Page 1

LARM

A

ODULE

M

The Alarm Output Module (AOM) enables you to use weather station alarms

or commands from your computer to automatically start or stop external

devices such as indicator lights, audio alarms, sprinkler controllers, relays, or

other low-voltage AC or DC loads. The AOM works with the GroWeather™,

Energy EnviroMonitor™, or the Heath EnviroMonitor™. The

GroWeatherLink

alarm outputs manually (by turning them on or off from the software), though

the software is not required for basic operation.

®

and Energy WeatherLink® also allow you to control two

UTPUT

O

CAUTION:

WHILE WE HAVE MADE EVERY EFFORT TO INSURE THAT THE ALARM OUTPUT MODULE

WILL WORK RELIABLY, YOU SHOULDNOT USE IT IN SITUATIONS INVOLVING POTENTIAL

PROPERTY LOSS OR HAZARDS TO HEALTH OR SAFETY OF PEOPLE OR LIVESTOCK. DAVIS

INSTRUMENTS CANNOT BE HELD LIABLE FOR ANY FAILURE OF THE ALARM OUTPUT

MODULE.

Product #7736

Page 2

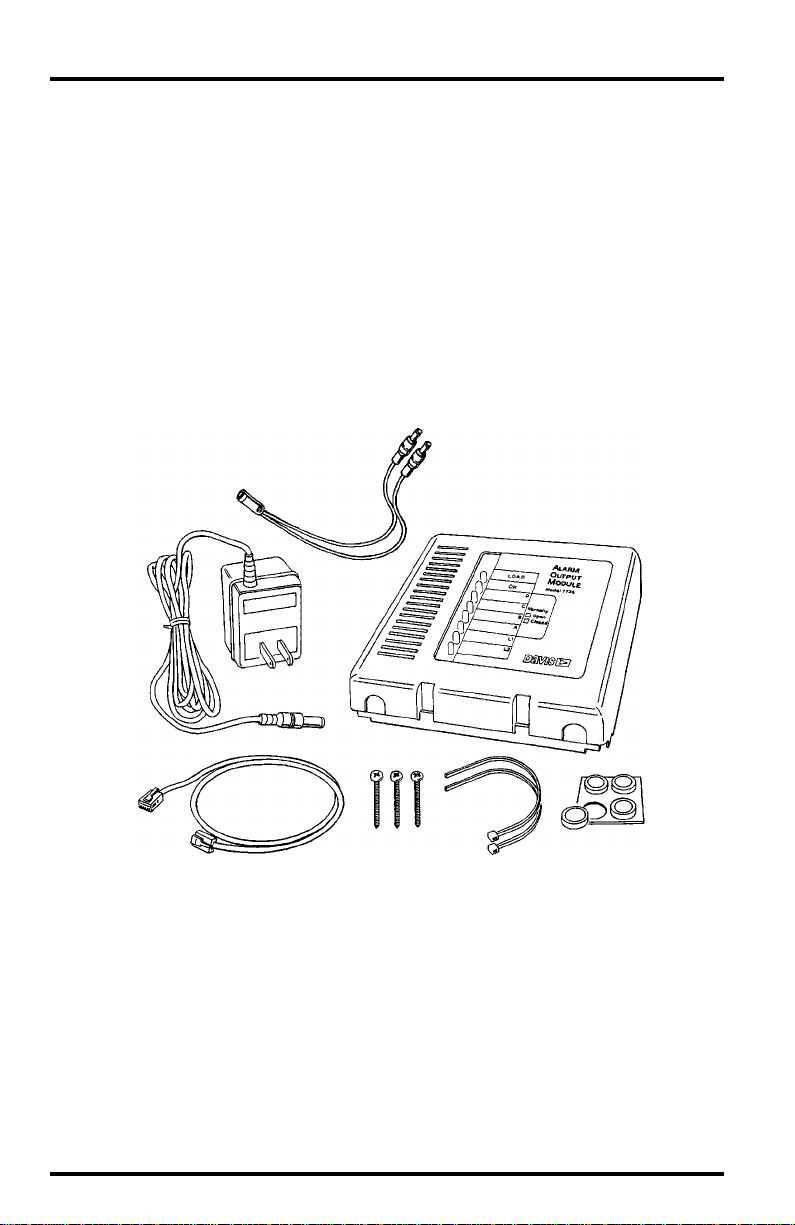

OMPONENTS

C

The AOM includes the following components. Please make sure you have all

listed components before continuing.

