

use the external temperature sensor/stainless steel temperature probe as the

“soil” temperature sensor, use the TEMP 2/S3 label.

✦

If you do not have a temperature/humidity sensor and want to use the external

temperature sensor/stainless steel temperature probe as your primary outside

temperature sensor, use the TEMP/S2 label.

✦

If you have a UV sensor (which needs to be attached at connector S3) and either

the external temperature sensor or the stainless steel temperature probe, use the

TEMP/S2 label.

✦

If you have both an external temperature sensor and a stainless steel temperature probe (or two of either), place the TEMP/S2 label on the sensor you are going

to use as the primary outside temperature sensor. Place the TEMP2/S3 label on

the sensor you are going to use as the “soil” temperature sensor.

Page 4

System Installation

Page 4 Standard System Installation Manual

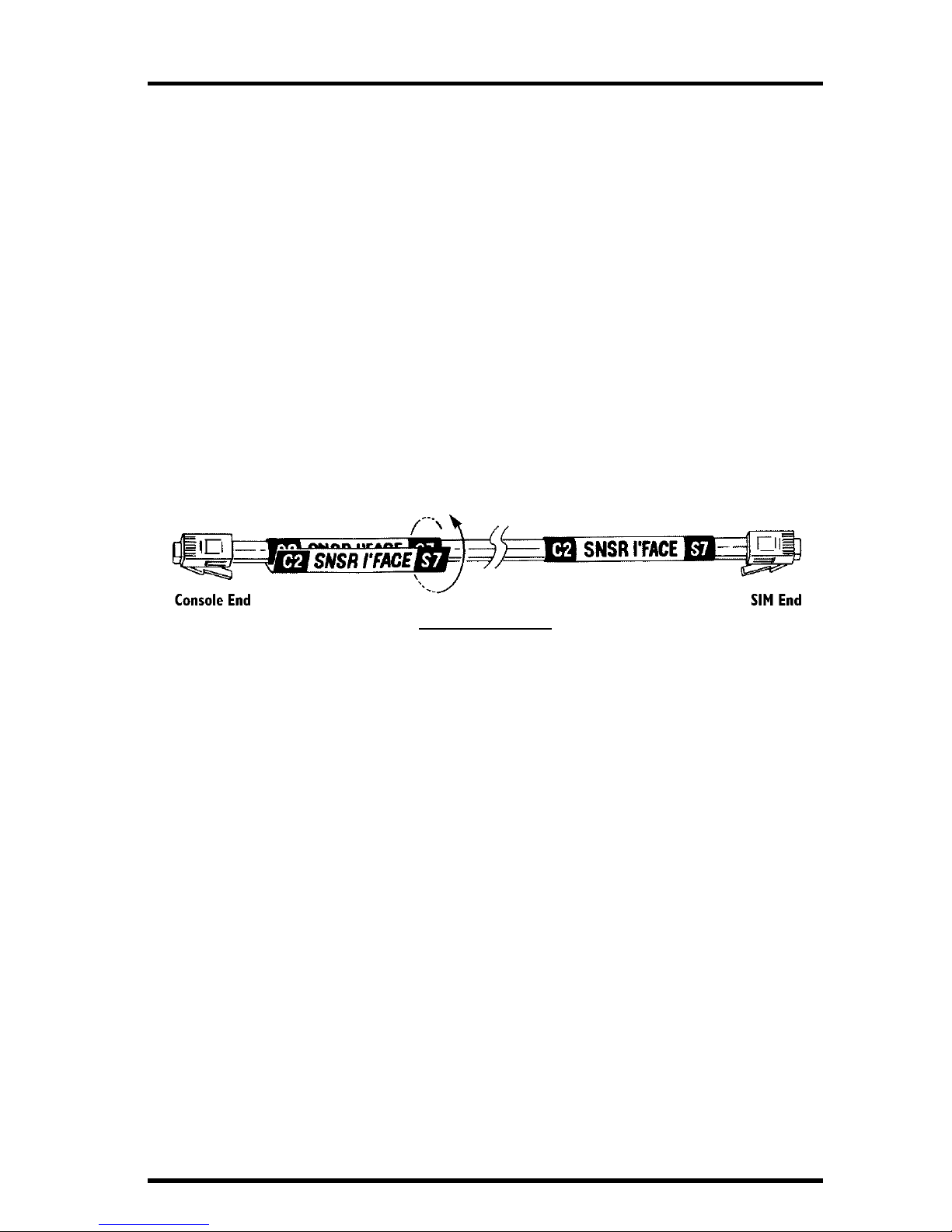

M

OUNTING

THE

S

ENSOR

I

NTERFACE

M

ODULE

You may mount the SIM on a wall or other vertical surface or you may simply

set it down on a horizontal surface. It should be sheltered from weather and

located near a grounding point. You may use our Complete System Shelter

(#7724) or Multi-Purpose Shelter (#7728) to provide protection from weather.

Use our Grounding Kit (#7780) if suitable ground is not otherwise available.

1. Remove the cover by pushing down on the tabs at the top until you can remove the

tabs from the slots.

R

EMOVE

C

OVER

2. If you plan to mount the SIM against a wall or other vertical surface, attach the base

to the mounting surface using the #6 x 1" screws. Otherwise skip this step.

Use two screws (as shown below) when attaching to a stud. Use three

screws (as shown below) in any other case. Drill pilot holes using a #36

(.106" or 2.5 mm) drill bit.

