Page 1

I Sears I

owners

manual

/

MODEL.NO.

SUBURBAN TRACTOR

597.261620

SEE

•

CAUTION:

Read

Safe

and

~----------------------

Rules

Operation

Instructions

Carefully

for

Sears,

and

Asse

•

Operating

•

Mainten

•

Repair

Simpsons

DER

mbly

---------------------------

Roebuck

AND

ance

Parts

and

Sears

Co.,

Chicago

Limited,

FERTILIZER

,

Ill.

60684

Toronto

U.S.A

.

Page 2

INTRODUCTION

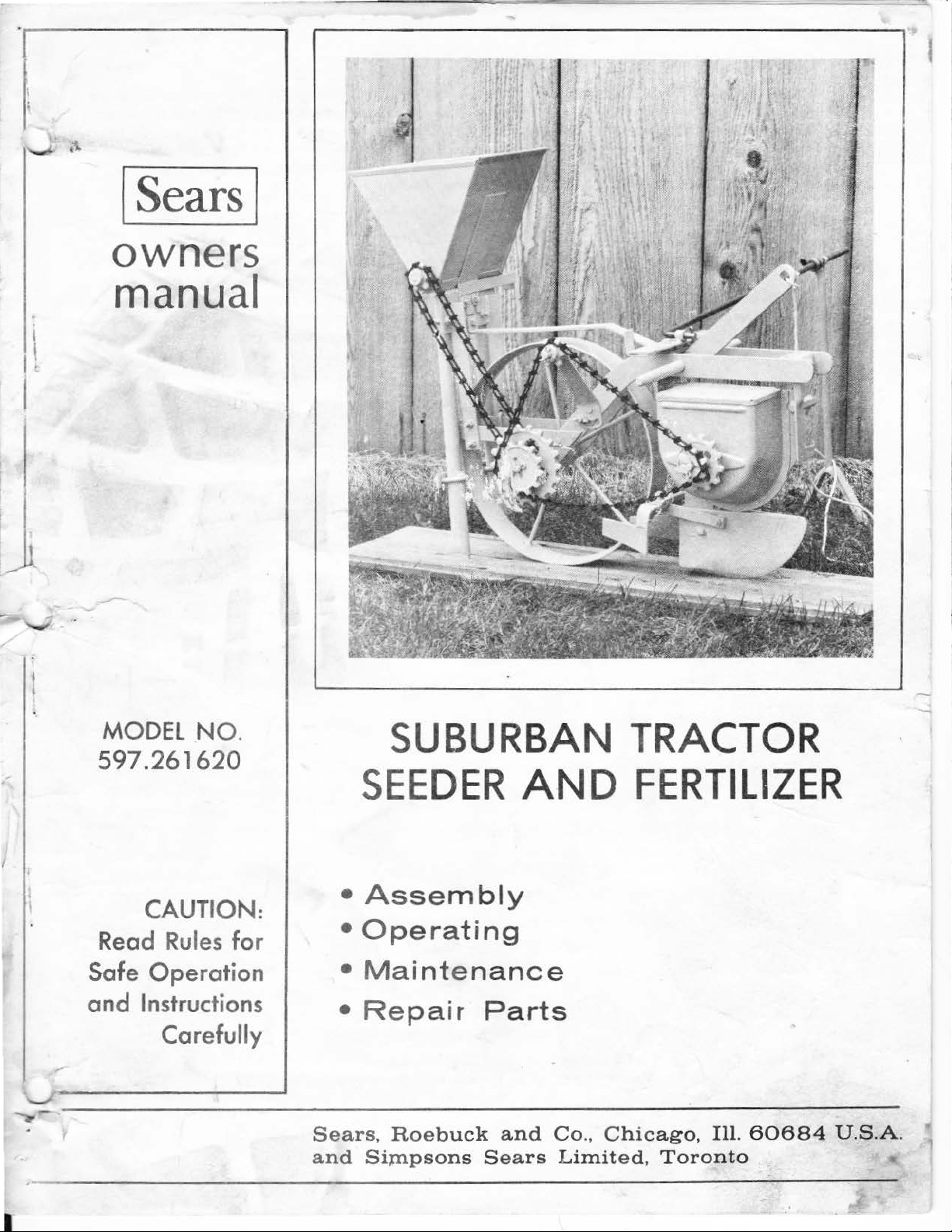

The Sears Seeder has been designed

Tractor. The

and

will eliminate the need

It

is

important

results.

Sears Tractor Seeder

The

The Fertilizer

is

extremely rugged and will operate under

attachment

placed as far

the

ground

of

fertilizer

Seeder will

that

attachment

will

allow its use

or

close

or

to

any

that

is required. Hopper design allows material

plant

a variety

for

thinning crops.

the instructions in

Mod

el597.261620 is shipped in one carton. Carto n #597.25.

is especially designed

for

to

seed

as

depths

to

4"

to

the

any normal

is

desired

below

permit

of

for

the

quick

mounting

seeds and will meter

manual be studied and followed closely in order

for

quick

easy on and o

many

type

all practical purposes. Fertilizer may also be placed

ground

types

use. The simple easy adjustments allow the fertilizer

. Simple finger tip adjustment permits control

to

and dismounting

the

seeds accurately

ff

mounting

of

conditions. The flexibility

flow

without

clogging.

to your Seeder.

