Datsun 320 Service manual

tO

t

e

DATSUN TRUCK

MODEL

SfRVICE

NISSAN

A

320

MANUAL

c

f

i

t

l

E

11

lJ

NI55AN

OTEMACHI

CAlLI

MOTOR

BLDG

TOKYO

ADDRISS

HONU

OTEMACHI

JAPAN

I

NISMO

211

I

5281

y

CO

CHIYODA

TOKTO

LTD

KU

Book

t

Sale

MODEL

1IO

U

NEW

MODEL

1IO

U

I

i

ThIS

INTRODUCTION

has

manual

been

comphes

for

purpose

of

asslstmg

for

effectIve

Model

P

L

components

comprehenSIve

pIete

these

Spare

dlsmanthng

assembltes

IS

It

emphasIsed

Parts

DATSUN

serVIce

320

IS

should

U

descnbed

mstructlOns

be

dIstnbutors

and

Each

assembly

10

assembImg

that

only

used

as

mamtenance

detaIl

are

gIven

and

genuine

replacements

and

dealers

of

the

addItIOn

In

for

mspectlOn

DATSUN

of

major

com

the

of

l

cfi4

SPEClFICA

TION

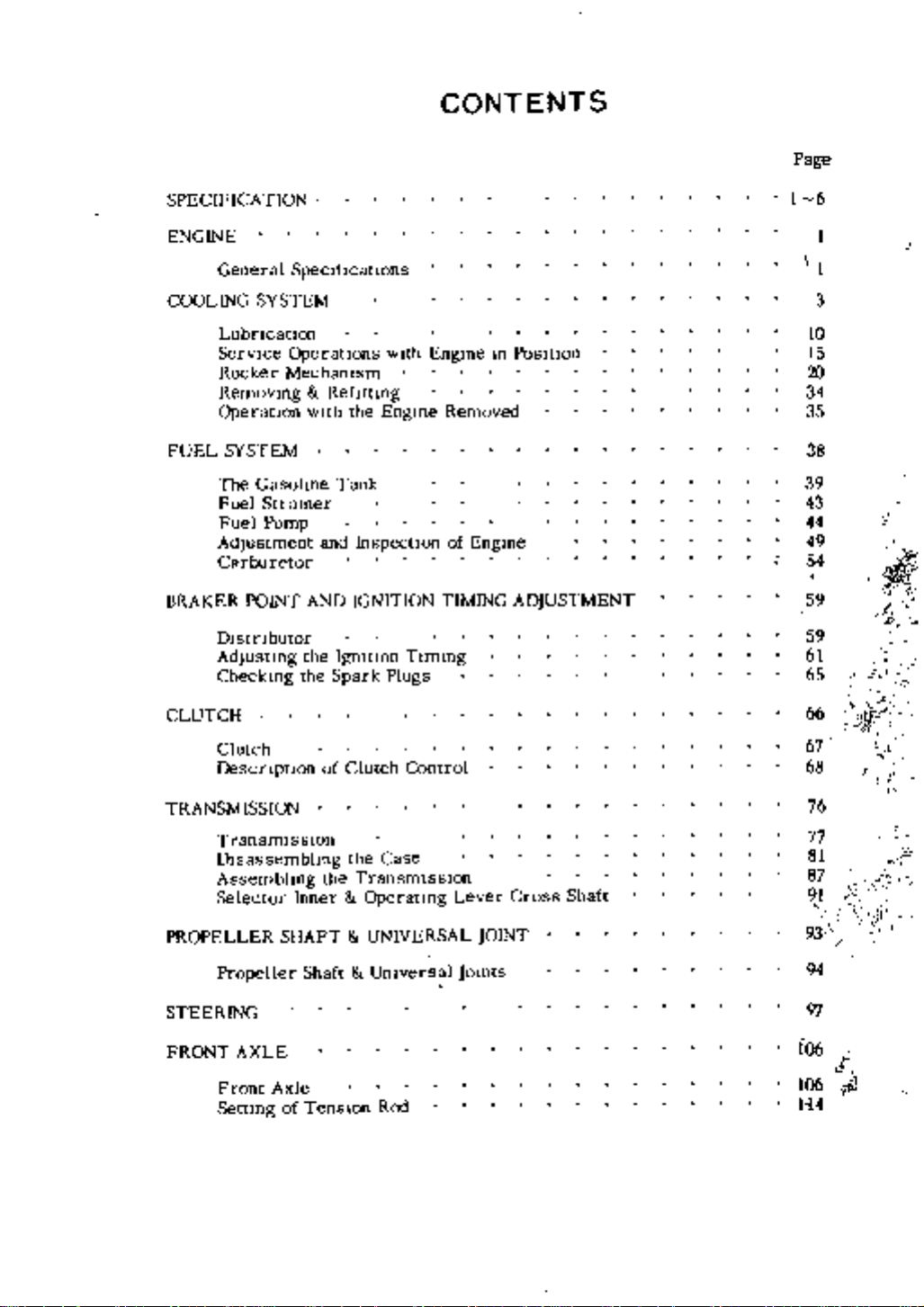

CONTENTS

Page

1

6

ENGINE

General

COOLING

Lubncatlon

ServIce

Rocker

Removmg

OperatIOn

FUEL

BRAKER

SYSTEM

The

Fuel

Fuel

Adjustment

Carburetor

POINT

Dlstnbutor

AdjustIng

CheckIng

CLUTCH

Clutch

Descnptlon

TRANSMISSION

TransmIssIOn

DIsassemblIng

Assembhng

Selector

SpecIftcatlOns

SYSTEM

OperatIOns

Mechamsm

WIth

GasolIne

Strainer

Pump

AND

the

the

Inner

wIth

RefittIng

the

Engme

Tank

and

Inspection

IGNITION

Igmtlon TImIng

Spark

Plugs

of

Clutch

the

the

Control

Case

TransmISSIOn

Operatmg

EngIne

Removed

of

EngIne

TIMING

Lever Cross

In

PosItion

ADJUSTMENT

Shaft

1

1

3

10

15

20

34

35

38

39

43

44

49

54

59

59

61

65

66

67

68

76

77

81

87

91

q

it

0

t

1

U1I

JJ

l

rt

i

1

PROPELLER

Propeller

STEERING

FRONT

Front

Settmg

AXLE

SHAFT

Axle

of

Shaft

TenSIon

UNIVERSAL

Umversal

Rex

JOINT

jomts

93

94

97

106

106

1

14

t

l

Page

REAR

AXLE

Rear

AssemblIng

BRAKE

IGNI

fI0N

ELECTRICAL

Starter

Battery

Axle

SYSFEM

SYSTEM

Motor

Adjustment

117

118

122

138

147

150

164

171

u

c

v

t

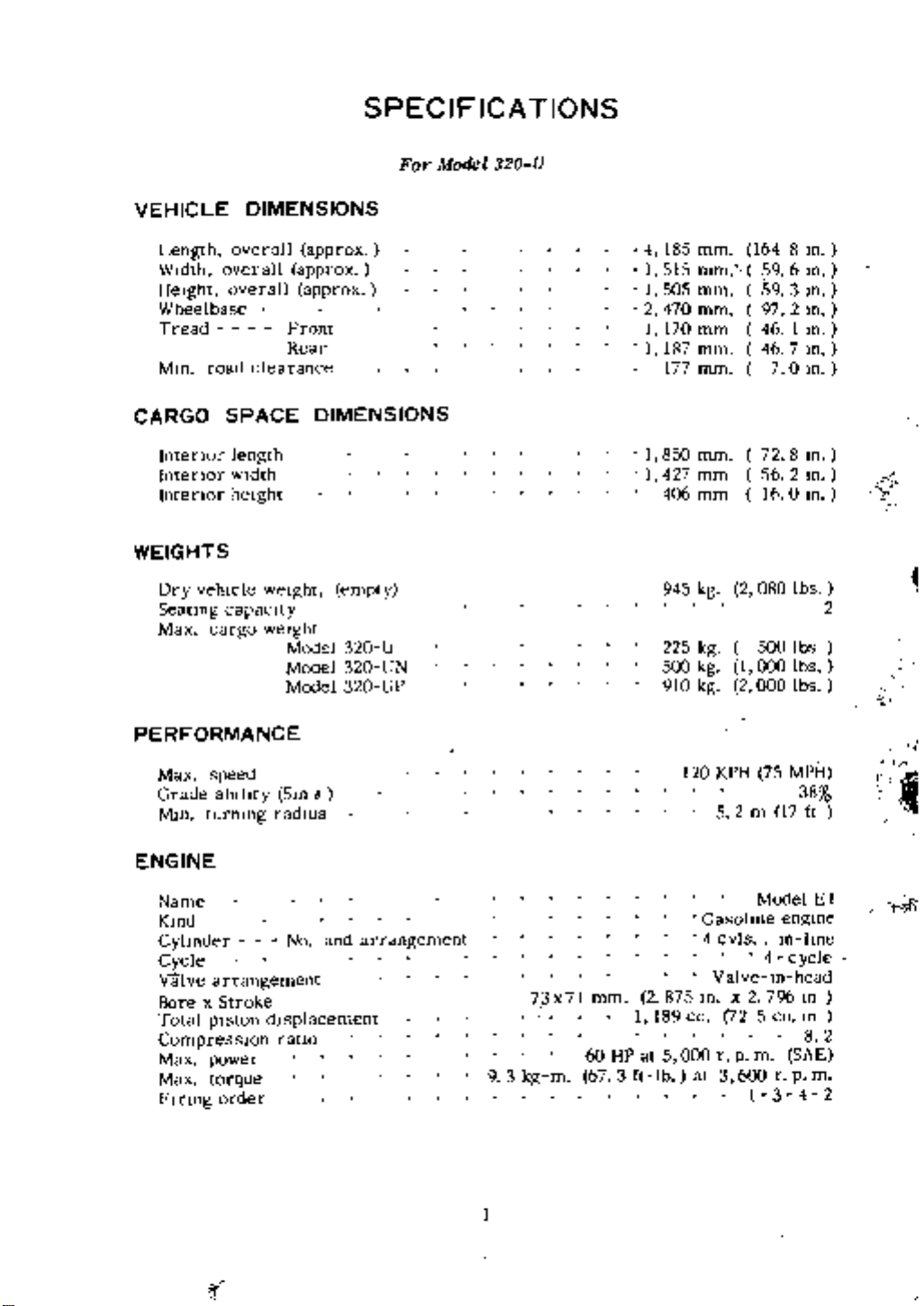

SPECIFICA

For

Model

320

TIONS

U

VEHICLE

Length

WIdth

HeIght

Wheelbase

Tread

Mm

CARGO

Intenor

lntenor

lntenor

WEIGHTS

Dry

Seating

Max

overall

road

vehIcle

cargo

DIMENSIONS

overall

overall

clearance

SPACE

length

wIdth

height

weIght

capacIty

weIght

approx

approx

approx

Front

Rear

DIMENSIONS

empty

Model

Model

Model

320

320

320

U

UN

UP

4

185

mm

1

515

mm

1

50S

mm

2

470

mm

I

170

mm

1

187

mm

177

mm

I

850

mm

1

427

mm

mm

406

945

kg

225

kg

500

kg

910

kg

164

m

8

6

59

m

59

3

m

2

In

97

46

1

In

46

7

m

0

In

7

72

8

m

2

In

56

In

16

0

2

lbs

080

500

lbs

lbs

000

1

2

000

lbs

r

1

2

PERFORMANCE

Max

speed

Grade

Mm

ablhty

turnmg

ENGINE

Name

Kmd

Cyhnder

Cycle

valve

arrangement

BorexStroke

Total

piston

CompressIOn

Max

power

Max

torque

FInng

order

Sm

6

radIUs

and

No

dIsplacement

ratio

arrdngement

9 3

kg

73x7l

J

KPH

75

MPH

120

38

2

m

17

Model

4

m

796

5

engme

m

cycle

head

m

m

cu

SAE

rpm

4 2

3

ft

lme

8

E

1

2

5

Gasohne

4

cvls

Valve

m x

at

2

72

rPm

3

600

1

2

HP

875

1

189

cc

at

5

000

lb

mm

60

m

673ft

t

f

ir

r

Valve

Inlet

Inlet

Exhaust

Exhaust

Valve

tlmmg

opemng

closmg

opemng

closmg

clearance

Both

m1et

and

exhaust

Hot

14

50

52

12

0

35

mm

deg

deg

deg

deg

0

B

T

ABC

B B

A

T

014

C

C

C

m

t

r

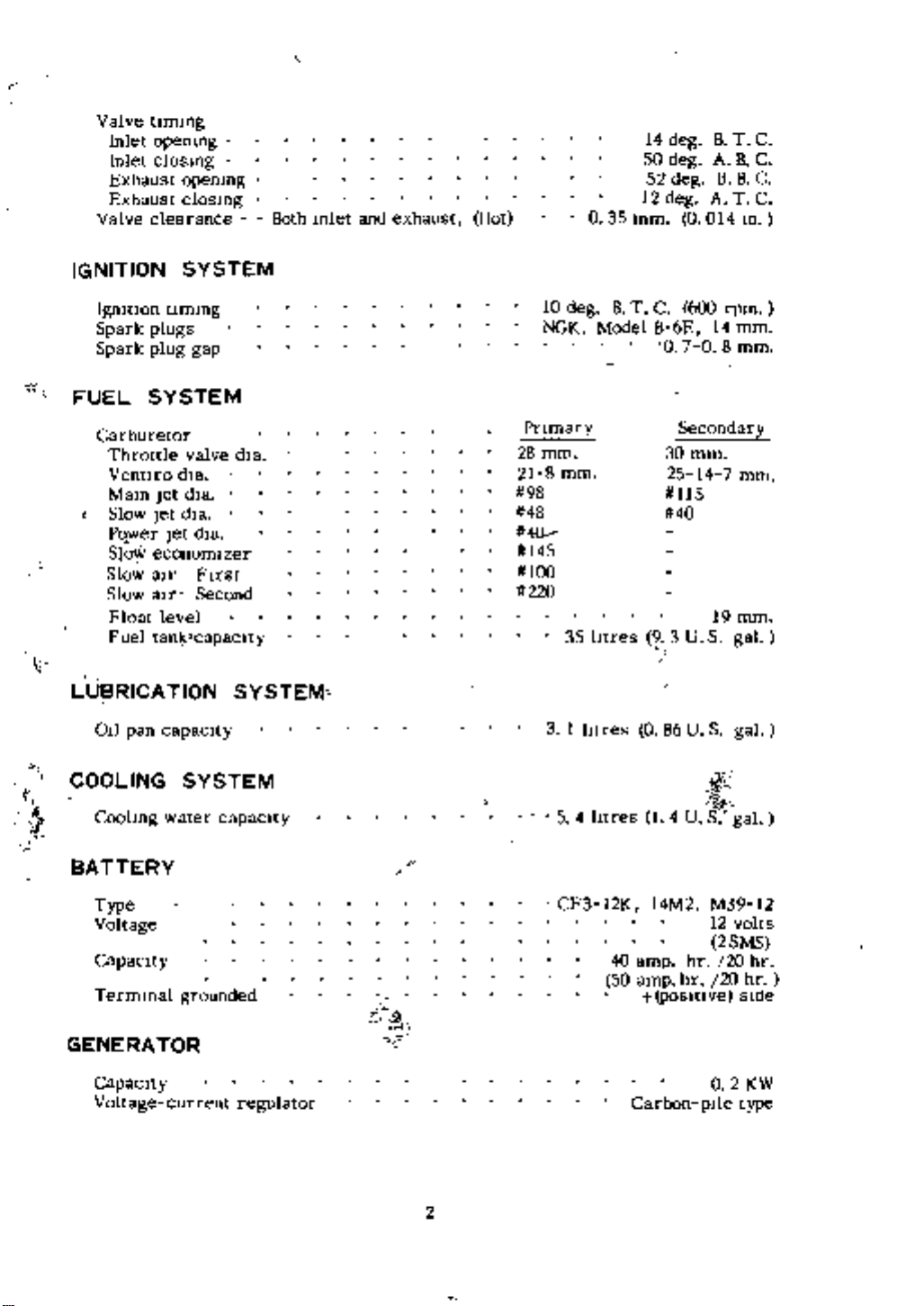

IGNITION

19mtlon

Spark

Spark

FUEL

Carburetor

Throttle

Ventlro

Mam

t

Slow

wer

PQ

Slo

Slow

Slow

Float

Fuel

Llj

RICATION

OIl

pan

COOLING

Coolmg

SYSTEM

tlmmg

plugs

plug

gap

SYSTEM

valve

dla

dla

Jet

dla

Jet

Jet

economlzer

aIr

atr

level

tanJ

l

capacity

SYSTEM

water

dla

FIrst

Second

capaclty

capacIty

dla

SYSTEM

10

NGK

Pnmary

28

mm

21

98

48

4Q

145

100

220

deg

8

mm

35

3

1

htres 0

54htres

Model

htres

BTC

600

6E

B

070

Secondary

30mm

25

115

40

3US

9

86US

14U

14

14

8

19mm

S

rpm

7

mm

mm

mm

gal

gal

gal

BATTERY

Type

Voltage

Capacity

Termmal

GENERATOR

Capacity

Voltage

grounded

current

regulator

CF3

12K

14M2

amp

amp

hr

hr

40

50

posltlve

J

Carbon

2

ptie

M39

12

volts

2

SMS

20

hr

20

sIde

02KW

type

12

hr

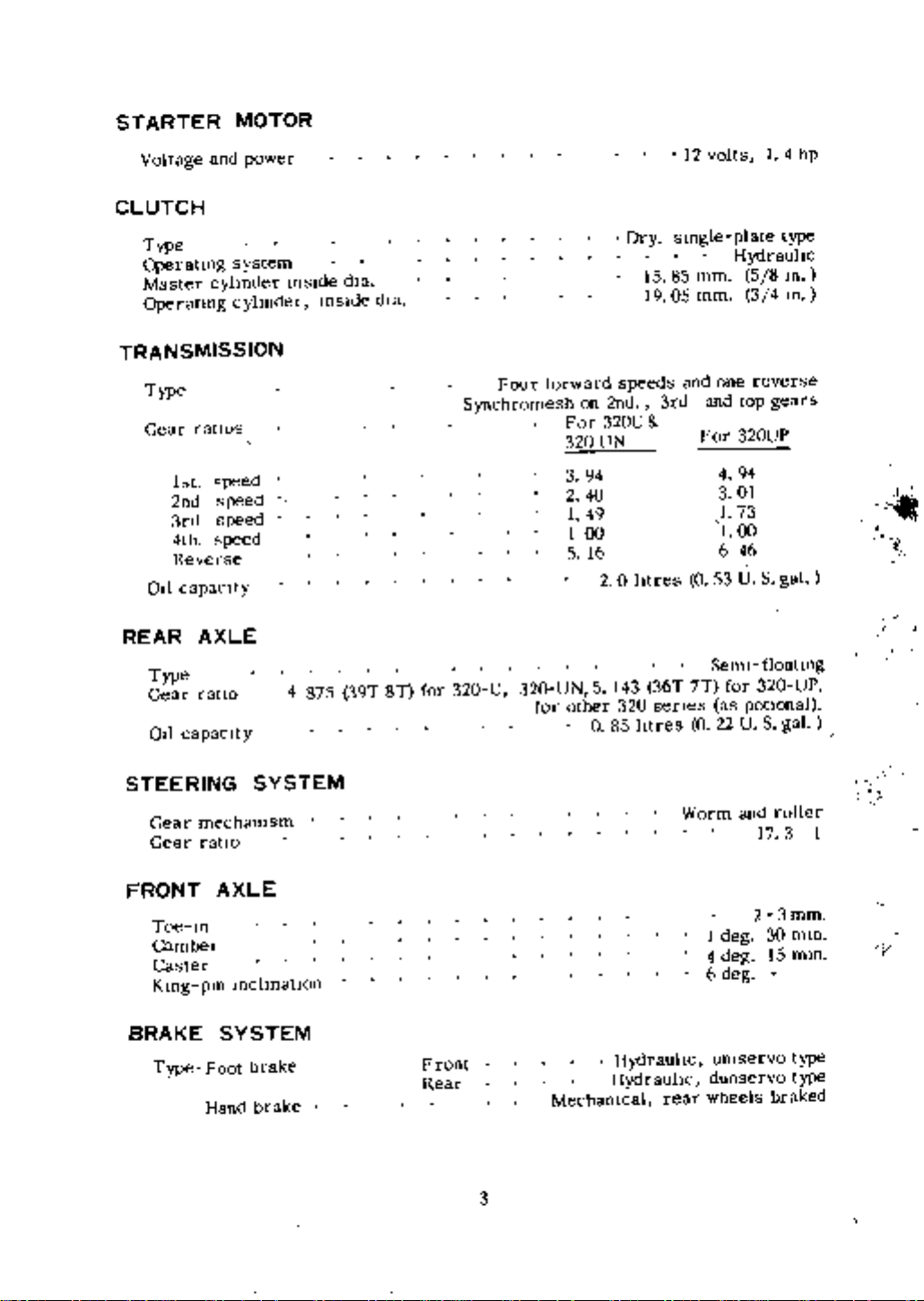

STARTER

Voltage

CLUTCH

and

MOTOR

power

12

volts

4

1

hp

Type

Operating

Master