Alarm Output Module

✦

Alarm Output Module Cable, 2-foot (0.6 m)

✦

✦

Power Y-Cable

AC-Power Adapter

✦

Two Cable Ties

✦

✦

Three #6 x 1” (25 mm long) Self-Threading Screws

Four Adhesive Pads

✦

OOL AND MATERIALS

T

N

EEDED

You will need some of the following tools and materials.

Relays

✦

Y ou may need to obtain your own r elays in or der to switch equipment at

voltages higher than 28 volts or power levels above 10 Watts or to provide time delays or other logic functions. Application notes discussing

this further are available from Davis Instruments.

Medium Phillips Screwdriver

✦

✦

Small Slotted Screwdriver

Page 2 Alarm Output Module

Page 3

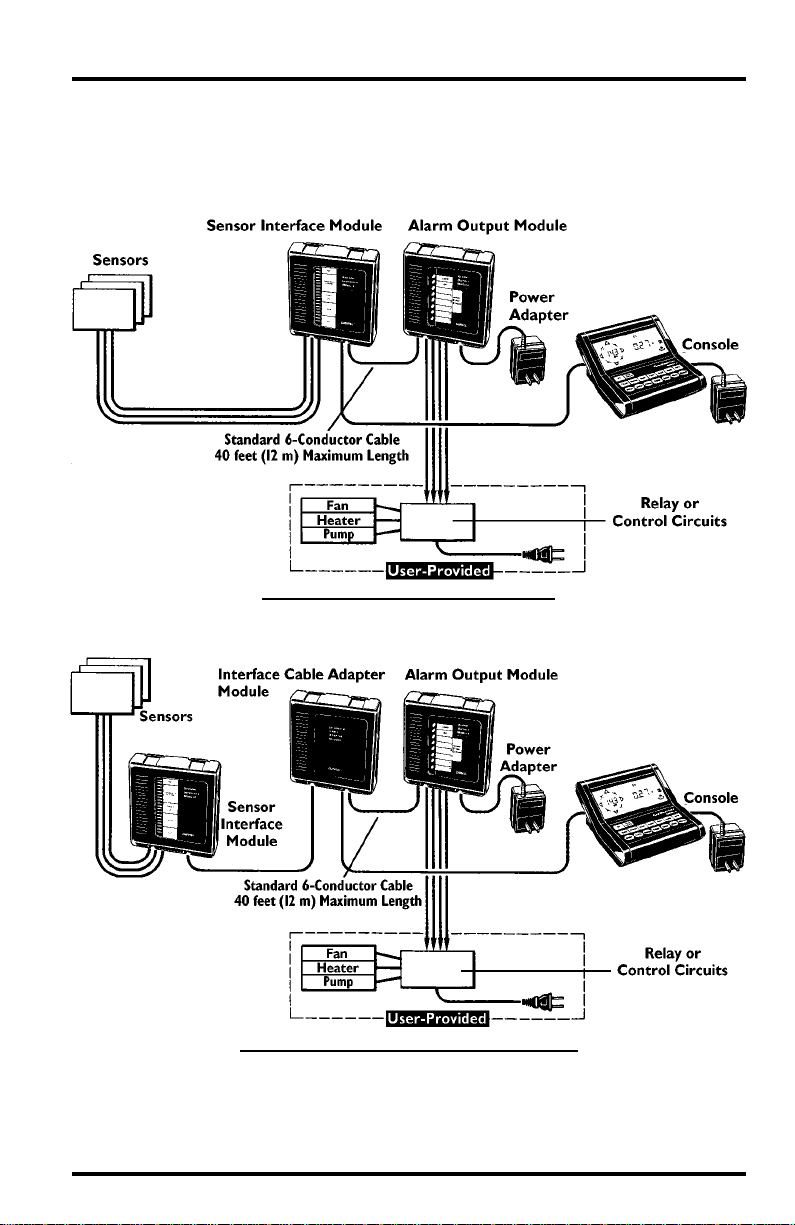

YPICAL

T

AOM I

NSTALLATIONS

The AOM may be connected to either the sensor interface module or to the

Interface Cable Adapter Module. The two illustrations below show typical

AOM installations.

