Page 1

LCD EWP/Fan Digital Controller Customer Instructions – Part #18922 (July17) Page 1 of 12

77 Taras Avenue

P.O. Box 363

Altona North

Vic 3025 Australia

Phone: +61(0)3 9369 1234

Fax: +61(0)3 9369 3456

info@daviescraig.com.au

www.daviescraig.com.au

LCD EWP®/FAN DIGITAL CONTROLLER INSTRUCTIONS

(SUITABLE FOR USE WITH ALL DAVIES, CRAIG EWP®s (ELECTRIC WATER PUMP), EBP®s

(ELECTRIC BOOSTER PUMP), AND THERMATIC

®

FANS)

PLEASE READ ALL THESE INSTRUCTIONS THOROUGHLY BEFORE YOU START WORK.

DON’T RUSH - ENSURE YOU HAVE FULL UNDERSTANDING OF THE WORK AHEAD BEFORE YOU

COMMENCE. ENSURE YOU HAVE ALL TOOLS AND COMPONENTS REQUIRED.

Congratulations on your purchase of the Davies, Craig EWP®/Fan Digital

Controller (PATENTS: USA 6425353, EU 1133624, AUS 756453). This Controller will

manage the operation of your chosen EWP

®

or EBP® by varying the speed of

your pump in response to coolant temperature and it will manage the on/off

control of your Thermatic

®

Fan.

The Controller will run the EWP

®

after ignition shutdown to dissipate

heat and avoid heat-soak.

The Controller has a push-button control to allow you to choose one of

nine set operating temperatures.

Generally, higher engine temperatures will offer improved fuel

efficiency and lower temperatures will increase power.

It’s recommended that engine operational temperatures be checked

against those nominated by your vehicle manufacturer.