cyhnder

Operatmg

TRANSMISSION

Type

ratIOs

Gear

1st

speed

2nd

speed

3rcl

speed

4th

speed

Reverse

all

capacIty

REAR

AXLE

Type

ratIo

Gear

all

capacIty

system

cy1mder

mSlde

4

875

mSlde

dla

39T

dza

8T

for

320

Four

forward

Synchromesh

U

320

for

UN

For

320

3

2

1

1

5

other

on

2nd

320U

UN

94

40

49

00

16

2

5

143

320

O

85

Dry

smgle

15 85

19

05mm

speeds

3rd

0 lures 0

36T

senes

htres

and

7T

0

mm

one

and

For

4

3

1

1

6

53

Semi

for

as

22US

type

plate

Hydrauhc

5 8

m

410

3

reverse

top

gears

320UP

94

01

73

00

46

S

U

gal

floatIng

320

potIonal

gal

UP

STEERING

Gear

Gear

FRONT

Toe

m

Camber

Caster

Kmg

BRAKE

Type

mechamsm

ratIO

AXLE

mchnatIon

pm

SYSTEM

Foot

Hand

SYSTEM

brake

brake

Front

Rear

Warm

Hydrauhc

Hydrauhc

Mechanical

3

rear

1

deg

4

deg

6

deg

umservo

duo

wheels

and

servo

17

2

roller

3

3

30

15

braked

mm

mm

min

type

type

I

c

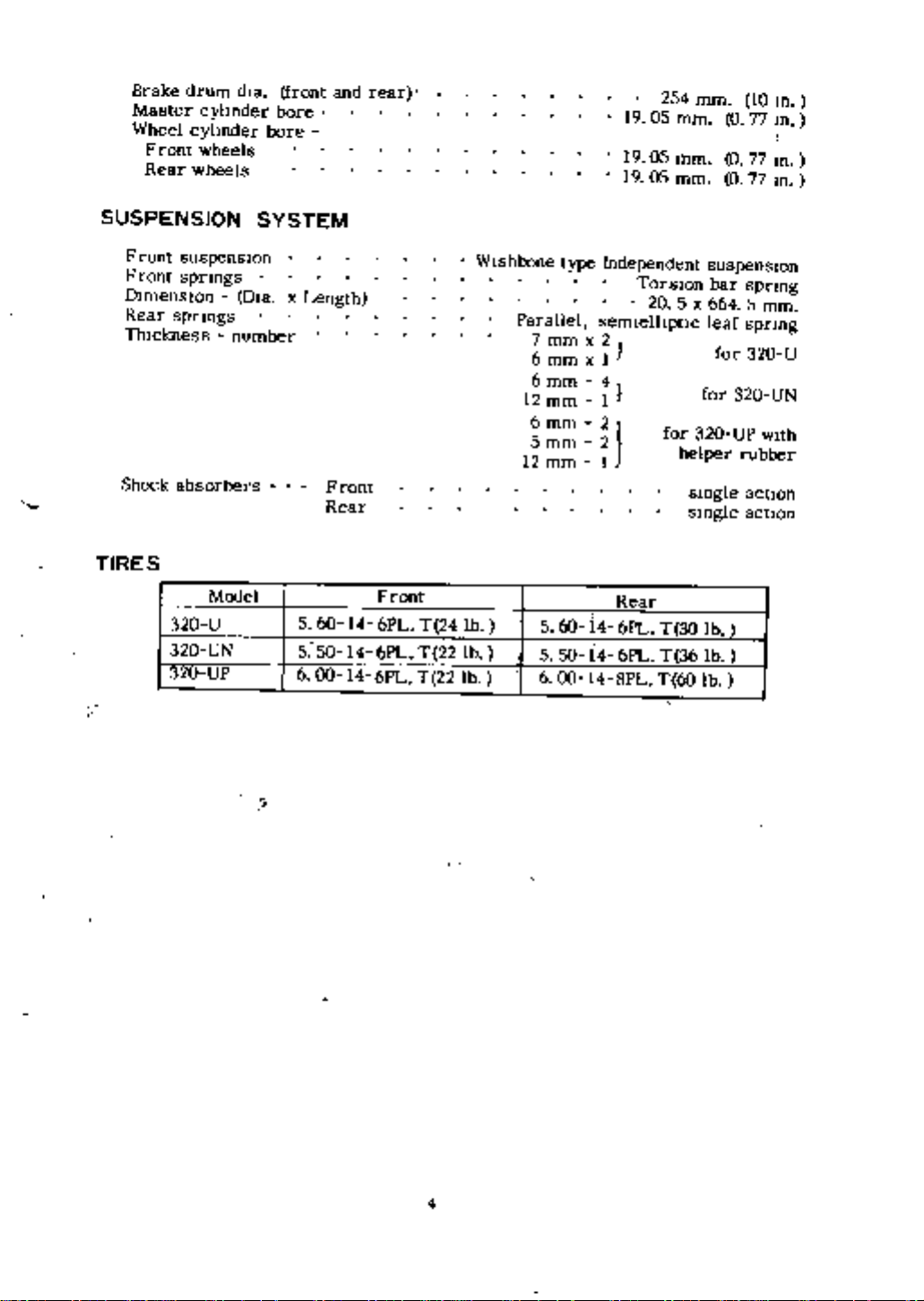

Brake

Master

Wheel

Front

Rear

drum

cylmder

cyhnder

wheels

wheels

dla

bore

bore

front

and

rear

254

rom

19

05

mm

19

05

mm

19

05

mm

10

10

10

0

77

0

77

lD

0

77

lD

SUSPENSWN

Front

Front

DimensIOn

Rear

spnngs

111lckness

Shock

TIRES

320

320

320

suspensIOn

spnngs

absorbers

Model

U

UN

UP

Ola

number

SYSTEM

x

Length

Front

Rear

5

60

5

50

6

00

Wishbone

Front

14

6PL

14

6PL

14

6PL

lb

T

24

T

22

lb

T

22

lb

Parallel

7

6

6mm

12

6mm

5

12

6

type

mm x

mm

mm

mm

mm

5

60 14

5

50

00

Independent

TorsIOn

semlelltptic

2

1

x

4

1

2

1

21

Rear

6PL

6PL

i4

14

8PL

20

5x604

for

helper

30

T

36

T

T

60

suspension

bar

leaf

f

or

for

320

smgle

smgle

lb

lb

lb

spnng

5

spnng

320

320

UP

rubber

action

action

mm

U

UN

With

I

4

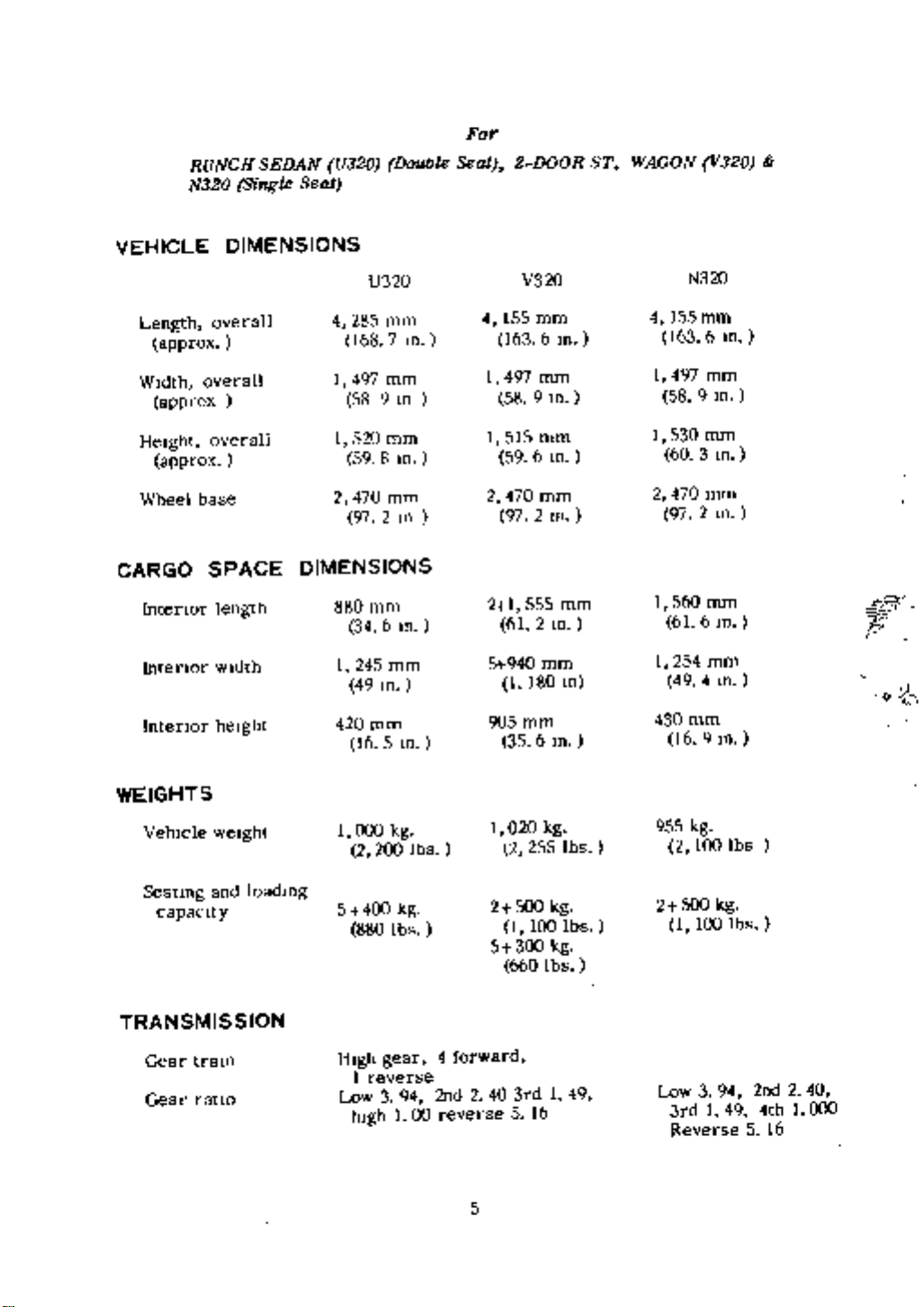

RUNCH

N320

SEDAN

Single

Seat

U320

Double

FOT

Seat

2

DOOR

ST

WAGON

V320

VEHICLE

Length

WIdth

approx

HeIght

approx

Wheel

CARGO

Intenor

Intenor

Intenor

approx

DIMENSIONS

overall

overall

overall

base

SPACE

length

wIdth

heIght

U320

4

285

168

1

497

58

1

520

59

2

470

97

DIMENSIONS

880

mm

34

1

245

49

420

mm

16

V320

mm

7

m

mm

9

10

mm

8

m

mm

2

10

6

m

mm

m

4

155

163

1

497

58

1

515

59

2

470

97

21555

61

5

940

180

1

mm

6

m

mm

9

m

mm

6

m

mm

2

m

mm

2

m

mm

10

N320

4

155

mm

163

6

m

1

497

mm

58

9

m

1

530

mm

60

3

m

2

470

mm

m

97

2

1

560

mm

6

m

61

1

254

mm

4

49

m

F

t

905mm

5

m

35

6

m

430

mm

16

9

m

WEIGHTS

VehIcle

Seatmg

capacIty

weIght

and

TRANSMISSION

Gear

tram

Gear

ratIO

loadmg

1

5

880

HIgh

1

Low

hIgh

000

2

400

reverse

200

gear

3

kg

kg

lbs

94

1

lbs

4

2nd240

reverse

00

forward

5

1

020

2

2

SOO

1

5

300

660

3rd149

5

255

100

16

kg

lbs

kg

kg

lbs

Ibs

955

kg

2

2

500

1

Low

3rd149

Reverse

100

100

3

lbs

kg

1bs

94

2nd240

4th1000

16

5

FINAL

GEAR

Gear

ratIO

5

143

36T

7T

4

875

39T

8T

SUSPENSION

Front

Rear

thickness

number

of

leaves

Supplemental

Shock

absorbers

spnng

Sp

and

Wishbone

suspensIOn

6

mm

12

mm

Front

Rear

4

I

type

wIth

Single

Single

Independent

torsIOn

acting

acting

bar

6

mm

mm

12

108

Single

Single

mm

action

action

I

1

80

mm

Optional

TIRE

1

PERFORMANCE

Front

Rear

SIZE

AND

PRESSURE

5

50

5

50

l4

6PL

T

22

lb

14

6PL

T

46

lb

5

14

50

5

50

6PL

14

6PL

iT

Max

speed

Grade

Min

ability

turning

radIus

NOTE Other

110

KPH

70

0

30

2

5

17

m

speclftcatlOns

320

120

0

5 2

30

U

MPH

ft

are

same

as

Model

KPH

m

17

74

6 MPH

ft

6

ENGINE

I

c

l

1

I

I

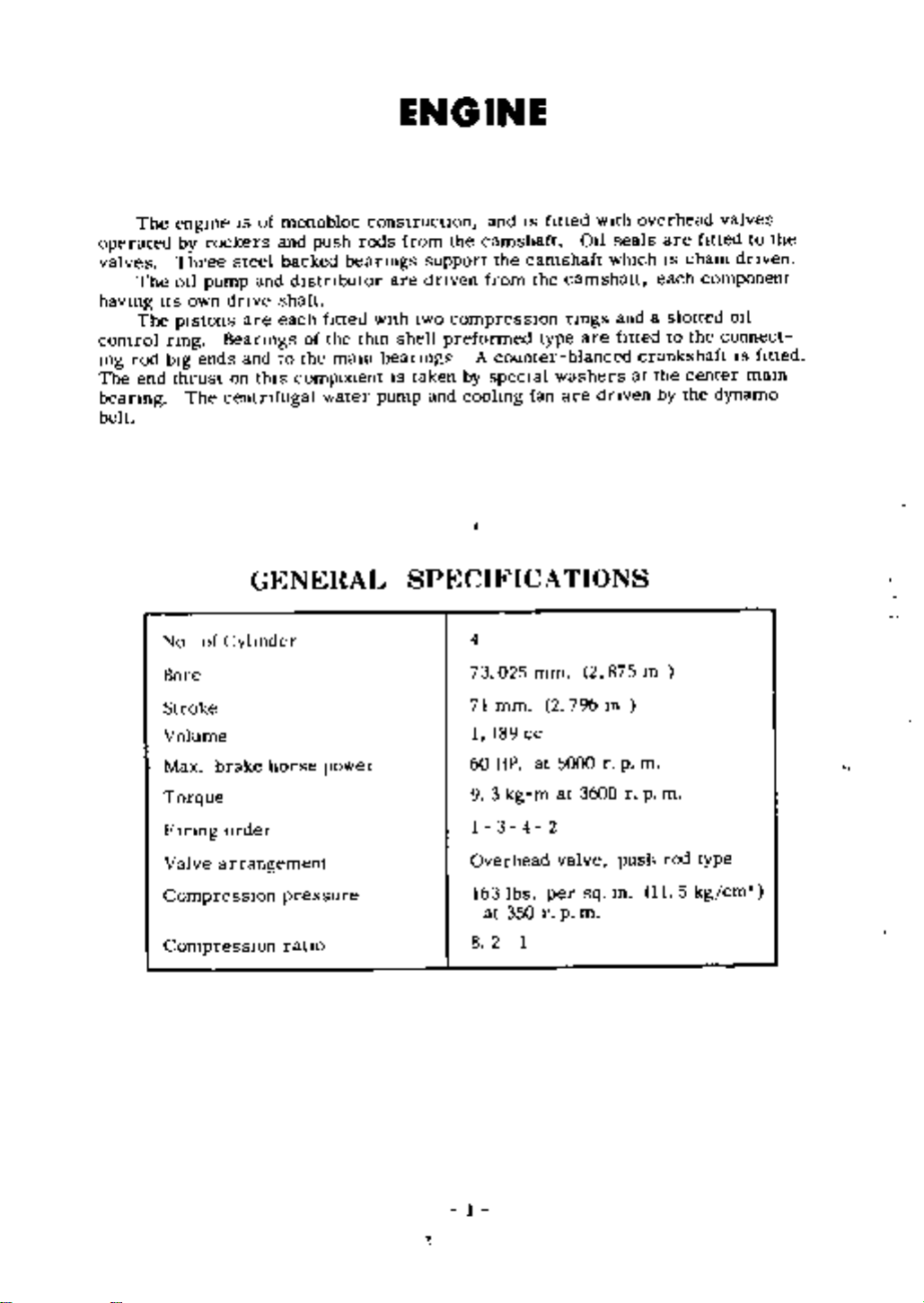

ENGINE

The

operated

valves

The

havmg

The

control

rod

109

The

end

beanng

belt

own

IS

rockers

steel

pump

dnve

engme

by

Three

OIl

Its

pIstons

nng

bIg

No

Bore

thrust

The

Beanngs

ends

on

centnfugal

of

Cyhnder

Stroke

Volume

Max

brake

Torque

Flnngorder

Valve

arrangement

CompressIOn

CompressIOn

of

monobloc

and

push

backed

and

dlstnbutor

shaft

each

are

of

and

this

the

to

component

GENERAL

horse

pressure

ratio

htted

the

malO

water

power

construction

rods

beanngs

with

thm

beanngs

pump

and

from

the

camshaft

the

from

compressIOn

