Davco fuel pro 382 Technical Manual

TABLE OF CONTENTS

Applications, Models, and Options.................. 1

How it Works................................... 1

“SEEING IS BELIEVING”

Dimensions and Specifications..................... 3

� Important Safety Precautions .................... 4

Installation Instructions ........................... 5

Installation Instructions - Diverter Cap............... 6

Coolant Heat Installation.......................... 7

®

........................ 2

12VDC and 24VDC Electric Pre-heater Installation

120VAC Electric Pre-heater Installation

.............. 9

..... 8

Water in Fuel Sensor (WIF) Installation .............. 10

Preventive Maintenance

......................... 11

Filter Change Procedure ......................... 12

Visual Diagnostics With Clear Cover................ 13

Visual Diagnostics - Air vs. Vapor Bubbles........... 14

Diagnostic Procedures - Air Leaks

. . . . . . . . . . . . . . . . . 15

Diagnostic Procedures - Heater Testing ............. 16

Check Valve Diagnostics......................... 18

Service Parts.................................. 19

Warranty Policy................................ 23

Parts Return Policy ............................. 24

FOR UPDATED INFORMATION, VISIT WWW.DAVCO.COM

F1271 REV J

2016 ©DAVCO Technology, LLC.

October 3, 2016 11:34 AM

FUEL PRO® 382

Technology, LLC

APPLICATIONS, MODELS, AND OPTIONS

Applications

Heavy duty engines with fuel flow up

to 180 GPH

Cold Weather Solutions

• 12VDC Pre-heater — Uses ignition switch to heat up fuel prior to

running the engine

• 120VAC Overnight heater — Prevents gelling while parkedovernight

• Coolant heat — Keeps fuel heated

while operating on highway

HOW IT WORKS

TECHNICAL MANUAL

Models and Options

• Base Model - Unheated

• Coolant Heat

• Electric Pre-heater Options (Heaters can be combined)

• 12VDC pre-heater

• 120VAC pre-heater

• Water-in-fuel Sensor (WIF)

