Page 1

USER'S

HANDBOOK

~

I

PARTNERTECH

SE-597

80

Åtvidaberg,

~--------INSTRUMENTS--~

Sweden

(

4705

1

c:latri

AUTOCAL MULTIFUNCTION 1

CALIBRATOR _

1 I

Page 2

USER'S

HANDBOOK

for

THE DATRON.4705

AUTOCAL

MUL TIFUNCTION

CALIBRATOR

860064

· Due

to

our

policy

of

contlnuously updatlng

speclflcatlon, components and clrcult design

matched

© 1986 Datron Instruments

to

your Instrument serlal number are avallable on request.

l11ue 1 (November 1988)

our

products, thls handbook may contaln minor dlfferences In

to

the Instrument actually supplled. Amendment.sheets preclsely

Page 3

..

DANGIR

HIGH VOLTAGE

THIS

...

INSTRUMENT

OF DELIVERING

A

lETHAl

.~

llECTRIC

· ·

..

, < terminals

THIS CAN KILL !

IS CAPABLE

SHOCK

FRONT

Full Output Voltage.

Guard terminal is

sensitive

voltage

or · REAR

carry

to

over-

the

!

..

Unless

it

DO

I+

I-

and

It

your

you

is

safe

NOT

Hi

terminals

NGIR

can

instrument!

are sure

damage

to

do so,

TOUCH

or

Lo leads

that

the

·

i,

Page 4

CONTENTS

SECTION 1 THE DATRON

Introduction ·

Standard and Optional F acilities

SAFETY

Optional F acilities

Accessories

Additional Documentation

Principles of Operation

4705

AUTOCAL

MULTIFUNCTION

CALIBRATOR.

Page

1-1

1-1

1-2

1-3

;.:

,_.\,

1-3

1

..

3,-

1-3

1-4

SECTION 2 INSTALLATION

U npacking and Inspection

. Preparation for Operation

Bench Mounting

Rack Mounting

Connectors and Pin Designations

SECTION 3 OPE.RATING CONTROLS

· Front

Front Panel Keys

Power Switch

OUTPUT

FUNCTION

OUTPUT

OUTPUT

Frequency

MODE

I+,

Rear Panel

SECTION 4

Preliminaries

Limiting Characteristics

SAFETY

Interconnections

Typical Lead Connections

General Sequence of Operations

Display Messages

Operating Routines

Test Key

-Test Sequence

W amings and Messages

Pan.el

Switching

Keys

RANGE

Display and t I f Keys

Selection Keys

1-, Hi, Lo, Guard and Ground Terminals

USING

DC

Voltage Outputs

AC Voltage Outputs

DC

Current

AC Current

Resistance

Additional F acilities

Frequency Store

'Spec' Mode

'Error' and 'Offset' Modes

Combining Offset and Error Modes

Keys _ .

THE DATRON

4705

2-1

2-1

2-1

2-2

2-2

2-3

3-1

J-1

3-1

3-1

3-2

3-3

3-3

3-4

3-5

3-8

3-9

3-11

4-1

4-1

4-1

4-1

4-1

4-4

4-6

4-6

4-7

4-7

4-7

4-9

4-9

4-9

4-10

4-10

4-10

4-12

4-16

4-16

4-17

4-20

ii

Page 5

SECTION 5 SYSTEMS APPLICATION

lntroduction

lnterface Capability

Bus Addresses

Interconnections

Typical System

Using the 4705 in a System

Programming Instructions

Programming of Operational Functions

Programming of Bus Transmissions

of

, Activation

Commands

Multiple Commands

Operational Sequence Guidelines

VIA

THE IEEE

488

INTERFACE

5-1

5-1

5-1

5-2

5-2

5-3

5-4

5-5

5-8

5-10

5-14

5-14

5-15

SECTION 6 SPECIFICATIONS

General

DC

Voltage

AC

Voltage

Voltage/Frequency Constraints

Capacitive Loading Constraints

DC

Current ,

AC

Current

Resistance

SECTION 7 SPECIFICATION VERIFICATION

Introduction

DC

Specification Verification

Equipment Requirements

of

Notes on the Use

the Null Detector

Specification Verification Report Sheet

Verification Procedures

DC

4705

4 705

Voltage Performance-

DC

Current Performance

4 705 Resistance Performance

Model 4705 Verification Report Sheet.

AC

Specification Verification

RSl

Choice of Verification Method

Parameters to be Verified

Summary of Equipment Requirements

Summary of Verification Procedures

Specification Verification Procedures

AC

Voltage Verification Procedure

Millivolts (LF) Verification Procedure

(HF)

Millivolts

AC

Current Verification Procedure

Verification Procedure

Model 4 705 Verification Report Sheet. RS2

6-1

6-1

6-2

6-4

6-6

6-7

6-8

6-1

6-1

7-1

7-1

7-1

7-1

7-2

7-2

7-3

7-3

7-4

7-5

7-7

7-9

7-9

7-9

7-9

7-10

7-11

7-12

7-13

7-14

7-18

7-19

1.

APPENDICES TO SECTION

1.

Verification Procedures

2.

Alternative Millivolt Verification Procedure

3.

Alternative AC Current Verification Procedure using Calibrated Standard AC Shunts

7:

For

4. Total Tolerance Limit Calculations

5.

U ncertainty and Traceability

6.

General Procedural Information

7.

Harmonic Distortion Measurement

Users with Fixed

DC

Voltage Standards

7-21

7-27

7-29

7-31

7-33

7-35

7-37

iii

Page 6

SECTION 8 ROUTINE

The 4705 Autocal Feature

DC

,Calibration

Autocal A vailability

Zero Calibration

Equipment Required for

Interconnections

DC

Calibration Sequence

4705

DC

Voltage Calibration

4705

DC

Current Calibration

4 705 Resistance Calibration

AC

Calibration

AC

Calibration Sequence

4705

AC

Voltage Calibration

4705

AC

Millivolts (LF) Calibration (lmV-lO0mV)·

4705

AC

Millivolts

4705

AC

Current. Calibration

AUiOCALIBRATION

DC

Calibration

(1

V-lO00V)

(HF)

Calibration (lmV-lO0mV)

(lmA-lA)

8-1

8-1

8-2

8-3

8-3

8-3

8-4

8-4

8-5

8-8

8-10

8-12

8-13

8-15

8-17

8-18

8-22

APPENDIX

4705

TO SECTION 8:

AC

Current Calibration (lO0µA -

lA)

8-23

Inside Rear Cover

DATRON SALES

Note

to

Readers

This handbook has been designed for you to get the best use from your

AND

SERVICE REPRESENTATIVES

WORLDWIDE

4 705. The sections are put together in a

sequence flowing logically from one subject to another, so that understanding increases as the text is read

is

naturally from front to rear. Here

Sect

1 . Introduction and· a brief account of the interna! design.

Sect

2. Physical connections and mounting - getting it installed.

Sect

3.

A brief scan of the available controls - where they are and what they do.

Sect

4. The correct procedures for making the 4 705 perform for you.

I

Sect

5. How your 4705 can operate within an

an alternative ( explanatory !) version of the Section Titles:

IEEE

488

system-

the device dependent codes you will need

to use.

Sect

6. Specifications - what accuracy you can expect to get from your instrument.

Sect

7. Verification that your 4705 matches the high specification it had when it left the factory.

Sect

8.

How to restore your 4705 to its original specification after it has suffered the ravages of time ·and

temperature.

We are confident that your

will

use this handbook to obtain maximum benefit from its many facilities.

4 705 will give you many years of accurate and reliable service, and hope that you

iv

Page 7

SECTION 1

THE DATRON

AUTOCAL

MULTIFUNCTION

4705

CALIBRATOR

I

General

View

of Datron

4705

Autocal Multifunction Calibrator

lntroduction

The Datron 4 705 Autocal Multifunction Calibrator

It

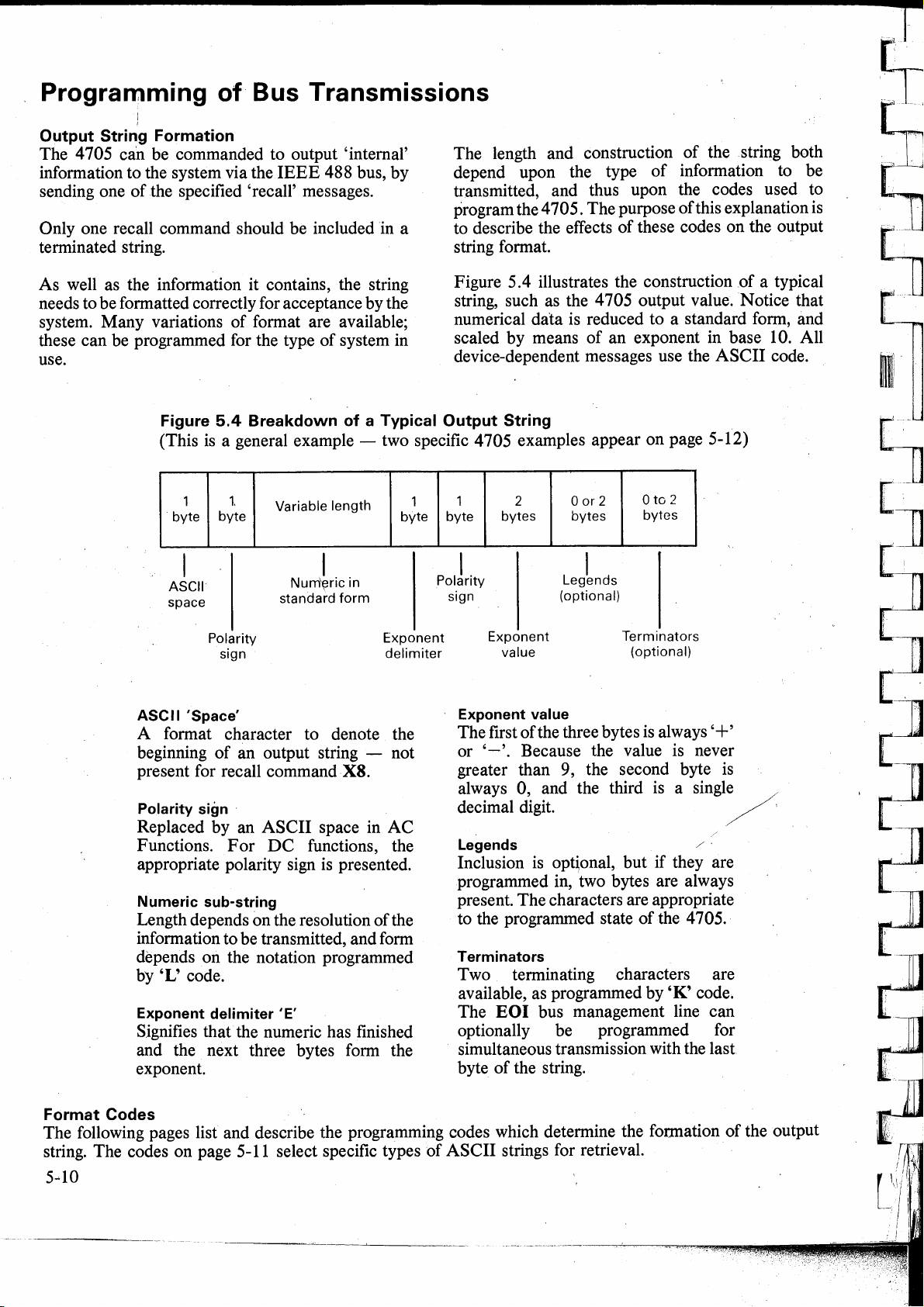

is

and full systems capability.

Current and Resistance functions in a single unit.

The basic instrument includes both

calibration sources.

The 4 705 incorporates a reference module containing precision temperature-compensation elements,,

maintaining a high accuracy specification over the ambient temperature range of 23 °C

stability

'Autocal' feature ensures that its 24-hour specifications are usable; not merely figures

The 4 705 uses a microprocessor

such as palibration

remote programming capability, allowing programmed calibration

is

achieved by use

of

of

hi~-quality digital multimeters. The

characterized by

DC

Voltage,

super-selected reference components and ultra-stab

for'

control management, simplifying its use in complex manual operations,

is

a high-precision calibrator which features high stability

·a

wide-range coverage

AC

Voltage,

DC

of

DC

Current,

Voltage,

AC

Current and Resistance

AC

Voltage,

+ 10°C. A high level

le

gain-defining resistors. The

of

merit.

IEEE

488 interface provides a comprehensive

of

the 4705 itself.

DC

of

1-1

----.

-

--

____________

___;

____

_

Page 8

Standard and Optional Facilities

I

DC.

Voltage Ranges

The instrument provides

facilities in eight decade ranges from +

+1100V.

on the + 1 000V range, when the output is limited to

1100V.

100% overrange

DC

Voltage calibration

100µ,

is

incorporated, except

V to

Resolution and Accuracy

The maximum resolution

facility for displaying the specified accuracy of any

output voltage. The 4705 specification

Section

6.

is

6½ digits with a unique

is

in

AC Voltage Ranges

The instrument provides

facilities in seven decade ranges from. 1 m V to

1100V.

the 1000V range (see page 3-6), when the output is

limited to 1100V.

DC Current Ranges

The instrument can be used to calibrate

in

AC Current Ranges

The instrument can be used to calibrate

in five decade ranges from 100µ,A to 1 A.

Resistance

The instrument can be used to calibrate resistance in

eight decade ranges from

l00%

five

decade ranges from 100µ,A to 1 A.

overrange

_AC

Voltage calibration

is

incorporated, except on

DC

Current

AC

Current

l0ohm

to l00Mohm.