A

TTACHING

TO

A

W

ALL

OR

V

ERTICAL

S

URFACE

Page 5

Mounting the Sensor Interface Module

Standard System Installation Manual Page 5

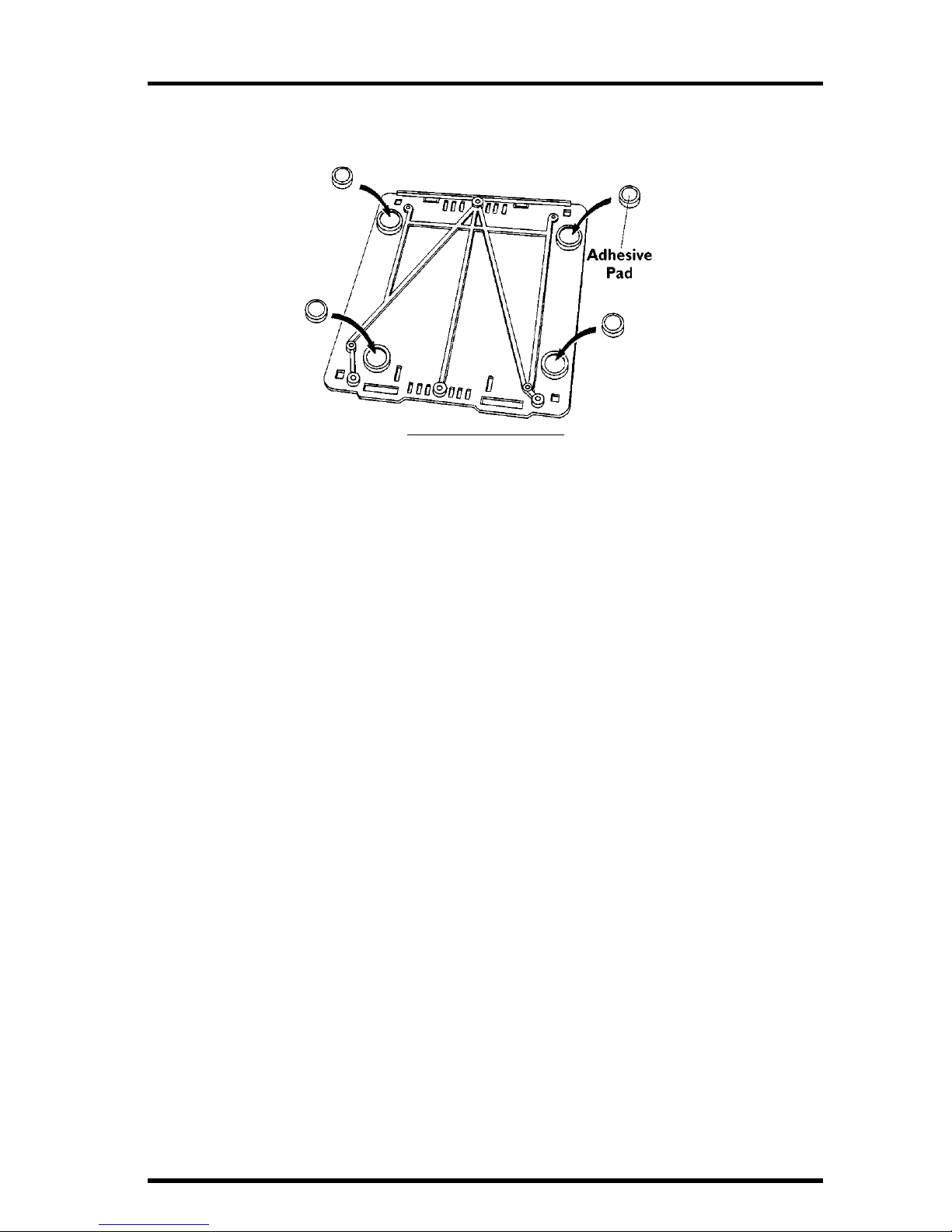

3. If you plan to place the SIM on a horizontal surface, attach one of the adhesive pads to

each of the four raised circles on the underside of the base as shown below.

A

TTACHING

A

DHESIVE

P

ADS

Page 6

System Installation

Page 6 Standard System Installation Manual

C

ONNECTING

TO

THE

S

ENSOR

I

NTERFACE

M

ODULE

Make sure that you install your sensors and run all necessary cables to the SIM

location before connecting cables to the SIM.