preformed

A

counter

by

specIal

coolmg

are

IS

support

dnven

two

shell

taken

and

SPECIFICATIONS

4

73

025

mm

71

1

189

60

HP

9 3

kg

1

3

Overhead

lbs

163

at

350

2

8

1

IS

fitted

camshaft

the

type

washers

fan

mm

2

cc

at

m

4 2

per

r

camshatt

rmgs

blanced

are

796

5000

at

valve

p

011

are

2

3600

sq

m

with

whIch

dnven

875

m

r

seals

and

fitted

p

rpm

push

m

overhead

are

IS

each

a

slotted

to

crankshaft

at

the

by

m

m

rod

11

fItted

cham

component

the

center

the

type

5

kg

valves

to

dnven

011

connect

IS

fitted

malO

dynamo

cm

the

1

Engine

1

side

Right

Engine

2

Left

side

COOLING

SYSTEM

effIcIent

An

runmng

Its

of

maIntance

Description

The

The

coohng

system

cap

the

engIne

water

an effIcient

fIller

remove

If

the

place

If

pOSSIble

the

fan

controls

ftller

IS

lost

use

coohng

engIne

system

cooled

IS

cap

runmng

through

clean

system

and

It

IS

maIntaIned

radIator

pressunsed

the

pressure

If

the

ToppIng

the

soft

water

IS

therefore

IS

and

and

at

temperature

overflow

of

major

necessary

water

by

thermostat

the

rehef

approxImately

of

should

up

pIpe

Importance

pump

valve

the

coolant

only

Top

to

pay

CIrculation

Incorporated

4

O

be

requIred

when

up

kg

IS

to

above

ensure

patlcular

per

sq

occasIOnally

the

engIne

the

attention

combIned

the

10

cm

IX

Jhng

IS

satisfactory

to

wIth

radIator

not

Do

or

poInt

to

re

cold

and

li

j

l

engIne

the

of

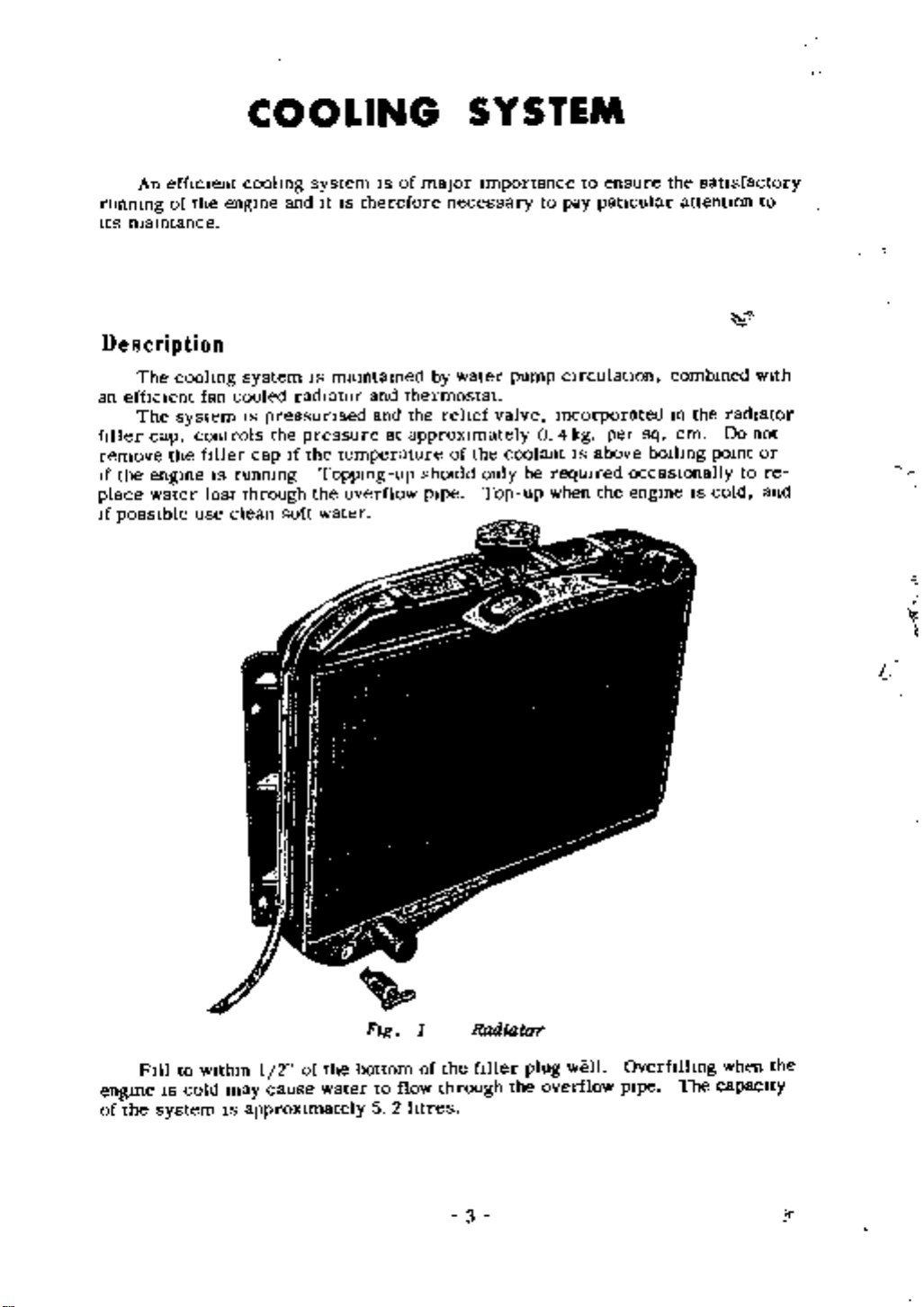

FIll

to

IS

system

cold

wIthIn

may

IS

1

cause

the

2

of

water

approxImately

Fig

bottom

to

5

flow

2

1

of

htres

Rmliator

the

fIller

through

3

the

plug

well

overflow

OverfIlhng

pIpe

The

when

capacIty

the

Therm

operating

thermostat

head

whIch

and

stncted

Jackets

will

a

therefore

can

hose

car

there

whIch

casting

pletely

aIr

valve

mostat

and

perature

carbomslng

lng

raIsed

t

valve

lQ

Ar

but

fitted

In

on

Due

gradually

full

The

be

reconnected

to

cannot

by

IfItfads

ostat

order

temperatures

The

controls

starting

to

wIll

of

flow

thermostat

removed

Should

are two

be

may

When

emptied

escape

and

then

opening

of

Immersing

to

the

should

to

IS

fttted

deVIce

thiS

qUIckly

expand

water

should

the

tapped

utlhzed

through

fmally

be

altered

71

It

IS

reqUIsite

open

to

ensure

consIsts

a

mushroom

the

engine

the

the

from ItS

to

thermostat

the

system

It

IS

set

IS

5

745C

pohcy

the

under

open

maxImum

within

being

temperature

nse

the

the

to

Itself

occasIOn

aVOId

holes

to ease

essential

the

top

by

It

to

thermostat

temperature

these

a

new

located

of

valve

the

thus

bellows

radIator

IS

detachable

housmg

laYing

be

on

has

thermostat

up

the

manufacturer

open

Dunng

test

umt

effIcIency

certain

In

metalhc

flow

of

of

ensunng

so

anse

and

up

tight

the

top

from

It

been

to

allow

The

at a

de

thiS

In

conditIOns

should

When

the

opening

the

com

ther

tem

open

water

hmlts

the

bellows

water

It

the

The

be

water

the

water

rapid

to

the

Fig

It

IS

To

outlet

fIlled

engine

the

In

warnllng

valve

J

essential

assist

radiator

the

l

J

2

IS

cyhnder

t

fr

to

keep

this

a

at

the

front

WIthavolatile

cold

thIS

IS

temporanly

head

The

up

and

ultlmatelly

r

f

i

J

I

4

J

t

Y

Jr

nlus

tTahng

the

of

its

Thermostat

Housing

bellows

valve

heat

it

0

of

t

the

the

hqUled

and

the

engine

type

cyhnder

IS

closed

cyhnder

so

generated

permitting

I

2

c

Remove

from

re

l

l

Overheating

Overheating

the

In

cyhnders

adjustment

Fan

Belt

fan

The

dynamo

hold

the

A

belt

the

New

dynamo

over

may

runmng

falhre

of

Adjustment

dnven

IS

can

m

fan

be

posltJon

belt

the

and

be

the

from

fitted

caused

WIth

water

the

onto

the

crankshaft

by

l

lld

the

by

to

ftrst

moving

fan

a

slack

Igmtlon

CIrculate

loosemng

pulley

the

4

fan

too

or

by

dynamo

thIS

bolts

carbon

Incorrect

also

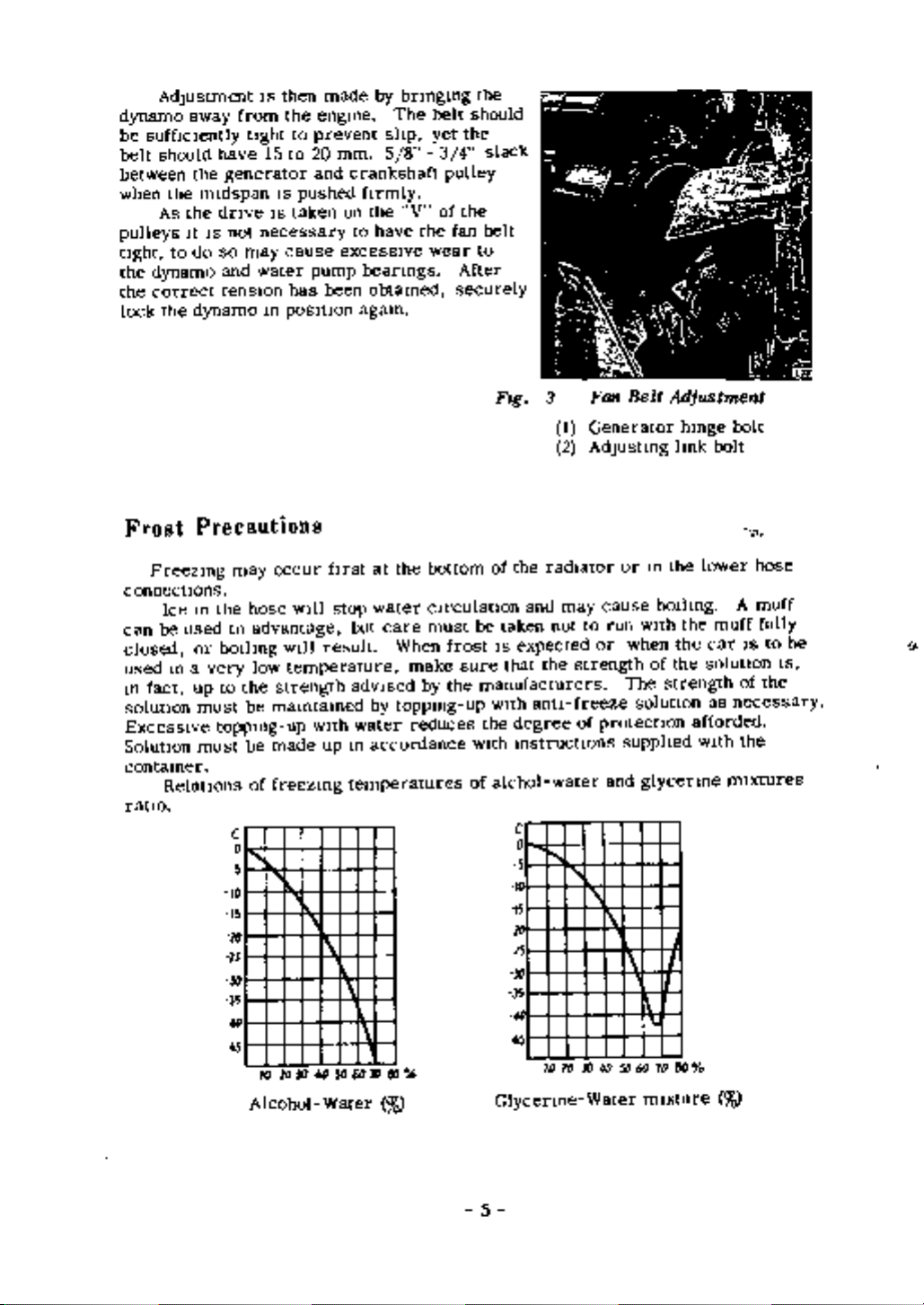

FIg

the

dnvlng

engine

depoSIt

carburetor

3

whIch

the

Shde

excessIve

belt

far

retarded

loss

of

water

a

V

belt

the

clamp

towards

Adjustment

dynamo

be

sufftclently

belt

should

