Page 1

English

◆

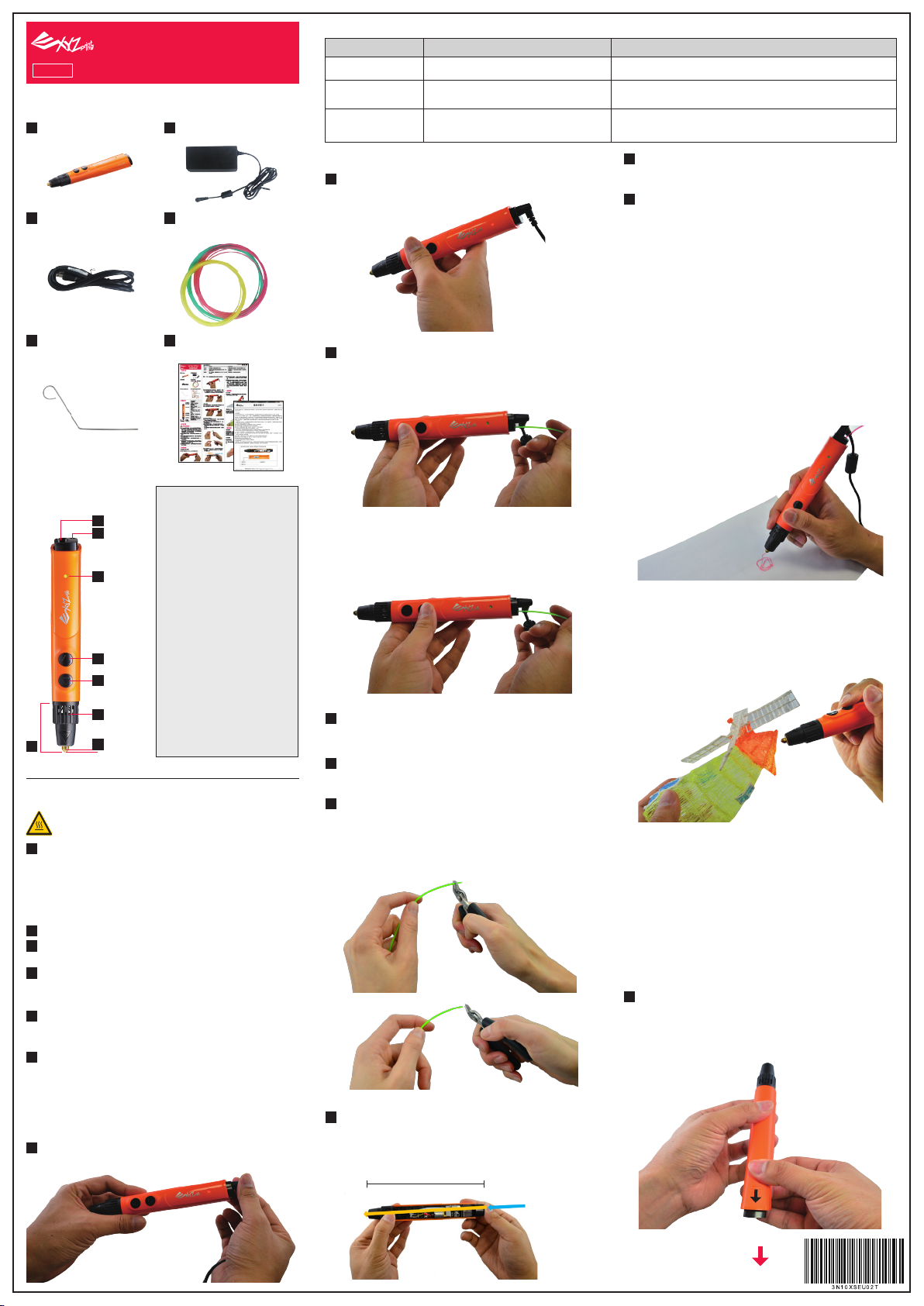

Package content

1

3D Pen

3

Power cord

da Vinci 3D Pen

Quick guide

2

Power adapter

4

(

Including 3x PLA filament. Length: 1 meter; color: random color

Trial filament

◎Load / Unload mode:

When you want to…

Extrude manually

Extrude continuously

Unload continuously

2

Press any button to begin heating up

(the LED indicator should be steady flashing red light).

)

How to operate the button

Press and hold the load button and release it to stop extrusion.

Press the load button twice and release the button. The pen will enter

continuous extrusion mode. Press any button to stop the extrusion process.

Press the unload button and allow continuous filament unloading for

about 50 seconds. You can click any button to stop unloading.

When to use the mode

When you want to best control the extruding at the right moment.

When you need continuous flows to build up successive structure.

When you want to replace filaments or when the feeding path is clogged.

5

To replace or remove the filament, ease unload the filament as

instructed process. Do not forcibly pull the filament out from the pen

as this may damage the internal components.