Connecting to the Sensor Interface Module

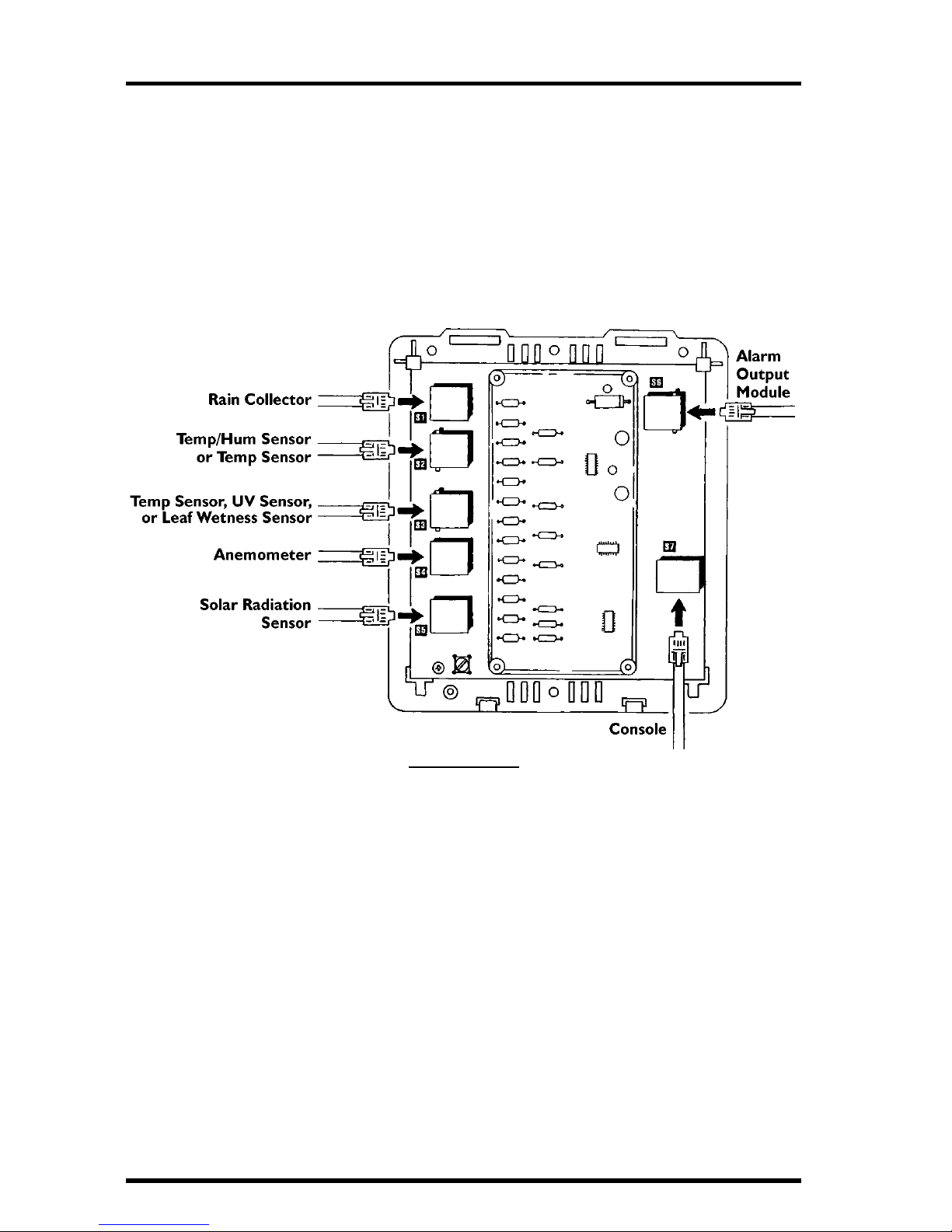

1. Attach one end of the 8-conductor cable (which runs from the SIM to the console) to

connector S7.

2. Attach the sensor cables to the appropriate connector as shown below.

A

TTACHING

C

ABLES

You may attach either the external temperature sensor, external temperature/humidity sensor, or the stainless steel temperature probe to

connector S2. The sensor connected at S2 will measure outside/air temperature (and humidity if applicable).

You may attach either the external temperature sensor, stainless steel temperature probe, leaf wetness sensor, or the UV sensor to connector S3. The

sensor connected at S3 will measure soil temperature (GroWeather), Leaf

Wetness (GroWeather), or UV (Energy EnviroMonitor).

