DAVIS VSS, DriveRight 8155VSS, DriveRight 8155VF, DriveRight 8160VSS, DriveRight 8160VF Installation Manual

Page 1

DriveRight

®

VSS Installation Guide

Product # 8155VSS, 8155VF,

8160VSS, 8160VF

Page 2

Product Number: 8155VSS, 8155VF, 8160VSS, 8160VF

Davis Instruments Part Number: 7395-062

DriveRight® VSS Installation Guide

Rev. D Manual (7/18/01)

© Davis Instruments Corp. 2001. All rights reserved.

This product complies with the essential protection requirements of

the EC EMC Directive 89/336/EC.

DriveRight is a registered trademark of Davis Instruments Corp.

Velcro is a trademark of Velcro Industries, Manchester NH.

Page 3

Page 1

I

NTRODUCTION

The following instructions explain how to complete a DriveRight VSS (Vehicle Speed Sensor) installation. VSS installation

is only possible on the DriveRight Trip 500AL.

C

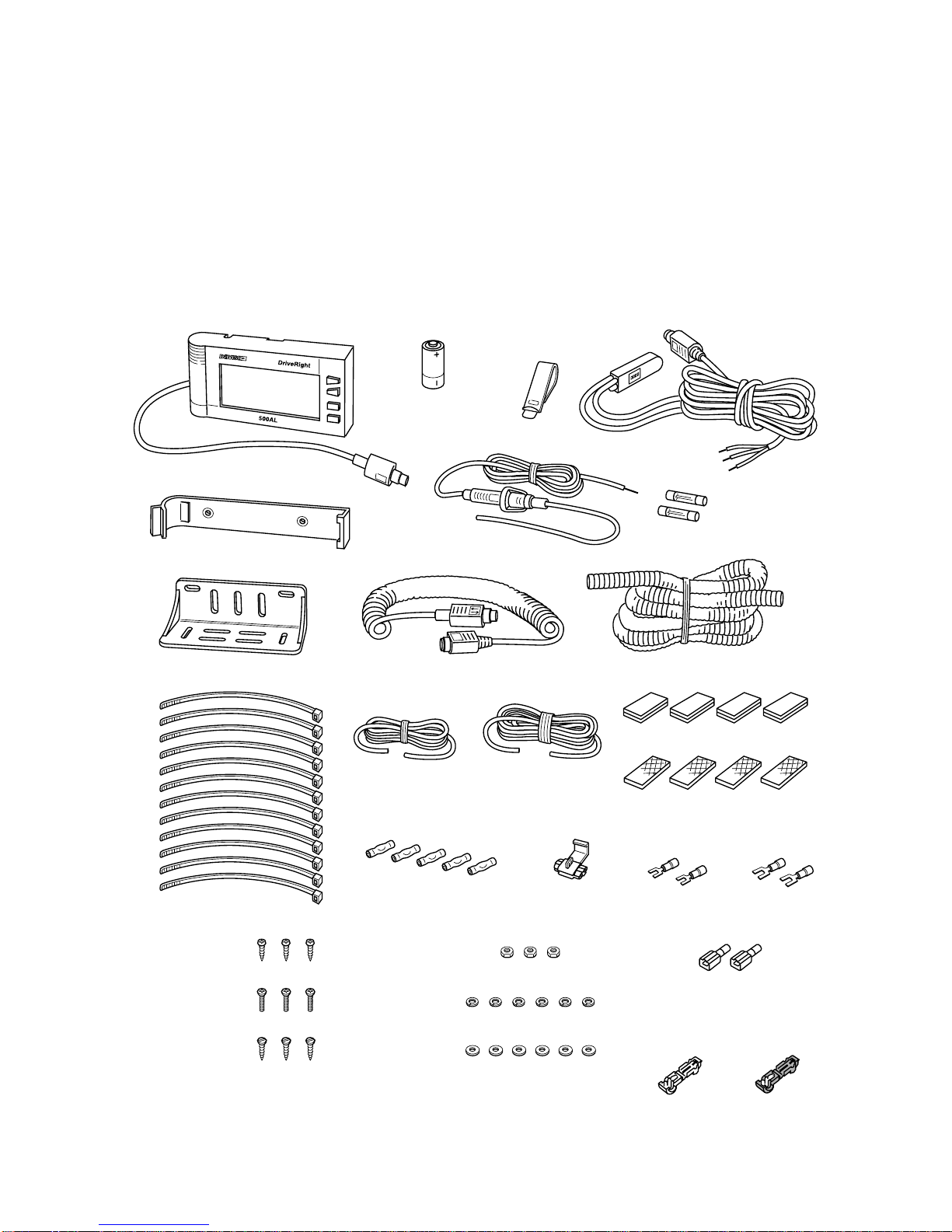

OMPONENTS

The DriveRight Trip 500AL (VSS Input) should come with all

of the materials shown below. Please make sure you have all

listed components before proceeding with the installation.