between

when

As

pulleys

tight

the

dynamo

the

correct

the

lock

the

to

away

have

the

generator

mIdspan

the

dnve

It

IS

do

so

and

tensIOn

dynamo

from

not

IS

tight

15

IS

necessary

may

water

m

then

the

to

to

IS

pushed

taken

cause

has

pOSItiOn

made

engme

prevent

20

and

pump

been

rnm

crankshaft

ftrmly

the

on

to

excessIve

beanngs

obtamed

agam

by

bnngmg

The

shp

5 8 3

V

have

belt

yet

pulley

of

the fan

wear

the

should

the

4

slack

the

belt

to

After

securely

FIg

3

Fan

I

Generator

2

AdJustmg

Belt

Adjustment

bolt

hmge

lmk

bolt

Frost

Freezmg

connections

Ice

be

can

closed

used

m

fact

solution

ExcessIve

Solution

contamer

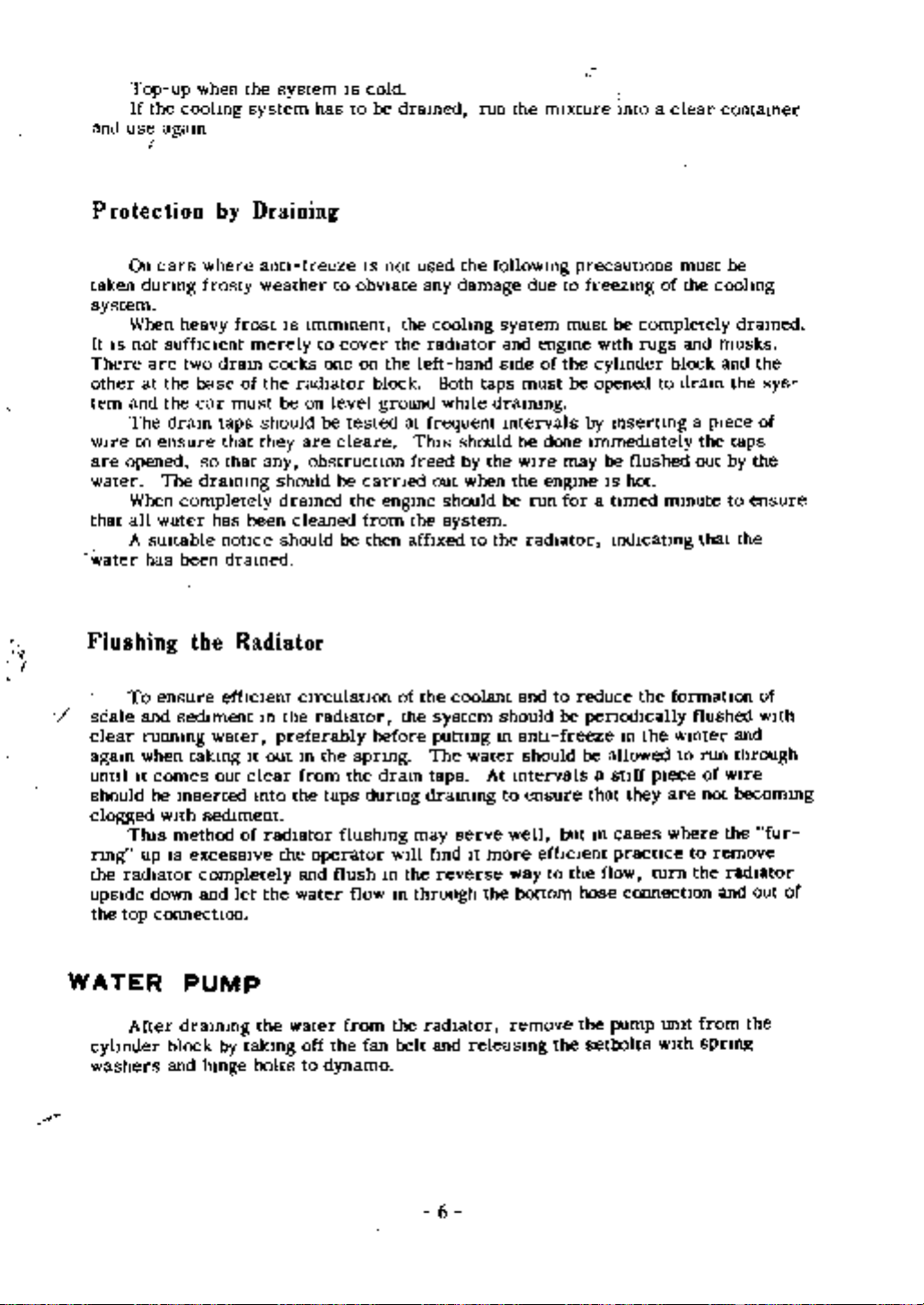

Relations

ratIO

Precautions

m

the

used

or

bOlhng

a

m

very

to

up

must

toppmg

must

may

hose

to

advantage

low

the

be

be

of

c

o

5

10

15

lD

IS

31

35

III

45

Alcohol

occur

wIll

wIll

temperature

strength

mamtamed

up

made

freezmg

lOYJ

10

ftrst at

stop

result

with

up

1

4Q

50

Water

the

water

but

care

When

adVIsed

toppmg

by

water

m

accordance

temperatures

a1

601lI

ro

bottom

cIrculation

must

make

by

reduces

be

frost

sure

the

manufacturers

up

WIth

of

the

of

taken

IS

expected

that

WIth

the

degree

mstructlons

alchol

c

o

5

10

i5

ID

15

JO

J5

41

45

Glycenne

and

anti

radIator

may

not

the

freeze

water

10 20 30

cause

to

run

or

strength

of

protection

and

1

40 50 60

Water

or

m

bOllmg

wIth

when

of

The

strength

solution

supphed

glycenne

1

70

mIxture

the

the

the

lower

the

afforded

WIth

80

muff

car

solution

as

necessary

mIxtures

ro

0

hose

A

muff

fully

to

be

IS

IS

of

the

the

5

and

Top

If

use

the

up

agam

when

coolmg

the

system

system

has

IS

cold

be

dramed

to

run

the

mIxture

mto a

clear

contamer

Protection

On

taken

dunng

cars

by

where

frosty

Draining

antI

freeze

weather

IS

not

to

obvIate

used

any

the

followmg

damage

due

precautions

to

freezmg

must

be

the

of

coohng

system

When

not

suffIcient

are two

the

at

and

the

The

to

ensure

opened

The

When

all

water

A

SUItable

has

To

ensure

and

runnmg

when

It

comes

be

with

Tlus

up

down

connectIon

heavy

dram

completely

been

sedIment

mserted

rnethod

is

It IS

There

other

tem

wIre

are

water

that

water

I

Flushing

scale

clear

agam

untIl

should

clogged

rlOg

the

radIator

upSIde

the

top

frost

dram

base

of

car

must

taps

that

that

so

drammg

has

notice

dramed

the

Radiator

effICIent

water

takmg

out

sedIment

of

excessIve

completely

and

let

merely

cocks

the

should

they

any

been

m

preferably

It

out

clear

mto

radiator

the

IS

radiator

be

are

should

dramed

cleaned

should

CIrculatIon

the

m

from

the

the

and

water

Immment

to

cover

one

on

level

be

cleare

obstruction

be

be

radIator

the

taps

flushmg

operator

flush

the

on

block

ground

tested

carned

the

engme

from

then affIxed

before

spnng

the

dralO

durmg

m

flow

the

coohng

the

radiator

left

at

frequent

Tlus

freed

out

the

the

of

the

system

puttmg

The

taps

drammg

may

Will find

the

m

through

hand

Both

while

should

system

coolant

serve

reverse

taps

should

by

when

to

water

it

system

and

SIde

drammg

mtervals

be

the

wIre

the

be

the

and

should

m

antI

At

mtervals

to

well

more

way

bottom

the

engme

of

must

done

engme

run

radIator

to

should

ensure

effiCIent

to

must

wIth

the

cyhnder

be

opened

by

immedIately

be flushed

may

IS

for

a

reduce

be

pencxhcally

freeze

be

a

that

but

m cases

the

flow

hose

be

completely

rugs

to

lOsertlng

hot

tImed

mdIcatlng

thefonnatIon

the

m

allowed

stIff

pIece

they

practIce

turn

connectIon

block

dram

mmute

wlOter

to

are

where

and

a

the

out

that

flushed

run

to

the

pIece

of

not

musks

and

Wire

the

remove

radIator

and

dramed

the

the

sys

of

taps

the

by

to

ensure

the

of

With

and

through

becommg

fur

out

of

4

WATER

cylInder

washers

After

PUMP

drammg

block

and

by

hmge

the

takmg

bolts

water

off

to

dynamo

the

from

fan

the

belt

radIator

and

6

remove

releasmg

the

the

setbolts

pump

unIt

WIth

from

spnnp

the

WATER

PUMP

