Page 1

M500 VSAT/SCPC Satellite Modem

PSM-500/PSM-500L/500LT

Installation and Operation Manual

Revision 0.91

Page 2

Page 3

PSM-500/500L/500LT SCPC Satellite Modem Table of Contents

i

Table of Contents

Safety Notice

.............................................................................................................. vii

EMC Notice ................................................................................................................. vii

Revision History .............................................................................................................................. viii

Pen and Ink Changes Made to this Manual ............................................................................. viii

Chapter 1 - PSM-500 Modem Description ........................................................................................ 1-1

1.0 Introduction ............................................................................................................................ 1-1

1.0.1 How to Use This Manual .............................................................................................. 1-1

1.0.2 Quick Start for Experienced Modem Users .................................................................. 1-2

1.0.3 What’s New – This Modem and This Manual ............................................................... 1-2

1.1 Modem Capabilities ................................................................................................................ 1-2

1.1.1 Modem IF Variations .................................................................................................... 1-2

1.1.2 Modem Feature Set Variations ..................................................................................... 1-3

1.1.3 Applications .................................................................................................................. 1-4

1.1.3.1 SCPC Point-to-Point Links .................................................................................. 1-4

1.1.3.2 SCPC Point to Multi–Point Links in a Broadcast Application .............................. 1-4

1.1.3.3 DAMA (Demand Assigned Multiple Access)....................................................... 1-5

1.1.3.4 TDMA (Time Division Multiple Access) Remote Site Applicati on ....................... 1-5

1.2 Modem Functional Assemblies .............................................................................................. 1-6

Figure 1-2 Modem Block Diagram ....................................................................... 1-7

1.2.1 Modulator ...................................................................................................................... 1-8

1.2.2 Demodulator ................................................................................................................. 1-9

1.2.3 Modem Bit Rate Timing .............................................................................................. 1-10

Figure 1-3 Clock Source Options ....................................................................... 1-11

1.2.4 Control Processor ....................................................................................................... 1-12

1.2.5 Acquisition Processor ................................................................................................. 1-12

1.2.6 Standard Data Interface ............................................................................................. 1-12

1.2.6.1 Data Interface Loop-Back Function .................................................................. 1-13

1.2.6.2 Data Interface BERT Function .......................................................................... 1-13

1.2.6.3 Data Interface 1:1 Redundancy Function ......................................................... 1-13

1.2.7 Standard Framing and IBS Multiplexer ...................................................................... 1-14

1.2.7.1 Modem Control Channel (MCC) .................................................................... 1-15

PSM-500/500L/500LT - Rev. 0.91

Page 4

PSM-500/500L/500LT SCPC Satellite Modem Table of Contents

ii

1.2.7.1.1 AUPC Control Channel (AUPC) ........................................................... 1-15

1.2.7.1.2 Remote Modem Control Channel (RMC) ............................................. 1-15

1.2.7.1.3 Auxiliary Bit Control Channels (RFC) ................................................... 1-15

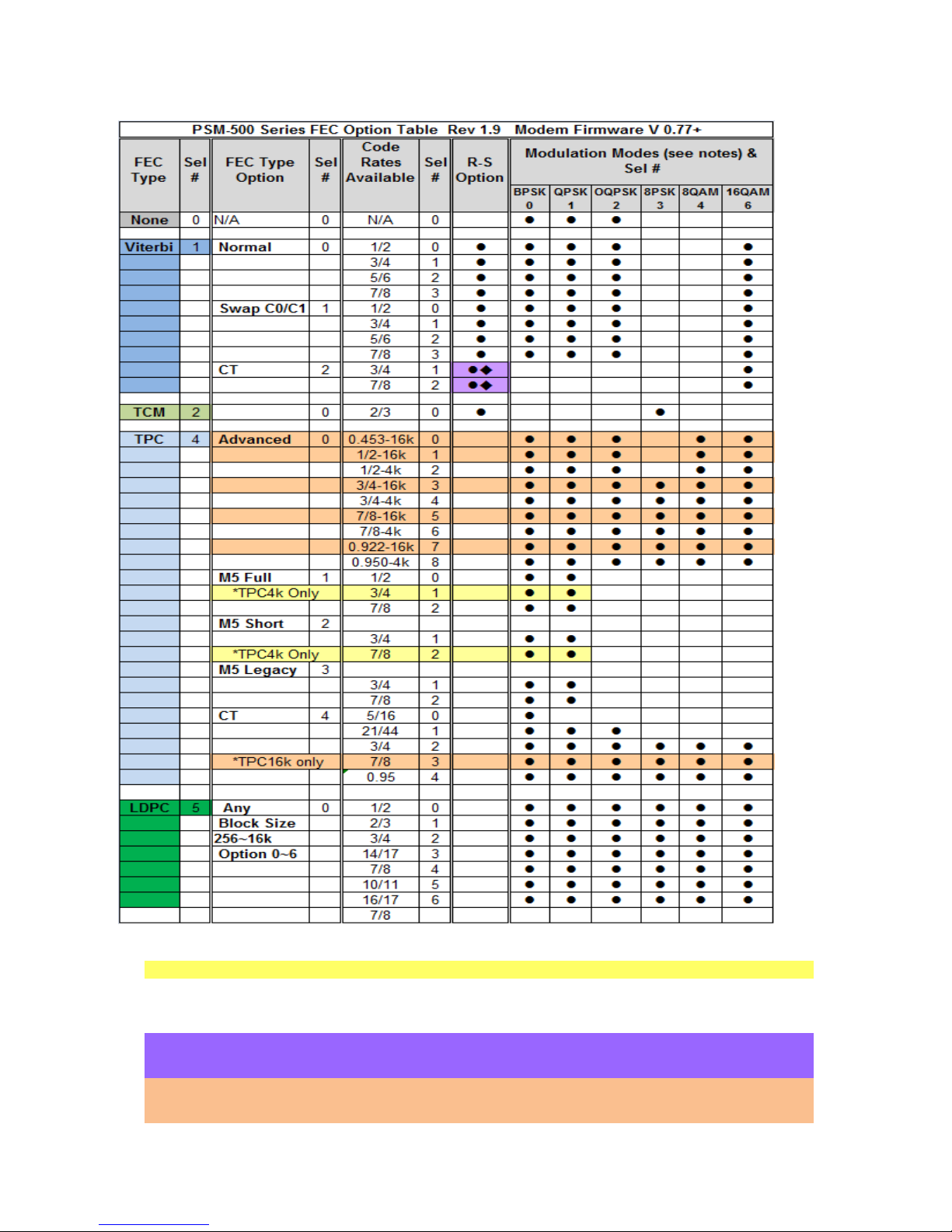

1.2.8 Standard and Optional Modem FEC Cards ............................................................... 1-15

1.2.8.0 Special Codec CT Modes ................................................................................. 1-18

1.2.8.1 Viterbi, Trellis Code Modulation Codec ............................................................ 1-18

1.2.8.2 Reed-Solomon Codec Capability ...................................................................... 1-18

1.2.8.3 Turbo Product Codes FEC Capability ............................................................... 1-20

1.2.8.4 LDPC FEC Capability ....................................................................................... 1-20

1.2.9 Optional Interface Capability ...................................................................................... 1-21

1.2.10 Modem Circuit Implementation ................................................................................. 1-21

Chapter 2 - Installation ....................................................................................................................... 2-1

2.0 Installation Requirements ...................................................................................................... 2-1

2.1 Unpacking .............................................................................................................................. 2-1

2.1.1 Removal and Assembly ................................................................................................ 2-1

2.2 Mounting Considerations ....................................................................................................... 2-1

2.3 Modem Connections .............................................................................................................. 2-2

Figure 2-1 Modem Rear Panel ................................................................................ 2-5

2.3.1 Data Interface Pin Connections .................................................................................... 2-6

Table 2–1 Data Interface Connector J3 Pin Assignment by Signal ................................. 2-6

2.3.1.1 Connecting the Data Interface to Other Equipment .................................................. 2-7

2.3.2 Remote Control Connection ......................................................................................... 2-7

Table 2–2. Remote Control Connector J6 Pin Assignment .............................................. 2-8

2.3.3 Alarm Connection ......................................................................................................... 2-8

Table 2–3. Alarm Connector J5 Pin Assignment ................................................. 2-8

2.3.4 Auxiliary (AUX) Connection .......................................................................................... 2-9

2.3.5 L-Band BUC Power Connection ................................................................................... 2-9

Table 2–4. BUC Power Connector J11 Pin Assignment ..................................... 2-9

2.3.6 Redundancy Connection .............................................................................................. 2-9

Figure 2-2 - Modem Connections for 1:1 Redundancy ............................................ 2-10

2.3.6.1 Set-Up Procedure for 1:1 Redundancy ................................................................... 2-11

2.4 Modem Checkout ................................................................................................................. 2-12

2.4.1 Initial Power-Up .......................................................................................................... 2-12

2.5 Modem Control from the Front Panel ................................................................................... 2-12

2.5.1 Parameter Setup ........................................................................................................ 2-13

PSM-500/500L/500LT - Rev. 0.91

Page 5

PSM-500/500L/500LT SCPC Satellite Modem Table of Contents

iii

2.6 Modem Terminal Mode Control ........................................................................................... 2-13

2.7 Self-Test Mode ..................................................................................................................... 2-14

2.8 IF Loop-back Test Mode ...................................................................................................... 2-14

2.8.1 Built-in BERT .............................................................................................................. 2-14

2.9 Modem Configuration ........................................................................................................... 2-15

2.9.0 Configuring the Modem for Operation ........................................................................ 2-15

2.9.1 Setting Essential Parameters ..................................................................................... 2-15

Modulator and Demodulator ..................................................................................... 2-15

Modulator .................................................................................................................. 2-15

Demodulator ............................................................................................................. 2-15

2.9.1.1 IBS Multiplexer and Reed-Solomon Selection ................................................... 2-16

2.9.1.2 Using The Proper Scrambler ............................................................................ 2-16

IESS-308 Scrambler Mode Operation ...................................................................... 2-16

IESS-309 Scrambler Mode Operation ...................................................................... 2-16

Fixed Scrambler Mode Operation ............................................................................ 2-16

Alternate Scrambler Mode Operation ....................................................................... 2-16

2.9.1.3 Using The L-Band PSM-500L Transmit RF Frequency Feature ...................... 2-16

2.9.1.4 Using The L-Band & L Receive RF Frequency Feature .................................. 2-17

2.9.2 Carrier Acquisition Parameters .................................................................................. 2-17

2.9.2.1 Initial Acquisition ............................................................................................... 2-18

2.9.2.2 Carrier Re-acquisition ....................................................................................... 2-18

2.9.3 Sample Configuration Setting ..................................................................................... 2-19

2.9.4 Setting Additional Parameters .................................................................................... 2-20

2.9.4.1 Data Interface Compatibility ....................................................................... 2-20

2.9.4.2 Automatic Correction .................................................................................. 2-20

2.9.4.3 Alarm configuration ..................................................................................... 2-20

Figure 2-3 - Alarm Processing .................................................................................. 2-21