AOM C

ONNECTED

S

ENSOR

I

TO

NTERFACE

M

ODULE

AOM C

ONNECTED

TO

I

NTERFACE

C

A

DAPTER

M

ODULE

ABLE

Typical AOM Installations Page 3

Page 4

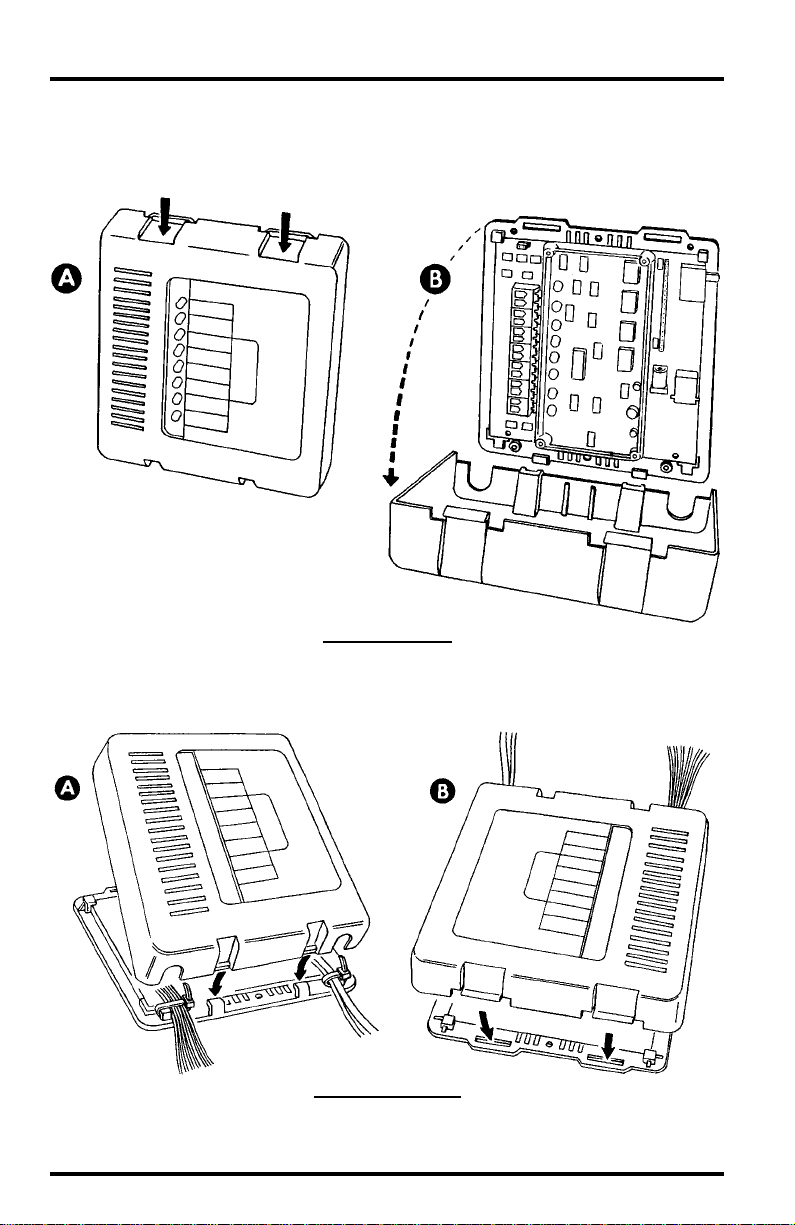

PENING

O

AND

Remove the cover by pushing down on the tabs at the top until you can remove

the tabs from the slots.