DriveRight Display

Mounting Bracket

Battery

(CR123 3V Lithium)

Visor Clip

Harness Cable

Red +12V Wire

with Fuseholder (22 AWG)

Fuses (2)

(3AG 1-1/4 x 1/4",

.25A, Slo-Blo)

Black Ground Wire

(22AWG)

White VSS Wire

(22AWG)

Split Flexible TubingCoiled Cable ExtensionRight Angle Adapter Bracket

Tie Wraps (12)

Butt Splices (5)

(26-22AWG or 24-20AWG)

In-Line Splice

Spade Terminal Sets:

T-Tap Disconnects:

Insulated Male Disconnects

(18-22AWG)

#8-10 Studs

(3.5 - 5 mm)

Velcro® Tape (4 pair)

Double-Sided Foam Tape (4 strips)

#6 x 1/2" Pan Head Self-Tapping Screws (3)

#6 x 1/2" Flat Head Self-Tapping Screws (3)

6-32 x 1/2" Flat Head Machine Screws (3)

6-32 Nuts (3)

#6 Flat Washers (6)

#6 Split Lock Washers (6)

NOTE: Small hardware includes spares not required for installation.

1/4" Studs

(6 mm)

Blue

(14-16AWG)

Red

(18-22AWG)

Page 4

Page 2

Tools and Materials Needed

The installation requires some or all of the following tools and

materials. Please make sure you have all necessary items before

proceeding with the installation.

❏

Medium Phillips Screwdriver

❏

Crimping Tool

❏

Pliers

❏

Electric Drill with 2.5 mm (7/64") Drill Bit

❏

Fuse Tap

❏

Multimeter

I

NSTALLATION

The instructions contained in the following sections provide

guidelines for installation of the Trip 500AL.

Planning the Installation

The installation is similar to installing a vehicle stereo or vehicle alarm. The DriveRight requires three electrical inputs;

+12 V, vehicle ground, and your vehicle's VSS signal. The steps

required to install the DriveRight are:

1. Determine where to mount the DriveRight display.

2. Locate and tap your VSS wire.

3. Locate and tap power (+12V from battery) and ground.

4. Connect the harness cable to the 3 main tap wires.

5. Choose the correct switch settings.

6. Mount the DriveRight in the vehicle.

7. Connect the DriveRight and go for a test drive.

WARNING: Installing the DriveRight can be hazardous to both the

installer and your vehicle’s electrical system if not done by

an experienced professional. This manual assumes you are

aware of the inherent dangers of working in and around a

vehicle and have a working understanding of electricity.