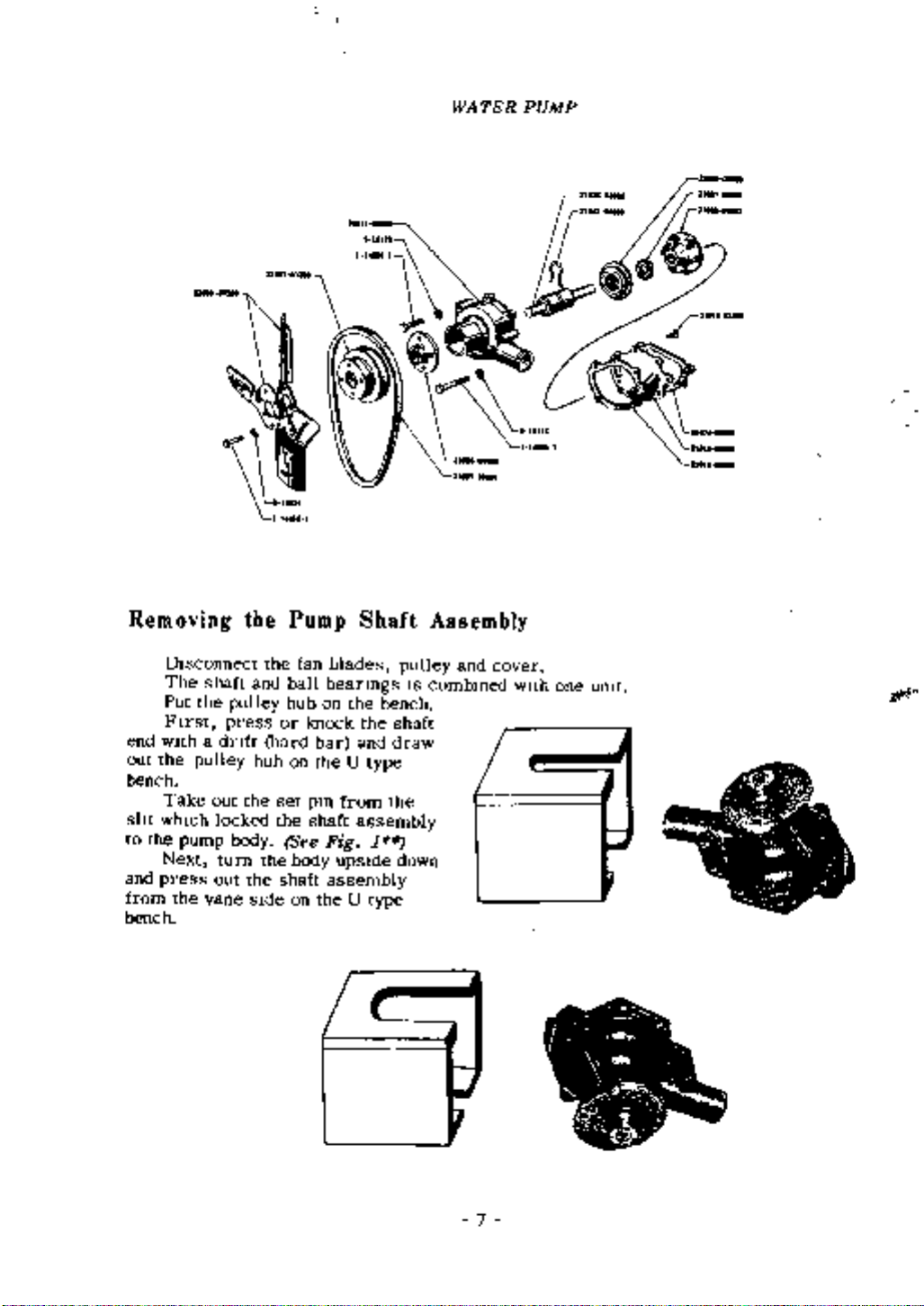

Removing

DIsconnect

The

the

Put

FIrst

end

WIth

out

the

the

pulley

Take

whIch

pump

Next

press

the

bench

sht

to

and

from

bench

shaft

a

out

out

vane

pulley

press

dnft

locked

body

turn

the

the

the

and

hub

SIde

the

hard

the

the

Pump

fan

ball

hub

or

on

set

See

body

shaft

on

blades

beanngs

on

knock

bar

the

pm

shaft

Fig

upsIde

assembly

the

Shaft

the

the

and

U

type

from

assembly

1

U

type

pulley

bench

shaft

draw

the

down

Assembly

IS

combmed

and

cover

with

one

umt

ji

7

The

Thus

shaft

take

and

out

ball

the

beanng

vane

assembly

floatmg

seal

can

and

be

seal

drewout

whIch

from

remamed

the

body

the

pump

body

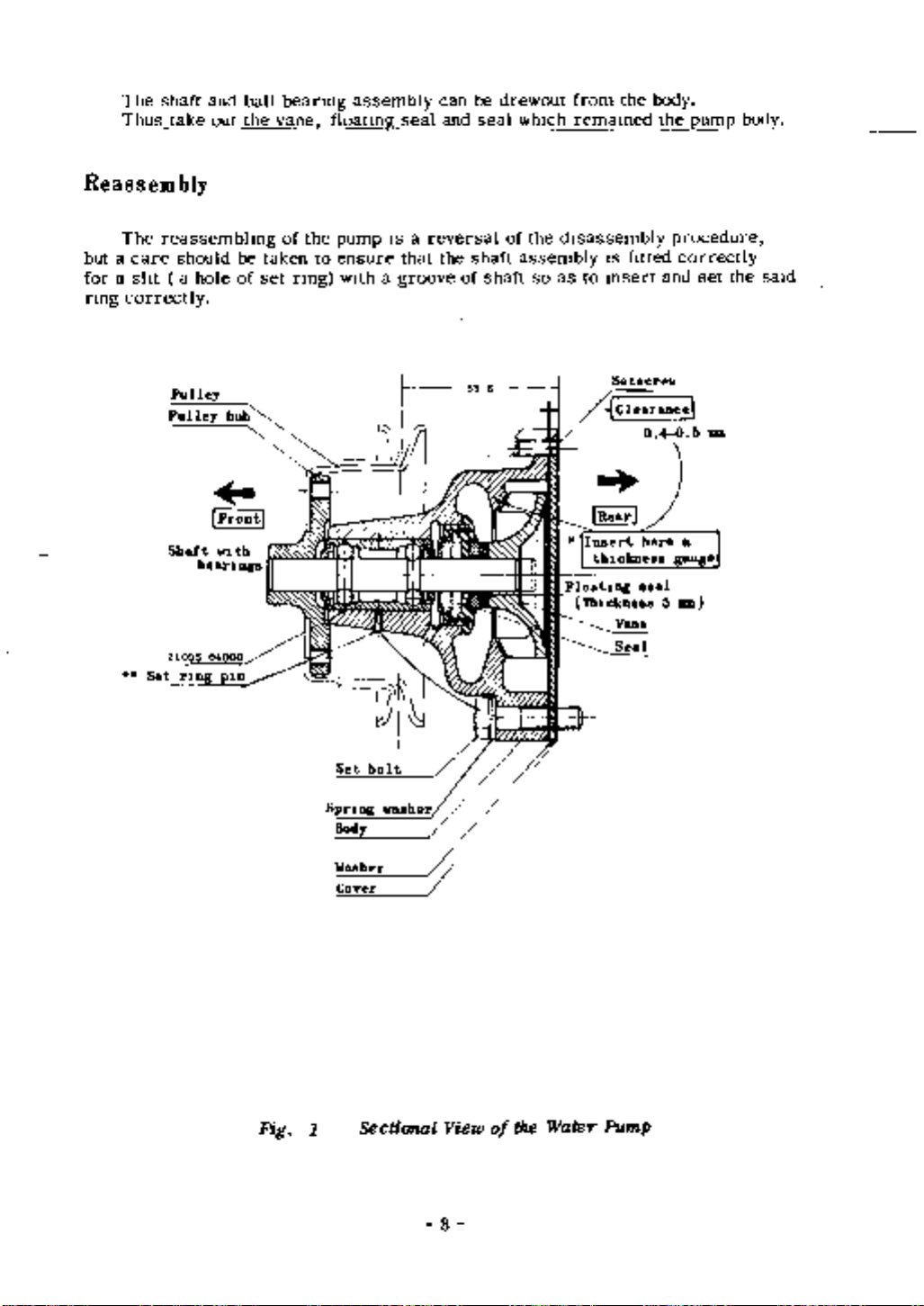

Reassem

The

but

a

care

foraslIt

nng

correctly

Set

bly

reassembhng

should

a

Pulley

Pulley

Shaft

rlDg

hole

WJ th

bearIngs

21035OOO

plD

be

of

hub

taken

set

pump

ensure

wIth

IS

a

a

that

groove

reversal

the

of

the

to

nng

of

shaft

shaft

of

the

assembly

so as

disassembly

IS

fItted

to

msert

procedure

correctly

and

set

the

saId

Fig

1

Set

SPrIng

Body

Washer

Cover

t

bol

washer

Sectional

View

8

the

of

Water

Pump

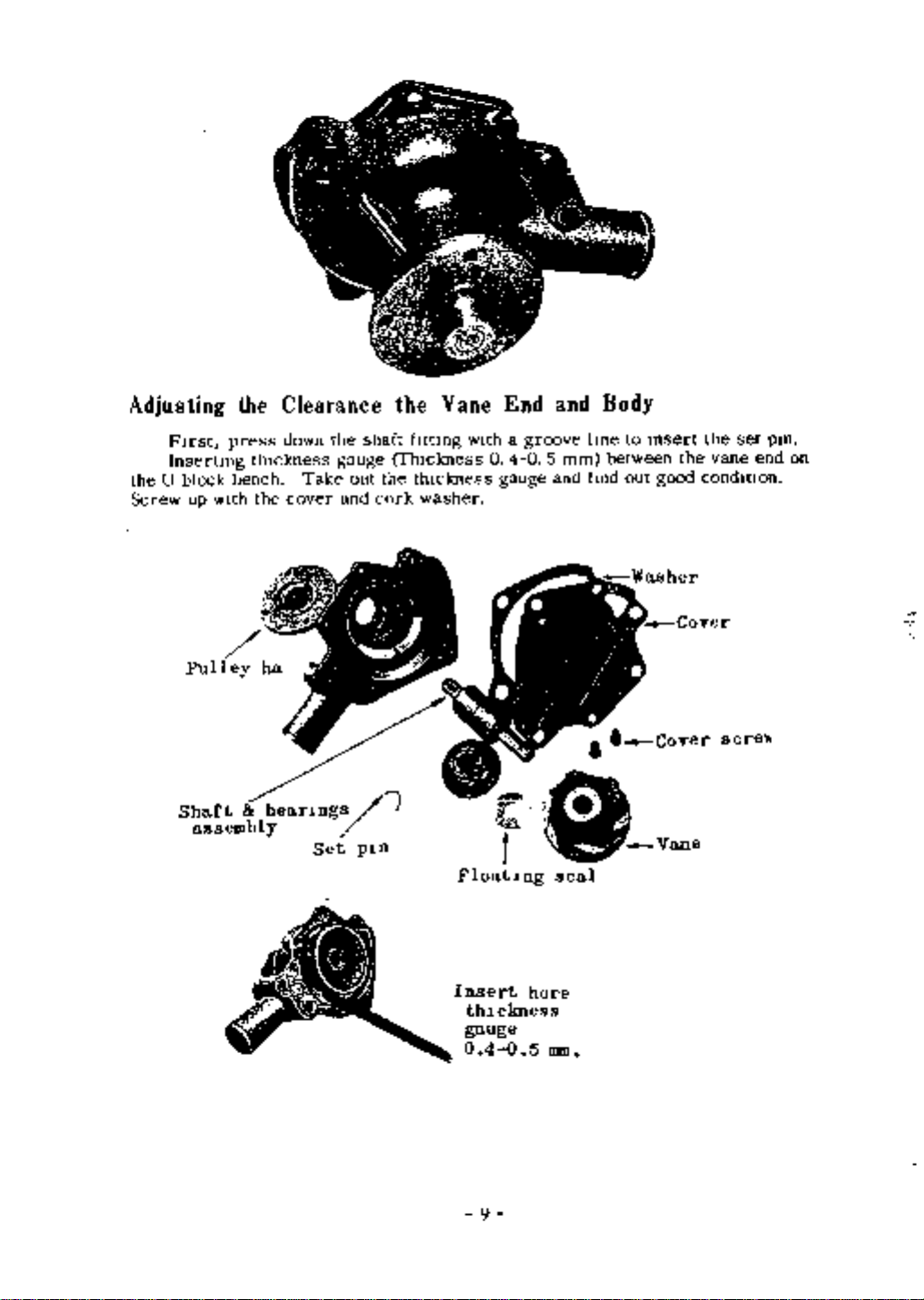

Adjusting

FIrst

Insertmg

the

U

block

Screw

up

wIth

the

press

bench

Clearance

thIckness

the

down

cover

Take

the

gauge

and

out

shaft

cork

the

fIttmg

fhlckness

the

thickness

washer

Vane

wIth

O40 5

End

a

gauge

groove

and

mm

and

Body

lme

fmd

to

between

out

msert

good

the

the

set

vane

condmon

end

pm

on

sere

Shaft

assembly

bear1llgs

Set

p1ll

Floa

Insert

thl

ga

0

uge

9

Y

f

tl

ckness

40

llg

here

5

0

seal

mm

Vane

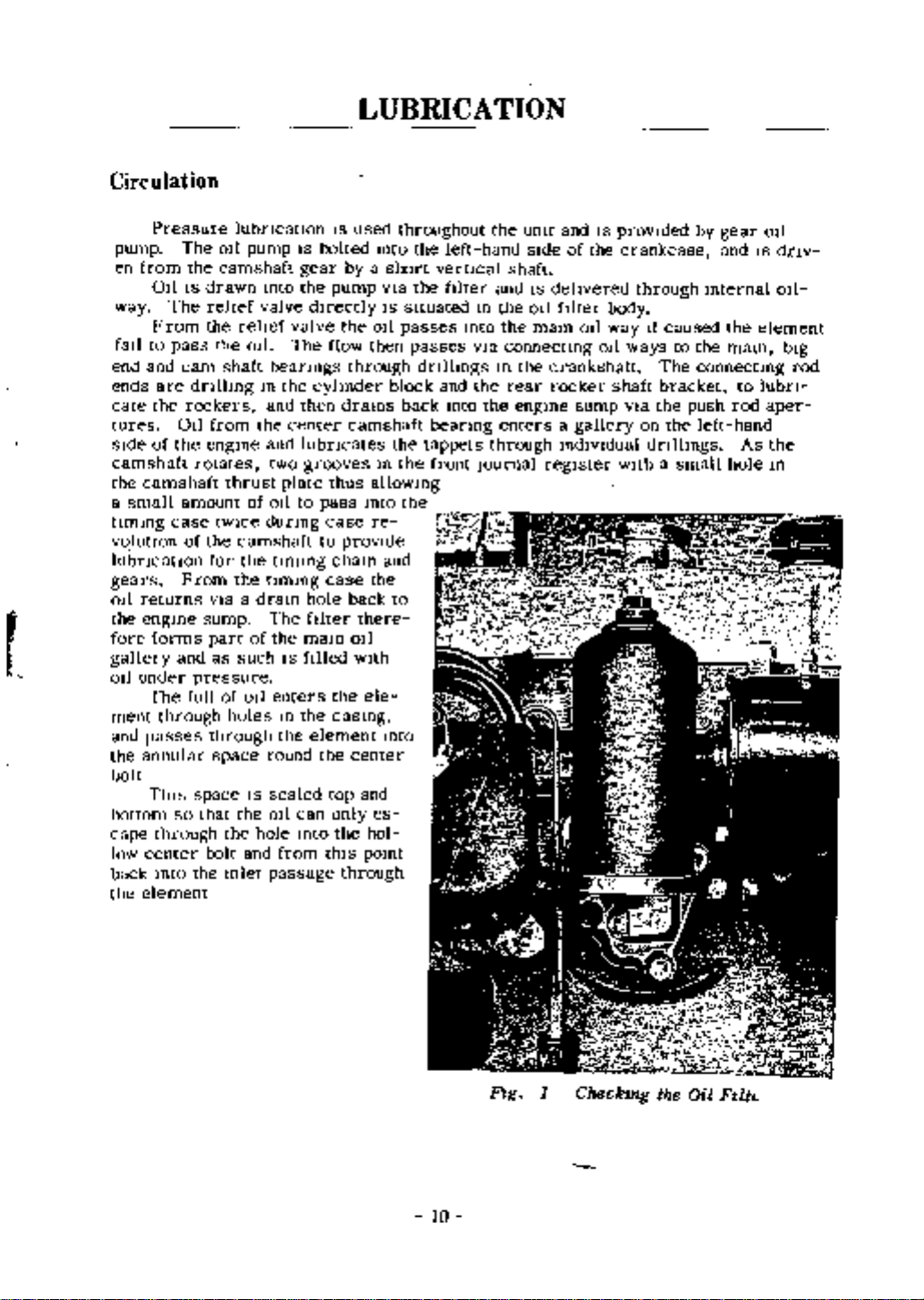

Circulation

LUBRICA

TION

Pressure

pump

en

from

OllIS

The

way

From

fml

to

and

end

ends

are

the

cate

tures

sIde

of

camshaft

the

camshaft

a

small

tlmmg

volution

lubncatlOn

gears

011

returns

the

engme

fore

forms

gallery

under

oJ

The

ment

through

and

passes

the

annular

bolt

ThIs

bottom

cape

through

center

low

back

Into

the

element

The

011

the

camshaft

drawn

rehef

the

rhe

pass

cam

dnlhng

rockers

from

all

the

engme

rotates

amount

case tWIce

of

the

for

From

VIa

sump

part

and

as

pressure

full

of

through

space

space

that

so

bolt

the

lubncatlon

pump

rehef

011

shaft

thrust

of

camshaft

the

the

a

of

such

011

holes

IS

the

the

and

mlet

mto

valve

beanngs

m

the

and

the

center

and

two

plate

011

dunng

tlmmg

tlmmg

dram

The

the

IS

enters

m

the

round

sealed

011

hole

from

passage

IS

gear

the

dIrectly

valve

The

cyhnder

then

lubncates

grooves

to

hole

ftlter

mam

fIlled

the

element

can

mto

IS

bolted

pump

flow

thus

pass

case

to

cham

case

the

casmg

the

top

only

the

thIS

used

mto

a

by

the

011

then

through

drams

camshaft

m

allowmg

mto

re

provIde

the

back

there

oJ

with

ele

center

and

es

hol

pomt

through

throughout

the

short

the

vIa

IS

situated

passes

passes

dnllmgs

block

back

the

tappets

the

the

and

to

mto

left

vertical

filter

Into

and

Into

beanng

front

the

hand

and

m

the

the

vIa

connectmg

m

the

rear

the

enters

through

Journal

umt

shaft

the

engme

sIde

IS

011

mam

crankshaft

rocker

regIster

and

of

dehvered

filter

011

sump

a

gallery

mdlvldual

IS

the

body

way

011

shaft

provIded

crankcase

through

If

caused

ways

The

bracket

the

vIa

on

the

dnlhngs

WIth

a

by

to

the

connectmg

push

left

small

gear

and

mternal

the

mam

rod

hole

to

hand

As

011

IS

dnv

011

element

lubn

aper

the

m

bIg

rod

Flg

1

Checkmg

the

Oil

FlUt

10

Draining

the

Sump

Oil

Pan

The

One

011

new

with

never

are

mam

Oil

pressure

to

run

Refillig

sump

new

after

Dram

It

any

Never

to

contammate

Pressure

The

normal

The

warmng

drops

the

a

IS

and

reconditiOned

the

first

the

011

when

sludge

use

petrol

completely

operatmg

below

engme

or

metal

or

lIght

pressmg

1000

the

sediment

or

paraffm

dIspersed

fresh

any

whIch

8

lbs

serIOus

km

engme

OIl

pressure

IS

sq

damage

engmes

and

IS

whIch

for

from

Oll

emboclted

m

the

the

dram

sump

with

subsequently

hot

smce

have accumulatted

