Page 1

S

TANDARD AND

I

NDUSTRIAL

A

NEMOMETER

NSTALLATION MANUAL

I

The anemometer enables you to measure and display wind-related conditions

such as wind speed, wind direction, wind run, wind chill, and the

temperature-humidity-sun-wind index.

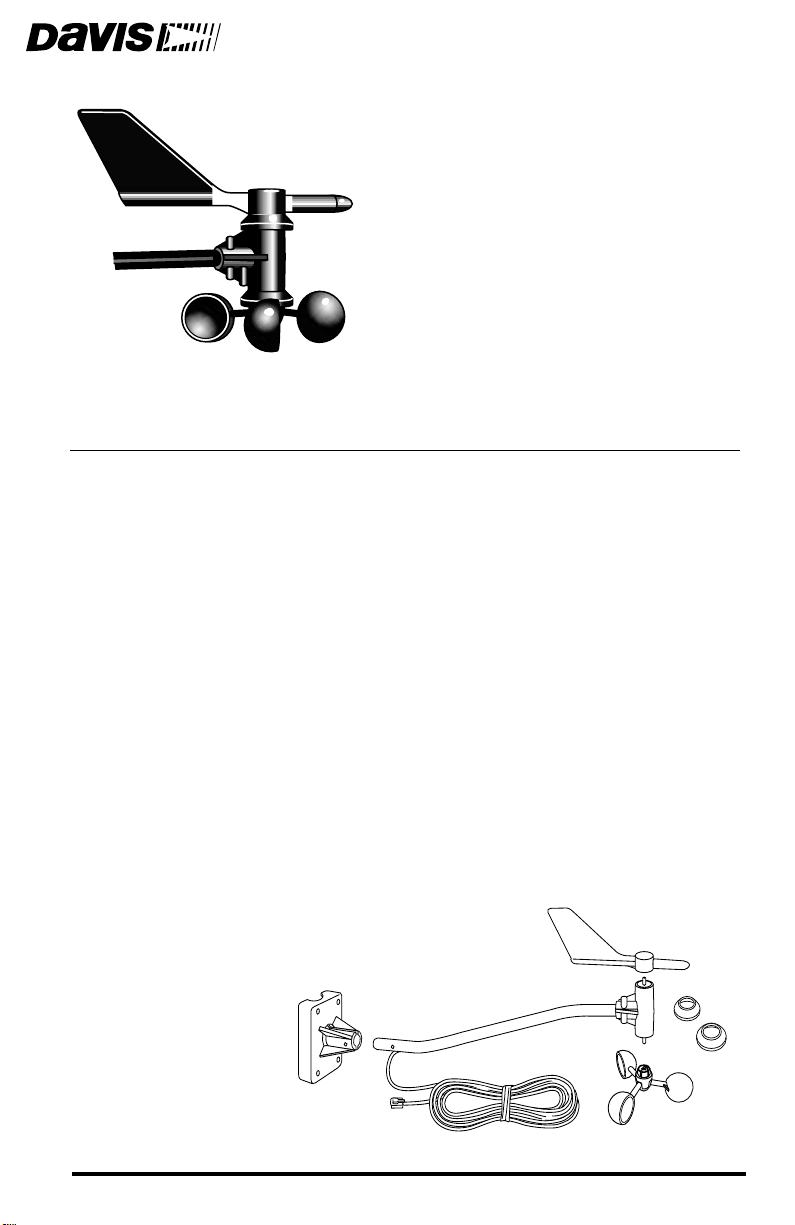

Components

The anemometer includes the components listed below. Please be sure you

have all listed components before continuing. The installation hardware kit

contains the items most commonly needed for the installation of the anemometer. Which items you use from the kit depend on where you install your unit.

You may need to adapt or purchase additional hardware to fit your individual

requirements. Assess your installation and make sure you have all necessary

parts, tools, and materials before you begin.

