Page 1

DATRON neo

Setup instructions

Page 2

Designation Setup instructions

Product DATRON neo

Language en

Target group Owner/operator, machine operator

DATRON AG

In den Gänsäckern 5

D-64367 Mühltal

© Copyright by DATRON AG 2016

It is not permitted to distribute or copy these operating instructions, or to utilize or communicate their contents, without the express permission of DATRON AG. All rights regarding the registration of patents, utility models or registered designs remain reserved.

Tel.: +49 - (0) 6151 - 1419 - 0

Fax: +49 - (0) 6151 - 1419 - 29

www.datron.de

Page 3

Contents

i

Contents

1 Setting up the machine...............................................................................................1-1

1.1 Transport............................................................................................................................................ 1-1

1.2 Setup site........................................................................................................................................... 1-1

1.3 Room climate.....................................................................................................................................1-2

1.4 Screen................................................................................................................................................. 1-3

2 Connecting the supply media.................................................................................... 2-1

2.1 Voltage supply...................................................................................................................................2-1

2.2 Internet connection...........................................................................................................................2-2

2.3 Network integration..........................................................................................................................2-2

2.4 Notes regarding the control computer........................................................................................... 2-4

2.5 Compressed air supply.................................................................................................................... 2-4

2.6 Cooling lubricant...............................................................................................................................2-5

2.7 Chip suction.......................................................................................................................................2-7

3 Technical data...............................................................................................................3-1

3.1 Dimensions and weight................................................................................................................... 3-1

4 Safety regulations for operating the machine.......................................................... 4-1

4.1 Dry machining...................................................................................................................................4-1

4.2 Processing with minimum-quantity cooling lubrication system.................................................. 4-2

4.3 Use of ethanol as cooling lubricant................................................................................................4-3

4.4 Safety instructions for cleaning...................................................................................................... 4-4

5 Vacuum cleaner (optional).......................................................................................... 5-1

6 Checklist........................................................................................................................6-1

Setup instructions neo

1.21

DATRON AG

i-1

Page 4

i

Contents

i-2

DATRON AG Setup instructions neo

1.21

Page 5

1 Setting up the machine

1.1 Transport

For safe transport to the setup site, the transport route must be

checked. In all areas, make sure that the width, height and loadbearing capacity are sufficient. Check the following:

■

Entrance and parking options for a truck

■

Access inside the building (stairs, doors, passageways)

■

Stairwells and elevators

■

Floor conditions and surfacing

1.2 Setup site

Setting up the machine

Setup site

1

CAUTION

CAUTION

Building damage due to impermissible load-bearing capacity!

When setting up the machine in residential buildings, the

permissible floor load must be checked by a structural engineer.

■

Here, observe the machine weight (see table in the chapter

"Dimensions and weight") and also note that the machine

generates dynamic loads of approx. 500 N with a frequency

from 0 to 5 Hz.

The machine is installed on site on a solid base. The floor of

the installation location must be sufficiently strong, rigid and

smooth. The height of the support feet is adjustable and they

are not screwed to the floor. The machine requires a minimum

all-round clearance to its surroundings to allow access to

components within the casing. See the Technical Data for the

various dimensions.

Also observe the legal regulations on occupational health and

safety and escape routes.

Risks of using cooling lubricants!

Flammable vapours may be generated when using cooling

lubricants.

■

Open flames, smoking, eating and drinking are prohibited in

the vicinity of the machine.

Setup instructions neo

1.21

■

The safety instructions of the manufacturer of the cooling

lubricant and material must be observed!

DATRON AG

1-1

Page 6

Setting up the machine

1

Room climate

1.3 Room climate

NOTE

Venting the set-up location

Air should be free of aggressive dusts and gases.