may

flushmg

the

engme

ThIs

may

IS

60

10

the

under

these

result

may

must

at

warm

purposes

lubncatiOn

cause

lb

per

mstrument

plug

be

mtervals

Oil

premature

sq

cIrcumstances

flows

m

dramed

Such

of

freely

cleamng

system

panel

and

5000

beanng

hght

do

and

and

not

refilled

km

medlUms

faIlure

If

takes

wIll

the

attempt

with

re

Oil

from

the

as

pOSSIble

the

reach

Check

If

up

off

with

Side

When

the

engme

Before

readmg

to

Check

nece

and

ascertam

sludge

of

the

refllltng

fIller

sump

for

the

sal

Oil

testing

Always

It

Low

v

ale

orifIce

before

level

pump

should

If

that

that

the

and mIslead

the

WIpe

readmg

Oil

of

the

the

no

bemg

sump

level

be

remembered

Pressure

m

OIl

warnmg

gauge

aIr

defectIve

do

of

the

the

leakage

the

dIp

the

not

Oil

stick

dIpstick

engme

Itgiit

stramer

pour

the

IS

eXIsts

remove

the

operator

ensure

clean

that

sump

still

m

11

the

time

at

OIl

m

too

qUIckly

as

the

to

quantity

must

means

strainer

umt

the

a

non

IS

vehIcle

fluffy

be

allowed

of

reftllmg

clean

and

rectify

the

uniOn

that

wIth

by

on

after

ump

the

the

dip

the

and

IS

as

cloth

as

on

the

It

of

for

stIck

sump

not

may

lubricant

near

before

new

choked

the

fault

overflow

level

011

and

switch

suction

10

talang

to

top

rr

J

Removing

A

new

The

hlter

It

IS

from

the

ItISneceE

when

remove

element

Wash

the

dry

bowl

the

hlter

fIlter

only

cylinder

sary

and

note

out

to

element

forms

necessary

to

the

the

obVIate

Filter

block

cover

body

the

bowl

should

of

part

to

complete

wIth

Take

assembly

WIth

any

be

the

mam

unscrew

some

care

of

pettol

contammatIon

fitted

wIth

of

not

the

so

every

011

gallery

the

center

the

element

to

rugs

lose

to

components

It

that

of

6

bolt

prevent

the

IS

clean

the

lubncatmg

000

of

rubber

the

km

when

For

from

engme

full

seahng

It

IS

the

flow

Important

011

bowl

flow

To

011

nng

remove

can

type

on

be

removed

E1

the

generator

Remove

to

thoroughly

the

engme

the

Replacing

4

the

Put

puttmg

shaft

posttJon

the

mto

by

the

element

element

posltlon

means

Filter

WIth

retamer

and

of

the

Flg

screw

seat

center

3

of

spnng

up

It

bolt

Components

the

It

on

and

with

bracket

the

ughtmg

12

of

gasket

torque

Oil

Cover

10

Rlter

posltlon

2

2

with

the

filter

Insert

5

m

kg

the

and

body

secure

after

center

mto

Removing

The

Remove

OIl

flange

pan

cunng

the

process

moviDg

WIth

011ISdrawn

the

011

pIck

The

hvery

pipe

Notice

correctly

Removing

sump

the

stramer

when

the

0

the

from

the

sump

mto

up

flange

that

the

Oil

capacIty

set screw

and

the

Strainer

the

the

to

may

bolts

there

reftttmg

Oil

the

engme

lowered

011

pump

are

Pan

IS

lower

pump

be

dIsmantled

the

Pump

3

bolts

J

and

1

htres

bolts

takmg

It

IS

unscrew

dowel

whIch

from

care

possIble

To

remove

pinS

Dram

for

are

the

not

to

the

cleamng

to

the

mserted

bottom

to

remove

the

secunng

the

011

edge

damage

stramer

purpose

cover

and

from

the

the

bolts

whICh

replace

the

of

the

Jomt

OIl

stramer

unto

by

must

the

undersIde

bell

washers

the

umon

removing

dram

housmg

through

be

posItIOned

plug

of

the

m

the

connecting

the

de

se

Lower

whIch

i

l

t

Remove

OIl

FIg

the

pump

pump

4

Illustrates

bottom

with

Dismantling

Remove

and

take

off

shaft

dnve

Refitting

the

of

the

to

matenal

washer

Smear

Into

Clean

positIOn

paraffm

011

pan

can

the

out

faces

Reassembling

the

the

the

and

the

the

and

Examme

be

and

ItS

the

cover

before

used

011

pan

cover

the

dnve

setscrews

the

Sump

sump

crank

again

of

the

Insert

the

are

pump

Oil

outer

reflttmg

the

JOint

and

shaft

Pump

On

by

case

JOint

If

the

Oil

pIck

long

In

explosed

and

tlltmg

rotor

washing

the

JOint

washer

It

IS

WIth

setscrews

Pump

strainer

up

enough

spnng

the

wIth

It

OIl

faces

sound

grease

to secure

washers

body

shde

In

pan

and

Into

form

out

paraffin

to

and

renew

but

and

the

Three

Unscrew

upSide

the

remove

It

IS

ftt

flange

the

whIch

down

the

engme

If

It

adVIsable

the

of

pump

secure

care

any