2.9.5 Using the Internal or an External Reference .............................................................. 2-22

2.9.5.1 Reference Calibration .............................................................................................. 2-22

2.9.6 Setting the Modem Station ID Name .......................................................................... 2-23

2.9.7 Setting the Modem Address for Command Mode Operation ..................................... 2-24

2.10 Interface Type Configuration .............................................................................................. 2-24

2.10.1 Adding or Changing the Optional Interface Type ..................................................... 2-24

2.11 Option FEC Card Installation ............................................................................................. 2-25

2.11.1 Turbo Product Codes Option Installation ................................................................. 2-26

PSM-500/500L/500LT - Rev. 0.91

Page 6

PSM-500/500L/500LT SCPC Satellite Modem Table of Contents

iv

Figure 2-5 FEC Option Card Installation ............................................................... 2-27

Chapter 3 - Operation ......................................................................................................................... 3-1

3.1 Operating Procedures ............................................................................................................ 3-1

3.1.1 Front Panel Control ...................................................................................................... 3-1

3.1.2 Front Panel Layout and Features ................................................................................. 3-1

3.1.2.1 Front Panel LCD Display .................................................................................... 3-1

3.1.2.2 Front Panel Keypad ............................................................................................ 3-2

3.1.2.3 Front Panel LED Indicators ................................................................................. 3-4

Modem LED Indicators ............................................................................................... 3-4

Modulator LED Indicators ........................................................................................... 3-4

Demodulator LED Indicators ...................................................................................... 3-4

3.1.3 Guide to Front Panel Monitor and Control.................................................................... 3-5

3.1.3.1 Navigating Modem Parameters .......................................................................... 3-5

3.1.3.2 Monitoring Modem Parameters ........................................................................... 3-6

3.1.3.3 Changing Modem Parameters ............................................................................ 3-6

3.1.3.4 Automatic Modem Parameter Sequences .......................................................... 3-7

3.1.3.5 Finding Modem Parameter Limits ....................................................................... 3-7

3.2 Front Panel Monitor and Control Parameters ........................................................................ 3-7

Table 3-1 PSM-500 Front Panel Parameter Matrix – Unit Sheet ..................................... 3-9

Table 3-4 PSM-500 Front Panel Parameter Matrix – Interface Sheet ............................ 3-11

Table 3-5. Modem (Unit) Parameter Detail .................................................................... 3-12

Table 3-6. Modulator Parameter Detail .......................................................................... 3-16

Table 3-7. Demodulator Parameter Detail ..................................................................... 3-20

Table 3-8. Interface Parameter Detail ............................................................................ 3-25

3.3 Terminal Mode Control ........................................................................................................ 3-27

3.3.1 Modem Setup for Terminal Mode ............................................................................... 3-27

Figure 3-2a. Terminal Mode – Example of Unit Status Screen ........................ 3-28

Figure 3-2b. Terminal Mode – Example of Unit Status Screen Selection ....... 3-28

Figure 3-3. Terminal Mode – Example of Unit Test Screen .............................. 3-29

3.3.2 Programming Modem Operational Values From the Terminal Screens .................... 3-29

3.4 Remote Command Interface Control ................................................................................... 3-30

3.4.1 System Unit Programming/Communications ............................................................. 3-30

3.5 Modem Checkout ................................................................................................................. 3-30

3.5.1 Power-Up .................................................................................................................... 3-31

3.6 L-Band Feature Operation ................................................................................................... 3-31

PSM-500/500L/500LT - Rev. 0.91

Page 7

PSM-500/500L/500LT SCPC Satellite Modem Table of Contents

v

3.6.1 L-Band BUC Control ................................................................................................... 3-32

3.6.2 L-Band LNB Control ................................................................................................... 3-32

3.7 Data Interface Clock Options ............................................................................................... 3-32

3.7.1 VSAT Mode ................................................................................................................ 3-32

3.7.2 SCPC Mode ................................................................................................................ 3-33

3.7.3 Transmit Interface Clock Auto Mode .......................................................................... 3-33

3.8 Automatic Uplink Power Control (AUPC) Operation ............................................................ 3-33

3.9 Demodulator Receive Data FIFO Operation ........................................................................ 3-35

3.10 Built-in 1:1 Redundancy Mode Operation .......................................................................... 3-36

3.10.1 Setting Up 1:1 Redundancy Mode ........................................................................... 3-37

3.10.2 Operating 1:1 Redundancy Mode ............................................................................ 3-38

3.10.2.1 Forcing a Transfer Switch in 1:1 Redundancy Mode ...................................... 3-38

3.10.3 Removal and Replacement of Units in Redundancy Mode ..................................... 3-39

3.11 Bit Error Rate Test (BERT) Set Operation ......................................................................... 3-39

3.12 Analog Monitor Output Operation ...................................................................................... 3-39

3.13 Storing and Recalling Configuration .................................................................................. 3-40

3.14 Automatic Configuration Recovery - ACR ......................................................................... 3-40

3.15 Special Control Mechanisms ............................................................................................. 3-41

3.15.1 Power-Up Behavior .................................................................................................. 3-41

3.15.2 Monitors and Outputs ............................................................................................... 3-41

3.16 Burst Mode Operation ........................................................................................................ 3-41

Chapter 4 - Maintenance .................................................................................................................... 4-1

4.0 Periodic Maintenance ............................................................................................................ 4-1

4.0.1 Internal Reference Calibration ...................................................................................... 4-1

4.1 Common Test Procedures ..................................................................................................... 4-1

4.1.1 Loop-Back Testing ........................................................................................................ 4-1

4.1.2 Using the Built-in BERT ................................................................................................ 4-3

4.2 Troubleshooting ..................................................................................................................... 4-4

4.2.1 Onboard Diagnostic Indicators ..................................................................................... 4-6

4.2.2 Onboard Processor Power-On Sequence and Diagnostics ......................................... 4-7

4.2.3 Built-in Lamp Test ......................................................................................................... 4-7

4.3 Updating Modem Software .................................................................................................... 4-7

4.3.1 Update Software Installation – ..................................................................................... 4-9

4.3.2 Performing the Software/Firmware Update – ............................................................. 4-10

4.4 Upgrading the Modem Feature Set ...................................................................................... 4-14

PSM-500/500L/500LT - Rev. 0.91

Page 8

PSM-500/500L/500LT SCPC Satellite Modem Table of Contents

vi

4.5 Frequently Asked Questions - FAQ ..................................................................................... 4-15

A. Link Set Up and Installation. ............................................................................................. 4-15

A.1 Compatibility with other Modems. ................................................................................. 4-15

A.2 Operating and Performance Questions. ....................................................................... 4-16

A.3 Why does It do that? ..................................................................................................... 4-18

B. Front Panel Control ........................................................................................................... 4-18

C. Remote Control ................................................................................................................. 4-19

D. Data Interface.................................................................................................................... 4-20

E. Manual .............................................................................................................................. 4-21

Appendices

Appendix A – PSM-500 Technical Specifications ............................................................... A–1

Appendix B – Remote Control Command Protocol ............................................................ B–1

Appendix C – Cabling Specifications .................................................................................. C–1

Appendix MUX – Framing/Multiplexer Addendum ......................................................... MUX–1

Appendix TPC – Turbo Product Codes FEC Addendum ............................................... TPC–1

Appendix HSSI – High Speed Serial Interface Addendum ........................................... HSSI–1

Appendix SNIP – SnIP Ethernet Interface Addendum .................................................. SNIP–1

Appendix LDPC – LDPC FEC Addendum ................................................................... LDPC–1

Note: All appendices may not be present in manual. Some Appendixes may be shipped with

the option.

PSM-500/500L/500LT - Rev. 0.91

Page 9

PSM-500/500L/500LT SCPC Satellite Modem Notices

vii

Safety Notice

This equipment has been designed in accordance with UL and CSA standards for Safety of

Information Technology Equipment.

The PSM-500 Modem contains potentially lethal voltages inside the case. Extreme caution should

be exercised when the cover is removed by following the precautions listed below

Never operate the equipment with the cover removed. Never remove the cover with power applied.

As a safety measure the power cord should be disconnected from the unit when preparing to

remove the cover.

This modem is designed for indoor use. Do not operate this equipment in a wet environment or

outdoors.

Do not operate the modem in an unsafe environment near explosive or flammable gases or liquids

Insure good grounding practices. The grounding lug on the rear of the modem should be connected

to a good earth ground with low impedance cable in rack installations.

The modem is supplied with an IEC filtered power inlet module designed to accept a 3-wire mains

connection consisting of an earth ground, neutral and line conductors. The mating power cord

should have a line cord and plug suitable for the country of operation.

EMC Notice

This equipment has been designed in accordance with FCC and CE standards.

FCC: Part 15, Subpart B, Class A

CE Emissions: EN 55022 Class A, EN 61000-3-2 Class A, EN 61000-3-3

CE Immunity: EN 55024

ICES-003, Class A

To maintain compliance with these standards the following the precautions must be observed.

The equipment must be operated with the cover and all cover screws in place.

Do not remove the rear panel option plate without replacing it with one designed for a specific opt i on

assembly.

All rear connections are designed to have integral shielding on the cable and connector assembly.

“D” type signal connectors must have grounding fingers on the connector shell.

PSM-500/500L/500L - Rev. 0.91

Page 10

Notices PSM-500/500L/500LT SCPC Satellite Modem

viii

About This Manual

This manual is composed of several separable documents. They include the main body of the

manual and several “Appendices”. The main body itself is separated into several “Chapters” and

“Sections”. A “Section is considered a sub-section of a Chapter, such as Section 4.1.2 is a

numbered section within Chapter 4. Page numbers include the Chapter, as in page 3-14.

This manual is available in a printed form and as an electronic “Portable Document Format” or .PDF

file. The electronic format is produced as a universal Adobe Acrobat readable file, and can be

requested directly from Datum Systems, Inc., or via download from the web at

www.datumsystems.com

Revision History

Revision 0.8 3/17/2006 Initial Public Release. ** Preliminary ** Requires minimum Modem

Software Revision 0.12.

Revision 0.83 12/4/2006 Still. ** Preliminary ** Includes additional FEC modes. Requires minimum

Modem Software Revision 0.21.

Revision 0.85 12/14/2006 Includes additional FEC modes and corrections. Requires minimum

Modem Software Revision 0.26.

Revision 0.86 8/12/2007 Includes additional FEC modes, corrections and new menu features f or

Unit Configuration, RTS Monitor and Transmit Mute. Requires minimum

Modem Software Revision 0.52.

Revision 0.87 1/10/2008 Includes added Advanced TPC modes and corrections. Requires minimum

Modem Software Revision 0.63.

Revision 0.88 4/10/2008 Includes added 8QAM modulation, HSSI references, r ev i s ed M500 Update

procedures and corrections. Requires minimum Modem Soft ware Revision

0.72.