Reattach the cover as shown below . Make sur e the tabs on top of the cover snap

back into their slots, locking the cover in place

LOSING

C

THE

LARM

A

R

EMOVING

THE

O

C

UTPUT

OVER

M

ODULE

R

EATTACHING

Page 4 Alarm Output Module

THE

C

OVER

Page 5

LARM

A

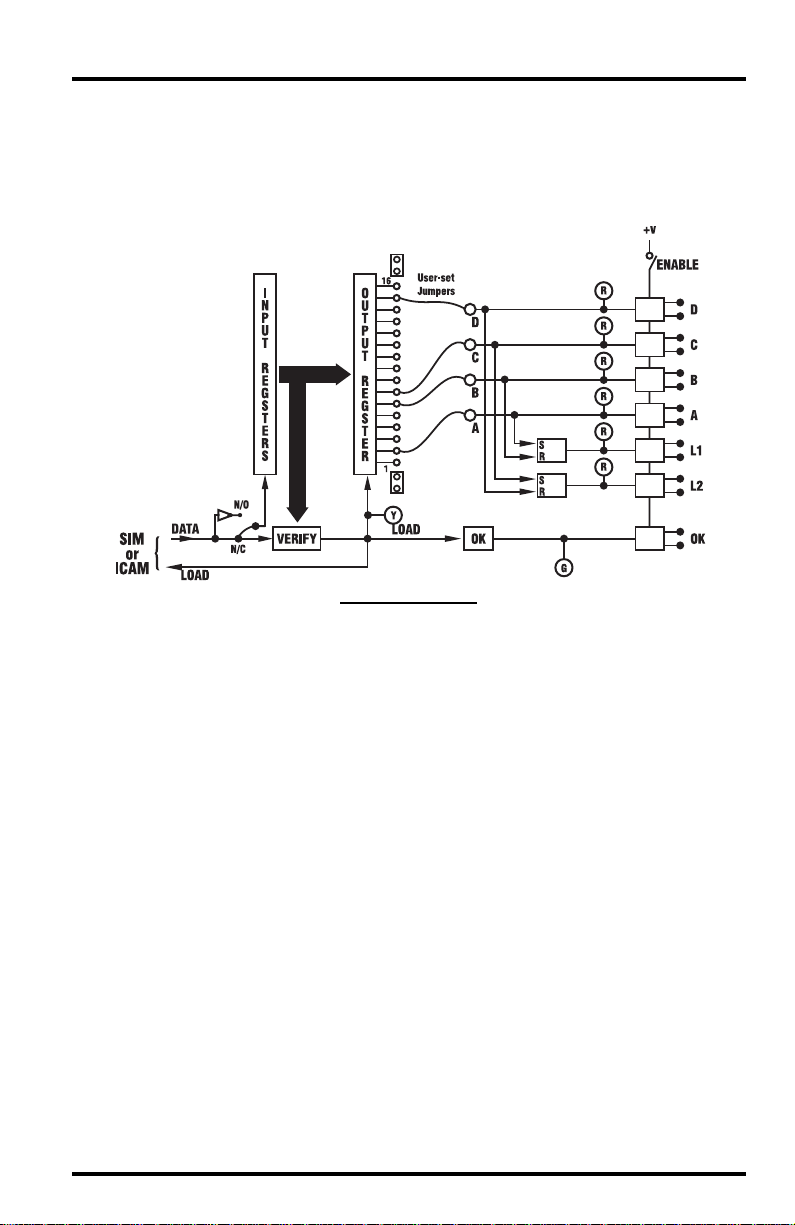

Circuit Operation

UTPUT

O

The section below provides technical information on the operation of the

Alarm Output Module. Installation instructions appear separately below.

The Console sends to the Sensor Interface Module (SIM) a serial data word

containing one bit for each alarm signal and user- and system-controlled output. From the SIM (or the Interface Cable Adapter Module) this is sent to the

Alarm Output Module. The data are sent twice, once in true form and once

inverted, and are shifted into the AOM’s Input Register.

When the Verify circuit confirms that the correct number of bits has been sent

and that the two data sets match correctly, it generates a LOAD pulse to transfer the data into the Output Register. All 16 bits of this register are available at

terminal strip J3 for selection as outputs. Four of the 16 are jumper-selected by

the user to drive the photo-coupled outputs and appear as contact closures A,

B, C, and D (closure indicated by lighted red LEDs).

Setting the ENABLE switch off causes all contacts to open (the LEDs continue

to indicate the state of the selected alarms).

The LOAD command pulse is sent back to the Console, where “quality of data

transfer” is determined and sent to the Link software. LOAD also flashes the

yellow indicator to show that a good transfer has occurred.

T wo Set/Reset (RS) Flip-flops can be used to latch the four outputs. Latch 1 is SET

by output A and RESET by B. Latch 2 is SET by output C and RESET by D. The

Latch contents are available as output contact closures L1 and L2 (set ON = closed).

The OK circuits check that a good transfer has occurred within the past 10 seconds or so, that the power voltage is good, and that the ENABLE switch is on.

This validity check result is indicated by the green LED and is available as the

OK output contact (OK = closed).

M

ODULE

PERATION

O

AOM C

IRCUIT

D

IAGRAM

Alarm Output Module Operation Page 5

Page 6

Available Outputs

The AOM provides four output contacts which may be selected from the conditions listed below. Each output (except time, daily ET, and the “User” outputs)

remains active as longs as the alarm condition exists. The time and daily ET

outputs remain active for one minute. The “User” outputs must be activated

and deactivated by the user via the W eatherLink Softwar e for that station. Also

shown in the table below are the pin assignments for each of the three consoles.

The “Radio Power” output is used to control switching of power to radio when

in the power-conserving mode (see “AOM Connections for Radio Power-Conserving Options” on page 12).