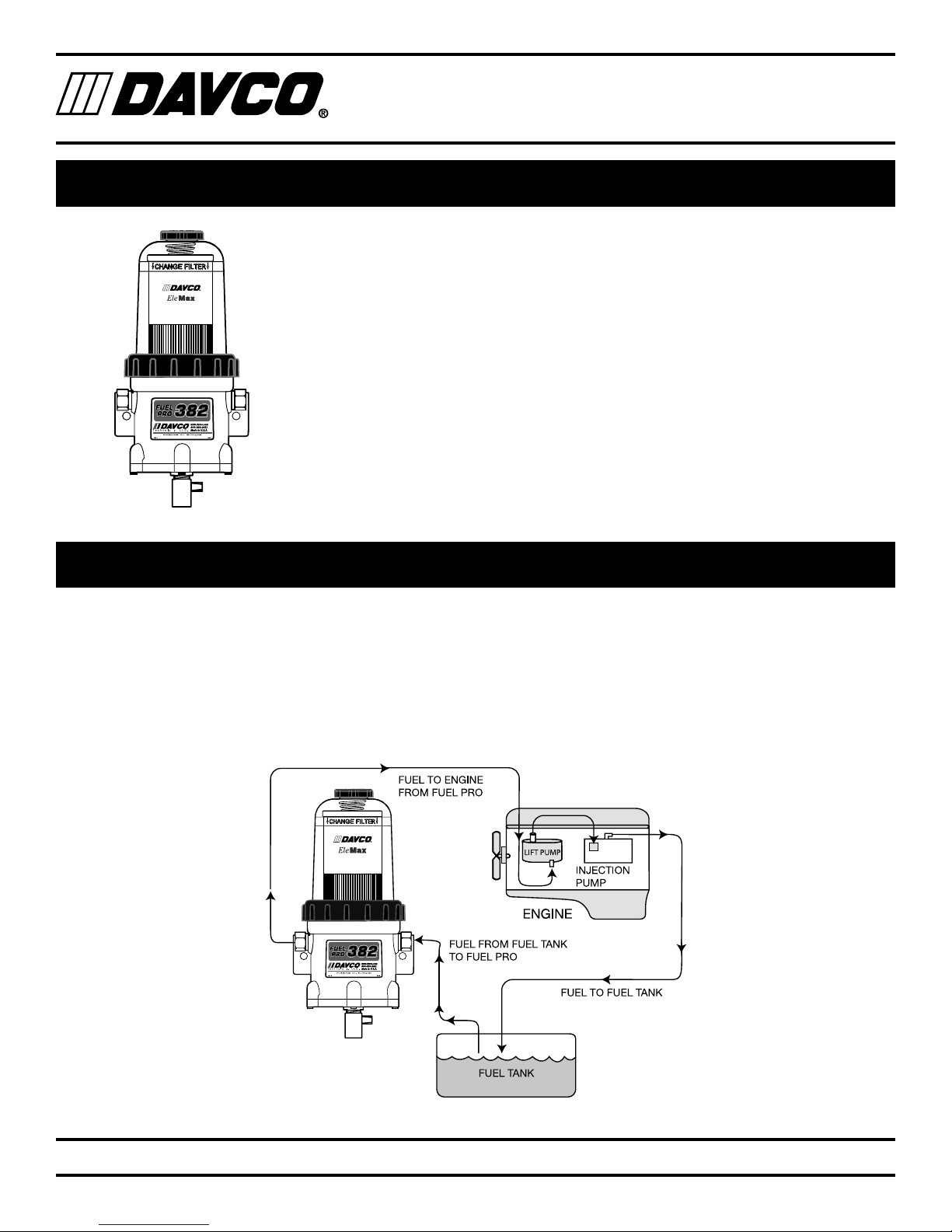

• Fuel from the tank enters the Fuel Processor body (suction side of the fuel system).

• Large contaminants and “free” water are separated from the fuel and remain in the body.

• Fuel rises into the clear cover.

• Contaminants and emulsified water are captured by the filter media.

• Fuel level rises to maintain a fuel path through the clean filter media with low restriction.

• Clean, water-free fuel exits the Fuel Processor and flows to the engine fuel injection system.

