Page 1

PartPro200 xTCS

Touch Screen Menu, Functions and Messages 7

The manual is mainly intended for users to understand how to use the

PartPro200 xTCS 3D printer (“200 xTCS”) correctly. In this manual,

users can learn more about the operating tips, application skills and

maintenance of the 200 xTCS 3D printer.

New member is required to register account on http://support.

xyzprinting.com before able to download latest manual &

software for better user experience.

For more information on the 200 xTCS, please contact your local

dealer or visit the ofcial website of XYZprinting: http://www.

xyzprinting.com.

User manual

Safety Precautions 2

Product Descriptions 3

Unpacking and Installation 5

Function Operation and Instructions 8

Printing 21

Scanning 22

Support detail 25

ENG

HD23FC1S166

Page 2

Safety Precautions

Safety and Compliance

Please read through this manual and all safety precautions carefully before using, operating, unpacking, replacing, removing any part or maintaining this product. Please also comply with the instructions of relevant safety precautions.

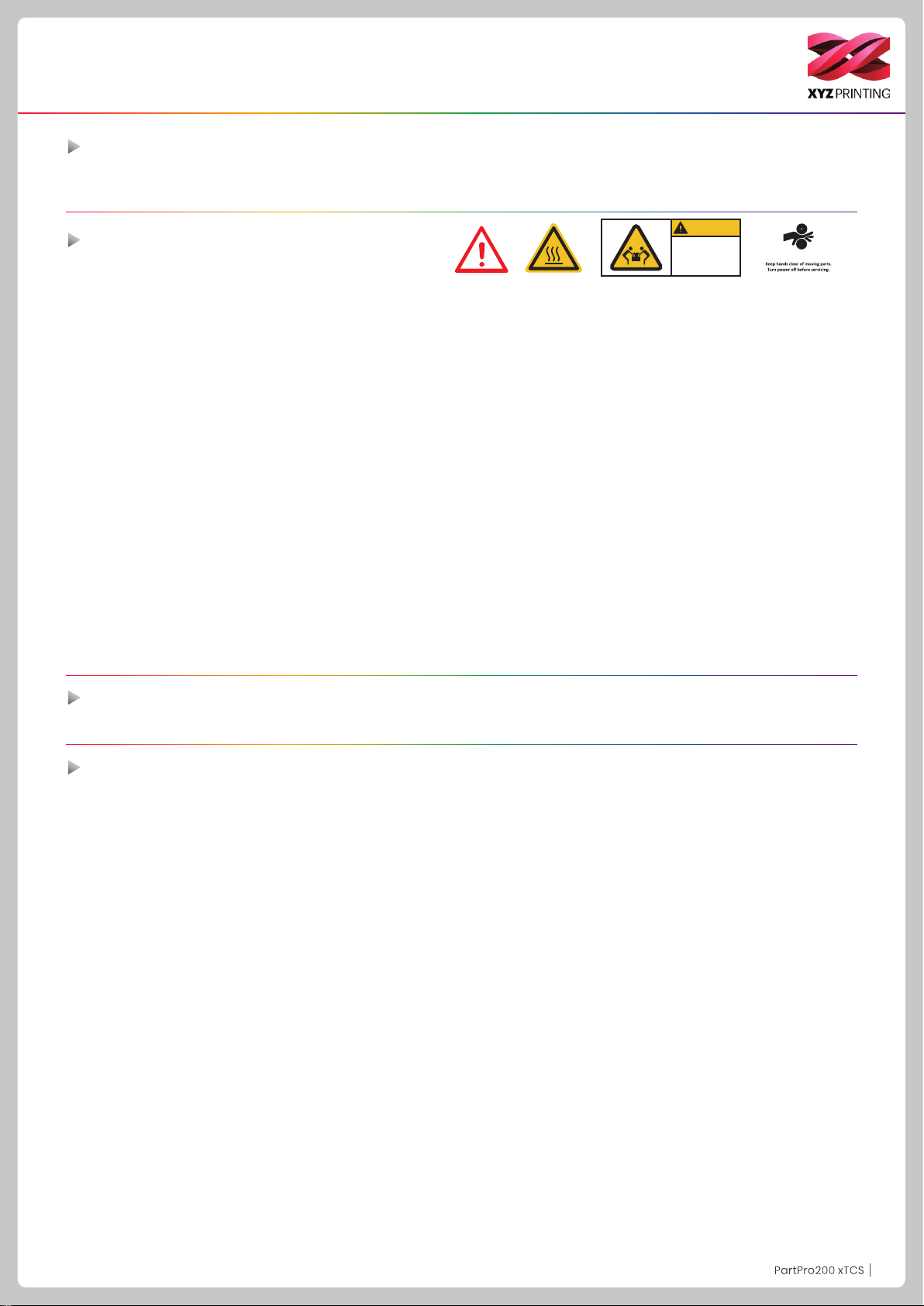

CAUTION

Important Safety Precautions

●

Do not move the machine by yourself as it is heavy.

●

Do not place the printer in a dusty, humid or outdoor environment.

●

Do not place the printer on a soft or tilted surface. Otherwise, the machine will fall / ip over and become damaged or

cause personal injury.

●

Do not leave the product or power cord to unattended children. Otherwise, personal injury or electric shock might occur.

●

Use the provided power cord. Otherwise, incorrect grounding might lead to damage.

●

Do not place any liquid container on top of the product. Otherwise, overow or spill might go into the machine and pose

the risks of danger or safety concern.

●

Do not wipe the printer with alcohol or ammable chemicals. Otherwise, danger might occur.

●

Do not move the machine when it’s powered on.

●

Do not reach into the machine with your hands during operation. Otherwise, risks of impact from moving printing parts or

burn from high temperature might occur.

●

The machine becomes hot during operation and thus run in high temperature. Do not touch or replace parts when they

are not cooled down.

●

After startup, the parts in the machine will heat up or move depending on the user’s instructions. During product

operation, do not touch or block the operation of the parts.

●

Weak odors may be generated during the printing process. We recommend working in a well-ventilated and open area to

ensure operational comfort.

●

Defect reparation must be carried out according to the contents of this instruction manual. Where the defect cannot be

repaired, please contact your printer dealer or the customer service center.

Heavy object.

2 person lift

required

Watch Your Hands.

Trademarks

All trademarks and registered trademarks are the properties of their respective owners.

Maintenance and Service

When the printer needs to be serviced during the term of the warranty, it is recommended that the machine is packed with

original packaging materials prior to shipment. For this purpose, the packaging materials are better to be kept. If other

packaging materials are used instead, the printer might be damaged during transportation. We reserve the right to assess

relevant service fees.

P2P2

Page 3

Product Descriptions

Product exterior

1. 5 inch color touch panel 2. Auto-feeding module 3. Print head 4. Print bed+EZ removable rubber magnet

5. Scan module 6. Filament spool holder 7. USB Port 8. USB Port

9. Power switch 10. USB Port (To PC) 11. Power jack

(WiFi dongle)

1

2

5

3

6

4

7

8

9

10

11

P3P3

Page 4

Product Descriptions

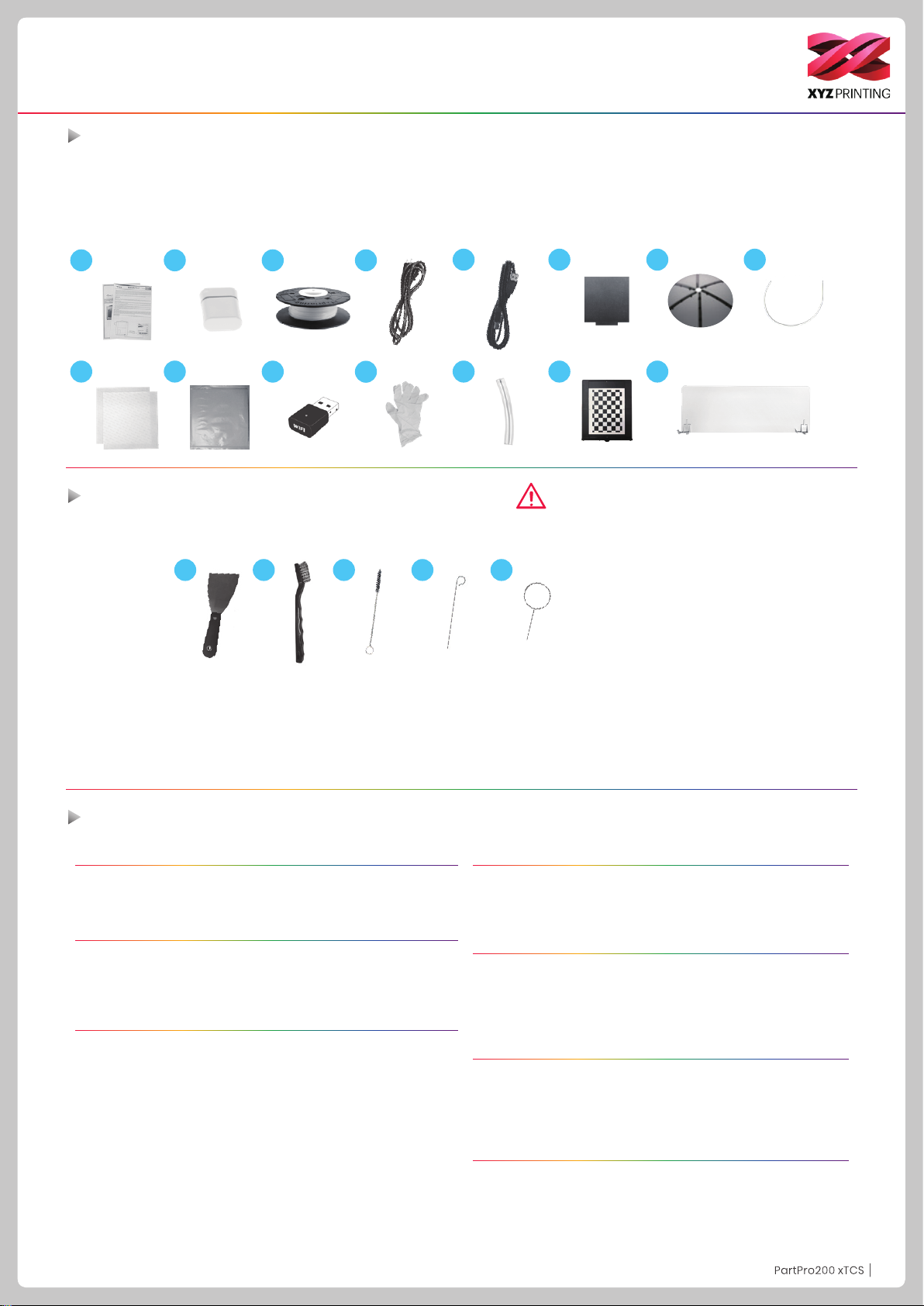

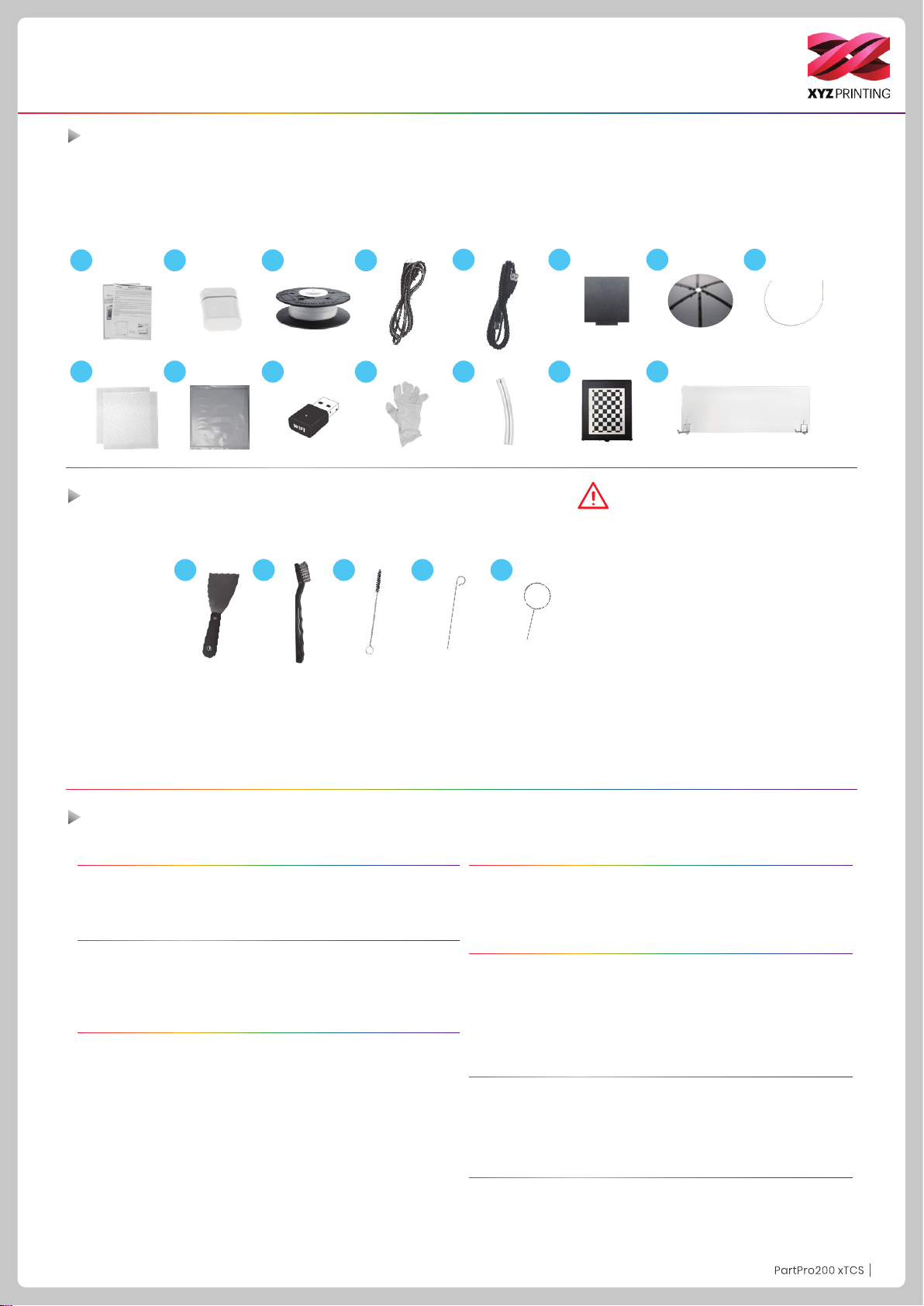

Accessory Checklist

1. User Manual 5. USB Cable 9. PC Mylar x 2pcs 13. Clear Tube

2.

USB Drive 6. EZ Removable Rubber Magnet 10. Mask Tape x 3pcs 14. Calibrating Plate

3. 3D Color-inkjet PLA 7. Top Cover 11. WiFi Dongle 15. Scan Backboard

4. Power Cord 8. Guide Tube 12. Pair Of Gloves

1 2 3 4

9 10

11

12

5 6

13 1514

7 8

Precautions and Instructions of Maintenance Tools

The following tools are intended for use under the guidance or guardianship of an adult only. Do not allow children unfamiliar with the

tools to have access to them in case of danger.

Scraper

31 2 4 5

●

Make sure the maintenance work of the printer is carried out when the print bed has cooled down.

●

When printing is completed and the print bed is cooled down to room temperature, the printed object can be removed from the print bed

with the scraper.

●

Filament residues generated during the course of printing may be stuck on the print head and gears of the printing module. The printing

quality and printer operation as well as the measurement of the print bed may be affected. When this happens, clean the printing

module with the wire brush.

1.

Wire brush

2.

Gear cleaning brush

3.

Feed hole cleaning wire

4.

Print head cleaning wire

5.

Specications

Printing

Printing technology 2D pattern: Inkjet printing

3D structure: Fused lament fabrication (FFF)

Dimensions and Weight

Dimensions (W*D*H) 600* 581* 640 mm

Net weight 32 Kg

Gross weight 43 Kg

Performance

Printing dimensions (W*D*H)

Thickness of printed layer 0.1 mm ~0.4 mm

Alignment precision X/Y : 0.0125 mm

Auto calibration Yes

Auto feeding Yes

Ofine standalone printing Yes

Mono color printing (without inkjet printing)

200 x 200 x 150 mm

Full color printing

185 x 185 x 150 mm

Materials

3D printing materials 3D Color-inkjet PLA, PLA, Tough PLA, PETG

Filament diameter 1.75 mm

Ink type CMYK cartridge with separate colors

Hardware

Print head diameter 0.4mm

User interface 5” color touch screen

Print bed Non-heated, removable

Transmission USB 2.0 drive / USB cable / wireless transmission

Software

User software XYZmaker

Supported le format AMF, OBJ, STL, XYZ Format (.3w), .3CP, .3MF

Operating system Mac OS X 10.10 / 10.11 / 10.12

Windows 7 /8/10 (64-bit)

Temperature

Machine operating temperature 15-30°C

Cartridge storage temperature 15-35°C

Filament storage temperature 0-38°C

P4P4

Page 5

Unpacking and Installation

1

Move the printer to a table or platform. (Do not move the printer by

yourself as it is heavy.)

2

Remove the plastic wrap and PP.

3

Remove the packaging materials, top cover box, assessory box and plastic cover.

4

5

6

Remove the tape on the

body (4 in total).

7

Remove the foam on the

cartridge holder.

Open front door, remove the tape at mark printer door

post.

8

Remove the foam next to the guide screws on both sides, and then remove the foam under

the print bed.

9

Remove the cable tie and foam in front and back of the front

door.

Open the front door. Remove

the tape from the supporting

materials and print bed.

