Page 1

INSTALLATION AND

OPERATING INSTRUCTIONS

CF Series

ISO2858 Heavy Duty

Industrial Centrifugal Pump

Please pass these instructions on to the operator of this equipment.

Page 2

Introduction

Thank you for purchasing a quality Davey product. It

is our commitment to satisfy our customers by offering

our very best service.

This manual contains instruction for installation,

operation and maintenance of ISOspec® CF

bareshaft, single stage, non-self priming, centrifugal

pumps. Therefore, please read it carefully before use

to obtain a long satisfying service life of the purchased

unit.

Davey ISOspec® CF bareshaft centrifugal pumps are

designed with high efciency and low maintenance

features.

Specications

Model designation (example) :-

CF 200×150-500

Nominal dia. of impeller (mm)

Dia. of outlet (mm)

Dia. of inlet (mm)

Series code of pump

Inspection of Pump

Always check on receipt of delivery you have

received the correct pump unit. To identify, see above

specications and label below. Check correct motor

kW & speed on motor nameplate (attached to motor)

prior to installation.

Installation Location

It is important to select a site as close to the

liquid source as possible. When a suction lift is

unavoidable, install the pump as near to the water

level as possible (see suction piping). You should

always check the maximum permissible lift of the

pump from its performance curve.

Foundations

The pump unit should be mounted on a foundation

that is substantial enough to withstand the weight of

the unit & large enough to accommodate all mounting

feet so they can be securely xed to avoid movement.

