Page 1

d

a

V

i

n

i M

c

ni Se

i

rie

s

User Manual

English

Specification

Product Overview

Button and Indicator light

Unpacking

Accessory Checklist

Important Safety Notes

Extruder module installation

Accessory installation

XYZware operation

Print

Wi-Fi setup (da Vinci Mini w only)

Advanced XYZware operation

Function descriptions

Using the accessory tools

Print Bed Adjustment

Error message and Action

V1 - 1 -

2

2

2

3

3

3

4

4

6

6

7

10

11

14

15

16

Page 2

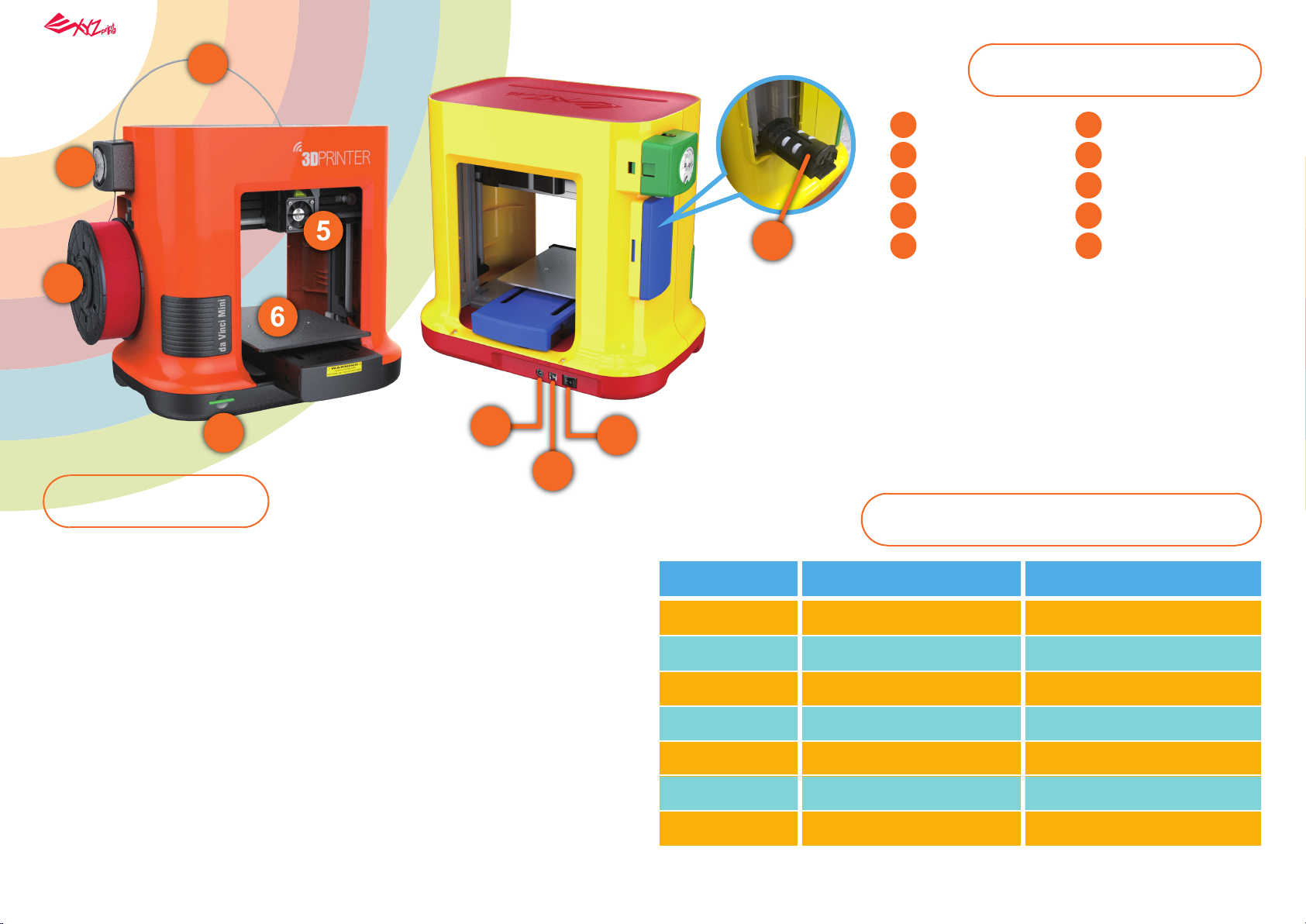

1

Product Overview

2

3

Specification

Dimensions

Weight

6

4

400 x 336 x 362 mm

8 KG

5

8

9

10

Guide tube

1

Feed module

2

Filament

3

Function button

4

/ status indicator

7

5

Extruder module

Button and Indicator light

Indicator signals Status Action

Print bed

6

Filament holder

7

Power connector

8

9

USB port

10

Power switch

Print Technology

Print Material

Filament Diameter

Nozzle Diameter

Print Dimension

Print Resolution

Connectivity

Print Software

File Format

Fuse Filament Fabrication (FFF)