A

LARM

O

UTPUT

LARM

A

J3

G

P

IN

W

RO

C

ONSOLE

IGNAL

S

EATHER

IN

P

SSIGNMENTS

A

E

NERGY

C

ONSOLE

EM

(J3)

H

EALTH

C

ONSOLE

16 Time Time Air Temp-Low

15 Daily ET Temp-Hum Index Air Temp-High

14 Dew Point Dew Point Inside Temp-Low

13 Radio Power Radio Power Inside Temp-High

12 Hum-Low Air Temp-Low Outside Hum-Low

11 Hum-High Air Temp-High Outside Hum-High

10 Air Temp-Low Hum-Low Inside Hum-Low

9 Air Temp-High Hum-High Inside Hum-High

8 Soil Temp-Low Wind Chill UV Dose

7 Soil Temp-High Wind Speed Outside Temp-Hum Index

6 User 1 User 1 Wind Speed

5 Temp-Hum Index Daily Rain Temp-Hum-Sun-Wind Index

4 Wind Chill Not Used Daily Rain

3 Wind Speed Not Used Inside Temp-Hum Index

2 User 2 User 2 Wind Chill

1 Daily Rain Barometer UV Index

EM

Contact Specifications

The “contact” closure is provided by a photo-coupled MOS device. Because it

is a solid-state device, it is not subject, as long as the load conditions are within

specification, to arcing and contact-welding as are mechanical relays. The Control Output and Status contacts are rated as follows:

Nominal Load Voltage: 28V AC or 48V DC, Maximum

Peak Voltage: ±100 V, Maximum

Load Current ±300 mA, Maximum at 77° F (25° C),

derated to 150mA at 176° F (80° C)

ON Resistance 4 Ohms, Maximum

Page 6 Alarm Output Module

Page 7

Basic AOM Information

The AOM outputs are updated by the console at intervals of approximately 3

seconds. The data are sent twice and checked for agreement before being output, providing a measure of error detection. Note the following information

concerning the jumpers, LEDs, switches, and jacks found on the AOM board:

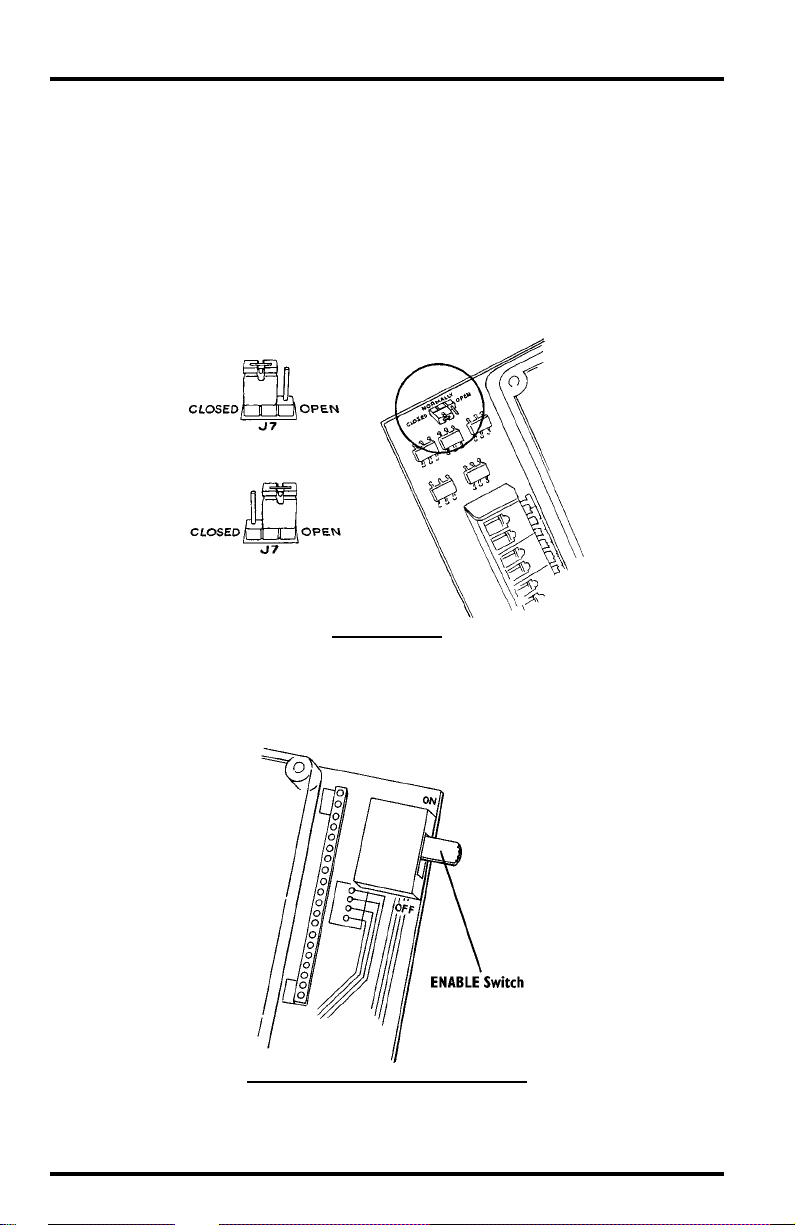

Normally-Open/Closed Jumper (J7)

✦

Jumper J7 enables the user to select whether the output “contacts” are

normally-open or normally-closed. One jumper selects the mode for all

four contacts.

