Page 1

TW7201I-MS

TW7201I

DHSL Remote Control Head

Operator/Technical Manual

Datron World Communications Inc.

Manual Part No. TW7201I-MS

Release Date: January 2008

Revision: E

3030 Enterprise Court

Vista, CA 92081, U.S.A.

Phone: (760) 597-1500 Fax: (760) 597-1510

E-Mail: sales@dtwc.com

www.dtwc.com

Page 2

Page 3

Change Description

Date of

Revision

Revision

Letter

Description of Changes

Pages

Affected

01/08 E Change ISDN designation to DHSL. All

TW7201I-MS i

Page 4

Page 5

© 2003 Datron W orld Communications, Inc. (Datron )

All rights reserved.

Datron World Communications, Inc.

This manual, as well as the software described in it, is

furnished under license and may only be used or copied

in accordance with the terms of such license. The information

in this manual is furnished for informational use

only, is subject to change without notice, and should not

be construed as a commitment by Datron. Datron

assumes no responsibility or liability for any errors or

inaccuracies that may appear in this book.

Except as permitted by such license, no part of this publication

may be reproduced, stored in a retrieval system,

or transmitted, in any form or by any means, electronic,

mechanical, recording, or otherwise without the prior

written permission of Datron.

Software License Agreement and Warranty

This software is licensed to the user (licensee) under the

express terms and conditions of Datron’s software

licensing policies and agreement as outlined below. By

receiving and installing this software package the user

(licensee) has indicated acceptance of the terms and conditions

of this agreement presented herewith.

As used in this document, the term “Software” shall

mean the application or control software in machine readable

format and the hardware protection key, along with any or all

supporting documentation, as well as all updated or enhanced

versions of the program supplied to the user at later date(s).

This software license does not include source code, and there

fore, no license is granted with respect to source code of any

kind utilized directly or indirectly in any Datron or Datron

supplied third party product. Note, in some cases, covered

software may be included in Datron products in RAM or

ROM, and/or forms of machine readable code, not readily

accessible to the user or licensee.

In consideration of the terms and conditions of this

agreement, Datron grants the user a non-exclusive, nontransferable license to install and operate one copy of the program.

Licensee agrees not to attempt, aid, authorize, or direct any

effort, either directly or indirectly to reverse engineer or

reverse compile the Software. Licensee further agrees they or

their agents are not authorized to

make derivative versions or changes to the Software.

Title to and ownership of the Software shall at all times

remain with Datron and/or its licensors. Further, no

license is granted to copy or reproduce in any form whatsoever

the Software supplied without the express written permission

of Datron, prior to any such contemplated action.

Datron may terminate this agreement and discontinue

further warranty coverage at any time due to failure to

comply with the terms and conditions of this agreement.

In such an event, Datron will provide the user

with written notice of such a “failure-to-comply” and the

user will have 10 days to demonstrate that a remedy has

been implemented. If the user fails to perform, the

agreement will be terminated by further written notice

from Datron. Upon termination, the user shall immediately

return all original Software, documentation, and

any copies of each to Datron.

This Software is licensed “AS IS” and Datron provides a warranty that covers the media upon which the Software is embedded for a period of 30 days from receipt of the product. Under

this warranty policy Datron’s sole obligation shall be to

replace or repair, at Datron’ s discretion, any such media that in

Datron’s opinion proves defective.

The user is obligated to provide Datron with a detailed

description of possible defects along with sample material

such that Datron can reproduce the identified defects.

By receipt and use, user (licensee) acknowledges that

certain software developed or distributed by Datron is

controlled by one or more governmental agencies. The

user (licensee) herewith acknowledges they will take all

necessary actions to comply with applicable regulations

concerning the use of licensed software. Further, Datron

is under no obligation to supply source code or documentation

of its software for any reason.

Datron makes no representation, express or implied, with

respect to any Software licensed under this document as to its

fitness for any particular purpose or intended use.

Furthermore, Datron shall have no liability under this

agreement for any incidental, special, or consequential

damages arising out of the use of any supplied software

programs. Datron reserves the right to make periodic

changes in it’s software for any purpose without any

obligation to notify users.

One Year Limited Warranty and Remedies

-

Datron warrants that its equipment is free from defects in

design, materials, and workmanship for a period of 12

months from the date of installation of the equipment,

but in no event later than 15 months from the date of

shipment. If the equipment does not provide satisfactory

service due to defects covered by this warranty, Datron

will, at its option, replace or repair the equipment free of

charge.

Should it be impractical to return the equipment for

repair, Datron will provide replacements for defective

parts contained in the equipment for a period of 12

months from the date of installation of the equipment,

but in no event later than 15 months from the date of

shipment.

This warranty is limited to the original purchaser and is

not transferable. Repair service performed by Datron is

warranted for the balance of the original warranty or 90

days, whichever is longer.

Exclusive Warranty: There are no other warranties

beyond the warranty as contained herein. No agent,

employee, or representative of Datron has any authority

to bind Datron to any affirmation, representation, or warranty

concerning the equipment or its parts that is not in

conformity with the warranties contained herein.

EXCEPT AS EXPRESSLY SET FORTH ABOVE, NO

OTHER WARRANTIES, EITHER EXPRESS OR

IMPLIED, ARE MADE WITH RESPECT TO THE

EQUIPMENT OR THE PARTS CONTAINED

TW7201I-MS iii

Page 6

THEREIN, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, AND

DATRON EXPRESSLY DISCLAIMS ALL WARRANTIES

NOT ST ATED HEREIN.

Limitations of Warranty: This warranty does not

cover:

Physical damage to the equipment or its parts that does

not involve defects in design, material, or workmanship,

including damage by impact, liquids, temperature, or

gases.

Damage to the equipment or its parts caused by lightning,

static discharge, voltage transients, or application

of incorrect supply voltages.

Defects or failures caused by unauthorized attempts to

repair or modify the equipment.

Defects or failures caused by Buyer abuse or misuse.

Return of Equipment - Domestic: To obtain performance

of any obligation under this warranty, the equipment

must be returned freight prepaid to the Technical

Support Services. Datron Worl d Communications Inc.,

3030 Enterprise Court, Vista, California 92081. The

equipment must be packed securely. Datron shall not be

responsible for any damage incurred in transit. A letter

containing the following information must be included

with the equipment.

a. Model, serial number, and date of installation.

b. Name of dealer or supplier of the equipment.

c. Detailed explanation of problem.

d. Return shipping instructions.

e. Telephone or fax number where Buyer may be contacted.

Datron will return the equipment prepaid by United Parcel

Service, Parcel Post, or truck. If alternate shipping is

specified by Buyer, freight charges will be made collect.

Return of Equipment - International: Contact Datron or

your local Representative for specific instructions. Do

not return equipment without authorization. It is usually

not possible to clear equipment through U.S. Customs

without the correct documentation. If equipment is

returned without authorization, Buyer is responsible for

all taxes, customs duties, clearance charges, and other

associated costs.

Parts Replacement: The following instructions for the

supply of replacement parts must be followed:

a. Return the parts prepaid to “Parts Replacement”

Datron W orld Communications Inc., 3030 Enterprise

Court, Vista, California 92081; and

b. Include a letter with the following information:

1. Part number

2. Serial number and model of equipment

3. Date of installation

Parts returned without this information will not be

replaced. In the event of a dispute over the age of the

replacement part, components date-coded over 24

months previously will be considered out of warranty.

Remedies: Buyer’s sole remedies and the entire liability

of Datron are set forth above. In no event will Datron be

liable to Buyer or any other person for any damages,

including any incidental or consequential damages,

expenses, lost profits, lost savings, or other damages

arising out of use of or inability to use the equipment.

1/95

Safety Considerations

This product and manual must be thoroughly understood

before attempting installation and operation. To do so

without proper knowledge can result in equipment failure

and bodily injury.

Caution: Before applying ac power, be sure that the

equipment has be properly configured for the available

line voltage. Attempted operation at the wrong voltage

can result in damage and voids the warranty. See the

manuals section on installation. DO NOT operate equipment

with cover removed.

Earth Ground: All Datron products are supplied with a

standard, 3-wire, grounded ac plug. DO NOT attempt to

disable the ground terminal by using 2-wire adapters of

any type. Any disconnection of the equipment ground

causes a potential shock hazard that could result in personal

injury. DO NOT operate any equipment until a suitable ground

has been established. Consult the manual section on grounding.

Servicing: Trained personnel should only carry out servicing.

To avoid electric shock, DO NOT open the case

unless qualified to do so.

Various measurements and adjustments described in this manual are performed in ac power applied and the protective

covers removed. Capacitors (particularly the

large power supply electrolytics) can remain charged for

a considerable time after the unit has been shut off. Use

particular care when working around them, as a short circuit

can release sufficient ener gy to cause damage to the equipment

and possible injury.

To protect against fire hazard, always replace line fuses

with ones of the same current rating and type (normal

delay, slow-blow, etc.). DO NOT use higher value

replacements in an attempt to prevent fuse failure. If

fuses are failing repeatedly this indicates a probable

defect in the equipment that needs attention.

Use only genuine Datron factory parts for full performance

and safety of this product.