PLA

1.75 mm

0.4 mm

150 x 150 x 150 mm

0.1/0.2/0.3/0.4mm

USB 2.0 (da Vinci miniMaker)

USB 2.0/ WiFi (da Vinci Mini w)

XYZware

STL / 3W

Solid green

Flashing green

Solid red

Flashing red

Solid orange

Flashing orange

Pulsing orange

If the printer encounters issues, please refer to the XYZware screen troubleshooting instruction to fix

the issues.

Standby/Ready to print

Receiving data

General error

Critical error

Printing

Paused

Job complete (printing complete /

printing cancellation complete)

-

-

Press the button to return to printing status, refer

to instructions in software to fix the issue.

Refer to instructions in the software to solve the

issue or reboot the Mini.

To pause the print, press the button once. To

cancel the print, press and hold the button for 5

seconds.

To resume the print, press the button once.

To return to Ready to print, press the

button once.

- 2 -

Page 3

Unpacking

• Before using this printer, remove all fixed materials from the extruder module and

print bed. Switching on the printer without removing these fixed materials may

damage the machine.

• Be sure to remove the 4 clips from the shafts as illustrated on the right.

Notes

Keep original packaging materials in case you need to send your unit back for repair

during the warranty period.

If other packing materials are used instead, the printer may become damaged during transportation.

In such a situation, XYZprinting reserves the right to charge a repair fee.

Accessory Checklist

1. Quick Guide, Warranty Card

6. Scraper

12. Feeding Path Cleaning Wire

2. Power Adapter 3. Power Cord 4. USB Wire 5. Extruder Module

7. Guide Tube 8. Bundled Filament 9. Filament Spool Ring

13. Cleaning Wire x 511. Cleaning Brush

Important Safety Notes

10. Bed Tape X 3pcs (Only replace

(installed on the filament spool)

14. Leveling tool

• Do not use the printer in dusty high humidity or outdoor environments.

• Place the printer on a stable and even surface to avoid it falling and causing serious injury.

• Do not put your hand into the machine during operation to avoid collision risk due to

movement of the machine or to avoid burn due to high temperature.

15. PET Protection cover

the reusable tape when it is worn.)

16. Feeding Tube Grip X1

(For replacing and installing

the Feeding Tube Grip,

please watch the tutorial

video on XYZprinting official

website)

