DATREND Systems vPad-TI Operating Manual

™

vPad-TI

Transport Incubator Tester

Operating Manual

MN-120

vPad-TI

TM

Transport Incubator Tester

Operating Manual

© 2019 Datrend Systems Inc.

130-4020 Viking Way

Richmond, BC • CANADA • V6V 2L4

Tel: 800.667.6557 (North America Only) or

604.291.7747 • Fax 604.294.2355

e-mail: customerservice@datrend.com

This manual is Datrend P/N: 6100-126

Revision

A Initial Release 2019-Jan-24

Revision History

Description Date

Copyright

Datrend Systems Inc. (“DSI”) agrees to a limited copyright release that allows you to reproduce manuals and other

printed materials for use in service training programs and other technical publications. If you would like other

reproductions or distributions, submit a written request to Datrend Systems Inc.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage

is found, stop unpacking the instrument. Notify the freight carrier and ask for an agent to be present while the

instrument is unpacked. There are no special unpacking instructions, but be careful not to damage the instrument

when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Claims

Our routine method of shipment is via common carrier. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in

good physical condition but does not operate within specifications, or if there are any other problems not caused by

shipping damage, please contact your local sales representative or Datrend Systems immediately.

Standard Terms and Conditions

Refunds & Credits

Please note only serialized products (products labelled with a distinct serial number) and accessories are eligible for

partial refund and/or credit. Non-serialized parts and accessory items (cables, carrying cases, auxiliary modules,

etc.) are not eligible for return or refund. In order to receive a partial refund/credit, the product must not have been

damaged, and must be returned complete (meaning all manuals, cables, accessories, etc.) within 90 days of original

purchase and in “as new” and resalable condition. The Return Procedure must be followed.

Return Procedure

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number,

obtained from Datrend Customer Service. All items being returned must be sent prepaid (freight, duty, brokerage,

and taxes) to our factory location.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15%. Products

returned in excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20%.

Additional charges for damage and/or missing parts and accessories will be applied to all returns. Products which

are not in “as new” and resalable condition, are not eligible for credit return and will be returned to the customer at

their expense.

Certification

This instrument was thoroughly tested and inspected and found to meet DSI’s manufacturing specifications when it

was shipped from the factory. Calibration measurements are traceable to the National Research Council of Canada

(NRC) and/or the National Institute of Standards and Technology (NIST). Devices for which there are no NRC/NIST

calibration standards are measured against in-house performance standards using accepted test procedures.

WARRANTY

Warranty and Product Support

Datrend Systems Inc. ("DSI") warrants this instrument to be free from defects in materials and workmanship under

normal use and service for one (1) year from the date of original purchase. This warranty will be automatically

extended to a maximum of two (2) years from the date of original purchase provided that calibration is performed

on an annual basis by a Datrend Authorized Service Center (refer to Chapter 7 of this manual). During the warranty

period DSI will, at our option, either repair or replace a product at no charge that proves to be defective; provided

you return the product (shipping, duty, brokerage and taxes prepaid) to DSI. Any and all transportation charges

incurred are the responsibility of the purchaser and are not included within this warranty. This warranty extends only

to the original purchaser and does not cover damage from abuse, neglect, accident or misuse or as the result of

service or modification by other than DSI. IN NO EVENT SHALL DATREND SYSTEMS INC. BE LIABLE FOR

CONSEQUENTIAL DAMAGES.

This warranty applies only to Datrend manufactured product and does not include OEM components which are

provided as part of a system. These OEM components include, but are not limited to netbook, laptop or desktop

computers, and these components shall be covered only by the OEM manufacturer’s limited warranty, and warranty

issues must be handled direct with the manufacturer.

No warranty shall apply when damage is caused by any of the following:

! Misuse or abuse of any form;

! Use of an AC power supply adapter other than the AC adapter specified for the instrument;

! Power failure, surges, or spikes;

! Damage in transit or when moving the instrument;

! Improper power supply such as low voltage, incorrect voltage, defective wiring or inadequate fuses;

! Accident, alteration, abuse or misuse of the instrument;

! Fire, water damage, theft, war, riot, hostility, acts of God, such as hurricanes, floods, etc.

Only serialized products (those items bearing a distinct serial number tag) and their accessory items are covered

under this warranty. PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT COVERED

UNDER THE WARRANTY. Items such as cables and non-serialized modules are not covered under this warranty.

This warranty gives you specific legal rights and you may have other rights, which vary from province to province,

state to state, or country to country. This warranty is limited to repairing the instrument to DSI's specifications.

When you return an instrument to DSI for service, repair or calibration, we recommend shipment using the original

shipping foam and container. If the original packing materials are not available, we recommend the following guide

for repackaging:

! Use a double-walled carton of sufficient strength for the weight being shipped.

! Use heavy paper or cardboard to protect all instrument surfaces. Use non-abrasive material around all projecting

parts.

! Use at least four inches of tightly packed, industrial-approved, shock-absorbent material all around the instrument.

DSI will not be responsible for lost shipments or instruments received in damaged condition due to improper

packaging or handling. All warranty claim shipments must be made on a prepaid basis (freight, duty, brokerage, and

taxes). No returns will be accepted without a Return Materials Authorization ("RMA”) number. Please contact

Datrend Systems, 1(604)291-7747 or email customerservice@datrend.com to obtain a Return Materials

Authorization (RMA) number and receive help with shipping/customs documentation.