Yellow LED Indicator (LOAD)

✦

The yellow LED flashes briefly for each successful transfer of alarm data

from the console to the output contacts (LOAD pulse).

✦

Green “Status” LED Indicator and Contact Output (OK)

The green LED is lighted and the contact is closed to indicate that the following are true:

✦

Power is on at the

AOM.

✦

A correct update has

been made within the

last 10 seconds.

The “enable” switch is

✦

set to “ON.”

✦

Alarm Outputs (A, B, C, D) and Red LED Indicators

The AOM has four alarm output contacts (A, B, C, D) to which you may

connect external devices. Each output contact may be connected to a different alarm signal by connecting the jumper wire from the desired

alarm output to the appropriate pin jack on jumper J3 (See “Programming the AOM” on page 9). The red LED indicators display the status of

each of the four selected alarm signals. When the LED is lighted, the output is closed (if the ENABLE switch is set to ON).

Alarm Output Module Operation Page 7

Page 8

✦

Latch Circuit Outputs (L1 and L2) and Red LED Indicators

The AOM includes two latch circuits; each has one output contact and a

red LED indicator. The latches are set and reset by selected alarms,

enabling the user to set up two simple control circuits in which each output “contact” is set on by one alarm and set off by another . (For example,

start a fan when the high temperature alarm becomes active and keep it

running until the low temperature alarm becomes active.) The red LED

indicators display the status of each of the latches. When the LED is

lighted, the output is closed.

If using latch circuits, jumper J7 must be placed in the NORMALLYOPEN position.

Latch Circuit L1 is set

✦

on (output CLOSED)

by alarm output A

and reset by alarm

output B.

Latch Circuit L2 is set

✦

on (output CLOSED)

by alarm output C and

reset by alarm

output D.

✦

“ENABLE” switch (in the upper right corner of the AOM board)

The ENABLE switch opens all outputs when set to “OFF”. The indicators continue to display the condition of the selected alarms or remote

control lines.

✦

Power Connector (A2)

To provide power to the AOM, you must connect the AOM power

adapter to connector A2.

AOM Cable Connector (A1)

✦

T o enable the console to update the status of the AOM outputs, you must

run the AOM Cable from connector A1 on the AOM to connector S6 on

the sensor interface module (SIM) or the interface cable adapter module

(ICAM).

✦

Alarm Signal Selection Panel (J3 and J5)

The row of pin jacks at J3 enables you to program specific alarms for

each of the four alarm outputs. Each of the numbered pin jacks at J3 is

assigned to an alarm on the station (see “Connecting alarm signals to

alarm outputs” on page 9 for a list of the pin assignments for each station). The four pin jacks next to the solid white rectangles provide locations to “park” unused jumper wires.

Terminal J5 contains four jumper wires, one for each alarm output (A, B,

C, D).To connect an alarm signal to one of the alarm outputs, insert the

desired jumper wire from J5 in the appropriate pin jack on J3.

Page 8 Alarm Output Module

Page 9

✦

AOM Cover Label

The label on the cover of the AOM provides spaces in which you may

write the name of the alarm condition connected to each output (A,B, C,

D) and each latch circuit (L1, L2). You may also mark the appropriate

check box to indicate whether the AOM is configured so the outputs are

normally open or closed.

PERATION

O

Operation of the AOM requires the following, each of which is described in a

separate section below:

Programming the AOM

Programming the AOM involves three main steps: connecting alarm signals to

alarm outputs, selecting between normally-open and normally-closed operation, and setting the ENABLE switch.

OF

THE ALARM OUTPUT MODULE

✦

Programming the AOM (page 9)

Connecting the Outputs (page 11)

✦

Connecting the AOM to the System and Powering the AOM (page 12)

✦

✦

Mounting the AOM (page 14)

✦

Connecting alarm signals to alarm outputs

To connect an alarm to an alarm output, insert the desired jumper wire

from J5 into the appropriate pin jack at J3. Use the table on page 9 to

determine pin assignments. Once you make your alarm output pin

assignments, you may find it useful to write them in the left-hand column of the table on page 9. Write the letter of the alarm output next to

the number of the pin to which that output is assigned.