Revision 0.90 10/20/2010 Removes references to PSM-500H m odem which is not available i n the

PSM-500 Series.

Revision 0.91 7/15/2011 Update data rate limits and add more LDPC information. Added AUPC

setup example.

. The electronic format on the web is always the latest revision.

Pen and Ink Changes Made to this Manual

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

PSM-500/500L/500LT - Rev. 0.91

Page 11

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-1

Chapter 1 - PSM-500 Modem Description

1.0 Introduction

The Datum Systems’ PSM-500 Series are multi modulation mode VSAT/SCPC Satellite Modems.

They are capable of BPSK, QPSK, OQPSK, 8PSK , 8QAM and 16QAM modulation modes on

transmit and receive independently Their main use is as part of the transmitting and receiving

ground equipment in a satellite communications system. The PSM-500 series uses the latest Digital

Signal Processing (DSP) technology and proprietary techniques to provide unsurpassed

performance at a low cost.

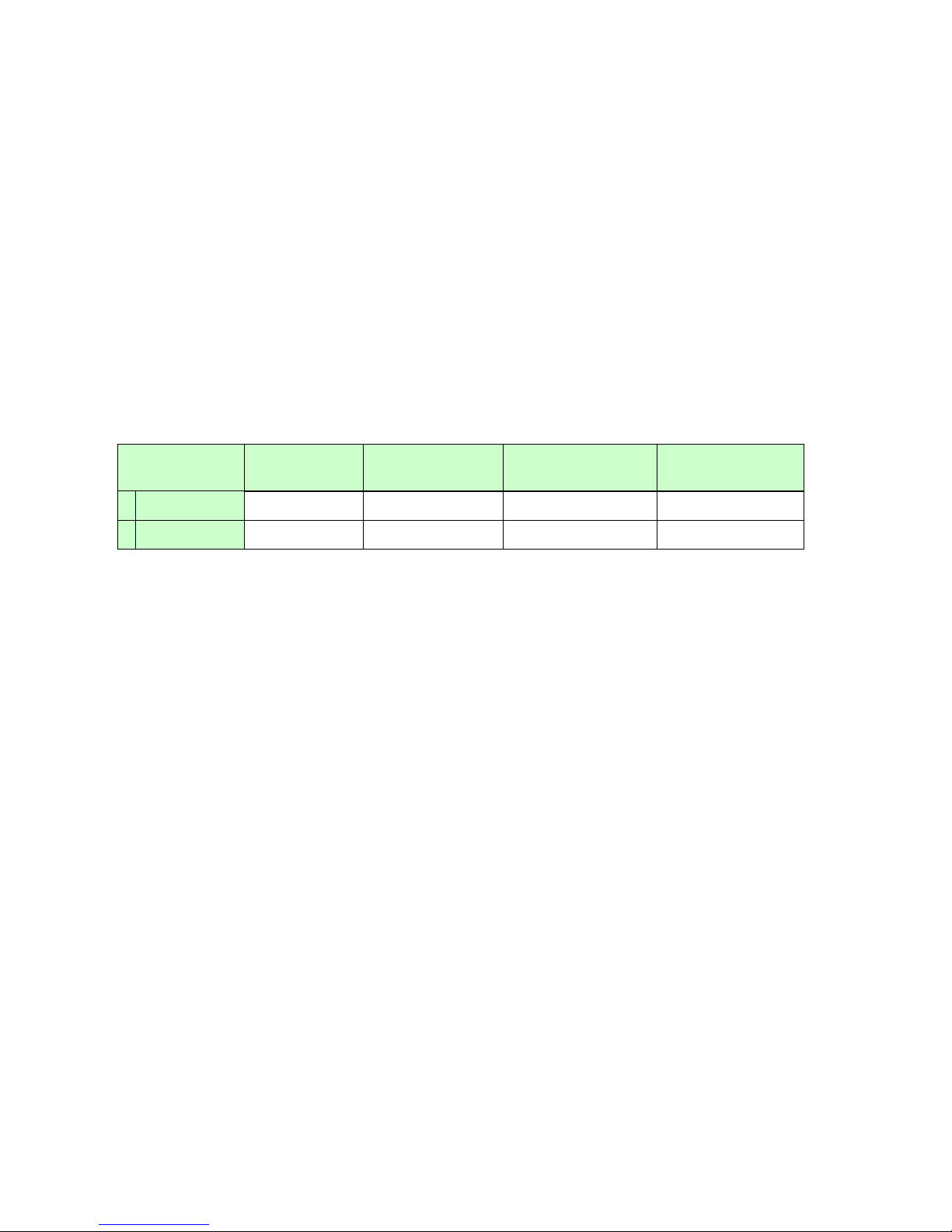

The PSM-500 series is available in 4 IF versions with 3 upgradeable “feature sets” in each. The

matrix below shows the current IF versions available or planned, and the matrix in Section 1.1.2 on

the next page shows the feature sets available. Note that the terms PS M-500S and N are not

normally used except to differentiate between different IF v ersions.

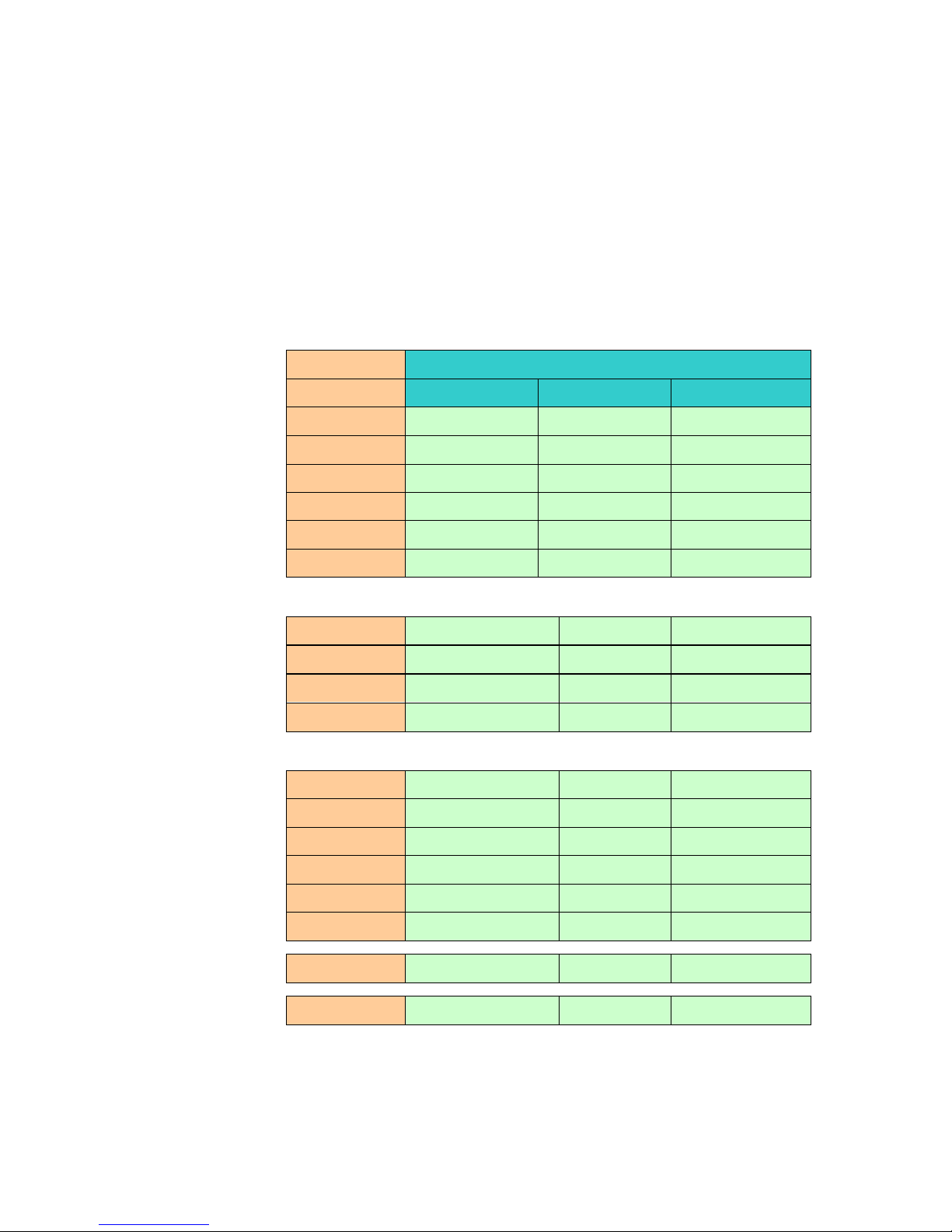

PSM-500 Series IF Interface Versions.

Interface

Versions PSM-500S PSM-500N PSM-500L PSM-500LT

IF Transmit 50 ~ 90 MHz 100 ~ 180 MHz 950 ~ 1750 MHz 950 ~ 1750 MHz

IF Receive 50 ~ 90 MHz 100 ~ 180 MHz 950 ~ 1900 MHz 950 ~ 1900 MHz

The PSM-500 with a standard 70 (or 140) MHz IF is the first member of Datum Systems’ M500

Class Modem products, representing a major extension to our fifth generation of innovative design

concepts proven and refined over ten years of production. The PSM-500L is the second, utilizing LBand frequencies for both the Transmit and Receive IF, it creates the ability t o bui l d extremely

simple and low cost high performance VSATs All M500 class products encompass significant

performance improvement over previous modems at reduced cost. The PSM-500LT is the third,

providing an integrated BUC power supply.

The modem is designed for service in varied types of satellite systems. Either SCPC sy st em s where

two modems are set for continuous operation with each other, or shared resource systems where

modem carriers are not continuous in nature, such as DAMA networks, where outgoing signals from

the modem can be operated in an extremely fast acquisition mode.

The modem is designed to be easily integrated into either a master or remote station via rack

mounting. A highly integrated design allows the PSM-500 to be built into a one rack unit (1 RU,

1.75”) high mounting case, using minimal power for dense applications. The modem is an integral

part of a satellite earth station’s equipment operating between the Data Terminal Equipment and the

station Up and Downconverter equipment.

1.0.1 How to Use This Manual

This manual provides Installation, Operating and Maintenance procedures for the PSM-500 Satellite

Modem and available options at the time of printing.

This manual is an integral part of the modem and is used to explain the installation and operating

procedures for the PSM-500 and present its capabilities and specifications. The manual is divided

into 4 Chapters with Appendices. The 4 Chapters are the Modem Description, Installation, Operation

and Maintenance. The Appendices include the Specifications, Remote Control Protocol and gives

further information on Options, Cabling and information related to placing the Modem i n serv ice.

The divisions of the manual are intended for use by personnel to answer questions in general areas.