P5P5

Page 6

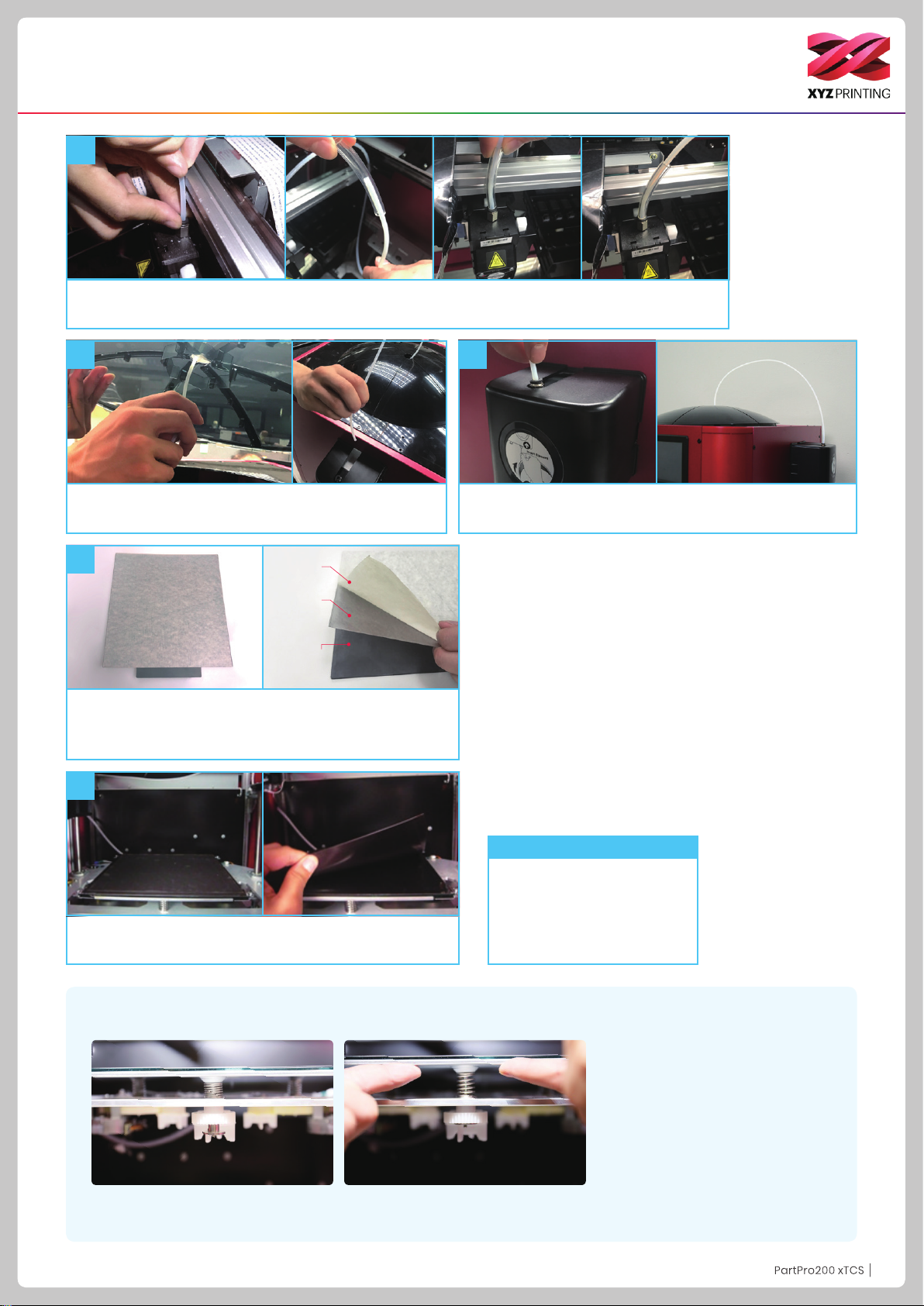

Unpacking and Installation

10

Ensure that the one end of guide tube(Accessory 8) has been tightly. inserted into the printing module

port, then insert the other end into the clear tube (Accessory 13) to the end.

11 12

Feed the guide tube through the top cover then attach the

top cover to the machine.

13

Please follow the order as image instruction, attach the PC

mylar (accessory 9) and mask tape(accessory 10) on the EZ

removable rubber magnet(accessory 6).

Mask Tape

PC Mylar

EZ Removable

Rubber Magnet

14

Conrm the rubber magnet is well placed on the print bed.

Insert the other end of the guide tube into the feed module

and secure it tightly.

Note

There is a sheet of PC lm to

rubber magnet with a double

sided adhesive, this PC lm is

replaceable, please replace it

when it's dirty or broken.

Precautions

1. Check if the print bed calibration screws

was stuck.

2. Used to 2 thumb to push up the printbed

to release the calibration screw.

P6P6

Page 7

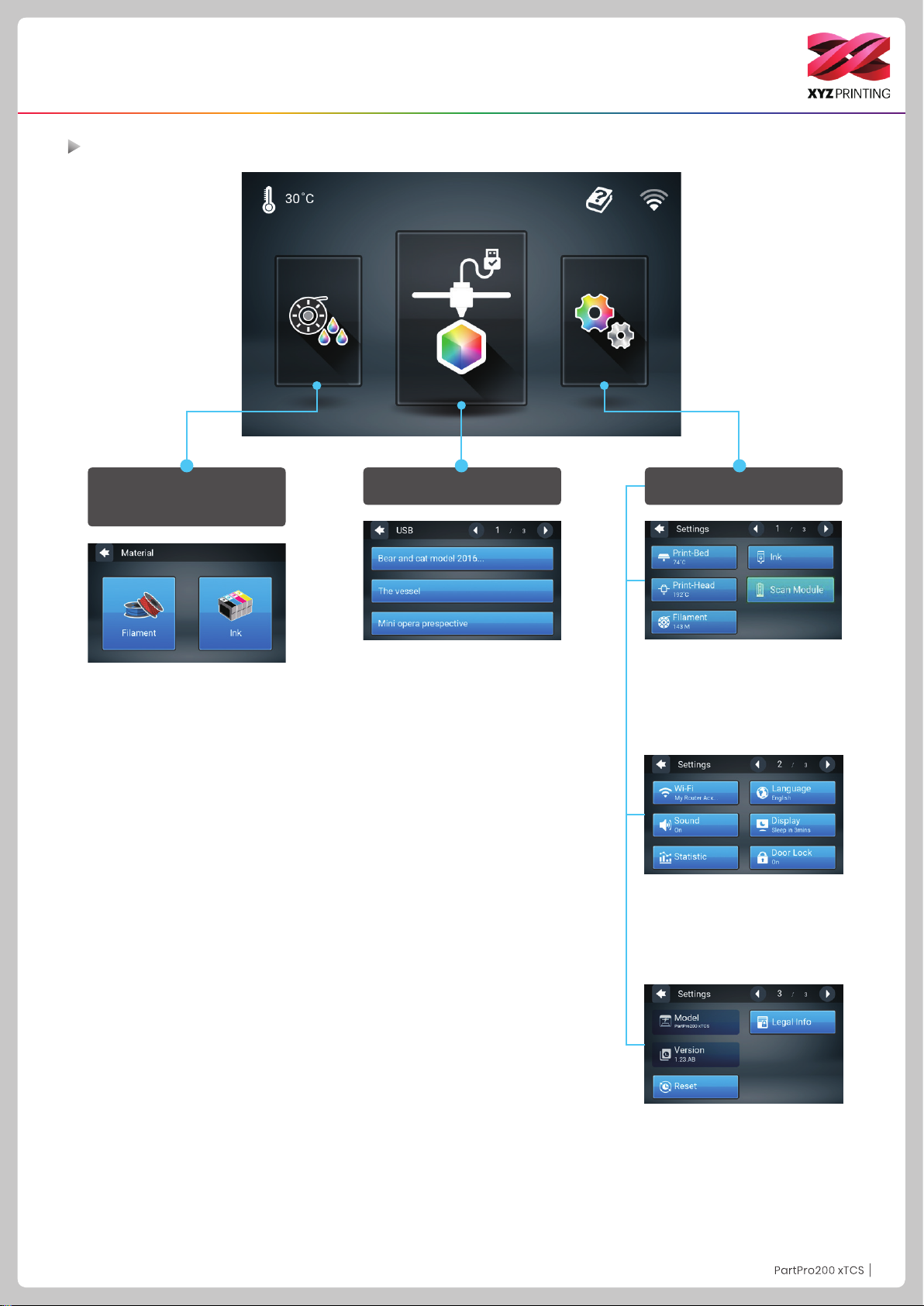

Touch Screen Menu, Functions and Messages

Main screen

Filament/Ink loading

and unloading

This includes Filament, Ink Load

and Unload.

USB Printing Menu

This menu can be used to import

les (.3cp) from a USB drive to the

machine for printing without a computer.

Settings

This includes the functions in Home

Page 1:

Settings of the Print-Bed, PrintHead, Filament, Ink and Scan

Module.

Next page includes

WiFi, Sound, Statistics, Language

and Display.

The last page includes

Model, Version, Reset and Legal

Info.

P7P7

Page 8

Function Operation and Instructions

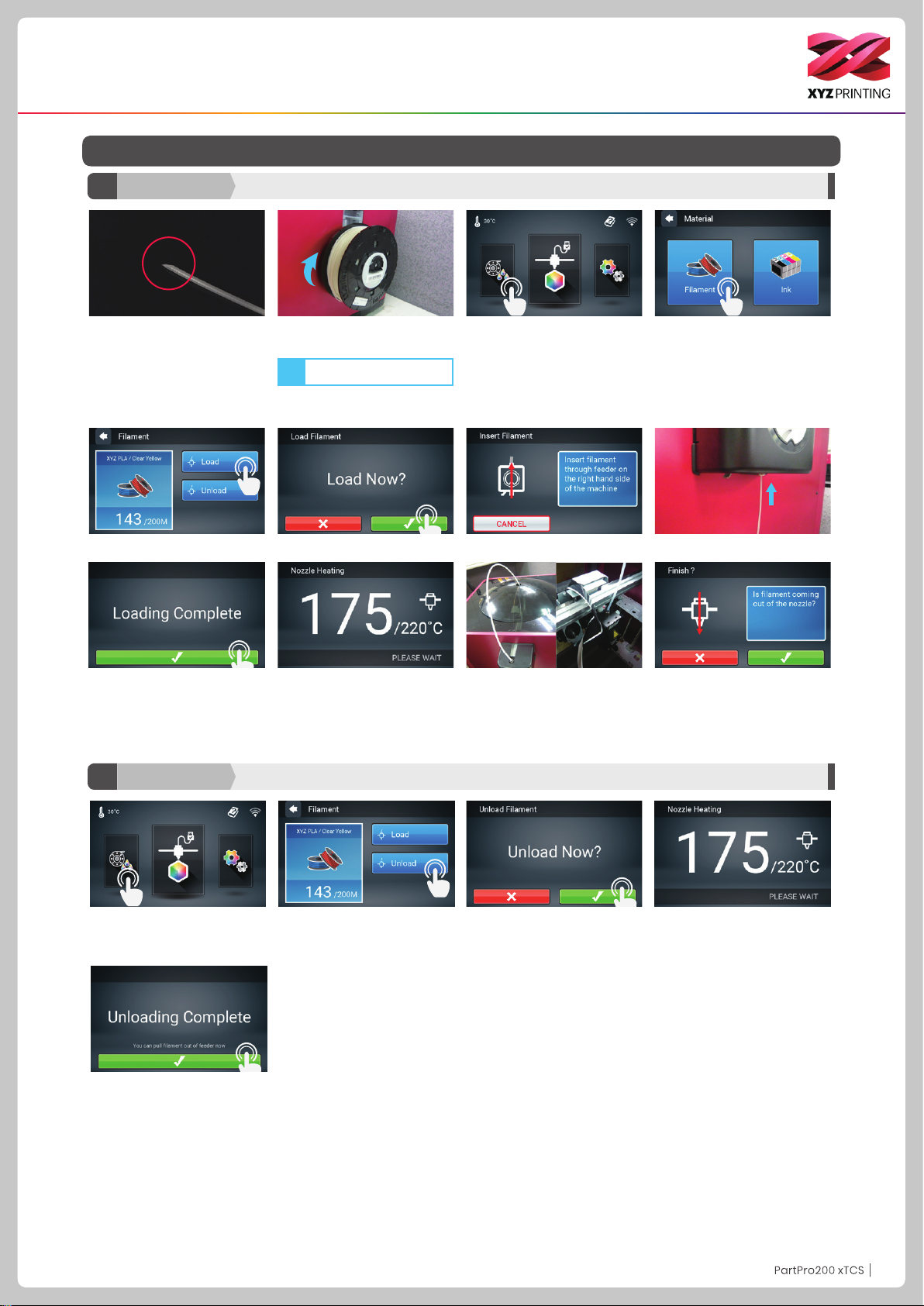

A. Load/unload laments

A1

1. Please cut the lament at 45

angle before auto loading the

lament into the printer. During

loading lament process, the

lament should be straighten at

least 4” of the Filament end as

shown in pictures.

5. Tap Load. 6. Conrm the operation. 7. Insert the lament into the feed module, it will be automatically loaded.

Filament

Load laments

2. Place the lament on the

spool holder.

Make sure the lament rotates

Note

clockwise when pulled.

3. Tap Filament Load and

Unload in the main screen and

select Filament.

4. Tap Filament.

8. Check if the temperature of the print head goes up to its operating temperature (Color PLA from

XYZprinting) after the lament is loaded. Once the set temperature is reached, the feeding motor will

feed the lament along the guide tube into the print head.

A2 Filament

1. Tap Filament Load and

Unload on the main screen.

5. When the unloading

operation completes, tap to

conrm.

Unloading laments

2. Tap “Unload” and conrm the

operation.

3. Conrm the unloading

operation.

9. Once lament has extruded

from the print head, the lament

will be successfully loaded.

Tap the screen to conrm and

continue.

4. When the print head has

been warmed up to 220 °C,

the feeding motor will eject the

lament.

P8P8

Page 9

Function Operation and Instructions

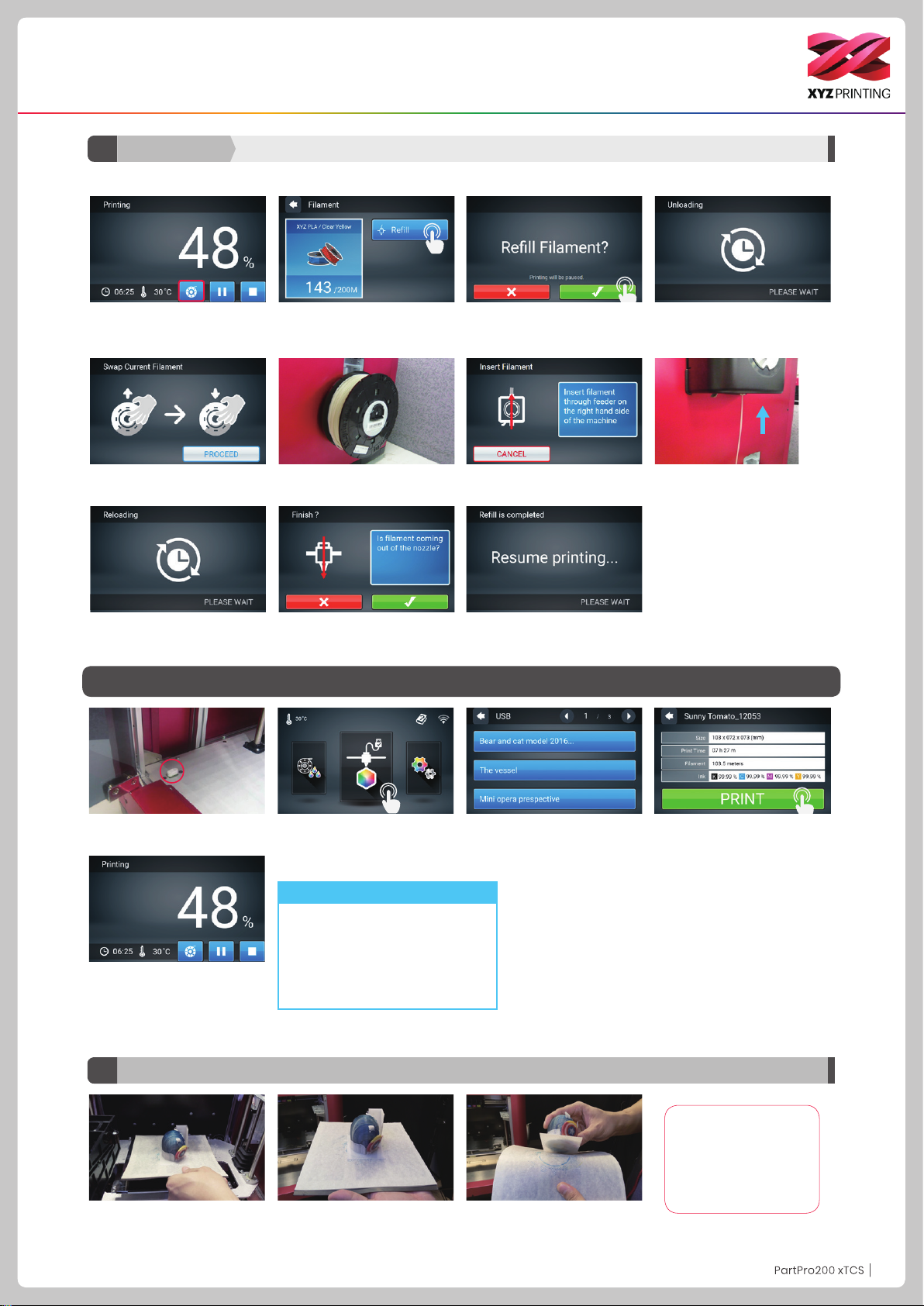

A3 Filament

200 xTCS will prompt you to rell material.

1. Tap the icon when printing.

5. Replace the empty spool with a new one. (please refer to the

LOADING section in this manual) and then tap "PROCEED" .

Rell Material

2. The screen will show lament

status, please tap "Rell" .

3. Conrm the operation.

6. The nozzle will be preheat and notify you when to insert lament

into the feed module.

4. The nozzle will be preheated

and the lament will be

unloaded automatically.

7. The lament will be

automatically loaded.

B. USB printing

1. Check if the USB drive is

plugged to the machine.

5. The screen will show the

print percentage when printing.

The Pause, Stop, and Rell

are shown below the print

percentage.

B1

Unload the prints

8. Check if lament is extruded from the nozzle, after conrmation,

the printer will resume printing.

2. Tap the USB Printing Menu in

the main screen.

3. Select the file you want to

print.

Note

By default, the front door will be

locked when printing. If you want to

change this setting, go to Setting >

Door Lock to change it.

4. Check file information and

tap “Print”.

Please removed the EZ Removable Rubber Magnet with printed object together from the printer.And

peel off the printed object from the rubber magnet.

Please avoid touching the led strip of the

printer because the

LED strip will be slight

hot due to long hours

of been light on.