Page 7

Connecting to the Sensor Interface Module

Standard System Installation Manual Page 7

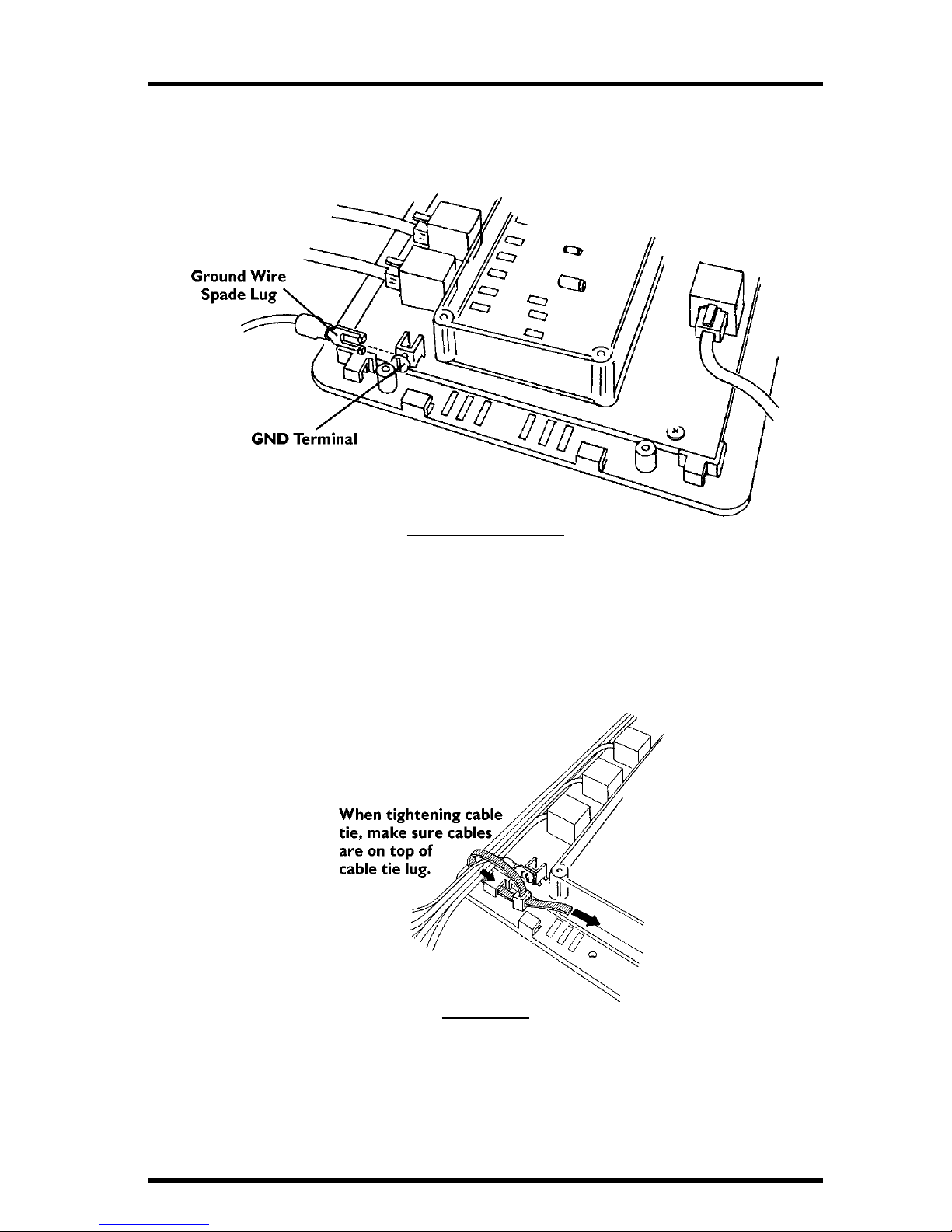

3. Connect the spade lug on the ground wire to the GND terminal at JP1.

You need to ground the SIM to take advantage of RFI and surge suppression

capabilities.

A

TTACHING

G

ROUND

W

IRE

Routing Cables out of Sensor Interface Module

1. Gather the cables connected on the left of the SIM (including the ground wire) and

secure them to the cable tie lug using a cable tie.

Even if you have only one cable, secure it to provide strain relief. When

tightening the cable tie, make sure the cables are on top of the lug.

S

ECURE

C

ABLES

2. Gather the cables connected on the right of the SIM and secure them to the cable tie

lug using a cable tie.

Even if you have only one cable, secure it to provide strain relief. When

tightening the cable tie, make sure the cables are on top of the lug.

Page 8

System Installation

Page 8 Standard System Installation Manual

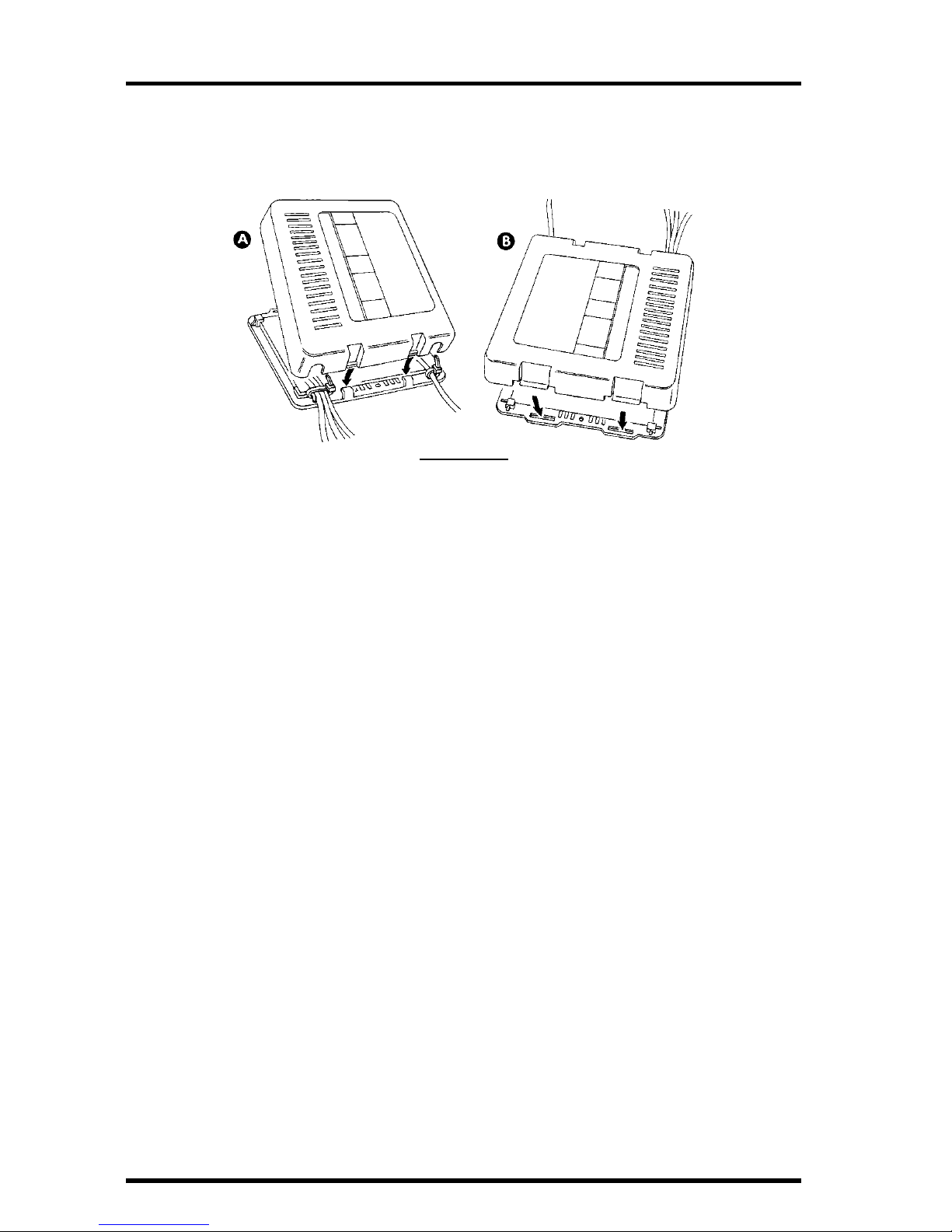

3. Finally, reattach the cover by putting the cover into place (as shown below) and pushing it onto the base until the tabs on top of the cover snap back into their slots.