to

at

the

Sears Suburban

all practical spacings

to

obtain

of

the fertilizer

good

Mounting

to

on

top

of

amount

be

of

HOW

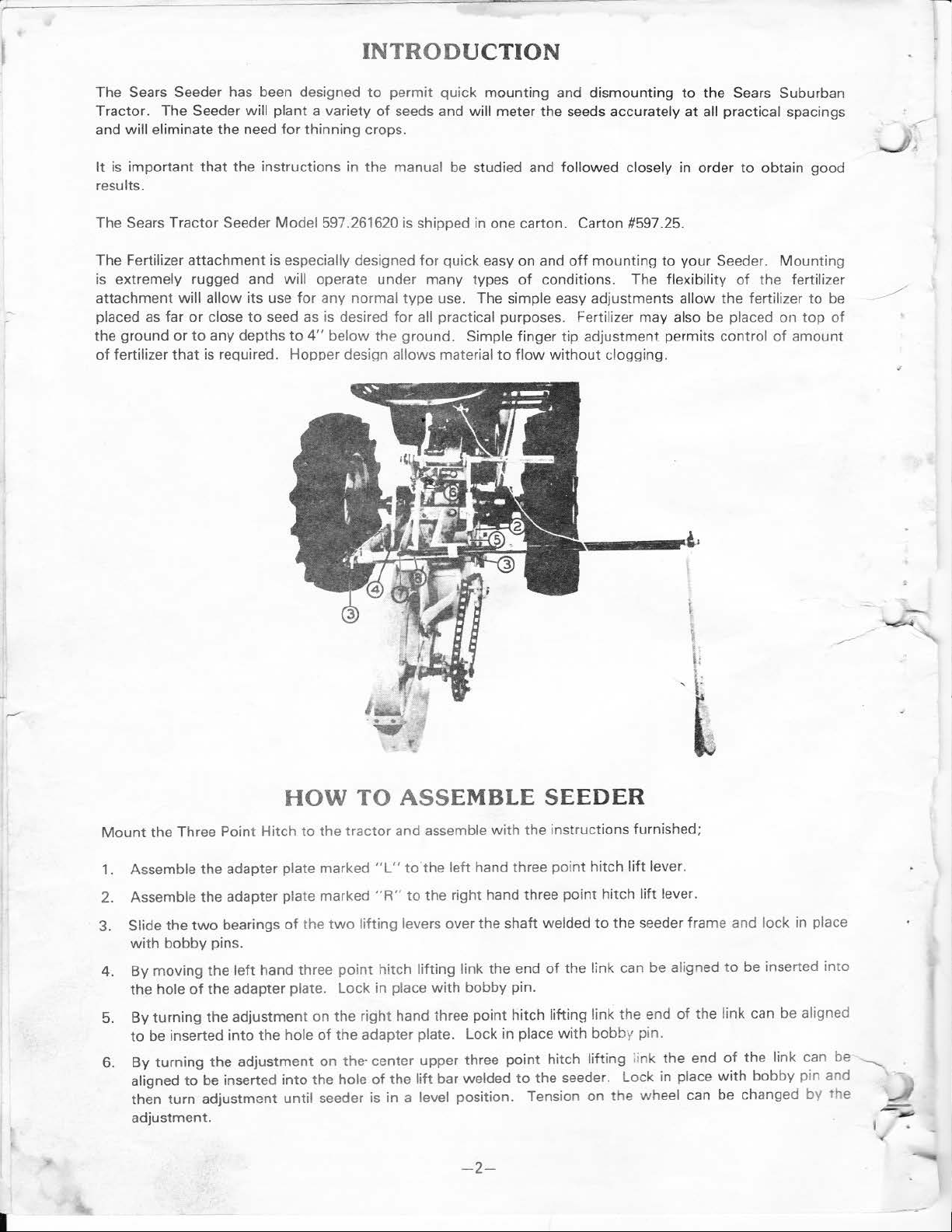

Mount

1.

2. Assemble the adapter plate marked

3.

4.

5. By

6.

I

the

Three Point Hitch

Assemble the adapter plate marked

Slide the

with

By

the hole

to

By

aligned

then

adjustment

two

bearings

bobby

moving the

turning

be

turning the adjustment

pins.

left

of

the adapter plate.

the adjustment

inserted

turn

into

to

be inserted

adjustment until seeder is in a level position. Tension

.

of

hand three

the hole

into

TO ASSEMBLE

to

the

tractor

the

two

point

Lock

on

the right hand three

of

the

on

the- center upper three

the

hole

and assemble

"L"

to

"R"

to

lifting

levers over the shaft welded

hitch lifting link the end

in place

adapter plate. Lock in place

of

the

SEEDER

with

the ins

tructions

the left hand three point hitch

the right hand three point hitch lift lever.

of

the

with

bobby pin.

point

hitch lifting link the end

with

point

hitch lifting ;ink

lift

bar welded

to

the seeder. Lock in place

-2-

furnished;

lift

lever.

to

the seeder frame and lock in place

link can

bobb

on

be

y pin.

the

the

wheel can be changed

aligned

of

to

be inserted

the link can be aligned

end

of

the

link can be

with

bobby pin and

by

into

the

t

~

-

Page 3

7.

When

seeder is in use

th

e back Hopper Brack

to

the

bracket

of

end

(2) holes located in the rear

the Moun

rear

ting

without Fertilizer Attachment,

et

(bracket closest

of

the Seeder. The stops

Bracket. Secure the Marker Bracket

hopp

er bracket.

to

wheel)

of

the Mounting Bracket are the two welded angles on each

mount

the Marker Mounting Bracket

of

the Seeder, keeping the stops on the marker

with

th&

two

(2) bolts provided, using the

to

the top

of

two

8. The bent end

t.

bracke

will rest in

Rod

9.