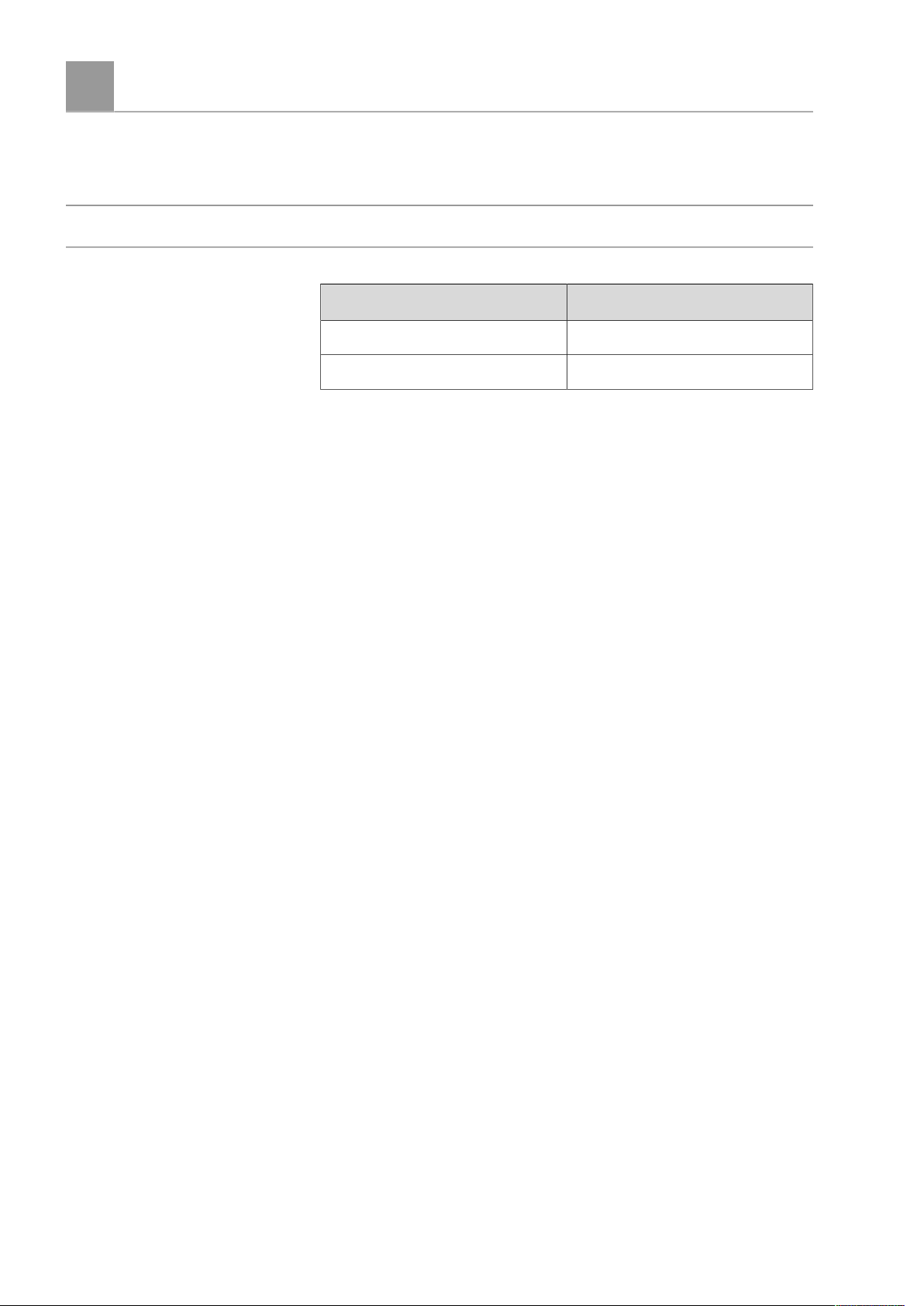

Required room climate:

Temperature 18 - 30 °C

Humidity < 65 % rel.

Make sure the room temperature is sufficient. The ideal room

temperature is 20 - 23 °C. The machine must be completely at

room temperature before commissioning. For perfect operation,

the spindles require a coolant temperature of at least 18 °C, ideal

would be 25 °C.

If there is a risk of frost during storage or transport of the DATRON

machine, the cooling water must be completely drained out of the

machine and the cooling device beforehand.

Make sure there is good ventilation in the set-up environment.

When machining materials which release harmful dusts, the dusts

which are formed must be suctioned off. Observe the statutory

regulations.