Re-calibration costs of instruments are not covered under the warranty.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other than Datrend Systems,

please be advised that the original warranty covering your product becomes void when the tamper-resistant Quality

Seal is removed or broken without proper factory authorization. We strongly recommend, therefore, that you send

your instrument to Datrend Systems for service and calibration, especially during the original warranty period.

In all cases, breaking the tamper-resistant Quality Seal should be avoided at all cost, as this seal is the key to your

original instrument warranty. In the event that the seal must be broken to gain internal access to the instrument (e.g.,

in the case of a customer-installed firmware upgrade), you must first contact Datrend Systems. You will be required

to provide us with the serial number for your instrument as well as a valid reason for breaking the Quality Seal. You

should break this seal only after you have received factory authorization. Do not break the Quality Seal before you

have contacted us! Following these steps will help ensure that you will retain the original warranty on your instrument

without interruption.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock

hazards or improper operation. Datrend Systems will not be responsible for any injuries sustained due to

unauthorized equipment modifications.

DSI DISCLAIMS ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION.

THIS PRODUCT CONTAINS NO USER-SERVICEABLE COMPONENTS.

UNAUTHORIZED OPENING OF THE INSTRUMENT SHALL VOID THIS AND

ALL OTHER EXPRESSED OR IMPLIED WARRANTIES.

vPad™, vPad-XPORT™, vPad-ES™, vPad-353™, vPad-AS™, vPad-A3™, vPad-NFPA™, vPad-IN™, vPad-TI™,

vPad-RF™, vPad-Record Manager™, vPad-RM™ , vPad-EQM™, vPad-Check™, vPad-Cal™, and Datrend Docs™

and CMX™ are trademarks of Datrend Systems Inc.

Android

™

is trademark of Google Inc.

vPad-TI OPERATING MANUAL

Table of Contents

1Specifications ....................................................... 1

1.1 General ......................................................... 1

1.2 Data Collection Specifications ........................................ 2

1.3 Standard Accessories .............................................. 3

1.4 Optional Accessories ............................................... 3

2 General Information ................................................... 5

2.1 Overview ........................................................ 5

2.2 Features ........................................................ 6

2.3 Controls and Interface Connections ................................... 6

2.4 Setup .......................................................... 9

2.5 Power On....................................................... 13

2.6 vPad-TI Software ................................................. 13

2.7 Incubator ....................................................... 14

3 Tablet Setup ....................................................... 15

4Operation .......................................................... 17

4.1 HOME Screen ................................................... 17

4.2 Startup ......................................................... 19

4.3 Test Settings .................................................... 19

4.4 Global Settings .................................................. 20

4.5 Create/Edit/Run Autosequences ..................................... 24

4.6 Run Test ....................................................... 31

5 Running a Test ..................................................... 33

5.1 Overview ....................................................... 33

5.2 Noise Sound Level Test ........................................... 33

5.3 Probe Test ...................................................... 38

5.4 Air Flow/Air Velocity Test........................................... 42

5.5 Warm Up Time Test .............................................. 44

5.6 Cold Ambient Temperature at 36°C .................................. 47

5.7 Air Temperature Control Regulation Error(ACTRE) at 36 .................. 52

5.8 Air Temperature Control Test - High .................................. 54

5.9 Air Temperature Control Test - Low .................................. 57

5.10 Baby Temperature Control ........................................ 59

5.11 Humidity and Temperature Checks .................................. 61

5.12 Temperature Overshoot .......................................... 62

5.13 Alarm Sound Level - Inside ........................................ 65

5.14 Alarm Sound Level - Outside ....................................... 66

5.15 Saving Test Reports ............................................. 68

6 Test Reports ....................................................... 70

6.1 Overview ....................................................... 70

6.2 Recalling Records ................................................ 70

6.3 View Raw Data .................................................. 71

6.4 Exporting data .................................................. 72

vPad-TI OPERATING MANUAL

7 Calibration and Maintenance ........................................... 73

vPad-TI OPERATING MANUAL

Abbreviations, Definitions and Symbols

The following abbreviations, terms and acronyms are used throughout this manual:

ACTRE Air Control Temperature Regulation Error

AIT Average Incubator Temperature

ATX Average Temperature of Temperature Sensor X, where X = 2 - 5

AV Air Velocity

BSL Background Sound Level

°C degrees Celsius (centigrade)

°F degrees Fahrenheit

Autosequence A series of measurements or test operations that are run

automatically in a predefined order, with or without user involvement.

DUT Device Under Test

GUI Graphical User Interface

IT Incubator Temperature

IIT Independent Incubator Temperature

NSL Noise Sound Level

STC Steady Temperature Condition

STS Skin Temperature Sensor

TC Temperature Control

TEMP Temperature

WT Warm Up Time

CAUTION: Read the instructions for use before operating this device.