Planners and potential purchasers may read the Introduction and Specifications to determine the

suitability of the modem to its intended use; Installers should read the I nst al l ation Chapter and the

PSM-500/500L/500LT - Rev. 0.91

Page 12

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-2

Cabling Specification Appendix; Operating Personnel would use the Operations Chapter to become

familiar with the Modem; while System Programmers would use the Remote Control Protocol to

determine control requirements.

The PSM-500, 500L and 500LT modems are fully interchangeable with the single exception of the IF

input frequency range. In addition all options available for the PSM-500 are usable with t he L or LT

version. The term PSM-500 is used throughout this manual where references apply to either the

PSM-500, 500L or 500LT modems. Where a subject is specific to one modem the “L” or “LT” suffix is

used or the specific differences in operation between the three modem versions are detailed.

1.0.2 Quick Start for Experienced Modem Users

If you are experienced with modems, but not this particular one, you may want to skip some of the

introductory material and learn how to operate the front panel to set up the modem im m edi ately. Go

directly to Section 3.1 – “Operating Procedures” and get a feel for how the front panel operates.

Then scan Tables 3-1 through 3-4 listing the parameters that can be changed, and set up the

modem for your application. We strongly recommend that you go back to learn more, as these

modems have extensive capabilities and features that are unique. A list of abbreviat i ons is locat ed at

the end of the “Frequently Asked Questions” (FAQ) in Chapter 4.

1.0.3 What’s New – This Modem and This Manual

If you are familiar with Datum Systems modems, especially the PS M-4900, t hen you should feel

comfortable with both this modem’s operation and this manual. There are some significant

differences you should review in the list below.

New in This Modem:

• The PSM-500 series is the first to include 8PSK, 8QAM and 16QAM modulation modes,

requiring new procedures and remote control interaction.

• The PSM-500 now includes remote control and firmware update via USB interface on the

rear panel. This was especially necessary since the 10 fold increase in firmware requires a

faster method to load new firmware configurations.

• Each PSM-500 IF version is capable of 3 standard value software upgradeable “Feature

Sets”, as described in section 1.1.2. Many features of the modem are field upgradeable

without adding new hardware. Subsets of these Feature Sets are available.

• There are two option slots on the main PCB used for FEC/processing options. One is

always used for the standard FEC set as a minimum. They are wired in parallel like the PCI

slots on a computer, but use an SO-DIMM form factor. Please don’t plug memory in!

• The IBS multiplexer with AUPC is now standard and built into the main board FPGA logic.

• The Reed-Solomon concatenated FEC is now standard and built into the standard FEC

card.

New in This Manual:

• A new “How-To” Appendix is added in Appendix H. It gives quick instructions on setting up

common features and capabilities.

1.1 Modem Capabilities

1.1.1 Modem IF Variations

The PSM-500 series is currently offered with 3 main Intermediate Frequency (IF) variations

designed to meet the needs of various station types. The standard PSM-500 modem has a 70 MHz

(or optional 140 MHz) transmit and receive IF which is typical for use in large stations with indoor or

outdoor up and down converters. The PSM-500L and PSM-500LT units feature an L-Band transmit

and receive making it ideal for low cost Vsat remote earth stations.

PSM-500/500L/500LT - Rev. 0.91

Page 13

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-3

���

�

���

�

���

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

1.1.2 Modem Feature Set Variations

Feature sets are specific capabilities that suit a modem for a particular purpose. The PSM-500

series is the first modem Datum Systems has offered with variable feature sets. The adv antage is

that a customer does not have to pay for features he does not use, but later feat ures can be

upgraded in the field electronically by adding new firmware Intellectual property to the modem. The

user has the best of both worlds. Feature sets are purposely kept to a minimum to make their control

easy and therefore reduce the cost. There are currently only 3 main feature sets offered for the

PSM-500 series, and they apply to any of the IF variations.

For comparison, the features available in the PSM-4900 modem are also shown. More detail on

maximum and minimum data rates are shown in Appendix A.

PSM-500 Series Feature and Option Matrix.

Original M5 PSM-500S/N/L/LT Series

Feature PSM-4900 M505 M511 M523

Modulation

BPSK

QPSK

OQPSK N/A

8PSK/QAM N/A Upgrade

16QAM/APSK N/A Upgrade Upgrade

Max Data Rate M523 rates slightly higher at higher FEC rates. See Notes below.

BPSK

2.46 Mbps 2.5 Mbps 5 Mbps 7.38 Mbps

QPSK/OQPSK 4.92 Mbps 5 Mbps 10 Mbps 14.76/28 Mbps

8PSK/QAM/TCM N/A N/A 10 Mbps 29.52 Mbps

16QAM/APSK N/A N/A N/A 29.52 Mbps

FEC Modes

Disabled

N/A

Viterbi

Reed-Solomon Option

TPC – 4K (2) Option Option Option Option

TPC – 16K N/A Option Option Option

LDPC-16k (2k) N/A Option Option Option

IBS Mux/AUPC Option

SnIP Ethernet Int. Option Option Option Option

There are multiple items lists as “Options”. Options are specifically hardware items that are installed

in the modem, while a “feature” is a software installation listed as an “upgrade”. To upgrade the

modem from one feature set to another refer to the instructions in Section 4.4.

PSM-500/500L/500LT - Rev. 0.91

Page 14

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-4

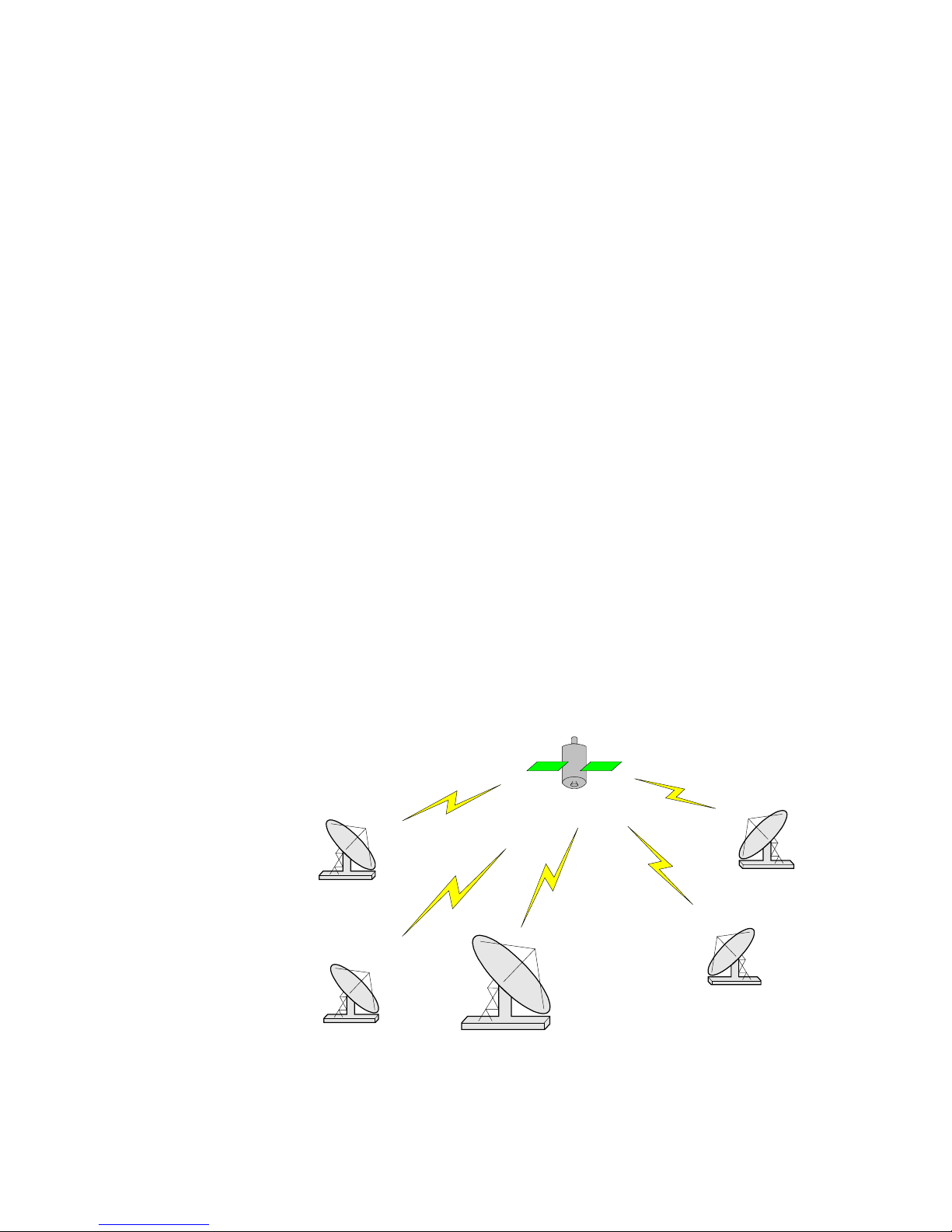

Figure 1-1 Simple Star Network

Hub Station

Remote A

Remote B

Remote C

Remote D

Satellite

Maximum data rates are dependent on many factors besides the basic capabilities of the interface,

including cabling, interface type, features and options installed. The TPC4K hardware codec is

limited to 5Mbps.

1.1.3 Applications

Following are just a few representative forms of satellite communications links and networks in

which the PSM-500 modem series may be used.

1.1.3.1 SCPC Point-to-Point Links

The most straightforward application for a satellite modem is to serve as the Data Communicati ons

Equipment (DCE) for a point-to-point data link. When used in this mode, two modems located at two

different sites are tuned to complementary transmit and receive frequencies. Each direction of the

communications link may have the same or entirely different transmission parameters. In this

application it is typical that the link is established and maintained on a continuous basis, although a

special “on demand” case is described later.

In SCPC point-to-point links the power required from the satellite or the size of the receive antenna

is dependent upon the modem receive performance. The PSM-500 modem uses the most rigorous

methods to maintain performance as close to the theoretical “waterfall” curves as possible. In most

cases the modem will perform at 0.1 to 0.2 dB from the curve (although we say “typi call y” 0.3 dB).

This consistent performance, plus advanced technology such as TPC results in the absolute

minimum power requirements, which equates to the minimum operating.

Ku Band satellite systems are subject to changing performance due to rain at one or more sites. The

PSM-500 contains built in software to perform Automatic Uplink Power Control (AUPC). If the

modems at each link end are provided with an external asynchronous channel of 300 bps they can

be set to automatically maintain a constant Eb/No within programmable limits. This can result in

significantly lower satellite power requirements in a large system in addition to maintaini ng proper

performance in any system. The optional Multiplexer/interface card can provide this low rate channel

in addition to an Earth Station to Earth Station ov erhead service channel.

1.1.3.2 SCPC Point to Multi–Point Links in a Broadcast Application

A broadcast application might involve the necessity of sending continuous or intermittent data from

one source and

“broadcasting” the

information to many

remote locations. For

instance, constant

pricing information and

updates may be sent by

a central location to

many store locations.

There may be minor

return information from

the remotes

acknowledging receipt.