P9P9

Page 10

Function Operation and Instructions

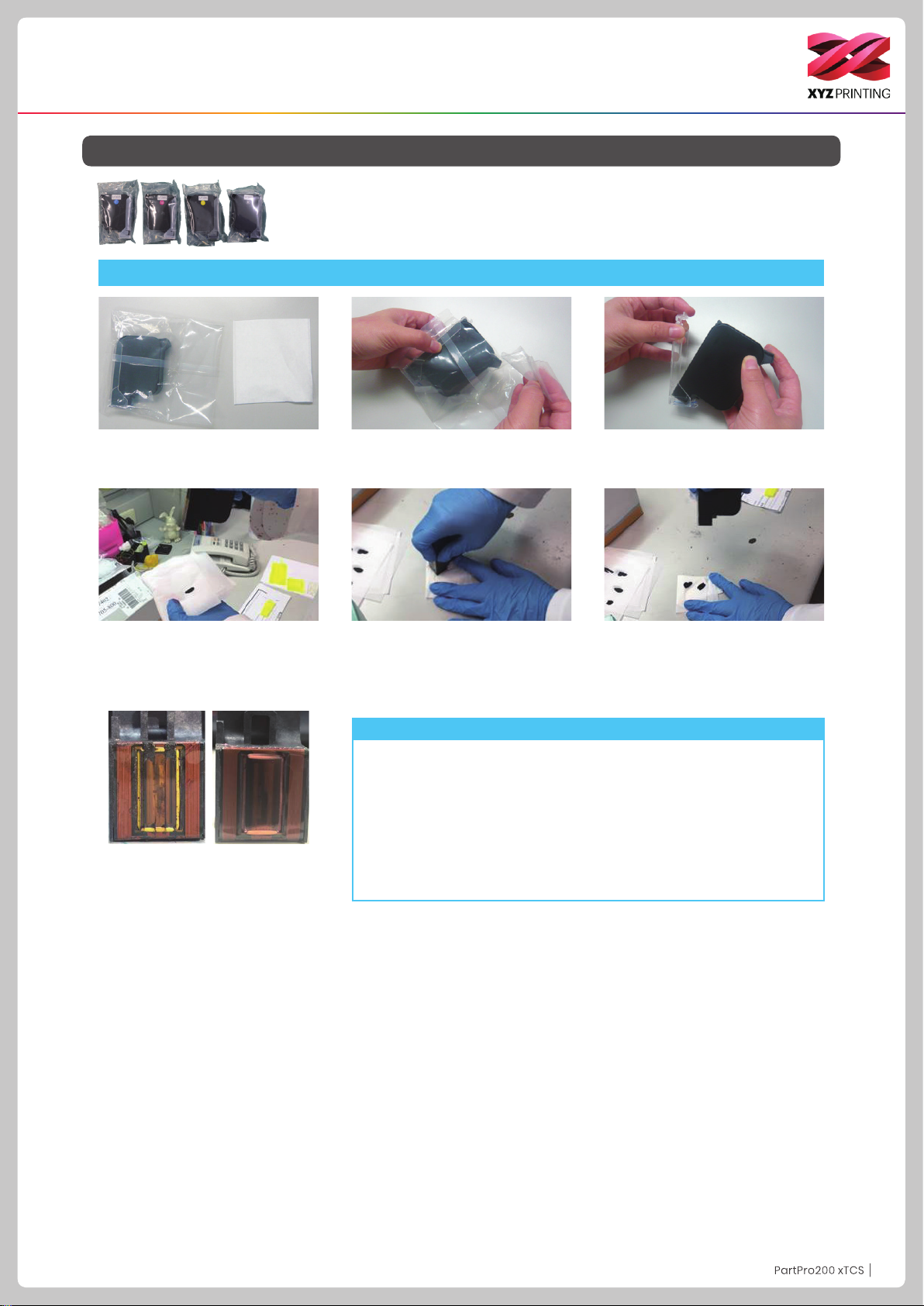

C. Ink Cartridge Installation

The 200 xTCS uses four color inks which can be replaced separately.

Ink Guidance

1. Prepare several paper towels and the

ink cartridge.

4. Press the cartridge head against the

paper towel to transfer some ink onto it.

7. If the ink did not transfer well, please

wet the paper towel with 75% Alcohol to

wipe the ink. After you clean the inkjet,

check to see if the ink transferred.

2. Unpack the ink cartridge. 3. Remove the cartridge cover.

5. If the ink did not transfer well, try

putting the paper towel on the table and

hold the ink pressed on the paper towel.

6. Check if the ink transferred to the

paper towel displays two straight lines.

If so, ink guidance is successfully

completed. Once ink guidance is done,

install the ink cartridge.

Note

To prevent the opened ink cartridge from drying out when a print is

nished or the printer will be idle for days, follow the procedure to store

the cartridge:

1. Clean the nozzle of the ink cartridge with alcohol.

2. Seal the ink cartridge with the protective cover, and store the cartridge

in room temperature at 15 ~ 35 degree.

For the best print quality, clean the nozzle of the cartridge with alcohol

after removing the protective cover from the cartridge, and then install the

cartridge back to the printer before the next print.

P10P10

Page 11

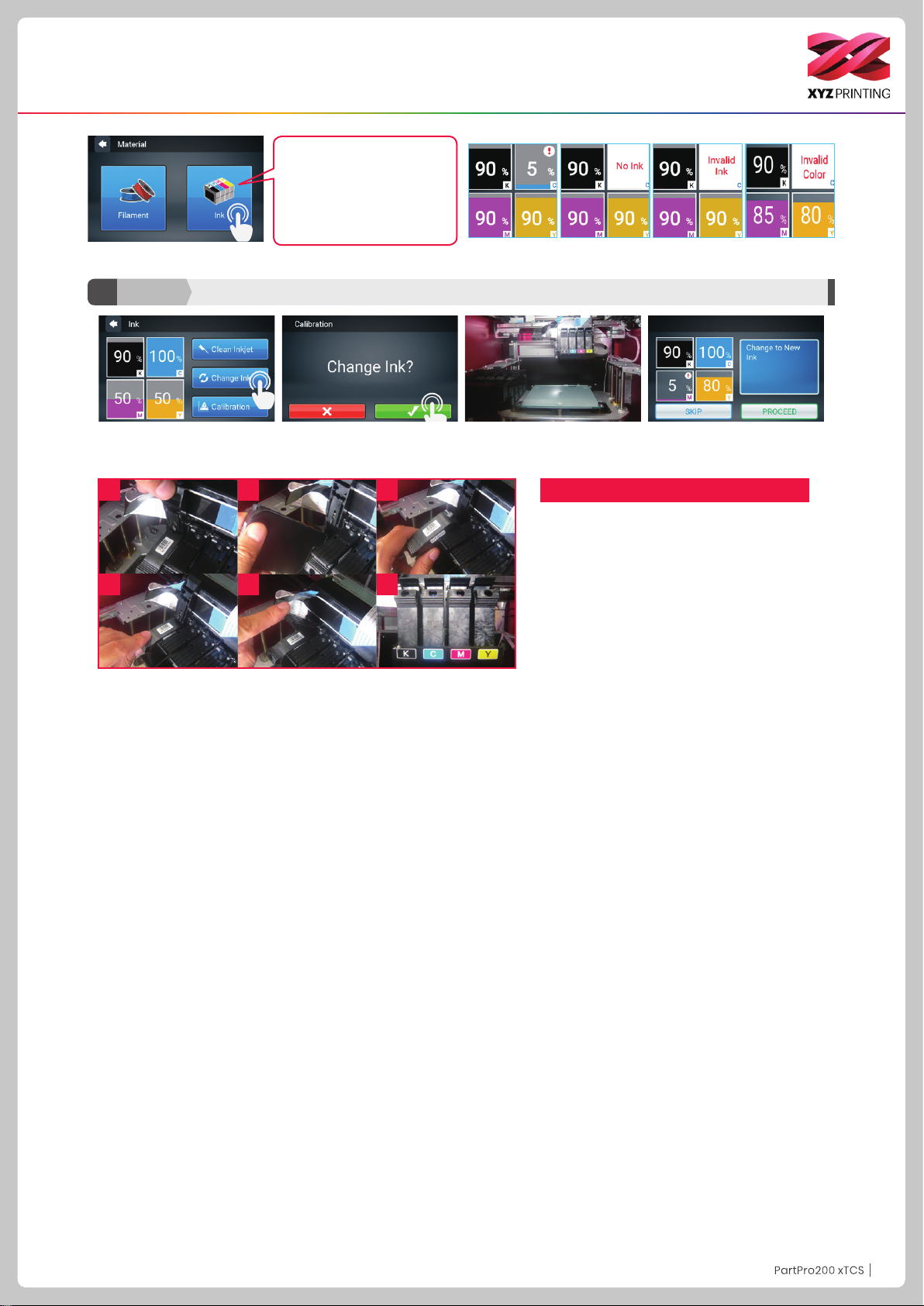

Function Operation and Instructions

Tap the ink, the screen will

show the status of the ink,

including "Ink Low", "No Ink",

"Invalid Ink", and "Invalid Color"

Change InkC1 Ink

1. Tap Change Ink and tap to

conrm.

1

4

2

5

2. Conrm the operation.

3

6

3.Wait until the cartridge moves

to the center of the print bed,

and then change the ink.

Cartridge Installation

1. Lift up the plate upwards.

2. Take out the cartridge.

3. Put in a new cartridge.

4. Check if the cartridge is placed properly.

5. Press down the plate on top.

6. Check if the order of the ink color is K(Black),

C(Cyan), M(Magenta) and Y(Yellow) from left

to right.

Note : Replacement of any ink cartridge, please

conduct inkjet calibration test.

4. Tap the PROCEED after you

change.

P11P11

Page 12

Function Operation and Instructions

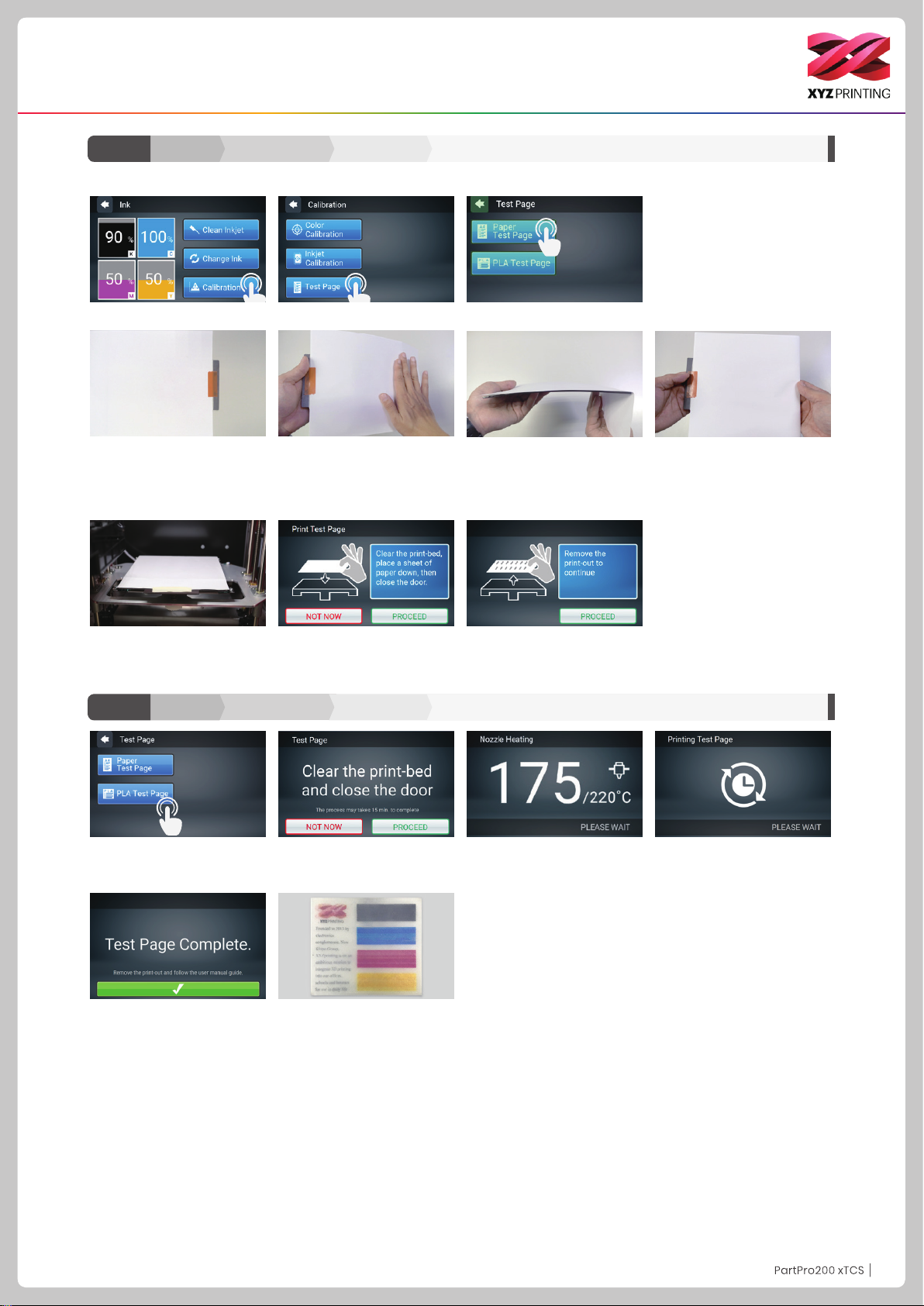

C2-1

We suggest you print a test page after you install the ink cartridge. Please prepare a sheet of paper.

4. Take out the EZ Removable

Rubber Magnet. Use tape to

secure the A4 in the portrait

direction on the front side of the

rubber magnet.

Ink

Calibration Test Page

2. Tap Test Page.

5. Tighten/pull the A4 paper so

it is at(no gap) on the rubber

magnet.

Paper Test Page

. Test Page.1. Tap Calibration.

3

6. Fold tightly the excess A4 paper to the back of the rubber

magnet.

7. Put the rubber magnet back

to print bed accordingly.

Calibration

1. You can also choose to print

the "PLA Test Page" to conrm

the ink status.

5. Conrm if the print job is

completed.

8. Fix the paper onto the print

bed and then tap PROCEED,

the printer will do a test print.

9. Remove the test page and

tap PROCEED.

Test PageInk PLA Test PageC2-1

2. Tap “PLA Test Page" to print. 3. Wait for the extruder to heat

6. Taken off the printing object

and check the coloring status.

up to operating temperature.

4. Printing "PLA Test Page".

P12P12

Page 13

Function Operation and Instructions

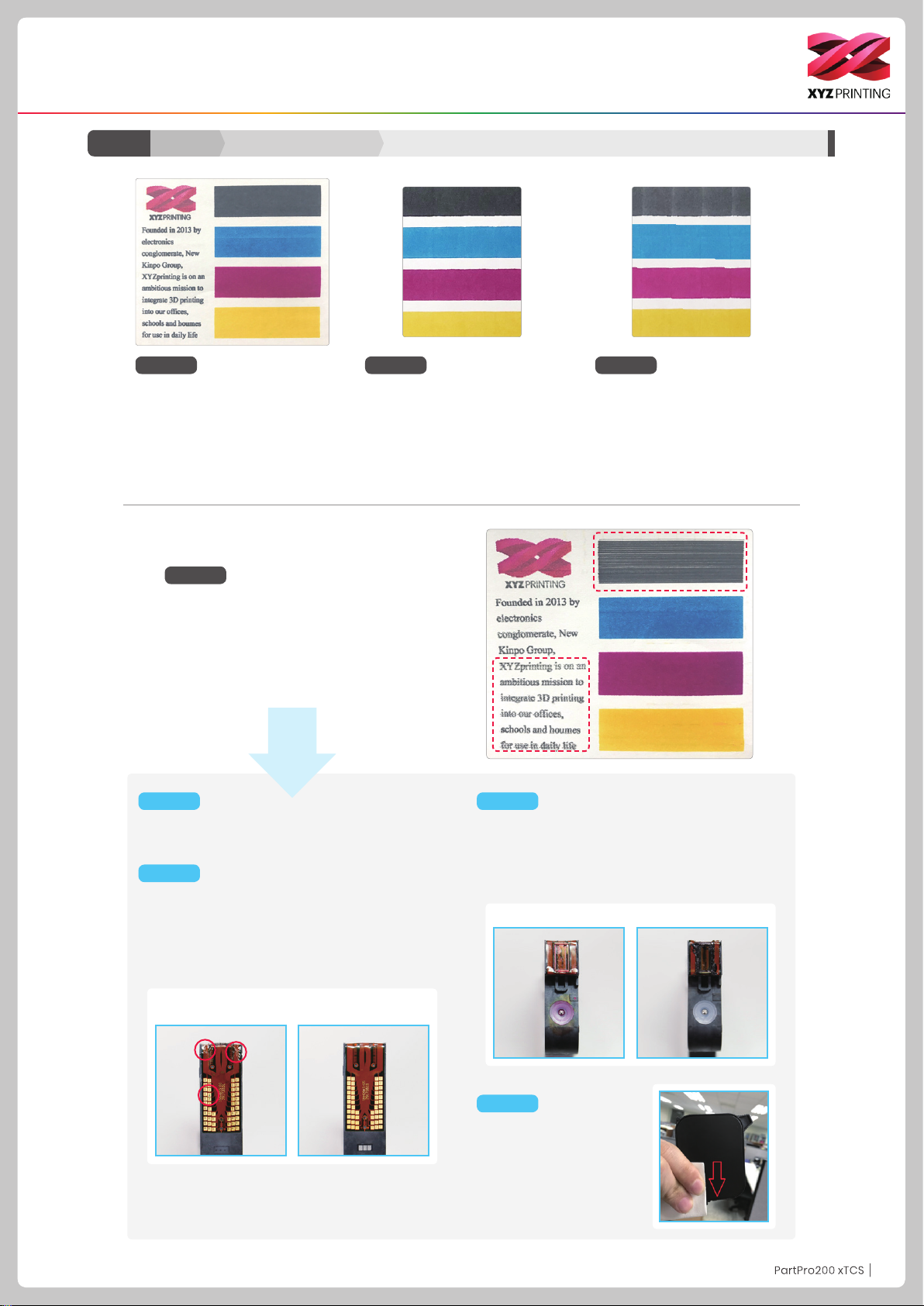

Ink Calibration

Pic 1 Pic 2 Pic 2-1

Picture 1 shows an example of

normal test page.

Pic 3

Picture 3 show example of no good test page.

While line was shown horizontal and vertical

color of bars.

Please conduct the below steps accordingly.

Ink Cartridge TroubleshootC2-2 Ink

Picture 2 show some slight color

offset on horizontal part of test

page.

It is under acceptance range. If the

rprint of the test page gets worst,

please proceed with the cleaning

procedure.

Picture 2-1 shown some slighly

black ink smudge on the horizontal & vertical part, it may happen

to other color.

This is within accaptable range

Stept 1

Please reinstall the cartridge and print the test page.

If problem not solved, please proceed with step 2.

Stept 2

Check for any torn cable or damaged contacting pad

in shown example.

If found torn cable, please change new cartridge

If found damaged contacting pad and also the pin in

cartridge station was also damaged, contact support

for replacement.

NG Cartridge

(Torn cable & pad)

Note : Please refer to our support website for

latest ink cartridge cleaning procedure.

Please refer C2-1 for preparing the A4 test page.

Normal Cartridge

Stept 3

Check for possible clog ink head cartridge as example shown.

Please conduct cartridge cleaning process in Pg 10

ink guidance paragraph.

If problem not solved, please proceed with step 4.

Clean Ink Head Clog/dirty Ink Head

Stept 4

Using paper towel to cover

the ink cartdrigde as shown in

the picture 4 and downward.

If the ink comes out, please

print the test page.

If not solved, please change

the new ink cartridge.

P13P13

Page 14

Function Operation and Instructions

Calibration

4. Take out the printed paper and tap

PROCEED.

Color CalibrationC2-3 Ink

3. Please x the printing paper onto the print bed.1. Tap Calibration. 2. Tap Color.

5. Check the printed calibration chart using the onscreen instructions. For each color select the line that

is the best aligned with black (K).

6. For horizontal alignment, enter each

color’s corresponding number. After

entering the number, tap PROCEED.

7. For vertical alignment, enter each

color’s corresponding number. After

entering the number, tap PROCEED.