When

the Fertilizer

the instructions provided

and the

with

Fertilizer. The washers are used

bracket and the Marker

of

the marker rod is inserted

This rod should be inserted

front

of

Attachment

two

bolts

which

HOW

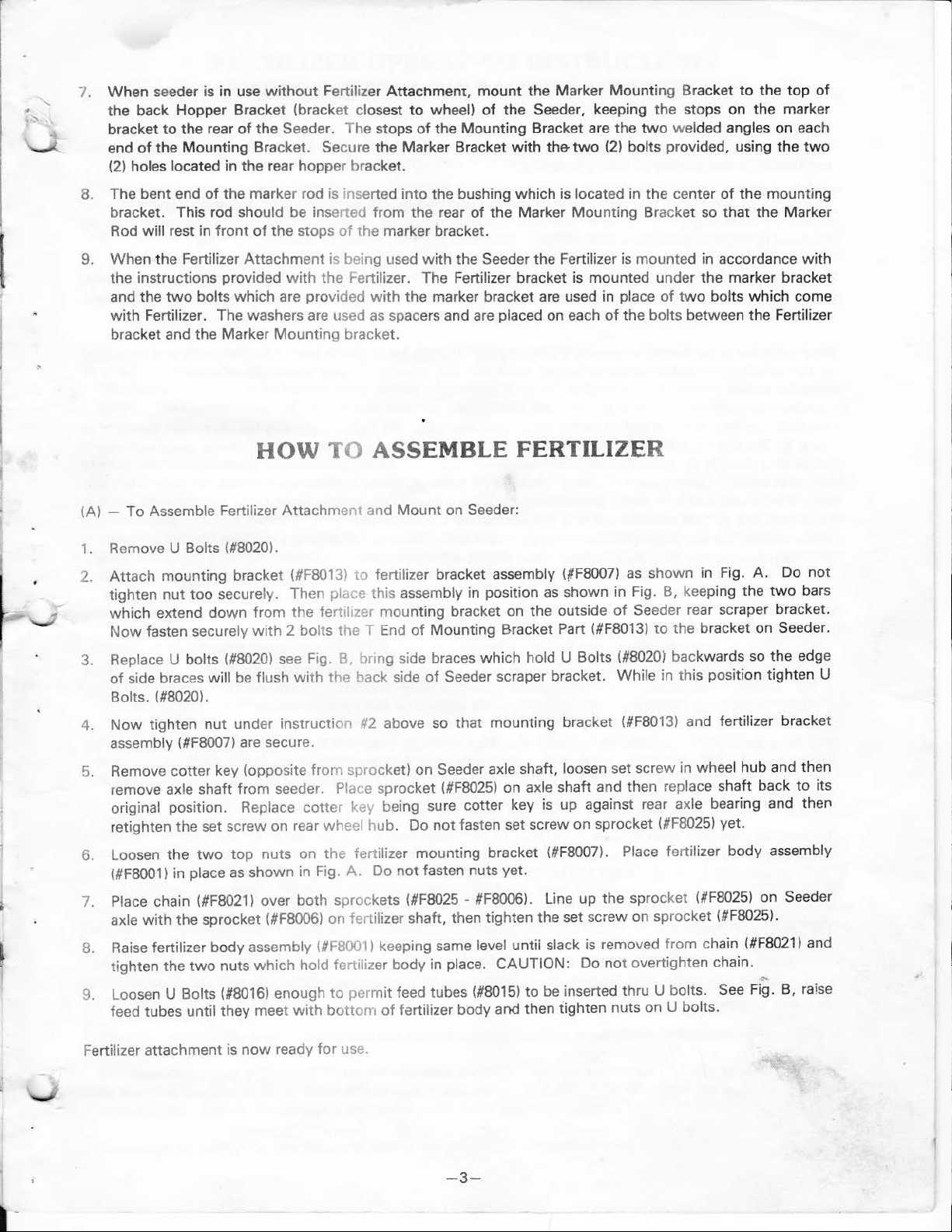

(A) -

To

Assemble Fertilizer

1. Remove U Bolts (#8020).

2.

Attach

tighten

which

Now

mounting bracket

nut

too

securely. Then pldce this assembly in position

extend

fasten securely

down

from

with

into

the bushing

from

the rear

the stops

with

are provided

Mounting

Attachm

(#F801

the fertilizer mounting bracket on the outside

2 bolts the T

of

the marker bracket.

is being used

the Fertilizer. The Fertilizer bracket is mounted under the marker bracket

with

as

bracket.

TO

ASS

ent

and

3)

to

fertilizer bracket assembly

with

the Seeder the Fertilizer is mounted in accordance

the marker bracket are used in place

spacers and are placed on each

EMBLE FERTILIZER

Mount

End

on Seeder:

of

Mounting Bracket Part (#F8013)

of

the Mark

which

is located in the center

er

as

of

the mounting

Mounting Bracket so that the

of

two

bolts which come

of

the bolts between the Fertilizer

(#F

8007)

as

shown in Fig. A. Do

shown in Fig. B, keeping the

of

Seeder rear scraper bracket.

to

the bracket on Seeder.

Mar

two

ker

with

not

bars

3.

Replace U bolts (#8020) see Fig.

of

side braces will be flush

(#8020).

Bolts.

4.

Now

tighten nut under instruction #2 above so

assembly

5. Remove cotter key (opposite fro m sprocket) on

remove

original position. Replace cotter key being sure cotter key is

retighten the set screw on rear wheel hub. Do

6.

Loosen the

(#F8001) in place

7.

Place chain (#F8021) over both sprockets (#F8025 - #F8006). Line

axle

8. Raise fertilizer body assembly (#F8001) keeping same level until slack is removed from chain

tighten the

9. Loosen U Bolts (#8016) enough

feed tubes until they meet

Fertilizer attachment is

(#F8007) are secure.

axle shaft from seeder. Place sprocket

two

top nuts on

as

shown in

with

the sprocket (#F8006) on fertilizer shaft, then tighten the set screw on sprocket

two

nuts

which hold fertilizer body in place. CAUTION: Do

now

ready

with

with

B,

bring side braces

the back

the

Fig. A.

to

bot

for

use.

side

of

fertilizer mounting bracket (#F8007). Place fertilizer body assembly

Do

not

fasten nuts yet.

permit feed tubes (#8015) to be inserted thru U bolts. See Fig. B, raise

tom

of

fertilizer body and then tighten nuts on U bolts .

which

Seeder scraper bracket. While in this positi on tighten U

that

Seeder axle shaft, loosen set screw in wheel hub and then

(#F8025)

not

fasten set screw on sprocket (#F8025) yet.

hold U Bolts (#8020) backwards so the edge

mounting bracket (#F8013) and fertilizer bracket

on

axle shaft and then replace shaft back to its

up

against rear axle bearing and then

up

the sprocket (#F80

(#F802

not

overtighten chain.

25)

on Seeder

5).

(#F

8021) and

,..

-3-

Page 4

SEEDER OPERATING INSTRUCTIONS

The ground intended

and should be

The depth

means

obtained by loosening the set screw on the hopper shoe and then raising

Row coverers, (illustration

hold them in place, the angles

as

Each sprocket is numbered according

- i.e.,

spro cket chain.