Make sure the cables run out the bottom of the SIM as shown below.

R

EPLACE

C

OVER

C

ONNECTING

THE

C

ONSOLE

In order to connect cables to the console, you must remove the mounting base

which comes attached to the console. To remove the mounting base, press

down on the large tab until it is free from its slot and pull the base away from

the console.

To connect the console to the SIM (or the ICAM), run the 8-conductor cable to

the console and plug it into the jack marked C2 (To Sensor I’face) on the underside of the console.

Primary Power

The console is powered by 9- to 12-volt DC (direct current). In North America,

the power adapter included with your unit converts 120-volt, 60-Hz AC (alternating current) to 9–volt DC, allowing you to run the unit on ordinary household current. If you are outside North America, in a location where the line

voltage is not 120–volt, 60–Hz, check to see if your local dealer has supplied a

power adapter that is appropriate for your electrical power before you connect

the power adapter to the console. If not, you must use a power converter/

transformer or the appropriate power adapter (9-12-volt, 2.5-mm female plug).

To power the console, simply connect the power adapter to the jack marked

C1 (Power) on the underside of the console. Plug the other end of the power

adapter into an appropriate power outlet. Once connected, the console should

run through a brief self-test procedur e. All of the display segments appear, and

the console beeps twice (three times if you have the WeatherLink hardware

module attached). When the self-test finishes, the time (reading 12:00 a.m.)

appears on the display.

Page 9

Displaying the Console

Standard System Installation Manual Page 9

Battery Backup

W e r ecommend that you also install a 9-volt alkaline battery as a backup power

supply. In the event of a power outage, the battery will power the console. Not

only will this prevent the loss of data stored by the console, but will also allow

you to continue observing weather conditions during the power outage. New

alkaline batteries will power the console for 24–48 hours. For maximum security, keep the battery backup fresh. You should replace batteries any time the

unit has operated on battery power for more than 18 hours. To prevent loss of

data when replacing batteries, make sure the unit is receiving power from the

adapter before changing batteries.

Note: The use of Ni-Cad batteries is not recommended. Ni-Cad batteries carry less power than alkaline

batteries and they will not be recharged by the console. In the event of a power outage, Ni-Cad

batteries will be able to power the console for a shorter period of time than alkaline batteries will.

To install the backup battery, remove the battery cover underneath the console,

snap the battery connector onto the battery, lower the battery into the compartment, and replace the battery cover.

I

NSTALLING

B

ACKUP

B

ATTERY

D

ISPLAYING THE CONSOLE

By changing the orientation of the mounting base, you may display the console

on a tabletop, set it on a shelf, or mount it on a wall.

Selecting a Site for the Console

Unless you use Davis’ Complete System Shelter or a similar weather-proof

shelter, you should locate the console indoors. For more accurate readings, follow these suggestions.

✦

Avoid placing the console in direct sunlight.

The black casing heats up in direct sunlight. This may cause erroneous

readings and/or damage to the unit.

✦

Avoid placing the console near radiant heaters or heating/air conditioning ducts.

✦

If you are mounting the console on a wall, choose an inner or interior wall.

Avoid walls which heat up or cool down depending on the weather.

✦

T o connect the console to an 8-conductor cable running inside the wall, attach the

mounting base to an empty switch box, using the two screw holes on the mounting base.

Page 10

System Installation

Page 10 Standard System Installation Manual

“Horizontal” Orientation

Use this mounting base orientation if the console’s LCD will be below eye level

once the console is positioned. Attach the mounting base as shown below and

then place the console onto any flat surface.

H

ORIZONTAL ORIENTATION

“ Vertical” Orientation

Use this mounting base orientation if the console’s LCD will be at or above eye

level once the console is positioned. Attach the mounting base as shown below

and then place the console onto any flat surface.

V

ERTICAL ORIENTATION

Page 11

Displaying the Console

Standard System Installation Manual Page 11

To Display the Console on a Wall

If you want to attach the console to a wall, follow the instructions below.

1. Mark the location of the two keyholes on the back of the mounting base.

2. Use a drill with a #29 (.136" or 3.5-mm) drill bit to make pilot holes in these locations.

3. Drive the two #8 x 3/4" pan head screws into the wall.

Leave at least 1/8" (3 mm) between the wall and the heads of the screw.

4. Attach the mounting base to the console in the vertical orientation position.

5. Slide the keyholes on the back of the mounting base over the two screw heads. Lock

the console into place by gently sliding it downward until it no longer moves.

ATTACHING CONSOLE TO A WALL

Page 12

System Installation

Page 12 Standard System Installation Manual

TYPICAL INSTALLATIONS

The sections below show some typical installations to aid you in connecting

your system. Specific instructions for mounting and connecting various sensors and components are contained in the manuals for those components.

WeatherLink with Short-Range Modem Pair

The illustration below shows a WeatherLink connection via our Short-Range

Modem Pair (SRM Pair). The WeatherLink cable plugs into the Short-Range

Modem Adapter in order to connect to one half of the SRM Pair. The other half

of the SRM Pair is connected to a free serial port on your computer. The SRM

Pair is connected using a 2-twisted pair cable (Davis Product #7884) which is

not included. Using 22 AWG cable, you may run up to 4 miles of cable between

the SRM Pair. Using 18 AWG cable, you may run up to 8 miles between the

SRM Pair.