Page 5

Page 3

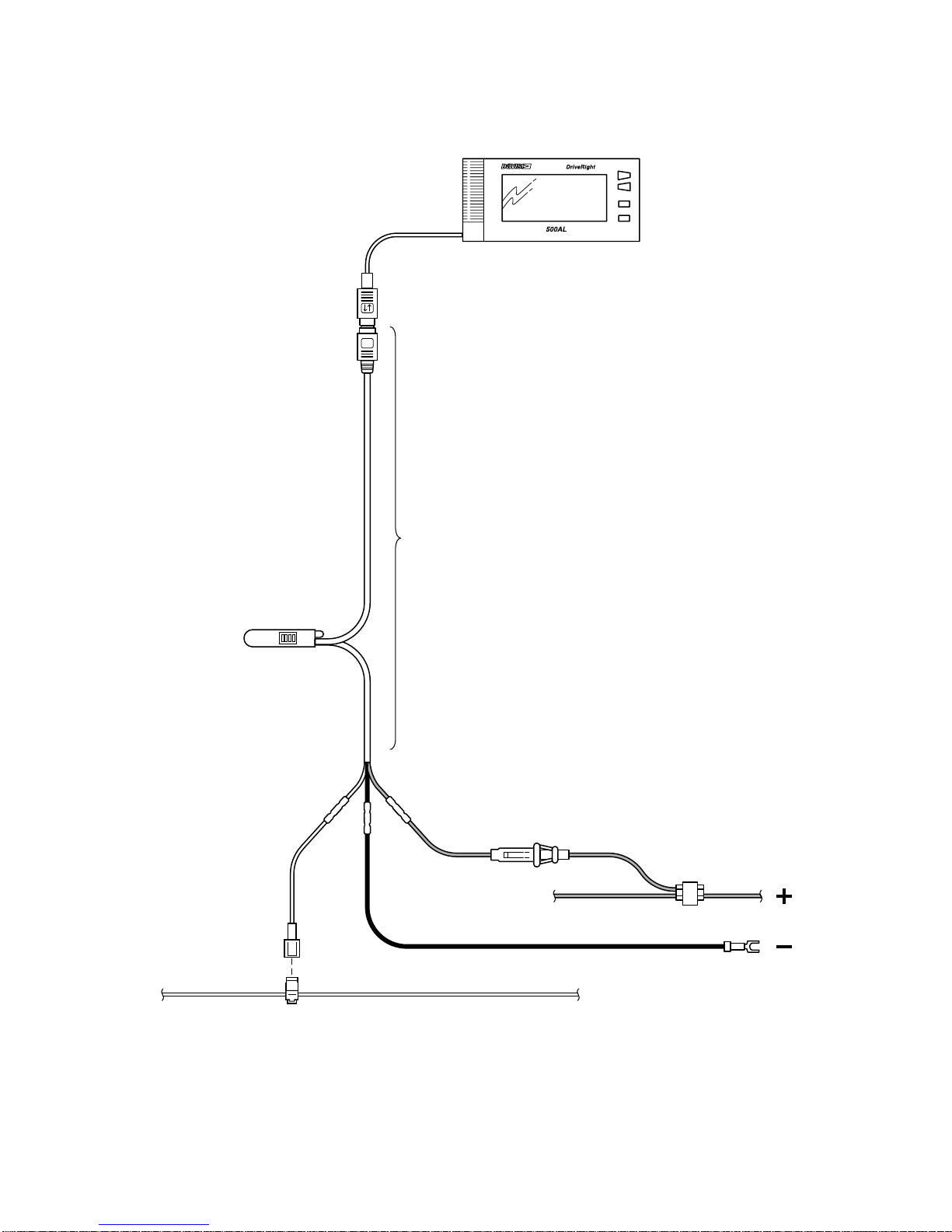

Wiring Diagram

The diagram below provides an overall picture of the Trip

500AL VSS installation.

DriveRight Display

Harness Cable

RedWhite

Black

Male Disconnect

Butt Splices (3)

Red Wire with Fuseholder

In-Line

Splice

T-Tap

Connector

Unswitched

+12V

Ground

Spade

Terminal

Vehicle Speed Sensor Wire

VSS

White Wire

(if needed)

Page 6

Page 4

Step 1 : Determine Where to Mount the Driveright Display

Knowing where you are going to mount the DriveRight display can help you make wiring decisions later on. For example, if your DriveRight is near the fuse box it will be

convenient to get +12V using a fuse tap connector. However, if

your DriveRight display is on the other side of the vehicle it

may be easier to find a lamp circuit. If the position of the display is not critical, you may wish to move to the next step,

and decide where to mount it after you've tapped the three

main electrical connections (+12V, Ground, VSS).

NOTE: If you need ideas about where the display might be mounted,

look at “Step 6: Mount the DriveRight Display in the Vehicle” on

page 9.

Step 2: Locate and tap your VSS wire

The location of the VSS wire for a given make and model of

vehicle can be found in the Vehicle Technical Information

Guide for Cruise Control book. This book is made available to

authorized DriveRight installers.

If you can not obtain a copy of this book, the information is

available on the World Wide Web at www.rostra.com. Go to

that Web address and click on “Rostra VSS & Tach Information

System". Enter the full year and manufacturer of the vehicle.

The information will specify a “location number” indicating

where the wire can be found, and it will specify the wire color.

NOTE: The web site “www.rostra.com’ is owned and operated by Ros-

tra Precision Instruments. Rostra does not provide support for

the DriveRight product. If you have trouble finding the VSS

wire, please contact Davis Instruments Technical Support at

510-732-7814.

NOTE: Some base model vehicles with manual transmission and no

cruise control may not have the VSS module installed. Also,

vehicles manufactured before 1992 may not have the VSS signal. Consult the service department at your vehicle dealership if

you are having trouble. If your vehicle has a cable driven speedometer, it may be possible for you to purchase a VSS pulse converter that can be installed to provide the VSS pulse. Otherwise,

you will be required to install the Trip 500 AL which uses the

drive shaft-mounted reed switch sensor.

Use the inline splice to make the connection to the VSS wire as

shown below. Select red or blue T-Tap disconnect to fit your

VSS wire.