Resolution and Accuracy

The maximum resolution

facility for displaying the specified accuracy of any

output voltage. The 4 705 specification

Section

Resolution and Accuracy

The maximum resolution

facility for displaying the specified accuracy of

output current. The 4 705 specification

Section

Resolution and Accuracy

The maximum resolution

facility for displaying the specified accuracy of

output current. The 4 705 specification is in

Section

Resolution and Accuracy

The maximum resolution

facility for displaying the specified accuracy of any

output resistance. The 4 705 specification is in

Section

6.-

6.

6.

6.

is

5 ½ digits with a unique

is

5 ½ digits with a unique

is

5 ½ digits with a unique

is

6½

digits with a unique

is

is

ih

in

Frequency

The output frequency

l0Hz

to

l00kHz

at a resolution

Any five frequency values within the range

instrument can be stored in volatile memory.

in four overlapping decade ranges,

of

1 %

of

the 4 705 extends from

of

nominal Frequency Range.

of

the

Autocal

All Datron A

make the removal of the covers for calibration

unnecessary, as

and functions can be carried out from the front panel

or over the

Accidental or unauthorized use of the calibration

routine

instrument rear panel. The procedure for calibrating

this instrument

1-2

UTOCAL

full

IEEE

is

prevented by a key-operated switch on the

is

instruments are designed to

routine calibration of all ranges

488 bus.

coptained in Section

8.

Output Deviation ,

A user may deviate the output voltage from the

output display value by introducing a gain 'Error'

within the general range

DC

functions, the output may be 'offset' by up to +

2%

of the range in use, or 200µV, whichever

greater.

+ 10%. Additionally, for

is

Remote Sense

The specified output voltage may be sensed at the

load, using 4-wire connections. Remote or Local

is

Sense

selectable from the front panel.

Remote Guard

This facility aliows the instrument' s interna! guard

shields to be externally connected.

Page 9

--------

.....

111!!!!1!!!!!!~~~~~~~~~========··-·=---=·-·=···=······=-·

=····=··-=··-··--··--···--·-··-··--··

··--

..

·····

--·--•·······---'------__:c...:...:~-

Self-test

· On power-up, the intemal calibration memory

automatically checked.

is

off and not under remote control, a user may .

conduct a sequenced test of the displays, keyboard,

safety circuitry and Reset function.

Message

Messages to the user are presented on the

display:

The two main groups are:

Fail

An intemal fault condition has been detected.

Error

A user has selected a

instrument' s capability.

At

any time when the output

Readout

task

which

MODE

is

outside the

Systems Use

The instrument can form part

of the

method of connecting to the system controller and

the command codes are described in Section

IEEE

488 standard digital interface. The

of

a system by means

5.

SAFETY

is

Optional Facilities ·

The available options for the 4 705 are

Option 42: Rear output terminals ( as a factory-

fitted alternative to front panel

terminals).

NB: The rear 'output option

recommended for best performance in

calibrating high bandwidth, low level

instruments.

Option 90: Rack-mounting kit.

as

follows:

is

not

Accessories

The instrument

accessories:

Description

Power Cable

Set of Calibration keys

U ser' s Handbook

Calibration and Servicing Handbook

(2 volumes) · (Volume

In addition the following accessories are available

for use with the 4705 instrument:

is

supplied with the following

Part Number

1)

(Volume 2) 850065

920012

700068

850054

850063

For

protection of the user, safety trip circuits are

incorporated to switch the

event of instrument faihires which might generate

dangerous output voltages.

UNDER

USERS

SENSE

THEY ARE FIRST SATISFIED THAT· NO

DANGEROUS

NO CIRCUMSTANCES ·

TOUCH ANY

OR

GUARD

VOLTAGE IS PRESENT.

OUTPUT

OF

TERMINALS

OFF,

THE OU'IPUT,

in the

SHOULD

UNLESS

Description Part Number

RMK Rack-mounting kit (Option 90) 440094

Special Lead Kit 440070

Additional Documentation

The Calibration and Servicing Handbook contains

information required to adjust and service the 4705

It

instrument.

circuits, trouble-shooting and calibration

procedures, parts lists, layout drawings and circuit

diagrams.

contains detailed descriptions of the

1-3

Page 10

Princ.iples of Operation

----

Galibration

Memory

..._

__

__,~

Front Panel Keys

->

Local Gontrol

lnputs

Gal

.-

Run

Micro-

processor

Gontrol

System

,.

i---.

Glock

&

Gounter

+

Precsion

Electronic

Divider

I

I

I

AG

DG

Master

Reference

Voltage

+

Voltage Ranging Gontrol

Frequency

Synthesizer

-

-

&

Oscillator

Output

Error Feedback

AG

Reference

~

Generator

,__

Output and Terminal Switching Gontrol

___.

i--.

Voltage

Gontrolled

Amplifier

Amplitude Sensing

Gomparator

"

AG/AG

f----+-

1..--

Ranging

and

Output

Switching

'

-

I+

~

-

I-

...

-

-

-

Hi

Lo

>AGV

'

....,

1+

I

I-

-

i

....,

Hi

I

Lo

-

....,

Guard

Remote Gontrol

lnputs/Outputs

__

0.;:;...._

IEEE

488

lnterface

..._

__

I\.

DG

I

I

,...___

Out Guard

·

_,

_.,

In

Guard

DG

Reference

Voltage

Gurrent Ranging Gontrol

I

Resistance Ranging Gontrol

I

L--------------------------------------------

Voltage Ranging Gontrol

Gurrent

AG

Gurrent Reference Voltage

~[

Voltage I

lo

Guri'ent

~

Gonvertor

1

Gurrent and Resistance

1

-

.

Ranging

and

Sensing

Gurrent

- r

~J

Ranging

/ r

r ..

_

· I Resistors

Prec1s1on

,Il

f T

':

I+

.

I-

"P'

-

.

"P'

-

.

Hi

Lo

AGI

I+

I-

I•

~~

I-

-

l

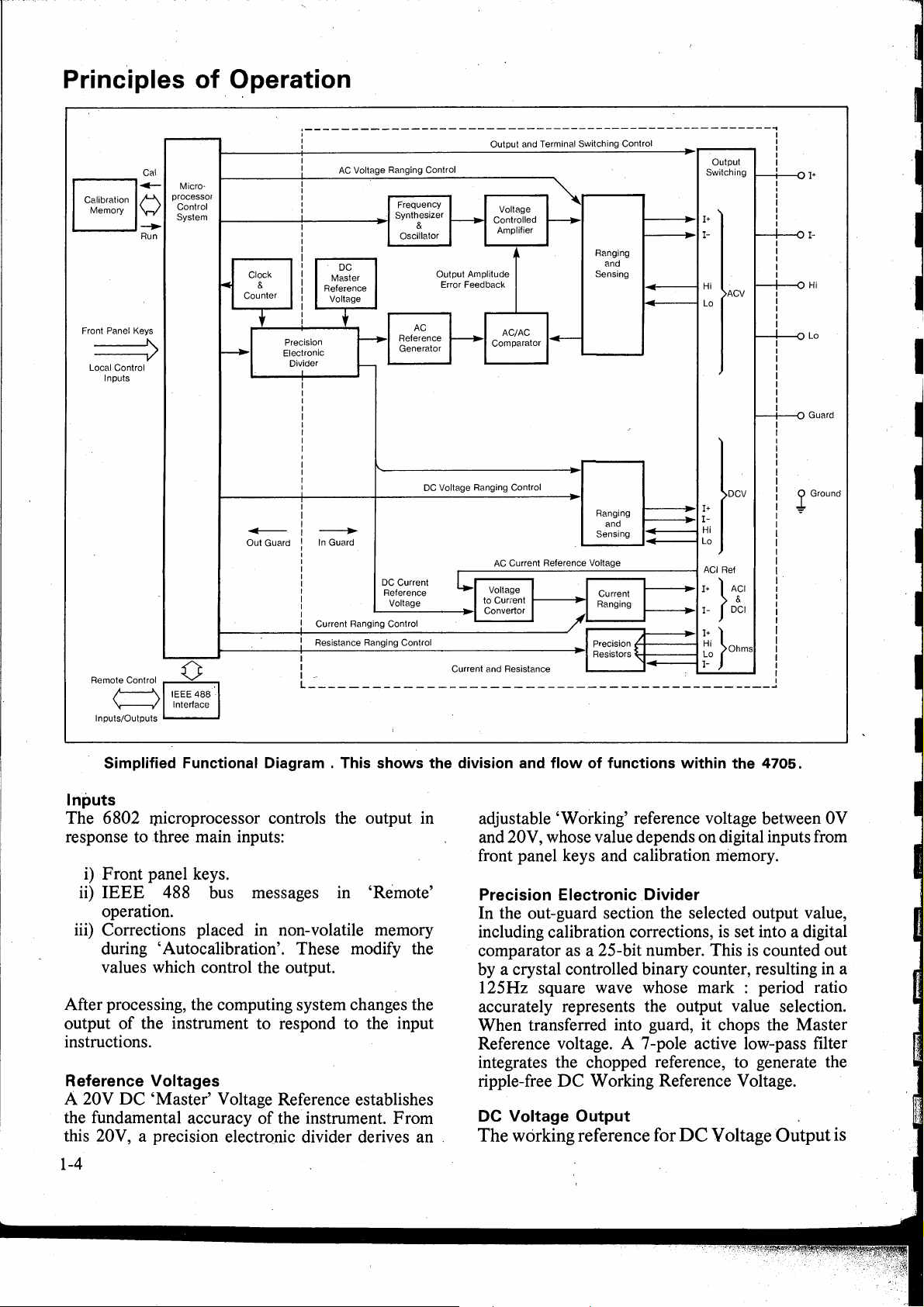

Simplified Functional Diagram . This shows the division and flow of functions within the 4705.

lnputs

The 6802 microprocessor controls the output in

response to three main inputs:

adjustable 'Working' reference voltage between 0V

and 20V, whose value depends on digital inputs from

front panel keys and calibration rriemory.

i)

Front panel keys.

ii)

IEEE

operation.

iii) Corrections placed in non-volatile memory

<luring

values which control the output.

488 bus messages in 'Remote'

'Autocalibration'. The se modify the

Precision Electronic .Divider

In the out-guard section the selected output value,

including calibration corrections,

comparator as a 25-bit number. This

by a crystal controlled binary counter, resulting

125Hz square wave whose mark : period ratio

After processing, the computing system changes the

output

of

the instrument to respond to the input

instructions.

accurately represents the output value selection.

When transferred into guard, it chops the Master

Reference voltage. A 7-pole active low-pass filter

integrates the chopped reference, to generate the

Reference Voltages

A 20V

the fundamental accuracy

DC

'Master' Voltage Reference establishes

of

the instrument. From

this 20V, a precision electronic divider derives an

ripple-free

DC

Working Reference Voltage.

DC Voltage Output

The

working reference for

DC

V oltage

)DGV

%

Ref

} ·i'

DGI

}

Ohms

is

set into a digital

is

counted out

Output

Ground

in

a

is

1-4

Page 11

a stable

resolution between O and

DC Voltage Ranging

Low Voltage Ranges

, range

(+19.99999

working reference. The 1 V and 1

achieved

The 1

DC

voltage, accurately variable

+ 20V.

(100µ.V-

of

the 4 705

is

Full Scale), derived directly from the

by

attenuation:

00m

V range attenuator is also used for 1

10V

+ 1 0V Full Range

00m

at

high

FR).

The

basic

V ranges are

Om

1 m V and 100 µV ranges, and the digital input to the

precision divider is scaled to provide the correct

working reference values:

Range

l0mV

lmV

l00µV

High Voltage Ranges

The 1 00V range

working reference.

AC

up

transformation.

W orking reference values

-2V

- + 2V

-200mV

-20mV

(1

00V

is

a direct amplification

The

1000V range employs step-

- + 200mV

- + 20mV

and 1

000V)

of

V,

the

Quadrature Oscillator

The oscillator' s output frequency

demand, between

l0Hz

and

is

l00kHz,

set close to any

by selectingthe

RC time constants ofits dual integrators; and then by

correcting

to

the actual demand by phasecomparison with the output from, the synthesizer.

The output sinewave purity and constant amplitude

are precisely defined by a sophisticated control loop,

and the RMS value

of

the sinewave is adjusted to be

roughly proportional to the demanded output voltage

data

or current. Timing

synchronize the actions

Generator and

Voltage-Controlled Amplifier (VCA}

AC/

is output from the source to

of

the A C Reference

AC

Comparator.

This has variable gain, amplifying the output from

the Sinewave Source and providing a buffered drive

to the output circuits. Its gain is determined by the

measured difference between the

sensed calibrator output and the

the

VCA

provides the correcti'ng fine adjustment för

values

AC

Reference; so

of

the

RMS

the output amplitude loop.

AC Voltage Ranging

Output Switching.

In

addition to switching

between functions, the output switching circuits

isolate terminals on

Sense and

AC Voltage Output

Guard

The working reference for

stable

DC

voltage, accurately variable at high

resolution between

AC Reference Generator

· The higher accuracy

AC/DC)

is exploited

O UTPUT O FF. Remote/Local

switching is incorporated.

AC

Voltage Output

+ 0.1 V and + 2V

of

AC/

AC

by

converting the

DC.

comparison ( over

DC

Working

Reference into a stepped waveform whose

characteristics match those

of

amplitude

controlled by the

Sinewave Source

Frequency Synthesizer

From

the frequency value set into the

FREQUENCY

this 'Quasi-sinewave'

DC

W orking Reference value.

display, the processor controls the

of

a sinewave. The

is

precisely

MODE/

synthesizer using an encoded 9-bit command. The

synthesizer translates the command into a pulse

train at a crystal-derived frequency between 240kHz

for,

and 4MHz, to be divided down

use as phase-

reference for the Quadrature Oscillator.