Made in the USA

iv TW7201I-MS

Page 7

CONTENTS

Chapter 1: Introduction

1.1 The TW7201I DHSL Remote Control Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 TW7000 Series Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Referenced Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2: Installation

2.1 Installation Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 The TW7000 Transceiver and 7000RI Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Audio Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-1 Audio Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-1 TW7201I Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2 Microphone Jack J9 and J10 Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-2 Microphone Connector (J9) and (J10) Pin Assignments . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3 TW7201I Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4 AC Voltage Selector Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5 DB9 Remote Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-6 DB Accessory Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-3 ACC 1 Accessory Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-4 ACC 2 Accessory Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chapter 3: Operation

3.1 Powering the TW7201I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Figure 3-1 TW7000 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Using Knobs, Buttons and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 VSWR Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4 Using Menus to Change Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

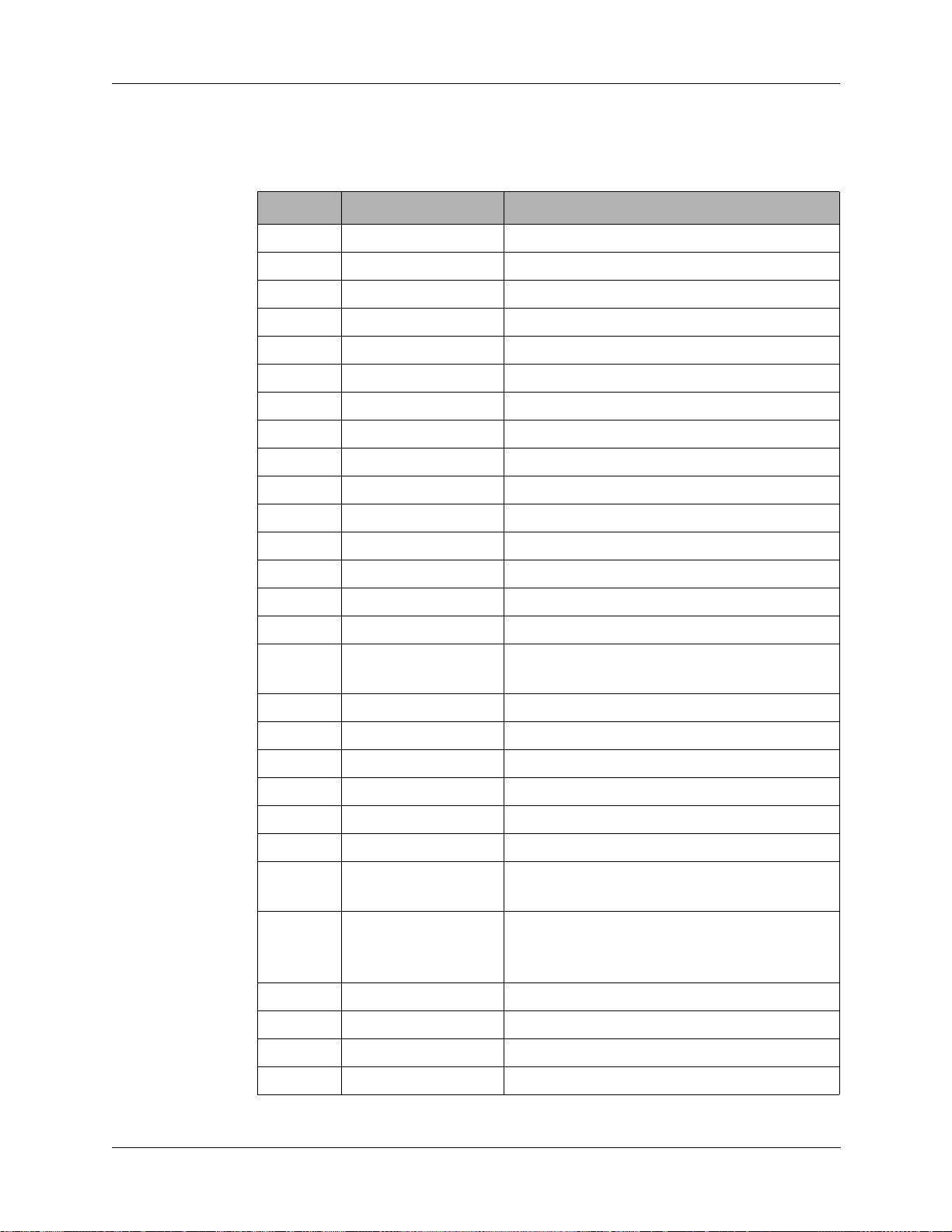

Table 3-1 Alpha Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-2 ALE Submenu - ALPHA 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.5 Programming Channels and Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.6 Scanning (for TA/TC only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.7 Placing an ALE Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.8 Placing a TransAdapt, Transcall or Selcall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.9 Activating the Noise Blanker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.10 Activating Encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.11 Activating Voice Enhancement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

TW7201I-MS v

Page 8

Chapter 4: Theory of Operation

4.1 TW7201I Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-1 TW7201I Remote System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Front panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2 Front Panel Assembly Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-1 Jumper Block J11 Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Rear Panel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-3 Power Supply/Interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-4 DHSL Modem Board Block Diagram (Remote Head). . . . . . . . . . . . . . . . . . . . . . . 4-9

4.4 7000RI Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-5 DHSL Modem Board Block Diagram (Transceiver) . . . . . . . . . . . . . . . . . . . . . . . 4-12

Chapter 5: Testing and Troubleshooting

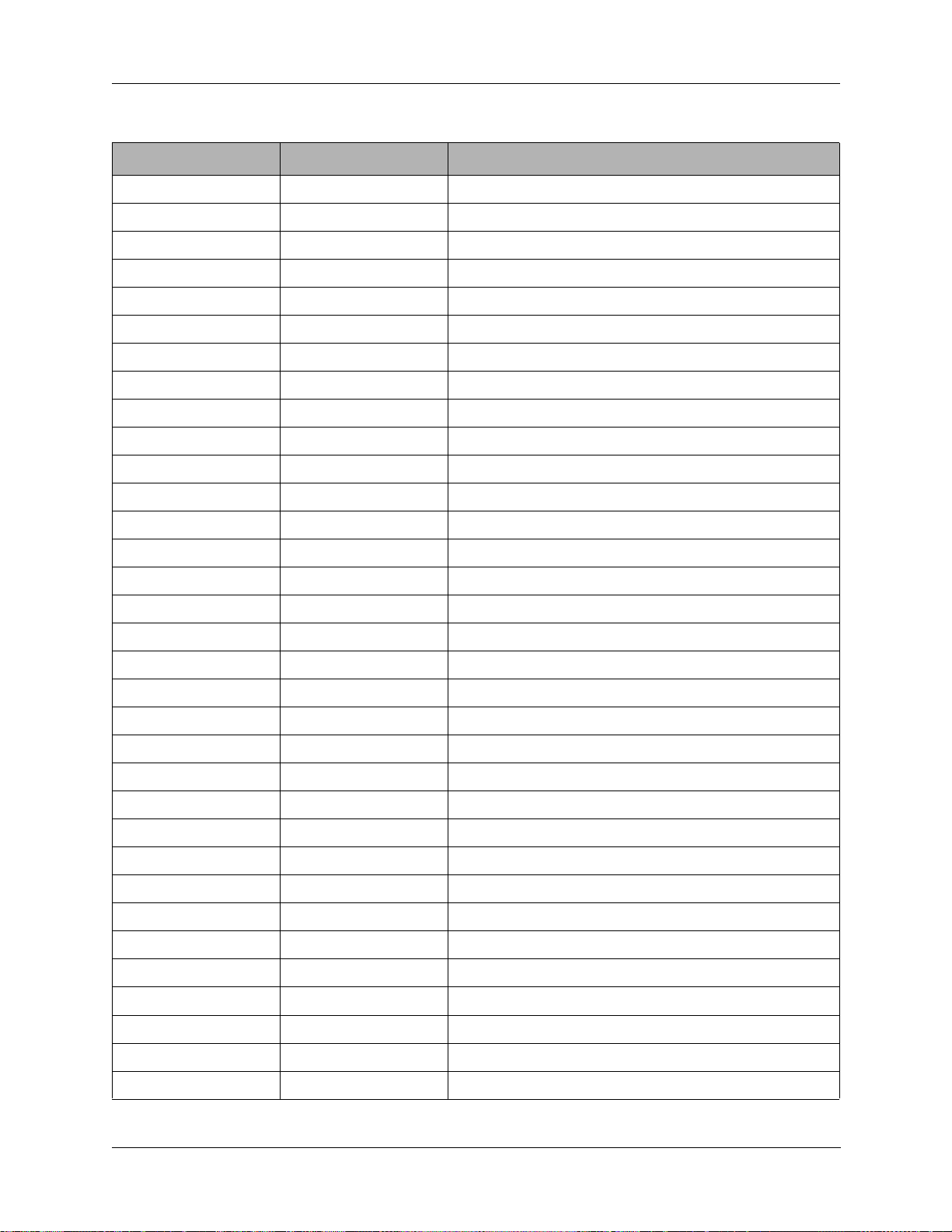

Table 5-1 TW7201I Subassemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Component Locations, Pin Assignments, Schematics and Part Lists . . . . . . . . . . . 5-6