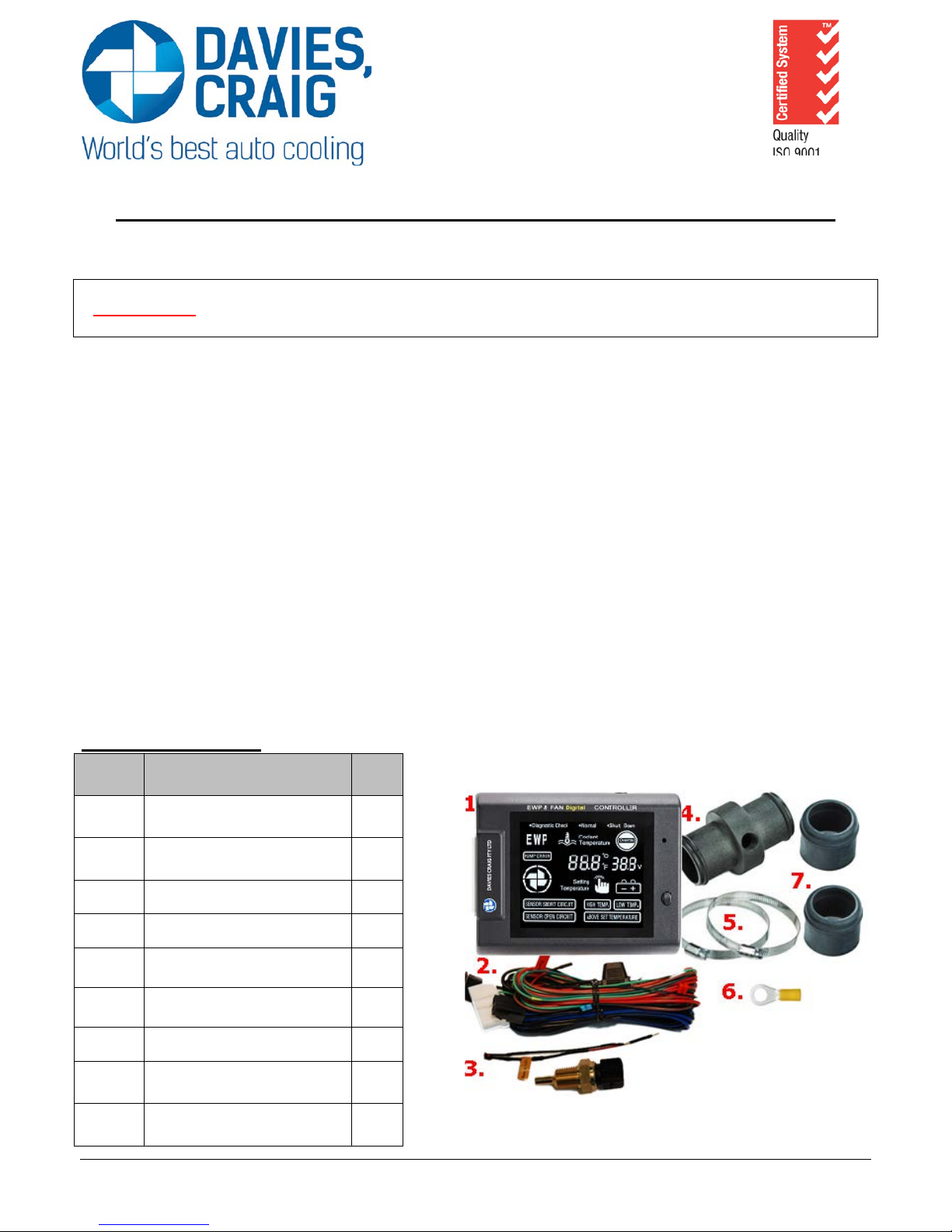

KIT CONTENTS:

Item

No.

Description Qty

1.

EWP Digital Controller

Assembly

1

2.

Wiring Harness

(Includes 10Amp Fuse)

1

3. Sensor Assembly 1

4. In-Line Adaptor 1

5.

Hose Clamps 2

6.

Ring Terminal 1

7. Rubber Sleeves 2

Not

Shown

Velcro 2

Not

Shown

Installation Instructions 1

Figure

1: LCD EWP/Fan Digital Controller Kit

Components.

Page 2

Page 2 of 12

INSTALLING THE LCD EWP®/FAN DIGITAL CONTROLLER

1. The Controller should be installed inside the pas senger compartment to mini mise its

ambient temperature and exposures to water as the unit is not waterproof. Also

minimise exposure to direct sunli ght. Locate a hole in the firewall (approx. 20 mm in

diameter) and pass the wiring harness (including the sensor & pump “T-connector”)

through. If a hole of adequate size cannot be located, then wires may be cut then rejoined as a last resort. Connect T-Plug in wiring loom to the pump.

2. Connect black Sensor Plug to the thermal sensor located in the thermostat

housing/inline adaptor (Refer to Digital Controller Wiring diagram, Page 3).

3. Connect the white plug in the wiring harness to the controller then mount the

controller with Velcro supplied. Ensure it is mounted where access to the

temperature adjustment button is easy. NOTE: Ensure a good earth connection

using the self-tapping scr ew provided. The ear th lead must be connected to a metal

part of the car body.

4. Connect the Red wire fro m the wiring harne ss to the batt ery positive us ing the ring

terminal provided. Connect the Green wire from the wiring harness to an ignition

source (accessor y +12V/24V or switched 12V/24V), the wires may be spliced then

soldered if necessary. Ensure no wire is exposed, by insulating the join with

electrical tape.

5. Connect the Green and Black striped wire to the fan rela y if you w ish to c ontro l the

Thermatic® Fan 3º C above the set temperature. NOTE: The Co ntroller will ea rth the

fan relay, not power it.

6. Mount ‘Remote Test Light’ in a locatio n where it will be visible. The ‘T est Light’ may

be fitted by inserting it through a 4.6mm diameter drilled hole in a plastic area of the

interior/dashboard or simply with adhesive tape. T he ‘Remote Test Light’ has a two

pin connections. Heat shrink or insulation tape can be applied to these pin

connections once th e te st lig h t is mo unted. This will ens ur e the co nne c tio n po i n ts ar e

insulated and secure.

NOTE:

In carrying out the wiring procedure, please bear in mind that it is adva ntageous

to minimise voltage drop by keeping the wiring as short as possible.

Remove the engine the rmos tat from the thermo stat ho using and i nstall the se nso r

using Method 1 or 2 as shown below.