N.B.

lf

required, the Frequency Synthesizer, can

toa

be locked

customer's

1MHz

or

10MHz

frequency, input via J53 on the rear panel.

isa

1V

Range

This is the basic

the

AC

working reference is variable between 0.1 V

and 2V RM~, it is compared in

sensed output.

directly to the output

1

00mV, 1 Om

The 1 V Buff er output is reduced

AC

The

1 V Buffer output

V and 1

voltage range

I+

and I - terminals.

mV

Ranges

of

the 4705.

1:

1 ratio with the

is

thus passed

by

precision

As

attenuators before being connected to the terminals, ,

the level being sensed before attenuation.

1

0V, 1 00V

The 1 V Buffer output is amplified on each

ranges. A separate amplifier is provided for the 1

range, the output sense signal being obtained

and 1

000V

Ranges

of

these

0V

at

the

terminals and attenuated before coinparison with the

reference. A common power amplifier is used for

On

the

l00V

both 100 V and 1000V ranges.

Range

the output is fed directly to the terminals, on the

is

1 000V Range the output

On

both ranges, the sensed terminal voltage is

stepped up by a transformer

reduced to the reference lev el by precision attenuators.

Output Sensing

On

the 1 V range and above, the output

the front panel

Hi

and

Lo

terminals. With Remote

Sense selected, these are isolated from

but in Local Sense Hi is internally connected to

and

Lo

to

I-.

As

described above, the lOV, 100V

and 1 0Ö0V ranges' sense signal

is

is

sensed at

I+

and

I-,

I+,

attenuated before

comparison with the reference.

-·-----

1-5

Page 12

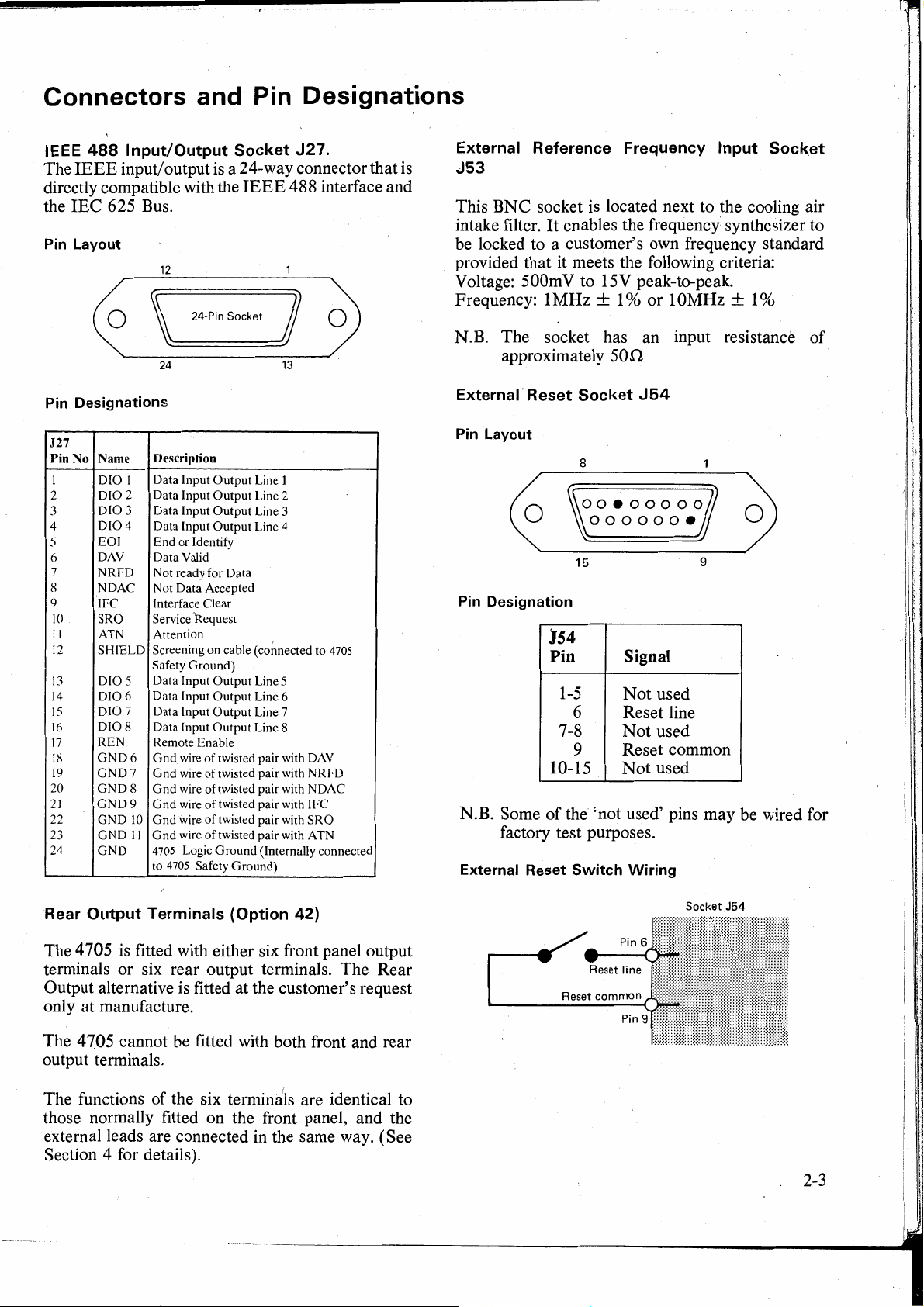

AC/

AC

Comparator

The comparator generates an error voltage

proportional to the difference between the RMS

values of the

alternately samples a number

AC

reference and the sensed output. It

of

cycles from its

'Ref

and 'Sense' inputs, computes and integrates the

squares

of

their instantaneous values, and uses a

'Sample and Hold' technique to subtract one from

the other, this being the 'error' voltage to control the

VCA. The loop thus controls the 4 705 output so that

the RMS value

equates to that

DC Current

On changing functions to

Reference voltage

of

the comparator' s sense input

of

its reference input.

DC

Current, the W orking

is

switched to drive a voltage-to-

current converter, and the OUTPUT display legend

is

changed to µA,

is

provided, and the Output lines are fused.

AC Current

An

AC

Current output

current converter. The 100

mA

or A. Over-voltage protection

is

produced by the voltage-to-

µA

and 1 A ranges are

driven directly from the basic 1 V range, and the

others from the 1

achieved

,by

protectiori against over-voltage

OV

range. Range selection is

switching internal shunts. Output

is

provided, and the

output lines are fused. The OUTPUT display legend

is

altered to µA,

mA

or

A.

Autocalibration

By setting the CAL

the rear panel to

·calibrated. (Refer to Section 8). The output value

measured and the microprocessor

ENABLE_

security keyswitch on

ENABLE, the 4705 can be

is

activated, to

is

add any new corrections to factors already retained

in

non-voltai_le

factors are applied in the normal R

Processor

memory. The updated correction

UN

mode.

A 6802-series microprocessor controls the intemal

performance

26K

bytes

2K

bytes

space, and

of

the instrument, employing

of

program memory.

of

memory are used for stack and work

2K

bytes are made non-volåtile by a

battery-pbwered back-up supply, storing calibration

correction factors.

With the exception

ofthe

Power

ON/OFF

switch,

each front and rear panel control provides an input to

the microprocessor system, which translates the

information to command the

4 705 analog and

calibration functions.

The processor also controls the display, the

IEEE

488 Interface Bus and the operation

of

the

restart and error circuitry.

Resistance

Remote Sense. One

resistors

I-,

is

internally 4-wire connected to the I+,

Hi and Lo terminals by operation

of

a set

of

eight precision

of

each

RANGE key. Simultaneously the 4-wire calibrated

value

of

the resistor

is

displayed (OUTPUT

display). Pressing the OUTPUT Zero key connects

a true 4-wire short to the terminals, and the

0 UTPUT display indicates zero. This zero display

value cannot be recalibrated.

Local Sense (Remote Sense LED Unlit).

The

connections to the resistor remain the same, hut the

display value includes the resistance of the

connections form the

Hi

and Lo terminals to the

resistor. The arrangement provides a calibrated

2-wire facility with external connection to the Hi and

Lo terminals. The Zero key shorts the Hi and Lo

terminals,

terminals

. When

4

705

in

this case the resistance between the

is

displayed and may be recalibrated .

n

is

selected from any other function, the

is

forced into Remote Sen se, hut this may be

deselected for 2-wire operation.

1-6

Page 13

SECTION 2 INSTALLATION

This section con~ains information and instructions for unpacking and installing the Datron

Unpacking and lnspection

E very care

to ensure that your equipment will reach you in

perf ect condition.

If

the equipment has been subject to excessive

mishandling in transit, the fäet will probably be

visible as extemal damage to the shipping carton.

the event

cushioning material should be kept for the carrier' s

inspection.

Unpack the equipment and check for extemal

damage to the case, sockets, keys etc.

found, notify the carrier and your sales

representative immediately.

Standard accessories supplied with the instrument

are as described in Section

is

taken in the choice of packing materials

of

damage, the shipping container and ,

If

damage

1.

lt;i

is

Power cable

The detachable supply cable, comprising two meters

of 3-core PVC sheath cable permanently moulded to

. a fully-shrouded 3-pin socket, fits in the

INPUT

home. ·

The supply lead should be connected to a grounded

outlet ensuring that the ground lead

Connect Black lead to Line, White lead to Neutral

and Green lead to Ground. (European: Brown lead

to Line, Blue lead to Neutral, and Green/Y ellow

lead to Ground).

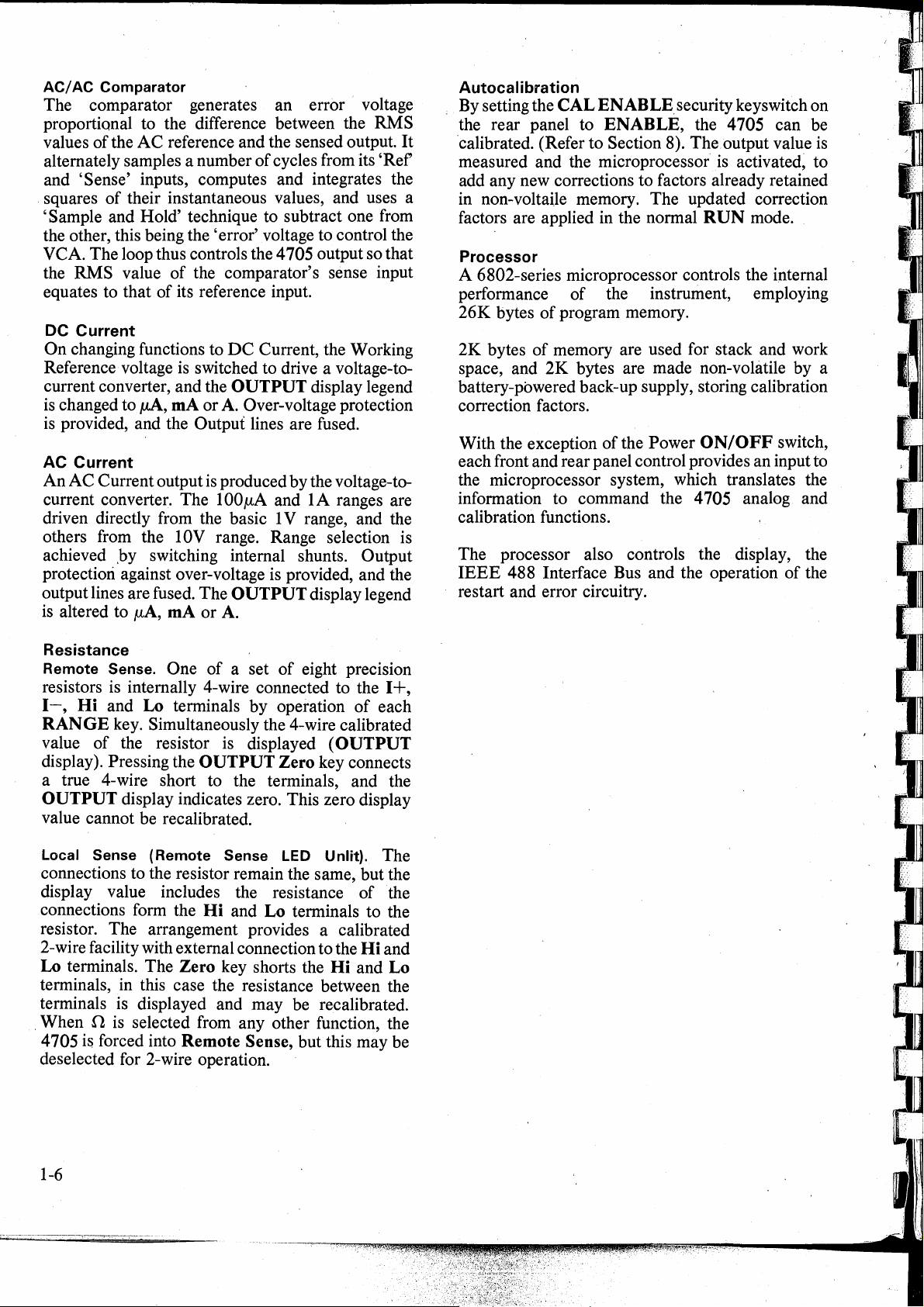

Line voltage

The 4 705

100/l

To

board

plug recess, and should be pushed firmly

is

operative within the line voltage ranges

15/120/220/230/240V

accommodate the ranges, a small

is

housed beneath the POWER FUSE.

+ 10%, 50 or 60Hz.

Preparation for Operation

4705.

is

PC

POWER

co~nected.

selector

DANGER

THIS INSTRUMENT IS CAPABLE OF

DELIVERING A LETHAL ELECTRIC

I+,

I-,

SHOCK. THE

ARE MARKED WITH

WARN USERS

UNDER

USERS TOUCH ANY OF THE FRONT

TERMINALS UNLESS THEY ARE FIRST

SATISFIED THAT NO DANGEROUS

VOLTAGE IS PRESENT.