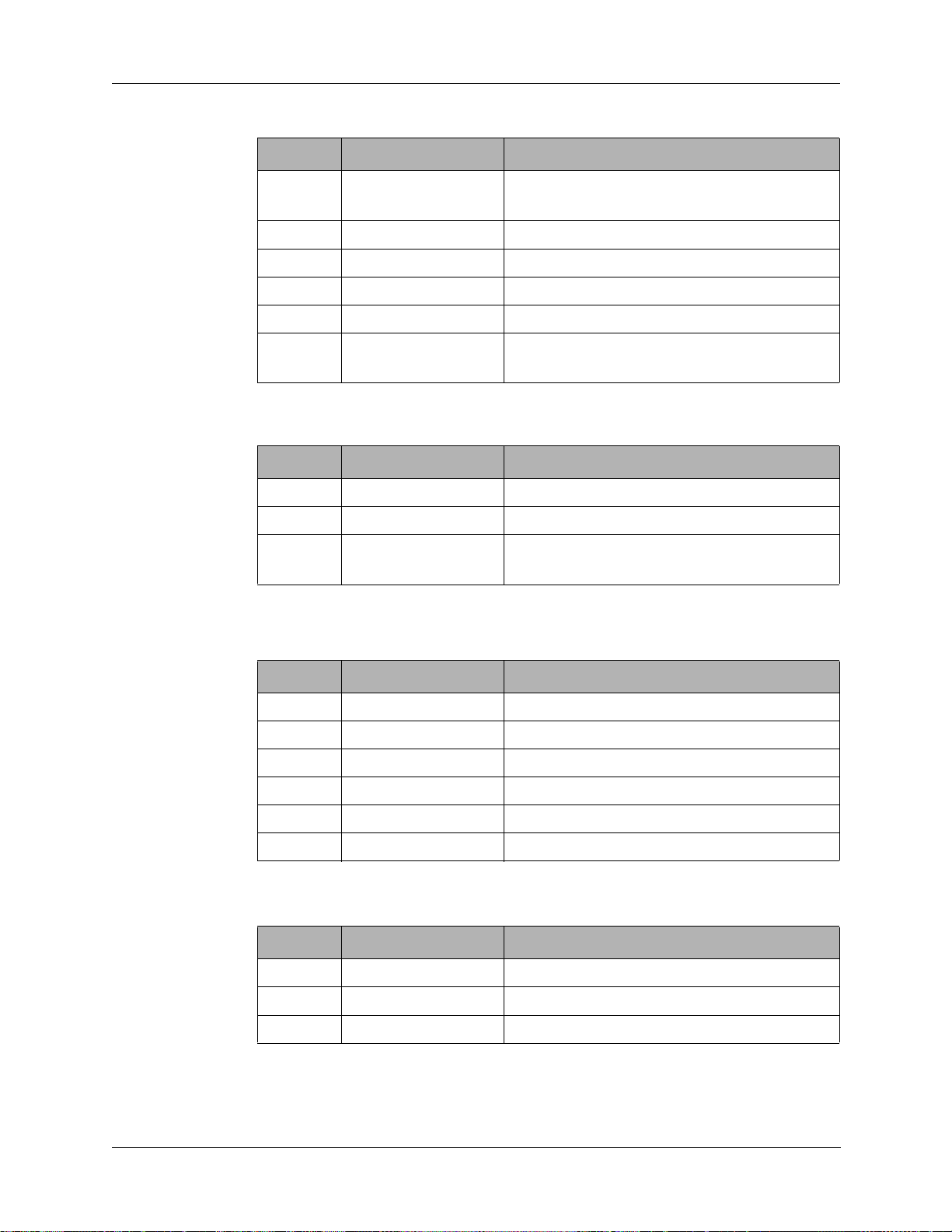

Table 5-2 Front Panel Processor J1 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Table 5-3 Front Panel Processor J3 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Table 5-4 Front Panel Processor J4 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-5 Front Panel Processor J5 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-6 Front Panel Processor J6 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-7 Front Panel Processor J7 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Table 5-8 Front Panel Processor J8 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Table 5-9 Front Panel Processor J9 and J10 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-1 Front Panel Processor Board Component Locations (738207 Rev. J) . . . . . . . . . . 5-10

Figure 5-2 Front Panel Processor Board Schematic Diagram (994359 Rev. E). . . . . . . . . . . . 5-11

Table 5-10 Front Panel Processor Board Parts List (001-03001 Rev. E) . . . . . . . . . . . . . . . . . 5-13

Table 5-11 DHSL Modem J1 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Table 5-12 DHSL Modem J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-13 DHSL Modem J3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-14 DHSL Modem J4 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-15 DHSL Modem J11 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Table 5-16 DHSL Modem J12 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Table 5-17 DHSL Modem Board Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-3 DHSL Modem Board Component Locations (738248 Rev. E) . . . . . . . . . . . . . . . 5-24

Figure 5-4 DHSL Modem Board Schematic Diagram (994184 Rev. E) . . . . . . . . . . . . . . . . . 5-25

Table 5-18 DHSL Modem Board Parts List (002-03100 Rev. L). . . . . . . . . . . . . . . . . . . . . . . 5-27

Table 5-19 Power Supply/Interface Board J1 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Table 5-20 Power Supply/Interface Board J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Table 5-21 Power Supply/Interface Board J3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Table 5-22 Power Supply/Interface Board J5 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Table 5-23 Power Supply /Interface Board J6 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-35

Table 5-24 Power Supply /Interface Board J7 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-36

Table 5-25 Power Supply /Interface Board J8 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-37

Table 5-26 Power Supply /Interface Board J9 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 5-37

Table 5-27 Power Supply /Interface Board J10 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . 5-37

Figure 5-5 Power Supply/Interface Board Component Locations (738277 Rev. B) . . . . . . . . 5-38

Figure 5-6 Power Supply/Interface Board Schematic Diagram (994222 Rev. D) . . . . . . . . . . 5-39

Table 5-28 Power Supply/Interface Board Parts List (003-03005 Rev. G) . . . . . . . . . . . . . . . 5-41

vi TW7201I-MS

Page 9

Figure 5-7 Switching Board Component Locations (738195 Rev. B) . . . . . . . . . . . . . . . . . . . 5-44

Figure 5-8 Switching Board Schematic Diagram (994149 Rev. A). . . . . . . . . . . . . . . . . . . . . 5-45

Table 5-29 Switch Board Parts List (001-00110 Rev. A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

TW7201I-MS vii

Page 10

Page 11

CHAPTER 1

INTRODUCTION

1.1 The TW7201I DHSL Remote Control Head

The TW7201I is the Datron High Speed Link (DHSL) remote control unit that

uses a high speed modem to provide remote operation of the TW7000 series

transceivers configured with the 7000RI option over a two-wire line. The

TW7201I includes a DHSL modem that communicates with its DHSL

counterpart (7000RI modem option) in the TW7000(F) transceiver.

The TW7201I is microprocessor controlled and features one full-duplex

digitized voice channel and two full-duplex data channels.

The TW7201I remote control head includes the following features:

• Full remote control and operation of TW7000 series transceivers

• Dual front panel microphone jacks

• Front panel LCD

• Alphanumeric keypad and function buttons

• Dual rear panel accessory connectors

• AC and DC power source support

TW7201I-MS 1-1

Page 12

1: Introduction

1.2 Specifications

Note: All specifications subject to change without notice or obligation.

Characteristic Description

General

Transmission type High speed modem and audio.

Modem channels 2 data channels, 1 voice channel.

Range 2 km (maximum).

Control Controls TW7000 series HF transceivers with

Display Front panel LCD.

Audio Internal loudspeaker (2W output).

Input power

AC

DC

7000RI option.

120 VAC or 240 VAC.

13.8 Vdc.

Protection Fused for AC and DC, overvoltage and reverse

polarity.

Modem

Format High speed slave modem (MC145426) in remote

head, master modem (MC145422) in transceiver.

Data 256 kHz modified differential phase shift burst.

Channels

voice

One full-duplex 64 kb/second digitized voice

channel.

data

Two full-duplex 9600 baud data channels.

Remote interface 2-wire (maximum distance 2 km).

Physical

Size (HWD) 10.16 cm x 33.02 cm x 15.24 cm.

(4 in. x 13 in. x 6 in.).

Weight 3.175 kg (7 lbs.).

Environmental

Temperature

operating

storage

–30° C to +60° C.

–40° C to +70° C.

1-2 TW7201I-MS

Page 13

1.3 TW7000 Series Family

The TW7000 series is a complete family of RF communications equipment

that includes the following components:

• Transceivers (TW7000, TW7000F)

• Internal options

• External options

• Accessories

• Remote control devices

The TW7201I modem operates in conjunction with an DHSL modem (7000RI

option) installed in a TW7000 series transceiver. The two modems connect

through a 2-wire remote line.

1.3.1

Front Panel

Control

When using transceivers such as the TW7000 that include front panel

controls, the transceiver controls are the master. In this case, the transceiver

controls are live from the transceiver and TW7201I. For security and limited

operation applications, the key functions can be inhibited at either the

transceiver or TW7201I control panels. Two variations of the TW7000 series

transceivers, the TW7000E and TW7000C, do not include control panels.