WEATHERLINK WITH SHORT-RANGE MODEM PAIR

Page 13

Typical Installations

Standard System Installation Manual Page 13

Alarm Output Module Connected to Sensor Interface Module

The illustration below shows an Alarm Output Module (AOM) connection

made at the Sensor Interface Module (SIM). The AOM connects to the SIM

using the provided 2’ AOM Cable or a 40’ (12 m) Standard 6-Conductor Extension Cable. You may not extend this distance beyond 40’ (12 m). If the AOM

needs to be more than 40’ (12 m) from the SIM, connect the AOM to the Interface Cable Adapter as shown on the next page.

The AOM can drive control circuits such as thermostats or sprinkler controllers. To control power equipment such as heaters, motors, etc., you will need to

provide relays or control circuits.

ALARM OUTPUT MODULE CONNECTED TO SENSOR INTERFACE MODULE

Page 14

System Installation

Page 14 Standard System Installation Manual

Alarm Output Module Connected to Interface Cable Adapter Module

The illustration below shows an Alarm Output Module (AOM) connection

made at the Interface Cable Adapter Module (ICAM). The AOM connection

must be made using either the 2’ AOM Cable or a 40’ (12 m) Standard 6-Conductor Extension Cable. You may not extend this distance beyond 40’ (12 m).

Therefore, if the AOM cannot be located within 40’ (12 m) of the Sensor Interface Module (SIM), you will need to connect the AOM to the ICAM instead.

Connect the SIM to the ICAM using up to 100’ of standard 8-Conductor cable.

Connect the Console to the ICAM (instead of the SIM) using a standard 8-Conductor cable. Connect the AOM to the ICAM using either the 2’ AOM Cable or

a 40’ (12 m) Standard 6-Conductor Extension Cable.

The AOM can drive control circuits such as thermostats or sprinkler controllers. To control power equipment such as heaters, motors, etc., you will need to

provide relays or control circuits.

ALARM OUTPUT MODULE CONNECTED TO INTERFACE CABLE ADAPTER MODULE

Page 15

Typical Installations

Standard System Installation Manual Page 15

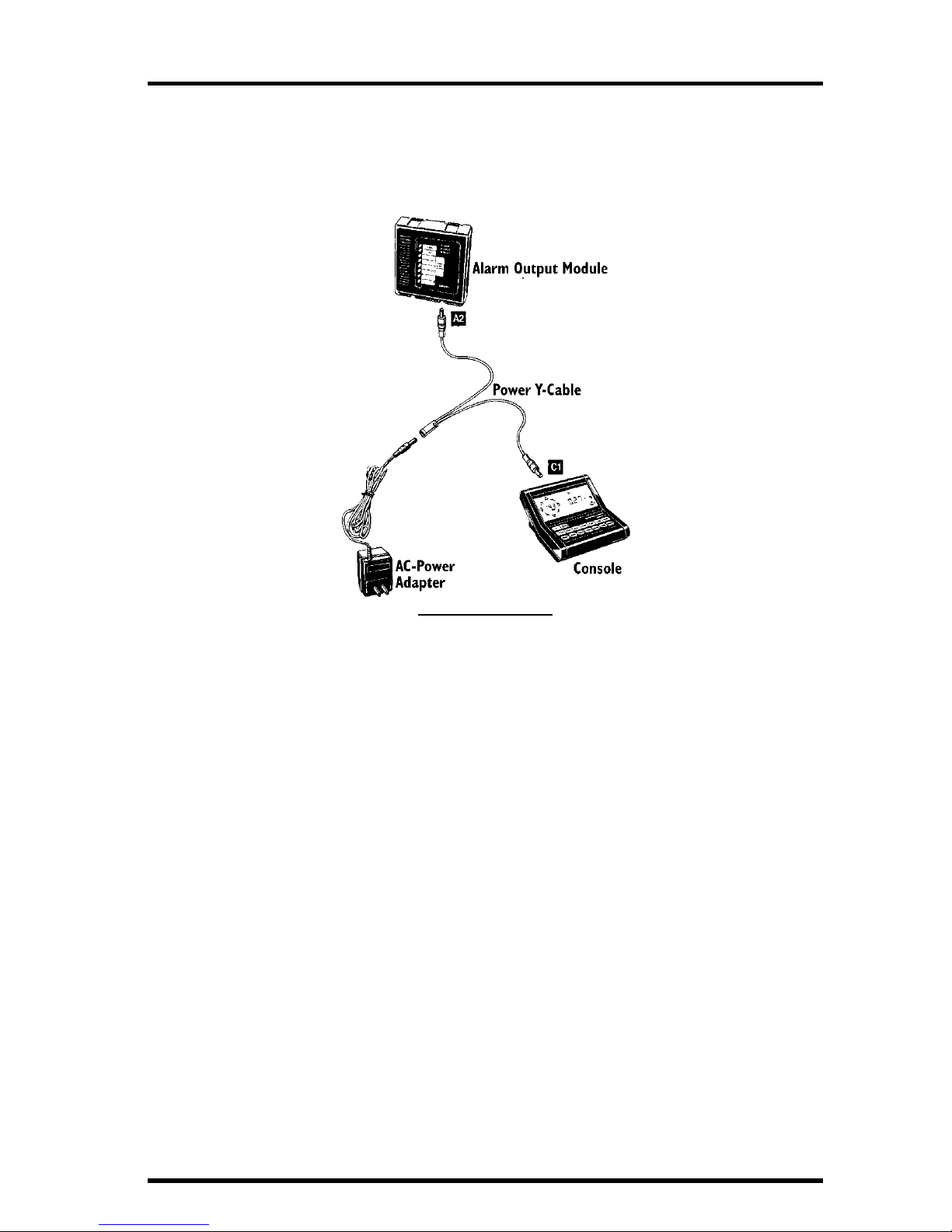

Using Power Y-Cable to Power Console and AOM

It is possible to use a power Y-cable to provide power to both the console and

the AOM using a single AC-power adapter, as shown below . The power Y-cable

is provided with the AOM.