- 3 -

Page 4

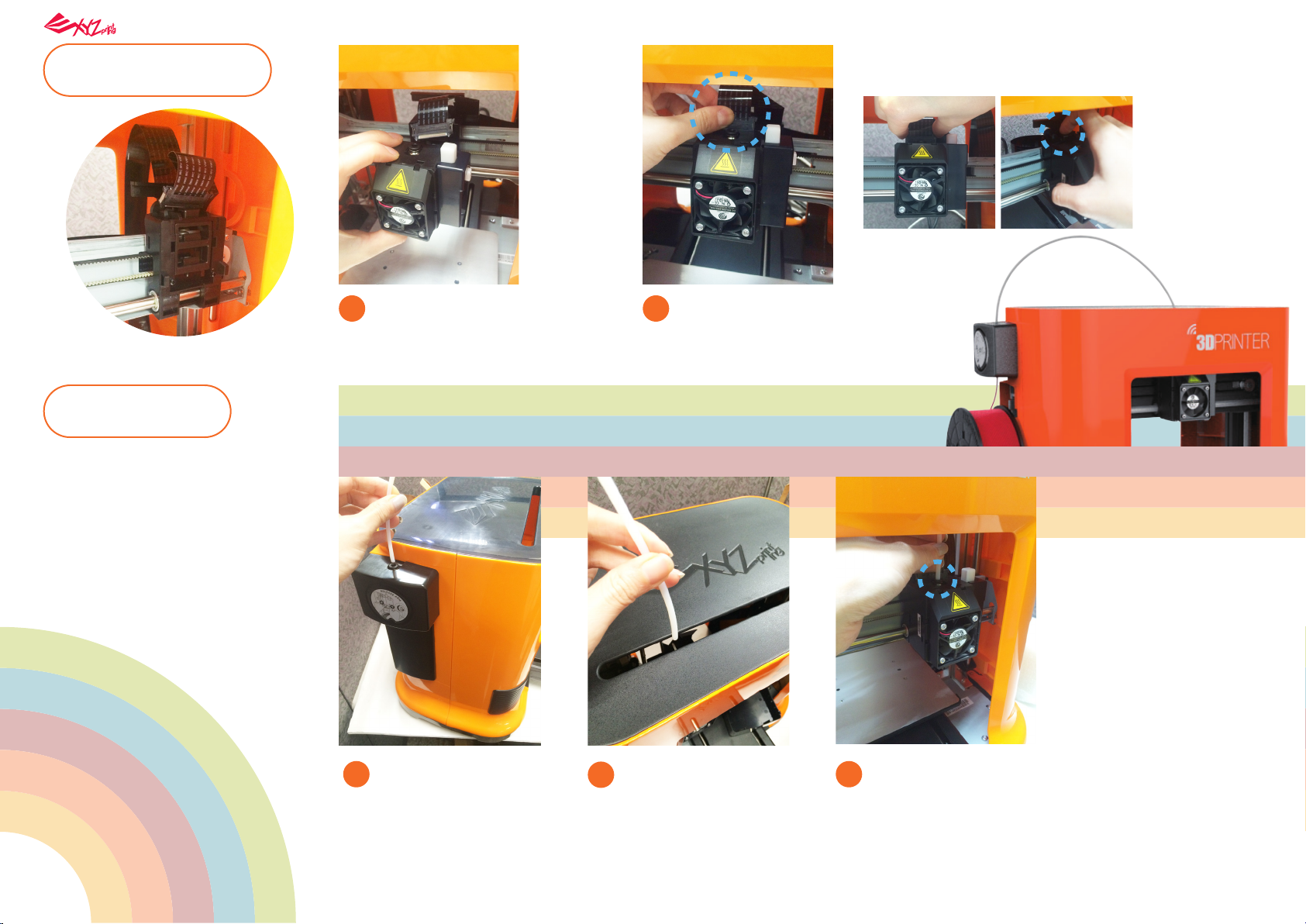

Installing the

Extruder module

NOTE: To unload the extruder module, first detach the

heating bus and press the black disengage button.

Installing the

Accessories

1. Install the guide tube

Make sure that the printer is

1

powered off. Place the extruder

module that the fitting pin is

secured the proper location.

Insert the black ribbon

2

connector to complete

the installation.

Ensure that the guide

1

tube has been tightly

inserted into the port.

Feed the guide tube

2

through the slot at the

top of the printer to

the extruder module.

Ensure that the guide tube

3

is properly inserted into the

feed port of the extruder

module to complete the

installation.

- 4 -

Page 5

2.Installing the Filament spool ring

21 3 4 5 6

(please refer to this step if the axle ring is not installed on the spool)

Use a phillips screwdriver to loosen the

securing screws of the

filament spool ring.

Separate the spool ring

from both sides of the

spool.

Retrieve the filament

spool and chip.

3.Installing the filament

Remove the side cover by pressing down

1 3

firmly at the center on the left side of the

cover and pushing aside the cover. (pay

attention to where you apply your force to

ensure proper dismantling) Keep the side

cover securely for future use.

Lower the filament spool

2

holder on the left side of

the printer until horizontal.

Install the sensor chip.

Note the orientation of

the sensor chip on the

spool ring.

Place the assembled

filament spool (with

the spool ring) on

the spool holder.

Feed both parts of the

spool ring through the

center hole of the

spool and assemble

them together.

Take the tip of the

4 5

filament and

insert it into the

feeding hole.

Use a phillips screwdriver to tighten and

secure the spool ring

to complete the

installation.

Press the release arm and

push the filament all the

way to the bottom so that

the front end of the

filament is completely

inserted into the extruder

module.

Handy tips

• The filament will load better when the tip of the filament is cut at a 45° angle.

• When the printer is not in use, raise the filament spool holder and close the side cover.

- 5 -

Page 6

XYZware operation

After completing the hardware installation, download XYZware from the XYZprinting official website and install it

on your computer.