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

1

October 3, 2016 11:34 AM

FUEL PRO® 382

Technology, LLC

TECHNICAL MANUAL

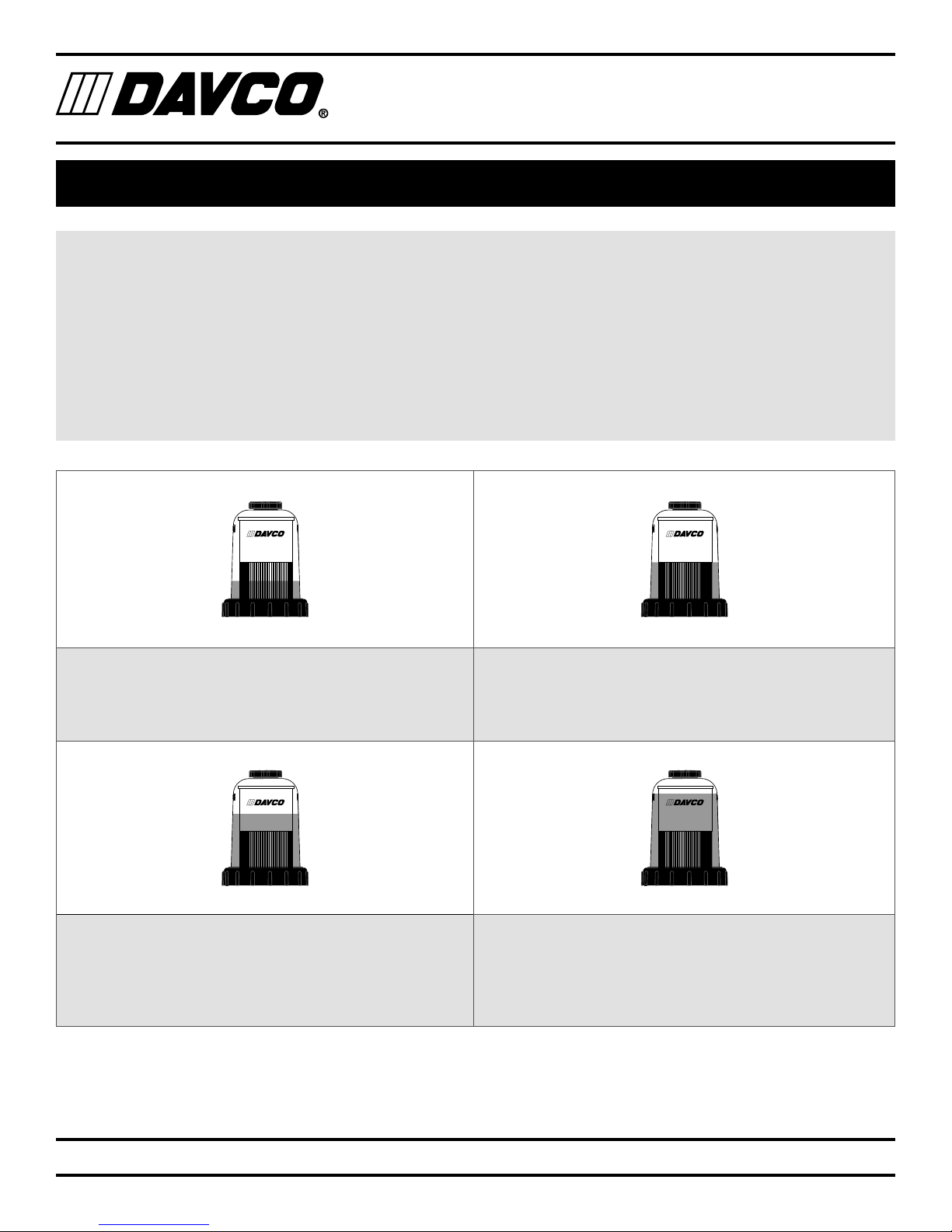

“SEEING IS BELIEVING”®

• See when NOT to change the fuel filter.

• See the condition of the fuel. Seeing what collects on the filter media or what’s happening inside the clear cover

can help diagnose many fuel and mechanical conditions.

• “Filter on Top” configuration. Water and debris removed from the fuel falls to the lower chamber and stays away

from the filter media resulting in longer filter life.

• Built in protection when priming the fuel filter. Unfiltered fuel is kept on the “dirty” side of the filter media during

priming ensuring only clean fuel reaches the engine.

• Patented media. The “Best in Class” StrataPore™ media removes 98% of free and emulsified water over the life of

the filter. This far exceeds the performance of cellulose media.

When new, the fuel level in the filter will be very low

with minimal restriction. As the filter is used, contami-

nants collect on the filter from the bottom up. Fuel rises

on the filter indicating remaining filter life.

Fuel level at filter wrap level. Even though the fuel

level is now more than half of the filter element, the fuel

is still flowing through clean media at minimal restriction levels. The filter still has significant life remaining.

Fuel level increases in clear cover. As contaminants

collect on the filter, the fuel rises to a non-contaminated

section of the filter, providing optimal filtration while

maintaining lowest restriction.

The filter element is now completely covered by

fuel. At this point, all of the media’s surface area is

utilized. Restriction is increasing and the filter element

should be changed at the next scheduled maintenance

interval.

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

2

October 3, 2016 11:34 AM

2.5

Differential Pressure (in-Hg)

FUEL PRO® 382

Technology, LLC

DIMENSIONS AND SPECIFICATIONS

SERVICE HEIGHT

1.5 (38.1)

3.28 (83.3)

16.25 (412.8) MAX

1/2" x 14 NPTF

FUEL OUTLET

3.9 (99.1)

1/2" x 14

NPTF

FUEL INLET

Ø .43 (11.0)

(2 PLACES)

6.75 (171.5) MAX

FUEL

IN

TECHNICAL MANUAL

5.91 (150.0)

6.58 (167.1)

.50 (12.7)

Specifications

Height Overall 16.25 in (412.8 mm)