USING POWER Y-CABLE

Page 16

System Installation

Page 16 Standard System Installation Manual

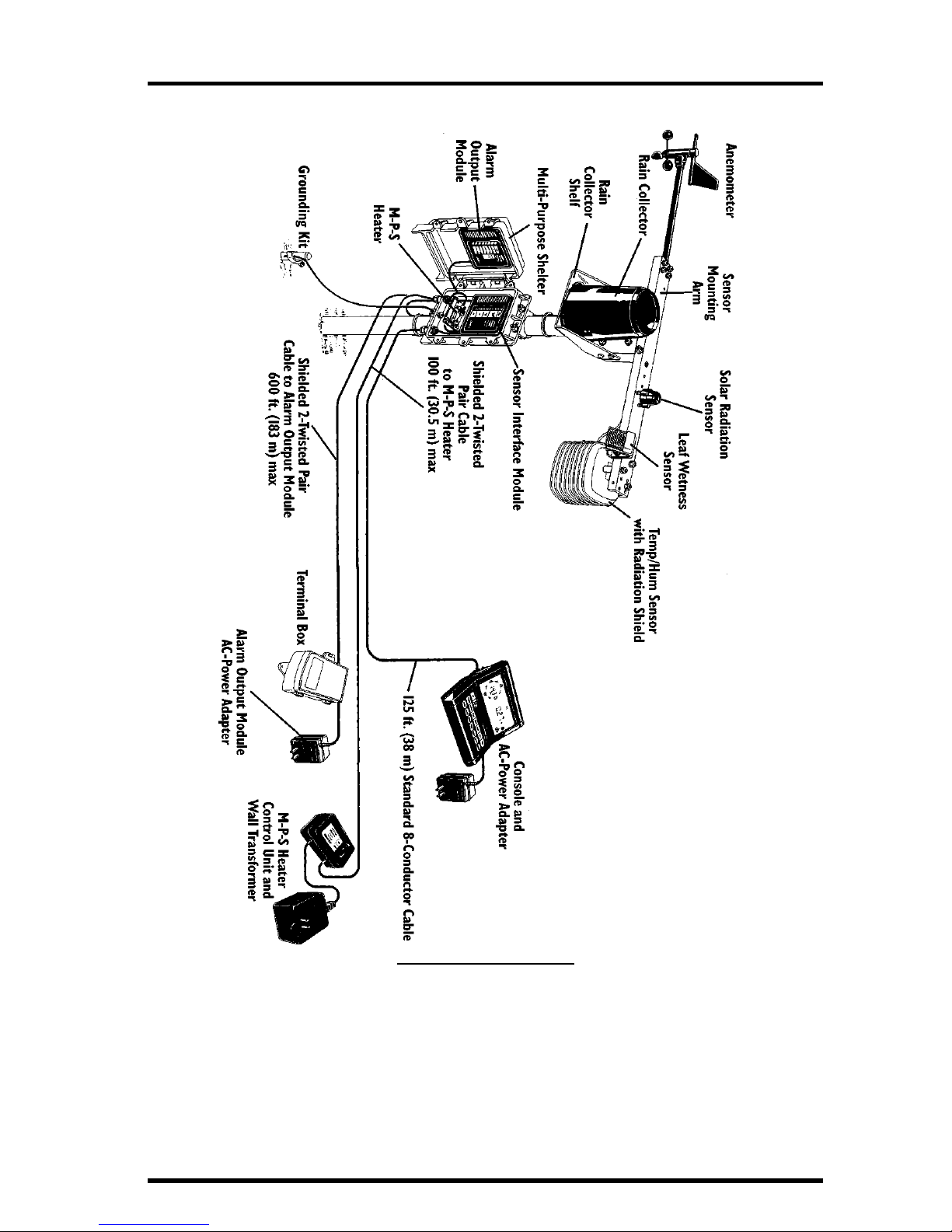

Field System Installation

The illustration on the following page shows an example of an installation in

which the sensor interface module is placed outside (using the Multi-Purpose

Shelter for protection) and a single cable is run from the SIM to the console,

which is located indoors. The sensor interface module (SIM) need not be

mounted on the Sensor Mounting Arm support mast; it may be located at any

intermediate point between the sensors and the console. If desired, you may

run shielded cable from the SIM to the ICAM and then run standard 8-Conductor Cable from the ICAM to the console, which will allow you to place the SIM

farther from the console.

Consult the table below to determine the maximum cable run for power cables

to the AOM and the Multi-Purpose-Shelter Heater (MPS Heater). You will need

to splice the power cable to the AOM’s AC power adapter using a Terminal

Box, Surge Protectors, or Waterproof Crimp-Type Splice Connectors (Terminal

Box shown). The power cable for the MPS Heater connects into the heater’s

control unit, which allows you to turn power to the heater on and off.