Power lnput

The recess POWER INPUT plug, POWER

and LINE VOLTAGE SELECTOR are contained

in

an integral filtered module at the center

panel. ·

The protective window allows the fuse rating and

line voltage selection to be inspected with the power

socket connected. This window slides to the left once

the socket has been disconnected, for access to the

fuse and voltage selector printed circuit board.

NO CIRCUMSTANCES

Hi and Lo TERMINALS

~

SYMBOL

OF

THIS DANGER.

TO

SHOULD

FUSE

ofthe

rear

\

220

Operating Voltage Selection

FIRST ensure the POWER CABLE

Slide the window to the left to reveal the fuse and

selector board.

Draw the fuse-extractor to the left and remove the

fuse.

Remove the

desired voltage

Reinsert the selector board firmly into the module

slot.

The desired voltage

fuse.

Retum the fuse extractor to the normal position.

Insert the appropriate

Slide the window to the right and insert the

CABLE.

Power

The fuse rating

3.15A for 220/240V line supply

6.25A for

Fuse

PC

selector board and rotate until the

is

on the left

is

visible in the cutout below the

is:

100/l

20V line supply

POWER

of

the upper surface.

FUSE

OOL

is

removed.

(see over).

PO WER

PC

D

is

located behind the window in the POWER

It

INPUT

the anti-surge or SLO BLO type.

module on the rear panel, and should be

of

2-1

Page 14

WARNING

MAKE SURE THAT ONLY FUSES WITH

THE REQUIRED RATED CURRENT

OF THE SPECIFIED TYPE ARE

REPLACEMENT. THE

FUSES

AND

THE SHORT CIRCUITING OF

USE

USED

op'

AND

FOR

MENDED

FUSE-HOLDERS · SHALL BE AVOIDED,

AND

RENDERS THE WARRANTY VOID.

Bench Mounting

Th,e

instrument

is

fitted with six plastic feet.

It

is

intended to stand flat on a bench, positioned so that

the cooling-air inlet and exhaust apertures are not

obstructed.

( 12 inches) of free space

It

is.

recommended that at least 30cm

is

at the rear.

R~ck Mounting

Option 90 permits the instrument to be mounted in a

standard 19 inch cabinet. ·

Remove the two rear spacers from the case sides by

releasing six screws.

slides to the rear

Fit

the two rack-mounting

of

the case sides and secure using

six of the shorter screws in the option kit.

N.B. The slides may be reversed to give rearward

extension.

Fit

the two rear rack-mounting ears tq the rear ofthe

In

cabinet, with tongues facing forward.

shallow

cabinets it may be necessary to trim the tongue.

CAUTION

is

Assistance

required to fit the 4705 into the

cabinet.

Lift the 4705 into position in the cabinet, locate the

tongues in the slides, and carefully slide backwards

until the front ears hutt up against the cabinet front.

Secure the front ears to the cabinet. Also clear

ventilation for fan

cooli11g

to opera te properly.

I

To Fit Option

90

CAUTION

is

Note that the 4705

front and

rear.

AT NO TIME should the 4705 be

designed to be supported

supported only by the front brackets.

and

account should the upper

lower covers be

removed.

SUITABLE RACK DEPTHS

DEPTH

0 REMOVE

2 OFF 450300 REARSPACERS

6 OFF 611038

M4X12mm

mm

<635

635-735 25-29

735-800 29-31;

SOCKET HD CSK SCREWS

in

<25

FIT

REVERSE RACK

at

On

no

NOTES

SHORTEN REAR RACK

MOUNTING

AS

SHOWN

SLIDES TO EXTEND PAST

EARS

BY DRAWING

MOUNTING

REAR PANEL

0 FIT

2 OFF 450312 RACK

2 OFF 450313 RACK

2 OFF 450314 RACK

12

AS

INSTRUCTED

OFF 611062

MOUNTING

MOUNTING

MOUNTING

M4X8mm

SOCKET HD CSK SCREWS

EAR FRONT

EAR REAR

SLIDE

2-2

@

©

Page 15

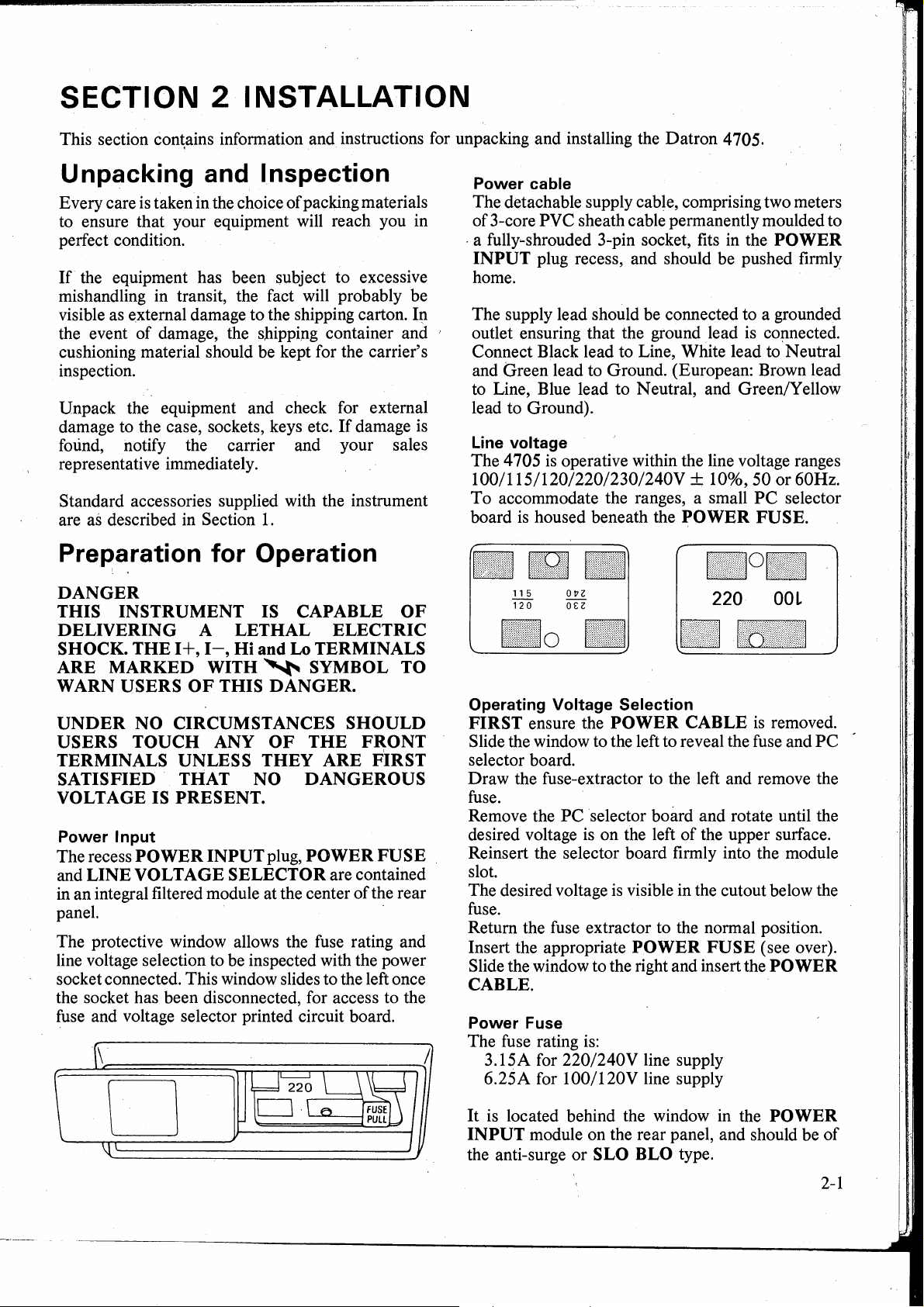

Connectors and Pin Designations

IEEE

488

lnput/Output

The

IEEE

input/ output

is

a 24-way connector that

directly compatible with the

IEC

the

Pin Layout

Pin Designations

J27

PinNo

1

2

3

4

5

6

7

8

9 IFC Interface Clear

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

625 Bus.

12

\

24-Pin

Socket )

24

Name Description

DIOl

DIO2

DIO3

DIO4

EOI

DAV Data Valid

NRFD

NDAC Not Data Accepted

SRQ

ATN Attention

SHIELD

DIO5

DIO6

DIO7

DIO8

REN

GND6

GND7

GND8

GND9

GNO

GNDll

GNO

Data Input

Data

Data

Data

End

Not ready for Data

Service

Screening on cable ( connected to 4705

Safety

Data

Data Input

Data Input

Data Input

Remote Enable

Gnd

Gnd

Gnd

Gnd

10

Gnd

Gnd

4705 Logic

to

4705 Safety

Output

Input

Output

Input

Output

Input

Output

or

Identify

Request

Ground)

Input

Output

Output

Output

Output

wire

of

twisted pair with DAV

wire

of

twisted pair with

wire

of

twisted pair with NDAC

wire

of

twisted pair with IFC

wire

of

twisted pair with

wire

of

twisted pair with ATN

Ground

Socket

IEEE

Ground)

J27.

488 interface and

13

Line 1

Line 2

Line 3

Line 4

Line 5

Line 6

Line 7

Line 8

(lnternally connected

NRFD

SRQ

is

External Reference Frequency lnput

Socket

J53

This BNC socket

intake filter.

is

located next to the cooling air

It

enables the frequency synthesizer to

be locked to a customer' s own frequency standard

provided that it meets the following criteria:

Voltage: 500mV to 15V peak-to-peak.

Frequency: 1

N.B. The socket has an input resistance

approximately

Externa1· Reset Socket

Pin Layout

MHz

± 1 % or 10MHz + 1 %

500

J54

8

of

ooeooooo

000000•

15

9

Pin Designation

J54

Pin

1-5

6

7-8

Signal

Not

used

Reset line

Not

used

9 Reset common

10-15

N.B. Some

of

the 'not used' pins may be wired for

factory test purposes.

Externa! Reset

Switch

Not

used

Wiring

Rear Output Terminals (Option

The 4

705

is

fitted with either six front panel output

42)

terminals or six rear output terminals. The Rear

Output alternative

is

fitted at the customer's request

only at manufacture.

The

4

705

cannot be fitted with both front and rear

output terminals.

The functions of the six termina

1

ls

are identical to

those normally fitted on the front 'panel, and the

externa} leads are connected in the same way. (See

Section 4 for details).

Reset

common

Socket

J54

2-3

Page 16

DANGIR

THIS

A

llTHAl

HIGH

VOLTAGE

INSTRUMENT

OF DELIVERING

lllCTRIC

...._

..

(

4

THIS CAN KILL !

FRONT

terminals

Full

or

Output

IS CAPABLE

SHOCK

REAR

carry

the

Voltage.

I

I

I

Guard terminal is

sensitive

voltage

It

can

your

Unless

. it is safe

DO

I+

you

NOT

I-

and

Hi

terminals

instrument!

are sure

TOUCH

or

to

damage

to

do

so,

Lo

leads

over -

that

the

2-4

DANGIR

Page 17

SECTION 3 OPERATING CONTROLS

This section summarizes the main operating features

Section 4. ·

Front Panel

MODE FREQUENCY

DANGER "I

HIGH VOL TAGE

~A

I+

I-

Guard

@@@

~{t)4)

\.

-=-

~

FREQUENCY RANGE

Store 100

1aaaaaa

-

F1 . F2

1k

10k

100k

F3

F4

FS

199ggg9

Guard Sen se Spec Error Offset Test

- Remote -

STO

MODE

SET

±0

CAL

of

the 4 705.

For

detailed operating procedures refer to

OUTPUT

,-,,-,nnn;n v

·uuu,uLu,

OUTPUT RANGE

1äBåeieletäå

100

1000

1k0

10k0

100k0

1MO 10MO 100MO

1ra9991~~99

O I AC

FUNCTION OUTPUT

DC

Reset

_:

ON ~ OFF

rdatron"

INSTRUMENTS

4705

AUTOCAL

MULTIFUNCTION

-..

CALIBRATOR

Power

.,

Power-up State

The controls are outlined in blocks, left and right,

The

associated with the appropriate display.

righthand blocks generally deal with function and output

definition, whereas the left-hand blocks are

concemed with frequency, mode and terminal

configurations.

Front Panel Keys

All user commands from front panel keys are

executed through main program firmware. A Key ·

LED

lit signifies that conditions are valid for the

selected operation, and not merely that the key has

made contact. ·

At

any time, the instrument status

of

combination

LED

states, display values and

is

described by the

display messages.

is

Gene·rally, if an invalid condition

selected, an

error message will be displayed and a buzzer will

sound, the command is ignored and the

remains

in

its previous state.

4

705

Power

Switch

WARNING

THE POWER SWITCH SHOULD NOT BE

TO

SET

AND

ON UNTIL THE LINE VOLTAGE

POWER FUSE RATING HAVE BEEN

SELECTED AS DETAILED IN SECTION 2

(INSTALLATION)

When set to the m

Power switch isolates the instrument from the

OFF

position, the 2-pole

supply.

I:]

ON,

When switched to

up, runs a self-test program and

the instrument powers

is

configured into the

following state:

OUTPUT

FUNCTION

OUTPUT

OUTPUT

RANGE

DISPLAY

FREQUENCY

RANGE

OFF

DC

1

.000,000V

Not

selected

MODE/FREQUENCY

DISPLAY

MODE

Guard

Sense

LEDs

Key

Lit

Blank

Not

selected

Local connection ( unlit)

Local connection ( unlit)

OUTPUT

OFF,

DC,

1

3-1

Page 18

QUTPUT

Switching

OUTPUT RANG E

100µ 1m

0

FUNCTION

-

OUTPUT

The 4 705 should normally be connected and set up

with its

Lo

of

MODE

lit.