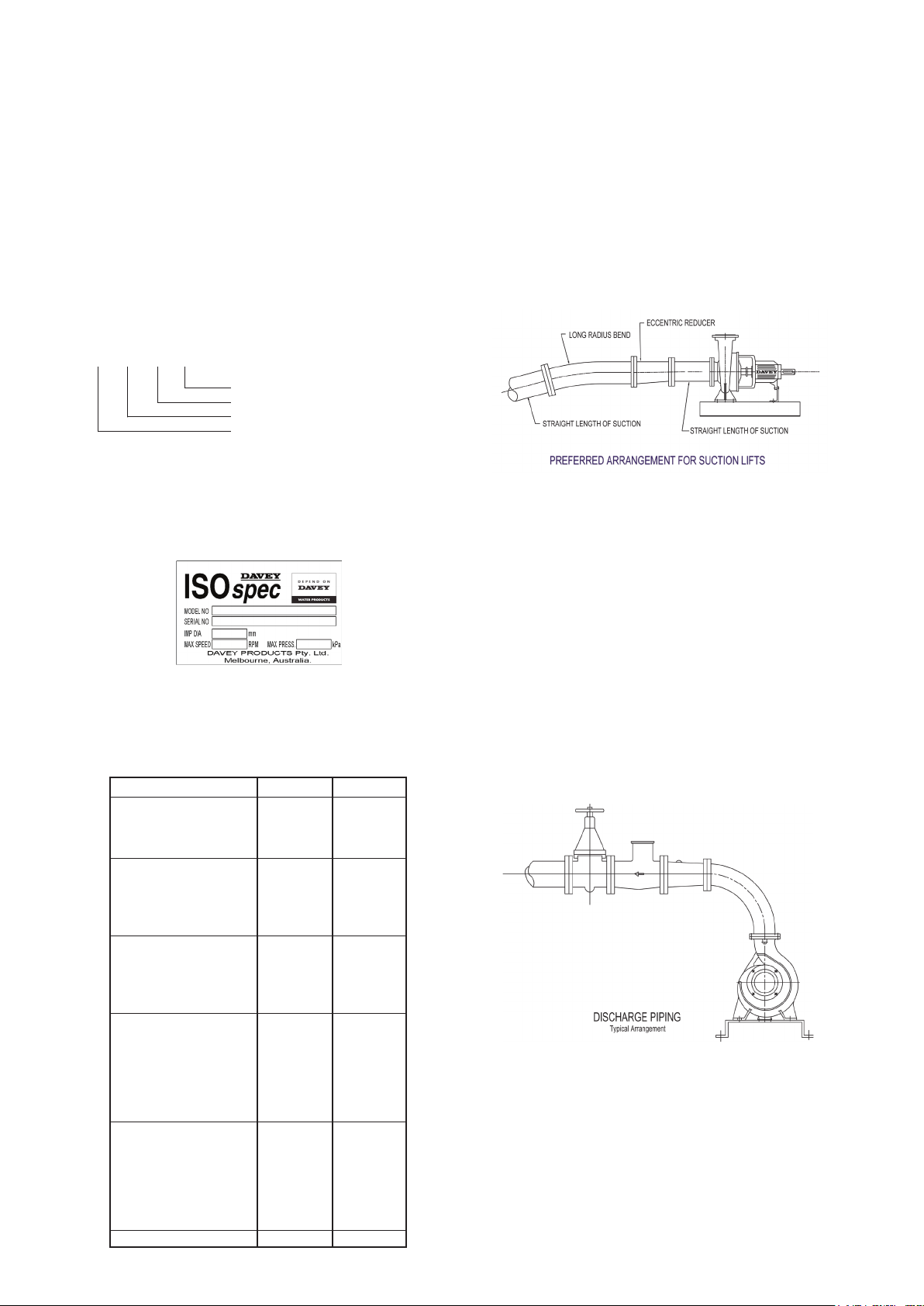

Suction Piping

All ttings & suction piping should be free of air leaks.

When a suction lift or long suction lengths are

unavoidable, consideration should be given to over

sizing the suction line to reduce suction losses. On

suction lifts a foot valve will be required, sized equal to

the suction line size. For applications on creek beds

or dams, please install a foot valve & strainer, well

submerged below the surface, to reduce whirlpools

& air inclusion. Air inclusion can result in cavitation

reducing the pump performance & eventually

destroying the pump or its components.

Driving Options

Your ISOspec® pump can be driven by a variety of

means. The best option is to direct drive via a suitable

coupling. If you must belt drive your ISOspec® pump,

lower speed (rpm). Limits may apply - see below:

Pump Size Direct Belt

50x32-160 3600 2900

65x50-160 3600 2900

80x65-160 3600 2900

100x80-160 3600 2850

50x32-200 3600 2900

65x40-200 3600 2900

80x50-200 3600 2900

100x65-200 3600 2250

125x100-200 3600 2060

65x40-250 3600 2480

80x50-250 3600 2050

100x65-250 3600 2180

125x100-250 3000 1620

150x125-250 2350 1440

65x40-315 3000 1800

80x50-315 3000 1800

100x65-315 3000 1450

125x100-315 3000 1380

150x125-315 2350 1420

200x150-315 1800 1150

250x200-315 1800 920

125x80-400 2350 1450

125x100-400 2350 1240

150x125-400 2350 1060

200x150-400 1800 920

125x100-500 1800 1240

150x125-500 1800 1060

200x150-500 1800 920

250x200-400 1800 920

Long radius bends should be installed & a straight

length of piping equal to 2.5, the impeller diameter,

should be observed. Supporters should be equipped

to the inlet pipeline and outlet pipeline to avoid the

pump ange bearing too much tension force.

Discharge Piping

Discharge piping must be selected of a size that

would equal the discharge of the pump. For long

discharge lengths, consideration should be given to

oversize to minimize discharge losses reducing ow.

Talk to your nearest Davey dealer to calculate all

system losses. To avoid air pockets in discharge

lines at high points, vent cocks may be required to

release air blocks accumulated within the system. Air

pockets may affect the performance of the pump. A

throttling valve should be installed in the discharge

line to ensure the pump works within the performance

curve.

~ 2 ~

Page 3

Starting

Caution: Do not attempt to run pump if it

has not been lled with water ( primed).

Severe damage will result to shaft seal.

1) Ensure the suction line & pump casing is full of water

open suction valve if tted.

2) Check power is off & rotate the pump shaft slowly to

release any trapped air within the pump casing.

3) Close the discharge valve.

4) Check the direction of rotation on the pump casing or

motor cover.

5) If this is correct you may now start the pump, when

it reaches full speed you will see the pressure in the

discharge line rise. Slowly open the discharge valve

until the pump adjusts to maintain its duty point.

Trouble Shooting

Pump is running but failing to deliver water or

desired pressure.

1) Turn the unit off.

2) Check suction line is free of debris or blockages

& check that the pump has not lost its prime. If

so, remove blockage & repeat Starting at step 1).

3) Check that the suction valve is open.

4) Check that the discharge valve is open.

5) Check for air leaks. These may not always be

visible to the naked eye unless pressure is applied

to the suction line.

6) Check that the suction line is not too long.

7) Is suction line to pump excessive?

8) Is the foot valve stuck open or undersized?

9) Is speed too slow?

10) Check motor direction rotation.

11) Check for possible clogging in impeller vanes

12) Is the discharge piping undersized for

applications.