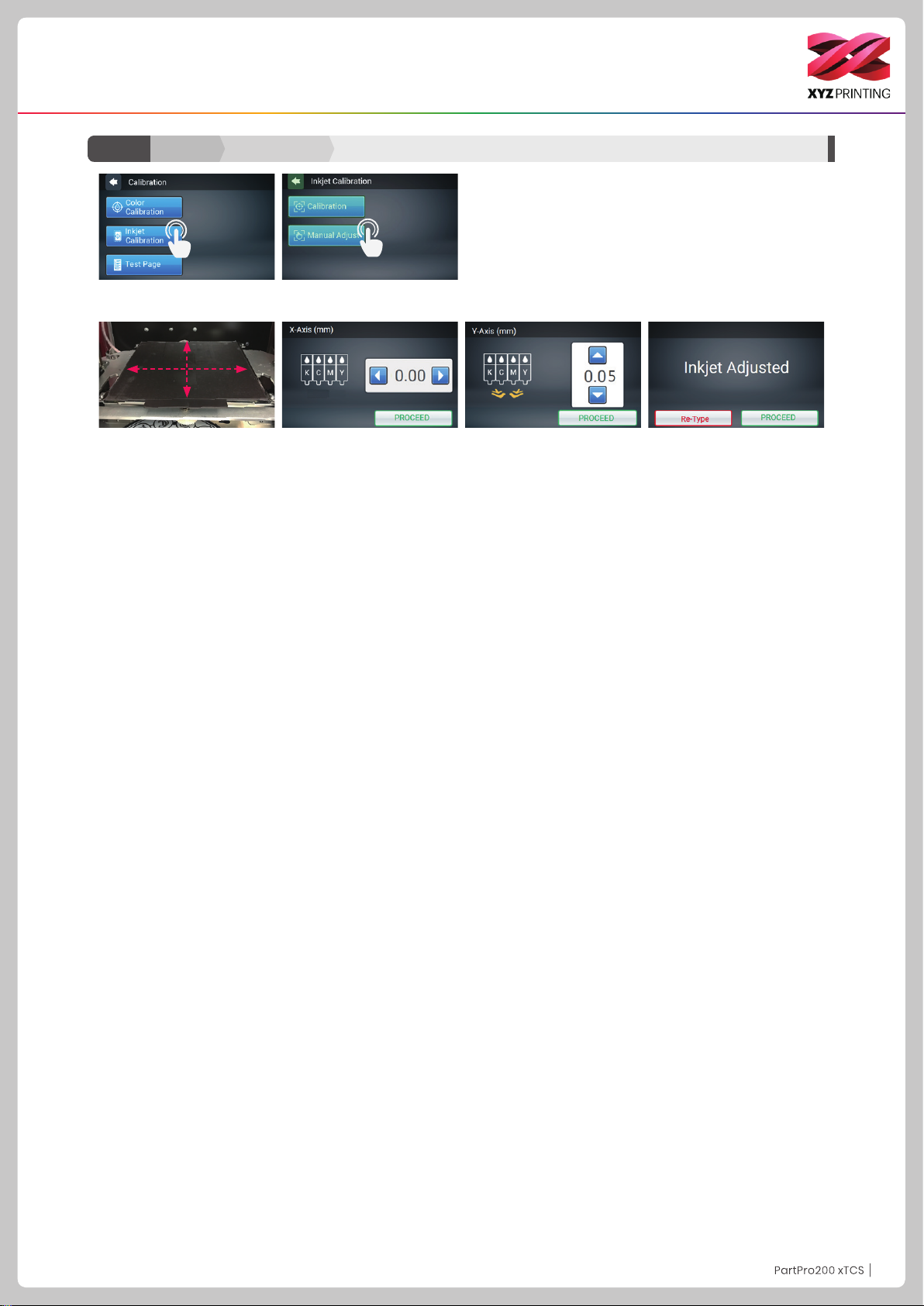

Calibration Inkjet CalibrationC2-4 Ink

1. Tap Inkjet Calibration. 2. Inkjet Calibration.

Caution: Please ensure the EZ Removable Rubber Magnet had

placed in the printbed.

5. The printer will print the

calibration card automatically.

This takes approximately 15

minutes. (Make sure you have

loaded the lament.)

8. Confirm the numbers entered in the

boxes and tap PROCEED.

3. Check that the print bed is

clear, then close the door.

6. After the printing is completed,

take out the calibration card.

4. The printing operation will

start once the print nozzle is

warmed up.

7. Horizontally and vertically,

nd the box where the ink is

the most aligned, and then tap

PROCEED.

8. Vertical direction: Enter the

number of the box you think the

lament and ink align the most,

and then tap PROCEED.

9. Horizontal direction: Enter

the number of the box you think

the lament and ink align the

most, and then tap PROCEED.

10. After the calibration is

completed, tap PROCEED to

nish the ink calibration.

P14P14

Page 15

Function Operation and Instructions

C2-4 Ink

1. After the color object is printed, if you nd color shift, you can

adjust the print position manually.

Y-Axis

2. The adjustment position

of X-Axis and Y-Axis was the

sample position, when facing

the printer.

Calibration Inkjet Calibration

X-Axis

Manually adjust the

movement of X-Axis

Select “X-AXIS” to move rightwards and leftwards.Press the

“Left” or “Right” button to select

the direction and distance to

be adjusted, each adjust has a

step of 0.05 mm.

Manually adjust the

movement of Y-Axis

Select “Y-AXIS” to move upwards and downwards.Press

the “Up” or “Down” button to

select the direction and distance

to be adjusted, each adjust has

a step of 0.05 mm.

Once parameter settings are

completed, tap "PROCEED" to

save and apply the settings that

you have specied.

If you want to reset, select “Re-

Type” to return to the X-Axis

moving position setting.

P15P15

Page 16

Function Operation and Instructions

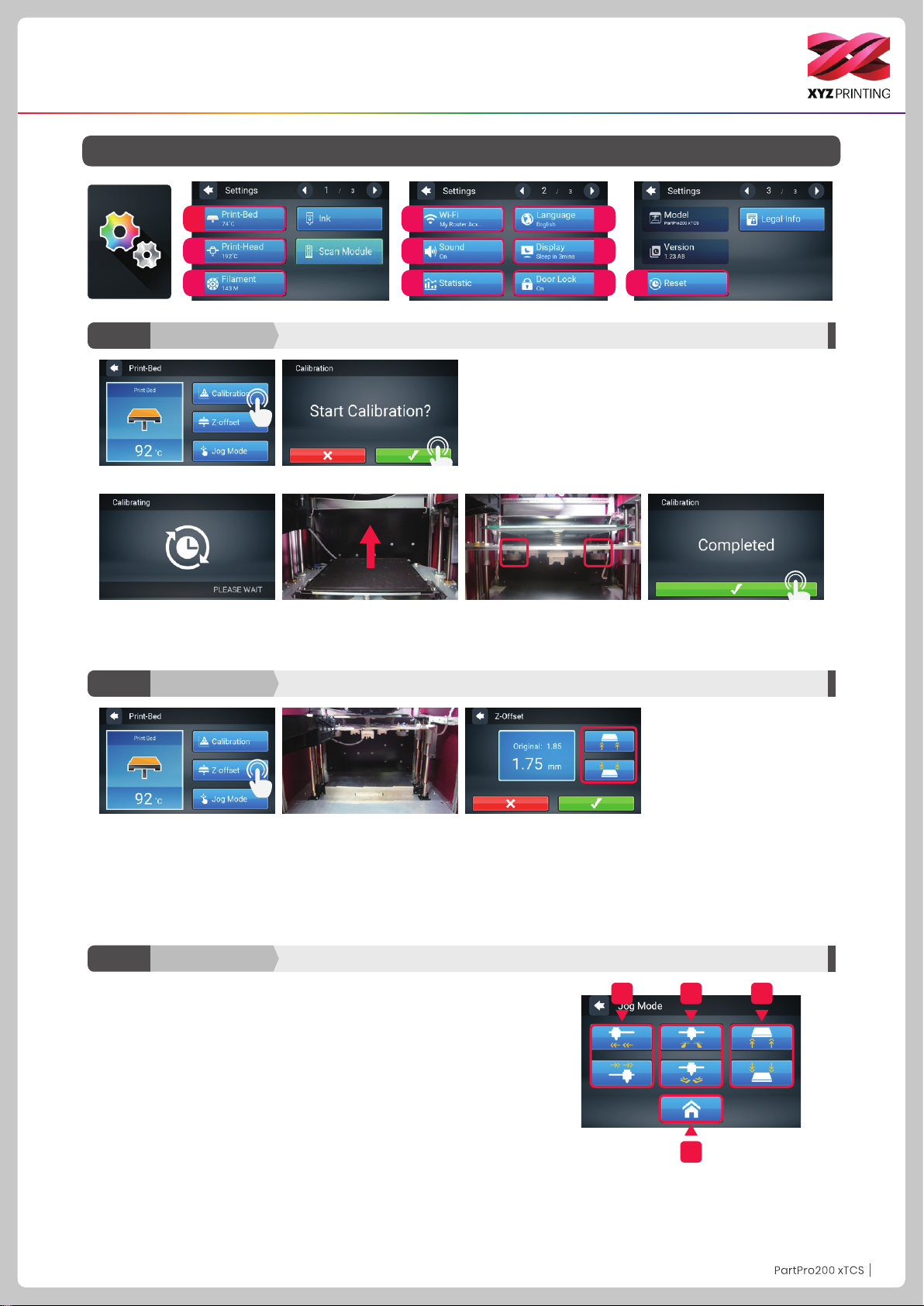

D. Setting

D1

D2

D3 D10

D1-1

1. Select Calibration. 2. Conrm the operation.

3. Wait while the sensor measures the height of the print bed at three different locations. Once the

measurement is complete, the printer will automatically level the print bed.

Caution: Please ensure the EZ Removable Rubber Magnet had placed in the printbed

Print-Bed

Calibration (leveling)

D4

D6

D8

D5

D7

D9

4. After the calibration is

successfully completed, tap to

conrm.

D1-2

1. Tap Z-offset. 3. Users can tap the icon to

Print-Bed

Z-offset

2. Move the print head to the

center of the print bed. It is

recommended that the space

between the print head and

the print bed just touch and the

nozzle can move smoothly on

the print bed.

higher or lower the print bed,

the higher value the bigger

distance and vice versa.

Jog ModeD1-3 Print-Bed

Jog mode lets manually move the print head via the touch screen.

How to move the print head:

1. Return to the Home point. Always return to the Home point prior to any movement in any direction.

2. Move along the X-axis.

3. Move along the Y-axis.

4. Move along the Z-axis. (Do not increase/shift upwards when print head at home

position avoid hitting the print bed.)

32 4

1

P16P16

Page 17

Function Operation and Instructions

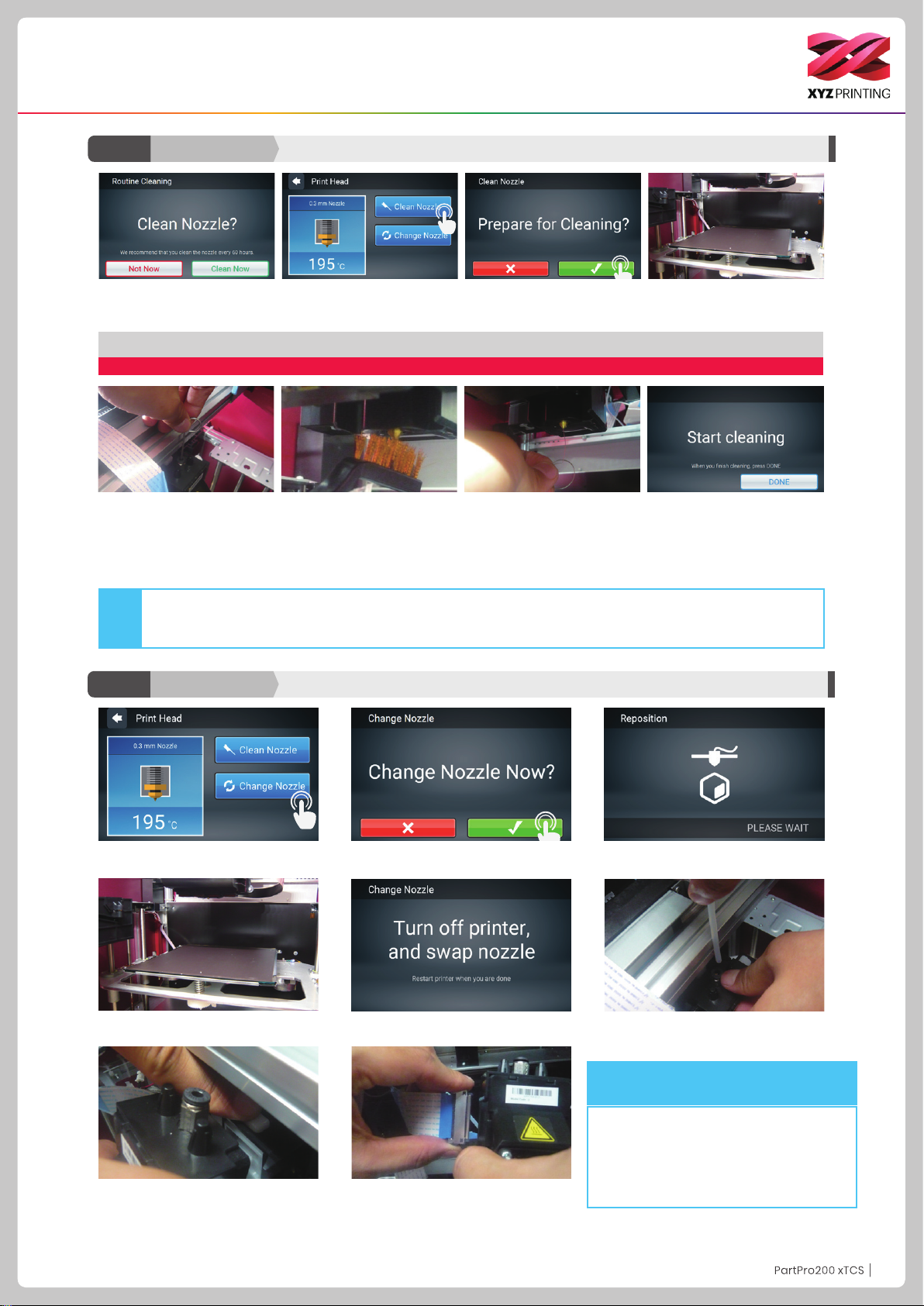

D2-1

1. Please clean the nozzle after

printing 60 hours.

Print-Head

Clean Nozzle

2. Tap Clean Nozzle in the print

head section.

3. Check if cleaning is necessary. Tap Check to clean it.

When the temperature of the print head reaches the operating temperature, the cleaning operation will start.

Note: do not touch the metal part of the print head as it becomes hot during the operation.

4. Inset the feed hole cleaning wire

into the feed hole and push it down-

wards to drive out the lament from

the print head. (It is recommended

that the operation is performed from

the top of the machine.)

In order to prevent print quality from impact due to residual and accumulated lament, which results in poor discharge, after

long-term use of print nozzle, it is recommended to enable the "CLEAN NOZZLE" (nozzle cleaning) function of the printer every

Note

60 hours of print to clear residuals with nozzle cleaning wire or feeding path cleaning wire. (Filament should be unloaded

from the extruder before cleaning the feeding path.)

5. Remove the lament residue from

the print head with a wire brush.

6. Insert the print head cleaning wire

into the nozzle from the bottom to

clean it.

7. After the cleaning operation is

completed, tap DONE.

D2-2 Print-Head

1. Tap Change Nozzle. 3. Wait until the print head moves to a proper

4. The position of the print head change is

shown above.

Change Nozzle

2. Tap to conrm that you want to change the

nozzle.

5. Turn off the power before changing the

print head.

position for change.

6. Change the print head from above the

machine.

Installation sequence of new print head:

1. Connect the bus.

2. Press the white release button on the print head

and assemble the print head and the mechanism.

After attaching the print head, check to see that it

7. Press the white release button to separate

the print head.

8. Hold the print head with one hand and

remove the bus with the other. The removal

of the print head is completed.

is secure and does not shake.

3. Turn on and use the printer.

P17P17

Page 18

Function Operation and Instructions

Filament

D3

Refer to the Change Filament function in the main screen. Unused lament for one day of longer should be stored in zip-lock bag.

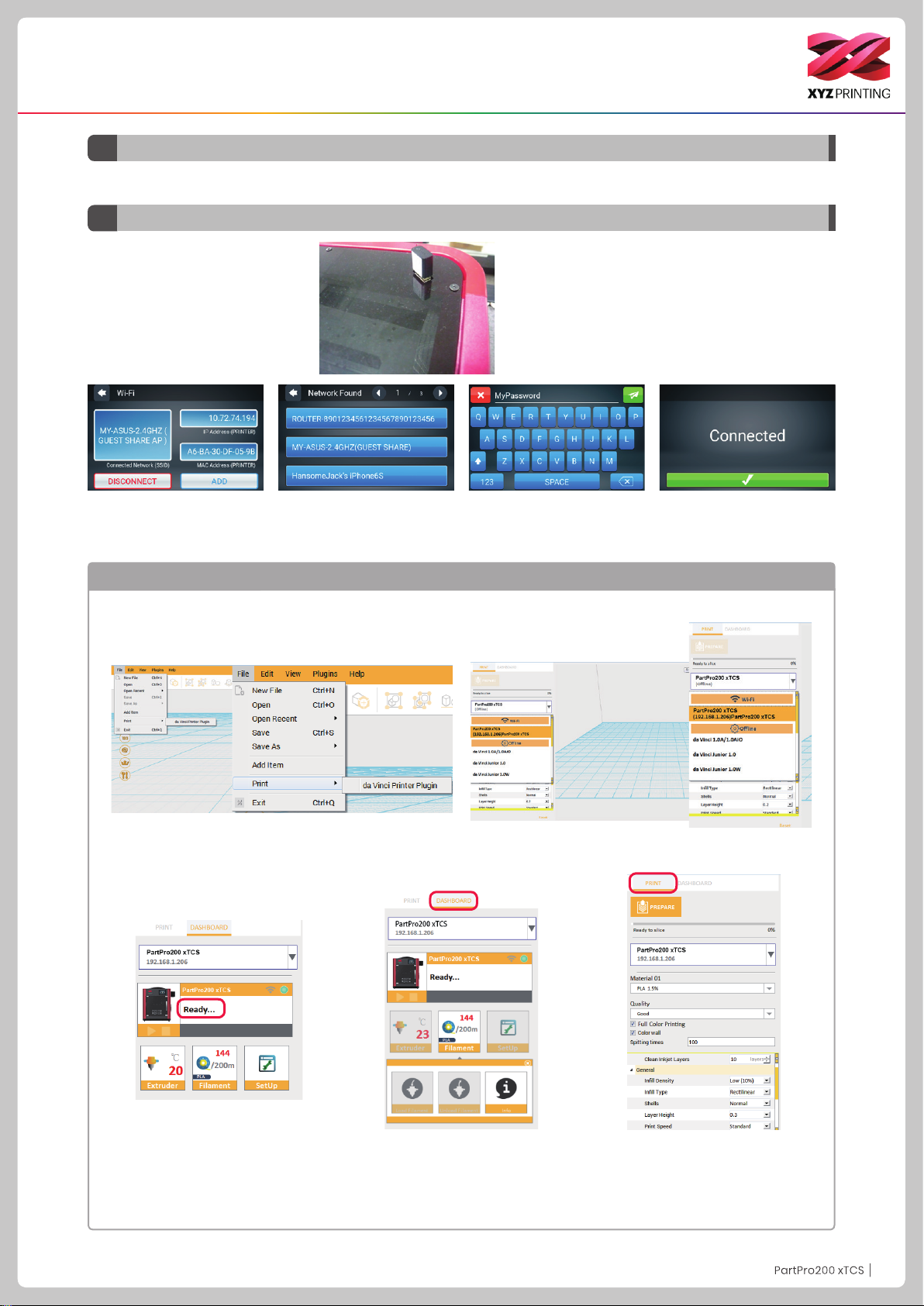

WiFi

D4

Before turning on the printer and setting

up the WiFi network, please insert the

WiFi dongle into the USB port on the

top of printer.