Anemometer Arm with cable

✦

Anemometer Base

✦

✦

Wind Cups

Wind Vane

✦

Drip Rings

✦

Wind Vane

Anemometer Arm

with 40 feet (12.2 meters)

of cable

Drip

Rings

Anemometer

Base

Wind Cups

Product # 7911, 7914

Page 2

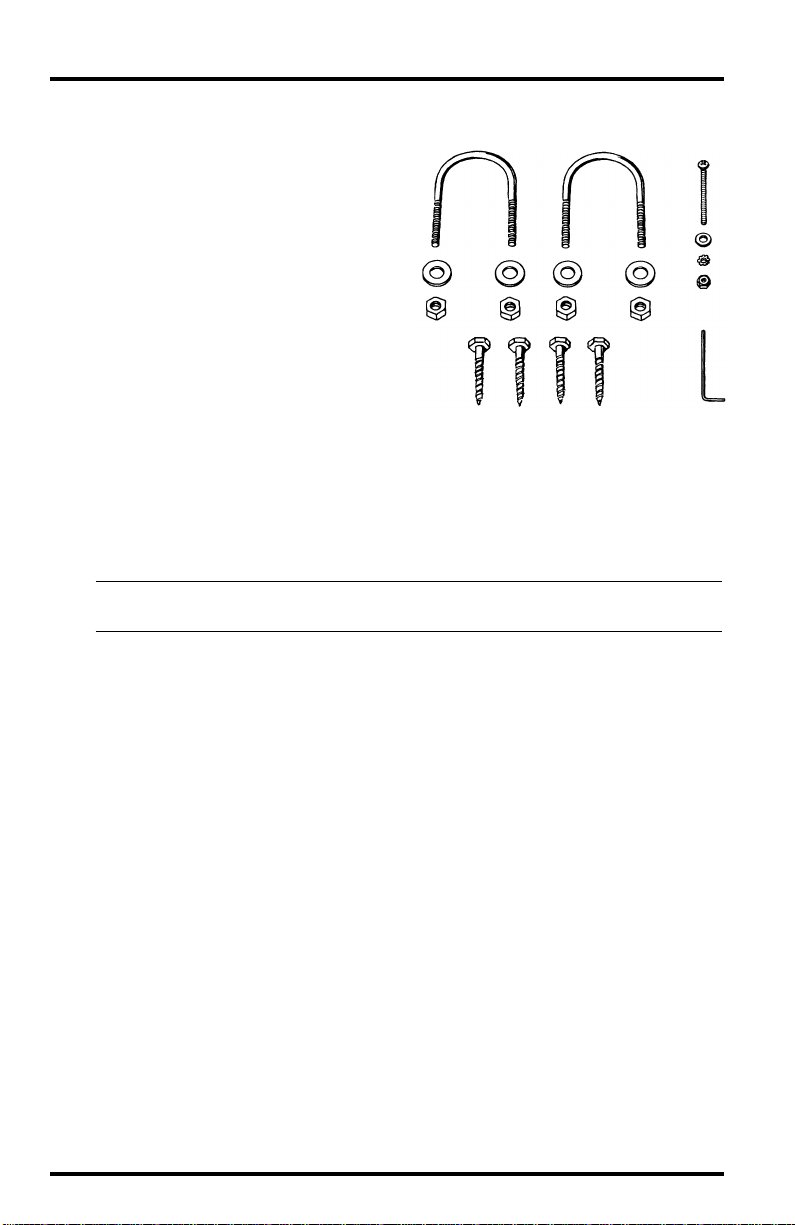

1.