The following must be observed when the machine is operated

with cooling lubricant:

During continuous machine operation the area around the

machine must be well ventilated or an exhaust system for the

removing the cooling lubricant vapour must be installed. When

installing the room exhaust system, note whether the cooling

lubricant in use is lighter or heavier than air. Install the room

exhaust system at the top or bottom as applicable. The AGW

values (maximum workplace concentration values) of the cooling

lubricant must be below the maximum limit.

In HVAC technology, the following general empirical values are

used for the air exchange numbers (i.e. exchanged air per hour):

1-2

DATRON AG Setup instructions neo

1.21

Page 7

Setting up the machine

Screen

1

CAUTION

Location

Workshops 3 - 6

Workshops where especially high levels of fumes

develop

Laboratories 5 - 15

Garages 3 - 5

Exchanged air

per hour

10 - 18

Hearing damage dur to noise during machine operation!

At idle the noise level at the machine is < 80 dB(A).

When machining a work piece, the noise level may be > 80 dB(A).

■

Wear suitable hearing protection at noise levels above

80 dB(A).

■

Hearing protection must be available at lower noise levels.

■

Work pieces and sheet material that tend to vibrate during

machining must be clamped flat (e. g. with a vacuum plate).

1.4 Screen

Screen

CAUTION

Possible damage to the screen!

Covering the screen leads to excessive heat development.

■

Never cover the screen during operation.

■

Keep ventilation slots free.

Setup instructions neo

1.21

DATRON AG

1-3

Page 8

Setting up the machine

1

Screen

1-4

DATRON AG Setup instructions neo

1.21

Page 9

2 Connecting the supply media

Malfunctions and trip hazards

Open and loose machine connections are trip hazards and may

CAUTION

affect machine functions due to damage.

Avoid loose and open installations of machine connections.

•

Install machine connections in enclosed and fixed paths.

•

Position machines to enable optimum use of connection ports

•

in the machine housing.

Connecting the supply media

Voltage supply

2

Connection options

2.1 Voltage supply

CAUTION

Information concerning personal

protection

The machine can be connected from below, e.g. through a cable

duct in the floor.

The power supply must meet the requirements of EN 60204 to

ensure trouble-free operation of the system.

Interference in domestic environments

The machine may generate electromagnetic interference, which

may affect electrical equipment in domestic environments.

■

If necessary, employ interference suppression measures in

accordance with DIN EN 61800-3

■

If the power supply is fitted with a residual current device (RCD

or FI), the device must conform to type B.

■

The machine must be connected to a separate power circuit.

WARNING

Setup instructions neo

1.21

■

Other consumers must be separately connected.

■

Observe the local legal requirements for connection.

Danger of injury and death due to high voltage!

Work on electrical devices requires technical knowledge, otherwise

there is a risk of injury and death by electrocution.

■

Electrical work must be performed by qualified electricians.

DATRON AG

2-1

Page 10

Connecting the supply media

2

Network integration

CAUTION

Power circuit interruption

If consumers other than the DATRON machine are connected to

the same power circuit, there is risk of circuit interruption.

■

Always connect the DATRON machine to a separate power

circuit protected by an RCD (3x16 A).

■

Do not connect any other consumers to the circuit used by the

DATRON machine.

Data

2.2 Internet connection

2.3 Network integration

Fig. 2-1: Voltage supply connection 3 x 400 V

Voltage

Frequency

Power consumption with

An Internet connection for the control computer integrated in

the machine is absolutely necessary to be able to make use of

remote maintenance. This is the only way DATRON can access the

machine control if support is needed, making immediate analysis

and help possible.

Integration of the DATRON machine into the customer's network

happens at the risk and responsibility of the customer.

3 x 400 V /16 A

50 Hz / 60 Hz

3.5 kW

2-2

If you have any questions about the network integration, consult

an IT specialist who can consider the situation at your site.

DATRON AG Setup instructions neo

1.21

Page 11

Connecting the supply media

Network integration

2

Data exchange

Fig. 2-2: Integration of the DATRON computer in a company

network

1

Control computer of the DATRON machine

2

USB port at the control computer

3

Hardware firewall

4

Company network

The establishment of a network connection (internet, in-house data

exchange) must be made without changing the configuration of

the control computer (for instance, integration into a domain).

For network integration, DATRON recommends using a hardware

firewall between the control computer and the company network

(see Fig. 2-2).