1. Tap ADD and the printer will

start to search for available

access points.

2. Tap the access point to be

used.

3. Enter the password for the

access point.

4. Conrm the connection is

completed.

Use the XYZmaker to verify if the WiFi connection is established successfully

●

Use a USB cable to connect the printer to the computer and run the XYZmaker.

●

Check if the WiFi function is activated on the computer and connect to the access point.

1. Run the XYZmaker. Click on File > Print > da Vinci Printer Plugin. 2. Select the printer to be used.

3. When the software displays ”

connection is established successfully.

Now, you can click on “DASHBOARD” to

monitor the printer or “PRINT” to print a

le.

READY

”, the

DASHBOARD:

ture, filament used and filament loading /

unloading.

Monitor print head tempera-

PRINT:

Set printing parameters and quality.

If only a le conversion is needed, tap “PREPARE”.

P18P18

Page 19

Function Operation and Instructions

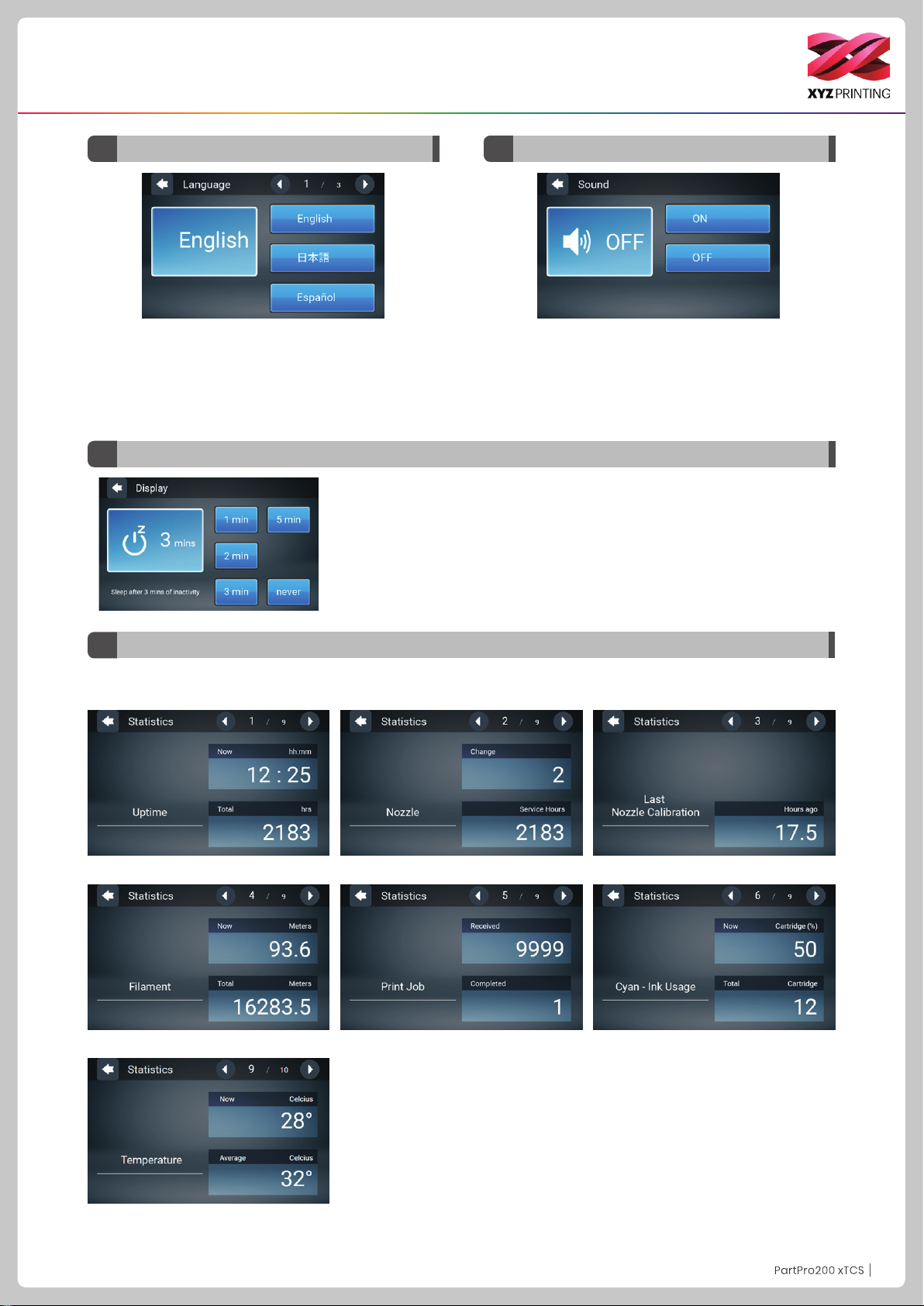

Language

D5

Change Language Setting

The 200 xTCS provides eight display languages,

including traditional and simplied Chinese, English,

Japanese, German, Italian, Spanish and French.

The language setting can be changed by tapping

Settings > Languages in the main screen.

Display

D7

The Display setting can set the touch

screen to turn off when it remains inactive after a set time. There are five

settings, including one minute, two minutes, three minutes, five minutes and

always on.

Sound

D6

The Sound option can be set to ON or OFF to control

the sound emitted when the touch screen is tapped

Statistics

D8

The Statistics function can record the history data since the printer was turned on, including:

Uptime

Filament

Temperature

Nozzle

Print Job

Last Calibration

Ink Cartridge

P19P19

Page 20

Function Operation and Instructions

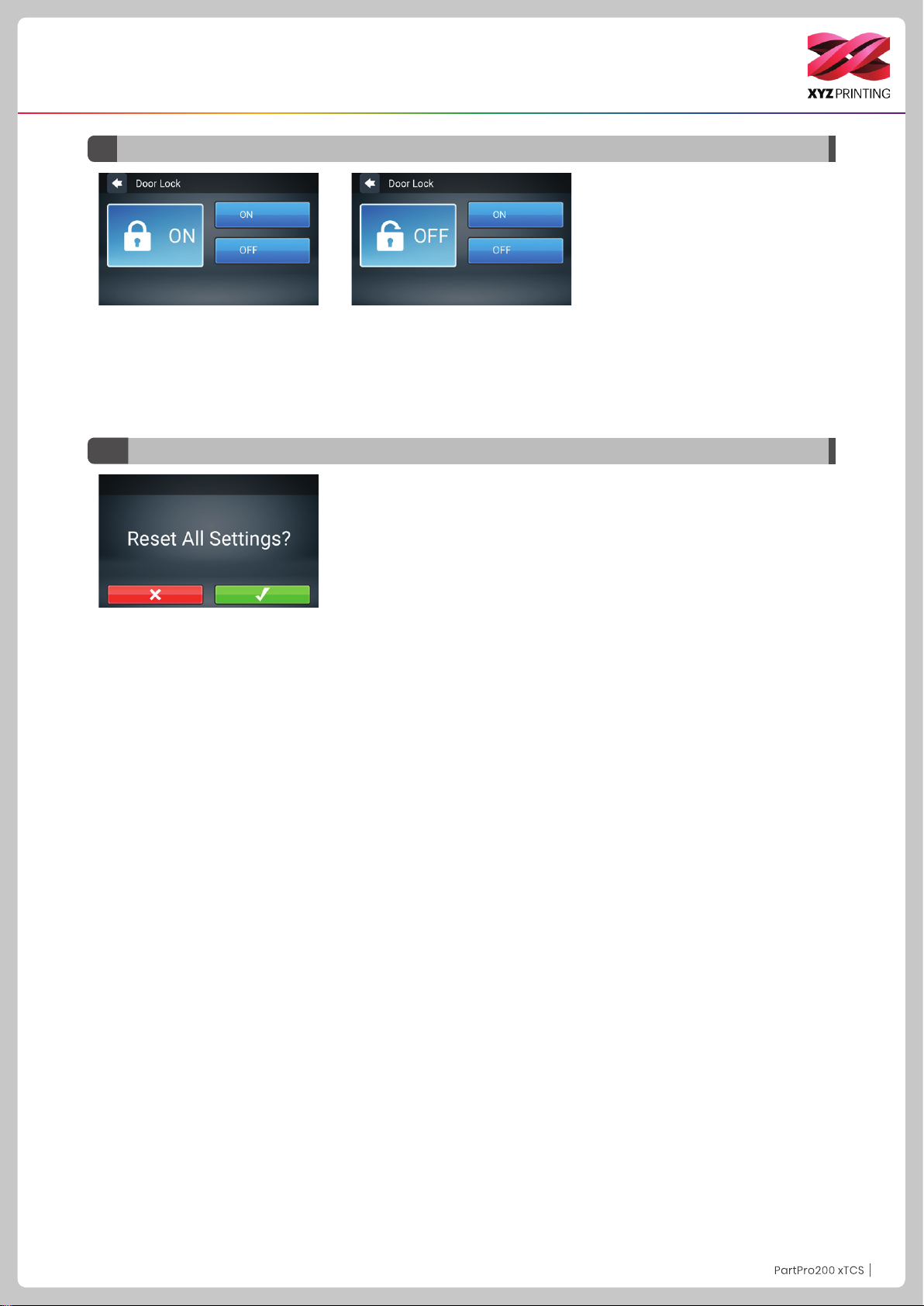

Door Lock

D9

1. Door lock on (ON) : when printing,

the door will be locked; 60 sec after

the print ends, the door will unlock. The

door will be unlocked when users tap

Pause or Stop during printing. The door

will lock again, when the door is closed

and printing is resumed.

D10

Reset

2. Door lock off (OFF) : the door won't

be locked during printing, pause, or stop

status.

Printer information will be deleted,

and returned to factory settings.

P20P20

Page 21

Printing

First-time printing

Users are able to do a rst print by following the steps below.

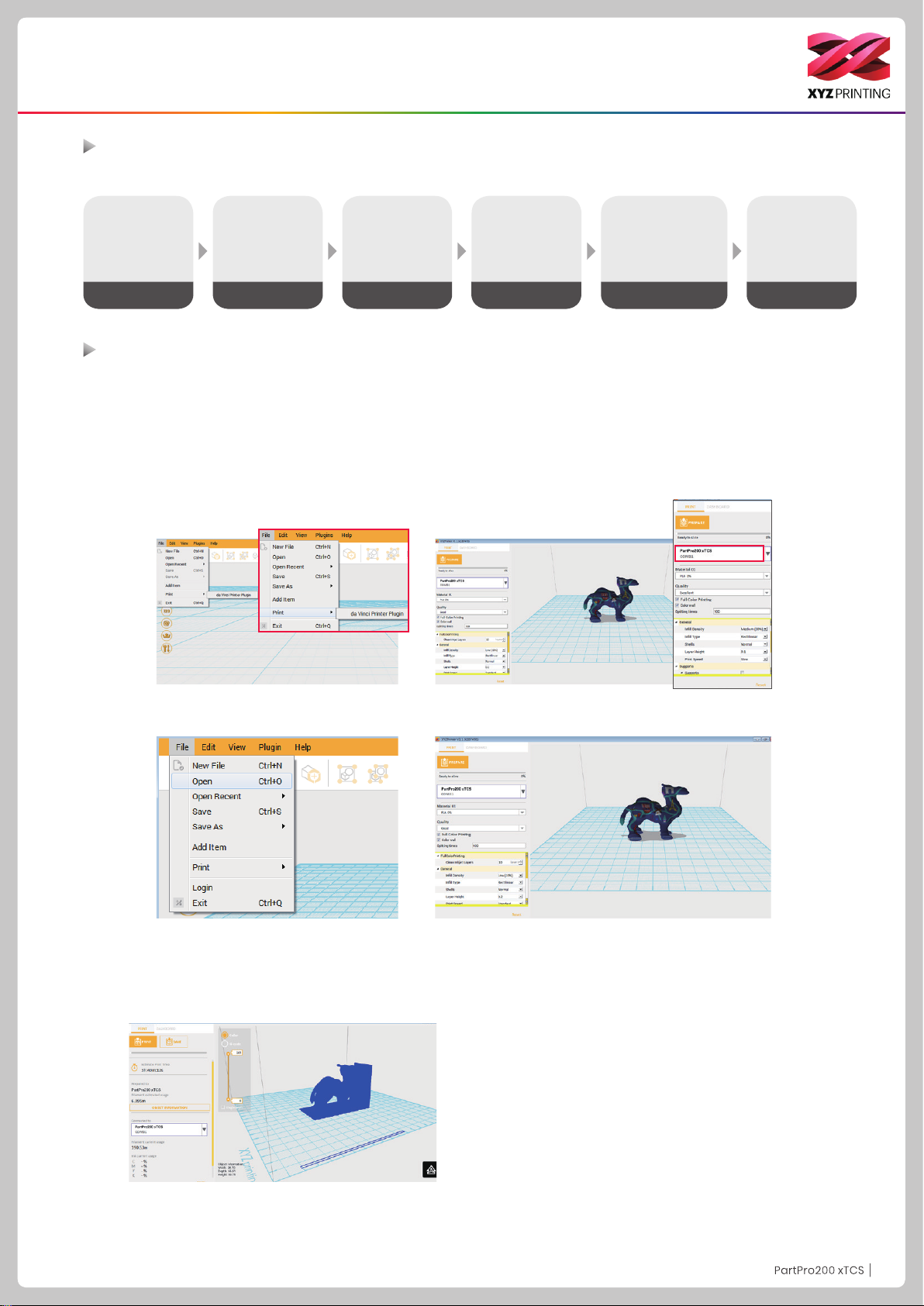

Calibration Z-offset Load Filament Change Ink

D1-1 B C C A

D1-2

- Test Page

- Color Calibration

- Ink Calibration

Calibration

Prepare the

le and then

execute the

printing

Transfer les to be printed via the computer software “XYZmaker”

Internet access is required for product registration and software login.

Connect the printer and computer with a USB cable and install the “XYZmaker” on the computer to transfer the les you want to

print.

The “XYZmaker” is compatible with 64 bit operating systems of Windows and Mac OS 10.10 10.11 and 10.12. You can install it by

using the included USB drive or downloading the installer from the ofcial XYZprinting website. The user manual of the software

can also be downloaded from the ofcial website.

For details, visit the ofcial website: http://www.xyzprinting.com/

1. Connect the computer and printer and select PartPro200 xTCS.

2. Click on OPEN to select the model le to be printed from

the folder. You can adjust the object size, printing position

and angle once the le is loaded. To print color objects,

save the le to be printed in the obj format and load it in

the XYZmaker.

3. You can change related settings to the desired printing result

and effect.

4. The Prepare function can convert a obj le to a .3cp le.

Once the le is edited and adjusted, click on Print to output

the object. The printing operation will start after the le is

sliced.

P21P21

Page 22

Scanning

Mount the scan module in the machine (see the installation steps) and install the “XYZscan Color” software on your

computer to operate the scanning fuction of your 3D printer.

Face the front side of the object to be scanned toward the scan module and it takes about 10-40 minutes to scan it,

depending on computer performance and scanning quality. When you scan an object, the turntable rotates clockwise. At

this time, the camera on the scan module will capture continuous images at a speed of 30 images per minute. When the

scan is completed, “XYZscan Color” will display the 3D image captured in the 3D image.

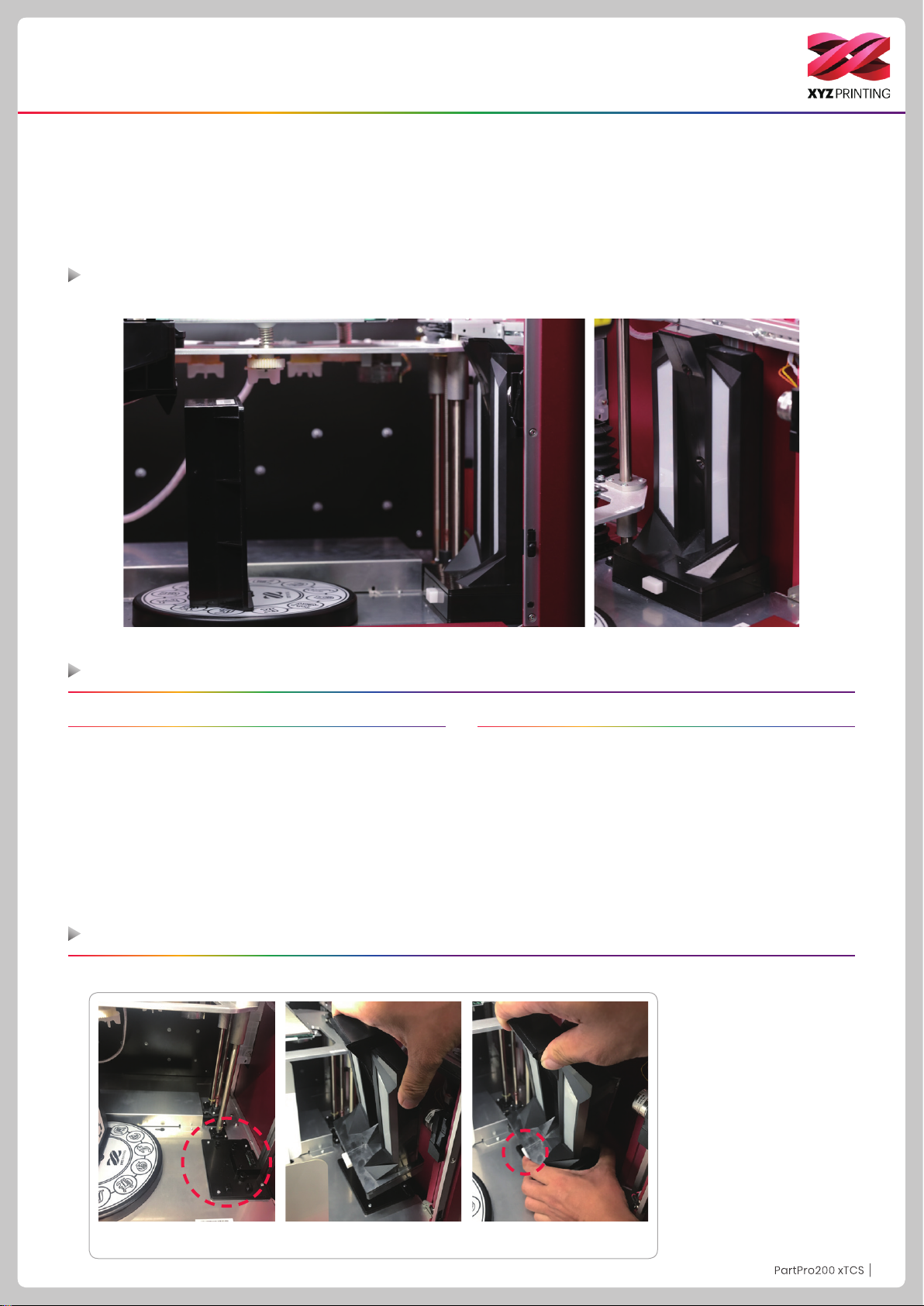

Product Overview

Scan Module

Hardware Requirements

Operating systems Windows 7, 8.1, 10 (64-bit)

Minimum system

requirements

CPU 4th Generation Intel® Core™ i5

USB 2.0

8GB/ Hard disk or more

Support the OpenGL 2.1 or above graphic

card

Scan Specication

Scan Technology Photogrammetry 3D

Scan Resolution

(Diameter x H)

Scan Software XYZscan Color

Turntable Payload ≦ 3 Kg/6.6lbs

Rescolution 5M pixel

Scan Accuracy 1.48 mm

File Types OBJ, STL

5cm ϕ x 5 cm – 14cm ϕ x 14 cm (H)

Install the scan module

To install the scan module, align it with the scanner base, press and hold the button, and attach it to the base vertically.