Definitions:

Some of the following definitions are paraphrased from the relevant sections and

clauses of IEC 60601-2-20, Edition 2

Air Control

Temperature

Regulation Error

Average Transport

Incubator

Temperature

Clause 201.12.1.106: an incubator operating in AIR

TEMPERATURE CONTROL shall have an AVERAGE

TEMPERATURE that does not differ from the CONTROL

TEMPERATURE of 36°C by more than ±1.5°C at an ambient

temperature between 20°C and 25°C; or, ±2°C at an ambient

temperature between 10°C and 20°C

Clause 201.3.203: the average of the maximum and minimum

INCUBATOR TEMPERATURES achieved during STEADY

TEMPERATURE CONDITION

vPad-TI OPERATING MANUAL

Average

Temperature

Clause 201.3.202: the average of the maximum and minimum

temperatures at any specified point in the COMPARTMENT

achieved during STEADY TEMPERATURE CONDITION

Compartment Clause 201.3.205: environmentally controlled portion of the

INCUBATOR intended to contain a baby

Control

Temperature

Clause 201.3.206: temperature selected on the incubator as the

desired temperature in the COMPARTMENT

Autosequence A series of measurements or test operations that are run

automatically in a predefined order, with or without user

involvement

Device Under Test The device (the transport incubator) being tested by VPad-TI

Graphical User

Interface

A display system for the test instrument (vPad-TI) which relies

on graphics to a large extent to display information. In the case

of vPad-TI, this is an Android tablet (10") with and Android type

operating system (5.1.1), or equivalent

Incubator Clause 201.3.205: an enclosure, intended to contain a baby and

having transparent section(s) which allow(s) for viewing of the

baby, provided with means to control the environment of the

baby primarily by heated air within the enclosure

Transport Incubator

Temperature

Independent

Incubator

Temperature

Clause 201.3.212: temperature of the air at a point 10 cm above

the center of the mattress surface in the COMPARTMENT

A temperature representative of INCUBATOR TEMPERATURE

provided by an independent indicator (not powered by the

incubator). Commonly an alcohol based thermometer (nonmercury), but may be of an alternate type)

NSL Noise Sound Level

Steady Temperature

Condition

Clause 201.3.211: the condition reached when the

INCUBATOR TEMPERATURE does not vary by more than 1

over a period of one hour

Skin Temperature

Sensor

Clause 201.3.210: a sensing device intended to measure the

baby’s SKIN TEMPERATURE

o

C

vPad-TI OPERATING MANUAL

1 Specifications

1.1 General Specifications

Environment:

• 15 °C to 40 °C (59 °F to 104 °F)

• 10% to 90% Relative Humidity

• Indoor Use Only

• Category II

• Pollution Degree 2

Note: Mains supply voltage fluctuations not to exceed +/- 10% of the nominal supply voltage.

User Interface:

vPad-TI is supplied with a 10" (nominal) Android tablet which has the vPad-TI application

pre-installed and ready to run. The software is controlled by touching a function button on

the graphical user interface (GUI) or, where applicable, by entering specific data via the

keyboard.

Display (10" Android Tablet):

1920 x 1200 color IPS touch screen LCD

Specifications/Chapter 1 # Page 1

vPad-TI OPERATING MANUAL

1.2 Data Collection Specifications

Temperature:

• Measurement Range: 25 °C - 50 °C

• Accuracy: Ta: ± 0.05 °C

• Resolution: 0.01 °C

• Convection: 5 ‘puck’ sensors (T6 - T10) - radiant warmer

• Air Conduction: 5 sensors (alternate ‘post’ Ta - Te) - incubator

1 mattress temperature

• Optional Skin Sensor

‘oven’ with thermal pad

contact:

Airflow:

• Measurement Range: 0.1 to 1 m/s

• Accuracy: ± 0.1 m/s

Relative Humidity:

• Measurement Range: 0 - 100%

• Accuracy: ± 3 %

• Resolution: 0.1% RH

Sound Level:

• Measurement Range: 30 dbA to 100 dbA, Type III

28 °C to 40 °C in 2 °C increments ± 0.01 °C resolution,

± 0.05 °C Accuracy

at 50% RH ± 15%

Non Condensing

• Accuracy: ± 3 dbA

• Resolution: 0.1 dbA

Data Retention:

• Capacity: up to 48 hours per test

• Sample Rate: 1/min or 1/sec, depending on parameter

Specifications/Chapter 1 # Page 2

vPad-TI OPERATING MANUAL

1.3 Standard Accessories

AC Adapter (all models): 100-240 VAC 50/60 Hz to 9 VDC (p/n 3000-611)

Blade Sets kit for P/N 3000-611: P/N 7500-490

(Includes: North America; Europe/Schuko; United Kingdom; China/Australia)

AA Battery, 1.2V 2300mAH: P/N 3310-012

1.4 Optional Accessories

For a complete list of available accessories, visit www.datrend.com or contact Datrend

Customer Service (see Chapter 7 for contact details)