Tools and Materials Needed

✦

Installation Hardware Kit

✦

Two U-Bolts

✦

Four 1/4” Flat Washers

✦

Four 1/4” Hex Nuts

Four 1/4” x 1 1/2” Lag

✦

Screws

One #4-40 x 1 1/4” Pan

✦

Head Screw

✦

One #4 Flat Washer

✦

One #9 Lock Washer

✦

One #4-40 Hex Nut

Allen Wrench

✦

Tools and Materials Needed

You will need the following tools and materials to install your anemometer:

✦

Cable Clips or Weather-Resistant Cable Ties

Note: Make sure the clips or ties you use to secure the anemometer cable have screw holes or other means

for mounting the cable. Do not use metal staples to secure the cables.

✦

Stainless Steel Hose Clamps

Small Screwdrivers

✦

✦

Adjustable Wrench

✦

Hand-Held Compass or Local Area Map

Testing the Anemometer

Before beginning your installation, follow the instructions below to test the anemometer wind speed and wind direction functions.

Connect the anemometer cable to the appropriate connector on your sensor

interface module (SIM) or junction box.

2.

Push the wind cups onto the smaller of the two stainless steel shafts at the

end of the arm.

3.

Spin the wind cups

them too hard you may knock them off.

4.

Check the display on your weather station to make sure you are getting a

wind speed reading.

5.

Grab the larger of the two stainless steel shafts at the end of the arm with

your fingers and twist the shaft about 1/2 turn.

gently

. You haven’t secured them yet, and if you spin

Page 2 Standard and Industrial Anemometer

Page 3

6.

7.

1.

2.

3.

Assembling the Anemometer

Check the display to make sure the wind direction reading on your display

changes.

Note: The wind direction readings will not change as rapidly as you turn the shaft. The station uses a low

pass filter to smooth out the constant small shifts in wind direction and keep the direction display

from jumping about in gusty winds.

Disconnect the cables when you are finished testing the anemometer.

Assembling the Anemometer

Attach the drip rings and the wind cups to the anemometer and check the

mounting base orientation before you install it. The wind vane is attached after

the anemometer has been installed.