For best results

page 9. The chart is intended as a general guide and is

shape and size.

tests.

two

your hand in a vertical position and hold in the same hand a flat piec e

of

the one pocket

backing and see

determine whether the seed disc pocket is too small

desired.

repeat the test until the proper disc is found.

of

desired.

In

or

more seeds at a time.

the disc where the pocket breaks through. Place the number

well leveled by raking

of

planting is first determined and then adjusted by raising or lowering the seed hopper unit by

loosening the

it

will

go

some cases one seed at a

If

the disc you tested does

to

be planted should be properly prepared and should be

or

rolling.

two

wing nuts

#26

and #27) are furnished,

of

the coverers may be changed, which will

on either wheel

it

is important

It

is recommended

of

the seed disc and

if

the seed will fall through the pocket. By following this procedure you will

or

to

select the ·proper seed disc.

time

To

select the correct disc, choose one that appears

which

to

the number

hopper shaft and will

that

the proper disc

is desired

see

if

the pocket will hold the seed

not

suit, select the next size larger

hold the hopper in place. Additional adjustment may be

which

of

teeth on it, and

go

not

always the

for

for

planting, while in other cases,

or

too

are adjustable. By loosening th e bolts

on either

To

help in selecting the disc refer to chart on

each purpose can

of

of

seeds you wish to

large

to

permit the plant'ng

of

a fine texture, free

or

lowering the shoe.

put

more

or

less dirt on the seeds

1s

both interchangable and reversible

way

which

allows proper alignment

most

accurate, srnce seeds

be

selected by a few simple

it

may

to

be correct, hold same in

steel

or

wood

backed against the side

be

or

seeds. Remove the

or

smaller

as

the test ·ndicates and

be

planted together ir,

of

desired

wood

seed

w1ll

be

or

of

trash,

which

vary in

to

plant

or

steel

able

seeds

of

to

as

with

When filling the seed hopper

in the hopper. Remove the hopper by loosening the

of

the slots

The

compartment. Adjust the

sowing a

and inserting the seeds directly

To

remove seed disc from hopper, take hold

compressing

disc, release hold on hopper shaft and revolve shaft which

disc.

The brush assembly is used

recommend its

Do

not

becomes clogged.

the seeder brackets. The hopper is easily cleaned by turning same upside down.

flow

control disc is used

flow

small quantity

the

clutch spring, which releases the seed disc

use

permit tractor

of

small seed

only

with

to

go backwards while planting shoe is engaged

any particular type

to

regulate the

control disc by rotating until the desired opening is obtained. Note: When

s,

better results are obtained by completely closing the

into

the sowing compartment.

to

rnsure positive ejection

the A and B disc.

of

seed, always make certain that there are

two

flow

of

of

the outer end

of

small seeds.

seeds from the targe compartment

no

lelt

overs

wing nuts and then slipping the wing nuts through

to

the sowing

flow-cont

of

the hopper shaft and pull outward thus

for

removal

will automatically engage seed disc

or

insertion.

It

1s

easily removed

with

the soil,

After

insertrng required

•r

replaced and

as

this wili cause shoes

with

rol disc

the drive

we

to

- 4-

Page 5

FERTILIZER OPERATING INSTR UCTIONS

1. To adj

2.

3.

4.

5.

ust

for the desired spacing

tubes

to

be sprea

To

place fertiliz

lower openers

Be

fore filling the hopper

(Shut

feed.

Fertilizer in

adjustment gauge

openings, each

NOTE: Fertilizer is fed when agitators are moving and

sprockets and agitatiors are

d apa

rt

to the desired position , then retighten the U bolts.

er

at

desired depth loosen t

to

obtain desired location and th

with

off

position so that fertilizer will not feed).

now

loaded into the hopper.

into

the

desired notch. There are 5 notches which permit a closing and 4 differe nt si

of

the notches regulating different amounts of fertilizer

tight

of

fertilizer loosen U bolt

he

nuts on U blots which are welded

en

retighten nuts. Position the openers

fertilizer pull Feed Adjustment gauge (#8010)

To

adjust

for

the requi

to

prevent any

of

these parts from slipping on shafts.

DESIGN FEATURES

The Seeder

seeds. The

beans.

For continuous-row,

disc are

discs are available.

hopper and deliver the seed through

ground tube and

accurate spacing between seed dropping regardless

stops made in crossing the field. This method will plant seeds

is

designed

large selection

of

a different size, corresponding to

to

handle every variety

of

various size seed ?iscs will permit

or

drill seeding any one

As

the disc turns,

out

through the opening shoe into the soil. This positive-feed method assures uniform,

of

practical problem that may confront the planter of garden

of

the

the

size

the

pockets on the disc pick the seeds

the

opening in the side

7 twelve-pocket seed discs is used. The pockets

of

the seed required. For hill seeding, four 2 pocket

of

how

s holding feed tubes enough

to

openers, then rai

out

to

the

red

amount

it

is important that the set screws on both

the

planting

of

the hopper, allowing them

fast the seeder

without

injuring the seeds.

of

fertilizer desired move feed

to

be fed.

of

every type seed

up

is

operated,

from the

to

per

as

in

photo

last notch

from

bottom

to

fall through

or the

number

mit feed

se

B.

of

finger

lettuce

of

each

seed

of

or

ze

to

the

the

of

hill seeding where one

For

it

the planting

m

furnished

full and adequate selection

A

Depending upon

combinations may

disc 7 more combinations are

practical spacings. Each combination sprocket is made in one solid piece, therefore, there are no

sprockets

wheel is fitted

The

difficult.

The seed hopper is instantly removable, so that any

to

a different type seed. Depth

ope

ning-plow

saving

A pair

coverage

operated.