1: Introduction

1.3.2

7000RI Option The TW7000 series transceiver must have a 7000RI option installed to

communicate with the TW7201I remote head. The 7000RI option includes the

DHSL Modem board, and a dual UART chip and two jumpers that must be

installed on the transceiver Processor board.

1.3.3

TW7201I

DHSL Remote

Control

Voice Channel The TW7201I provides one voice channel. The voice audio is digitized before

Data Channels The TW7201I provides two data channels, using one channel for

The TW7201I includes a DHSL Modem board that communicates with the

DHSL Modem board (7000RI option) installed in the transceiver through a

remote line using a high speed data packet format. The information is

compressed and sent between the master (transceiver) and slave (remote

head). Line loss and balance variations do not effect the system performance.

The DHSL modem requires wide bandwidth so it does not work over standard

analog telephone channel. This system is ideal for distances of 1.6

or less (2

being sent over the modem link. This provides excellent voice quality even

with poor line conditions and requires no adjustment even when line

conditions change.

communications between the transceiver and the remote head. The other data

channel is a spare, normally used by accessory equipment or other special

functions. The second channel is typically used for an external computer

km max.) over a 2-wire pair.

km (1 mile)

TW7201I-MS 1-3

Page 14

1: Introduction

control device. This configuration allows for full computer control of the

transceiver at the remote control head. Both channels are high speed data

channels with a 9600 N81 standard interface.

Operating Modes The TW7201I is designed to be a high speed modem link to the transceiver for

both voice and data. The high speed characteristic allows for a wide variety of

voice and data capabilities. The TW7201I supports all standard operating

modes including USB, LSB, CW, PCS, and AME.

1.3.4

Options and

Accessories

The TW7201I supports the following accessories:

• PM palm microphone for voice operation

• DM desk microphone for voice operation

• KEY CW key

• EPL lightweight headset

• TW7201MM mobile mounting kit

• TW7201RM rack mounting kit

The TW7201I is supported with the following optional maintenance and

service items:

• TW7201I-TK tool kit

• TW7201I-MRK module repair kit

• TW7201I-MK module kit

• TW7201I-PSK spare parts kit

1.3.5

Accessory

Equipment

The TW7201I supports the following optional external devices through the

rear panel accessory connectors:

• Telephone couplers

• Data terminals

• Voice encryptors

• External speaker

1.4 Manual Conventions

Bold type denotes all items that appear in the display and for any button, knob

or switch on the front panel. For example:

• Press ALPHA 17, then press E.

• Press 1 to set the status to OFF.

1-4 TW7201I-MS

Page 15

1.5 Referenced Manuals

• RC2-MSOP Radio Control 2 Operator Manual

• 7000ENCR-MSOP 7000-Series High-level Encryption Operator Manual

• 7000ALE-MSOP 7000ALE Radio Control Program Operator Manual

1: Introduction

TW7201I-MS 1-5

Page 16

Page 17

CHAPTER 2

INSTALLATION

2.1 Installation Types

The TW7201I can be installed in the following configurations:

• Desktop

• Mobile

• Rack

The desktop model is the standard configuration for the TW7201I and requires

no additional mounting hardware.

For vehicle and marine applications, the TW7201I can be ordered with mobile

mounting brackets (TW7201MM) that are designed for either top or bottom

mounting.

For rack mount applications, the TW7201I can be ordered with the rack mount

kit (TW7201RM).

For local operation, the TW7201I requires a 2-wire line between the remote

head and the transceiver. The line connections are transformer-coupled at each

end. The line length is limited by the time delay of the high speed packets as

they travel from each end. Datron offers the C992307 10m (33 ft.) DHSL

interface cable.

Datron offers an unterminated remote cable (C992309) for connecting to

pre-existing wiring system. T wo C992309 cables would be required: one for the

transceiver; the other for the TW7201I.

2.2 The TW7000 Transceiver and 7000RI Option

To use the TW7201I with a TW7000 series transceiver, the transceiver must

have the 7000RI option installed. This option includes the DHSL Modem

board, a serial dual UART IC and jumpers that are installed on the transceiver

Processor board. The remote system uses a 2-wire cable between the

transceiver and the remote head.

TW7201I-MS 2-1

Page 18

2: Installation

A

2.3 Audio Connections

The TW7201I front panel hosts two 6-pin microphone connectors. These two

connectors are wired in parallel and are compatible with various audio

accessories. The input impedance is 150 ohms (nominal). The TW7201I

supports most dynamic, ceramic and magnetic microphones.

Part Number Description

DM Dynamic desk microphone

PM Heavy-duty hand microphone

HP Headphones, twin

EP Headphones

EPL Lightweight headphones

KEY CW key (Morse key)

All Datron audio accessories have the correct mating connector . Datron of fers

mating adapters for other low-level audio accessories.

Table 2-1 Audio Devices

OPTIONS

STATUS

PRICALLSCAN TUNE

POWER

AUDIO CONNECTORS

OFF

Figure 2-1 TW7201I Front Panel

5

4

3

6

1

2

6

5

1

2

3

Figure 2-2 Microphone Jack J9 and J10 Pinouts

B

1

C

J

K

4

L

S

T

7

U

/

\

.

+

G

D

H

E

23

I

F

M

P

Q

N

5

6

R

O

Y

V

Z

W

8

9

-

X

S

P

0

C

4

E

F

CLAR (PUSH)

2-2 TW7201I-MS

Page 19

Table 2-2 Microphone Connector (J9) and (J10) Pin Assignments

Pin Description Pin Description

1 GND 4 TX AUDIO

2 RX AUDIO 5 CW

3 PTT 6 +12 Vdc

2.4 Rear Panel Description

The rear panel provides the AC and DC power connections and fuse blocks,

accessory connectors and the remote line connector to the transceiver.

2: Installation

13.8VDC

DC INPUT

AC INPUT

Fuse

Fuse

Pull

Pull

ACCESSORY 1

ACCESSORY 2

FUSE

GND

REMOTE

Figure 2-3 TW7201I Rear Panel

2.4.1

Input Power The TW7201I can accept input power from either an AC or DC power source.

AC Power The rear panel includes a standard IEC AC power connector that can be

configured for 120 or 240 VAC. A standard AC power cable is included with

the TW7201I (769004 IEC320 to NEMA 5-15). The AC connector includes a

fuse holder and the AC voltage selector card. The AC fuse should be a 1A

slow blow 3AG fuse (550014).

The AC power voltage selector card must be configured for the intended

power source. The AC power is preconfigured for the AC power level in the

area where it is shipped.

CAUTION: Always verify the correct AC power setting on the AC

voltage selector card before applying AC power.

To reconfigure the AC power setting:

1. Move the clear plastic fuse cover to the left so that it covers the AC power

connector. The AC voltage selector card is located just below the fuse.

The current AC power setting is visible on the voltage selector card.

TW7201I-MS 2-3

Page 20

2: Installation

2. Pull the fuse ejector tab toward you and to the left. This forces the fuse

partially out of the fuse holder.

3. Remove the fuse.

4. Using a long nose pliers, remove the AC voltage selector card.

5. Orient the card to the correct AC level to be used. The voltage selector

card has two numbers on each side corresponding to AC power levels,

100 and 220 on one side, and 120 and 240 on the other side. To get the

correct setting, hold the voltage selector card toward the AC

connector/fuse holder, with the correct setting facing you as shown in

Figure 2-4 below. In this example the TW7201I is configured for

220 VAC.

Fuse

Fuse

Pull

Pull

Figure 2-4 AC Voltage Selector Card

6. Insert the card below the fuse holder, install the fuse and push the fuse

extractor handle back into the fuse holder.

7. Slide the fuse cover to the right to cover the fuse holder. Install the AC

power cable into the AC power connector.

DC Power The TW7201I rear panel also includes a DC power connector and fuse holder.

The DC input circuitry is designed for 13.8 Vdc with a typical current

requirement of approximately 300

Vdc to 16 Vdc. An optional 2m (6.5 ft.) 3-conductor DC power cable is

is 12

mA. The recommended DC voltage range

available (C991829). One end of the DC power cable is left without a plug for

convenient connection to a variety of DC power sources.

The DC fuseholder should include a 3A 250VAC fast 3AG fuse (550003) and

a spare fuse of the same rating. To access the fuse, push to the left on the

fuseholder cover and pull out.

2.4.2

Remote

Connector

The TW7201I communicates with the TW7000 series transceiver through a

10m (33 ft.) remote cable (C992307). The remote cable connects to the

TW7201I through the rear panel 9-pin D Submini socket. The FSK remote

head uses the same remote cable.

2-4 TW7201I-MS

Page 21

2: Installation

The 2-wire DHSL system uses the DHSL1 and DHSL2 lines to communicate

between the remote head and the transceiver. The following table provides the

pin assignments for the remote connector.

Note: Datron offers an unterminated remote cable (C992309) for connecting

to pre-existing wiring system. Two C992309 cables would be required: one for

the transceiver; the other for the TW7201I.

Note: The C992307 remote cable is actual ly a 9-conductor cable. The DHSL

modem in the remote head uses only two of the nine wires to communicate

with the transceiver DHSL modem.