Only virus-tested media may be connected to the USB port of the

control computer.

Data is exchanged with program administration sing a USB stick.

Setup instructions neo

1.21

DATRON AG

2-3

Page 12

Connecting the supply media

2

Compressed air supply

2.4 Notes regarding the control computer

Observe the following points to ensure the process reliability of

the machining system and quick help in the event repairs are

needed:

■

The DATRON machine may only be operated with the control

components included in delivery. These are an integral part of

the system.

■

Do not install any other applications, and also no virus

scanners on the control components, which are not expressly

approved of by DATRON. Additionally installed applications

can lead to non-reproducible, sporadically occurring errors.

2.5 Compressed air supply

Required air purity

NOTE

The compressed air must meet the requirements of the spindle

manufacturer (see the original spindle operating instructions).

It must be dry, clean and oil-free. Otherwise, the components

through which the air flows could be damaged (especially the

spindle).

Solid contaminants

Water content

Total oil content

DATRON urgently recommends that an air treatment system be

connected in front of the system!

Any air treatment system available on the market can be used

which fulfils the above requirements. Our commissioning

personnel is instructed to use a suitable air dryer when there is

moisture in the compressed air. This is available for purchase.

Class 3

Class 4 Max. pressure dew point +3 °C

Class 3 Max. oil content 1 mg/m³

Max. particle size 5 µm

max. Particle content 5 mg/m³

2-4

If the machine is operated with insufficiently pure compressed air,

the warranty for the spindle and components through which air

flows is invalid.

DATRON AG Setup instructions neo

1.21

Page 13

Data

Connecting the supply media

Cooling lubricant

Fig. 2-3: Compressed air connection 1/2" rapid action hose

coupling

2

Compressor

2.6 Cooling lubricant

Required pressure

Connection

Compressed air

consumption

Design your compressed air supply so that there is a continuous

supply available to the DATRON machine. Depending on the

type of compressor, the capacity must lie much higher than the

consumption of the machine and the supply buffered via a boiler,

so that the compressor has sufficient cooling-off time available.

Please have the manufacturer help you with the design of the

compressor.

Select a suitable cooling lubricant depending on the application.

In the following cases, ethanol is not permissible as a cooling

lubricant:

7 to 10 bar

1/2" rapid action hose coupling (NW 7.2 mm)

max. 300 l/min Machine

approx. 100 l/min Compressed air gun

WARNING

Setup instructions neo

1.21

■

Ethanol must not be used as a cooling lubricant when

machining steel or other metals that generate sparks during

machining. Danger of burns due to spark formation! Use a

different suitable cooling lubricant (e.g. fatty alcohol).

■

Ethanol is not permitted as a cooling lubricant when suctioning

chips. Danger of explosion in the vacuum cleaner!

DATRON AG

2-5

Page 14

Connecting the supply media

2

Cooling lubricant

When machining non-ferrous metals, use the following cooling

lubricant for perfect operation and the best machining results:

Ethanol (99%, denatured)

Ethyl alcohol 642

EEC designation 200-578-6 (EINECS)

Ethanol can be purchased tax free without any formalities when

the following denaturants are involved: Methyl ethyl ketone,

shellac, pininic colophonium, toluol or cyclohexane.

Germany Austria

Impermissible cooling lubricants

NOTE

BCD Chemie GmbH

Frankfurt Office

Carl-Benz Strasse 4-6

D-60314 Frankfurt am Main

Tel.: +49 - (0) 69 - 40101 - 0

Fax.: +49 - (0) 69 - 425994

Frankfurt@bcd-chemie.de

LACTAN

Vertriebsgesellschaft m.b.H. & Co KG

c/o Mr Reibenschuh

Puchstrasse 85

A-8020 Graz

Tel.: +43 - (0) 316 - 23692 - 12

Fax.: +43 - (0) 316 - 323692 - 19

reinhard.reibenschuh@lactan.at

Tab. 2-1: Examples for ethanol suppliers

Do not use any drilling emulsions, cooling lubricants with high

solid content or such which tend to flocculate (milky emulsion).

The DATRON machine is not designed for such cooling lubricants

and potential material damage could result. If this is not observed,

it will invalidate the warranty.