Pressing the OUTPUT

I - Hi and

'

circuits.

ON/OFF

output off. This isolates the

terminals from their interna! circuitry regardless

RANGE- FUNCTION, FREQUENCY or

sele~tions.

Lo

'fhe

terminals to their energized interna!

10m 100m 10 100 1000

I

AC

I+,

I-,

Hi and

OUTPUT

ON

key connects the

OFF

LED

I+,

is

datrc:n

INSTRUMENTS

4705 , AUTOCAL

MUL TIFUNCTION

CALIBRATOA

r70

Power

••

OUTPUT

Under certain abnorma! conditions which might

compromise safety, the 4705 output will trip off,

accompanied by a

display. Control

keys.

If

the F AIL, 5 message

automatic recovery from the tripped state whether

interna! conditions have or have not returned to

normal.

OFF Trip - Fail 5 Massage

FAIL 5 message on the

is

removed from the front panel

is

present, there

MODE

is

no

OUTPUT

Certain instrument states are prohibited,. and some

transfers between states are restricted by program

firmware.

result in the output being switched

Sectiön 4, Operating Routines.

OUTPUT

On

Output terminals

switch the output on, as labelled. In addition,

polarity may be reversed by using the

step the output across zero value. The

describe the polarity AT THE OUTPUT

TERMINALS,

"error" and "offset" modes these two could be

opposite).

In

functions, the

outputs to appear at the output terminals. The

key will cause the error buzzet to sound and

Error 8 to appear in the

display.

3-2

OFF Default

For

safety reasons some

ON - +

DC

Voltage or Current, the polarity at the

is

determined by the Key

of

these transfers

off. Refer to

+ I + keys to

not on the OUTPUT display. (In

AC

Voltage,

AC

Current and Resistance

ON + key will cause the selected

MODE/FREQUENCY

O N

us~~

LEDs

ON

to

-

Reset Key

The Reset Key has two functions:

1.

It

allows a user to reset the safety trip to test

whether conditions have returned to normal.

they have; the F AIL message will disappear, the

previous instrument state will be restored but

with

OUTPUT OFF, and front panel control

will be returned to

abnorma! the

further attempt may be made after a suitable

interval. The

'Test' mode. ·

2.

It

returns the instrument to power-up conditions

in all cases except the following:

• Self-test mode

• F AIL conditions

• In remote control mode ( where it

inoperative

Other Massages ;

A full list

The fault conditions which generate Fail messages

are analyzed

Handbook.

of

4

705

in

tb-e

user.

If

conditions are still

F AIL state will persist, and a

Reset

LED

is

inoperative except in

is

).

messages appears in Section

the Calibration and Servicing

If

4.

Page 19

FUNCTION

Keys

100µ 1m

Selected

Function

DC

AC

n

DC

AC

OUTPUT RANGE

10m 100m

and I

and I

10 100 1000

Reset

_:

OUTPUT

ON

~

OFF

Specified

Output

DC

Voltage

AC

Voltage ·

Resistance

DC

Current

AC

Current

When

output is automatically set to

from

automatically set to zero.

OUTPUT

new function, the

changing from one function to another the

OFF.

n,

to AC

RANGE

When

or

DC, the OUTPUT value is

If

the corresponding

or value is not available on the

4 705 displays

Error

changing

8 and sounds

its error buzzer.

n selection forces the 4 705 into Remote Sense for

4-wire operation.

OUTPUT RANGE

Each

OUTPUT

selected by the user, setting the legend and decimal

point on the

OUTPUT display to match. Full range

values for voltage and current are marked above the

keys. Nominal values

n function are marked below the keys.

the

OUTPUT RANGE

100µ 1m 10m 100m 1 10

100

1000

Voltage and current ranges are selectable as follows,

the actual output value being selected by use

OUTPUT display tl, keys:

DC

1aaaaaaaa

100

1000

1k0

10kO

100k0

1MO

AC

DC

AC

Voltage

Voltage

Current

Current

Resistance

o

FUNCTION OUTPUT

AC

DC Reset

_:

ON

~

OFF

If

OUTPUT is

remains on unless the change

ranging-up to more than 75V RMS in

DC

on

l00V

range. In these cases OUTPUT

defaults to OFF. Any range selection which would

exceed the internally de

frequency limit

limits are described on page 3-6.

Keys

RANGE

key scales the output as

of

each precision resistor for

100µ,V to 1000V

lmVto

100µ,A to

100µ,A to

lO!l

ON

is

automatically inhibited. These

1000V RMS

IA

IA

RMS

to

lO0M!l

when changing ranges, it

is

to 1 000V range, or

AC

or 1

fin

ed voltage-

of

I0V

the

in

3-3

Page 20

Key

se.ections

100µ

10

lm

100

10m

lk

100m 1

10k

100k

10

lM

100 1000

lOM

lO0M

DC

Voltage

AC

Voltage

DC

Current

AC

Current

Resistance

OUTPUT

Output Resolution

The Output and display

Range

DCV

ACV

DCI

ACI

0 (2-wire)

0 (4-wire)

Display and t

I · 11 11 11 11 9

- -

_,

l00µV

*

l00µA

l00µA

100

lmV

lmV

lmA

lmA

1000

* Error 8

I+

Keys

OUTPUT

- -

are_

resolved as follows:

100µ

10

3½

5½

5½

3½

6½

.lm

100

4½

3½

5½

5½

5½ 5½

6½

l0mV

l0mV

l0mA

l0mA

IkO

~

10m

lk

5½

4½

5½

5½

6½

l00mV

l00mV

l00mA

l00mA

l0kO

100m

10k 100k

6½

5½

5½

5½

6½

6½

lO0kO

6½ 6½

5½

5½

5½

6½

6½

IV

IV

lA

lA

1

lOV

lOV

100V

100V 1000V

1000V

* * *

* .

lMO

10 100 1000

lM

5½ 5½

6½

6½

·*

lOMO

lOM

6½

6½

6½

l00MO

100M

6½

5½

6½

6½

*

The O

which always indicate the correct units for the Range

and Function selected.

Output and Display Control

Each

display digit above

the display may be set within the range permitted by

the function selected.

key adds 1 to its digit: pressing the

If

also changed by the same increments as the display

( subject to the instrument interlocks

On O ranges, only the overrange t I t keys are

operative. These duplicate the action

Range/Zero Keys.

The Resistance value displayed

value

the nominal value

periodic calibration. The value displayed depends

on the selection

3-4

UTPUT

vertical pair

display

of

it.

Each

is

supplemented by legends,

+ I + keys is assigned to the

Thus the value registered on

momentary press

t key subtracts

OUTPUT

of

is

ON,

the Output terminal value is

).

is

the calibrated

the standard internal resistor selected ( not

).

This may · be updated

of

Local (2-wire) or Remote (4-

of

the Full

of

the •

<luring

1.

wire) Sense, and should be recalibrated in the

correct Sense mode (See Section

Auto-1 ncrement/Decrement

When a + I t key is pressed for more than ½ second,

is

its digit

approximately 3 digits per second until the key is

released.

Overflow and Underflow

As a digit is stepped from 9 to 0, the value ofthe next

higher-order digit

0 to 9 decreases the value by

therefore acts as a counter, with full 'carry' and

'borrow' action.

Range of Adjustment for DC Functions

The

+It

minimum

l00mV

for Current Ranges. The 1 00µV Range has a Full

Scale

ranges are truncated.

increased or decreased

is

increased by

keys adjust the readings between a

of

0000000

- 100V and between

of

1100.000; the 100µ,V,

and 1999999 full scale on

8).

at

a rate

1.

Stepping from

1.

The whole display

000000

and 199999

' . l

lmV

and lOmV

of

Page 21

Range

of

Adjustment

for

AC

Functions

The l I t keys adjust the reading between a minimum

of009000

of

199999 full scale on 1

Ranges. The 1000V. Range has a Full Scale

1100.00; the

N.B.

There

(9%

ofNominal

lmV

is

no range

and

Range), and maximum

00m

V.....,... 1 00V

l0mV

of

ranges are truncated.

adjustment on Resistance

and Current

of

functions.

Leading Zeroes

For

fractional readings, a leading zero is presented to

of

the left

except for

lm

the decimal point to emphasise its position,

O

and

UTPUT

1.

RANGE

selections

output terminals.

AC

Voltage - an intemal short circuit is connected

across the output terminals.

DC

and

AC

Current - output terminals are opencircuited.

On

n ranges in Remote Sense with

OUTPUT

ON,

the Zero key connects a true 4-wire intemal short

circuit to the

With

Remote Sense

OUTPUT

is connected, but the actual resistive value

terminals as shown below.

LED

UNLIT,

the same short

of

this

short may be calibrated ( See Section 8 and diagram

below).

I+

I+

DC ZERO and polarity. On DC voltage and current, a

is

polarity sign

present except

at

zero. The numerical

display represents the rriagnitude of the output.

. As the display value is stepped to zero, the polarity

sign disappears, and the opposite sign appears as

stepping continues in the same direction.

0

UTPUT

is

O N

<luring

the sequence, the change in

If

the

output polarity is signalled by a changeover from one

polarity

N.B.

If

ON

the 4

LED

705

to the other.

is

in Offset Mode, with an offset

present, the display and output zeroes do not

coincide.

positive sign on the display, and the

LED

When using the

It

is therefore possible to have a

lit; and vice-versa.

+ I , keys or Zero key to obtain a

ON.:_

zero, the polarity is not changed over and the, same

OUTPUT

ON

LED

remains lit. The polarity

LEDs

change over only when the opposite polarity appears

at the output terminals.

Full Range Key

When the Full Range key

reverts to the nominal value

OUTPUT

is

already

ON,

is

pressed,the display

of

the range selected.

Jf

the terminal value follows

the display value· unless: ·

·

1.

The combination of output voltage and frequency

would exceed the instrument' s intemally defined

limits. (Refer to Section 6).

Hi

I

'Remote

Deselection of Zero

The size

significant. A half-size

'Zero

Sense'

in '

4705

True

4 - Wire

in

of

the characters on the 'Zero' display is

Ohms

Zero

AC Functions ·

·'O'

above any +

Lo

I-

14-w;:e

-~

Ohms

1,

key

indicates that it cannot be used to desetect Zero,

because it increments values which are less than

10%

of

nominal range.

Any

+ key with a full-size

'O'

above it ( and any key to its left) deselects Zero and

adds its increment.

Selection of High Voltage Outputs

The 4

705

is capable

of

delivering

LETHAL

output

voltages so program interlocks are used to ensure

that users do not inadvertently select outputs in

excess

of 1 I0V

in

DC

or 75V RMS in AC. Details

of the High Voltage selection procedure are given in

Section

4.

2.

Offset or Error Mode

off set or gain error

is

selected: the user-input

is

not cancelled from the

output.

Zero key

This reduces the display value to zero.

is

ON, the terminal value

DC

Voltage - an active zero

is

also set to zero:

is

presented to the

If

OUTPUT

Frequency

The

AC

voltage output of the 4705 extends from

0Hz

to 1

MHz

in

five

1

a resolution of 1 %

five

Any

frequency values within the range

overlapping decade ranges, at

of

nominal Frequency Range.

instrument can be stored in volatile memory.

of

the

3-5

Page 22

FREQUENCY RANGE keys

Auto-1 ncrement/ Decrement

When a +

digit is increased or decreased

approximately 3 digits per second until the key is

released.

Overflow and Underflow

As a digit is stepped from 9 to 0, the value ofthe next

higher-order digit

0 to 9 decreases the value by

therefore acts as a counter, with full 'carry' and

'borrow' action.

1,

key is pressed for more than ½ second its

at

a rate of

is

increased by

1.

Stepping from

1.

The whole display

Guard Sense Spec Error Offset Test

- Remote -

Decade Ranging

Generally, selection

frequency by a whole number

ranging-up from a frequency -between lOHz and

30Hz, or ranging-up to the

decade frequency would have been higher, causes

Error 7 to be displayed and buzzer to sound.

Selection of Nominal Range Value

Once a Frequency Range has been selected, it can be

set to its nominal value by re-pressing its key.

FREQUENCY DISPLAY

STO

SET

MODE

of

a new range changes the

MODE FREQUENCY

/

I •

±0

l00kHz

/7

/7

LI

LI"'

of

range when the

GAL

decades; but

k

Autoranging

Stepping the frequency beyond the span

automatically switches range up or down, but further

steps are inhibited until the • or

_ key could be below a decimal point). When the

range-change occurs, the alarm buzzer sounds and

FREQUENCY display is blanked for

the

approx. 1 second.

is

When the display

remembered the last frequency on the old range, and

sets the new range to its next incremental frequency

in the original direction. After releasing the original

key, stepping-can be continued to any increments

the new range.

Autorange Limits

The 4705 displays an Error 7 and sounds its buzzer

when any attempted frequency increment or

decrement is made which would produce an invalid

of

combination

or FREQUENCY. Neither will it incremen'.t or

decrement to a frequency beyond the limits

next frequency range up or down.

FUNCTION, OUTPUT RANGE

reinstated, the 4

t key is released ( the

of

a range

705

of

has

of

the

Il

Resolution

The output frequency

the selected FREQUENCY RANGE nominal

value, matching the display resolution. Legends are

appended on the display as appropriate,

leading zero is presented to the left of the decimal

point for fractional values.

FREQUENCY t lf Control

Each vertical pair

display digit above

is

the display

Each momentary press of the • key adds 1 to its digit,

and each

output frequency

increments as the display ( subject to the instrument

interlocks

inactive. ,

adjusted by manipulation ofthese keys.

t key subtracts

).

Keys below decimal points are

is

adjustable in steps of 1 %

Keys

of

+

1,

keys

is

assigned to the

it.