Another broadcast

application could be

transmitting background

music from a central

location to many store

sites. In this case there

would be no return path.

The topology of the

network in both of these broadcast examples would typically be called a “Star” network. As shown in

PSM-500/500L/500LT - Rev. 0.91

Page 15

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-5

Figure 1-1, the shape of the configuration is drawn with the central “Hub” as the center of the star

and the remotes as points of the star. In both cases the transmit frequency and other parameters

may be shared by the receive of all the remotes.

The PSM-500L and LT are ideally suited for use at remote or small stations. Since the receive downconverter requirement is significantly reduced in this version, requiring only that a data grade LNB

(Low Noise Block down-converter) be connected to the modem. The L-Band version modems can

even supply power and reference to the LNB if needed. In addition the PSM-500L and PSM-500LT

modems are designed for use with a Block Up Converter or “BUC” and can supply power and

reference signals on the transmit cable. Most BUCs today are designed to receive these signals on

the cable.

In Broadcast type systems where the remotes only require a receiver, the L or LT is very low cost

and the transmit modulator section can be simply turned off.

A “Star” network configuration is also commonly used with multiple point-to-point links where the hub

is common to every link. An example might be where each remote represents a house or building

with voice or data traffic all destined for a common switch located near the hub. Each link is then

usually dedicated to that customer and the link resources are wasted when no traffic is carried. That

loss is partially offset by being able to use smaller antennas and power at each of the remotes,

concentrating costs at the hub.

1.1.3.3 DAMA (Demand Assigned Multiple Access)

Suppose that we wanted to simulate a telephone network with a virtual switch between modems

carrying digitized voice information. We might use a central computer to assign a pair of frequencies

for any conversation and send this connection information to the proper sites to set up the

connection. Many systems of this type use “Star” network topology, but thi s has t he di sadv antage

that for a person at Remote A to talk to someone at Remote D the traff i c must go through the hub.

The resulting delay through 2 satellite hops is just at the limit of what is t ol erabl e for voice traffic.

In this application a new network configuration is usable. That is a “Mesh” network where any of the

voice modems at any site can be programmed to link with any other modem directly at any other

site. The resulting link diagram looks like a mesh of interconnects. Now there must be sufficient

antenna size and power at each remote to link to every other remote. The station costs can go up

significantly, and are multiplied by the number of stations.

Since the frequencies can be assigned on demand, the network is then called “Demand Assigned,

Multiple Access”, or DAMA. One important characteristic of a DAMA system used for voi ce

information is the lock-up time of the modem. At the low data rates used to di gi tize voice today (4.4

to 32 kbps) the modem receive acquisition method of sweeping results in lock-up times of tens of

seconds to minutes. The PSM-500 modem is uniquely designed to significantly reduce this time:

The fast acquisition digital signal processor used in the PSM-500 looks at the receive signals within

its acquisition range much like a person might view the same region using a spectrum analyzer. It

then “homes in” and locks to the most probable carrier. This acquisition mode can reduce the

receive acquisition time to approximately 1/3

rd

of a second at 9.6 kbps in QPSK mode over +/- 30

kHz, and less in BPSK mode.

1.1.3.4 TDMA (Time Division Multiple Access) Remote Site Application

In a TDMA network the central Hub continually transmits a stream of outbound data containing

information for multiple remote sites, while the remotes transmit back to the Hub on a timed basis.

Each of these remotes is said to “burst” its information back on a specific frequency. This may be the

same inbound frequency for all sites. Each of the remotes is responsible for accessing its own

information from the outbound data stream by reading the address assigned to specific parts of the

data.

The TDMA network usually looks like the Star network described above. The outbound (from the

Hub) data rate may be quite high to accommodate many remotes with low latency, whil e the inbound

data rate may be low to allow use of a small antenna and power amplifier at the many remote sites.

PSM-500/500L/500LT - Rev. 0.91

Page 16

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-6

The PSM-500L is specifically designed to be usable as the remote site modem of a TDMA network

when coupled with a proper “Burst” demodulator at the hub site. Note: As of the time of this

manual the “TDMA burst” mode is a special factory request option and not installed in

standard modems.

Another variation could use both the DAMA (star or mesh configuration) with a concurrent TDMA

system as the monitor/control network for the DAMA. Again the PSM-500 modem is ideally suited for

both modem applications at both low and high speeds.

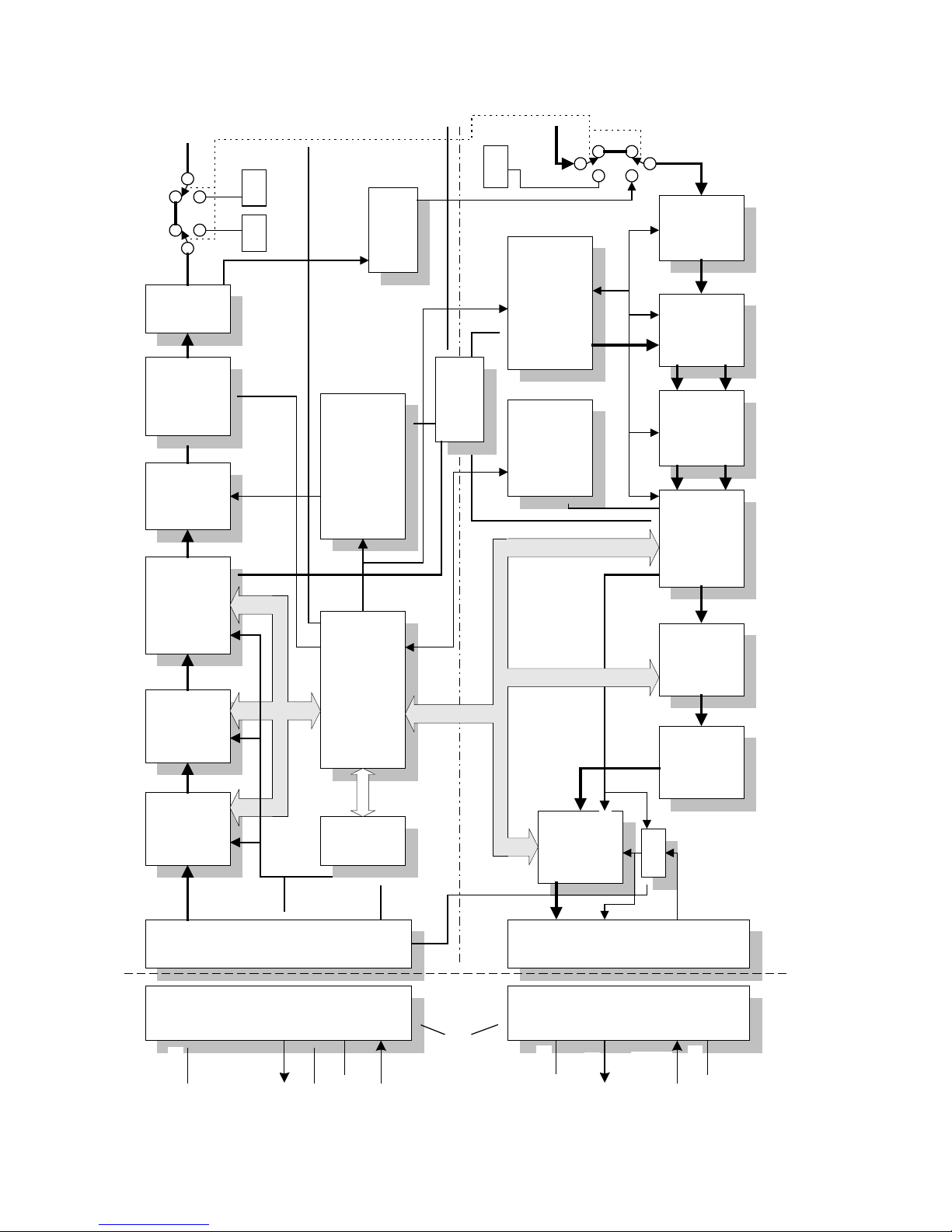

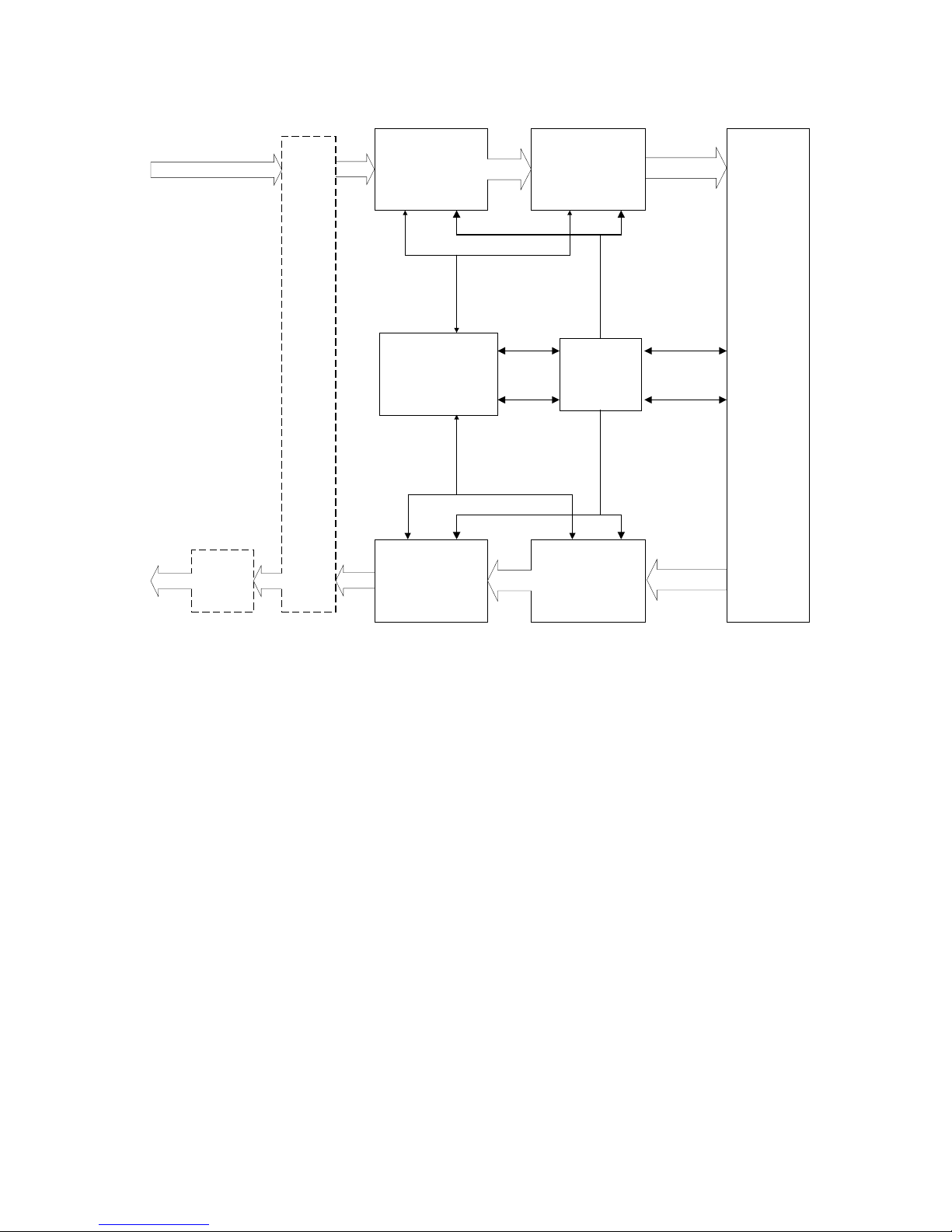

1.2 Modem Functional Assemblies

The PSM-500 VSAT/SCPC Modem consists of seven main functional elements arranged on three

electronic printed circuit assemblies, as shown in Figure 1-2.