C

ONNECTING ALARMS TO ALARM OUTPUTS

Operation of the Alarm Output Module Page 9

Page 10

✦

Selecting between normally-open and normally closed operation

If you select normally-open operation, each of the four alarm outputs

will close when the alarm connected to that output is active. If you select

normally-closed operation, each of the four alarm outputs will open

when the alarm connected to that output is active.

If using either of the

two latch circuit outputs, you must select normally-open operation.

select normally-open operation, place the jumper plug over the two pins

closest to the side labeled “OPEN.” To select normally-closed operation,

place the jumper plug over the two pins closest to the side labeled

“CLOSED.”

To

Setting the ENABLE switch

✦

S

ETTING JUMPER

J7

Make sure the ENABLE switch is set to the “ON” position. Otherwise,

the outputs will remain open.

ENABLE S

(J

WITCH

UMPER WIRES NOT SHOWN)

Page 10 Alarm Output Module

Page 11

Connecting the Outputs

The output devices are photo-coupled MOS transistors. They provide floating

“contacts” suitable for low-voltage AC or DC loads, as specified in “Contact

Specifications” on page 6. Each output contact is connected between the two

like-colored terminals (A, B, etc.) of terminal block J4 (labelled CONTACTS).

T o make connection to the outputs install the two wir es fr om the external cir cuit,

one to each terminal of the pair, in J4. To place wires into the cage clamp, strip

about 5/16” (8 mm) of the insulation off each wire in the cable. Use a small

screwdriver to push down on the lever next to the cage clamp, insert the exposed

wire into the opening created, and release the lever. When you release the lever,

the wire(s) will be held in place by the cage clamp If the external load voltage is

DC, insert the more-positive voltage wire in the + side of the terminal pair.

INSTALLING WIRES

When finished, gather all wires together and secure them to the cable tie lug

using a cable tie. as shown below. When tightening the cable tie, make sure the

wires are on top of the lug.

SECURING WIRES

Operation of the Alarm Output Module Page 11

Page 12

AOM Connections for Radio Power-Conserving Options

For power conservation when using a solar-battery-powered wireless WeatherLink, the AOM is used to switch radio power ON for only brief intervals. Make

the connections for this case as follows:

1. Insert the jumper wire for output D (at J5) into pin jack 13 (at J3).

2. Connect the yellow wire from the Solar P ower Kit to the D+ terminal (at jumper block

J4). Connect the green wire to D-.

3. Strip approximately 5/16” (8 mm) of insulation from the yellow and green wires, and

insert at B3 (To Switch) on the regulator circuit. (Consult the Solar Power Kit manual

for more details.)

Insert the yellow wire into the terminal labeled “Yel.” Insert the green wire

into the terminal labeled “Grn.”

4. Strip approximately 5/16” (8 mm) of insulation from wires in the radio’s power cable,

and insert at B4 (Switched Power) on the regulator circuit.

Insert the wire with the white stripe into the terminal labeled “Wht.” Insert

the black wire (no stripe) into the terminal labeled “Blk.”

Connecting the AOM to the System and Powering the AOM

The AOM may be connected to either the sensor interface module (SIM) or the

interface cable adapter module (ICAM), depending on your installation. (See

“Typical AOM Installations” on page 3 for illustrations.)A 2’ (0.6 m) AOM

cable is provided to make this connection. You may also use a 40’ (12 m) standard 6-conductor cable (available from Davis Instruments). The maximum

cable length for this connection is 40 feet (12 m).

1. Using the label sheets provided with your station, attach one of the S6/ALARM/A1

labels onto each end of the AOM cable.

Make sure the S6 end of the label is closer to one end of the cable and the A1

end of the label is closer to other end of the cable.

2. Attach the S6 end of the AOM cable to connector S6 on the SIM or the ICAM.

3. Attach the A1 end of the AOM cable to connector A1 on the AOM.

4. Attach one of the A2/ALARM POWER/P1 labels onto the end of the AC-power adapter

cable or the power Y-cable, depending on which you are using (see “Powering the

AOM” below).

5. Attach the jack at the end of your power source to connector A2 on the AOM.

6. Gather the AOM cable and the power cable together and secure them to the cable tie

lug using a cable tie.

When tightening the cable tie, make sure the cables are on top of the lug.