The Marker Assembly is provided so that the desired spacing

of

time and labor

of

adjustable

of

one

as

standard equipment. The F-2, E-2, and

which

be

to

get mislaid

insures sowing in a straight, narrow row, which permits close cultivation and a considerable

of

dirt

over

or

more seeds will be required in each hill, four-2 pocket discs are used, which per -

or

more seeds in each hill

of

seed spacing is provided through the

of

the

shafts each sprocket is placed on, and on which

selected. By using a

available. The total

or

lost, since

with

a scraper

by

elimination

row

coverers is furnished

the

seed regardless

both

to

of

planting is regulated by a quick simple adjustment. The design

at

intervals

J-2

12

pocket disc 7 combinations

of

combination sprockets are always in use on the seeder.

keep

the

soil from sticking

left

of

thinning and a great reduction in

which

can

of

the

uneveness

of

16 -24 -36

discs are available

14

combinations will make

over seeds can be easily emptied

be

adjusted

of

the ground over which the seeder is being

bet~en

- 48 -

or

72 inches. The G-2 disc is

by

special order.

use

of

the

two

combinations sprockets.

way

it

is

are

possible.

to

it

and making operation clumsy and

the

amount

to

each individu

rows can be maintained when pla

By

it

possible

of

al

need

placed any one

using the 2 pocket

to

plant at all

out

when changing

weeding necessary.

to

insure proper

of

"spare"

of

the

nting.

7

The extension clamp is provided

by

inserting the Marker Collar between

marker

To change the marker

I

collar. Secure

thumb

for

use

screw on marker collar when desired position is found.

from

to

permit adjusting

the

eyes

one side

to

to

various desired spacings. The Marker is held in place

of

the Marker and sliding

the other side, swing the marker rod

the

marker rod through the eyes and

-5-

with

the

rope.

Page 6

SEARSSUBURBANTRACTORSEEDER

.-----------------------------------,

I I

37

I

I

I

I

I

FIGURES 3 AND

- 6-

3A

CUTAWAY

SE

E.D

HOPPER

0~

Page 7

SEARS

SUBURBAN

TRACTOR

SEE

DER

PARTS

LIST

Ill

us.

No.

1 1#17034R

2

3

4 1#17117

5

6 1#10000 5/ 16 7

8 1#17019

9

10

ll

12

13

14

15 1#17062

16

17

18

19

20

21

Part

No.

Hl7112B

1#17093

Hl7182B

1#17081

#10001

1#17046 Re

#17045

#17018

1#170

55

1117092

1117058

Ill

70

61

11

17102

ff170b3

1117064

1#17020Al2

lll7020Bl2

II17020Cl2

1#17020D12 5/16

1#17020El2

1#17020Fl2

lll7020Gl2

Part

Name

Cha&,sis Ass

Concave Rear Wheel

Rear Scraper

C

oncave Wheel Scraper

Idler L

Id

ler

Spr

Lar

ge

1

2T-l

Spr

ocket

Link

Be

ar

Axle

Rear Wheel Bushings

Sma

ll

Double

6T - 1

2T

H

opper

Hop

pe r

Assembly

Fl

ow

Control

Spr

in g

Hop

per

W

asher

Flow

Brush

D

Dr

1

3/16 Diam. Pocket

1/4 Diam. Pocke

3/ 8

1

9/16 Diam.

Control

Assembly

riving

ivi

ng

/8

Diam.

(12 Pocket

(

12

Pocket Seed Disc)

(12 Pocket

Diam.

(12

Pocket

Diam.

(1

2 P

/2

Diam. Pock

(12 P

(12

Pocket

embly

Bracket

ever

Ass

embly

18

Wing

ocket

Double

8T

Cha

1t 45

Shaft

Sleeve

Flow

D1sc

Disc Assembly

ocket Seed

ocket Seed

Nut

6T

Sprocket

in

1125

Links

Sprocket

Di

sc

Disc

Dis

c

Sp r

ing

P o

cke

t

Seed

t

Seed

Pocket

Seed Disc)

Pocket

et

Poc

ket

Seed Disc)

Disc)

Disc)

Disc)

Disc)

Ill

us.

No. No.

22

23

24

.

25

26

27

28

29

30

31 1#17024

32

33 1#17078H

34

--="'

35

36

37 1#17313

Part

·

lll7020E

1#17020F 2

1#17020G 2

1#17020J 2 3/4

1#17097

1#17094

#17060

1#18093

1#18090

1#18089

1#18091

#fl7303A

1#17302A

1#17025R

1#17310

1#17311

1#17312

3/8

2

1/2

9/16

Hopper

5/16-

Hopper

Hopp

L.

R. H.

Coverer

L.H.

R.H.

Marker

Marker

Marker

Marker

Marker

tviarker

Complete

(2

(2

(2

(2

Assembly

Assembly

Assembly

Assembly

Part

Name

Diam.

Pocket

Diam.

Pocket

Diam.

Pocket

Diam.

Pocket

Cover

18

Wing

Welded

e r

Shoe

H.

Coverer

Coverer Blade

Bracket

Adapter

Adapter

Collar

Rod

Mg.

Assembly

Ext.

Ext

Marker

Pocket

Seed

Pocket

Seed

Pocket

Seed

Pocket

Seed

Blade

Plate

Plate

Bracket

Rod

.

Clamp

Disc)

Disc)

Disc)

Disc)

Nut

NOTE: The Seed Discs (T

discs are

optional and are available

ow

Pocket

),

E-2,

F-2,

by

special orders.