Before launching XYZware, connect the printer to your computer using the supplied USB cable and turn it on. For

an optimal user experience, we recommend following the instructions below:

Print

Handy tips

Registration via XYZware before your

first print is strongly recommended.

When registered with XYZprinting, you

will receive latest technical supports

and updates. To register, simply click

"Register Now".

Before you start printing, please attach

the bed tape to the print bed. The print

bed tape is reusable, and can be

replaced worn.

If the room you are printing in is below

25 ℃/ 77 ℉, for greater adhesion,

apply glue to the bed tape.

After printing has started, check if the

first layer is stuck to the print bed.

Good base layer is one of the keys to

successful printing.

Open XYZware

1

Load filament

4

Import 3D file

2

Click Import and select the file to print.

Close Functions panel

5

Open Functions panel

3

Print

6

- 6 -

Page 7

The printing status, including the printing progress,

7

elapsed time, and remaining time, will be shown while

printing. You can pause or cancel the printing task in this

window.

Wi-Fi setup (da Vinci Mini w only)

When done, "Printing Complete"

8

will be shown on screen.

After the print has finished,

9

use a scraper to remove the

printed object.

●Pre-setup

1. The network printing function is only available when the printer and the

computer are both connected to the same wireless network.

2. Before connecting the printer, your wireless network settings need to be

adjusted. For more information, refer to the instruction manual of your

wireless router.

3. The wireless network's channel width needs to be set to 20 MHz for the

printer to connect to it wirelessly. Refer to the vendor instruction manual for

more information.

4. The Mini supports WEP, WPA, and WPA2 security encryption standards.

Wireless pass word information will be requested when setting up the

printer connection.

• WEP • WPA • WPA2

●Setting up Wi-Fi

Connect the printer to your computer with the USB cable, and open

1

"XYZware".

Click the "Printer Monitor" button on the lower right corner on the

2

screen, open "Operation Function".

Select the "Printer Monitor" icon to open the Wi-Fi connection settings.

3

- 7 -

Page 8

In the "Printer Monitor" window, select My

4

Printer > Scan to search for the connected

printer.

Select the USB COM port, click Connect >

5

Establish printer connection.

Click "Wireless Setting"

6

to view wireless print settings.

Enter the printer name, then press the Scan

7 8 9

button.

Use the pull-down menu to view a list of

Wi-Fi connections available in the area, and

select the Wi-Fi connection that you wish to

connect to.

Wait for the printer to obtain the correct

information, provide the wireless password

and press Start wireless connection.

- 8 -

Page 9

Update the printer connection method.

10

XYZware will use the USB connection to

11

update the printer settings.

Once the connection method has been changed from

12

USB to Wi-Fi, you can unplug the USB cable and

continue with the printing process.

OK

Note:

• Name the printer and wireless network with the alphanumeric characters only.

• If no connection is detected within 90 seconds, the printer will time-out. If this is the

case, check that the configuration process is correct and try again.

• Confirm your wireless network's security key on the router's wireless settings page.

- 9 -

Page 10

When using the software to operate the printer, one must first place filament spool ring

pre-loaded with the filament at the axis to activate XYZware.

Click on the Printer Monitoring function at the lower right corner to activate the operating

function.

Then select the Printer Monitoring function icon to activate the USB connection (this step

would be similar to Wi-Fi setup steps 1 to 5).

The USB cable can be removed once the printing file

has been transferred. To monitor printing status,

please re-connect the printer and computer with the

USB cable and re-activate the Printer Monitoring

(function).

If information shown

on-screen is not

updated accordingly,

you may switch off

the operation function screen and then

switch it on again.

(Reload)

Operating the printer with XYZware

A

Import: Import .stl, .3w files

B

Export: Convert to .3w file

C

Save: Save .stl file

D

Print: Set print preference, transfer print file

E

Setting: Set software display language, preview color, Printer Type

About: Query, update software and firmware versions, open link to official website

F

Adjust display scale

G

View: Switch preview angle rapidly

H

Move: Move location of the model

I

Rotate: Change angle of the model

J

Scale: Adjust size of the model

K

Info: Display information about the model

L

Remove: Delete the model from the virtual platform

M

Printer Monitor: Open functio

N

G

H

J

K

L

M

A

B C D E F

I

N

- 10 -

Page 11

Functional descriptions

1

Extruder

Clean Nozzle

Once this function is

selected, the nozzle will

heat up automatically

and move the nozzle to

a proper location

where you can easily

clear away all residual

filaments in the nozzle.