The frequency registered on

1.

If

OUTPUT

is

also changed by the same

is

ON, the

of

å.nd

3-6

a

_ combinations

· selected.

OUTPUT/FREQUENCY

AC Voltage and Frequency

Under most conditions, the output amplitude and

frequency are adjustable throughout their full

scales:

Voltages - from

Frequencies - from lOHz to

On

the

l00V

of

voltage and frequency cannot be

The diagram below illustrates the boundaries.

The 1

comparison.

The

combination outside these constraints. The

temporary message

approximately 1 second before reverting to the

original display.

0V

Range span is also shown for

4

705

refuses to select any Voltage/Frequency

CONSTRAINTS

90µ,V

to 1100V RMS

lO0kHz.

and 1000V Ranges, certain

Error 7

is

displayed for

Page 23

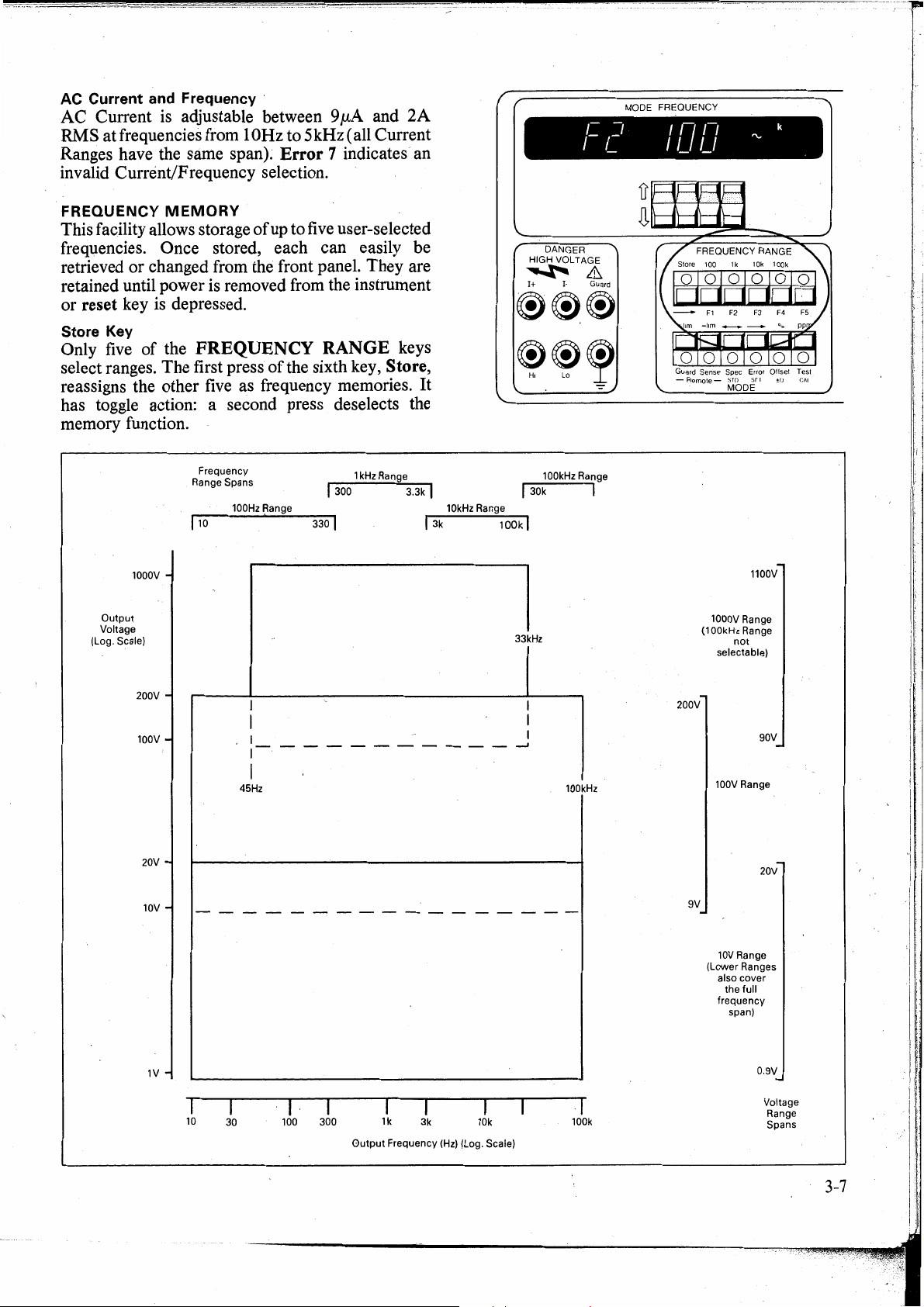

AC Current and Frequency ·

AC

Current

RMS at frequencies from 1

Ranges have the same span).

is

adjustable between 9µA and

0Hz

to 5 kHz ( all Current

Error 7 indicates an

invalid Current/Frequency selection.

2A

MODE FREOUENCY

1=2

IDL7

~

k

FREQUENCY

This facility allows storage

MEMORY

ofup

to

five

user-selected

frequencies. Ortce stored, each can easily be

retrieved or changed from the front panel. They are

retained until power is removed from the instrument

or

reset key

is

depressed.

Store Key

Only

five

of the FREQUENCY RANGE keys

select ranges. The first press

reassigns the other

five

ofthe

sixth key, Store,

as frequency memories. It

has toggle action: a second press deselects the

memory function.

1000V

Output

Voltage

(Log. Scale)

Frequency

Range

110

Spans

100Hz Range

1kHz Range

I 300 3.3k I

330 I

10kHz Range

!

3k

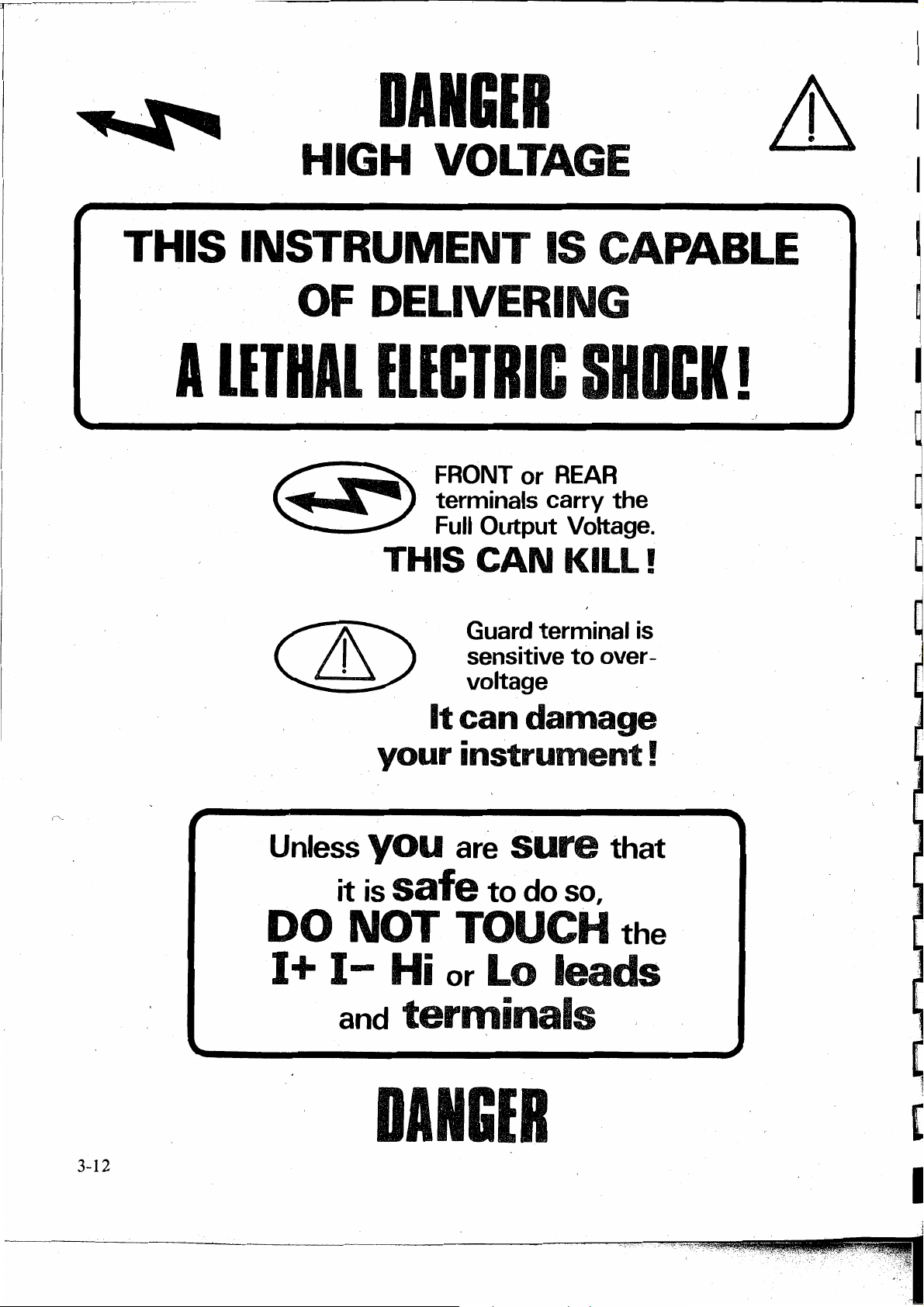

DANGER

HIGH VOLTAGE

~&

I+

I·

Guard

®®®

~~,

100kHz Range

I

3ok

10Dkl

33kHz

I

Guard Sense Spec Error Oflset Test

-

Remote-

sro

sr,

±o

MODE

1000V Range

(1

OOkHz

not

selectable)

1100V

Range

C.At

200V

100V

20V

10V

1V

200V

SOV

------------'

9V

(Lower

100V Range

20V

10V Range

Ranges

also

cover

the

full

frequency

span)

0.9V

Voltage

Range

Spans

45Hz

I

10

30

I· I

100 300

Output

1k

Frequency

I I

3k

(Hz) (Log. Scale)

10k 100k

100kHz

.1

3-7

Page 24

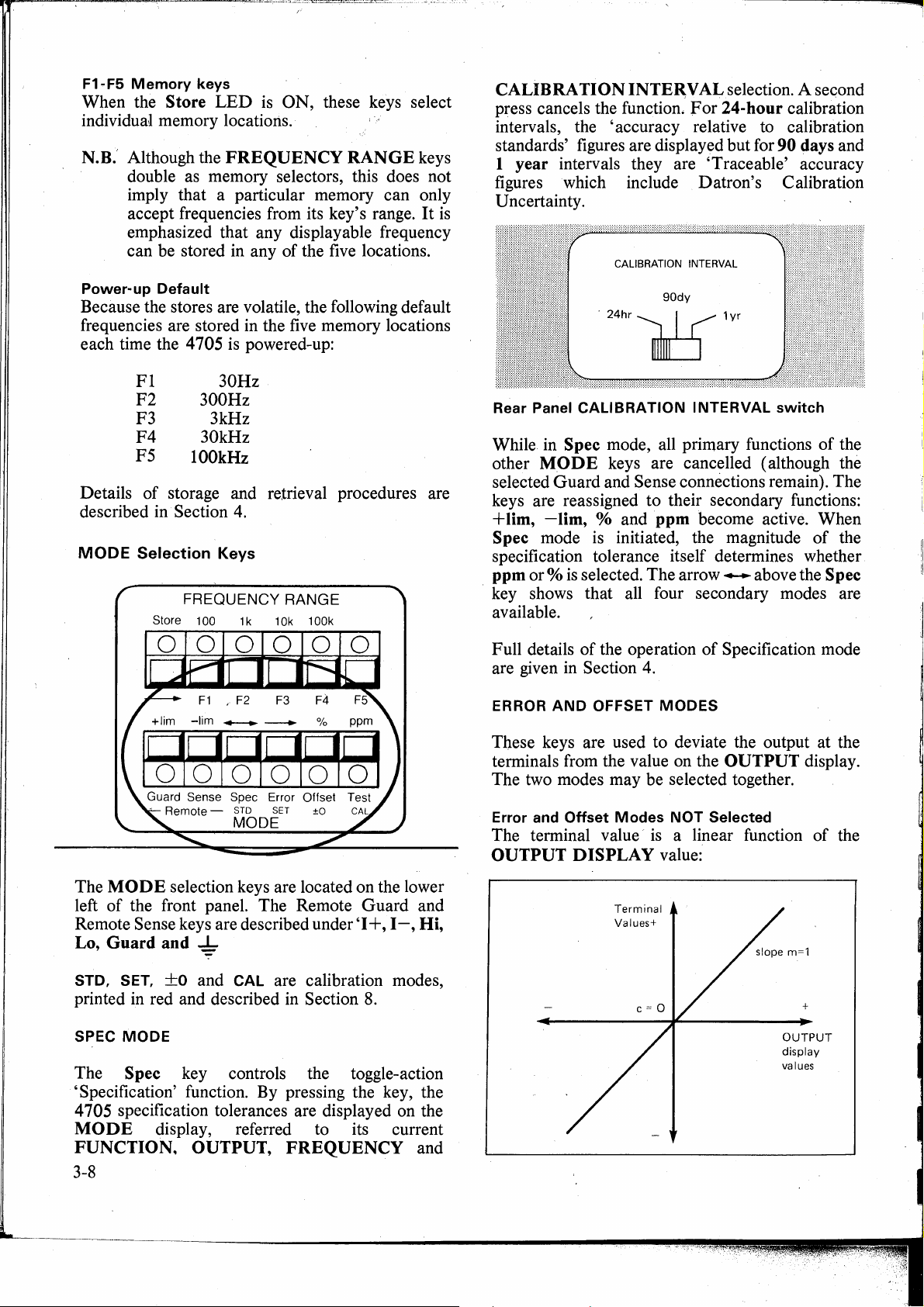

F 1-

F5

M emory keys

When the Store

LED

is

ON, these keys select

individual memory locatiorts.