Depth Overall 6.58 in (167.1 mm)

Width, max. 7.3 in (185.2 mm)

Mount Bracket Centers 5.91 in (150 mm)

Weight, dry 8-12 lbs

Fuel In Connection 3/4"-14 NPTF

Fuel Out Connection 3/4"-14 NPTF

Filter Service Clearance Min

Max Fuel Flow 180 gph

Electric Pre-heater 12VDC, 250 W, 18 A

Fluid Heat Connection 3/8"-18 NPTF

1.5" (38 mm)

24VDC, 250 W, 12 A

120VAC, 75 W, .65 A

3.46 (88.0)

All dimensions are in inches (millimeters)

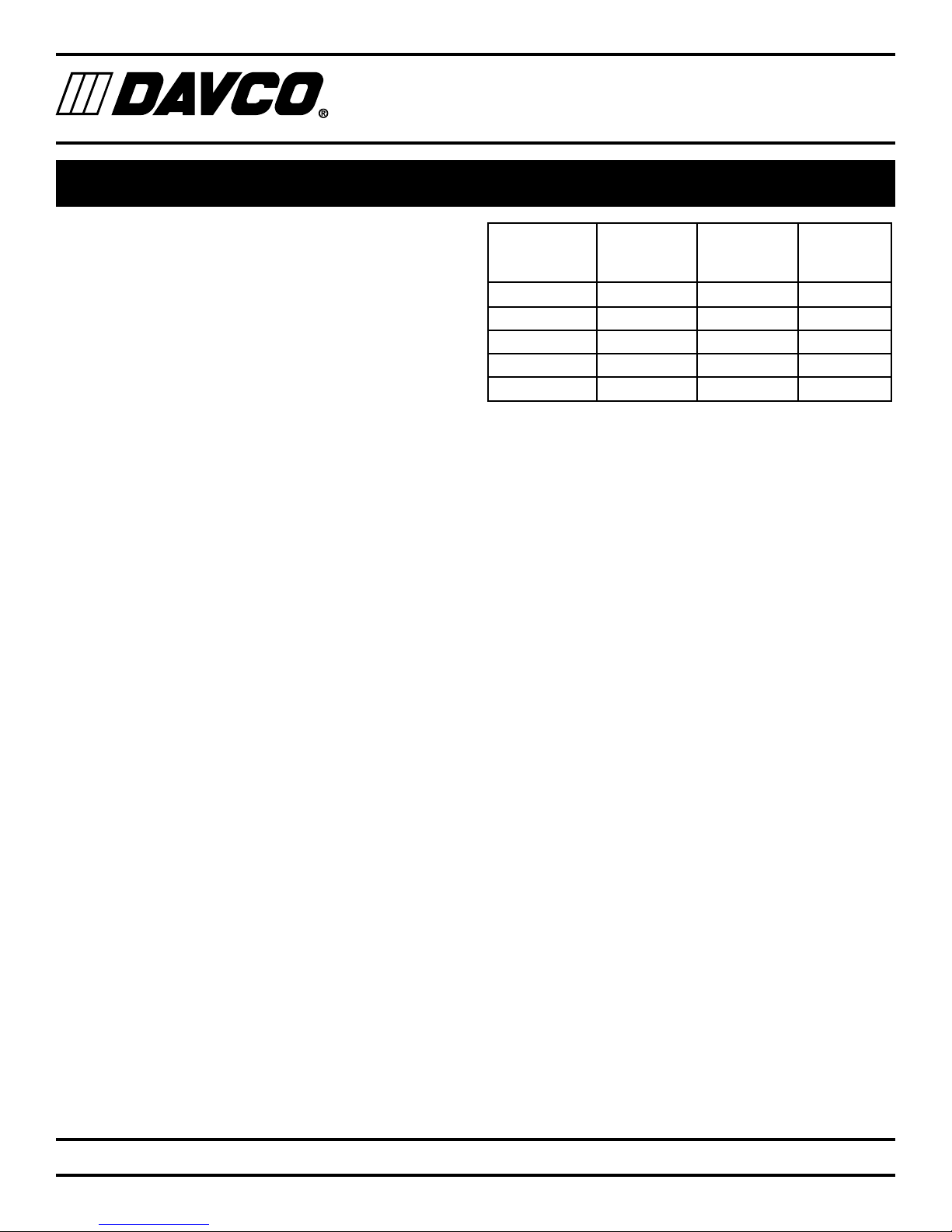

Filtration Performance at 100 GPH (EST.)