Export restriction for initial filling of the machine with cooling

lubricant and coolant for spindle cooling unit.

DATRON machines are not filled with cooling lubricant when

exported to countries outside the European Union. In this case, the

customer must procure the suitable cooling lubricant.

Check your order confirmation.

2-6

DATRON approves the following products for use without

reservation:

Coolant for spindle cooling unit: Antifrogen-N with a water

•

content of 25 % - max. 27 %

cooling lubricant for workpiece machining ProCut 200,

•

ProCut 56 and ProCut 56-2

If in doubt, consult DATRON.

DATRON AG Setup instructions neo

1.21

Page 15

2.7 Chip suction

Connecting the supply media

Chip suction

Only use suctioning systems which are permitted for the material

to be machined.

2

Setup instructions neo

1.21

DATRON AG

2-7

Page 16

Connecting the supply media

2

Chip suction

2-8

DATRON AG Setup instructions neo

1.21

Page 17

3 Technical data

3.1 Dimensions and weight

Technical data

Dimensions and weight

3

CNC base system

Machine

Distance

Installation width

Operating terminal

Support feet

Chip tray

Machining traverse paths

DATRON neo

Weight approx. 700 kg

Width (with screen)/depth approx. 1300/1290

Height 1880

Width with flaps open approx. 2275

Depth with flaps open approx. 2310

Free space above the machine at least 400

Free space right of the machine at least 1000

without packaging, without terminal 805

width/depth 350/570

Distance 700/980

Extension length right 900

Traverse path (X/Y/Z) 520/420/230

Dimensions (mm)

Portal access

Transport dimensions

when packed in wrapping

on the pallet (terminal

mounted)

Height 175

width/depth/height 980/1480/2160

Setup instructions neo

1.21

DATRON AG

3-1

Page 18

Technical data

400

2275

2310

348

60

1087

570

1880

1296

980

800

63 157

1290

805

700

109

587

1000

492

52 52

265

3

Dimensions and weight

Fig. 3-1: Machine dimensions

3-2

DATRON AG Setup instructions neo

1.21

Page 19

Safety regulations for operating the machine

4 Safety regulations for operating the machine

The following points are an excerpt from the operating

instructions. Please observe the complete operating instructions

when operating the machine.

4.1 Dry machining

In dry machining, the material is machined without the cooling

spray function. The released dusts must be suctioned by a

deduster.

Damage to health due to harmful dusts!

When dry machining materials, dusts which are harmful to health

WARNING

can be released.

■

For this, observe the information on the safety data sheet of the

respective material.

Dry machining

4

CAUTION

■

In the case of harmful dusts, you must use a suitable vacuum

cleaner.

Machine damage due to released dusts!

During machining, the dusts that are released have to be suctioned

off by a suitable vacuum cleaner.

■

Check the compatibility of the vacuum cleaner and the material

to be machined.

Setup instructions neo

1.21

DATRON AG

4-1

Page 20

Safety regulations for operating the machine

4

Processing with minimum-quantity cooling lubrication system

4.2 Processing with minimum-quantity cooling lubrication system

Hazard posed by using cooling lubricants!

When using cooling lubricants which have not been explicitly

CAUTION

recommended by DATRON, observe the manufacturer

specifications with regard to fire and explosion hazards. If in

doubt, consult a safety professional.

■

Canisters with cooling lubricants must be labelled.

■

Only use the cooling lubricants recommended by DATRON,

since these are optimally suited for the system. Nonrecommended cooling lubricants can lead to poor results and

damage of the machine.

■

When using cooling lubricants, make sure there is sufficient

ventilation at the setup site.

CAUTION

■

Observe the safety data sheet of the used cooling lubricant.

Danger of blockage in the vacuum cleaner!

Suctioning is not allowed when machining with cooling lubricants.

■

Switch the vacuum cleaner off beforehand.

4-2

DATRON AG Setup instructions neo

1.21

Page 21

Safety regulations for operating the machine

4.3 Use of ethanol as cooling lubricant

When using ethanol as a cooling lubricant, observe the following

safety information:

Use of ethanol as cooling lubricant

4

Ethanol

WARNING

Chip suctioning

NOTE

Fire hazard due to spark formation!