Specifications/Chapter 1 # Page 3

vPad-TI OPERATING MANUAL

Specifications/Chapter 1 # Page 4

vPad-TI OPERATING MANUAL

2 General Information

2.1 Overview

vPad-TI is a portable data logging system for temperature, air flow, humidity, and sound level;

specifically configured to test infant transport incubators and, optionally, incubators and radiant

warmers to applicable IEC performance standards. The data collection system is designed to

operate for up to 48 hours from a rechargeable 4.8VDC nickel-metal hydride (4 AA cells)

battery, or alternatively, from a 5VDC switch mode AC adapter. The sensors and the data

collection system are placed on the mattress of the transport incubator, and external to the device

under test (DUT), a user interface based on an Android tablet communicates wirelessly to the

sensor system via Bluetooth, and provides the user with the ability to control the test operation

and display the results without disturbing the test environment.

vPad-TI incorporates all the functionality necessary to meet the requirements of the IEC

standard, related to temperature, airflow, humidity, and sound level tests. vPad-TI incorporates a

graphical user interface which interfaces wirelessly to 6 temperature sensors, 1 airflow sensor, 1

humidity sensor, and 1 sound level meter. vPad-TI also incorporates a non-volatile memory or "data

log" which is used to save test data, such tests typically being conducted by the user over several

hours or days.

Overview/Chapter 2 # Page 5

vPad-TI OPERATING MANUAL

2.2 Features

IEC 60601-2-20 ed.21 is a standard which specifies safety and performance requirements for an

infant transport incubator. Some of the parameters that lend themselves to testing are

temperature, sound level, air flow and humidity. These parameters are monitored at specific

locations within the incubator and are expected to conform to the values defined by the

Standard. vPad-TI provides the mechanical framework to hold the sensors in the appropriate

locations, and provides the ability to adjust the framework to fit incubators of various sizes.

vPad-TI provides 5 temperature sensors which are positioned according to the standard, with

one central sensor and one sensor in the center of each of four quadrants on the mattress. The

central sensor is an integral component of the data collection and wireless communication hub

of the system. In addition to the 5 temperature sensors, vPad-TI provides mattress

temperature, airflow, sound level and humidity sensors in separate packages which connect to

the central hub. The test protocols are designed to perform all the temperature tests in one

contiguous time block to avoid numerous long heating and cooling cycles. Tests of airflow,

sound and/or humidity are performed either before or after the temperature tests so that the

sensors can be moved about in the incubator without disrupting a temperature test.

2.3 Controls and Interface Connections

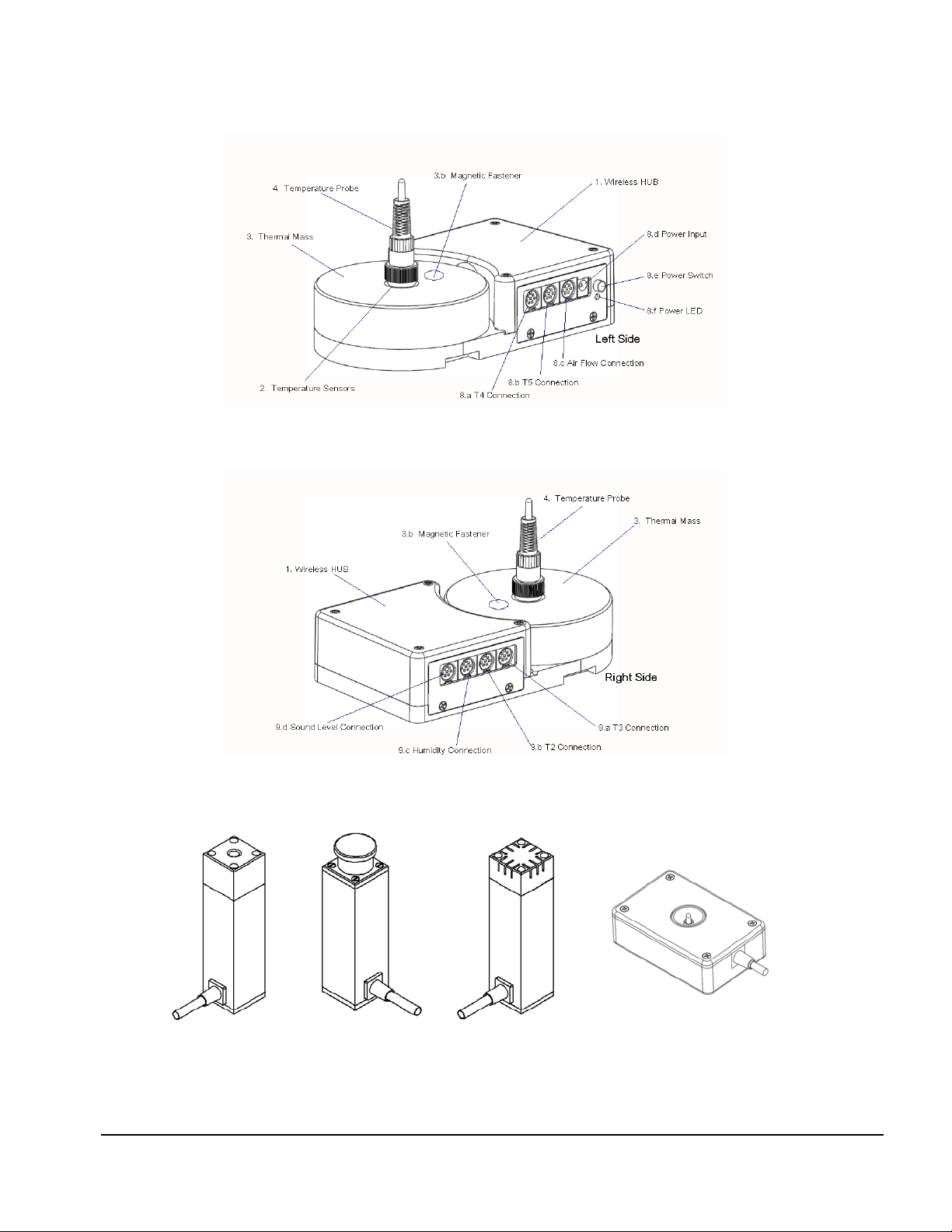

Referring to Figure 1 through Figure 5, the following components, controls and interfaces of

the vPad-TI Transport Incubator Test system are:

1. Sensor Electronics and Wireless

Hub (the HUB)

2. Temperature Connectors Temperature Probes (Ta - Te) are connected on

3. Thermal Mass (the Puck)

4. Temperature Probe (Ta - Te) Bypasses the thermistor in the Puck and places the

Provides the connection point for all sensors used

internally to the incubator or warmer under test.

Also referred to as the DAT unit.

the top of a large, black thermal mass (Puck) to

place the thermistor in the correct position above

the mattress.

Thermal mass to mimic the infant body for

convection warming in a radiant warmer. Contains

Magnetic Fastener (3.b) for attachment of other

sensors

thermistor at the correct position above the

mattress, per the Standard.

1

Throughout this manual, IEC 60601-2-20 ed.2 is referred to as the “Standard”

Overview/Chapter 2 # Page 6

vPad-TI OPERATING MANUAL

5. Mattress Temperature Measures the temperature of the mattress

6. Airflow Sensor Measures the flow of air, and can be moved as

required. Held in place on the Puck magnetically.

7. Sound Level Sensor Measures sound level. Can be moved within the

device under test (DUT) and can also be connected

to an extension cable for external sound/alarm

level measurements. Held in place on the Puck

magnetically.

8. Humidity Sensor Measures Humidity. Can be moved within the

device under test (DUT). Held in place on the

Puck magnetically.

9. Hub Connections - Left Side a. T4 (Td) Temperature Input

b. T5 (Te)Temperature Input

c. Airflow Sensor Input

d. Power Input

e. Power LED

f. Power Switch

10. Hub Connections - Right Side a. T3 (Tc)Temperature Input

b. T2 (Tb)Temperature Input

c. Humidity Sensor Input

d. Sound Level Sensor Input

11. Positioning Frame Allows Tb - Te Pucks to be positioned with respect

to Ta at the center of the mattress

12. Positioning Frame Components a. longitudinal positioning bar

b. horizontal positioning bar

c. T bracket

Each of the sensors has an internal magnet on the bottom which will hold it in place on the

Thermal Mass. Each sensor also has a cable with a miniDIN connection to connect to the

HUB.

When used, the

Mattress Temperature sensor connects to the HUB in the Humidity

position, and the Humidity Sensor connects to the Mattress Temperature module in a daisy

chain fashion.

Overview/Chapter 2 # Page 7

vPad-TI OPERATING MANUAL

Figure 1: Wireless HUB - Left Side View

Figure 2: Wireless HUB - Right Side View

Figure 3:

Sound Level Sensor

Figure 4:

Air Flow Sensor

Overview/Chapter 2 # Page 8

Figure 5:

Humidity Sensor

Figure 6: Mattress

Temperature Sensor

vPad-TI OPERATING MANUAL

2.4 Setup

To test a transport incubator according to the Standard, the Sensor System must be placed on

the mattress of the DUT with the Temperature Probe of the Hub in the center of the mattress,

and the Temperature Probes of the remaining 4 Temperature Pucks placed in the center of

each of the 4 quadrants of the mattress. The positioning frame is designed to assist in the

positioning of the Pucks and to hold them in place during a test.