If you often operate in very cold climates, drill 2 x 5mm holes in the thermostat

plate before reinstalling.

Ensure there is no damage to the thermostat-housing gasket, and re-fit the

thermostat housing without the thermostat.

Page 3

Page 3 of 12

OPERATION OF DIGITAL CONTROLLER

CONTROLLER ALGORITHM-PUMP OPERATION

The ‘set point’ can be programmed to any setting betw ee n 40°C (104°F) to 110°C

(230°F).

Figure 2: Digital Controller Wiring Diagram

Digital Controller Operation Chart.

Page 4

Page 4 of 12

OPERATION of LCD

THEMPERATURE INDICATOR

Rises with increased engine temperature

EWP SYMBOL

FLASHING = EWP

®

operating in ‘pulsing’ mode – Refer Digital Controller Operations

Curve, areas &

ON = Electric Water Pump (EWP®) working at full speed.

FAN SYMBOL Circulating = fan operating

DIAGNOSTIC CHECK

System warning has been triggered. Therefore, refer to “Diagnostic Chart” in order to

determine possible cause, and take measures to correct the problem.

REMOTE TEST LIGHT (RED)

This light will “flash” when the system works in diagnostic check mode.

SYSTEM CHECK:

Every time the ignit ion is turned ON, all s ymbols will illum inate. This featur e allows you

to check all functions are operational.

SHUT DOWN MODE:

Your Controller will continue to operate your EWP® for three (3) minutes or until the

coolant temperature has reduce d -10°C/-14°F below your set point – whichever occurs

first. The “Shut Dow n” feature will eliminate heat so ak and reduce engine temperature

evenly. The feature protects your engine against gasket damage due to hot spots. This

Figure 2: LCD EWP

®

/Fan Digital Controller.

A

B

C

Page 5

Page 5 of 12

cooling efficiency can be improved further with the use of high performance Davies

Craig Thermatic® Fan/s.

VOLTAGE DISPLAY:

Indicates the controller input voltage.

OVERRIDE:

When controller is at “Normal” mode, by pressing & holding the “Set Button” for 5

seconds the EWP® will override (7 Seconds for EWP & FAN). This feature benefits for

drive the EWP® at full speed similar as hot wire the pump. To cancel the “Override”

mode, press & hold the set button for 5 seconds or switch off the ignition.

°C to °F change:

When controller is at “Normal” mode, by pressing & holding the “Set Button” for 3

seconds the controller will change to °C to °F or °F to °C.

DIGITAL CONTROLLER THERMAL SENSOR INSTALLATION

There are two installation methods available.

METHOD 1: IN-LINE ADAPTOR METHOD (supplied & recommended)

As with other Davies Craig products the In-line Adaptor has universal application.

NOTE: Top Radiator Hose Measurements to Sleeve.

30 to 35 mm inside diameter (ID) – use adaptor without sleeves.

36 to 42 mm ID – use 2 sleeves included in the kit

42+mm ID – contact Davies, Craig for thicker 6mm sleeves (Part #18511)

1. Thermal Sensor Fitting

Apply a couple of layers of Teflon sealant tape around the threaded body of the

sensor, Fit the sensor assembly into the threaded black In-line Adaptor and tighten.

Do not over tighten, which may damage the sensor body or adaptor.

2. Hose Fitting

• When the cooling system is cold, remove top radiator hose and confirm that the

inside diameter of your top radiator hose is between 30 to 42 mm prior to cutting

hose. If the hose is more than 42mm, call Davies Craig and await 6mm sleeves.

Use the “O” ring supplied with

the sensor.

Apply PTFE sealant tape (not

supplied)

on to the threaded

body before tightening to the

adaptor.

Figure

3: Thermal Sensor and In-line Adaptor Installation

Page 6

Page 6 of 12

• If the parts supplied (adaptor and/or sleeves) are suitable, select an appropriate

location in a straight section of the hose then cut the radiator hose.

• Temporarily slide radiator hose clamps on each end of the hose. Fit both cut ends

of hose onto the In-line Adaptor (with or without sleeves as appropriate). If fitting

is tight, use silicon base grease or petroleum jelly to assist fitment of adaptor to

hoses.