69

2.4.3

Accessory

Connectors

1

Figure 2-5 DB9 Remote Connector Pinout

Pin Signal Pin Signal

5

1 GND 6 DHSL2

2 Not used 7 REMRXA (not used)

3 Not used 8 REMTXA (not used)

4 Not used 9 Not used

5 DHSL1

The rear panel hosts two DB25 accessory connectors ACC 1 and ACC 2 (refer

to T able 2-3 on page 2-7 and Table 2-4 on page 2-8) that support the following

accessories:

• External encryption devices

• Audio interface devices

• Data terminal equipment (DTE)

• External speaker

Encryption

Devices

Audio Interface

Devices

An external encryption device can connect to either connector ACC 1 or

ACC 2.

Audio interface devices such as Datron’ s ACU1000 and ACU-T can use either

accessory connector.

DTEs The TW7201I can interface with data terminal equipment (computers)

through accessory connector

ACC 1. The TW7201I includes two data

channels—the main channel provides full transceiver control; the spare

channel is designed to interface with a computer (DTE) (data transmission

only) so it can use RC2 or DatronLINK to operate and control the TW7000.

TW7201I-MS 2-5

Page 22

2: Installation

Note: DatronLINK is a proprietary data network management and

messaging program designed to automate message file transfers over radio

links, LANs and through the Internet.

External Speaker The TW7201I includes a standard speaker mounted on the inside of the front

panel. An external loudspeaker can be added to the transceiver through the

ACC 2 accessory connector.

Note: If using the optional external speaker, turn off the internal speaker

(push the SPKR button; the status icon displayed on the LCD above the SPKR

button should be set to OFF).

2-6 TW7201I-MS

Page 23

14 25

2: Installation

1

Figure 2-6 DB Accessory Connector Pinout

Table 2-3 ACC 1 Accessory Connector Pin Assignments

Pin Signal Description

13

1 GND Chassis ground

2 COM1RXD Receive data line for DTE connection

3 NC No connection

4 COM1TXD Transmit data line for DTE connection

5 NC No connection

6 BALRXA1 Balanced line receive audio 1

7 BALRXA2 Balanced line receive audio 2

8 BALTXA1 Balanced line transmit audio 1

9 BALTXA2 Balanced line transmit audio 2

10 EXAUDPTT\ External audio PTT (active low)

11 NC No connection

12 NC No connection

13 +12V ACC +12 Vdc supply for the accessory devices

14 EXTCWKEY External CW key

15 NC No connection

16 DCD Not used

17 FPWSP1 Front panel spare port (not used)

18 NC No connection

19 NC No connection

20 NC No connection

21 NC No connection

22 NC No connection

23 NC No connection

24 NC No connection

25 NC No connection

TW7201I-MS 2-7

Page 24

2: Installation

Table 2-4 ACC 2 Accessory Connector Pin Assignments

Pin Signal Description

1 GND Chassis ground

2 GND Chassis ground

3 PWRON\ Remote power on/off (active low)

4 NC No connection

5 NC No connection

6 BALRXA1 Balanced line receive audio 1

7 BALRXA2 Balanced line receive audio 2

8 BALTXA1 Balanced line transmit audio 1

9 BALTXA2 Balanced line transmit audio 2

10 EXAUDPTT\ External audio PTT (active low)

11 NC No connection

12 NC No connection

13 +12V ACC +12 Vdc supply for the accessory devices

14 GND Chassis ground

15 NC No connection

16 DCD Not used

17 NC No connection

18 NC No connection

19 NC No connection

20 TC/SCALM Transcall/Secall alarm

21 NC No connection

22 EXTSPKR External speaker audio

23 NC No connection

24 +12V ACC +12 Vdc supply for the accessory devices

25 +12V ACC +12 Vdc supply for the accessory devices

2-8 TW7201I-MS

Page 25

CHAPTER 3

OPERATION

The procedures discussed in this chapter use the TW7201I front panel to

program the TW7000 series transceiver.

Note: The TW7000 transceiver must be powered on to program the

transceiver from the TW7201I.

To program the transceiver from a computer, refer to the Radio Control 2

Operator Manual (RC2-MSOP); the 7000ALE option must be installed in the

radio.

3.1 Powering the TW7201I

To turn the TW7201I and TW7000 (or TW7000F) on, turn the PWR OFF/VOL

knob clockwise until an audible click is heard. Power is off in the full

counterclockwise position. When the transceiver is turned on, the LCD

displays the software version level.

Display: TW7000

VER 701xx (where xx is the version level)

The BITE system runs automatically and verifies that the boards are

functional.

Display: TW7000 OK

MODULES

The BITE system searches for any installed options. The LCD displays the

following information:

• Options

• Current channel number (upper left corner)

• Channel frequency (upper center)

• Clarifier offset (if any, below the frequency).

TW7201I-MS 3-1

Page 26

3: Operation

Channe

E

l

Rx

Atten-

uator

Call

xterna

RF

Amplifier

Squelch

Tune

Priority

Alpha

Speaker

Send

l

Internal

Options

RF Power

Level

Scan

Group

Scan

Mode

Select

Figure 3-1 TW7000 Front Panel

Keypad

Power/

Volume

Clarifier

3.2 Using Knobs, Buttons and Indicators

Front panel knobs, buttons and displayed indicators provide TW7201I

function control and status including access to advanced features from menus.

For the knob, button and indicator locations, refer to Figure 3-1 above.

3.2.1

Power/Volume The PWR/VOL knob provides power to the TW7201I. It also provides volume

control for the internal speaker. To increase volume, turn the

knob clockwise.

3.2.2

Clarifier The CLAR knob provides frequency fine tuning by adjusting the channel

frequency to clarify the signal. The knob has continuous rotation and provides

a maximum of -600 Hz and +600 Hz offset in 10 Hz steps. Turn the

knob counterclockwise for negative offset and clockwise for positive offset

(USB mode). The offset value is displayed on the right side of the LCD and is

nulled by turning the knob until the offset reads +000 Hz, or by pressing the

knob (off). When the clarifier is off, no clarifier information is displayed.

Pressing the knob a second time restores the previous offset and refreshes the

display.

PWR OFF/VOL

CLAR

3-2 TW7201I-MS

Page 27

3.2.3

n

Keypad The keypad provides the following operations:

• Enters numeric or alpha characters

• Saves data

• Selects channels and frequencies

• Scrolls within menus

3: Operation

Entering

Numbers

Entering Text

To enter numbers:

1. Press the desired keypad number.

The display has a permanent

decimal and comma in the

frequency field.

2. If a value is entered that is below

10.000000 MHz, use the decimal

button.

Alpha characters are entered using a

combination of two buttons. For

example:

1. On the keypad, press the top

bracketed button, then 1 to enter

character A.

2. Press the middle bracketed button,

then 1 to enter character B.

3. Press the bottom bracketed button,

then 1 to enter character C.

Scroll up

Scroll left

Scroll dow

Scroll right

Enter

Frequency

Channel

Editing Text To enter a space, press any bracketed button, then 0.

To delete a character, use the left and right arrows to position the cursor, then

press the C button. All trailing characters move to the left.

Menu Navigation To scroll through the menu selections, use the up and down arrow buttons.

These arrows convert to left and right scrolling when editing in the text

message mode. The scrolling rate remains constant while an arrow button is

held down. The arrows remain active until another control function is

selected.

Channel and

Frequency

Selection

The C, F, and E buttons enter channel and frequency information into memory.

To select a channel:

1. Press the C button.

2. Enter the channel number using the keypad.

TW7201I-MS 3-3

Page 28

3: Operation

3. Press E to enter the channel selection.

To select a frequency:

1. Press the F button.

2. Enter the frequency.

3. Press E to enter the frequency into memory.

3.2.4

Function

Buttons

The TW7201I front panel includes preprogrammed function buttons such as

CALL, SEND, TUNE and ALPHA. The LCD displays the icons at the left and

bottom section of the LCD.

Alpha The ALPHA button provides access to the Alpha menu. The Alpha button is in

the group of five buttons immediately to the right of the LCD. The ALPHA

button is the fourth from the top.

1. Press the ALPHA button to access the Alpha Menu.

2. To exit the menu, press ALPHA again.

Call The CALL button initiates a call sequence in the ALE option or in the

Transcall, Selcall, TransAdapt option. If these options are not installed or if

they are turned off, this button is disabled.

For information on placing ALE calls, refer to Section 3.7 “Placing an ALE

Call” on page 3-22. For information on placing Transcall, Selcall or

TransAdapt calls, refer to Section 3.8 “Placing a TransAdapt, Transcall or

Selcall” on page 3-23.

External RF

Amplifier

The EXT AMP button transfers PTT control to an external amplifier connected

to the TW7000 ACC 3 accessory connector.

1. To automatically set and lock RF power in the H (high power) position,

set it to

ON.

2. To restore control, set it to OFF and the TW7000 no longer requires an

external amplifier.

Priority Channel The PRI button sets the TW7000 to a channel defined as the priority channel.

The priority channel is preset to channel 001. To change the number of the

priority channel, refer to Section 3.4 “Using Menus to Change Settings” on

page 3-7.