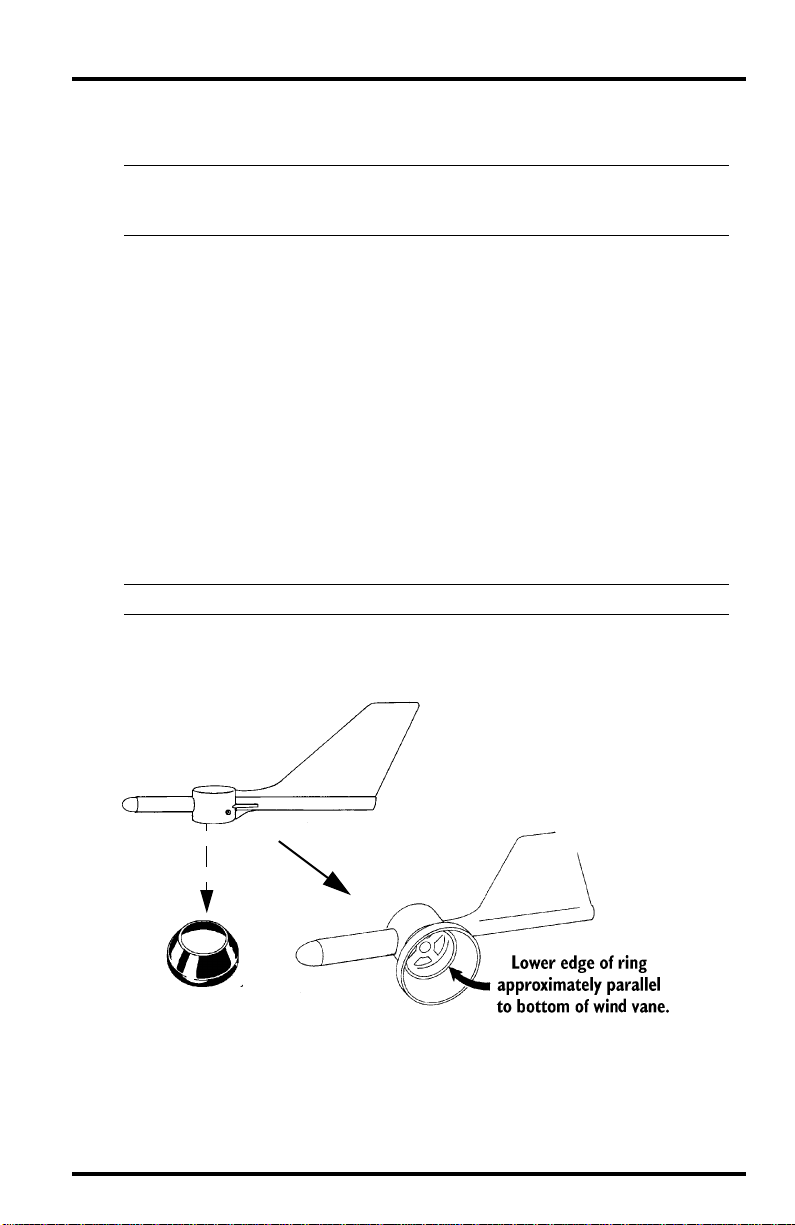

Attaching the Drip Rings

The anemometer drip rings provide protection against icing of the wind vane

and wind cups. Follow the instructions below to attach the two drip rings.

Place one of the drip rings on a flat surface with the small hole facing up.

Securely press the wind vane on top of the drip ring.

Note: You may want to start with the vane tilted slightly.

Make sure the ring fits securely between the two ridges on the vane with the

lower edge parallel to the bottom of the wind vane.