Micron Coarse

Water

Removal

(%)

7 mic

10 mic

25 mic

99.4 80.5 70

99.9 95.5 85

99.6 97.8 110

50 mic 97 <20 90

Emulsified Water

Removal (%)

Dirt Holding

Capacity (grams)

Restriction vs. flow

2.0

1.5

1.0

0.5

0.0

Differential Pressure (in-Hg)

0 20 40 60 80 100 120 140 160 180 200

Flow (gph)

7 micron

10 micron

25 micron

50 micron

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

Flow (gph)

3

October 3, 2016 11:34 AM

FUEL PRO® 382

Technology, LLC

TECHNICAL MANUAL

IMPORTANT SAFETY PRECAUTIONS

General Safety Precautions

• Read all instructions before use to avoid injury.

• To avoid serious injury or death, follow the safety information in this document.

• Keep this manual. If you need to replace the manual, call customer service at 800-328-2611

or visit www.davco.com/documents for a replacement.

• Read all product safety labels.

• Refer to appropriate regulations for environmental and workplace safety rules.

WARNING: To prevent personal injury

• Scalding hazard: When diesel fuel is circulated through an operating engine, it can become very hot. Do not al-

low fuel to come in contact with eyes or unprotected skin. Allow the engine and fuel to cool to ambient temperature before replacing the fuel filter or performing service operations which could result in spillage of fuel from the

fuel system.

• Fire Prevention: Heated fuel can form combustible vapor mixtures in the area around the fuel source. To elimi-

nate the potential for fire, keep open flames, sparks or other potential ignition sources away from the work area.

Do not smoke during filter replacement or service operations.

• Inhalation Precaution: Always perform engine or vehicle fuel system maintenance in a well ventilated area that is

kept free of bystanders.

• The ignition key must be in the off position, unless otherwise directed. To avoid unintentional engine startup, use

a lockout key and/or signage to alert personnel that work is being performed.

Government Regulations

• Engine fluids (oil, fuel, and coolant) may be a hazard to human health and the environment. Handle all fluids and

other contaminated materials (such as filters and rags) in accordance with applicable regulations. Recycle or dispose of engine fluids, filters, and other contaminated materials according to applicable regulations.

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

4

October 3, 2016 11:34 AM

FUEL PRO® 382

Technology, LLC

INSTALLATION INSTRUCTIONS

Installation Location

The Fuel Pro must be installed between the fuel tank and

the fuel transfer pump. In some cases, the Fuel Pro can be

used as the only fuel filter in the system. This is generally

dependent on the engine model year. Consult the engine

manufacturer for their recommendation. If the Fuel Pro can

be used as a single filter, DAVCO offers a diverter cap to

replace the secondary filter. (See diverter cap installation

section)

Mounting the Fuel Pro

Mount the Fuel Pro keeping the following points in

mind:

• Do not install the Fuel Pro directly on the engine.

• Mount vertically with the cover and element pointing

up.

• Make sure there is enough top and side clearance for

the cover to be conveniently removed for filter replacement.

• The Fuel Pro MUST be installed so that the Filter Element is above the "FULL" level of the fuel tank.

� The ignition key must be in the off position, unless

otherwise directed. To avoid unintentional engine

startup, use a lockout key and/or signage to alert

personnel that work is being performed. Chock the

wheels.

1. With the engine shut down and at ambient temperature,

close the fuel shutoff valve (if equipped) and place a

suitable container under the fuel filters.

2. Remove the primary fuel filter element assembly, sedimenter, and/or water separator. Drain the used element

and dispose of it in an environmentally responsible

manner, according to state and/or federal (EPA) recommendations.