necessary

JOint

tlghtlng

the

the

the

Pay

washer

ftve

to

long

Inner

to

traces

to

bolts

the

crankcase

bolts

the

cover

rotor

remove

patlcular

of

The

ftt

a

new

Lift

them

old

up

secunng

and

to

with

any

attentIOn

Jomtlng

old

one

the

evenly

remove

the

traces

JOint

OIl

the

b6dy

ItS

pan

tills

result

the

The

chamfer

In

body

outer

the

and

rotor

be towards

cover

brmg

FIg

IS

tightened

the

rotors

the

slotted

ItISof

to

assemble

end

great

of

Importance

In

the

thIS

dnve

4

has

a

base

Into

of

down

chamfered

the

Insert

mesh

body

edge

ftlure

the

way

shaft

that

Will

Into

13

Oil

pump

dnve

spmdle

01l

Lock

Oil

pump

pump

washer

plaln

bolt

washer

Oil

strainer

Oil

pump

ass

I

gear

shaft

y

eJ

Dowel

ass

y

V

Oil

l

D

pin

pump

cover

Fig

f

f

i

4

Oil

Pump

14

a

Removing

SERVICE

Starting

ENGINE

Nut

and

OPERATIONS

IN

POSITION

Pulley

WITH

Remove

fan

belt

Bend

dog

A few

Pull

nut

off

mg

Removing

The

tImmg

washer

shape

dIately

remove

washer

to

the

a new

of

and

The

below

Take

damage

Jomt

washer

the

JOint

and

spnng

the

back

sharp

IS

out

Care

the

If

the

by

usmg

the

the

a

special

f1tted

the

the

cover

washer

damage

cleanmg

surfaces

radIator

the

tab

blows

crankshaft

Timing

cove

next

washers

bolt

set

and

should

on

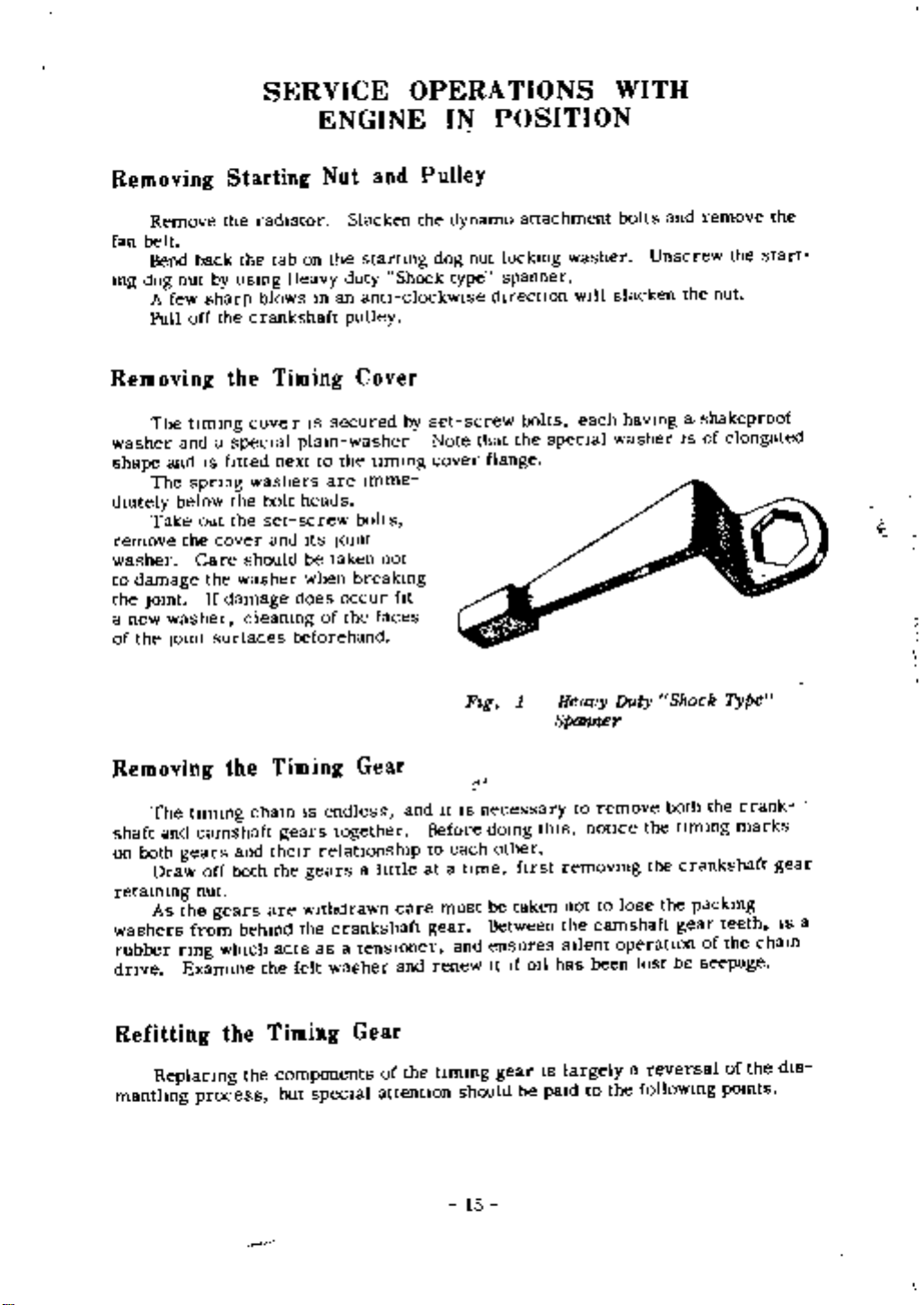

Heavy

m

r

IS

plam

to

are

heads

screw

Its

be

taken

when

does

of

beforehand

Slacken

the

startmg

Shock

duty

an

ant1

clockwlse d1reCtIOn

pulley

Cover

secured

washer Note

the

Jomt

occur

the

by

tImmg

Imme

bolts

not

breakmg

fit

faces

the

set

cover

dynamo

dog

type

Fag

nut

screw

that

flange

attachment

lockmg

spanner

bolts

the

1

washer

WIll

each

specIal

Heavy

Spanner

and

bolts

slacken

Unscrew

the

remove

the

nut

havmgashakeproof

washer

Duty

IS

Shock

of

elongated

Type

the

start

t

Removing

The

shaft

and

on

both

gears

Draw

retaining

As

the

washers

rubber

dnve

from

nng

Examme

Refitting

ReplaCing

mantlmg

tImmg

camshaft

off

nut

gears

Wh1Ch

the

process

the

and

both

behind

the

Timing

cham

gears

theIr

the

are

acts

the

Timing

components

but

IS

endless

together

relatIonshIp

gears

w1thdrawn

the

crankshaft

as

felt

washer

spec1al

a

tenslOner

Gear

Gear

a

httle

of

attentlon

care

and

the

and

It

Before

to

at a

must

gear

renew

tlmmg

1S

each

t1me

and

should

15

JI

necessary

domg

other

be

Between

ensures

It

gear

taken

If

hrst

be

011

thIS

has

1S

pa1d

to

notIce

removmg

not

the

camshaft

SIlent

been

largely

to

remove

to

operatIon

the

the

the

lose

lost

a

reversal

follOWing

both

tImmg

the

gear

be

the

crankshaft

packmg

of

seepage

marks

teeth

the

of

pomts

crank

the

gear

IS a

cham

dIS

FIt

the

tlmmg

Turn

WIth

Its

Place

the

on

and

other

The

must

be

alIgnment

adjust

FIt

wards

the

crankshaft

marks

the

engme

are

and

opposIte

crankshaft

keywaymapproximately

shafts

mime

same

replaced

the

the

the

the

of

the

alIgnment

011

front

gears

Ensure

number

thrower

of

unless

gear

Dnve

the

mto

It

that

of

faces

Will

car

pOSitIOn

the

packmg

a

behmd

camshaft

the

gears

new

and

be

necessary

and

and

mime

until

the

ensunng

tJmmg

home

washers

crank

measuremg

the

crankshaft

check

gears

the

one

marks

or

that

mto

keyway

0

clock

that

taken

camshaft

the

to

vary

the

theIr

IS

posJtJon

the

the

on

from

alIgnment

the

gear

felt

at

keys

gears

has

so

washer

respective

T

D C

behmd

been

number

that

and

are

present

are

opposite

the

fitted

wIthafeeler

of

packmg

Its

concave

IS

In

posJtJon

shafts

the

m

crankshaft

In

thIs

Ensure

camshaft

keyways

each

to

gauge

washers

face

case

It

gear

the

To

to

Valve

Rocker

Remove

brackets

Removing

Dram

the

for

the

flUId

It IS

If

the

to

necessary

four

cylmder

find

because

water

Notice

plate

Completely

assembly

Dismantling

To

dIsmantle

lockmg

shaft

from

bemg

push

shaft

a

shaft

Remove

SlIde

the

The

drawn

rod

Unlock

Withdraw

Sometimes

screwdnvel

eaSily

plate

end

two

reacher

the

aIr

Remove

the

coolmg

If

It

IS

of

the

ItS

way

that

under

Complete

the

from

the

split

the