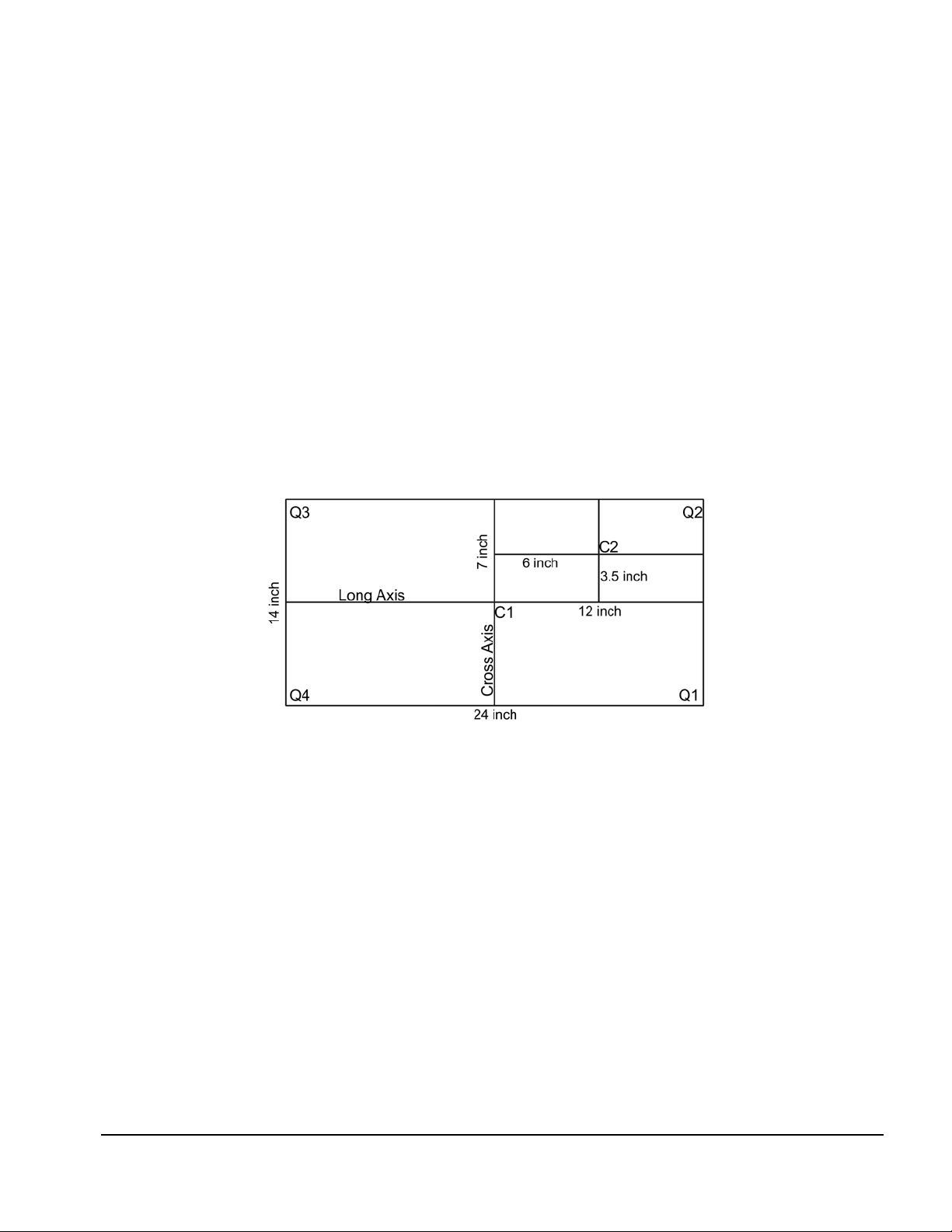

Measure the mattress to determine its size. For instance, the AirShields C200 has a nominal

mattress size of 14 inches wide (36 cm) by 24 inches long (61 cm). Divide the mattress into 4

quadrants, each quadrant being 7 inches (18 cm) by 12 inches (30.5 cm). For this mattress, the

center of quadrant Q2 is 3.5 inches above the long axis and 7 inches from the cross axis, see

point C2, Figure 7.