Page 7

Page 5

Step 3: Locate and tap power (+12V) and ground

The DriveRight requires a constant +12 volts and has a negligible drain on the vehicle battery (8 ma). You can obtain the

+12V from several different places. Generally, you can easily

obtain +12V from the fuse box using a fuse tap connector (not

supplied) or using the supplied in-line splice connectors to tap

into a KNOWN circuit that does not involve safety related

equipment (headlights, tail lights, air bag, etc.). Possible candidate wires include those from the cigarette lighter, dome light,

glove compartment light, clock, tail gate light, or other convenience functions.

After locating +12V, connect it to the red +12V wire (the one

with the fuse holder) using the in-line splice as shown below.

Do not install the fuse into the fuse holder until instructed to

do so in step 4.

If you are getting +12V from your fuse box, use a fuse tap connector appropriate for your vehicle.

In-Line Splice

Unswitched

+12V

from Vehicle

Trim off flush

stripped wire

Red +12V Wire with Fuseholder

Page 8

Page 6

A ground can be made by inserting the spade terminal under

the head of a screw threaded into the vehicle chassis and then

crimping the spade terminal onto the black ground wire, as

shown below. Check that the screw is actually grounded using

a multimeter before making the connection.

Crimp Tool,

22-18 AWG Position

(red dot)

Vehicle

Ground

Spade Terminal

Black Ground Wire (22 AWG)

3/16 - 1/4"

(5 - 6 mm)

Page 9

Page 7

Step 4: Connect the Harness Cable to the 3 Main Tap Wires

Use the butt splice to connect the VSS in-line circuit input

wires to your three main tap wires (+12V, Ground, VSS) by

matching the wire colors. Red is used for +12V, black for the

ground wire, and white for the VSS wire. Make sure the wiring

harness extends to where you can plug the DriveRight display

into it. Once the harness cable is connected, install the fuse

into the fuse holder in the red (+12V) tap wire.

Step 5: Choose the Correct Dip Switch Settings

Because not all VSS signals are the same, you may need to

change the default dip switch setting on the VSS in-line circuit. As a technical note, the switches have following functions. Switch 1 is required if your VSS signal is a square wave

which does not go to ground. Switch 2 AC couples the signal

in and is used for sine wave VSS signals. Switch 3 improves

the sensitivity of the AC coupled signals. Switch 4 turns on

the LED test circuit.

NOTE: No dip switch settings are required for the Ford F-250 truck har-

ness cable supplied with DriveRight Trip500AL VSS #8155VF

and DriveRight VSS Installation/Mounting Kit #8160VF. The

Ford F-250 cable is for use on F-250 trucks only. Do not use the

F-250 cable on other cars or trucks unless instructed to do so by

Davis Instruments.

Page 10

Page 8

Use this flow chart to determine the optimum dip switch setting.

NOTE: You will need to test drive the vehicle and observe the green test

LED which is enabled using switch 4. 0 (zero) means the switch

is off and 1 means the switch is on. The DriveRIght unit must

be plugged in for the LED to indicate.

0 = OFF

1 = ON

Set

1 2 3 4

0 1 0 1

Drive 2 mph.

Green LED flashing

or dimmed?

Drive 2 mph.

Green LED flashing

or dimmed?

Yes No

Yes No

Set

1 2 3 4

1 0 1 1

Turn Test LED Off (SW4)

and you are done.

Set

1 2 3 4

1 1 0 1

VSS not

working.

See

Trouble-

shooting.

NoYes

Drive 2 mph.

Green LED flashing

or dimmed?

Page 11

Page 9

Step 6: Mount the DriveRight Display in the Vehicle

The following illustrations show possible mounting options

for the display.

Bumps (3)

OR

Loops

Hooks

OR

Velcro on underside

of unit for dashtop

mounting.

Pan Head

Self-Tapping

Screw (2x)

Split-Lock Washer

Flat Washer

Hex Nut

Split-Lock Washer

Flat Washer

Right Angle

Adapter Bracket

Mounting

Bracket

Flat Head

Machine

Screw

(2x)

Flat Head

Self-

Tapping

Screw

(2x)

Mounting

Bracket

Mounting

Bracket

Double-Sided

Foam Tape

OR

TOP OF DASHBOARD (Horizontal Surfaces)

FACE OF DASHBOARD (Vertical Surfaces)

VISOR

Page 12

Page 10

Step 7: Connect the DriveRight Display and Go for a Test Drive

Insert the battery into the DriveRight as shown below.