• Refit top radiator hose, ensure no twisting of hose and tighten all clamps.

METHOD 2 - IN THERMOSTAT HOUSING OR RADIATOR

Please check wall thickness of thermostat housing/radiator as it is recommended that

the Thermal Sensor only be installed if there is a wall thickness of at least 3mm.

If the thickness is less than 3mm, please proceed with installation Method ‘1’.

We suggest removal of the thermostat ho using before be ginning the installatio n process

so that metal shavings do not enter the cooling system.

1. Mark location on thermostat

housing where sensor assembly is

to be fitted – “top of dome is

recommended”.

2. Drill an 11.0mm (7/16”) hole

through the marked area. For your

safety and to avoid drilling on an

angle, please ensure thermostat

housing is well secured before

beginning the drilling process.

3. Using a ¼” NPT tap, tap the hole

to allow the sensor assembly to

“just” protrude the thickness of the

thermostat housing. It is

recommended that the fitment of

the sensor assembly be checked

regularly to achieve the condition

in the diagram.

Page 7

Page 7 of 12

4. Once the tapping process is

completed, apply a couple of

layers of PTFE sealant tape (not

supplied) to the thread on the

brass body, then screw it into the

thermostat housing.

SETTING THE LCD EWP®/FAN DIGITAL CONTROLLER

It’s recommended as a mi nimum the Digita l Controller’s s et-point is fixed to that of the

engine manufacturer’s mechanical thermostat opening temperature. You may use a

lower ‘set-point’ to run the engine colder or a higher ‘se t-point’ to run the engine hotter

if appropriate. Gen erally, running the en gine slightly colder w ill increase the power and

running the engine slightly hotter will improve the fuel efficiency.

The LCD EWP & Fan Dig ital Controller has been set at the factory at 85°C/185°F. This

setting can be altered up or down by using the ‘set-point’ adjustment button on the

right hand side as follows:

1. Pushing the ‘set’ button once will indicate the present setting.

2. Push set button repeatedly until the desired set temperature displays. Hold set

button down 2 seconds until Controller beeps. The ‘set’ temperature will then

illuminate

3. If the new s e tt ing is not confirme d within 2 sec, the D ig i tal Controller will r e ve r t to

previous ‘set’ temperature.

4. To check ‘set’ temperature, repeat Step 1 above.

Note: Controller will keep the last state of “Set Temp” memory, when disconnected

from the power source

NOTE: Monitor the existing engine temperature gauge to check that your set engine

temperature is similar to the actual engine temperature. The engine temperature sender

unit may be located in a different position than your Thermal Sensor and may display a

temperature variation.

Figure 4: Sensor Installation in to Thermostat Diagram

Page 8

Page 8 of 12

FAN ONLY OPERATION

The Davies, Craig LCD EWP/Fan Digital Controller is programmed to earth the electric

fan relay at 3°C above the set point. The Controller will continue to operate the fan until

the coolant temperature is below the set point.

To enable fan only control without using an Electric Water Pump, connect the remote

LED (supplied) to the controller wires labelled “PUMP” as shown below

Please refer to the Figure 6 (page 9) for fan to controller wiring details. Please call

Davies, Craig at (03)93691234 if you require another remote LED to complete the

wiring.

EWP & FAN DIGITAL CONTROLLER TECHNICAL

SPECIFICATIONS

Input Voltage

12VDC to 29VDC

Output Voltage

6V to 29V

Max. Current

12A

Operating

Temperature

-20ºC to 120ºC (-4ºF to 248ºF)

Setting

Temperatures

C

40º

To

110º

F

104º

To

230º

Fan Cut in

Temperature

+3ºC/5.4°F above t he set temperature

Sensor Type

Thermistor

Time Out

3 Min. (or Set –10ºC/14°F) after ignition OFF

Weight

100 grams (3.5 oz.)

Dimensions

110mm (L) X 90mm (W) X 30mm (D)

[41/3” (L) x 31/2” (W) x 1.1” (D)]

A 12V LED connected to the Pump

connector

Figure 5: Fan Only Connec t ion Wiring Diagram

Page 9

Page 9 of 12

THERMATIC® FAN WIRING TO THE DIGITAL CONTROLLER

Please follow the instructions 1&2 below if you are using the Davies

Craig Universal Fan Fitting Kit (Parts #1000, 12V; #1001, 24V).