Scan Module Slot Button

Attach scan module to the

base vertically.

P22P22

Page 23

Scanning

The limitations of the object to be scanned

The object should be stable and stationery. It must not be shaken or moved during the rotation of the turntable.

•

Scan area for the object mode is 5cm ϕ x 5 cm – 14cm ϕ x 14 cm (H).

•

The object should not be reective, tranparent, or translucent ones.

•

The object with a reective surface, metal, or transparent material will have an impact on the scanning quallity. If you

•

want to scan an object like this, it is recommended to spray the developer on the surface before scanning it.

If the object has a solid color, or does not have obvious textures or an obvious shape, you may not have the best scan-

•

ning results.

The round object will have scanning results, while the slime and long or sharp objects won’t have good scanning re-

•

sults.

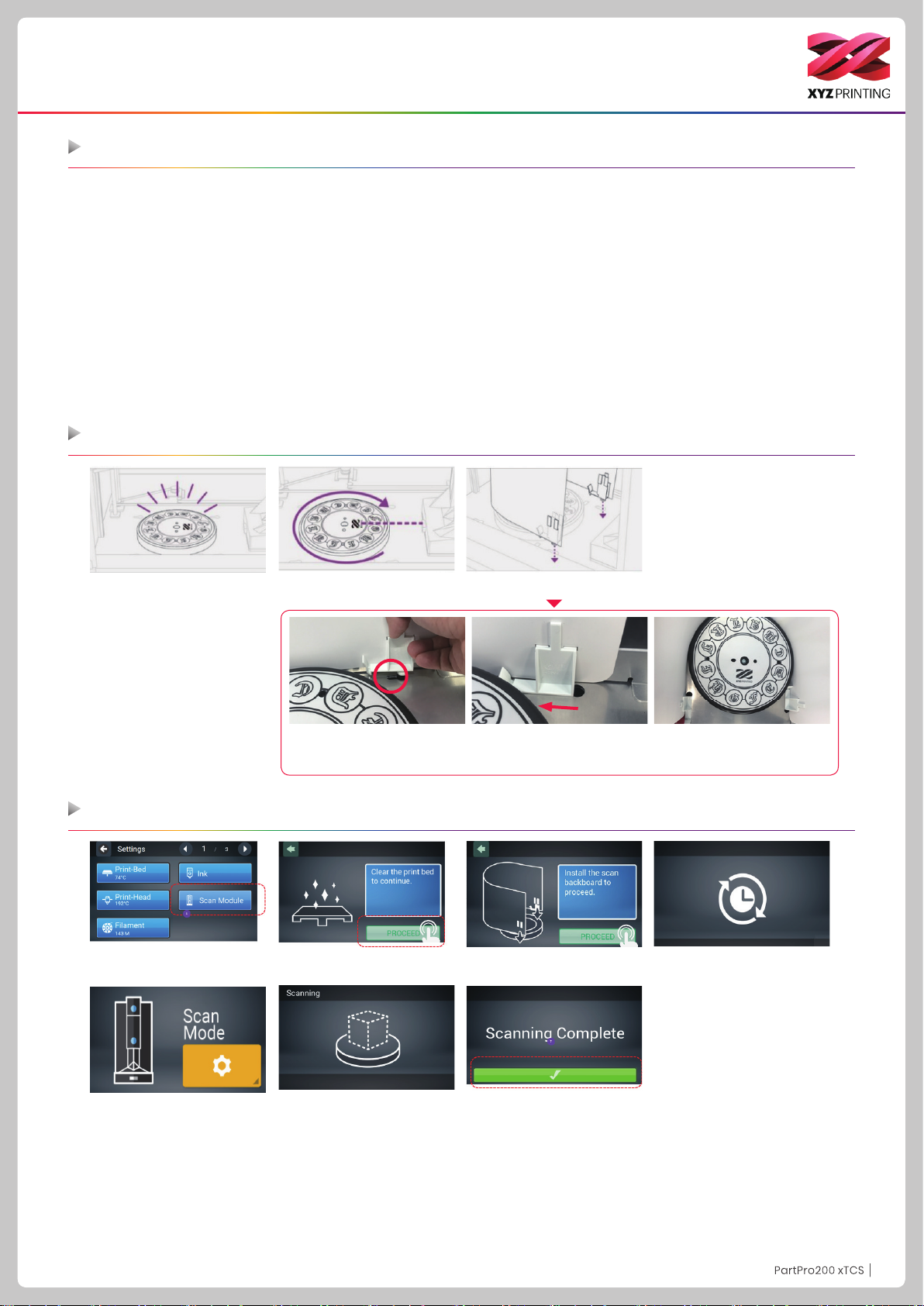

Scan steps - Install the scan backboard

1. Remove the object from the

tumtable.

Scan steps

1. Select the scan module in the

Settings.

2. Wait until the scan turntable

returns.

bottom of the scan backboard

into the holes and secure them.

2. Empty the printer platform.

3. Install the scan backboard.

Direction of the latch.Insert the two sides at the

3. Install the scan backboard.

The installation of the scan

backboard is completed.

4. Wait until the printer platform

returns.

5. Pleace the object to be

scanned.

6. The object is being scanned.

7. When the scan is completed,

you can nish the scan job and

perform other jobs.

P23P23

Page 24

Scanning

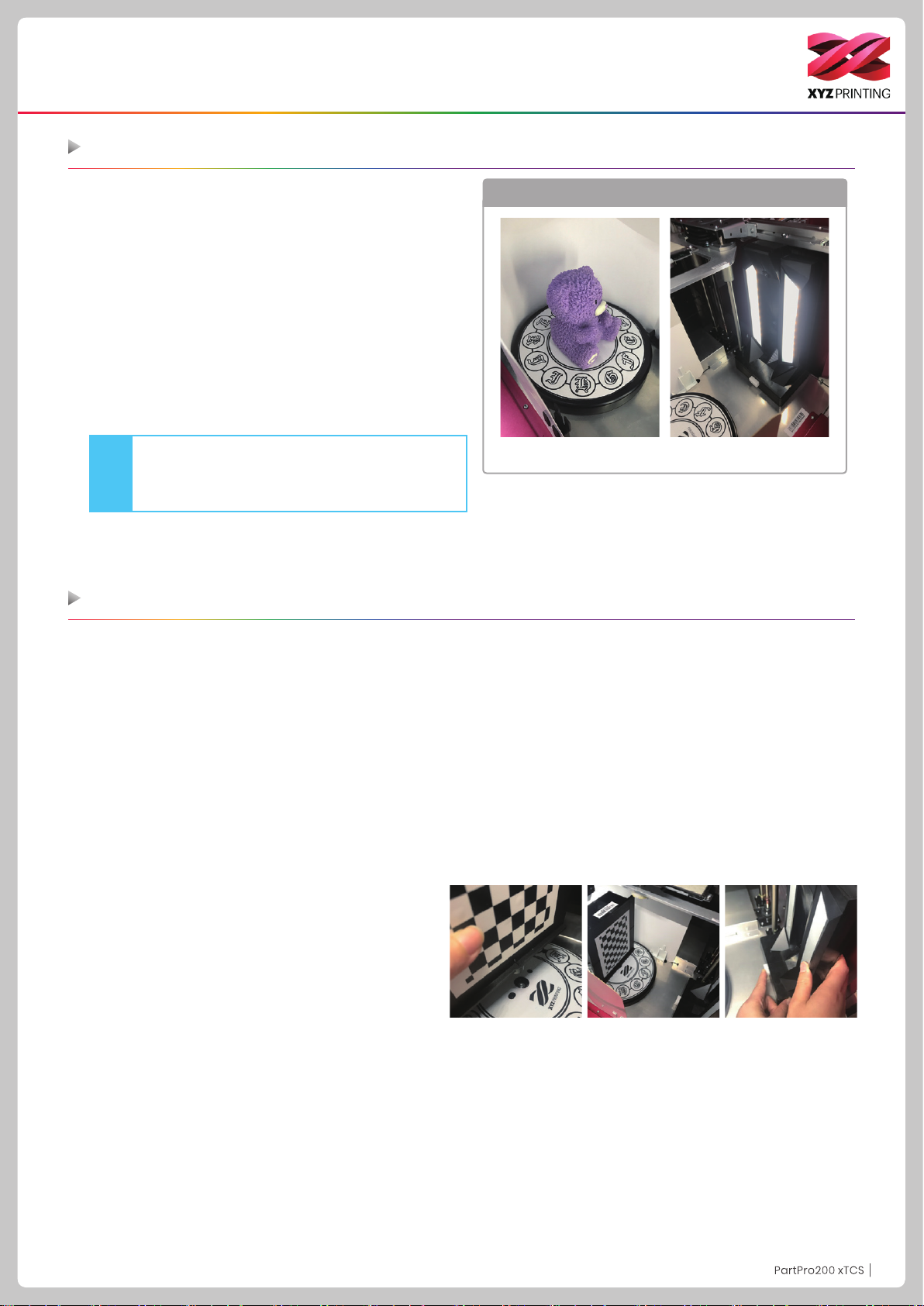

Scan software: Operate XYZscan Color

Make sure that the scan backboard is properly installed in

your 3D printer and press the "Scan" button on the machine,

make sure the machine enters scan mode.

1. Open the scan software.

2. Check the ambient brightness in the preview screen.

Adjust the preliminary settings. If no error is found, click

"Scan" to perform the process.

3. In the Model Preview area, the model slowly rotates. Wait

until the scan point clouds are created.

4. Wait until the scan point clouds are created. Press

Continue and perform meshing.

5. The scan is completed.

1. You can have better performance under good

Note

* For details about the scan feature, refer to the "XYZscan

Color Software User's Manual"

lighting conditions.

2. The front side of the object must face the scan

module.

Use the calibration plate

Environmental illustration

Rotating Table Module Scan Module

When the printer is relocated, or the scan result is not accurate, peform the following steps to calibrate the scan module:

1. Remove the object from the tumtable.

2. Perform "Settings" > "Calibrate" in the main menu of "XYZscan Color."

3. Use the calibration plate.

When the screen prompt asks you to place the calibration plate follow the instructions and place the calibration plate in

the middle of the turntable. (The side with the checkered patten faces the scan module and then snap the bottom latch

into the middle notch of the turntable) Click "Calibrate Now" in the software.

4. Check if the calibration plate is properly displayed in the preview screen. If correct, click "Calibrate" to perform the

calibration process.

5. Wait for the XYZscan Color performs calibraiton with the printer (it takes about 2 miniutes.)

6. When the XYZscan Color prompts that the cabiliation is completed, remove the calibration plate from the turntable.

7. Click "Conrm" in the software to exit this function to proceed with scanning.

P24P24

Page 25

Support detail

When the problem occurs with the printer, please refer to the following troubleshooting instructions. If the problem persists, please

contact the Customer Service Center.

Problem code and handling

When a problem occurs with the printer, the service code will be displayed on the printer screen and / or the software interface. Please

refer to this service code description form for preliminary testing.

Service

Code

Symptom Action

OO11 Print head heated for too long

please check the Flexible at cable and reboot

OO14 Print head heated issue -- temperature exceed

OO30 Abnormal--X axis

OO31 Abnormal--Y axis

check the cable of the motor and the sensor, and check the

position of the sensor

OO32 Abnormal--Z axis

OO50 Internal communication error -- memory error reboot the printer

OO52 Print head memory error replace the print head

OO55 inkjet head error replace the inkjet head

OO56 inkjet data error reboot the printer

Maintenance and Service

Keep original packaging material in the event of sending your unit back for repair during the warranty period. If other packing materials are

used instead, the printer may be damaged during the transportation process.. In such situation, the XYZprinting the right to charge repair

fee.

Federal Communications Commission (FCC) Statement

You are cautioned that changes or modications not expressly approved by the part responsible for compliance could void the user’s

authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following measures:

● Reorient or relocate the receiving antenna.

● Increase the separation between the equipment and receiver.

● Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

● Consult the dealer or an experienced radio/TV technician for help.

XYZprinting is not responsible for any radio or television interference caused by using other than recommended cables and connectors

or by unauthorized changes or modications to this equipment. Unauthorized changes or modications could void the user's authority to

operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

This device complies with FCC radiation exposure limits set forth for an uncontrolled environment and it also complies with Part 15 of the

FCC RF Rules. This equipment must be installed and operated in accordance with provided instructions and the antenna(s) used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all persons and must not be co-located or operating

in conjunction with any other antenna or transmitter. End-users and installers must be provided with antenna installation instructions and

consider removing the no-collocation statement.

P25P25

Page 26

PartPro200 xTCS

Touchscreen-Menü, Funktionen und Meldungen 7

Die Anleitung soll Nutzer vorwiegend mit der richtigen Bedienung

des 3D-Druckers PartPro200 xTCS („200 xTCS“) vertraut machen.

In dieser Anleitung erfahren Nutzer mehr über Bedienungshinweise,

Anwendungsmöglichkeiten und Wartung des 3D-Druckers 200 xTCS.

Siehe Support. http://support.xyzprinting.com, um das

neueste Handbuch & die neueste Software für eine besser

Benutzererfahrung herunterzuladen.

Neumitglieder müssen ein Konto auf der Website anmelden,

bevor sie auf diese Ressourcen zugreifen können.

Bedienungsanleitung

Sicherheitsmaßnahmen 2

Produktbeschreibung 3

Auspacken und Installieren 5

Funktionsbedienung und Anweisungen 8

Printing (Druck) 21

Scannen 22

Einzelheiten zum Kundendienst 25

DEU

Weitere Informationen zum 3D-Drucker 200 xTCS und zur

vollständigen XYZprinting-Produktreihe erhalten Sie von Ihrem

örtlichen Händler oder der ofziellen Webseite von XYZprinting.

Page 27

Sicherheitsmaßnahmen

Sicherheit und Konformität

Bitte lesen Sie diese Anleitung und sämtliche Sicherheitshinweise sorgfältig, bevor Sie dieses Produkt auspacken, benutzen, bedienen, warten oder ein Teil davon ersetzen oder entfernen. Beachten Sie zudem alle sicherheitsrelevanten Anweisungen.

CAUTION

Wichtige Sicherheitsmaßnahmen

●

Transportieren Sie das Gerät nicht eigenhändig. Es ist sehr schwer.

●

Stellen Sie den Drucker nicht an sehr staubigen oder feuchten Orten bzw. im Freien auf.

●

Stellen Sie den Drucker nicht auf einen weichen oder geneigten Untergrund. Andernfalls könnte das Gerät umkippen /

herunterfallen und beschädigt werden oder Verletzungen verursachen.

●

Lassen Sie Produkt oder Netzkabel nicht unbeaufsichtigt in der Nähe von Kindern. Andernfalls können Verletzungen und

Stromschläge auftreten.

●

Verwenden Sie nur das mitgelieferte Netzkabel. Andernfalls könnte eine unsachgemäße Erdung Schäden verursachen.

●

Stellen Sie niemals mit Flüssigkeit gefüllte Behälter auf das Produkt. Flüssigkeit kann auslaufen oder verschüttet werden,

so in das Gerät gelangen und eine gefährliche Situation verursachen.

●

Wischen Sie den Drucker nicht mit Alkohol oder entammbaren Chemikalien ab. Andernfalls drohen gefährliche

Situationen.

●

Bewegen Sie das Gerät nicht, während es eingeschaltet ist.

●

Greifen Sie im Betrieb nicht mit den Händen in das Gerät. Andernfalls drohen Gefahren durch bewegliche Druckerteile und

Verbrennungen aufgrund hoher Temperaturen.

●

Das Gerät wird im Betrieb heiß. Berühren oder ersetzen Sie Teile erst, wenn Sie abgekühlt sind.

●

Nach dem Start können sich Teile im Gerät je nach Anweisungen des Bedieners erhitzen oder bewegen. Berühren oder

blockieren Sie im Betrieb keine Teile.

●

Während des Drucks können leichte Gerüche auftreten. Zur Gewährleistung Ihres Wohlbendens sollten Sie in einem gut

belüfteten, offenen Bereich arbeiten.

●

Reparaturen müssen entsprechend den Anweisungen in dieser Bedienungsanleitung durchgeführt werden. Wenn ein

Defekt nicht behoben werden kann, wenden Sie sich bitte an Ihren Druckerhersteller oder den Kundendienst.

Heavy object.

2 person lift

required

Watch Your Hands.

Marken

Alle Marken und eingetragenen Marken sind das Eigentum ihrer jeweiligen Inhaber.

Wartung und Reparatur

Wenn der Drucker im Rahmen der Garantie repariert werden muss, müssen Sie das Gerät vor dem Versand in der

Originalverpackung verpacken. Daher sollten Sie das Verpackungsmaterial nach Möglichkeit aufbewahren. Falls stattdessen andere Verpackungsmaterialien genutzt werden, kann der Drucker während des Transport beschädigt werden. Wir

behalten uns das Recht vor, in diesem Fall entsprechende Gebühren zu erheben.

P2P2

P2

Page 28

Produktbeschreibung

Produktaufbau

1. 5-Zoll-Farb-Touchscreen 2. Automatisches Zuführungsmodul 3. Druckkopf

4. Druckplatte + abnehmbarer EZ-Gummimagnet 5. Scan-Modul 6. Filamentspulenhalter

7. USB-Port 8. USB-Port (WLAN-Dongle) 9. Ein-/Ausschalter

10. USB-Port (an PC) 11. Netzanschluss

1

2

5

3

6

4

7

8

9

10

11

P3P3

P3

Page 29

Produktbeschreibung

Prüiste zum Zubehör

1. Bedienungsanleitung 5. USB-Kabel 9. PC-Mylar x 2 13. Transparenten Schlauch

2.