rockers

of

the

end

rockers

out

the

tappet

the

the

under

Repeat

Cover

cleaner

the

Rocker

system

to

be

dram

to

rocker

head

from

the

unscrew

with

Assembly

the

rocker

the

rear

pms

shaft

ThIS

may

Its

lowest

adJustmg

split

pm

valve

No

the

Removal

rocker

Assembly

used

the

shaft

nuts

the

nght

the

brackets

rocker

flat

brackets

and

may

be

pOSItIOn

flat

spnng

2

rocker

procedure

Unscrew

cover

If

agam

are

coolmg

hand

rocker

shaft

washers

clean

be

achlved

screw

and

anti

system

ftxmg

not

rear

and

assembly

bracket

and

out

dIsmantled

spnng

have

WIll

thus

for

the

the

and

freeze

and

nuts

slackened

system

shaft

rockers

and

spnngs

the

by

and

allOWing

No

cap

slacken

also

rocker

ftrst

spnng

OIl

without

turmng

screw

washers

to

be

8

nuts

cork

IS

dlstonatlOn

mto

blacket

from

way

slIghtly

rocker

Jomt

m

secure

the

stud

remove

the

It

the

secunng

washer

use use

the

cylmder

the

cylmders

nut

nuts

washers

the

the

whole

engme

back

as

and

slide the

compressed

end

may

IS a

and

the

shaft

rocker

the

a

clean

cylmder

result

and

speCIal

remove

grub

from

Unscrew

rocker

hand

by

far

as

to

engme

head

screw

each

It

rocker

slIde

IIftmg

contamer

nuts

head

and

pump

lockmg

the

end

assembly

untIl

WIll

go

off

by

levenng

off

allow

rocker

and

the

No

of

the

plug

I

the

the

16

Fr

2

g

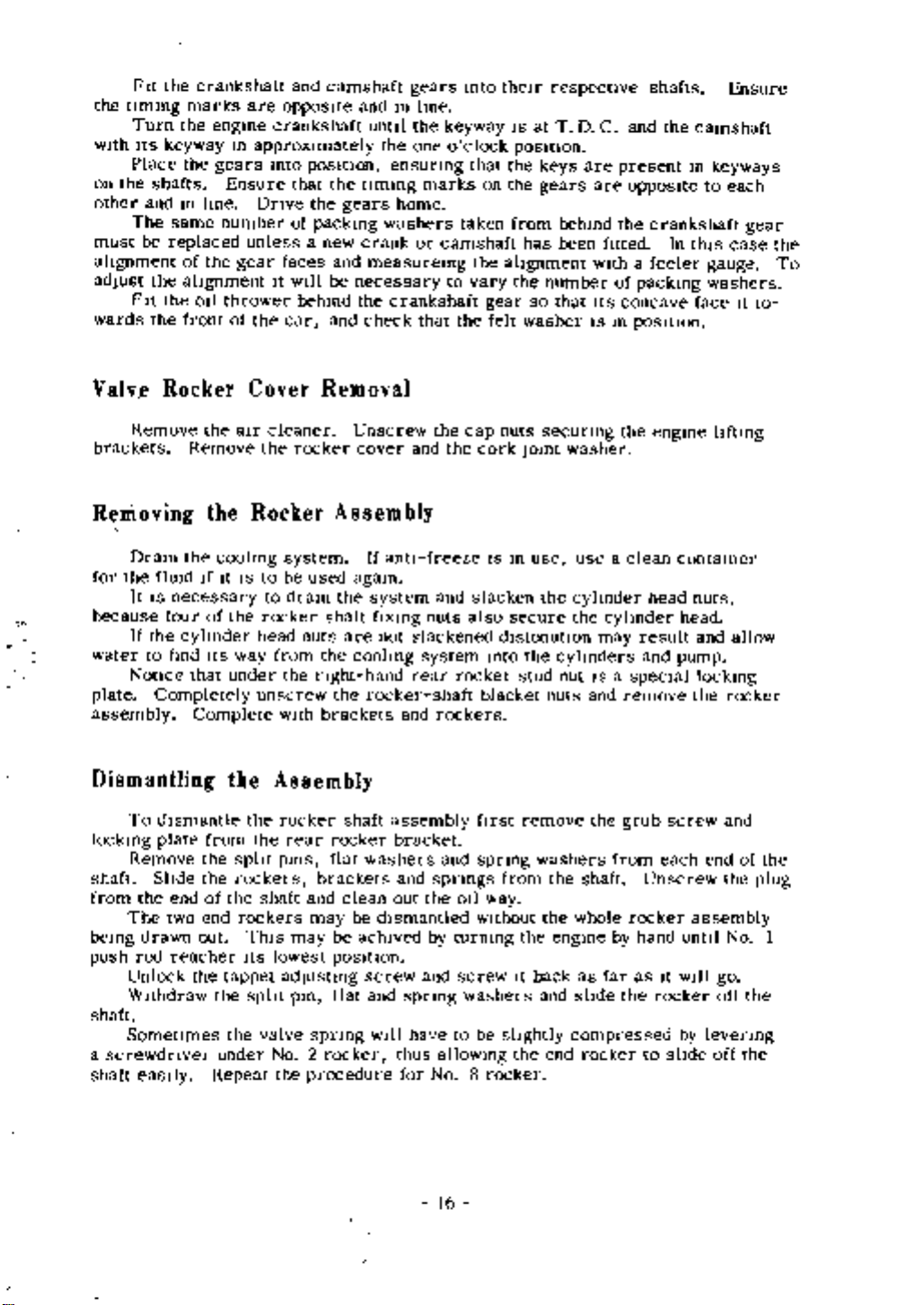

Reassembling

Rear

the

Locking

Rocker

Plate

1

Plate

2

Locatmg

Stud

On

workmg

of

No

2

repeating

completely

and

the

The

ends

of

lock

plate

Replace

shaft

front

of

that

the

cover

gasket

otherwIse

Push

If

the

for

IS

the

WIthout

Remove

Slacken

screwdnver

reassembly

dIagonally

left

of

the

process

stnpped

bushes

rockers

the

shaft

the

Replace

the

engme

rubber

or

OIl

leaks

Rod

Removal

valve

push

detaclung

the

all

with

No

reamed

and

spnng

the

bushed

the

rocker

rods

the

aIr

the

tIghten

from

3

and

until

down

down

spnng

Remember

and

rocker

Secure

and

rubber

will

assembly

to

be

rocker

cleaner

tappet

the

rocker

the

nut

to

so

on

they

and

to sIze

must

flat

cover

the

engme

bushes

result

hfted

assembly

and

adJustmg

pedestal

nut

returmng

are

rebushed

be

to

replace

washers

and

cover

hftlng

has

out

rocker

shaft

left

all

before

replaced

gasket

are

already

They

screws

as

by

found

a

bracket

nut

tight

the

the

wIth

means

plates

cover

fulcrum

of

No

from

If

OIl

assembly

m

rocker

the

The

are

be

to

been

on

may

their

to

secunng

1

the

the

holes

theIr

spht

vent

of

the

faulty

removed

the

depress

nuts a httle at a

pedestal

left

nut

rocker

wIll

have

on

the

ongmal

shaft

locating

pms

pIpe

two

cap

m

positIOn

they

other

full

extent

the

bracket

of

No

assembly

to

shaft

pOSJtJon

on

the

should

nuts

If

must

all

that

hand

then

valve

4

be

screw

ends

the

be

bracket

has

rednlled

be

ensunng

be

remams

taken

usmg

sprmg

nght

on

and

of

the

at

rocker

renewed

time

nut

and

been

the

the

out

a

17

sltde

All

withdrawn

push

wards

the

rocker

but the

rods

ensure

reassembly

after

end

sIde

the

that

ways

push

removal

IS a

the

and

rods

of

ball

straIght

can

ends

Itft

the

out

be

two

regIster

forward

the

withdrawn

end

push

rockers

In

reversal

the

rod

In

thIs

from

tappet

of

the

way

the

cups

dIsmantling

These

shaft

From

wIll

When

have

here

process

to

be

replacing

on

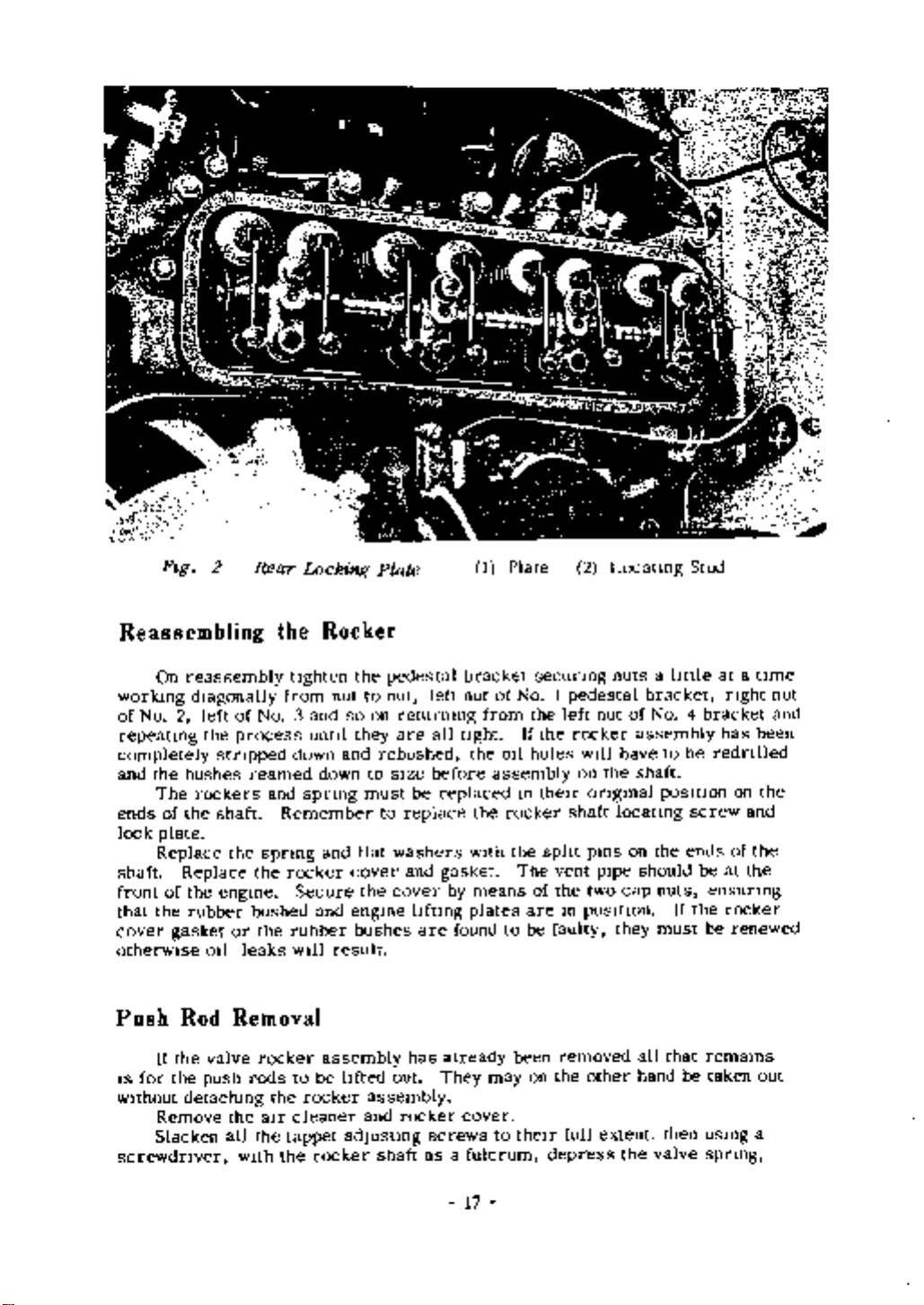

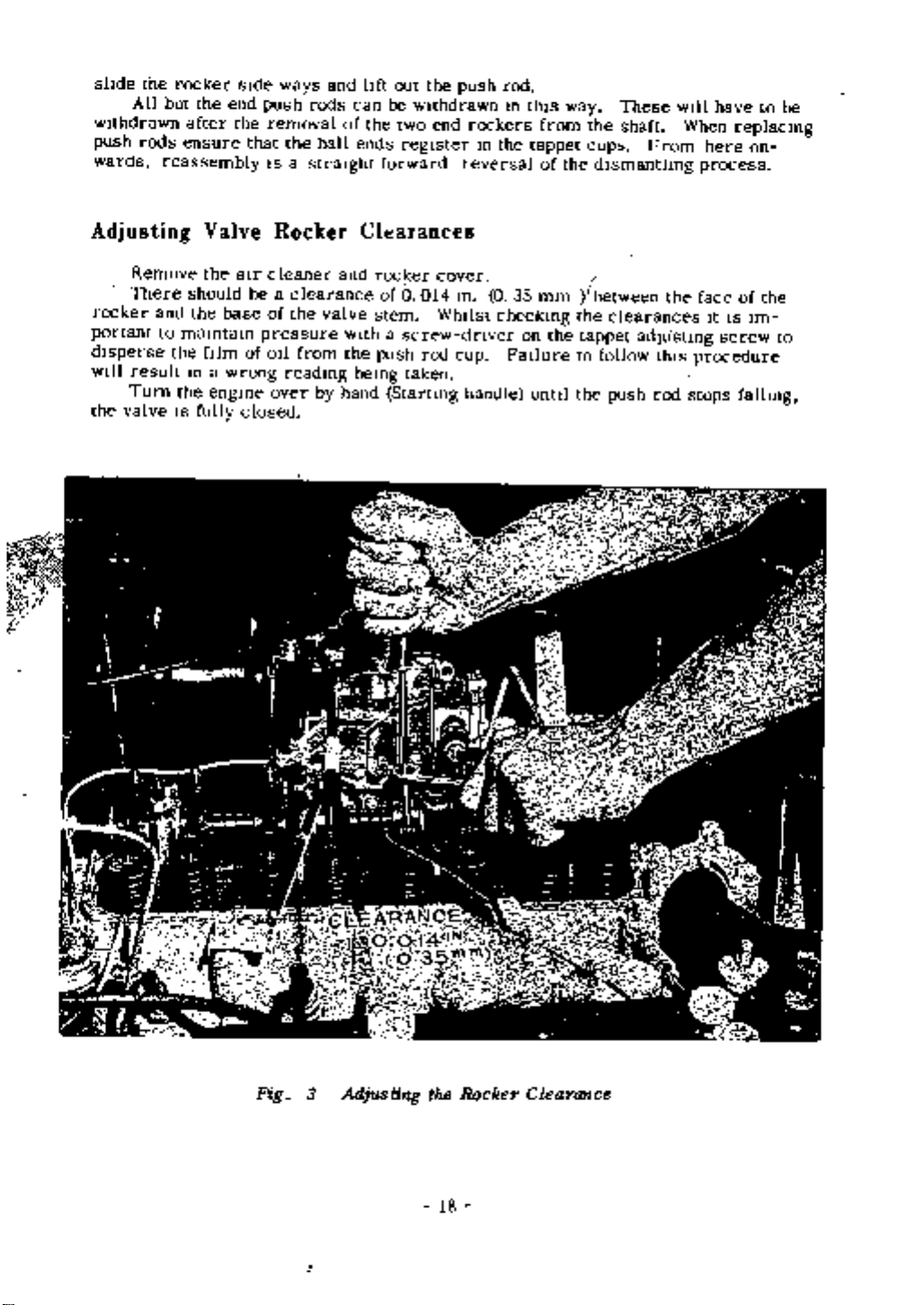

Adjusting

Remove

There

rocker

portant

dIsperse

WIll

the

and

to

result

Turn

valve

the

the

IS

should

the

maintain

In

fully

Valve

the

base

fIlm

a

wrong

engine

aIr

be

of

closed

Rocker

cleaner

a

clearance

of

the

pressure

011

reading

over

from

valve

by

and

wIth

the

hand

Clt

rocker

of

stem

push

being

arances

O

014

a

screw

rod

taken

Starting

cover

In

Whtlst

cup

dnver

handle

0

3S

mm

checking

on

Fallure

untll

the

fbetween

the

clearances

tappet

to

follow

the

push

the

adjusting

thIs

rod

face

of

IS

It

screw

procedure

stops

falling

the

lm

to

Fig

3

Adjusting

the

18

Rocker

Clearance

Loading...

Loading...