N.B.' Although the

FREQUENCY

RANGE

keys

double as memory selectors, this does not

imply that a particular memory can only

accept frequencies from its key' s range.

It

is

emphasized that any displayable frequency

can be stored in any of the

Power-up Default

five

locations.

Because the stores are volatile, the following default

frequencies are stored in the

each time the

4705

is

five

memory locations

powered-up:

CALIBRA

press cancels the function.

TION

INTERVALselection. A second

For

24-hour calibration

intervals, the 'accuracy relative to calibration

standards' figures are displayed but for

90

days and

1 year intervals they are 'Traceable' accuracy

figures which include Datron's Calibration

Uncertainty.

CALIBRATION INTERVAL

90dy

'24hr~1yr

Fl

F2

F3 3kHz

F4

F5

Details

described

MODE

30Hz

300Hz

30kHz

lOOkHz

of

storage and retrieval procedures are

in

Section

Selection Keys

FREQUENCY RANGE

Store 100

4.

1k

10k 100k

0

Guard Sense Spec Error Offset

Remote -

STO

MODE

SET

±0

Rear Panel CALIBRATION INTERVAL switch

While in S pec mode, all primary functions

other

MODE

keys are cancelled (although the

of

the

selected Guard and Sense connections remain). The

keys are reassigned to their secondary functions:

+ lim,

Spec mode

-lim,

% and ppm become active. When

is

initiated, the magnitude

of

the

specification tolerance itself determines whether

ppm or %

is

selected. The arrow .,_... above the S pec

· key shows that all four secondary modes are

available.

Full details

are given

ERROR

in

AND

the operation

Section

OFFSET

4.

of

MODES

Specification mode

of

These keys are used to deviate the output at the

terminals from the value on the

OUTPUT

display.

The two modes may be selected together.

Error and Offset Modes

The terminal value ·

OUTPUT

DISPLAY

NOT

Selected

is

a linear function of the

value:

The

MODE

left

of

Remote Sense keys are described under

Lo, Guard and

STD, SET, +o and CAL are calibration modes,

printed

SPEC

MODE

selection keys are located on the lower

the front panel. The Remote Guard and

'I+,

I-,

Hi,

~

in

red and described

in

Section

8.

The S pec key controls the toggle-action

'Specification' function. By pressing the key, the

4

705

specification tolerances are display ed on the

MODE

FUNCTION,

display, referred to its current

OUTPUT,

FREQUENCY

and

3-8

Terminal

Values+

+

OUTPUT

display

values

Page 25

Error mode selected

Terminal

Values +

~

±10%

~

displayed

Value

of

Terminal

Values+

+

OUTPUT

display

values

Full details

in

~ection 4.

of

the operation

of

Error mode are given

Offset mode selected {DC Functions only)

In

Offset mode, the intercept ( c) may be adjusted to

any value within the Offset limit.

Offset Limits: 100µ,V and

Other Ranges:

lmV

Ranges: +200µ,V.

+2%

of

Full Range

value.,

·Terminal

Values+

offset

selected-

TEST

MODE

Test mode selected

Full details

in Section

1+,

1-,

4.

Hi,

ofthe

operations in Test mode are given

Lo,

Guard

and~

(Ground) Terminals ·

Local and Remote Switching

MODE FREQUENCY

not

selected +

OUTPUT

display

values

selected

+.

Output

display

values

Offset and Error

Mode

Combination.

Offset cannot be selected or deselected when the

4 705

is

already

The intercept (

then the slope (m)

Full details

combined mode are given

in

Error

c)

is

established first

is

of

the operation

Mode.

adjusted

of

in

in

Offset mode,

in

Error

mode.

Error, Offset and the

Section

4.

DANGER

HIGH VOL TAGE

~&

I+

I·

Guard

®®®

FREQUENCY RANGE

Store 100

121aaaaa

-

+-hm

1999t51199

Guard Sense Spec Error

-

-lim

Remote-

F1

F2 F3 F4

,..___.

",JIJ

MODE

1k

10k 100k

---

-..r

r

0

Olls~I

FS

o

ppm

Test

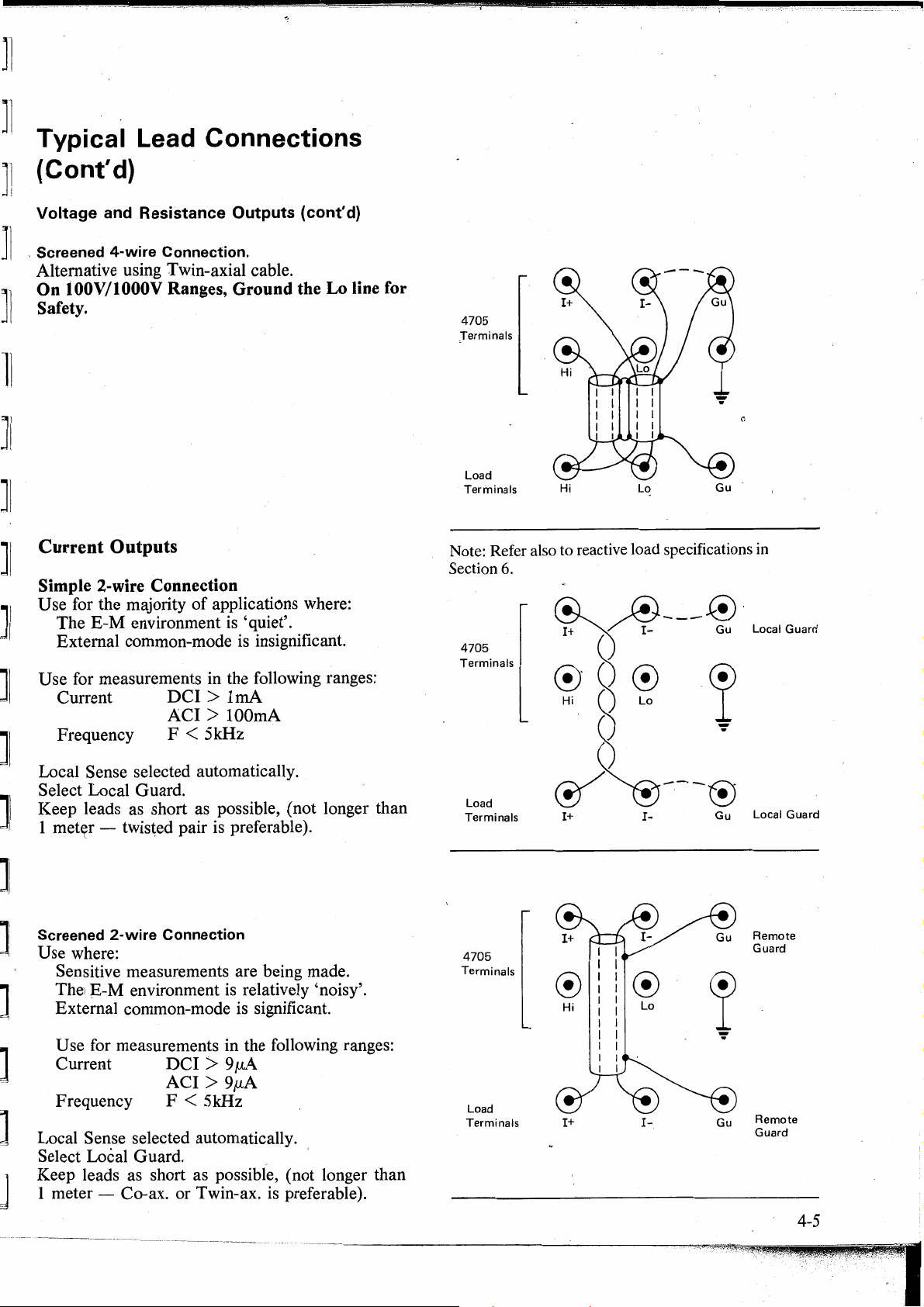

These terminals are located on the lower left of the

Front Panel.

1+

and I-Terminals

The output from the interna! power circuits

· delivered to the

I+

terminal, I-being its Return

Analog Common.

Hi and

Lo

Terminals

These terminals provide a differential input to the

amplitude sensing circuitry.

is

3-9

Page 26

Remote Sense

The Remote Sense key has 'toggle' action.

Successive presses altemate between

OFF. '

N.B. Sense connections can only be switched

with OUTPUT OFF.

ON

and

For

Voltage outputs

should be attached to the Hi and Lo terminals.

Various configurations of

detailed

in

Section

in

local sense the two leads

4

705

load connections are

4.

The specified voltage output

produced either at its output terminals (Local Sense

for high impedance loads) or at the load terminals

(Remote Sense for cases in which lead resistance

and load impedance produce a significant effect).

With Remote Sense OFF, the

isolated, and the voltage output

terminal. ·

With Remote Sense ON, the output voltage

across the

sensed extemally, using leads connected to the

and Lo terminals. ·

Remote Sense

ranges.

On Ohms ranges, Local Sense

connections, and· Remote Sense for 4-wire.

(Changing FUNCTION into

Remote Sen se, hut this may be deselected for 2-wire

operation). The Remote Sense

indicates the true connection:

Lit

I+

and I - terminals only, and must be

is

not available on lO0µV - lO0mV

It

is

not applicable to Current outputs.

= Remote; U nlit = Local. .

of

the 4

705

may be

I+

terminal

is

fed to the

is

used for 2-wire

is

is

Hi

fed

Hi

n forces the 4705 into

LED

always

Guard Terminal

The Guard terminal

interna! guard shields:

Remote Guard

The Remote Guard key has 'toggle' action.

Successive presses altemate between

OFF.

With Remote Guard OFF, Guard

connected to the I - terminal.

With Remote Guard ON, the interna! link to

is

removed. The . Guard terminal can then be

connected extemally to reduce common mode

interference.

Ground Terminal

The

-:-

( Ground) terminal connects directly to the

4

705

in.tema! Ground shields and to Safety Ground

via the power-cable.

Output Connections

Connections to the output terminals may be made

either with leads or via a shrouded connector.

3-10

is

permanently connected to the

ON

is

intemally

and

I-

Page 27

Rear Panel

(Shown with alternative Rear Output terminals).

r/

u

..._

-----

MODEL

SERIAL

No

RtNEW

BATT

AT

TS

See

INPUT VDL

FREOUENCY 48-62Hz

POWER 400VA

OPTIONS

POWER

INPUT

IJr&J

Power

Approx

POWER FUSE

11

D

lnput

,,,

J27

IEEE

488

~,-

CALIBRATION

INTERVAL

90<1y

24hr

CALIBRATION

ENABLE

*

""~

7~

1 yr

SH1AH1T6

TE0L4LE0'

SR1RL2PPIJ'

DClDT~C~El

•

S53

lllllllCJ

OFF

DN

J53

0

-----

rJ

w.-.-:;

7 r

\..

\..

DANGER HIGH VOL

....

;

~i~

TAGE

_&

~

j)

i i

'

.,

L

~

-

-

"'-

)

~

POWER

INPUT

The recessed POWER INPUT plug, POWER

FUSE

located in the center

within a single moulded unit. Details

selection ofline voltage and

REAR

and LINE VOLTAGE SELECTOR are

'Of

the rear panel, contained

of

connections,

fuse

are given in Section

OUTPUT

ALTERNATIVE (Option 42)

2.

This can be incorporated at manufacture, to provide

six output terminals on the rear panel instead of the

six on the front. Their functions and connections are

identical.

SOCKET

(Externa! Reference Frequency lnput)

['-..

J53

This BN C socket is located next to the cooling air

It

intake filter.

may be used to lock the internal

frequency synthesizer to a customer' s own

frequency standard. Voltage and frequency criteria

are given in Section

located above this socket

facility.

is

Ifthe

switch

not present, error message 'Error EF' is

2.

An

on-off switch; S53,

is

provided to enable this

is

on and an external frequency

displayed.

SOCKET

The

J27

{IEEE

IEEE

488 Input/Output(D-type) socketJ27

488

lnput/Output)

a 24-way micro-ribbon connector that

compatible with the

IEEE

48 8 interface and the

IEC-defined system.