Page 12 Alarm Output Module

Page 13

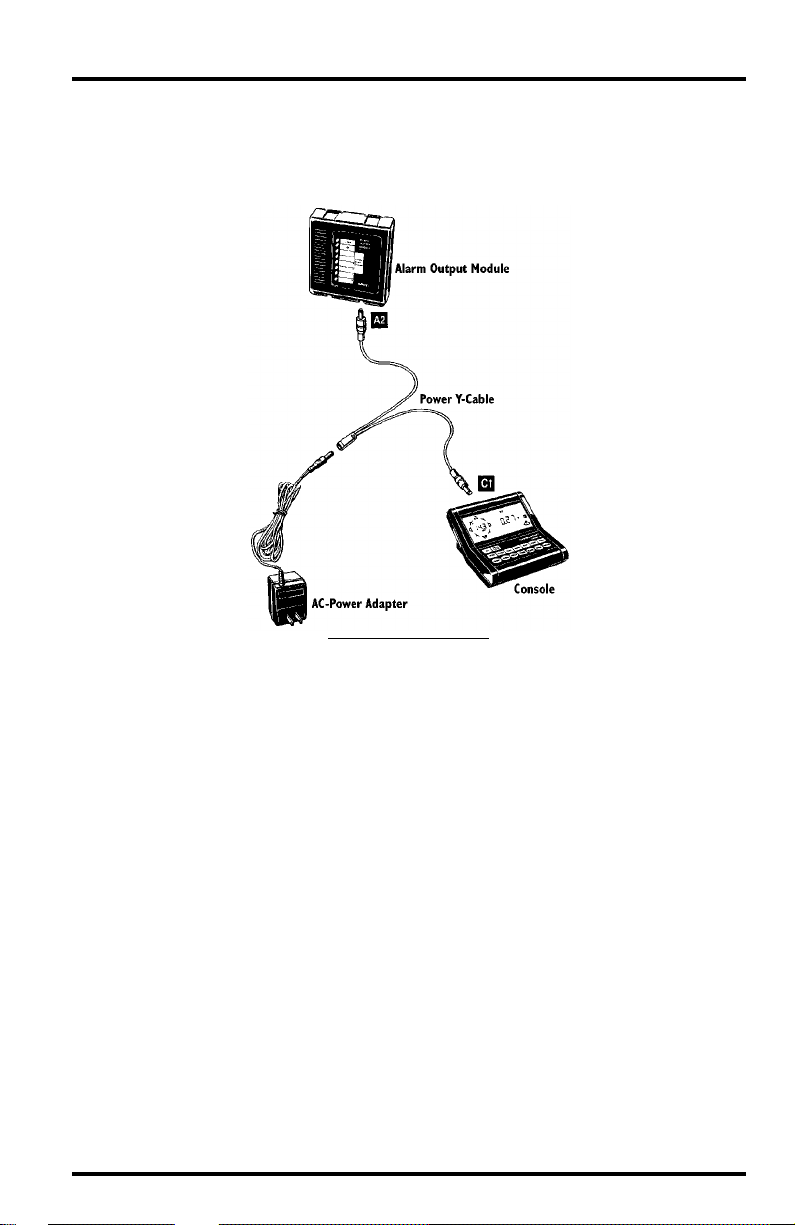

Powering the AOM

You may use a separate AC-power adapter for the AOM and the console, or

you may use the power Y-cable as shown below to connect power to both the

console and the AOM from a single adapter.

USING THE POWER Y-CABLE

Operation of the Alarm Output Module Page 13

Page 14

Mounting the AOM

You may mount the AOM against a wall or other vertical surface or you may

simply set it down on a horizontal surface

Note: Consult the appropriate shelter manual if installing the AOM in either the Complete System

Shelter or the Multi-Purpose Shelter.

To mount the AOM against a wall or other vertical surface, attach the base to the

✦

mounting surface using the #6 x 1” screws.

Use two screws (as pictured below) when attaching to a stud. Use three

screws (as pictured below) in any other case. T ighten the scr ews until the

base is securely fastened to the mounting surface. Do not overtighten.

ATTACHING THE BASE TO THE MOUNTING SURFACE

✦ If you plan to place the AOM on a horizontal surface, attach one of the adhesive

pads to each of the four raised circles on the underside of the base.

ATTACHING ADHESIVE PADS

Page 14 Alarm Output Module

Page 15

Operation of the Alarm Output Module Page 15

Page 16

Product Numbers: 7736

Davis Instruments’ Part Number: 7395-085

Alarm Output Module Manual

Rev. B Manual (7/7/99)

This product complies with the essential protection requirements of the EC EMC

Directive 89/336/EC.

© Davis Instruments Corp. 1996. All rights reserved.

Loading...

Loading...