The Main Modem Circuit Assembly consists of the following major assemblies:

1. The Modem digital PSK/QAM modulator with carrier generation in the 50 to 90 M Hz

range for standard modem, or 950 to 1750 MHz in the L-Band versions.

2. The Modem digital PSK/QAM demodulator accepting signals in the 50 to 90 MHz range

for the standard modem and 950 to 1900 MHz in the L-Band versions.

3. The Modem microprocessor monitor/control subsystem.

4. The Modem Digital Signal Processor Acquisition subsystem.

5. The Programmable Data Interface. Seven standard data interfaces are built onto the

main modem assembly. The unit can also accept special interfaces via an optional

interface card.

The other two printed circuit assemblies are the Front Panel Control Assembly, and the Power

Supply Assembly.

In addition the main PWB can accept two plug-in sub-assemblies for Forward Error Correction

(FEC). The first subassembly normally contains either the standard Viterbi and Reed-Solomon FEC

set or a combination card containing Viterbi/TCM, Reed-Solomon and either a 4k block size Turbo

Product Codes (TPC) or a 16k block size TPC. The TPC could also be installed alone on a card

placed in the second plug in location. The second location could also be one of a number of FECs

that are be available for the M500, such as FlexLDPC.

The IBS Multiplexer circuitry that was on another daughter card in previous modems is now part on

the main board’s FPGAs.

Note in the functional block diagram below that, with the exception of the receiv e FIFO buffer, there

are complementary signal processing blocks in the transmit and receive paths. Note also that there

are no typical superhetrodyne mixing and filtering blocks. That is because there are none used in the

direct modulation and demodulation scheme used in the PSM-500, sometimes referred to as Zero

IF.

The following sections described more detail on the design of the modulator and demodulator.

PSM-500/500L/500LT - Rev. 0.91

Page 17

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-7

Doppler

FIFO Buffer

Program

mable

Transmit

Interface

DB37

Female

at J3

RS-449

or

V.35

or

RS-232

etc.

FEC

Encoder

Baseband Signal

Processing

Modulator

TClk

TData

RTS

CTS

V.35/Intelsat

and

Differential

Encoder

Programmabl

e Attenuator

Transmit SynthesizerProcessor Control

Option

Interface

Connector

P1

TT

Clk

Program

mable

Receive

Interface

DB37

Female

at J3

RS-449

or

V.35

or

RS-232

etc.

RClk

RData

Ready

Option

Interface

Connector

P1

Ext

FIFO

Clk

XMT Out

70 MHz

or L-Band

Figure - M500 Modem Block Diagram

FEC

Decoder

Baseband Signal

Processing

Demodulator

V.35/Intelsat

and

Differential

Decoder

Front end

AGC/Amp

A/D

Conversion

Receive Synthesizer

RCV In

70 MHz

(or L-Band)

Out Clk

In Clk

Modem

Reference

Oscillator

MODULATOR

DEMODULATOR

Interface & Loop-

Back Circuits

DSP Aquisition

Processor

25 dB

Loopback

Attenuator

Term

Term

Low

Pass

Filter

Term

Ext. Reference In

Clock

Control

Aux.

Con-

nection

at J4

PSM-500/500L/500LT - Rev. 0.91

Figure 1-2 Modem Block Diagram

Page 18

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-8

1.2.1 Modulator

The PSK/QAM modulator in the modem employs a unique digital modulation scheme requiring no

heterodyne operations (mixing and filtering to an IF) to arrive at the transmit RF frequency. The

desired carrier frequency is synthesized and directly modulated with the baseband signal. The

baseband signal is itself digitally derived and generated using a digital to analog (D/A) convert er.

The digital signal processing of the transmit signal includes the equivalent of a 144 tap FIR filter

function.

As previously shown in Figure 1-2, synchronous transmit data and clock signals are accepted by the

modulator, then processed by the V.35/Intelsat scrambler and differential encoder. The m odulator

can be set by the processor to operate at a number of data rates between 1.2 kbps (BPSK, rate 1/2)

and 20 Mbps (8PSK +, M520 feature set). Refer to the specification in Appendix A for exact rate

capabilities. The data is then encoded for Forward Error Correction (FEC) at rate 1/2, 3/4, 5/6 or 7/8

resulting in an encoded signal at between 2.4 and 14,760 ksps (kilo symbols per second). The

Viterbi convolutional encoder can be programmed for rate 1/2, 3/4, 5/6 or 7/8 and is set for a

constraint factor (K) of 7 for use by a (receiving end) Viterbi convolutional decoder with the same

rate and K factor. A Reed-Solomon FEC is available for concatenated operation with the Vit erbi

Codec and two types of “Turbo Codes” Codecs are also available to replace the Viterbi Codec. A

special case is 8PSK, which only operates in a Trellis Code Modulation (TCM) mode at rate 2/3,

unless a non-Viterbi FEC is added such as TPC or FlexLDPC.

The FEC is followed by an optional differential encoder. The differential encoder out put is then sent

to the transmit baseband signal processor whose main function is to convert the data stream into

analog baseband I and Q channels for modulating the carrier. The actual conversion process is

accomplished in a lookup table, latch and D/A converter. The lookup table represents a digitally

preprocessed function required to produce the proper RF signal output when mixed with the desired

carrier frequency. A low-pass filter is applied to the D/A output to reduce the level of sampli ng

components.

Transmit Local Oscillator generation is accomplished in two parts. A PLL step synthesizer is used to

generate a basic LO in the 52 to 92 (or 104 to 184 or 952 to 1752) MHz range with 500 kHz step

size. A Direct Digital Synthesizer (DDS), consisting of an NCO and D/A conversion, is used to

generate an approximate 2 MHz signal with fine step size of approximately 1 Hz and a range of

±1.25 MHz. When the DDS is subtracted from the step synthesizer output in a second PLL, the

available LO can be tuned in 1 Hz steps over the full range of 50 to 90 MHz (100 to 180 MHz if built

for that version).

The processed baseband signal is then mixed with the transmit synthesizer's LO carrier signal to

generate an output modulated carrier in the 50 to 90 MHz range (or 950 to 1750 MHz in the L-Band

modem). A classic IQ modulator with two mixers is used and the LO is fed into the second mix er

shifted 90 degrees from the first. The modulated baseband signal can take two forms at this point

depending on whether BPSK or QPSK modulation is used. In BPSK mode, the baseband signal fed

to the two mixers is identical. In QPSK mode, the two signals represent the baseband I and Q

channels of the baseband.

The resultant RF signal is then low pass filtered and amplified to produce a signal at approximately

over 5 dBm into 75Ω. An output attenuator controlled by the onboard processor is used to set t he

modulator output level over a range of +5 to –35 dBm. The actual attenuator is a set of pin di odes

whose voltage is derived from the processor via a 12-bit D/A converter. The processor also holds a

calibration table of DAC input vs. RF output level/frequency in non-volatile memory.

No physical adjustments are present in the modulator. All necessary adjustments are electronically

performed during calibration and are intended to last the life of the unit without requiring resetting.

The modulator is capable of operating in two different modes: Continuous mode for SCPC use and

“Burst” mode for use at a VSAT location. When set to VSAT operating m ode, the transmit signal is

turned off and on according to the status of the data interface control lines and framing information in

the data stream as described in the “Operation” Chapter of this document. The burst mode allows

multiple station modulators to link up consecutively with a single master station “burst dem odul ator”.

PSM-500/500L/500LT - Rev. 0.91

Page 19

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-9

Note: As of the time of this manual the burst mode is a special factory request option and not

installed in standard modems.

The Modulator IF output can be routed to the Demodulator input using a built-in “IF Loop-back”

function. The loop-back path provides a 25 dB attenuator to avoid overloading the receive input.

1.2.2 Demodulator

The Modem Demodulator uses direct conversion techniques for recovery of data from an incoming

carrier, and therefore like the modulator does not use heterodyning, and has no internal IF signal or

processing. Referring to Figure 1-2, the input RF signal is first input to the receive AGC amplifier.

The AGC amplifier has a range of greater than 40 dB at any data rate, allowing input s ov er that

range while still meeting performance criteria. The range is controlled in several steps depending on

the data rate extending over the range of –20 dBm at high data rates to –84 dBm at l ow dat a rat es.

The proper AGC gain is digitally determined as that which produces an optimal output from the A /D

converters and is thus derived after the A/D converters.

The RF input is then demodulated using a “Costas Loop”, phase locked loop demodulator where the

signal is split using a 90 degree hybrid into I and Q channels. In BPSK mode, the I channel carries

the data information and the Q channel represents the noise and carrier phase information in the

Costas loop. For QPSK operation, the I and Q channels each carry data information. The I and Q

channel “eye” signals are not available as in many other modems because the signal/data

representation at this point is still strictly digital for direct signal processing.

A receive synthesizer generates the demodulator local oscillator which is at the desired receive

carrier frequency. The synthesizer is tunable over the range of 50 to 90 MHz (or 950 to 1900 MHz in

the L-Band modems) and has two tuning components; the LO step synthesizer used to tune in steps

of 500 kHz, and a Direct Digital Synthesizer (DDS) component used to acquire and track the

received carrier. The DDS control has two tuning sources; (1) the digital Costas demodulation loop

phase detector used to track an already “locked” signal and (2) the processor control used to set the

carrier frequency and acquire new signals. The processor controls the acquisition search over a

programmable range from ±100 Hz to ±1.25 MHz.

The I and Q channel baseband outputs of the Costas Loop demodulator are converted to digital data

streams by parallel 12 bit D/A converters. The digital information is then filtered via a Datum

Systems’ proprietary programmable digital filter. The filtered sample output is sent to the input of the

Forward Error Correction (FEC) process (either Viterbi convolutional, concatenated Reed-Solomon,

8PSK TCM rate 2/3, Turbo Codes or LDPC decoder) circuit. Multiple bits of the filtered A/D

converter are used for “soft decision” decoding in the FEC, providing an improvement in

performance over hard decision decoding.