and J-

- 7-

2,

are

not

furnished

as

standard equipment. These

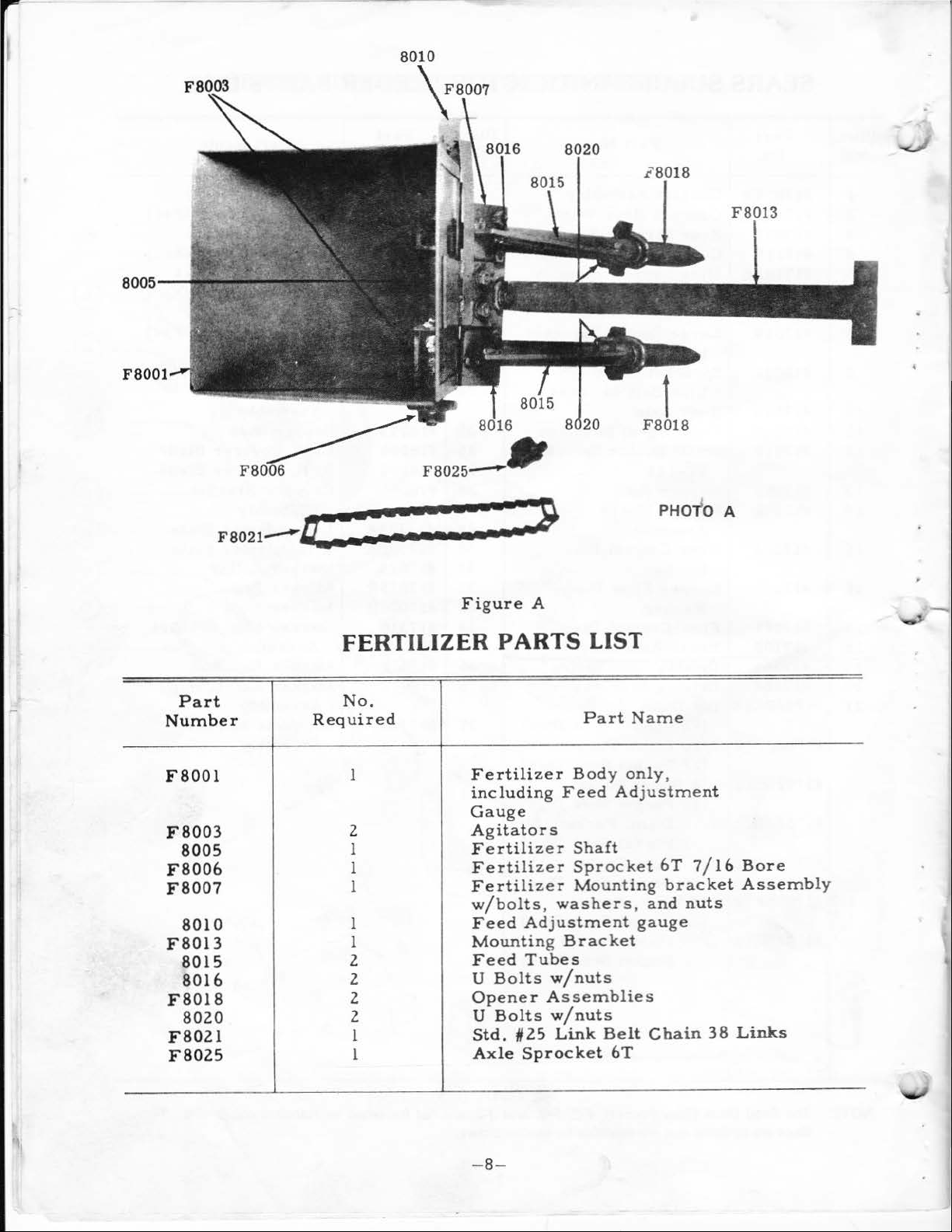

Page 8

8005

8010

F8003

"'8007

8020

i'8018

F8013

Part

Number

F8001

F8003

8005

F8006

F8007

8010

F8013

8015

8016

F8018

8020

F8021

F8025

FERTILIZER

No.

Required

1

2

1

1

1

1

1

2

2

2

2

1

1

Figure

Fertilizer

including

Gauge

Agitators

Fertilizer

Fertilizer

Fertilizer

w/bolts,

Feed

Mounting Bracket

Feed

U

Opener

U

Std.

Axle Spro

A

PARTS

Feed

washer

Adjustment

Tubes

Bolts

Bo

lts

#25

w/nuts

Assembli

w/nuts

Link

LIST

Part

Body

Shaft

Sprocket

Mounting

cket

PHO"fO A

Name

only,

Adjustment

6T

bracket

s,

and

gauge

es

Belt

Chain

6T

7/16

nuts

38

.........