Structural Representation

1. Bearing housing 2. Shaft

3. Rear casing cover 4. Pump casing

5. Impeller 6. Impeller key

7. Impeller washer 8. Impeller nut

9. Volute drain plug 10. Bronze wear ring

11. Mechanical shaft seal 12. Bearing housing foot

13. Bearing lip seal 14. Bearing

15. Bearing cap 16. Water slinger

Excessive Vibration

1) Turn unit off

2) Check motor is rotating in correct direction

3) Check both motor feet & pump feet are secured

properly.

4) Check coupling rubbers are not worn

5) Check drive couplings are secured tightly to the

pump & drive shafts.

6) Check pump & motor bearings are OK

7) If so, alignment will need to be performed

8) Impeller could be partially blocked causing

imbalance

Noisy Operation

1) Turn unit off

2) Check pump or motor bearings

3) Check pump is primed

4) Check suction line is not damaged causing

insufcient supply & resulting in cavitation

5) Check you are not pumping solids

High Power Consumption

1) Check direction of rotation

2) Check operating speed on the motor matches the

intended performance curve speed.

3) Check that the estimated head is correct as pump

may be running down on its curve producing high

ow but drawing more power. Throttle the pump

back on to its curve via discharge gate valve or

reduce impeller diameter.

4) The Specic Gravity or Density of the liquid is

greater than 1kg/litre affecting power draw.

5) Check impeller diameter for the correct size to

establish maximum power requirement at duty

point.

In accordance with AS 3350.2.41 we are obliged

to inform you that this pump is not to be used by

children or inrm persons and must not be used

as a toy by children.

Lubrication

Pump bearings are greased for life.

Motor bearings refer to Motor manufacturers

recommendations.

~ 3 ~

Page 4

Davey® Repair or Replacement Guarantee

In the unlikely event in Australia or New Zealand that this Davey product develops any malfunction

within one year of the date of original purchase due to faulty materials or manufacture, Davey will at

our option repair or replace it for you free of charge, subject to the conditions below.

Should you experience any difculties with your Davey product, we suggest in the rst instance that

you contact the Davey Dealer from which you purchased the Davey product. Alternatively you can

phone our Customer Service line on 1300 367 866 in Australia, or 0800 654 333 in New Zealand, or

send a written letter to Davey at the address listed below. On receipt of your claim, Davey will seek to

resolve your difculties or, if the product is faulty or defective, advise you on how to have your Davey

product repaired, obtain a replacement or a refund.

Your Davey One Year Guarantee naturally does not cover normal wear or tear, replacement of product

consumables (i.e. mechanical seals, bearings or capacitors), loss or damage resulting from misuse

or negligent handling, improper use for which the product was not designed or advertised, failure to

properly follow the provided installation and operating instructions, failure to carry out maintenance,

corrosive or abrasive water or other liquid, lightning or high voltage spikes, or unauthorized persons

attempting repairs. Where applicable, your Davey product must only be connected to the voltage

shown on the nameplate.

Your Davey One Year Guarantee does not cover freight or any other costs incurred in making a claim.

Please retain your receipt as proof of purchase; you MUST provide evidence of the date of original

purchase when claiming under the Davey One Year Guarantee.

Davey shall not be liable for any loss of prots or any consequential, indirect or special loss, damage or

injury of any kind whatsoever arising directly or indirectly from Davey products. This limitation does not

apply to any liability of Davey for failure to comply with a consumer guarantee applicable to your Davey

product under the Australian or New Zealand legislation and does not affect any rights or remedies that

may be available to you under the Australian or New Zealand Consumer Legislation.

In Australia, you are entitled to a replacement or refund for a major failure and for compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Should your Davey product require repair or service after the guarantee period; contact your nearest

Davey Dealer or phone the Davey Customer Service Centre on the number listed below.

For a complete list of Davey Dealers visit our website (davey.com.au) or call:

AUSTRALIA

Customer Service Centre

6 Lakeview Drive,

Scoresby, Australia 3179

Ph: 1300 367 866

Fax: 1300 369 119

Website: davey.com.au

NEW ZEALAND

Customer Service Centre

7 Rockridge Avenue,

Penrose, Auckland 1061

Ph: 0800 654 333

Fax: 09 527 7654

Website: daveynz.co.nz

Davey Water Products Pty Ltd

Member of the GUD Group

ABN 18 066 327 517

® Davey & ISOspec are registered trade marks of Davey Water Products Pty Ltd.

© Davey Water Products Pty Ltd 2011.

* Installation and operating instructions are included with the product when purchased new.

They may also be found on our website.

P/N 49719-4 supersedes P/N 49719-3

Loading...

Loading...