RF Power Level The RF PWR button allows scrolling through the L (low), M (medium), and H

(high) power settings. Default settings for the three RF power levels are listed

in the following table.

RF Power Level Factory Preset ALPHA 5 Setting

L (low) 10W (average power) 10

M (medium) 25W (average power) 30

3-4 TW7201I-MS

Page 29

3: Operation

RF Power Level Factory Preset ALPHA 5 Setting

H (high) 100W (average power) 200

To change these values, refer to Section 3.4 “Using Menus to Change

Settings” on page 3-7.

RX Attenuator The ATTN button reduces a strong receive signal by 20 dB by changing the

status of the input receiver attenuator from ON (+20 dB input RX pad) to OFF.

Scan The SCAN button initiates the function that searches the channels in the

selected scan group for a clear frequency.

1. Press the SCAN button to begin scanning the channels in the selected scan

group.

2. Press SCAN a second time to terminate the scan sequence and revert the

TW7000 to the last channel scanned.

For more information, refer to Section 3.6 “Scanning (for TA/TC only)” on

page 3-20.

Scan Group A scan group is a collection of channels grouped together. After defining the

scan groups, use the SCAN GROUP button to select a scan group. For more

information on scan groups, refer to Section 3.6 “Scanning (for T A/TC only)”

on page 3-20.

Send The SEND button sends an ALE call to the last station with an established link.

Press the SEND button to send an ALE call. For a more detailed description,

refer to Section 3.7 “Placing an ALE Call” on page 3-22.

Speaker The SPKR button switches the internal speaker on and off. To mute the

speaker, press the SPKR button (located beneath the SPKR icon on the lower

right side of the display). The status of the speaker (ON or OFF) is displayed

under this icon.

Squelch The SQ button changes the status of the squelch circuit from ON to OFF, or

vice versa. In the

ON setting, background noise is muted.

Tune The TUNE button activates the tune cycle when using automatic antenna

tuners like the RAT1000C with the TW7000.

Mode The MODE buttons, located beneath the mode icon on the lower left side of the

display , select an operational mode. Press the up or down arrow

MODE buttons

to scroll through the following choices.

Mode Description

USB Upper sideband voice: Standard voice grade IF filter and

voice AGC time constants.

LSB Lower sideband voice: Standard voice grade IF filter and

voice AGC time constants.

TW7201I-MS 3-5

Page 30

3: Operation

Mode Description

USB/LSB

DATA

USB/LSB

AME

FSK AGC time constants, optional USB/LSB wideband

data filter, 300-3300 Hz bandwidth.

Same as USB/LSB mode with addition of carrier in

transmit mode at a level of -6 dB relative to PEP.

USB PCS Same as USB mode with addition of carrier in transmit

mode at a level of -16 dB relative to PEP.

USB/LSB

Optional narrowband filter with 500 Hz bandwidth.

CW

Note: The LCD only displays these modes if a mode option is installed

(7000WB1 or 7000CW). The mode buttons are disabled if the Lockout or

Frequency Blank functions are turned on. For information on these functions,

refer to Section 3.4 “Using Menus to Change Settings” on page 3-7.

3.2.5

Internal Options The OPTION and STATUS buttons change the status of the following installed

options.

Option Displayed Icon

FED-1045 ALE ALE

Transcall/Selcall TC/SC

TransAdapt TA

Noise Blanker NB

Voice Enhancement OPT

Encryption ENCR

When an option is installed in the TW7000, a corresponding icon is displayed

on the outer edge of the LCD. The LCD displays the icon and the option’s

current status (

ON or OFF).

To change the status of an installed option:

1. Press OPTION or STATUS. The icon of the last entered option flashes.

2. If you want a different option, press OPTION until the desired icon

flashes.

3. Press STATUS to toggle between ON and OFF.

Note: If you press a button other than OPTION and STATUS, the icon

stops flashing and the radio performs the function of that button. The icon

also stops flashing after a time-out of 10 seconds.

3-6 TW7201I-MS

Page 31

3.3 VSWR Feature

VSWR is a measurement of how much power is delivered to the antenna

system. A high VSWR reading indicates a significant impedance mismatch

between the transceiver and the antenna system. A low VSWR reading

indicates a good impedance match resulting in more power transferred to the

antenna system.

When the microphone is keyed, the LCD displays the VSWR on the second

text line (except when using ALE, TA/TC/SC and tune). If there is adequate

power transfer from the radio to accurately measure VSWR and VSWR is less

than 9:1, the LCD displays VSWR n-1, where n is the ratio n:1. If the ratio is

9:1 or higher, the LCD displays VSWR 9+. If the power out is too low for a

reliable determination of VSWR, the LCD displays VSWR ----.

Modes USB/LSB DATA are not available for selection unless the 5 MHz IF

board includes the 7000WB1 or 7000CW options.

Note: The VSWR feature requires that firmware 701AU (or later version) and

Reference/Control board 001-00206 are installed.

3: Operation

3.4 Using Menus to Change Settings

The TW7000 provides two menus for adjusting settings. The Alpha menu is

for changing settings specific to the 7000TC option (Transcall, Selcall, and

TransAdapt). The Alpha menu also provides access to the ALE submenu,

which includes a set of functions for changing settings specific to the ALE

option.

To access the Alpha menu:

1. Press ALPHA to display the first function on the menu.

2. Press the number of the desired function.

3. Press E to enter the selection.

4. After selecting and entering a function, use the arrow buttons on the

keypad to scroll through any further selections within that function.

5. Press E to enter a selection.

For example, press ALPHA 17, then press E to access the ALE submenu.

TW7201I-MS 3-7

Page 32

3: Operation

3.4.1

Alpha Menu

Table 3-1 Alpha Menu

ALPHA

Function

Description

1 OPTION (not used)

2 SCAN SET CHANNEL (for non ALE)

3 SCAN RATE (for non ALE)

4 PRIORITY CHANNEL

5 RF POWER (TX)

6 FREQ BLANK (blanks LCD frequency and disables mode

changes)

7 LOCKOUT (disables frequency and mode changes

8 RECEIVE SET Rx ONLY (disables TX operation)

9 SET CLOCK (if option installed)

10 ALARM TIMER ON/OFF

11 SET ALARM

12 Time and date display

13 TA/TC/SC Rx ADDR (TransAdapt/Transcall/Selcall rec eive

address)

14 TRANSADAPT BER NUM (TA bit error rate)

15 SCAN GROUP NUMBER (for non ALE)

16 TA/TC/SC/ Tx ADDR (TransAdapt/Transcall/Selcall trans mit

address)

17 ALE Submenu (access to the ALE functions in Table 3-2 on

page 3-13.)

18 RECEIVE SET Rx/Tx (activated TX operation)

19 RF POWER ATU SET (tune power set)

20 BITE TEST INITIATED

21 OPTION 1 TYPE (Voice Enhancement Modulation)

22 COM 1 BAUD (comport configuration).

23 COM 2 BAUD (comport configuration).

24 BACKLITE OUT (ON/OFF).

25 FREQ INC HZ (frequency increment from 1 Hz to 10 MHz).

26 TEST REAR PANEL I/O (factory test).

27 ENC PASSWORD (Encryption menu).

28 PTT TIMER (sets maximum PTT time).

3-8 TW7201I-MS

Page 33

Table 3-1 Alpha Menu (continued)

3: Operation

Alpha Menu

Descriptions

ALPHA

Function

Description

29 PRINTER.

30 CLONE RADIO.

31 GLOBAL POSITION SYSTEM (optional).

32 CW HOLD TIME.

33 SPLIT SITE (2 radios: TX and RX).

34 CLARIFIER ON/OFF.

35 100 CHANS

Note: These functions only apply if the 7000TC option is installed. The

exception is function Alpha 17 which allows access to the 7000ALE option.

(1) OPTION Not currently available.

(2) SCAN SET CHANNEL

For customizing the selected scan group (selected with

ALPHA 15). For more information on how to use this

function, refer to Section “Customizing a Scan Group”

on page 3-21.

(3) SCAN RATE For setting the rate at which channels within a selected

scan group are scanned. Enter a speed between 1 and

30 seconds per channel.

(4) PRIORITY CHANNEL

For changing the number of the priority channel. The

default is channel 1. To change the priority

channel:

1. Press ALPHA 4 and E. The existing priority channel

is displayed.

2. Enter the new priority channel number, then press E.

The new priority channel number is displayed.

3. Press the PRI button to set the new priority channel.

(5) RF POWER For changing RF power output settings of the TW7000.

The defaults for the three power output levels are 10,

30, and 200. To change a value:

1. Connect a power meter to the antenna connector on

the rear of the TW7000.

TW7201I-MS 3-9

Page 34

3: Operation

2. Press RF PWR (refer to Figure 3-1 on page 3-2))

until the desired level (L, M, or H) is displayed.

3. Press ALPHA 5, then E. The LCD displays the

current power level.

4. CW key the TW7000, then scroll to the power level

indicated on the power meter. When the LCD

displays the desired power level, press E.

5. Adjust the other two levels in the same manner.

6. Press E twice to exit this mode.

(6) FREQ BLANK For blanking the frequency on the LCD so that only the

channel number is displayed. Each time you press

ALPHA 6 the selection toggles between ON and OFF.