TECHNICAL MANUAL

Fuel Line Routing

To minimize fuel system restriction, observe the following guidelines when plumbing the fuel system:

• Keep the fuel line routing as smooth as possible with

no low-hanging loops which can trap water.

• Use 90° elbows only when necessary.

• If the fuel hoses are cut to length on the job, be sure

that the inner liner of the fuel hose is not cut by the fitting, which can cause check valve performance issues.

Make sure hoses are clean and free of debris before

installing.

• To avoid damaging the aluminum Fuel Pro body, do not

overtighten fuel lines or fuel line fittings.

1. Route the fuel supply line from the pick up on the fuel

tank to the Fuel Pro inlet (labeled “Fuel In”).

2. Route the fuel outlet line from the Fuel Pro outlet (labeled “Fuel Out”) to the inlet of the fuel pump.

Priming the Fuel System

1. Check to make sure the drain valve at the base of the

Fuel Pro is closed.

2. Remove the vent cap from the top of the clear cover.

Fill the Fuel Pro full with clean fuel. Reinstall the vent

cap. Tighten the vent cap by hand until it clicks.

3. Start the engine. When the lubrication system reaches

its normal operating pressure, increase engine RPM to

high idle for one to two minutes. After the air is purged

loosen the vent cap until the fuel level lowers to just

above the collar. Tighten the vent cap by hand until it

clicks.

4. Tightening the collar with the wrench—simultaneously

apply downward pressure to the top of the clear cover

until it is seated on the body of the Fuel Pro and hand

tighten the collar until it no longer spins freely. Torque

the cover assembly by rotating the collar clockwise

three additional ribs using the collar wrench (~18 ft-lbs).

Note: The clear filter cover will not fill completely during

engine operation. It will gradually fill over time and the fuel

level will rise as the filter becomes contaminated.

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

5

October 3, 2016 11:34 AM

FUEL PRO® 382

Technology, LLC

INSTALLATION INSTRUCTIONS - DIVERTER CAP

Diverter Cap Installation

If a single fuel filter system is approved by the engine

manufacturer, the following steps are to be taken to install a

diverter cap properly.

1. Select the required secondary filter head diverter cap

from those listed in Table 1. The required diverter cap is

determined by the size of the spin-on filter stud and the

filter sealing surface diameter.

2. Drain and remove the secondary fuel filter element.

3. Lightly lubricate the seal on the top of the diverter cap

with clean engine oil.

4. Thread the adapter onto the secondary filter stud and

tighten.

5. Install the “Do Not Remove” label on the diverter cap.

TECHNICAL MANUAL

Diverter Cap

Part Number

101480 1"-14

101589 1"-14 3.225" 3.435"

101570 M16 x 1.5 2.475" 2.895"

101466 ¾"-16 2.475" 2.895"

101492 7/8" x 14 2.475" 2.895"

Required

Filter Head

Stud Size

Table 1

Required

Filter Head

Seal ID

2.475" 2.895"

Required

Filter Head

Seal OD

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

6

October 3, 2016 11:34 AM

FUEL PRO® 382

Technology, LLC

COOLANT HEAT INSTALLATION

Most truck OEMs currently offer engine return fuel as the

heat source for the DAVCO Fuel Pro 382. Current common

rail engines generally do not have enough return fuel heat

or flow rate to be used as a heat source for Fuel Pros. To

address this, a DAVCO Fuel Pro 382 can be easily plumbed

for engine coolant to provide adequate heat at the primary

filter (Figure 2).

TECHNICAL MANUAL

Determine if the bottom plate is equipped with a fluid heat

assembly. (Figure 3) If the Fuel Pro 382 has a deep bottom

plate it is a heated assembly with a heater loop and can

be upgraded to use coolant heat.(Refer to form F3029 on

www.davco.com for upgrade instructions).

If the bottom plate is flat, order the DAVCO fluid heat bottom plate upgrade kit, DAVCO P/N 382029-23DAV.

Figure 2

Fluid heat bottom plate

Flat Bottom Plate

Figure 3

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV J

7

October 3, 2016 11:34 AM

Loading...

Loading...