Installing the drip ring onto the wind vane

Page 3

Page 4

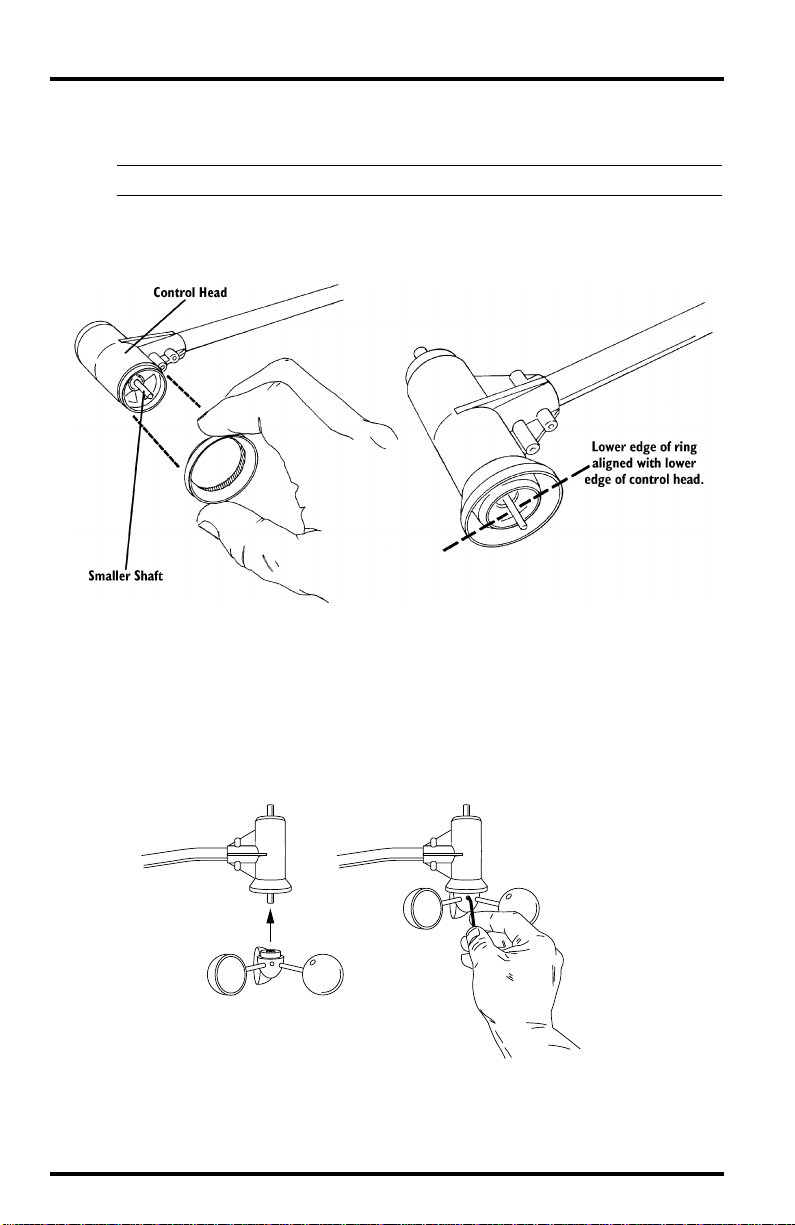

Assembling the Anemometer

Install the small end of the other drip ring on the wind cup end of the anemometer control head as shown below.

Note: The wind cup end of the control head has the smaller of the two stainless steel shafts.

Gently push up the drip ring until it reaches the groove on the control head.

Make sure the lower edge of the drip ring is aligned with the lower edge of

the control head.

4.

5.

6.

1.

2.

Installing the drip ring onto the anemometer control head

Attaching the Wind Cups

Before installing the anemometer, attach the wind cups. Wait until you have

installed the anemometer before you attach the wind vane.

Push the wind cups onto the smaller of the two stainless steel shafts at the

end of the arm.

Push cups onto

stainless steel

shaft

Attaching wind cups to the anemometer

Slide the wind cups as far up the shaft as possible.

Page 4 Standard and Industrial Anemometer

Tighten set screw

with allen wrench

Page 5

3.

4.

5.

1.

2.

3.

4.

Choosing the Best Anemometer Location

Use the allen wrench provided to tighten the set screw on the side of the

wind cups.

Note: When you let go of the wind cups, they should drop slightly.

Spin the wind cups. If they do not spin freely, loosen the set screw, lower the

cups slightly, then retighten the set screw.

Repeat Step 4 until the wind cups spin freely.

Checking the Anemometer Base Orientation

You will need to know which way to orient the base before installing it.

Insert the anemometer arm into the base

Attempt to push the #4-40 x 1 1/4” pan head screw through the holes in the

arm and the base as described in “Attaching the Wind Vane” on page 8.

If the screw does not slide easily through the holes, rotate the base 180˚ to

line up the opposite holes, then try again.

Note the correct base orientation for use when you install the base later in

the installation process.

Choosing the Best Anemometer Location

Use the following guidelines to determine the best location for your anemometer.

✦

Make sure you install the anemometer in a location where wind flow is

unobstructed by trees and nearby buildings.

For the most accurate readings, the anemometer should be mounted at

✦

least 4 feet (1.2 m) above the roof line.

You may do this by mounting the anemometer on a television antenna

mast, a wooden post, or a metal pipe.

Make sure the antenna mast or metal pipe is properly grounded. You may

✦

want to use Davis’ Grounding Kit.

✦

If you are not certain about how to ground your installation, consult a

qualified professional for national and local codes.

Note: If you live in an area subject to frequent thunderstorms, installing a lightning rod nearby can reduce the

risk of damage.

Page 5

Page 6

1.

2.

3.

1.

2.

Installing the Anemometer

Installing the Anemometer

Use the following procedures to mount the anemometer.

Installing on a Sensor Mounting Arm

Consult the Sensor Mounting Arm manual for instructions. You will need to

return to this instruction manual after installing onto the Sensor Mounting Arm

for instructions on attaching the wind vane (see “Attaching the Wind Vane” on

page 8).

Installing the Base on a Wooden Post or Surface

Hold the anemometer base against the

wood surface and use a pencil to mark the

location of the four holes on the base.