1. Cut the ring terminal off the black wire (8 5) from the Fan wiring loom to a sufficien t

length, this wire (w ith relay) to be join ed with the black/green wire from the Digital

Controller.

2. Cut the green wire, then join suffic ient length of wire to connect to battery positive

as shown in the diagram below (86).

Note: To wire the controller for duel fan operation repeat the wiring instructions above

for a second relay (not supplied). Pin 85 on both relays should be connected to the

green wire with black stripe from the controller. We recommend getting a second Davies

Craig Universal Fan Fitting Kit (Parts #1000, 12V; #1001, 24V) for proper fan

installation.

Figure 6: Fan Controller Wiring Diagram

Page 10

Page 10 of 12

CONTROLLER DIAGNOSTIC CHART

Condition Troubleshooting

Controller does not operate / No display

• Blown fuse

• Check all the wire connections

12V voltage indicator flashing

• Controller receiving low voltage <

10.5V

• Controller receiving high voltage >

17.5V

24V voltage indicator flashing

• Controller receiving low voltage <

21.5V

• Controller receiving high voltage >

27.5V

Sensor open circuit

• Check sensor wiring for any open

circuits

Sensor short circuit

• Check sensor wiring for any short

circuits

Low Temp

<40°C (104°F) after 5 Minutes

• Check engine temperature

Above Set Temperature

• Sensor temperature is at least 10°C

(18°F) above the set temperature.

Pump Error

• Check pump wiring for open/short

circuits

Override ON

• EWP manually override by the user.

• To turn OFF, Press & hold the set

button for 5 to 7 seconds or switch

OFF & ON the IGN.

ERR • Temp sensor Open or Short circuit

Page 11

Page 11 of 12

INSTALLATION RECOMMENDATIONS

• For improved heater pe rf or manc e on vehicle s w hic h hav e the heater inlet (retur n) an d

outlet ports in the mechanical pump housing, Davies Craig has available an Electric

Booster Pump Kit, EBP15 #9001 (12V) or EBP23 #9050 (12V) or EBP40 #9040

(12V). These compact units fit neatly into the heater hose and boosts coolant flow

through the heater circuit and/or cylinder heads.

• LPG (Liquid Petroleum Gas) vehicles require constant coolant flow through the LPG

converter once a EWP Combo Pack has been fitted. We strongly recommend the

installation of Ele ctric Boo ster Pump Kit , EBP15 #9001 (12V) or EBP23 #9050 (12V)

or EBP40 #9040 (12V) to overcom e freezing of the conv erter on engine start-up.

CAUTIONS

• Engine temperature must be monitored cl osely at all times, especially,

immediately after EWP

installation and until the EWP operation and

capability have been confirmed.

• Do not use the vehicle’s engine management system or wiring

connected to the vehicle’s engine ma nagement system as an ignition

source because it may cause failure of the management system

and/or the electrical system. The ignition source must be a steady

positive supply of 12-29V DC.

These installation instructions may suit most applications but there are

circumstances surrounding some engine designs, environments, and the nature

of system involved, which may require other installation arrangements not

outlined here. Frequently Asked Questions (FAQ) are listed on our website

www.daviescraig.com.au . Emails can be directed to info@daviescraig.com.au

or Telephone +61 (0) 3 9369 1234 during business hours.

WARRANTY

Davies, Craig Pty Ltd warrants for a period of two years or 2000 hours continuous

running (whichever is the lesser) from the date of purchase. Davies, Craig shall carry

out, free of cost, any repairs that are reasonably necessary to correct any fault in the

operation of your Davies, Craig product provided that s uch a faul t is directly at tributable

to a defect in the workmanship or materials used in the manufac ture of the part(s) and

is not due to installation other than described in these instructions. Labour and

consequential costs are excluded.

DAVIES, CRAIG PTY. LTD.

Register your warranty at: daviescraig.com.au

Page 12

Page 12 of 12

Loading...

Loading...