Figure 7: Mattress Quadrants and Center Locations

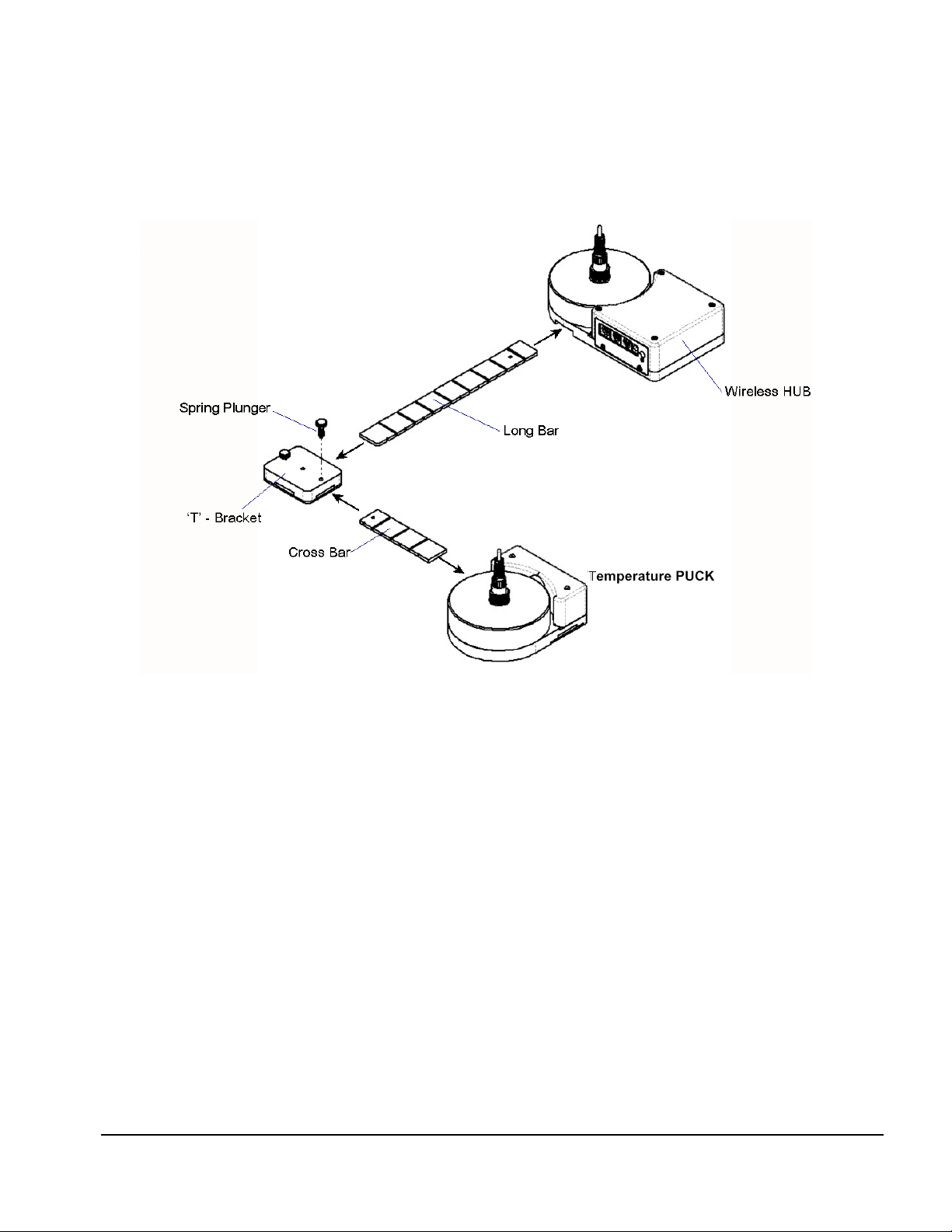

In setting up the positioning frame, the longitudinal (long) bar would be placed in the body of

the HUB, with the end having a small hole about 1" from the end sliding into the slot in the

HUB, as indicated in Figure 8. The ‘T- bracket’ is placed over the long bar and slid into the

position marked ‘6’ inches on the long bar. Similarly, the horizontal (cross) bar is slid into the

‘T- bracket’ and locked in place with the spring plunger. The smaller Temperature Puck is

then slid into place to the position marked ‘3.5’ inches on the cross bar. If the positioning

frame is placed with the temperature probe of the HUB in the center of the mattress at C1,

then the second temperature probe would be in the center of the mattress quadrant Q2 at

position C2 in the diagram. For mattresses of other sizes, the ‘small’ Pucks can be moved

along the bars as required to meet the dimensional requirements.

Overview/Chapter 2 # Page 9

vPad-TI OPERATING MANUAL

If the smaller Temperature Puck seems too close, it can be rotated 180 degrees, in which

case, add 3.5" to the markings on the long bar. In the example above, the 9.5 inch marking (6"

+ 3.5" = 9.5") would be used.