Use a drill with a 3/16” (5-mm) drill bit to

make pilot holes in these locations.

Drive the lag screws through the holes in

the anemometer base and into the wood.

Attaching base to wooden post

Installing the Base on an Antenna Mast or Metal Pipe: Outside

Diameter 7/8” to 1 1/4” (22 to 32 mm)

Hold the anemometer base against the pipe and

insert the two U-bolts through the back of the

base so that the U-bolts wrap around the pipe.

Place a 1/4” washer and a 1/4-20 hex nut over

each end of the U-bolts and use a wrench to

tighten the hex nuts.

Attaching base to a pipe

using U-bolts

Page 6 Standard and Industrial Anemometer

Page 7

1.

2.

1.

2.

Installing the Anemometer

Installing the Base on a Metal Mast or Pipe: Outside Diameter

Greater than 11/4 inch (32 mm)

Use stainless steel hose clamps to attach the mounting base to masts or pipes

larger than 1 1/4” diameter.

Use two stainless steel hose clamps large enough

to fit around the mast or pipe and the anemometer

base.

You may purchase hose clamps at your local hardware store.

Hold the anemometer base against the pipe and

fasten the hose clamps over the anemometer base

and around the metal mast or pipe.

Attaching base to a pipe

using hose clamps

Attaching the Anemometer Arm to the Base

Insert the anemometer

arm into the anemometer

base.

Guide the anemometer

cable through the slot as

you insert the arm.

Insert the pan head screw

into one of the holes in the

base and slide it through

the arm.

Inserting arm into base

3.

Secure the pan head

screw using the flat washer,

lock washer, and hex nut as

shown.

Attaching the anemometer arm to the base

Page 7

Page 8

Installing the Anemometer

Attaching the Wind Vane

To mount the wind vane, you will need to look at the console display in order to

orient the vane accurately. You may wish to have a friend or family member on

the ground do this for you. Or, you may wish to bring the console and SIM/junction box onto the roof with you.

1.

Connect the anemometer cable to the

SIM/junction box.

2.

Press WIND key on console if

necessary to display wind direction in

degrees.

3.

Use the compass or map to determine

270° W90° E

in which direction (N, S, E, W,) the

anemometer arm is pointing.

4.

Use the wind direction chart to find

the degree reading which corresponds

to that direction.

5.

Slowly turn the wind direction shaft

Wind direction chart

with your fingers. Stop turning when the weather station display reaches

the degree reading obtained in step 4.

Because of the low pass filter used by the station (see “Testing the Anemometer” on page 2), the wind direction reading requires approximately 5 seconds to stabilize each time you turn the shaft. You will need to turn the

shaft, wait, and turn it again until you eventually “zero in” on the desired

wind direction reading.

6.

Being careful to keep the stainless steel shaft from turning, place the wind

vane on the shaft with the bullet-shaped nose of the vane pointing in the

same direction as the arm.

0° N

180° S

45° NE315° NW

135° SE225° SW

Push the

wind vane

onto the

stainless steel

shaft

Installing the wind vane

Tighten set screw

with allen wrench

Page 8 Standard and Industrial Anemometer

Page 9

Slide the wind vane down onto the shaft as far as it will go.

Use the allen wrench provided to tighten the set screw on the side of the

wind vane.

Test your assembly by pointing the wind vane in any direction and (using

the compass or map as a guide) making sure the console displays the correct

wind direction. Readjust the vane if necessary.

Because of the low pass filter used by the station (see “Testing the Anemometer” on page 2), you need to allow the wind direction reading approximately 5 seconds to stabilize after you turn the vane.

10. Spin the wind cups to make sure you get a wind speed reading. Readjust the

cups if necessary.

11.

Secure the cable to the metal mast or pipe with electrical tape. Secure the rest

of the cable according to the directions below.