Connect the harness cable to the DriveRight display cable as

shown below. It is important to hold the DriveRight display

cable as shown below (on the cable, not the sheath) in order

to achieve a secure connection. The cables should “click” into

place when a secure connection is made.

Once plugged in, the display should “wake-up” into the Current Readings screen. If the display screen remains blank,

make sure the battery is in the unit. If it is, try pressing MODE.

If the screen remains blank after pressing MODE, press both

the MODE and PLUS simultaneously. If it remains blank after

that, check both the +12V and ground connections.

Plastic

Sheath

Hold cables as shown

to connect.

DriveRight Display CableHarness Cable

Page 13

Page 11

Go for a test drive and check that the DriveRight matches the

speedometer. If it is not close at all, do not be discouraged

since it may be uncalibrated. Consult the calibration section

of the Trip 500AL User’s Guide for the Trip 500AL for instructions on calibrating the unit. If after calibrating the unit it still

does not register speed correctly, move on to the troubleshooting section.

It is also possible that the unit may alarm unexpectedly during an initial test drive, which can be caused by incorrect calibration along with the alarm being set or just by the login

alarm being set. Enter a Driver ID code on the unit to silence

the second case. If this does not work, you need to turn the

alarm off. Consult the Trip 500AL’s User’s Guide for specific

instructions on entering a Driver ID code or turning an alarm

off.

NOTE: Remember to turn off the Test LED once the DriveRight is

installed.

A

PPENDIX

1: T

ROUBLESHOOTING

If your speed is not regsitering correctly, consult the following

check list to help you identify the cause of the problem.

❏

Make sure the display is reading in the units

(km/hr or mph) you expect.

Hold down the Set/Clr button in the Current

Screen to change the units.

❏

Make sure the unit has been calibrated correctly.

Check the calibration section of the DriveRight display manual.

❏

The switch settings on the VSS in-line circuit

are not correct.

Go back to step 5.

❏

Double check your power and ground connections using a multimeter.

Note that the BAT segment will not be visible

on the display if it is getting +12V.

❏

Make sure the VSS wire is correct.

If the green test LED of the VSS in-line circuit

does not flash at low speeds, you may not

have the correct wire (switch 4 must be on to

Page 14

Page 12

enable the test circuit). The following other

methods can be used to see if you have the correct wire. In order of preference:

❏

Use a portable oscilloscope and verify the

square wave or sine wave VSS signal.

Watch the signal frequency change with

speed.

❏

Using a multimeter to measure the frequency of the VSS pulse. Usually, the PPM

(pulses per mile) of the VSS signal is

known. At 40 km/hr (25 mph) the following frequencies should be:

2000 PPM : 14 hz

4000 PPM : 28 hz

5000 PPM : 35 hz

8000 PPM : 56 hz

❏

A voltmeter can be used on square wave

signals to verify the 2 DC levels when the

vehicle is moved. Note, in most cases the

vehicle must be running and driven

slowly to detect this change.

❏

Check with your local vehicle dealership to

make sure the vehicle make and model is

equipped with a complete VSS signal.

A

PPENDIX

2: VSS C

OMPATIBILITY

The DriveRight can work with many different VSS signals provided the switch settings of the VSS in-line circuit are set correctly. However, if the signal does not meet the specifications

below it may not work.

❏

Maximum VSS frequency at 25 mph is 1 khz

(144,000 PPM).

❏

Minimum peak to peak amplitude at 5 mph is

1 volt.

❏

Maximum peak to peak amplitude is 25 volts.

❏

Input Impedance of VSS inline-circuit is 22k.

Page 15

Page 13

Technical Support

If you are experiencing problems with your DriveRight VSS,

first be sure to check all cable connections. If you are unable

to solve the problem, please call Davis Technical Support.

We’ll be glad to help. Most questions can be answered while

you’re on the phone. You can also email us for support, or

visit our website. Sorry, we are unable to accept collect calls.

NOTE: Please do not return items to the factory for repair without prior

authorization.

(510) 732-7814 for Technical Support, Monday – Friday, 7:00

a.m. – 5:30 p.m. Pacific Time.

(510) 670-0589 Fax Customer Service or Tech Support.

www.davisnet.com Download copies of user manuals from

the “Support” page. Watch for FAQs and other updates. Subscribe to the e-newsletter.

support@davisnet.com E-mail your technical support ques-

tions.

Page 16

3465 Diablo Avenue, Hayward, CA 94545-2778

510-732-9229 • Fax: 510-732-9188

E-mail: info@davisnet.com • www.davisnet.com

Loading...

Loading...