Info

2

Filament

Load Filament Unload Filament

Please follow the on-screen instructions.Please follow the on-screen instructions.

The printing module will automatically move

to the working position. The nozzle will then

heat up to the operating temperature. Please

wait for the extrusion process to finish.

Verify that the nozzle is capable of extruding

the filaments to demonstrate proper loading

of the filaments. If not, please repeat the

filament loading process.

The printing module will automatically

move to the working position. The

nozzle will then heat up to the operating

temperature. Please wait for the unload

filamentprocess to finish.

Info

The extruder module

information, including

Temperature, Nozzle

Diameter, Total Print

Time, and Serial

Number.

Information related to filament use

Note: The end tip of the ejected filament may exhibit

some residual effects. This is considered a normal

phenomenon.

- 11 -

Page 12

3

SetUp

1. Jog Mode

1. Jog Mode

2. Calibrate 3. Z-Offset 4. Others 5. Info

Manually adjust the movement of X/Y/Z Axis for printer maintenance.

First click on [Home Axes]. The printing device will be returned

to the initial axis position at the lower left corner of the printing

area. Then adjust the positions of the printing module (X-AXIS),

printing platform (Y-AXIS), and printing axes (Z-AXIS).

Select “X-AXIS” to move extruder rightwards and leftwards.

Select “Y-AXIS” to move print bed forwards and backwards.

Select “Z-AXIS” to move the print axis (Z-AXIS) upwards and

downwards.

The user may manually enter the adjustment value:

Range: 1 to 150; step: 1 mm

- 12 -

Page 13

2. Calibrate

Platform calibration may be implemented before

the printing process.

The printing device may move to the lower left

corner of the printing area. Please refer to the

platform calibration instructions provided in the

software.

Before calibration, press Button A of the printing

module. After calibration, press Button B on the

printing module in order to retract the sensor

device.

If calibration was faild, please make sure that

Button A (detector) has been pressed before

restarting the calibration process.

Button A

Button B

3. Z-Offset

Upwards and downwards to adjust the printing distance between the

bed and printing module.

Each adjust has a step of 0.05 mm.

If the first layer distance is too high (too large) or too low (too close), we

recommend you using z-offset to adjust the printing distance.

4. Others

●Automatic horizontal calibration

Automatic horizontal calibration may either be ON or OFF. Default: ON.

The software would automatically implement horizontal calibration and

compensation accordingly.

Printing speed may be improved if automatic horizontal calibration has

been switched OFF. However, this may affect printing quality.

●Buzzer

Buzzer is turned on by default, you can select "OFF" to change the

setting.

When the buzzer is turned on, the printer will output an audible signal

when a button is pressed, receiving data, print job is finished, or issue is

detected.

1 2

3 4

5. Info

●Restore Default

Clicks "Restore Default" all settings will be reset to factory default.

Printer Info

Printer Name and

Printer Type

Serial Number

Firmware Version

Total Print Time

Last Time

Connection Info Calibrate Info

Connection Type

Printer IP

WiFi MAC Address

SSID

WiFIi Signal Strength

Calibrate Value

- 13 -

Page 14

Using the accessory

Maintenance Tools

Usage Application method

tools

Scraper

Accessory tools can be used only in an

environment with guidance or monitoring by adult. Do not allow children

to obtain maintenance tools in unfa-

PET Protection cover

miliar situations in order to avoid

danger.

Filament should be unloaded from the extruder before cleaning the feeding path.

Care should be taken during the operation to avoid potential burn injuries.

Taken off the

printing object

Keep your hands

away from the

printing and

operations area

when the machine

is printing.

After print is finished, the printing object may be taken off with Scraper.

Once the PET protective casing has been assembled, apply double sided tape at the

specified locations. Check that the adhesion areas on the printer are clean. Peel away

the carrier film and apply slight pressure to attach the PET casing to the front of the

printer.

Instructions for re-using the double-sided tape of the PET shielding:

Pieces of tape can be re-used if they were kept clean and properly maintained. However,

multiple use or dirt on the tape may reduce the strength of adhesion. Please gently

remove the PET shielding from the printer and then slowly peel away the double-sided

tape from the PET shielding. Do not pull at the tape directly. Stickiness may be restored

by cleaning it with soap water and then drying it.

Cleaning Tools

Feeding Path Cleaning

Wire

Cleaning Brush

Cleaning Wire

Usage Application method

Clean Nozzle

In order to prevent print quality

from impact due to residual and

accumulated filament, which

we recommend you to clean nozzle for every 25

hours of print. Please clamp the nozzle cleaning

wire with needle-nosed pliers to insert it into the

opening of the nozzle carefully for cleaning.

results in poor discharge.