6

If you are about to change the color of the filament, please unload

the filament before it goes inside the feeding path completely and

becomes too short to be pushed out by the gear. When switching

between materials of different colors, the tip of the new filament may

mix with the old residual material. The extrusion of materials with

mixed colors would be normal. You may push out the filament left

inside with the unblocking tool before inserting the filament of

different color if you don't need the unexpected color.

5

Unblocking tool

6

Quick guide /

Warranty card

◆

Product Diagram

1

DC in terminal

2

Feeding hole

3

LED indicator

Unload

4

button

Load

5

button

6

Air vents

7

8

Nozzle

[LED Messages]

◎ Solid red light:

Powered on; cooled down.

(nozzle temperature < 60°C)

◎ Steady flashing red light:

Idling. Cooling down.

(Nozzle temperature between 60°C and 180°C)

◎ Quick flashing red light:

Heating up

(Nozzle temperature between 60°C and 180°C;

under cooling mode, heating will take another

2 minutes)

◎ Solid green light:

Nozzle heated up, it's ready to load/unload

filament now.

(Nozzle temperature: > 180°C)

The nozzle cools down when idling for 60

seconds. To heat up the nozzle, simply press

any button.

Extruder

module

◆ Precaution

BURN HAZARD:

1

The nozzle of the 3D pen will become heated. Do not let the nozzle of the pen

come in contact with surrounding components before it completely cools. Do

not touch plastic materials that have yet to set to prevent burns.The heated

nozzle of the pen and heated plastic materials may damage other objects,

plastics, fabrics, or materials. Avoid touching anything with these heated

objects before complete cooling.

2

Keep the air vents open to ensure that the 3D pen works properly.

3

The heated filaments would generate certain smells during heating. Please use

this product in a well-ventilated space.

4

Please use PLA filaments provided by XYZprinting and refer to user instructions

when using this product to avoid damages. Warranty void if non-XYZprinting

filaments are used.

5

The product is fully tested on the production line. The testing material may be

left in the nozzle. The color of the extruded filament might differ from the

feeding filament in the first use.

6

The material in the nozzle may cause slight cracking sound while heating up.

3

Once the heating is complete (green indicator is ON), press the

[Load Button] twice to activate continuous extrusion mode. Insert

XYZprinting filaments into the feeding hole. Let go of the filament

once you feel the pen taking in the filament on its own.

◎Replacement / unloading

When the indicator is Green, press the unload button to unload the

filament. Once the filament unloading has stopped, click any button to

stop unloading and pull out the filament.

◎Reminders for using the filament

1

If there is no filament left in the pen, please allow about 1 minute

after activating the feeding function to drive the filament into the

nozzle of the pen.

You may cut the length of the filament to the desired length.

2

The maximum length of the filament should not exceed 3 m to

ensure that the feeding process works properly.

3

For best operation, it is suggested to unload the filament left in the

pen after you have done your creation. Be sure to cut off, the molten

tip of the filament before reuse to prevent it from clogging up the

feeding path.

When cutting the filament or when you notice that the tip of the

filament has been partially melted, cut the tip off the make it flat.

◆ 3D drawing tips

◎Create the foundations

When you start drawing, draw a base on paper or on the surface of an

solid object will be a good start. And then you can go free in the air.

◎Follow the gravity

Heated PLA filament is soft. It may take a while for hardening. When

creating bridges and other 3D structures, we recommend adjusting the

angle of your drawing so that the partially molten plastic will droop

down naturally and achieve a more natural finish.

◆ Troubleshooting

◎LED indicator is off

If the LED indicator fails to turn on after connecting the power to the 3D

pen, please check if the power plug is properly inserted into the power

source and the 3D pen. If the light is still off after everything was plugged

in properly, please contact the customer service center for help.

◎The feeding path gets clogged

1

Clean the guide tube

If the pen cannot extrude normally, please first unload the filament, then

remove the back cover (by pushing it towards the back), remove the

guide tube, remove all residual filament inside, and reinstall it.

◆ Operation

◎Loading/extruding the filament

1

Connect the bundled power source to the 3D pen

(LED should be solid red light).

4

When the filament left inside is too short, the internal feeding

mechanisms would be unable to push the filament. If this occurs,

please insert another strand in filament through the feeding hole to

push the filament out.