This advantage of this installation is that it keeps sensor cable runs relatively

short; the longer portion of the cable run to the console is made with a single 8conductor cable, which is easier to route and lower in cost than multiple sensor

cables. However, the standard cables supplied with the sensors are 40’ in

length which may result in a surplus of up to 30’ (9 m) of cable.

M

AXIMUM CABLE RUN

FOR

AOM POWER CABLE

MAXIMUM CABLE RUN

FOR

SHELTER HEATER POWER

C

ABLE

TYPE OF CABLE

600 feet (180 m) 100 feet (30 m) 2-Twisted Pair Cable

(#7884)

600 feet (180 m) 100 feet (30 m) 20 AWG Pair (0.75 mm

2

)

800 feet (240 m) 160 feet (48 m) 18 AWG Pair (1.0 mm

2

)

1200 feet (360 m) 250 feet (75 m) 16 AWG Pair (1.5 mm

2

)

Page 17

Typical Installations

Standard System Installation Manual Page 17

FIELD INTERFACE INSTALLATION

Page 18

System Installation

Page 18 Standard System Installation Manual

Field System with AC Power

The illustration below shows an installation in which the console is located

with the SIM (and, optionally, the AOM) in the field near the sensors. The console and modules are housed in the Complete System Shelter (CSS). The Complete-System-Shelter Heater might also be included.

AC power is wired, according to code, to an enclosure or shelter containing a

receptacle box and a power adapter. The power adapter cable is routed into the

CSS, where a power Y-cable distributes power to the console and AOM.

The WeatherLink (optional) is connected via a Short-Range Modem Pair and

two-twisted-pair cable to a computer in the office at a distance of up to 8 miles,

depending on the wire gauge used. If a cable to the computer is not feasible,

data may be uploaded to a laptop or other portable computer at the sensor site.

The advantages of this system:

✦ The Console is located near the sensors.

Data may be viewed at the sensor site. In addition to making weather

data available in the field, this is useful for the alignment, adjustment,

and monitoring of sensors.

✦ The WeatherLink cable to the computer can be very long, and (comprising only

four conductors) it is low in cost.

The Link cable is also relatively immune to noise and voltage surges, and

additional protection is low in cost.

FIELD SYSTEM WITH AC POWER

Page 19

Typical Installations

Standard System Installation Manual Page 19

Field System with Wired DC Power

This system configuration has the same characteristics and advantages as those

of the AC-powered system described in “Field System with AC Power” on

page 18. In this case AC power is not wired to the site. Rather, the power

adapter is plugged into an available circuit in a sheltered location, and the

(nominal) 12-Volt DC output is supplied to the station with a two-wire cable

(twisted-pair is preferred, but not requir ed). The two wir e cable is connected to

the power Y-Cable using a single Surge Protector, Terminal Box, or splice connectors. The Surge Protector may be housed in a Small Surge Protector Shelter

as shown below, or it may be attached to the back panel of the shelter. The table

below lists some recommended maximum distances, which are determined by

the wire gauge used.

FIELD SYSTEM WITH WIRED DC POWER

MAXIMUM CABLE RUN TYPE OF CABLE

460 feet (140 m) 24 AWG Pair (.20 mm2)

600 feet (180 m) 22 AWG Pair (.32 mm

2

)

1000 feet (300 m) 18 AWG Pair (.82 mm

2

)

Page 20

System Installation

Page 20 Standard System Installation Manual

Solar-Powered Field System

The illustration below shows an installation in which the Complete System

Shelter (CSS) houses the console, a battery, and the charging regulator. As

shown in “Field System with AC Power” on page 18, data may transmitted via

Link cable, read visually from the display, or uploaded to a computer brought

to the site.

SOLAR POWERED FIELD SYSTEM

Page 21

Typical Installations

Standard System Installation Manual Page 21

Solar-Powered Field System with Radio

The illustration below shows a solar-powered system (see “Solar-Powered

Field System” on page 20) in which the WeatherLink commands and data are

communicated via a user-supplied radio. The 1200- or 2400-baud WeatherLink

is compatible with any transparent communications channel. Because the solar

panel and battery of the Solar Power Kit are not sufficient to supply the radio

for continuous operation, the Alarm Output Module is used to switch on

power to the transmitter for short scheduled periods.

SOLAR-POWERED FIELD SYSTEM WITH RADIO

Page 22

System Installation

Page 22 Standard System Installation Manual

“Outbuilding” System Configuration

This variation of the “Field System Installation” (page 16) places the console

and WeatherLink in a barn or other shelter and then uses a Short-Range

Modem Pair (or radio) to communicate with the computer at the “central” site.

The figure below shows the use of Surge Protectors (optional) on the SIM-toconsole and WeatherLink cables.

“OUTBUILDING” SYSTEM CONFIGURATION

Page 23

Typical Installations

Standard System Installation Manual Page 23

“Outbuilding” System Configuration with ICAM and AOM

The figure below shows an “outbuilding” system configuration with the addition of an Interface Cable Adapter Module and Alarm Output Module,

enabling the weather station, the user, or a computer program to provide

inputs to controllers of heaters, fans, motors, or other equipment in the vicinity

of the barn or shelter.

“OUTBUILDING” SYSTEM CONFIGURATION WITH ICAM AND AOM

Page 24

System Installation

For Product Numbers: 7450 (GroWeather), 7460 (Energy EM), and 7470 (Health EM)

Davis Instruments Part Number: 7395-073

Standard System Installation Manual

Rev. B Manual (7/13/99)

GroWeather and EnviroMonitor are trademarks of Davis Instruments Corp.

WeatherLink is a registered trademark of Davis Instruments Corp.

© Davis Instruments Corp. 1997. All rights reserved.

Loading...

Loading...