·

127

is

located at the top

with the

IEEE

488 address switch. The pin layout

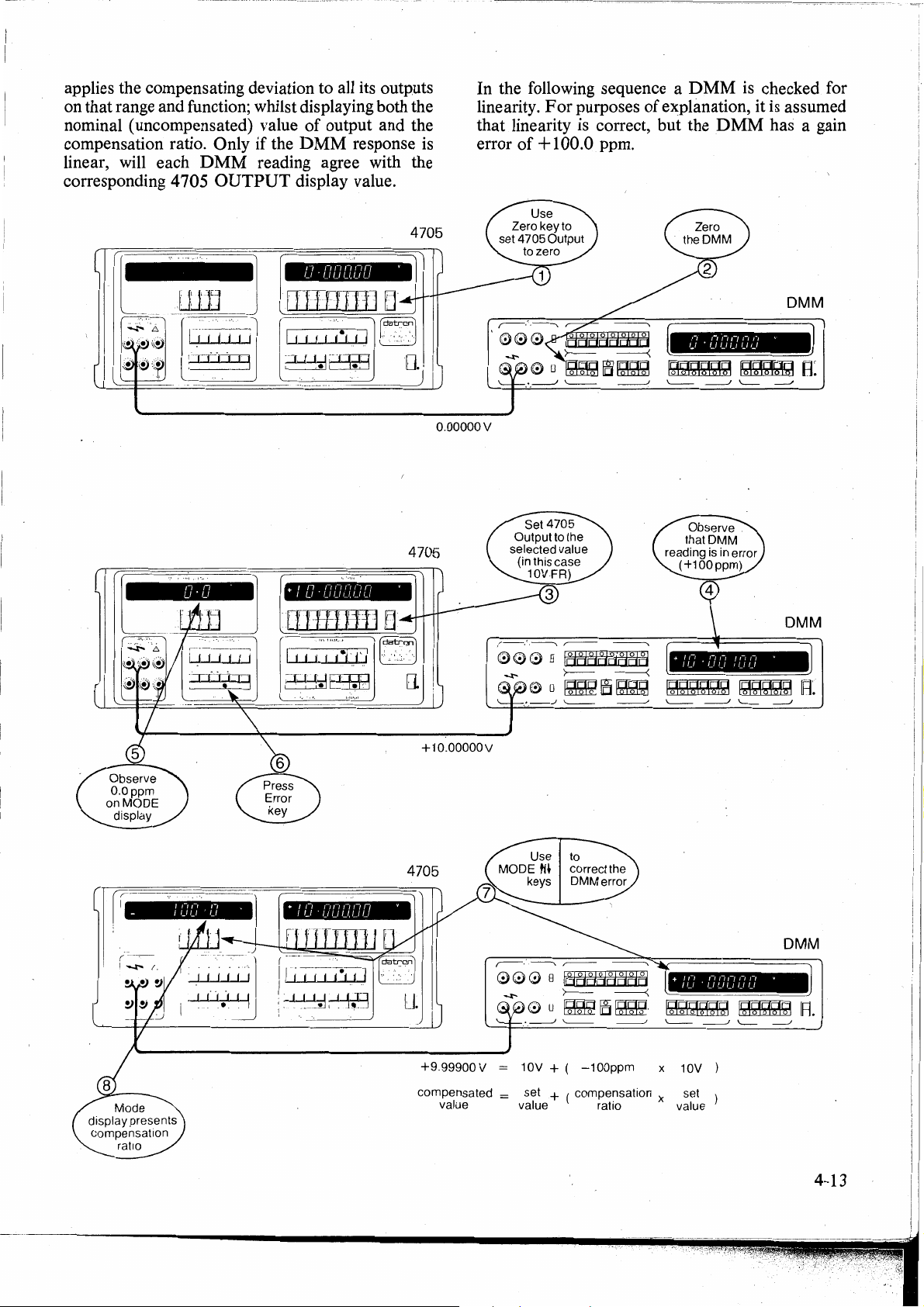

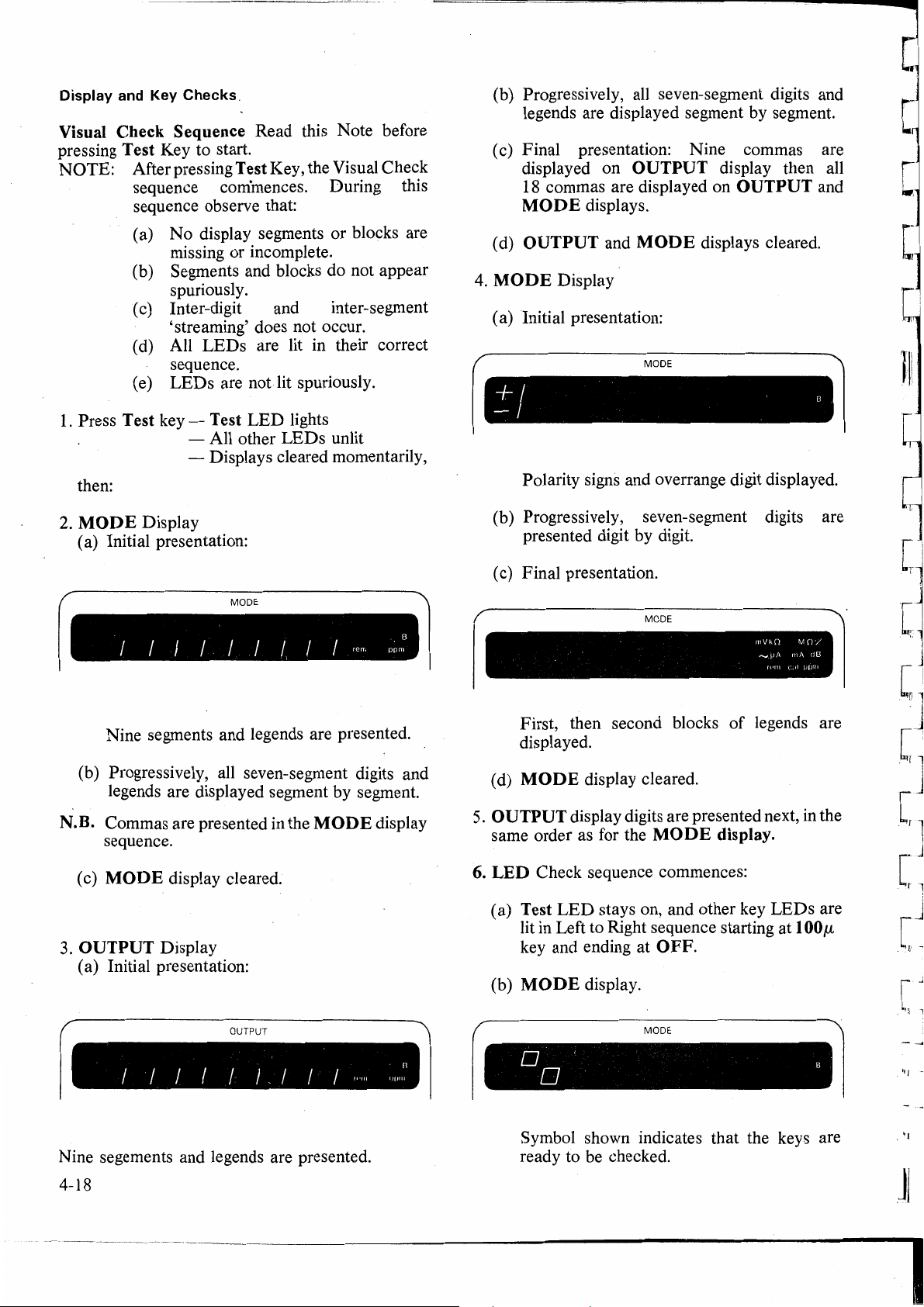

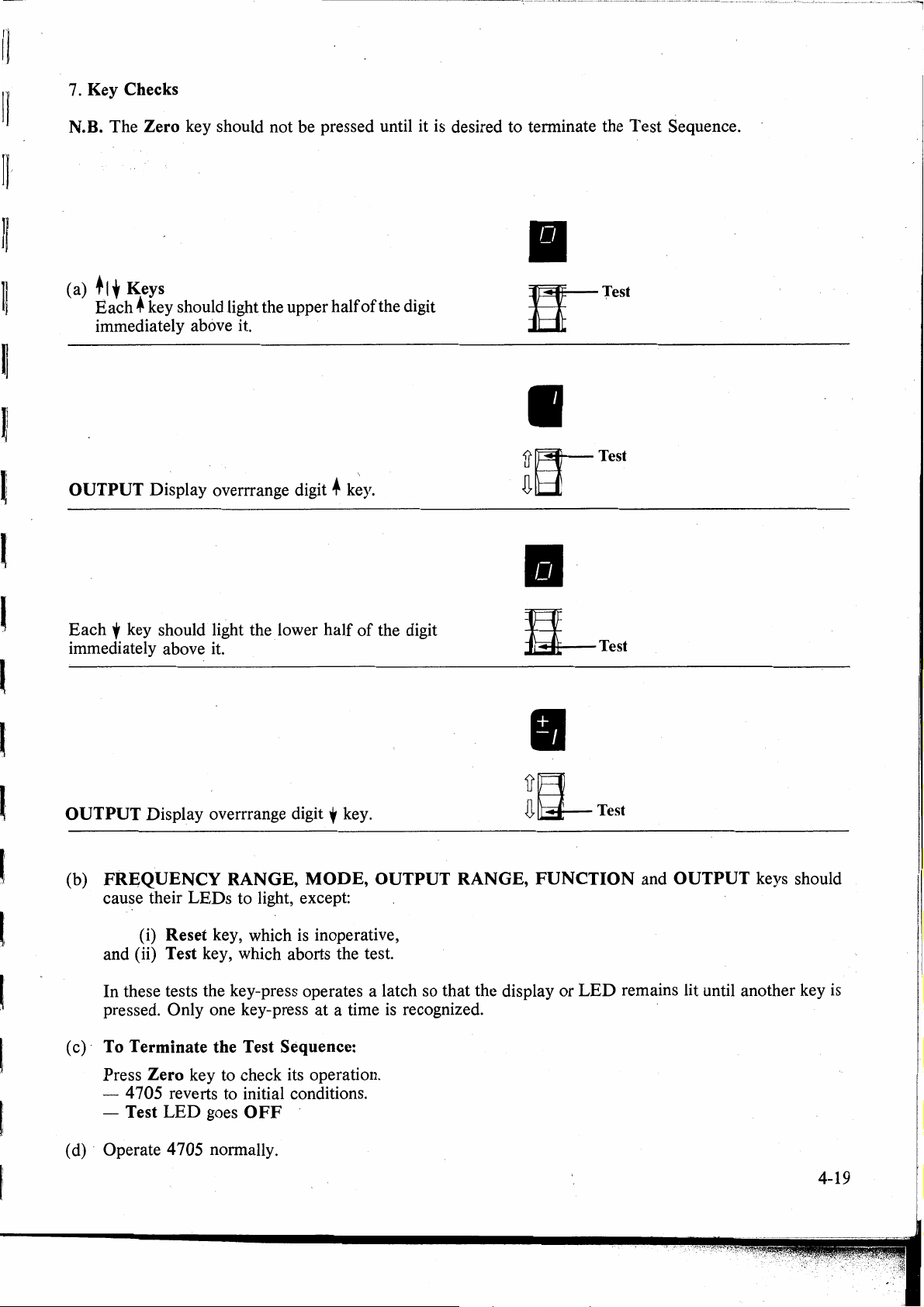

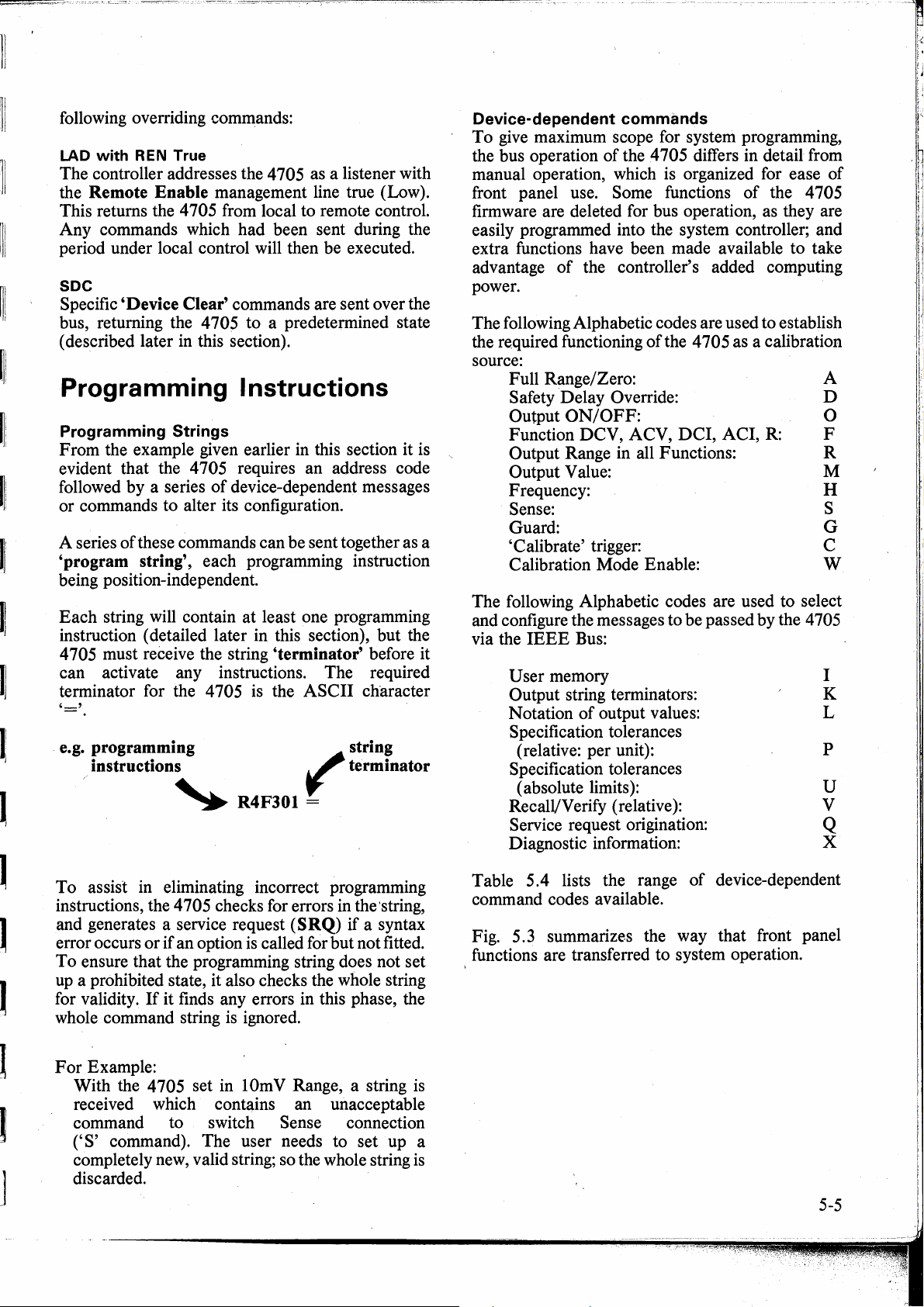

of