Filament left inside is too short

Insert another filament

through the feeding hole

-1-

Page 2

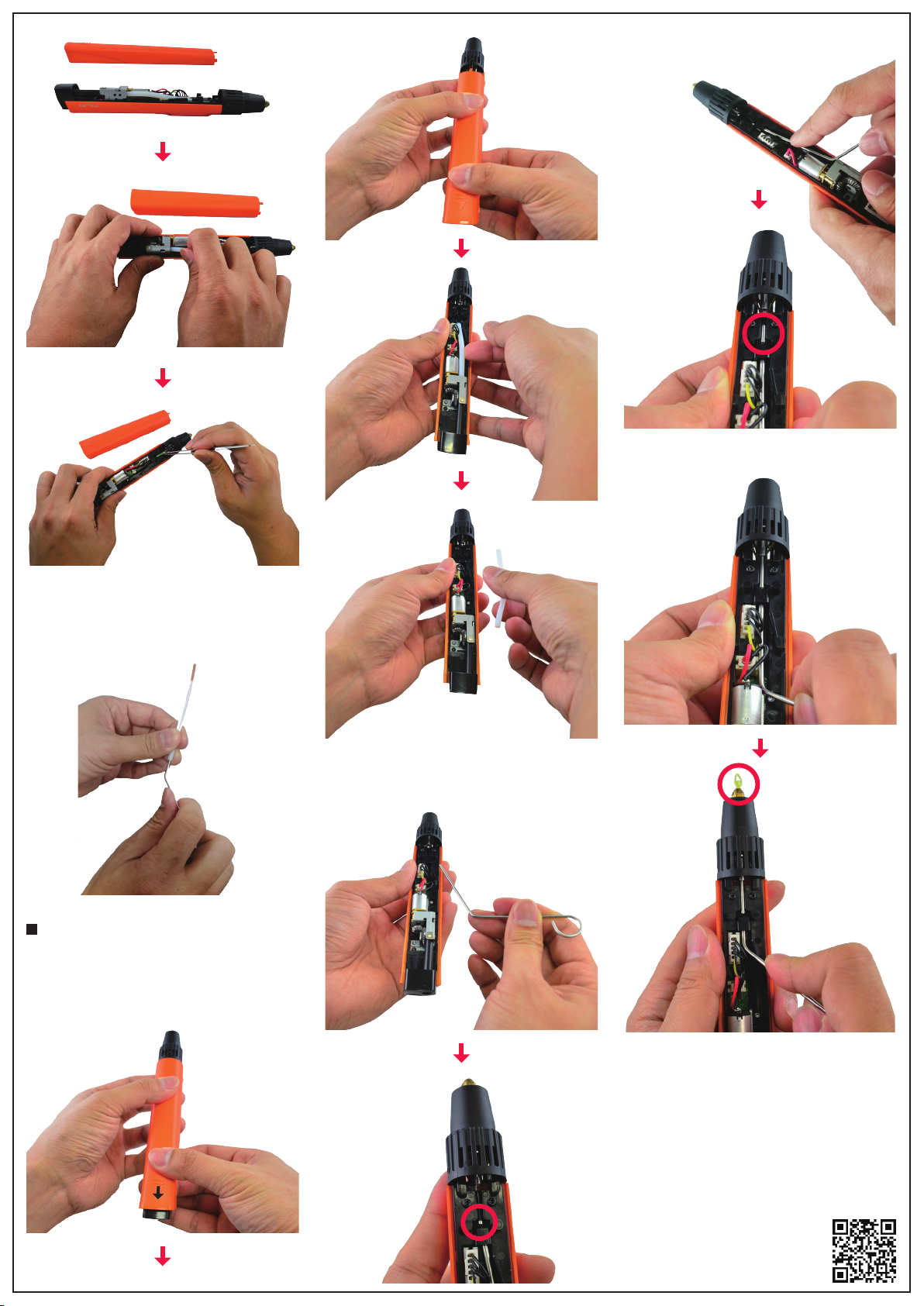

Press the tool slightly so that it is fully inserted into the feeding route. The

tip of the tool will move about 1 cm through the round opening.

Push and pull tool. Residual materials from the extrusion module can be

pushed out from the opening.

Use the unblocking tool to remove any residue within the white guide

tube. Make sure that all remain filaments have been removed from the

guide tube, reinstall the back cover, and restart the feeding process.

2

Clean the extruder module

After using the pen or when the pen fails to extrude, the blocking tool can

be used to clean the extruder module. Please first unload the filament,

then keep the pen in continuously extruding mode. Make sure that the

pen is kept in a heated state to facilitate the removal of residual materials

from the extruder module of the pen. Take the back cover and push it

backwards and take out the white guide tube.

Place the unblocking tool in the feeding path and insert the sharp tip of

the tool into the round opening at the top of the insertion route.

◆

Technical Support and Tutorial Video

◎Contact information

[US]

XYZprinting, Inc.

Add: 9877 Waples Street San Diego, CA 92121

Website: http://us.xyzprinting.com

Contact Information

Technical Support: 855-999-3348 | Service Hour: Monday-Friday 9am-9pm (EST)

Online Service Desk:

http://support.xyzprinting.com/us_en/Help/ticket/home

[EU]

XYZprinting Netherlands B.V.

Add: Wagenmakerstraat 7, 2984BD Ridderkerk The Netherlands

Website: http://eu.xyzprinting.com

Online Customer Service Desk:

http://support.xyzprinting.com/eu_en/Help/ticket/home

[Global]

Add: No. 147 Sec. 3 Beishen Rd. Shenkeng Dist. New Taipei City Taiwan

Online Service Desk:

http://support.xyzprinting.com/tw_zh_tw/Help/ticket/home

◎Tutorial Video

For tutorial videos, please go to:

http://support.xyzprinting.com/eu_en/Help/tutorial

-2-

Loading...

Loading...