Clean gearwheel

After long periods of use, the

automatic feed system may

have experience unstable

extrusion of the filaments due

The printer filament feed module should be

cleaned after cleaning the nozzle. To do this,

please switch off the power first.

Open the feed module cover and clean the gears

using a gear cleaning brush.

to buildup of residual materials

within the filament channels.

Clean Feeding Path

If the cleaning cycle does not

unclog the extruder, try cleaning the feeding path by useing

the feeding path cleaning wire.

1. Switch on the power and activate the "Clean

Nozzle" function by using the software.

2. Release the extruder module (don't remove the

heating cable at the side).

3. Insert the thick cleaning wire into the feeding

path all the way down and “floss” the inside

of the nozzle to push the residue out.

4. After cleaning the feeding path, reinstall the

extruder module.

- 14 -

Page 15

Print Bed Adjustment

1 2

4

3

Leveling tool T10 screw drivers

1 2

Tools to prepare:

Use Jog Mode and Home Axes functions to

1

move the Z-AXIS to its original position at the

bottom.

Open the cover in front of the left side.

2

Use Jog Mode and move the Z-AXIS upwards

3

by 10 mm.

Manually move the printing module to the right

4

side to prevent affecting its calibrated position.

Place the adjustment tool on the platform

5

directly below the X-AXIS support.

Loosen the 4 screws shown on the diagram.

6

Do not loosen any of the other screws. (Note:

You only need to loosen the screws, not

remove them completely).

Use the Jog Mode and move the Z-AXIS downwards 1 mm at a time until

7

it is completely aligned with the X-AXIS support and calibration tool.

Check that the calibration tool and X-AXIS support are in full-contact

8

with each other, then tighten the 4 loosened screws.

2

At least 10 cm

Within 1-cm diameter

1cm diameter

of the circle

Support Details

As the printer encounters issues, please refer to the following troubleshooting instruction to fix the issues. If the issue cannot be removed, please contact

customer service center.

Maintenance and Service

Keep original packaging material in the event of sending your unit back for repair. If other packing materials are used instead, the printer may be damaged

during the transportation process.. In such situation, the XYZprinting the right to charge repair fee.

- 15 -

Page 16

Error message and Action

In the event of problems, related service code will be shown on the software interface. Please refer to the

description table of the service code for preliminary examination.

Error Code No.

0007

0008

0011

0014

0016

0028

0029

0030

0031

Software interface

Cartridge 1 Error. Please remove cartridge and install again. If errors exist, please

contact service center for support.

Cartridge 1 Error. Please remove cartridge and install again. If errors exist, please

contact service center for support.

Heating Error.

Please turn off the printer and contact service center for support.

Heating Error.

Please turn off the printer and contact service center for support.

Cartridge 1 not installed properly. Please reinstall Cartridge 1 ("Unload Filament" then

"Load Filament") on your printer. If error persists, please contact service center for

further support.

Cartridge 1 can not be found. Please install one.

There is no filament left in Cartridge 1. Please replace Cartridge 1 before printing.

Printer motor Error(X-Axis)

If errors exist, please contact service center for support.

Printer motor Error(Y-Axis)

If errors exist, please contact service center for support.

Action

Reinstall or replace the filament cartridge.

Reinstall or replace the filament cartridge.

Check whether the connections are connected properly and restart as

required.

Check whether the connections are connected properly and restart as

required.

Reinstall the filament cartridge.

Reload or replace the filament.

Replace filament immediately.

Check motor/sensor connections. Check sensor position.

Check motor/sensor connections. Check sensor position.

0032

0051

0052

0054

0201

020D

Printer motor Error(Z-Axis)

If errors exist, please contact service center for support.

Flash ram cannot be read/written.

Memory in the extruder cannot be read/written.

Incompatible Nozzle Turn off printer and reinstall compatible nozzle, then turn your printer

Computer and printer connection issues.

File is printable by: da Vinci XXX

Check motor/sensor connections. Check sensor position.

Reboot the printer.

Replace the nozzle.

back on. If this error persists, please contact service center.

Re-connect the computer with the printer. Alternatively, you may use

hot plugging of the USB cable to connect the computer with the

printer.

This shows that this file type is not supported. Please select a proper

printer model instead.

- 16 -

Loading...

Loading...