Securing the Cable

To prevent fraying or cutting of the anemometer cable where it is exposed to

weather, it is very important that you secure it so it doesn’t whip about in the

wind. Use cable clips or weather resistant cable ties to secure the cable. Place

clips or ties approximately every 3 to 5 feet (1 to 1.6 m).

Maintenance

7.

8.

9.

Securing cable (standard cable shown)

Note:

Do not use metal staples or a staple gun to secure cables. Metal staples—especially when installed

with a staple gun—have a tendency to cut the cables.

Maintenance

Your anemometer does not require any regular maintenance.

CAUTION:

DO NOT attempt to lubricate the wind cup shaft and bearings or the wind vane shaft. Natural or

synthetic lubricants will inhibit the normal operation of the anemometer.

Page 9

Page 10

Troubleshooting

Troubleshooting

While your anemometer is designed to provide years of trouble-free operation,

occasionally problems may arise. If you are having a problem with your unit,

please check the following troubleshooting procedures before sending the unit in

for repair . You will be able to solve many of the pr oblems yourself. If, after checking these procedures you are unable to solve the problem, please call Davis Technical Support for further instructions (see “Contacting Davis Instruments

T echnical Support” on page 11.) Please do

receiving prior authorization from Davis Technical Support.

Wind speed reads 0 all the time or intermittently

• Make sure anemometer cable is plugged into the jack marked WIND on the

junction box.

• Check for broken wire along length of anemometer cable. Carefully check

areas where the cable has been secured.

• Try dropping the wind cups approximately 1/16” to 1/8” (1.5 to 3 mm) lower

on the mounting shaft. Use the included Allen wrench to loosen and retighten

the wind cup assembly.

• If you still do not get a reading, the problem is probably with the anemometer.

Contact Davis Technical Support for return authorization.

not

return your unit for repair without

Wind speed reading seems too high or too low

• Check installation by spinning wind cups. If the wind cups spin freely and

your weather station displays a wind speed then the wind cups are installed

correctly. If the wind cups don’t spin freely, then try dropping the wind cups

approximately 1/16” to 1/8” (1.5 to 3 mm).

• Check calibration number and adjust if necessary.

• Check for any obstructions blocking the wind near the anemometer.

Wind direction reading is dashed out

• Make sure anemometer cable is plugged into the jack marked WIND on the

junction box.

• Check for broken wire along length of anemometer cable. Carefully check the

places where the cable has been secured.

Note:

If these steps do not solve the problem, the problem is probably with the anemometer. Call Davis Technical Support for return authorization.

Page 10 Standard and Industrial Anemometer

Page 11

Contacting Davis Instruments Technical Support

If you have any questions about our products, please call Davis Technical Support. We’ll be glad to help. Most questions can be answered while you’re on the

phone. You can also email us for support, or visit our website. Sorry, we are

unable to accept collect calls.

Voice Line: 510-732-7814, Monday - Friday, 7:00 am - 5:30 pm, PST

Fax: Line 510-670-0589

Email: support@davisnet.com

World Wide Web: www.davisnet.com

Specifications

Wind Direction

Display Resolution: 16 points (22.5˚) on compass rose, 1˚ in digital display

Accuracy: ± 7˚

Wind Speed

Range: 2 to 175 mph., 4 to 280 kph, 2 to 152 knots, 0.9 to 78 m/2s

Accuracy: ± 5%

Specifications

Page 11

Page 12

Product Numbers: 7911 & 7914

Davis Instruments Part Number: 7395-032

Anemometer, Standard & Industrial

Rev. B Manual (3/14/2001)

This product complies with the essential protection requirements of the EC EMC

Directive 89/336/EC.

© Davis Instruments Corp. 2001. All rights reserved.

3465 Diablo Avenue, Hayward, CA 94545-2778

510-732-9229 • Fax: 510-732-9188

E-mail: info@davisnet.com • www.davisnet.com

Loading...

Loading...