Bore

Assembly

Links

-8-

Page 9

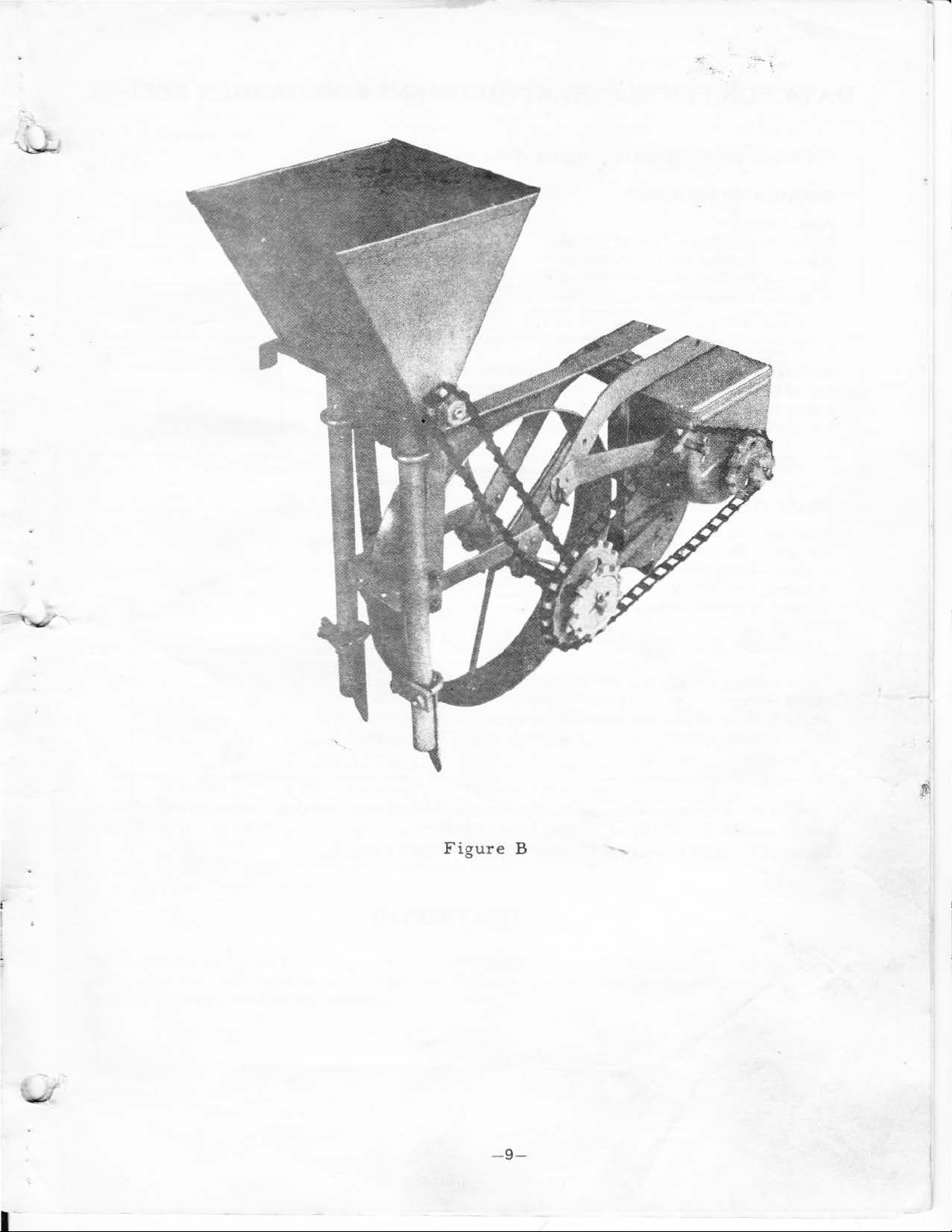

r

Figure

B

- 9-

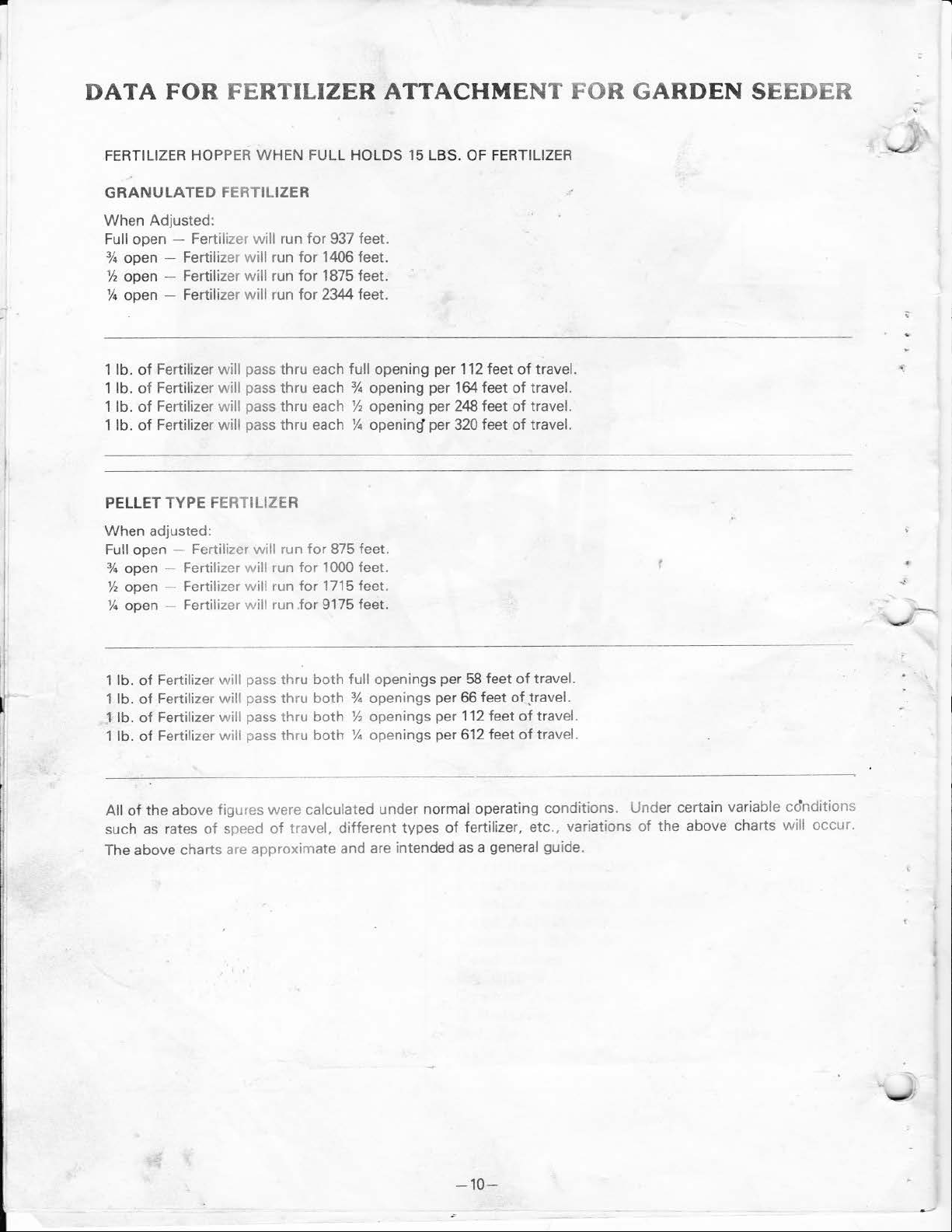

Page 10

•

DATA

FERTILIZER HO

FOR FERTILIZER ATTACHME NT

PPER

WHEN FULL

GRANULATED FERTILIZE R

When

Adjusted:

Full open - Fertilizer

% open - Fertilizer

Y2

open - Fertilizer

!14

open - Fertilizer

1

lb.

of

Fertiliz

er

1

lb.

of

Fertilizer

1

lb.

of

Fertilizer

lb.

of

1

Fertilizer

PELLET TYPE

When

adjusted:

Full open - Fertilizer

% open - Fertilizer

Y2

open - Fertilizer will run

will

will

will

will

will

pass

will

pass

will

pass thru each

will

pass

FER

TILIZER

will

will

run

for

937 feet.

run

for

1406 feet.

run

for

1875 feet.

run

for

2344 feet.

thru

each full opening per

thru

each % openi

thru

each % opening per 320 feet

run

for

875 feet.

run

for

1000 feet.

for

1715 feet.

% open - Fertilizer will run .for 9175 feet.