Note: Setting to ON disables the mode select buttons.

(7) LOCKOUT Prohibits changing any of the channel frequencies.

Every time you press ALPHA 7, the selection toggles

between ON and OFF.

Note: Setting to ON disables the mode select buttons.

(8) RECEIVE SET Rx ONLY

For making the displayed channel a receive-only

channel by locking out the PTT. The status is

automatically set to ON whenever you press ALPHA 8.

Press ALPHA 18 (TX) to reverse the receive-only state.

(9) SET CLOCK To set the internal clock (if installed) starting from the

year, down to the second. Enter the year, date, hour,

minute and second pressing

(10) ALARM TIMER To automatically change the status of the timer from

OFF to ON whenever ALPHA 10 is pressed. In the ON

position, you can set the alarm using

(11) SET ALARM Sets a time for the sounding of the internal alarm. Turn

the alarm

ON using ALHPA 10. Enter the year, date,

hour, and minute pressing

(12) TIME AND DATE Automatically displays the setting of the internal clock.

(13) TA/TS/SC Rx ADDR

E after each value.

ALPHA 11.

E after each value.

For selecting a self ID. The LCD briefly displays the

current self ID. Use numbers from 000 to 255. This

number is usually the last three digits of a serial

number.

3-10 TW7201I-MS

Page 35

(14) TRANSADAPT BER NUM

For setting the bit error rate (BER) to evaluate channel

performance. The higher number corresponds to the

better performing channel. The default is 70.

(15) SCAN GROUP NUMBER

For selecting a scan group. This is the scan group when

using ALPHA 2 and ALPHA 3. The default is scan group

00.

Note: Also use the SCAN GROUP icon on the front

panel to select a 7000TC scan group (provided ALE is

OFF or not installed).

(16) TA/TC/SC Tx ADDR

For identifying the address for the station being called.

Numbers from 000 to 255 are available. This number is

usually the last three digits of a serial number.

3: Operation

(17) ALE Submenu For configuring the ALE system. For information about

the ALE submenu and how the system is configured,

refer to Section “ALE Submenu Descriptions” on page

3-14.

(18) RECEIVE SET Rx/Tx

For automatically configuring the displayed channel to

an RX and TX channel. Entering ALPHA 8 changes the

setting back to an RX channel.

(19) RF POWER ATU SET

For entering an RF power to use during the tune cycle

for an external automatic antenna tuner. The default is

12. Enter a level from 0 to 33.

(20) BITE TEST INITIATED

Automatically starts the TW7000 BITE system.

(21) OPTION 1 TYPE For activating the Voice Enhancement option if the

7000VEM is installed in the option card slot. For more

information, refer to Section 3.11 “Activating Voice

Enhancement” on page 3-26.

(22) COM 1 BAUD For configuring the TW7000 COM1 port for

communicating with a computer . Use the arrow buttons

to scroll through and enter the baud rate, data bits, stop

bits, and parity.

TW7201I-MS 3-11

Page 36

3: Operation

(23) COM 2 BAUD For configuring the TW7000 COM2 port for

communicating with a computer . Use the arrow buttons

to scroll through and enter the baud rate, data bits, stop

bits, and parity.

(24) BACKLITE Automatically toggles the LCD backlight ON and OFF.

(25) FREQ INC HZ For setting the amount frequency increases or decreases

when the arrow button is pressed to change frequency.

The default is 100 Hz. Increments can be set from 1 Hz

to 10 MHz.

(26) TEST REAR P ANEL I/O

For manufacturing use only.

(27) ENC PASSWORD To access the Encryption menu for configuration, if the

7000ENCR option is installed. For detailed

information, refer to the 7000-series High-level

Encryption Operator Manual (7000ENCR-MSOP).

(28) PTT TIMER For changing the internal PTT time-out. It can be set

from one second to one hour. Entering 0 sets it to OFF

(no time-out). The default is 300 seconds.

(29) PRINTER For automatically printing complete channel

information for the TW7000, if connected to an

external printer.

(30) CLONE RADIO For cloning another transceiver by downloading all

frequency and channel settings.

(31) GLOBAL POSITION SYSTEM

For configuring an external GPS device.

(32) CW HOLD TIME For setting the continuous wave hold time, in

milliseconds.

(33) SPLIT SITE For configuring two radios: receive only (master),

transmit only (slave). The receive radio controls the

transmitter.

• Polling is set to 1 (OFF) or 2 (ON).

• Alarm timer sets the interval in minutes between

system polling from the receiver to the transmitter.

• FP alarm activates the internal alarm when loss of

communication occurs. Set to

3-12 TW7201I-MS

1 (OFF) or 2 (ON).

Page 37

3.4.2

ALE Menu

3: Operation

• External alarm activates the external alarm when

loss of communication occurs. Set to 1 (OFF) or 2

(ON).

(34) CLARIFIER For toggling the clarifier between ON and OFF

(primarily for the RT7000 which does not have an

off/on clarifier switch on the front panel).

(35) 100 CHANS Supports the RAT1000 (1 kW tuner with 14 memory

channels) or the RAT1000C with 100 memory

channels). Selecting this feature toggles it ON or OFF.

Table 3-2 ALE Submenu - ALPHA 17

ALE

Function

Description

1 SCAN RATE

2 SCAN GRP (scan group)

3 TUNE GRP (tune group)

4 Rx SELCT (tune select)

5 SELF ADRS (self address)

6 SELF NAME

7 OTHR ADRS (other address)

8 OTHR NAME (other name)

9 MOD GRP (modify scan group)

10 SND SELCT (sound select)

11 SND ADRS (sound address)

12 SND LEN (sound length)

13 SND INT (sound interval)

14 CALL LIM (call limit)

15 SLF TMOUT (self time-out)

16 OTR TMOUT (other time-out)

17 AUTO FILL

18 LQA EXCNG (Link Quality Analysis exchange)

19 LQA DECAY (Link Quality Analysis decay)

20 BER THRSD (BER threshold)

21 GOLAY THD (Golay threshold)

22 ERR THRSD (error threshold)

TW7201I-MS 3-13

Page 38

3: Operation

Table 3-2 ALE Submenu - ALPHA 17 (continued)

ALE Submenu

Descriptions

ALE

Function

Description

23 MESSG OUT (message out)

24 NEW MESSG (new message)

25 MESSG IN (message in)

26 HANDSHAKE

27 NET ADRS (network address)

28 NET NAME (network name)

29 NET SLOT (network slot)

30 NET OTHER (network other)

31 SET TO

32 GET LQA

33 EXIT MENU

To access ALE functions, enter ALPHA 17 from the Alpha menu. Navigate

through the ALE menu in one of two ways:

• Press the desired function number, then press E or

• Use the arrow buttons to scroll through the menu to the function, then

press E.

For information on placing an ALE call, refer to Section 3.7 “Placing an ALE

Call” on page 3-22. For detailed ALE operating instructions, refer to the

7000ALE Radio Control Program Operator Manual (7000ALE-MSOP).

(1) SCAN RATE For selecting the rate at which scanning proceeds. The

arrow buttons toggle between 2 and 5 channels per

second. The number to the left of the scan rate refers to

option 1 (two seconds per channel) or option 2 (five

seconds per channel).

(2) SCAN GRP For selecting an ALE scan group (from 0 to 9). This

becomes the specified scan group when using

GRP

and (9) MOD GRP.

(3) TUNE GRP For automatically tuning an ALE scan group (from 0 to

(3) TUNE

9). This tunes all the channels in the selected scan

group.

(4) Rx SELCT For selecting a receive type:

• 1 for normal ALE receive/transmit (Rx/Tx)

• 2 for receive only (Rx ONLY)

3-14 TW7201I-MS

Page 39

3: Operation

• 3 for channel setup (CH Rx/Tx) of the RC2 software.

(5) SELF ADRS For selecting an address number to review, change, or

add for this station (from 00 to 19).

1. To enter a new self address, enter the number.

2. To change an existing address, scroll to the number,

then enter a new one.

(6) SELF NAME For entering a new self address name for the address

number selected in (5) SELF ADRS. Any existing

address name is briefly displayed.

1. Use the alpha characters on the keypad to enter from

3 to 15 characters (no spaces or punctuation).

2. To delete a name enter three periods (...).

(7) OTHR ADRS For selecting an address number to review, change or

add for a station where messages are sent (from 00 to

99).

1. To enter a new other address, enter the number.

2. To change an existing address number, scroll to the

number, then enter a new one.

(8) OTHR NAME For entering a new or different name for the other

address selected in (7) OTHR ADRS. Any existing other

address is briefly displayed.

1. Use the alpha characters on the keypad to enter from

3 to 15 characters (no spaces or punctuation).

2. To delete a name enter three periods (...).

(9) MOD GRP For modifying or defining channels to include in a scan

group.

1. Scroll to the channel to set.

2. To include a channel in a scan group, enter 1 (ON).

3. To remove a channel from a group enter 2 (OFF).

(10) SND SELCT For enabling or disabling sounding. Enter 1 for

sounding

(11) SND ADRS For setting the sounding feature to the self address

selected in

OFF and 2 for sounding ON.