The A/D output is also available to a special Digital Signal Processor (DSP), which is used to

examine the incoming signals for known energy patterns and acquire carriers significantly faster

than conventional sweep acquisition. This DSP controlled acquisition is especially useful at low data

rates and can improve over a typical sweep by more than 2 orders of magnitude.

The receive signal processing shown in Figure 1-2 serves the following multiple functions:

1. Generates the soft decision symbol information for input to the FEC.

2. Recovers the bit rate clock from the incoming signal.

3. Measures the Es/No of the received signal.

4. Generates the receive AGC signal to set the input stage gain.

The FEC decoders are contained on one or two adaptor cards plugged into the main board (all

except the TPC are contained with the adaptors FPGA), which is under control of the onboard

processor.

A differential decoder and INTELSAT / V.35 descrambler for the received data signal can be

individually enabled or disabled by the processor based on the current FEC and other settings. It is

no longer under control of the front panel or command interface. This configuration is held in the

PSM-500/500L/500LT - Rev. 0.91

Page 20

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-10

nonvolatile EEPROM and does not have to be reconfigured on power-up. The resulting received

data and clock signals are sent to the interface assembly. Receive interface clocking can take

several forms as explained below.

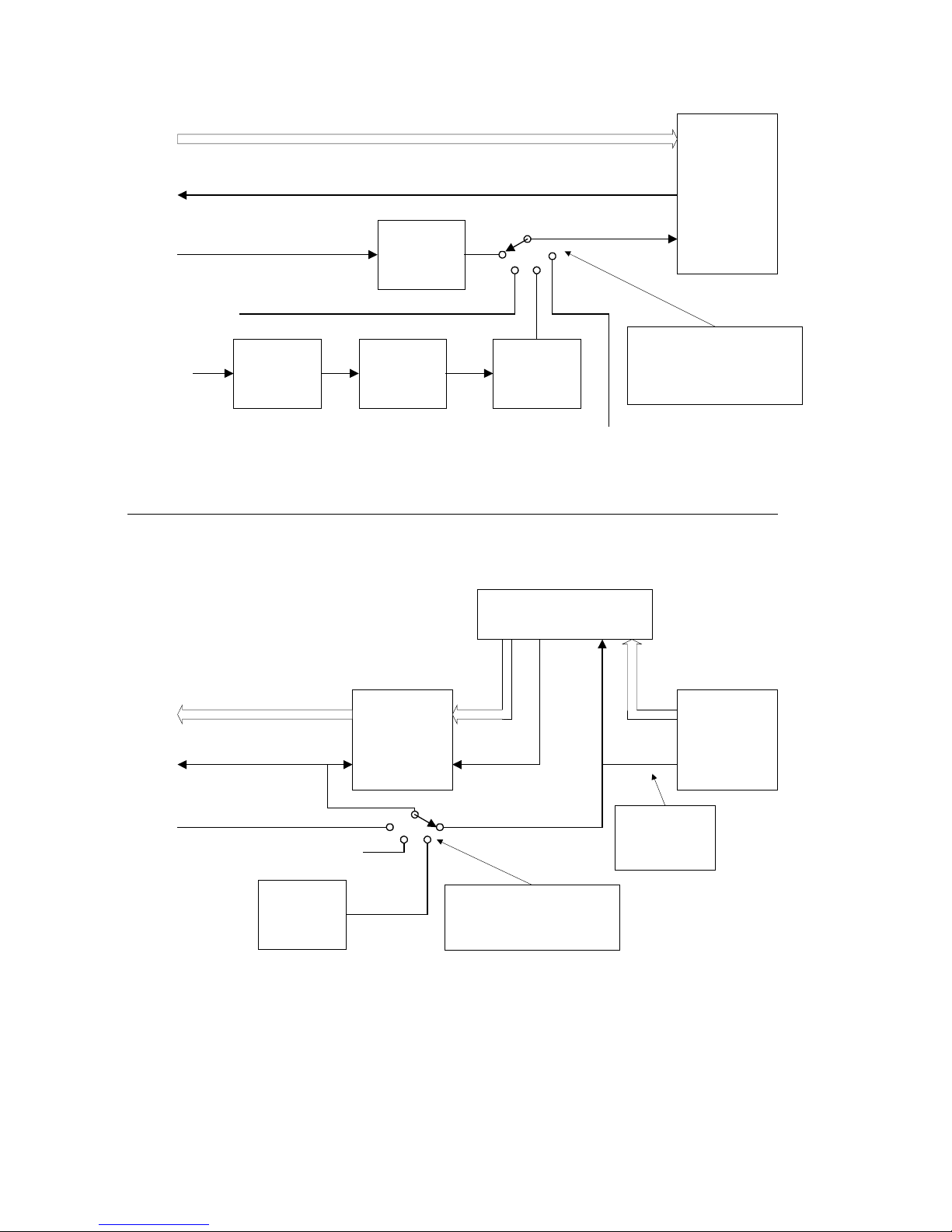

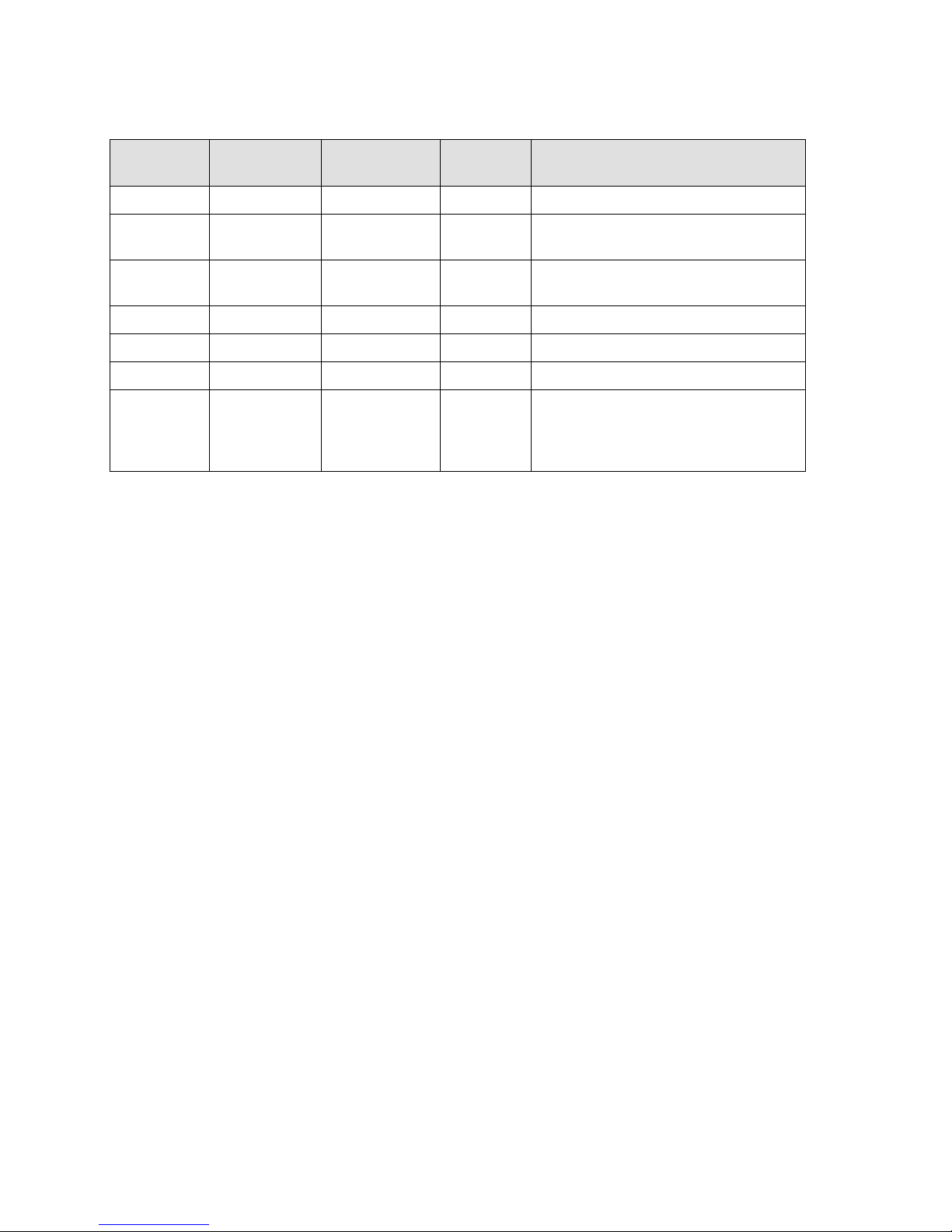

1.2.3 Modem Bit Rate Timing

The Modulator and the Demodulator each have 4 possible sources for their bit rate timing.

The Modulator always outputs the Send Timing signal, but the source of this tim i ng m ay be either:

1. An Internally generated bit rate NCO locked to the Internal Reference,

2. The Demodulator Receive Clock,

3. An External input at the data rate or

4. An external input on the Interface Terminal Timing input.

The modem’s internal reference is a 2.0 parts per million clock oscillator, which is sufficiently

accurate for most applications. If system timing requirements dictate a better reference, the i nternal

oscillator may be phase locked to an external reference applied at the rear panel.

The Demodulator always outputs the Receive Timing signal. The receive demodulator clock derived

from the receive signal is synchronous with the Receive Data and is the normal source of the

receive timing. If the system requires a different clock (which still must be the same av erage rate as

the demodulator’s receive clock) then provisions are made to buffer the data in a programmable

FIFO. The demodulator receive clock is always used to clock the data into the FIFO. The clock

output can be either:

1. The Demodulator Receive Clock,

2. The Modulator Clock

3. An internally generated bit rate NCO locked to the Internal Reference, or

4. An External FIFO Clock applied on the interface connector.

If the demodulator receive clock is selected then the FIFO itself is physically bypassed by switching

circuitry.

The internally generated bit rate NCO locked to the Internal Reference oscillator is settable to 40 bi t

accuracy. That is 1 part in 10 to the 12 or 1 part per trillion.

The PSM-500 series includes two changes to previous modems to insure proper operation. First, the

modem detects if no data is present on the input by a lack of transitions for approximately 5 seconds

and will produce a programmable alarm after that time. Second, due to the higher data rat es the

PSM-500 input circuitry automatically fine tunes the clocks to attempt to place the data period at the

optimal point with respect to the clocks. This also helps tremendously when using the TT clock to

create the transmit timing.

A block diagram simplified representation of the Transmit and Receive clock sources are shown in

Figure 1-3.

PSM-500/500L/500LT - Rev. 0.91

Page 21

Page 1-11

Transmit Clock Sources

Receive Clock Sources

Demodulator

Modulator

Receive FIFO

Buffer

DATA

CLOCK

DATA

IN

INOUT

OUT

DATA

Optional Reed-Solomon Decoder

& IBS Multiplexer

CLOCK

Demodulator RCV

External

Reference Input

(Rear Panel)

From Modulator

bit timing

CLOCK

Internal

Reference

Oscillator

External

Reference PLL

Terminal

Timing

Terminal

Timing

From

Interface

Demod output

clock is phase

locked to receive

bit timing

FIFO output clock selected from

"RCV Clock", "Internal", "External"

or "Mod Clock". Selection of "RCV

Clock" bypasses the FIFO buffer.