HOLDS

Y2

15

LBS.

ng

per

164

opening per 248 feet

OF

FERTILIZER

112

feet

feet

of

of

of

of

FOR GARDEN

travel.

travel.

travel.

travel.

SEEDER

1

lb.

of

Fertilizer

1 lb.

of Fertilizer

l lb.

of

Fertilizer will pass thru

1 lb.

of

Fertilizer

of

the

All

such as rates

The above charts

above figures were calculated under normal operating conditions. Under certain variable cdnditions

of

will

pass thru

will

pass thru

will

pass thru

speed

are

approximate and are intended

both

full openings per

both

% openings per

both

Y2

openings per

both

% openings per 612 feet

of

travel, different types

58

feet

of

travel.

66

feet

of

,travel.

112

feet

of

travel.

of travel.

of

ferti lizer, etc., variations

as

a general guide.

of

the

above charts will occur.

-1

0-

Page 11

l

Pocket

Sprocket

Disc

A

A12

B12

c

12

D12

Ell

F

12

G

12

E2

F2

G2

J2

-

.:..rrangemen

Seed

Lettuce

Carrots

Onions

Spinach

Radish

Parsnip

Beets

Swiss

Pea

Sweet

Peas

Kidney

For

For

inch

time

Chard

Beans

Corn

Beans

Muskmelon

Field

es

are

is

desired

DRILL

and

to

be

18

I 2 T'

Cucumber

These

planted.

t

Corn, Sweet

desired.

SOWING

Tooth

400

400

300ft.

230

120ft. per

185

185ft. per

400ft. per lb.

400

415ft.

200ft. per lb.

ooth

165

Corn,

On

On

ft.

ft.

ft.

ft.

ft.

ft.

Seed

Wheel

Hopp

per

oz.

per

oz.

per oz.

per oz.

per

oz.

oz.

per

oz.

oz.

per

lb.

per

lb.

Peas,

Discs

er

Kidney

also

CHART

12

Tooth

12

Tooth

600 ft.

600ft.

450ft.

350f

t.

250

ft.

350ft. per oz.

2 7 5 ft.

275

ft.

600

ft.

600

ft.

625

ft.

300ft. per lb.

Beans,

can

be

when

used

On

Whe

On

Hopper

per oz.

per

oz.

per oz.

per

oz.

per

oz.

per

oz.

per

per lb.

per lb.

per

spacings

where

oz.

lb.

e l

more

12

Tooth

18

Tooth

900

ft.

900

ft.

600ft. per oz.

470ft.

335

ft.

470ft. per oz.

370ft. per oz.

370ft. per oz.

900ft. per

900

ft.

835

ft.

400 ft.

from

16

inches

than one

On

Wheel

On

Hopper

per oz.

per

per

oz.

per oz.

per lb.

per

per

seed

oz_

lb.

lb.

lb.

to

at

72

a

I

Spacing

1

inch

2

inches

3

inches

4

inches

6

inches

8

inches

12

inches

16

inches

24

inches

36

inches

48

inches

72

inches

l

HILL

18

Tooth on

12

Tooth

18

Tooth

12

Tooth

1.

t

~'

ooth

6

Tooth

6

Tooth

18

Tooth

12

Tooth

12

Tooth

6

Tooth

6

Tooth

SO

Sprocket

Wheel

On

Wheel

On

Wheel

On

Wheel

On

Wheelll-

On

Wheel

On

Wheel

On

Wheel

On

Wheel

On

Wheel

On

Wheel

On

Wheel

WING

IMPORTANT

The Sears Suburban Tractor Seeder is guaranteed

used in accordance

these instructions are

with

the preceding instructions.

not

read and followed.

CHART

Arrangement

6

Tooth

6

Tooth

12

Tooth

12

Tooth

18

Tooth

12

Tooth

1 8

Tooth

12

Tooth

12

Tooth

18

Tooth

12

Tooth

18

Tooth

for

reasonable accuracy, dependability .and economy

We

cannot guarantee best results and full satisfaction

On

On

On

On

On

On

On

On

On

On

On

On

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Hopper

Pocket

Disc

12

12

12

12

12

12

12

2

2

2

2

2

when

if

\\

Page 12

[Sears

1·

owners

The Model

s

ide

of

the

when

requesting

Fertilizer.

All

parts

ROEBUCK

When

on

you

ordering

request

will

be billed

Number

frame.

listed

AND

parts

or

parts

will

be

found

Always mention

service

herein

acco

CO ..

by

will

mail,

rdin

or

may

or

be

shipped

gly.

repair

on a

plate

atta

the

Model

parts

for

your Seeder

be

ordered

SIMPSONS-SEARS

selling

at

through

prices

prevailing

will

ched

Number

SEARS,

LIMITED.

be

furnished

prices

to

the

and

and

\

....

-

manual

MODEL

597.261620

How

Repair

to

NO

.

Order

Parts

WHEN

ING

1.

2.

ORDERING

INFORMATION

The

PART

The

PART

PARTS. ALWAYS

AS

SHOWN

NUMBER

DESCRIPTION

GIVE

THE

IN

THIS

LIST.

3.

The

MODEL

597.261620

4.

The

NAME

Seeder

When you b

from

something

can

offer ...

Across

country, wherever

move

Service

ing

trustworthy

serv1ce

See>rs

and

uy

Sears you

that

Sears

town

in

the U.S.A.,

follow

technicians

specified

FOLLOW-

NUMBER

OF

ITEM-

Fertilizer

mercha

get

an

nobody

Service.

or

acro

ss the

you

live

Sear

s yo

u,

provid

,

CC'".•p.JtP

using

fact~ry

parts.

ndis

extra

else

o•·' •

~,

only

e

~

~

-

~

.......

' '

l

'

•

,

SEARS

IS

AT

WHEREVER

IN

YOUR

OR

MOVE

THE

SERVICE

SERVICE

YOU

U.S.A

LIVE

.

-----------------------------------------------------------------

Sears,

and

Roebuck

Simpsons

and

Sears

Co.,

Chicago,

Ill.

Limited, Toronto

60684

U .S .A.·

PRINTED

IN

.;

--

U S A.

Loading...

Loading...