■

When machining steel or other metals where sparks are

formed during machining, pure ethanol may not be used as a

coolant/lubricant. Use another suitable coolant/lubricant (e.g.

fatty alcohol).

■

If ethanol is being used as a coolant: No more than 5 l of

ethanol may be stored in a flame-resistant canister for

operational use at the machine.

■

Do not place any objects on the top of the machine. If the air

vent at the top is covered, there is a danger that a flammable

atmosphere may form inside the machine.

Only use as little cooling lubricant as possible and as much as

necessary: Ethanol max. 500 ml/h!

Cleaning

WARNING

Danger of explosion in the vacuum cleaner!

■

Suctioning chips is not allowed when ethanol is being used as

a coolant.

■

Only use extraction equipment which is suitable for extracting

swarf from the material to be machined.

When you clean the machine, wait until the ethanol has

evaporated and use a vacuum cleaner which is free of ignition

sources.

Setup instructions neo

1.21

DATRON AG

4-3

Page 22

Safety regulations for operating the machine

4

Safety instructions for cleaning

4.4 Safety instructions for cleaning

Health hazard due to milling scrap!

When cleaning the machine and when in contact with milling

scrap, observe the information in the safety data sheet of the

WARNING

respective material.

■

When carrying out cleaning work and when in contact with

milling scrap, wear protective gloves, protective goggles and

light breathing protection, especially when you come in contact

with harmful dusts or with coolants/lubricants.

Empty the chip tray regularly, no later than when it is more

than half-full. Observe the information regarding cleaning in the

operating instructions of the machine.

4-4

DATRON AG Setup instructions neo

1.21

Page 23

5 Vacuum cleaner (optional)

Vacuum cleaner (optional)

5

Description

Connection

The vacuum cleaner can be moved and is installed ready to use. A

separate power circuit is required for operation.

The vacuum cleaner is connected to the machine for suction with

the hose included with it.

The vacuum cleaner is actuated by the machine software after

connection with a cable included with it.

Technical Data

Setup instructions neo

1.21

Vacuum cleaner

Dimensions LxWxH (mm)

Weight

Power

Voltage

Negative pressure

Air output max.

Sound level

Volume

Filter category

DATRON AG

Technical Data

544 x 456 x 600

40 kg

1.1 kW

100-230V

2100 Pa

285 m³/h

<66 dB(A)

18 l

H10

5-1

Page 24

Vacuum cleaner (optional)

5

5-2

DATRON AG Setup instructions neo

1.21

Page 25

Checklist

6

6 Checklist

The following checklist provides an overview and summary of all necessary preparatory work for

setting up a DATRON machine. The items point out the individual steps. For exact details, please refer

to the respective chapter. Using this checklist, please check whether everything is ready for bringing

the machines in to you.

If you should have any further questions regarding this checklist, we will be happy to answer them.

yes No Checklist for machine setup

Are the access routes to the setup site free of obstacles? Is there a freight elevator, and

is this suitable for the weight of the machine (see Chapter 1, "Setting up the machine")?

Is there enough room for setup and the surrounding area and is the setup site suitable

for the weight of the machine (see Chapter 1, "Setting up the machine" and Chapter 3,

"Technical data")?

Can the required room climate be complied with, and is there sufficient ventilation (see

Chapter 1, "Setting up the machine")?

Is there a suitable Internet connection available for remote maintenance (see

Is the compressed air connection with the corresponding air treatment available (see

Is a cooling lubricant appropriate for the application required (see Chapter 2.6, "Cooling

If a compact deduster is to be used, is there a designated power connection for this (see

Is there a suitable central suction system? If so: What kind of suction nozzle is required?

If your country has import restrictions on hazardous liquids, such as oil, cooling lubri-

Is the required voltage supply available (see Chapter 2.1, "Voltage supply")?

Chapter 2.2, "Internet connection")?

Is a suitable network available (see Chapter 2.3, "Network integration")?

Chapter 2.5, "Compressed air supply")?

lubricant")?

Chapter , "Compact deduster (optional)")?

Suction nozzle: _________________________________

cants and coolant, the method of supply must be clarified on site.

Setup instructions neo

1.21

DATRON AG

6-1

Loading...

Loading...