Bit Rate NCO

From

Receive

Clock

Send Data

From

Interface

Send

Timing To

Interface

Modulator bit clock source is

selected from "Internal", "Terminal

Timing", "External" or "RCV

Clock". The Send Timing is

always an output from the modem.

Receive

Data To

Interface

Receive

Timing To

Interface

External

FIFO Clock

From

Interface

Bit Rate NCO

"Internal"

External Send Timing Input

(Rear Panel)

PSM-500/500L/500LT SCPC Satellite Modem Description

These Clock sources may be used in various ways in a system implementation to provide correct

timing at a destination. Each of the clock sources can be set either from the front panel or from an

external monitor and control system.

PSM-500/500L/500LT - Rev. 0.91

Figure 1-3 Clock Source Options

Page 22

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-12

1.2.4 Control Processor

A single microprocessor manages all monitor, control and communications functions on the modem

board. The processor continuously monitors all onboard status signals.

The modem control processor uses external address and data buses to connect to external Flash

PROM containing the instruction code. The processor uses both internal and external RAM for all

operations and maintains configuration and permanent parameters in parallel EEPROM. The

processor also connects to the FEC, the custom ASICs, the DSP processor, the front panel, and

various onboard peripheral functions via the address and data bus.

The control processor also maintains a serial peripheral interface to connect to several onboard

peripherals. These include external D/A converters holding calibration and current analog settings,

identification EEPROMs on option and interface cards and step synthesizers.

The control processor also contains an internal 12-Channel 10-bit A/D converter for gathering

analog information from various onboard monitored points including the phase locked loop tuning

voltages.

Digital I/O used to monitor and control the modem is handled mainly through the DSP circuits and

their interface to the processor. Such parameters as the current Eb/No and receive offset frequency

information are read by the processor from the DSPs while most configuration information is writt en

to the DSPs.

The control processor uses a full-duplex Universal Asynchronous Receiver/Transmitter (UART) for

communications with either the RS–232 / RS–485 remote command port or with a separate VT100

type “console” terminal device connected to the modem. In addition a USB control int erf ace i s

provided.

The control processor has provisions for communicating with another PSM-500 modem for

implementation of Automatic Uplink Power Control (AUPC). The channel for this communications is

normally provided by equipping the unit with the optional IBS multiplexer interface card.

1.2.5 Acquisition Processor

The acquisition processor, a Texas Instruments 320C5xxx Digital Signal Processor, manages the

receive signal acquisition and lock functions to achieve fast acquisition performance at low data

rates. This DSP is controlled by the control processor via a communications protocol managed

through a special bi-directional parallel interface to the main processor.

The signal acquisition DSP accepts sampled data from the receive chain A/D Converters and

mathematically determines the location of the incoming carrier. This is accomplished in a multi–step

process which continues to narrow down the exact frequency until it is known within the lock range

of the PLL demodulator. At data rates below 16 kbps this process is more than an order of

magnitude faster than a standard sweep method. Typical signal acquisition times at 16 kbps QPSK

are 0.2 seconds using the acquisition processor vs. over 20 seconds using a standard sweep.

1.2.6 Standard Data Interface

The standard Interface in the PSM-500 is built onto the main PWB and contains the driv ers and

receivers for one of five possible data interface standards (seven including minor variations of each).

All interface standards are selected under program control via the front panel or remote control. Five

of these standards are common interfaces used in the communications industry:

• RS-449, terminated and un-terminated

• V.35,

• V.36

• Synchronous RS-232 (Limited to 128 kbps by drivers and receivers.)

• EIA-530 and EIA-530A

• Asynchronous RS-232 (Limited to 115 kbps by various protocols).

PSM-500/500L/500LT - Rev. 0.91

Page 23

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-13

The un-terminated versions of these standard interfaces and are used to implement one for one

(1:1) redundancy between two PSM-500 units.

A single 37 pin “D” type female connector is available on the rear panel at J3 providing the terrestrial

data interface. The interface standard is electronically selectable via front panel or remote control.

Optional interfaces are provided by a separate option interface card which is mounted inside the

modem chassis. The provision of an optional interface “adds” to the available interfaces which can

be selected under program control. An interface field kit of parts to add an option interface is

available from the manufacturer for installation by qualified technical f i eld servi ce personnel. When

an optional interface is installed the main processor automatically queries and installs the necessary

software controls for accessing the interface.

1.2.6.1 Data Interface Loop-Back Function

The standard and most optional interfaces also provide the data loop-back function. Ethernet

interfaces do not have this function. The data loop-back can be controlled from the front panel or via

remote control command. The data towards both the terrestrial and satellite sides can be looped

back individually by enabling this function via the front panel or remote control

⇒

Caution: Enabling the “Data Loop-Back” functions will result in loss of traffic. It

should not be used in operating links without prior arrangements.

The data loop-back allows testing of the signal path connection up to the loop-back and back to the

source. Since both terrestrial and satellite sides of the signal path can be looped, the connection

from a local DTE can be checked on the terrestrial side while the connection from the far end DTE

over the satellite and through the modem can be checked on the satellite side.

More information on use of the loop-back modes is given in Section 4.1 Common Test Procedures.

1.2.6.2 Data Interface BERT Function

The standard interfaces also include a programmable Bit Error Rate Test (BERT) set. It is located

between the modem’s satellite and terrestrial data loop-back functions. Ethernet interfaces do not

have this function. The BERT can be controlled from the front panel or via remot e cont rol comm and

and provides extensive test result data.

⇒

Caution: Enabling the “BERT” function will result in loss of traffic. It should not be

used in operating links without prior arrangements.

New in this modem is the ability to set the BERT set to point toward t he “Li ne” side external cabling,

acting as a DCE device. More on use of the BERT functions and modes is given in Section 4.1.2

“Using the Built-in BERT”.

1.2.6.3 Data Interface 1:1 Redundancy Function

The standard interfaces are also capable of operating in a special 1:1 redundancy mode. In this

mode the data interfaces are tied directly in parallel using a special “Y” cable. Software control built

into the modem can then be set to indicate that the two connected modems are operating in a

redundant mode. The two modems communicate with each other to determine the alarm status of

each and force the “off-line” unit’s data interface into an un-terminated condition. This allows both

interfaces to receive incoming data and clock signals, which are necessary to ascertain correct

functioning. At the same time the transmit and receive IF ports are also connected together through

the stations (or separately supplied) transmit and receive IF combiner/splitter assemblies.

The alarms that are used to determine switching criteria are programmable, and the first modem set

up for this mode automatically loads its configuration information to the second or “back-up” unit.

These features create a very low cost redundancy system that is both flexible and easily set up.

More information on the set-up and use of the 1:1 redundancy functions and modes is given in

Sections 2.3.5 “1:1 Redundancy Connection” and 3.10 “Built-in 1:1 Redundancy Mode Operation”.

PSM-500/500L/500LT - Rev. 0.91

Page 24

Description PSM-500/500L/500LT SCPC Satellite Modem

Page 1-14

Compatibility

Ratio

Disabled

N/A

1/1 Standard

IESS-309

16/15

Fixed synchronous ESC, No AUPC, No MCC

MCC).

Also variable data load per frame.

1.2.7 Standard Framing and IBS Multiplexer

The framing/multiplexer is capable of multiplexing a relatively low speed overhead channel onto the

terrestrial data stream resulting in a slightly higher combined or “aggregate” data rate through the

modem. The overhead channel is recovered at the far end. This added channel is termed variously

an overhead channel, ESC, service channel, “asynch” channel or, in IESS terminology, an E S to ES

data channel. A simplified block diagram of the data multiplexer is shown in Appendix RS .

The basic frame structure used by the multiplexer is that specified in the IESS-309 standard, P age

60, Figure 10, resulting in a 16/15 aggregate to through data ratio. This means that when the

multiplexer is enabled the modem aggregate operating data rate is computed as the terrestrial

connection (through) data rate multiplied by 16/15. The user sets only the desired through data rate

while the modem computes the aggregate rate required. The multiplexer is also capable of

expanded operating modes which include custom setting of the ratio of data to framing by tes.

The Multiplexer provides the following modes of operation. They are described more fully i n T he IBS

Multiplexer/Reed-Solomon Appendix RS.

Mode Standard/

Overhead

Notes

Enhanced Modified IESS-309 16/15 M4 compatible ESC and AUPC (limited

Custom Modified IESS-309 Variable Full ESC and MCC including AUPC, Remote

Modem Control, 2 one=bit control channels.

The ESC Data Channel can be set under software-control to either RS-232 or RS-485 mode. The

pin assignments for both modes are shown in Section 2.3 and Appendix RS. These pin assignments

appear on the rear panel “AUX” (Auxiliary) connector J4 only when the Multiplexer function is

enabled. The RS-485 Transmit Data Drivers can set to “RS-485” or “RS-485 ON” when in

“Enhanced” mode. The “ON” setting forces the driver continuously on while the “RS-485” setting

controls the output into tri-state when the modem is not transmitting data, al lowing m ul tiple modem

outputs to be connected together. In the standard IBS mode only the “RS-485 ON” mode is

available.

In Enhanced or Custom mode a 2 wire receive operating mode can be selected for the receive data

into the ESC channel. In this mode the receive input is muted while the transmit data output is

active. In 4 wire mode the receive is always enabled. In the standard IBS mode only the 4 wire mode

is available. Note that the transmit and receive pairs are physically separate wires and must be

connected together if true RS-485 2 wire connectivity is desired.

The processor on the main board performs software/hardware assignment of bits to specific

purposes in the Custom mode and buffers the ESC Data Channel to standard asynchronous data

rates.

The user does not have to compute data framing variables to use the Custom Multiplexer Mode.

When placed in this mode the entry parameters are the ESC and MCC channel rates selected from

standard asynchronous data rates (300 to 38,400 bps). The modem then computes the proper

relationship between the framing and terrestrial data rates to achieve the proper operation. The

modem also displays the terrestrial data to aggregate ratio.

PSM-500/500L/500LT - Rev. 0.91

Page 25

PSM-500/500L/500LT SCPC Satellite Modem Description

Page 1-15

1.2.7.1 Modem Control Channel (MCC)

The MCC is available in both the Enhanced and Custom Multiplexer modes. In the Enhanced mode

the MCC provides for an AUPC channel. In the Custom mode the MCC provides for the AUPC plus

the Remote Modem Control (RMC) Channel and the Auxiliary control bits (RFC).

1.2.7.1.1 AUPC Control Channel (AUPC)

When the modem is placed into either the “Enhanced” or “Custom” modes the AUPC control

channel becomes available. The AUPC operation itself is under control of the modem while the

AUPC facility in the MCC provides the channel for the information. Thi s channel prov i des a m i ni m um