USB-Laufwerk 6. Abnehmbarer EZ-Gummimagnet 10. Plattenklebeband 14. Kalibrierungsplatte

3. 3D Color-inkjet PLA 7. Obere Abdeckung 11. WLAN-Dongle 15. Schattierungsplatte

4. Netzkabel 8. Führungsschlauch 12. Handschuhe (ein Paar)

1 2 3 4

9 10

11

12

5 6

13 1514

7 8

Warnhinweise und Anweisungen zu Wartungswerkzeugen

Die folgenden Werkzeuge dürfen nur von oder unter Aufsicht eines Erwachsenen verwendet werden. Halten Sie die Werkzeuge von Kindern fern, die nicht damit vertraut sind.

Schaber

31 2 4 5

●

Achten Sie darauf, die Wartungsarbeiten des Druckers erst auszuführen, wenn die Druckplatte abgekühlt ist.

●

Wenn der Druck abgeschlossen und die Druckplatte auf Zimmertemperatur abgekühlt ist, kann das gedruckte Objekt mit dem Schaber

von der Druckplatte entfernt werden.

●

An Druckkopf und Zahnrädern des Druckmoduls können während des Drucks erzeugte Filamentreste haften. Dies kann Druckqualität

und Druckerbetrieb sowie die Messung der Druckplatte beeinträchtigen. Reinigen Sie das Druckmodul in diesem Fall mit der

Drahtbürste.

1.

Drahtbürste

2.

Zahnrad-Reinigungsbürste

3.

Reinigungsdraht für Zufuhröffnung

4.

Reinigungsdraht für Druckkopf

5.

Technische Daten

Printing (Druck)

Drucktechnologie 2D-Muster: Tintenstrahldruck

3D-Struktur: Fused Filament Fabrication (FFF)

Abmessungen und Gewicht

Abmessungen (B x T x H) 600* 581* 640 mm

Nettogewicht 32 Kg

Bruttogewicht 43 Kg

Leistung

Druckabmessungen (B x T x H)

Dicke der gedruckten Schicht 0.1 mm ~0.4 mm

Ausrichtungsgenauigkeit X/Y : 0.0125 mm

Automatische Kalibrierung YES (Ja)

Automatische Zuführung YES (Ja)

Autonomer Ofine-Druck YES (Ja)

Einfarbiger Druck (ohne Tintenstrahldruck)

200 x 200 x 150 mm

Vollfarbiger Druck

185 x 185 x 150 mm

Materialien

3D-Druckmaterialien 3D Color-inkjet PLA, PLA, Tough PLA, PETG

Filamentdurchmesser 1.75 mm

Tintentyp CMYK-Patrone mit separaten Farben

Hardware

Druckkopfdurchmesser 0.4mm

Nutzerschnittstelle Farbiger 5-Zoll-Touchscreen

Druckplatte Nicht erhitzt, abnehmbar

Übertragung USB-2.0-Laufwerk / USB-Kabel /

kabellose Übertragung

Software

Nutzersoftware XYZmaker

Unterstütztes Dateiformat AMF, OBJ, STL, XYZ Format (.3w), .3CP, .3MF

Betriebssystem Mac OS X 10.10 / 10.11 / 10.12

Windows 7/8/10 (64-bit)

Temperature (Temperatur)

Betriebstemperatur des Gerätes 15-30°C

Lagerungstemperatur der Patrone 15-35°C

Lagerungstemperatur des Filaments 0-38°C

P4P4

P4

Page 30

Auspacken und Installieren

1

Stellen Sie den Drucker auf einen Tisch

oder eine Plattform.

(Transportieren Sie das Gerät nicht

eigenhändig. Es ist sehr schwer.)

2

Entfernen Sie Plastikfolie und PP.

3

Entfernen Sie die Verpackungsmaterialien, den Karton mit der oberen Abdeckung, den Zubehörkarton und die Kunststoffabdeckung.

4

5

6

Entfernen Sie das Klebeband am

Gehäuse (insgesamt 4 Stück).

7

Entfernen Sie den Schaumstoff

am Patronenhalter.

Die Frontklappe öffnen und das Klebeband an der Markierung

der Druckklappenposition entfernen.

8

Entfernen Sie den Schaumstoff neben den Führungsschrauben an beiden Seiten, entfernen Sie dann

den Schaumstoff unter der Druckplatte.

9

Entfernen Sie Kabelbinder und Schaumstoff an der Vorder- und

Rückseite der vorderen Klappe.

Öffnen Sie die vordere Klappe.

Entfernen Sie das Klebeband von

Stützmaterial und Druckplatte.

P5P5

P5

Page 31

Auspacken und Installieren

10

Stellen Sie sicher, dass ein Ende des Führungsschlauchs (Zubehör 8) fest in die Öffnung am Druckmodul eingesteckt

ist, stecken Sie dann das andere Ende in den transparenten Schlauch (Zubehör 13) am Ende.

11

Führen Sie das Führungsrohr durch die obere Abdeckung und

setzen Sie diese dann wieder auf die Maschine.

13

Bitte befolgen Sie die auf den Bildern beschriebene Reihenfolge und

befestigen Sie das PC-Mylar (Zubehör 9) und das Plattenklebeband

(Zubehör 10) auf dem abnehmbaren EZ-Gummimagnet (Zubehör 6)

Plattenklebeband

PC Mylar

Abnehmbarer

EZ-Gummimagnet

14

12

Stecken Sie das andere Ende des Führungsschlauchs in das

Zuführungsmodul und sichern Sie es.

Stellen Sie sicher, dass der Gummimagnet richtig auf der Druckplatte

platziert ist.

Vorsichtsmaßnahmen

1. Prüfen, ob die Kalibrierungs schrauben

der Druckplatte klemmen.

2. Die Druckplatte mit beiden Daumen

nach oben drücken, um die Kalibrierungsschraube zu lösen.

Hinweis

Am Gummimagnet ist eine

PC-Folie mit doppelseitigem

Klebeband angebracht. Diese

PC-Folie kann ersetzt werden.

Tauschen Sie sie aus, falls sie

schmutzig oder beschädigt ist.

P6P6

P6

Page 32

Touchscreen-Menü, Funktionen und Meldungen

Hauptbildschirm

Filament/Tinte

laden und entladen

Dies beinhaltet Optionen zum

Laden und Entladen von Filament

und Tinte.

USB-Druckmenü

Über dieses Menü können Sie

Dateien (.3cp) zum Drucken ohne

Computer von einem USB-Laufwerk

auf das Gerät importieren.

Einstellungen

Dies beinhaltet die Funktionen der

Startseite 1:

Einstellungen zu Print-Bed (Druckplatte), Print-Head(Druckkopf),

Filament, Ink (Tinte) und Scan

Module(Scan-Modul).

Nächste Seite enthält

WiFi (WLAN), Sound (Ton), Statistics (Statistik), Language (Sprache),

Display (Anzeige) und Door Lock

(Klappenverriegelung).

Die letzte Seite enthält Model (Mod-

ell), Version, Reset (Rücksetzen)

und Legal Info (Rechtliche Informa-

tionen).

P7P7

P7

Page 33

Funktionsbedienung und Anweisungen

A. Filament laden/entladen

A1

1. Das Filament mit einem 45 GradWinkel abschneiden, bevor es

automatisch in den Drucker geladen

wird. Während des Vorgangs zum

Laden des Filaments sollte das

Filament am Ende mindestens 4”

gerade sein, wie in den Bildern

dargestellt.

5. Tippen Sie auf „Load (Laden)“. 6. Bestätigen Sie den Vorgang. 7. Stecken Sie das Filament in das Zuführungsmodul. Es wird automatisch geladen.

Filament

Filament laden

2. Platzieren Sie das Filament im

Spulenhalter.

Das Filament muss

sich beim Ziehen im

Hinweis

Uhrzeigersinn drehen.

3.Tippen Sie am Hauptbildschirm

auf „Filament Load and Unload

(Filament laden und entladen)“ und

wählen Sie Filament.

4. Tippen Sie auf „Filament“.

8. Prüfen Sie, ob die Temperatur des Druckkopfs auf 210 °C steigt (farbiges PLA von XYZprinting), nachdem

das Filament geladen wurde. Sobald die eingestellte Temperatur erreicht wurde, führt der Zuführungsmotor das

Filament durch den Führungsschlauch in den Druckkopf ein.

Filament entladenA2 Filament

1. Tippen Sie am

Hauptbildschirm auf „Filament

Load and Unload (Filament

laden und entladen)“.

5. Tippen Sie nach Abschluss

des Entladens zum Bestätigen.

2. Tippen Sie auf „Unload

(Entladen)“ und bestätigen Sie

den Vorgang.

3. Bestätigen Sie den Vorgang. 4. Wenn sich der Druckkopf auf

9. Sobald das Filament am

Druckkopf extrudiert wird, wurde das

Filament erfolgreich geladen. Tippen

Sie zum Bestätigen und Fortfahren

auf den Bildschirm.

220 °C erwärmt hat, gibt der

Zuführungsmotor das Filament

aus.

P8P8

P8

Page 34

Funktionsbedienung und Anweisungen

A3 Filament

Material auffüllen

200 xTCS fordert Sie zum Auffüllen von Material auf.

1. Tippen Sie beim Drucken auf das

Symbol.

5. Ersetzen Sie die leere Spule durch eine neue. (Bitte beachten Sie den

Abschnitt zum Laden in dieser Anleitung.) Tippen Sie dann auf „PROCEED

(Fortfahren)“.

2. Der Bildschirm zeigt den

Filamentstatus. Tippen Sie auf „Rell

(Auffüllen)“.

3. Bestätigen Sie den Vorgang.

6. Die Düse wird aufgeheizt und Sie werden benachrichtigt, sobald Sie

Filament in das Zuführungsmodul stecken sollen.

4. Die Düse wird erhitzt und das

Filament wird automatisch entladen.

7. Das Filament wird automatisch

geladen.

B. USB-Druck

1. Prüfen Sie, ob das USB-Laufwerk

an das Gerät angeschlossen ist.

5. Der Bildschirm zeigt den

Fortschritt des Drucks in Prozent.

Unter dem Prozentsatz werden

Pause, Stop (Stopp) und Rell

(Auffüllen) angezeigt.

B1

Drucke entnehmen

8. Prüfen Sie, ob Filament aus der Düse extrudiert wird. Nach der

Bestätigung setzt der Drucker den Druck fort.

2. Tippen Sie am Hauptbildschirm

auf das USB-Druckmenü.

3. Wählen Sie die Datei, die Sie

drucken möchten.

Hinweis

Die vordere Klappe ist

beim Drucken standardmäßig

verriegelt. Wenn Sie diese

Einstellung ändern möchten,

rufen Sie Setting (Einstellung) >

Door Lock (Klappenverriegelung)

auf.

4. Prüfen Sie die Dateiinformationen

und tippen Sie auf „Print (Drucken)“.

Den abnehmbaren EZ-Gummimagneten zusammen mit dem gedruckten Objekt vom Drucker entnehmen.

Das gedruckte Objekt vom Gummimagneten abziehen.

Den LED-Streifen des

Druckers nicht berühren,

da der LED-Streifen durch

die lange Zeit mit eingeschaltetem Licht heiß sein

wird.

P9P9

P9

Page 35

Funktionsbedienung und Anweisungen

C. Tintenpatrone installiert

Der 200 xTCS nutzt vier Farbtinten, die separat ersetzt werden können.

Tintenführung

1. Halten Sie einige Papiertücher und

die Tintenpatrone bereit.

4. Drücken Sie den Patronenkopf gegen

das Papiertuch, damit etwas Tinte

darauf übertragen wird.

7. Falls die Tinte nicht richtig übertragen

wurde, feuchten Sie das Papiertuch

zum Abwischen der Tinte bitte mit

75-prozentigem Alkohol an. Prüfen Sie

nach Reinigung der Tintenstrahldüse,

ob die Tinte richtig übertragen wird.

2. Packen Sie die Tintenpatrone aus.

5. Falls die Tinte nicht richtig übertragen

wurde, versuchen Sie, das Papiertuch

auf den Tisch zu legen und den

Patronenkopf auf das Papiertuch

gedrückt zu halten.

3. Entfernen Sie die Patronenabdeckung.

6. Prüfen Sie, ob die auf das Papiertuch

übertragene Tinte zwei gerade Linien

anzeigt. Falls ja, ist die Tintenführung

erfolgreich abgeschlossen. Sobald

die Tintenführung durchgeführt

wurde, können Sie die Tintenpatrone

installieren.

Hinweis

Um zu verhindern, dass die geöffnete Tintenpatrone austrocknet, wenn

ein Druck abgeschlossen ist oder der Drucker mehrere Tage lang nicht

benutzt wird, sollten Sie die Patrone wie folgt lagern:

1. Die Düse der Tintenpatrone mit Alkohol reinigen.

2. Die Tintenpatrone mit ihrer Schutzfolie abdecken und die Patrone bei

Raumtemperatur (15 bis 35 Grad) lagern.

Zum Erzielen der besten Druckqualität sollten Sie die Düse der

Tintenpatrone nach dem Entfernen der Schutzfolie von der Patrone mit

Alkohol reinigen und die Patrone dann wieder in den Drucker einsetzen,

bevor Sie mit dem Drucken beginnen.

P10P10

P10

Page 36

Funktionsbedienung und Anweisungen

Tippen Sie auf die Tinte und

der Bildschirm zeigt den

zugehörigen Status, wie „Ink

Low (Tintenstand gering)“, „No

Ink (Keine Tinte)“ oder „Invalid

Ink (Ungültige Tinte)“.

C1

1. Tippen Sie auf „Change Ink

(Tinte wechseln)“. Tippen Sie

dann zum Bestätigen.

Ink (Tinte)

1

4

Change Ink (Tinte wechseln)

2. Bestätigen Sie den Vorgang.

2

5

3

6

3. Warten Sie, bis sich die Patrone

in die Mitte der Druckplatte

bewegt hat. Wechseln Sie die

Patrone anschließend.

Patrone installieren

1. Heben Sie die Platte nach oben.

2. Nehmen Sie die Patrone heraus.

3. Setzen Sie eine neue Patrone ein.

4. Prüfen Sie, ob die Patrone richtig platziert ist.

5. Drücken Sie die Platte nach unten.

6. Prüfen Sie die Reihenfolge der Tintenfarben.

Sie muss von links nach rechts wie folgt sein:

K (Schwarz), C (Cyan), M (Magenta) und Y

(Gelb).

Hinweis: Bei Austausch einer Tintenpatrone bitte

den Tintenstrahl-Kalibrierungstest durchführen.

4. Tippen Sie nach dem

Wechsel auf „PROCEED

(Fortfahren)“.

P11P11

P11

Page 37

Funktionsbedienung und Anweisungen

C2-1 Ink (Tinte)

Wir empfehlen, nach Installation der Tintenpatrone eine Testseite zu drucken. Bitte bereiten Sie ein Blatt Papier vor.

(Kalibrierung)“.

4. Den abnehmbaren EZ-Gummimagneten herausnehmen.

Das A4 mit einem Klebeband in

Hochformat an der Vorderseite

des Gummimagneten befestigen.

Calibration (Kalibrierung) Test Page (Testseite)

2. Tippen Sie auf „Test Page

(Testseite)“.

5. Das A4 Papier so glattziehen,

dass es ach (ohne Lücke) am

Gummimagneten anliegt.

. Test Page.1. Tippen Sie auf „Calibration

3

6. Das restliche A4 Papier fest an die Rückseite des Gummimagneten falten.

Paper Test Page

7. Den Gummimagneten wieder

entsprechend an der Druckplatte einsetzen.

1. Sie können sich auch

entscheiden, die "PLATestseite" zu drucken, um den

Tintenstatus zu bestätigen.

5. Bestätigen, ob der

Druckauftrag abgeschlossen

wurde.

8. Befestigen Sie das Papier auf

der Druckplatte, tippen Sie dann

auf „PROCEED (Fortfahren)“

und der Drucker führt einen

Testdruck durch.

Calibration (Kalibrierung) Test Page (Testseite)C2-1 Ink (Tinte)

2. "PLA-Testseite" tippen, um

zu drucken.

6. Druckobjekt herausnehmen

und die Farbgebung überprüfen.

9. Entfernen Sie die Testseite

und tippen Sie auf „PROCEED

(Fortfahren)“.

3. Warten Sie, bis sich der

Extruder auf Betriebstemperatur

erwärmt hat.

PLA Test Page

4. "PLA-Testseite" wird

gedruckt.

P12P12

P12

Page 38

Funktionsbedienung und Anweisungen

Tintenkalibrierung

Bild 1 Bild 2 Bild2-1

Bild 1 zeigt ein Beispiel einer

normalen Testseite.

Bild 3

Bild 3 zeigt ein Beispiel einer schlechten Testseite.

Waagerecht und senkrecht ziehen sich

Farbbalken.

Bitte die nachfolgenden Schritte durchführen.

Bild 2 zeigt einen leichten Farbversatz im waagerechten Teil der

Testseite. Dieser liegt im akzeptablen Bereich. Wenn der Druck

auf der Testseite schlechter wird,

das Reinigungsverfahren durchführen.

Fehlersuche TintenpatroneC2-2 Ink (Tinte)

Bild 2-1 zeigt eine leicht

schwarze Tintenverwischung im

waagerechten & senkrechten Teil,

das kann auch bei einer anderen

Farbe der Fall sein.

Sie liegt im akzeptablen Bereich.

Schritt 1

Patrone wieder installieren und Testseite drucken.

Wenn das Problem nicht behoben ist, mit Schritt 2

fortfahren.

Schritt 2

Prüfen, dass kein gerissener Draht oder ein beschädigter Kontaktblock vorhanden ist, wie im

Beispiel gezeigt.

Wenn der Draht gerissen ist, eine neue Patrone

einsetzen.

Wenn der Kontaktblock und der Pin in der Patronenstation beschädigt sind, den Support bezüglich eines

Austauschs kontaktieren.

NG Patrone (gerissener

Draht & Block)

Hinweis: Auf unserer Website ndet man das

neueste Patronenreinigungsverfahren.

Siehe C2-1, um die A4-Testseite vorzubereiten.

Normale Patrone

Schritt 3

Prüfen, ob der Tintenpatronenkopf eventuell verstopft ist, wie im gezeigten Beispiel.

Bitte Patronenreinigungsverfahren von Seite 10

Abschnitt Tintenführung durchführen.

Wenn das Problem nicht behoben ist, mit Schritt 4

fortfahren.

Druckkopf reinigen

Schritt 4

Mit einem Papiertuch die

Tintenpatrone abdecken, wie

in Bild 4 dargestellt, und nach

unten halten.

Wenn die Tinte herausläuft,

die Testseite drucken.

Wenn das Problem nicht behoben ist, eine neue Tintenpatrone einsetzen.

Verstopfter/verschmutz-

ter Druckkopf

P13P13

P13

Page 39

Funktionsbedienung und Anweisungen

C2-3 Ink (Tinte)

(Kalibrierung)“.

5. Prüfen Sie das gedruckte

Kalibrierungsdiagramm anhand

der Bildschirmanweisungen.