(5) SELF ADRS.

(12) SND LEN For setting the length of each sounding transmission.

The recommended sounding length is 5 or 10 seconds.

(13) SND INT For setting the time intervals for sounding. Enter from

1 minute to 24 hours (0001 to 1439 minutes).

TW7201I-MS 3-15

Page 40

3: Operation

(14) CALL LIM For limiting the number of attempts made on each

channel when trying to establish an ALE link

(00 to 99).

(15) SLF TMOUT For setting the length of time this (self) transceiver

remains linked after the transmission of all outgoing

messages (000 to 600 in 15-second intervals).

(16) OTR TMOUT For setting the length of time the other radio remains

linked when there are no incoming responses (000 to

600 in 15-second intervals).

(17) AUTO FILL For enabling the transceiver to automatically add the

address of any station ALE hears to the list of approved

other addresses. Enter 1 for OFF and 2 for ON, or use

the arrows to toggle between OFF and ON.

(18) LQA EXCNG For requesting that a calling or called station exchange

a measurement of the link quality received on the other

end. Enter 1 for OFF (no request) or 2 for ON (yes

request), or use the arrows to toggle between OFF and

ON.

(19) LQA DECAY For entering the time period in which an LQA memory

cell linearly decays from a state of perfect (30) to a

state of dead (0). Selectable in periods of 0, 1, 2, 4, or 8

hours.

(20) BER THRSD For entering the acceptable bit error rate threshold

(00 to 48) for received ALE words. A threshold of 00

allows for no errors; a threshold of 48 is the maximum

amount of allowable errors. The default is 48 allowable

errors.

(21) GOLAY THD For controlling the error correcting capability threshold

(0 to 4). A value of 0 allows for no corrections while a

value of 4 is the maximum amount of corrections

allowable. The default is three allowable errors.

(22) ERR THRSD For controlling the number of errors allowed before a

word is rejected (0 to 4). A value of 0 allows for no

errors while a value of 4 is the maximum amount of

errors allowable. The default is three allowable errors.

(23) MESSG OUT For assigning a number to an outgoing message (from 0

to 9). Enter a new assigned number or an existing

number to review or change. T o enter a new or different

message, use

(24) NEW MESSG.

3-16 TW7201I-MS

Page 41

3: Operation

(24) NEW MESSG For creating a new outgoing message for the number

assigned in (23) MESSG OUT. Any existing message is

briefly displayed. Use the alpha characters on the

keypad to create a new message up to 90 characters.

(25) MESSG IN For selecting an incoming message for review (from 0

to 9). Messages are deleted when a tenth message is

received.

(26) HANDSHAKE For setting the message exchange compatibility with

other radios. Enter 1 for NO Tx, or 2 for NO Rx.

(27) NET ADRS For assigning a number to a network address.

1. Enter a new number or an existing number to review

or change.

2. To enter a new or different address name, use (28)

NET NAME

(28) NET NAME For entering a new network address for the number

.

assigned in (27) NET ADRS. The address you last

entered is briefly displayed.

1. Use the alpha characters on the keypad to enter up to

15 characters.

2. To delete a name enter three periods (...).

(29) NET SLOT For assigning network timing slots to stations for

network call responses (01 to 16).

Note: You must set (27) NET ADRS and (28) NET NAME

first.

(30) NET OTHER For indicating whether a station is part of the network.

1. Scroll to find and display the ID number of the

station.

2. Enter 1 for ON (part of the network) or 2 for OFF

(not part of the network).

(31) SET TO For selecting a Other station (address) to determine its

LQA score for each of its channels (applies to radios

with software version 701BD or later).

1. Use the up and down arrow buttons on the keypad to

scroll through the Other Addresses until the desired

other station is found. Or, enter the number using the

keypad.

2. Press E to enter the selection (the Other ID and

Other Address line goes blank).

TW7201I-MS 3-17

Page 42

3: Operation

3. Select (32) GET LQA to view the LQA score for each

channel for that address.

(32) GET LQA For viewing the LQA score of the channels for the

Other Address selected using (31) SET TO. The radio

displays the LQA score for the first channel of the

selected address. There are two score positions for each

channel. The first score position is an analysis of the

Other address by this radio with a range of 1 to 9. The

second score position is an analysis of this radio with a

possible range of 1 to 9. Scroll through the channels to

view their scores.

(33) EXIT Exits the ALE Submenu.

3.5 Programming Channels and Frequencies

The TW7000 associates a frequency , mode, clarifier status, and offset value (if

on) to each channel number. These can be different for each channel and can

be viewed whenever that channel number is entered. Once frequencies are set

to channels, you can assign channels to scan groups.

3.5.1

Selecting a

Channel and

Scrolling

3.5.2

Entering a

Channel

Frequency

Note: Scan groups are defined by channel number, not by frequency.

Changing the frequency of a channel also changes the frequency of that

channel within each scan group.

1. Press C.

2. Enter the desired 3-digit channel number.

3. Press E. The channel number with its frequency and the clarifier offset is

displayed.

4. Use the arrows on the keypad to scroll through the channel numbers.

Acceptable transceiver frequencies range from 0.100000 MHz to

30.000000 MHz in the receive mode and 1.6 MHz to 30.000000 MHz in the

transmit mode. Simplex operation uses identical RX and TX frequencies and

must be in the transmit mode range.

Enter semi-duplex (split frequency) as an RX frequency first and then as a TX

frequency. If you enter a frequency that is out of range, an error message is

displayed and the previous frequency is restored.

When you enter a frequency , always include the decimal point unless there are

all zeros after the decimal point. You do not need to enter leading or trailing

zeros.

3-18 TW7201I-MS

Page 43

3: Operation

Entering a frequency between 0.100000 MHz and 1.6 MHz in the simplex

mode makes the radio receiver-only (PTT inhibited).

Entering a

Simplex

Frequency

Entering a

Semi-duplex

Frequency

To select a channel and assign a new frequency:

1. Press C, then enter the 3-digit channel number.

2. Press E.

3. Press F, then enter the frequency in MHz, including the decimal point.

4. Press E. The channel number updates with the new frequency.

Example: To change the frequency of channel 041 from

13.330,000 MHz to 8.572,000 MHz:

1. Press C, then press 041, then E.

Display: CH FREQ

041 13.330,000 MHz

Rx

2. Press F, then press 8.572, then E.

Display: CH FREQ

041 8.572,000 MHz

Rx

To select a channel and assign a new frequency:

1. Press C, then enter the 3-digit channel number.

2. Press E, then F.

Display: xx. xxx, xxx

Rx

3. Enter the receive frequency.

4. Press F again.

Display: xx. xxx, xxx

Tx

5. Enter the transmit frequency, then press E. The LCD displays the new

channel frequency.

6. Press F to toggle between the receive and transmit frequencies.

Example: To enter an RX frequency of 21.2 MHz and a TX frequency of

29.3

MHz on channel 041:

1. Press C, then press 041, then E.

TW7201I-MS 3-19

Page 44

3: Operation

Display: CH FREQ

041 xx.xxx,xxx (where xx.xxx,xxx is the

existing channel frequency)

2. Press F, then 21.2.

Display: 041 21.200,000

Rx

3. Press F, then press 29.3, then E.

Display: 041 29.300,000

Tx

Note: If you enter any numbers after pressing F, the existing frequency

changes.

Assigning RX

Only Channels

Using the Manual

Channel

To automatically limit a channel to a receive-only operation:

1. Enter ALPHA 8.

2. To convert the channel back to a standard RX/TX channel, enter

ALPHA 18.

To change a displayed frequency:

1. Press F.

2. Use the up arrow button to increase the frequency and the down arrow

button to decrease the frequency.

3. Press E to store the new frequency in channel memory.

Note: The default frequency increment is 100 Hz for scrolling. To change

this increment, access ALPHA 25.

The manual channel allows you to create frequencies without worrying about

overwriting a frequency on another channel. This channel is defined as

channel 000. Frequency settings on the manual channel can be copied to a

fixed channel.

To copy the channel 000 data to another channel:

1. Press C, then enter the 3-digit channel number to indicate where data is

stored.

2. Press C, then E. This copies data from the manual channel to the new

channel. Data is retained in the manual channel.

3.6 Scanning (for TA/TC only)

Scan groups are arranged in the TW7000 according to number. You can have

up to 32 different scan groups in the radio at one time, each one having a

different scan group number. Each scan group can have up to 64 channels.

3-20 TW7201I-MS

Page 45

3.6.1

Creating or

Selecting a Scan

Group

3: Operation

Because the TW7000 scans channels, not frequencies, you must assign a

channel number to all desired frequencies in a scan group. Channel numbers

are not exclusive to a particular scan group; the same channel can be used in

different scan groups.

1. Do one of the following:

•If ALE is ON, press the SCAN GROUP button or select (2) SCAN GRP

from the ALE submenu.

•If ALE is OFF, press the SCAN GROUP button or ALPHA 15.

Display: SCAN GRP xxx

2. Use the arrow buttons to scroll to a scan group number for identifying the

group, or use the keypad to enter a scan group number.

3. Press E. The display briefly indicates the new scan group number.