Wählen Sie bei jeder Farbe

die Linie, die am besten an

Schwarz (K) ausgerichtet ist.

Calibration (Kalibrierung) Color Calibration (Farbkalibrierung)

2. Tippen Sie auf „Color

(Farbe)“.

6. Geben Sie bei der

horizontalen Ausrichtung die

entsprechende Nummer jeder

Farbe ein. Tippen Sie nach

Eingabe der Nummer auf

„PROCEED (Fortfahren)“.

3. Bitte befestigen Sie das Druckpapier auf der Druckplatte.1. Tippen Sie auf „Calibration

4. Nehmen Sie das bedruckte

Papier heraus und tippen Sie

auf „PROCEED (Fortfahren)“.

7. Geben Sie bei der vertikalen

Ausrichtung die entsprechende

Nummer jeder Farbe ein.

Tippen Sie nach Eingabe

der Nummer auf „PROCEED

(Fortfahren)“.

8. Bestätigen Sie die in

den Feldern eingegebenen

Nummern und tippen Sie auf

„PROCEED (Fortfahren)“.

Calibration (Kalibrierung)

1. Tippen Sie auf „Inkjet

Calibration (Tintenkalibrierung)“.

Vorsicht: Bitte sicherstellen, dass der abnehmbare EZ-Gummimagnet an der Druckplatte angebracht ist.

5. Der Drucker druckt die

Kalibrierungskarte automatisch.

Dies dauert etwa 15 Minuten.

(Stellen Sie sicher, dass Sie

das Filament geladen haben.)

2. Inkjet Calibration.

Inkjet Calibration (Tintenkalibrierung)C2-4 Ink (Tinte)

3. Stellen Sie sicher, dass

sich nichts auf der Druckplatte

bendet.

6. Nehmen Sie die

Kalibrierungskarte nach

Abschluss des Drucks heraus.

4. Der Druck beginnt, sobald

sich die Druckdüse erwärmt

hat.

7. Suchen Sie horizontal und

vertikal nach dem Kästchen,

in dem die Tinte am stärksten

ausgerichtet ist, und tippen Sie

auf „PROCEED (Fortfahren)“.

8. Vertikale Ausrichtung: Geben

Sie die Nummer des Kästchens

ein, von dem Sie denken, dass

Filament und Tinte am stärksten

ausgerichtet sind, und tippen Sie

dann auf „PROCEED (Fortfahren)“.

9. Horizontale Ausrichtung: Geben

Sie die Nummer des Kästchens

ein, von dem Sie denken, dass

Filament und Tinte am stärksten

ausgerichtet sind, und tippen Sie

dann auf „PROCEED (Fortfahren)“.

10. Tippen Sie nach Abschluss

der Kalibrierung zum Fertigstellen

auf „PROCEED (Fortfahren)“.

P14P14

P14

Page 40

Funktionsbedienung und Anweisungen

C2-4 Ink (Tinte)

1.Wenn Sie eine Farbverschiebung nden, nachdem das

Farbobjekt gedruckt wurde, können Sie die Druckposition manuell

anpassen.

Y-Axis

X-Axis

2. Die Einstellposition der

X-Achse und der Y-Achse war

die Probeposition, wenn man

dem Drucker zugewandt ist.

Calibration (Kalibrierung) Inkjet Calibration (Tintenkalibrierung)

Manuelle Einstellung der

X-Achsen-Bewegung

“X-ACHSE” wählen, um nach

rechts und links zu bewegen.

Die Taste “Links” oder “Rechts”

drücken, um die einzustellen-

de Richtung und den Abstand

auszuwählen; jede Anpassung

bedeutet einen Schritt von 0,05

mm.

Manuelle Einstellung der

Y-Achsen-Bewegung

“Y-ACHSE” wählen, um nach

oben und unten zu bewegen.

Die Taste “Aufwärts” oder

“Abwärts” drücken, um die

einzustellende Richtung und

den Abstand auszuwählen;

jede Anpassung bedeutet einen

Schritt von 0,05 mm.

Sobald die

Parametereinstellungen

abgeschlossen sind, auf

"WEITER" tippen, um die

spezizierten Einstellungen zu

speichern und anzuwenden.

Wenn Sie zurücksetzen

möchten, “erneut eingeben”

auswählen, um zur Einstellung

der X-Achsen-Bewegung zurückzukehren.

P15P15

P15

Page 41

Funktionsbedienung und Anweisungen

D. Einstellungen

D1

D2

D3

D1-1

1. Wählen Sie Calibration

(Kalibrierung).

3. Warten Sie, während der Sensor die Höhe der Druckplatte an drei verschiedenen Positionen misst.

Sobald die Messung abgeschlossen ist, gleicht der Drucker die Druckplatte automatisch aus.

Vorsicht: Bitte sicherstellen, dass der abnehmbare EZ-Gummimagnet an der Druckplatte angebracht ist.

Print-Bed (Druckplatte)

2. Bestätigen Sie den Vorgang.

D4

D6

D8

D5

D7

D9

Druckplatte kalibrieren (ausgleichen)

D10

4. Tippen Sie nach erfolgreicher

Kalibrierung zur Bestätigung.

D1-2 Print-Bed (Druckplatte)

1. Tippen Sie auf „Z-offset

(Z-Versatz)“.

2. Bewegen Sie den Druckkopf

in die Mitte der Druckplatte. Der

Abstand sollte so sein, dass

sich Druckkopf und Druckplatte

ganz knapp berühren, sodass

sich die Düse mühelos auf der

Druckplatte bewegen kann.

Z-offset (Z-Versatz)

3. Sie können das Symbol zum

Erhöhen oder Absenken der

Druckplatte antippen. Je höher

der Wert, desto größer der

Abstand und umgekehrt.

Jog-ModusD1-3 Print-Bed (Druckplatte)

Der Jog-Modus ermöglicht die manuelle Bewegung des Druckkopfs über den

Touchscreen.

So bewegen Sie den Druckkopf:

1. Setzen Sie Kopf auf die Startposition zurück. Setzen Sie ihn vor Bewegung in

eine beliebige Richtung immer auf die Startposition zurück.

2. Führen Sie die Bewegung entlang der X-Achse aus.

3. Führen Sie die Bewegung entlang der Y-Achse aus.

4. Führen Sie die Bewegung entlang der Z-Achse aus. (Wenn der Druckkopf in

der Ausgangsposition ist, nicht erhöhen/nach oben schieben, um die Druck-

platte nicht zu berühren.)

32 4

1

P16P16

P16

Page 42

Funktionsbedienung und Anweisungen

D2-1

1. Bitte reinigen Sie die Düse nach

60 Druckstunden.

Print-Head (Druckkopf)

2. Tippen Sie im Druckkopfabschnitt

auf „Clean Nozzle (Düse reinigen)“.

Düse reinigen

3. Prüfen Sie, ob eine Reinigung erforderlich ist. Tippen Sie zum Reinigen

auf „Check (Prüfen)“.

Sobald die Temperatur des Druckkopfs Betriebstemperatur erreicht, beginnt die Reinigung.

Hinweis: Berühren Sie den Metallteil des Druckkopfs nicht, da dieser während des Betriebs heiß wird.

4. Stecken Sie den Reinigungsdraht

in die Zufuhröffnung und drücken

Sie ihn zur Beseitigung des

Filaments im Druckkopf nach unten.

(Sie sollten diesen Vorgang von der

Oberseite des Gerätes durchführen.)

Damit die Druckqualität nicht durch Ausgabeprobleme aufgrund von Filamentresten nach langfristiger Benutzung der

Hinweis

Druckdüse beeinträchtigt wird, sollten Sie die Funktion „CLEAN NOZZLE“ (DUESE REINIGEN) (Düsenreinigung) alle 60

Betriebsstunden ausführen und angesammelte Reste mit dem Düsenreinigungsdraht oder Zufuhrpfad-Reinigungsdraht

entfernen. (Filament sollte vor der Reinigung des Zufuhrpfades aus dem Extruder entladen werden.)

5. Entfernen Sie Filamentreste am

Druckkopf mit einer Drahtbürste.

6. Stecken Sie den Reinigungsdraht

des Druckkopfs zur Reinigung von

unten in die Düse.

7. Tippen Sie nach Abschluss der

Reinigung auf „DONE (Fertig)“.

1. Tippen Sie auf „Change Nozzle

(Düse wechseln)“.

5. Schalten Sie das Gerät vor dem

Druckkopfwechsel aus.

2. Tippen Sie zur Bestätigung, dass

Sie die Düse tauschen möchten.

6. Wechseln Sie den Druckkopf von

oberhalb des Gerätes.

Installation des neuen Druckkopfs:

1. Verbinden Sie den Bus.

2. Drücken Sie die weiße Freigabetaste am Druckkopf

und montieren Sie Druckkopf und Mechanismus.

Prüfen Sie nach Anbringung des Druckkopfs, dass

er sicher sitzt und nicht wackelt.

3. Schalten Sie den Drucker ein und benutzen Sie ihn.

Düse wechselnD2-2 Print-Head (Druckkopf)

3. Warten Sie, bis sich der Druckkopf

an eine für den Wechsel geeignete

Position bewegt.

7. Drücken Sie zum Trennen des

Druckkopfs die weiße Freigabetaste.

4. Die Position des

Druckkopfwechsels wird oben

gezeigt.

8. Halten Sie den Druckkopf mit

einer Hand und entfernen Sie den

Bus mit der anderen Hand. Damit

ist die Entfernung des Druckkopfs

abgeschlossen.

P17P17

P17

Page 43

Funktionsbedienung und Anweisungen

Filament

D3

Beachten Sie die Funktion Change Filament (Filament wechseln) am Hauptbildschirm. Filament, das einen Tag oder länger nicht benutzt

wird, sollte in einem Beutel mit Reißverschluss aufbewahrt werden.

WLAN

D4

Bitte schließen Sie vor dem Anstellen

des Druckers und vor der WLANEinrichtung den WLAN-Dongle an

den USB-Port an der Oberseite des

Druckers an.

1. Tippen Sie auf „ADD

(Zufügen)“ und der Drucker

beginnt mit der Suche nach

verfügbaren Zugangspunkten.

2. Tippen Sie auf den

gewünschten Zugangspunkt.

3. Geben Sie das Kennwort des

Zugangspunkts ein.

4. Bestätigen Sie den

Verbindungsaufbau.

Bestätigen Sie mit Hilfe von XYZmaker, ob die WLAN-Verbindung erfolgreich hergestellt wurde

●

Verbinden Sie den Drucker über ein USB-Kabel mit dem Computer und führen Sie XYZmaker aus.

●

Prüfen Sie, ob die WLAN-Funktion am Computer aktiviert ist, und stellen Sie eine Verbindung zum

Zugangspunkt her.

1. Führen Sie XYZmaker aus. Tippen Sie auf „File“ > „Print “ > „da Vinci

Printer Plugin“.

2. Wählen Sie den gewünschten Drucker.

3. Wenn die Software „READY (Bereit)“

anzeigt, wurde die Verbindung

erfolgreich hergestellt. Nun können

Sie zur Überwachung des Druckers

auf „DASHBOARD (Dashboard)“ oder

zum Drucken einer Datei auf „PRINT

(Drucken)“ tippen.

DASHBOARD (Dashboard):

Sie Druckkopftemperatur, verwendetes Fila-

ment und Laden/Entladen von Filament.

Überwachen

PRINT (Drucken):

rameter und -qualität ein. Falls nur eine

Dateikonvertierung erforderlich ist, tippen

Sie auf „PREPARE (Vorbereiten)“.

Stellen Sie Druckpa-

P18P18

P18

Page 44

Funktionsbedienung und Anweisungen

Language (Sprache)

D5

Spracheinstellung ändern

Der 200 xTCS bietet acht Anzeigesprachen: Traditionelles Chinesisch, vereinfachtes Chinesisch,

Englisch, Japanisch, Deutsch, Italienisch, Spanisch

und Französisch. Die Spracheinstellung kann durch

Antippen von Settings (Einstellungen) > Languages

(Sprache) am Hauptbildschirm geändert werden.

Display (Anzeige)

D7

Die Einstellung Display (Anzeige) kann den Touch-

screen so kongurieren, dass er sich nach einer

bestimmten Zeit der Inaktivität abschaltet. Es gibt

fünf Einstellungen: Abschaltung nach einer Minute,

zwei Minuten, drei Minuten oder vier Minuten und

Deaktivierung der automatischen Abschaltung.

Sound (Ton)

D6

Die Option Sound (Ton) kann zur Steuerung des bei

Berührung des Touchscreens ausgegebenen Tons auf

ON (Ein) oder OFF (Aus) gesetzt werden.

Statistics (Statistik)

D8

Die Funktion Statistics (Statistik) kann Verlaufsdaten seit Einschaltung des Druckers aufzeichnen, wie:

Uptime (Betriebszeit)

Filament

Temperature (Temperatur)

Nozzle (Düse)

Print Job (Druckauftrag)

Last Calibration (Letzte Kalibrierung)

Ink Cartridge (Tintenpatrone)

P19P19

P19

Page 45

Funktionsbedienung und Anweisungen

Door Lock (Klappenverriegelung)

D9

1. Klappenverriegelung aktiv (ON (Ein))

: Beim Druck wird die Klappe verriegelt;

60 Sekunden nach Abschluss des

Drucks wird sie entriegelt. Die Klappe

wird entriegelt, wenn Sie während

des Drucks Pause oder Stop (Stopp)

antippen. Die Klappe wird erneut

verriegelt, wenn Sie sie schließen und

den Druck fortsetzen.

D10

Reset (Rücksetzen)

2. Klappenverriegelung inaktiv (OFF

(Aus)) : Die Klappe wird während des

Drucks sowie bei Pause oder Stopp

nicht verriegelt.

Druckerinformationen werden gelöscht

und auf die Werkseinstellungen

zurückgesetzt.

P20P20

P20

Page 46

Printing (Druck)

First-time printing (Erstmaliger Druck)

Sie können anhand der nachstehenden Schritte einen ersten Druck durchführen.

Calibration

(Kalibrierung)

D1-1 B C C A

Z-offset

(Z-Versatz)

D1-2

Load Filament

(Filament laden)

Change Ink

(Tinte wechseln)

(Kalibrierung)

(Testseite)

- Test Page

- Color Calibration

- Inkjet Calibration

(Farbkalibrierung)

(Tintenkalibrierung)

Calibration

Datei

vorbereiten,

dann Druck

ausführen

Zu druckende Dateien über die PC-Software „XYZmaker“ übertragen

Für Produktregistrierung und Software-Login ist ein Internetzugang erforderlich.

Verbinden Sie Drucker und Computer über ein USB-Kabel und installieren Sie „XYZmaker“ auf dem Computer. Anschließend können Sie die zu druckenden Dateien übertragen.

Der „XYZmaker“ ist mit den 64-bit Betriebssystemen von Windows, sowie Mac OS 10.10.10.11 und 10.12 kompatibel. Sie können

sie über das mitgelieferte USB-Laufwerk oder durch Herunterladen des Installationsprogrammes von der offiziellen XYZprinting-Webseite installieren. Die Bedienungsanleitung der Software können Sie ebenfalls von der ofziellen Webseite herunterladen.

Einzelheiten nden Sie auf der ofziellen Webseite: http://www.xyzprinting.com/

1. Verbinden Sie Computer und Drucker und wählen Sie PartPro200 xTCS.

2. Wählen Sie die zu druckende Modelldatei aus dem Ordner,

indem Sie auf OPEN (Öffnen) tippen. Sie können Objektgröße, Druckposition und Winkel anpassen, sobald die Datei

geladen ist. Drucken Sie farbige Objekte, indem Sie die zu

druckende Datei im OBJ-Format speichern und in XYZmaker

laden.

3. Sie können relevante Einstellungen ändern, damit das

gewünschte Druckergebnis erzielt wird.

4. Mit der Funktion Prepare (Vorbereiten) können Sie eine OBJDatei in eine .3cp-Datei umwandeln.

Sobald die Datei bearbeitet und angepasst wird,

klicken Sie zur Ausgabe des Objekts auf Print (Drucken).

Der Druckbetrieb beginnt nach Aufschichtung der Datei.

P21P21

P21

Page 47

Scannen

Montieren Sie das Scan-Modul in der Maschine (siehe Installationsschritte) und installieren Sie die „XYZscan Color“ Software auf Ihrem Computer, um die Scan-Funktion Ihres 3D-Druckers zu bedienen.

Richten Sie die Vorderseite des zu scannenden Objekts zum Scan-Modul hin aus und es wird etwa 10-15 Minuten dauern, es zu scannen. Wenn Sie ein Objekt scannen, dreht sich die Rotationseinheit im Uhrzeigersinn. Dabei nimmt die

Kamera am Scan-Modul eine durchgehende Serie von Bildern bei einer Geschwindigkeit von 30 Bildern pro Minute auf.

Wenn das Scannen abgeschlossen ist, zeigt „XYZscan Color“ das aufgenommene 3D-Bild als 3D-Bild an.

Produktübersicht

Scan-Modul

Hardwarevoraussetzungen

Betriebssysteme Windows 7, 8.1, 10 (64-bit)

Mindestsystemanforderungen

CPU 4. Generation Intel® Core™ i5

USB 2.0

8GB Festplatte oder mehr

Unterstützt die OpenGL 2.1 oder

höhere Grakkarte

Scan-Spezikationen

Scan-Technologie Photogrammetry 3D

Scan-Auösung

(Durchmesser x H)

Scan-Software XYZscan Color

Tragkraft der Rotationseinheit ≦ 3 Kg/6.6lbs

Auösung 5M pixel

Scan-Genauigkeit 1.48 mm

Dateitypen OBJ, STL

5cm ϕ x 5 cm – 14cm ϕ x 14 cm (H)

Installieren Sie das Scannermodule

Um das Scanmodul zu installieren, richten Sie es an der Scannerbasis aus, drücken und halten Sie die Taste und

befestigen Sie es vertikal an der Basis.

Scannermodule-Steckplatz Taste

Befestigen Sie das Scanmodul

vertikal an der Basis.

P22P22

P22

Page 48

Scannen

Begrenzungen für das zu scannende Objekt

Das Objekt sollte stabil und unbeweglich sein. Es darf während des Drehens der Rotationseinheit nicht gerüttelt oder

•

bewegt werden.

Der Scan-Bereich des Objekt-Modus beträgt 5 cm ϕ x 5 cm – 14 cm ϕ x 14 cm (H)

•

Das Objekt sollte nicht reektierend, transparent oder durchscheinend sein.

•

Ein Objekt mit einer reektierenden Oberäche, Metall oder einem transparenten Material hat Auswirkungen auf die

•

Druck-Qualität. Wenn Sie ein solches Objekt scannen möchten, wird empfohlen, das Entwickler-Spray oberächlichaufzusprühen, bevor Sie es scannen.

Die Scan-Qualität kann bei einfarbigen Objekten oder Objekten ohne merkliche Besonderheiten oder mit einem gro-

•

ßen Bereich in einer schlichten Form variieren.

Runde Objekte weisen gute Scan-Ergebnisse auf, während schmale und lange oder scharfe Objekte keine guten

•