Figure 8: Positioning Frame Assembly

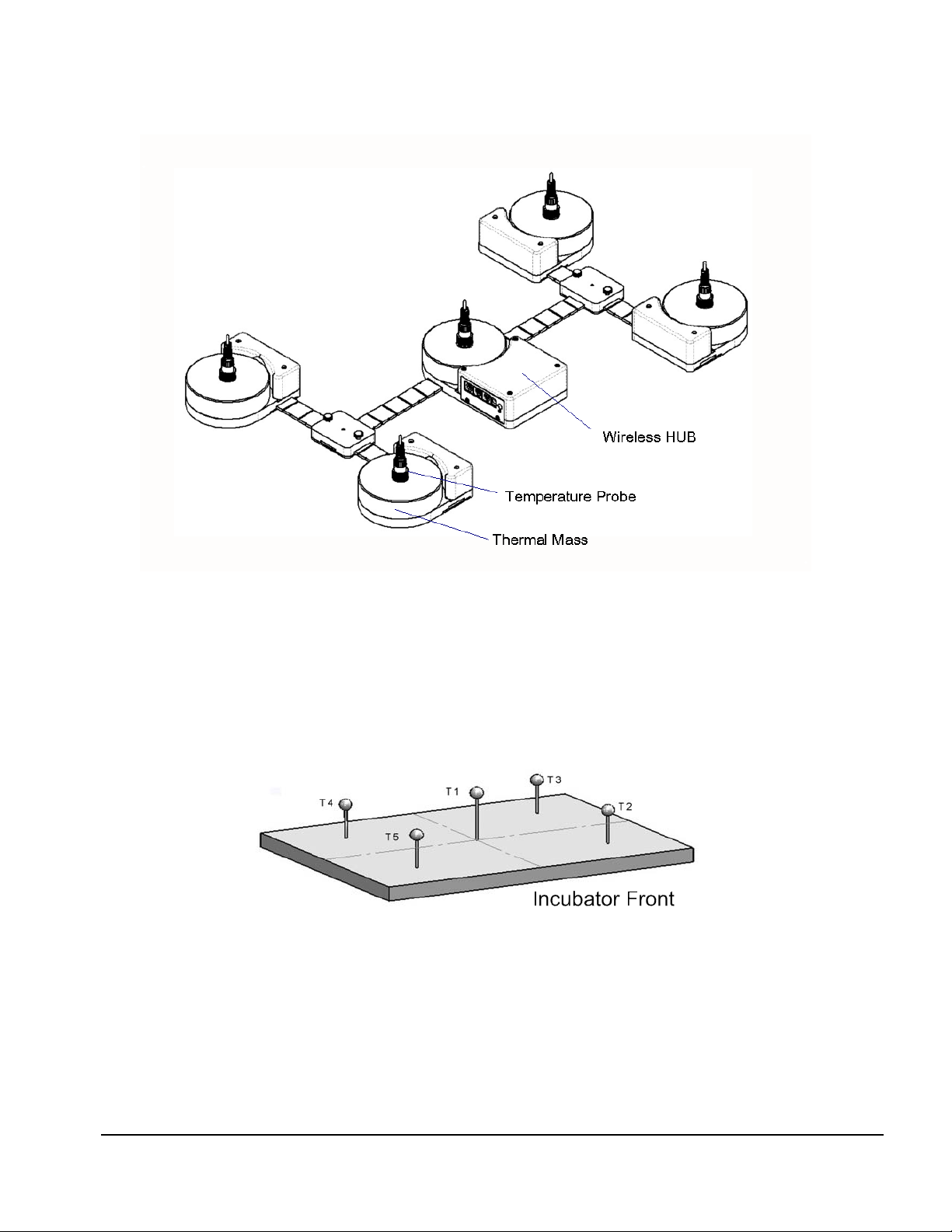

Temperature Pucks for each of the other three quadrants are set up in the same manner. The

fully assembled system is shown in Figure 9Figure 9.

The vPad-TI Transport Incubator test system is now configured mechanically, according to the

Standard, to take temperature and other measurements in the center of the incubator and in the

center of each of the four quadrants of the mattress. It is now necessary to make the electrical

connections for each of the sensors.

As previously described, the large round ‘Puck’ represents a thermal mass imitating the infant

body in a convection warming environment. This ‘Puck’ is made of aluminum with a black

heat absorbing coating, with a temperature sensor embedded in the aluminum block. In this

configuration, the temperature measured by the ‘Puck’ is specifically configured to test

warmers

. For testing

incubators

, a Temperature Probe is inserted into the connector at the

radiant

center of each Puck. This Temperature Probe bypasses the thermistor in the Puck and elevates

the thermistor in the Probe to a position approximately 10 cm above the mattress, in

accordance with the Standard.

Overview/Chapter 2 # Page 10

vPad-TI OPERATING MANUAL

Figure 9: Sensor Frame Fully Assembled

In the Test Reports generated by the test software, the temperatures are referred to as Ta (1) for

the center of the incubator, and Tb (2), Tc (3), Td (4) and Te (5) for each of the quadrants as

shown in Figure 10.

Figure 10: Temperature Sensor Positions

Overview/Chapter 2 # Page 11

vPad-TI OPERATING MANUAL

The cables from the individual Pucks will connect to the HUB as indicated in Figure 11,

Figure 1 and Figure 2.

Figure 11: Temperature Sensor Connection Locations

The sensors for Sound, Airflow and Humidity also connect to the HUB, as indicated in Figure

1 and Figure 2. These sensors are utilized when the relevant test is selected in the software test

setup. When utilized, the sensors are held in place on the Puck by magnets.

The tablet connects wirelessly via Bluetooth to the wireless HUB.

The tablet also provides connection to the Skin Sensor Oven through the USB port so

that Skin Temperature Probes can be checked for accuracy.

Overview/Chapter 2 # Page 12

vPad-TI OPERATING MANUAL

2.5 Power On

After the System has been setup for the required mechanical positions, it may be turned on by

pressing the Power On switch on the HUB, shown in Figure 1. If the HUB is being charged,

with the AC Adapter plugged into the Power Input connector, a small LED below the Power

On switch will illuminate RED, regardless of the position of the Power On switch. If the

Power On switch is activated but the AC Adapter is not plugged in, the LED will illuminate

YELLOW. If the AC Adapter is not plugged in and the Power On switch is NOT activated,

the LED will not illuminate.

The HUB may be powered by battery or by AC Adapter.

Once turned ON, the HUB will wait for the tablet to initiate communications.

2.6 vPad-TI Software

The vPad-TI software is pre-loaded on the tablet. When turned on, the tablet presents the

Android Home screen, where selecting the vPad-TI icon will run the vPad-TI Application.

When you exit the Application, the tablet will return to the Home screen. It is recommended

no other apps be loaded onto the tablet so as to avoid conflicts with other apps, or accidentally

infecting the computer with a virus or other malware. Problems which arise from loading other

apps on the tablet are not covered by warranty.

NOTE: The vPad-TI software is setup to test Infant Transport Incubators. The large

black PUCKs are the required thermal mass for Radiant Warmer testing and have

embedded temperature sensors for that purpose. The vPad-RW app is available for

Radiant Warmer testing.

The software will allow the user to create different test protocols that may not encompass the

complete requirements of the Standard, but which are suitable for testing or verifying different

parts of the incubator’s operation. The Default test protocol includes all of the tests required

by Section 8 (Accuracy of Data) and some parts of Section 11(Additional Requirements) of the

Standard. User defined protocols may be created, saved and recalled for future use.

In addition, the user can create a mini database of the incubators and warmers that have been

or are to be tested. In order to do a test, the user must input an identification number (ID)

and/or a serial number, so that the test report can be identified. The test technician’s initials

are also required so the report will show who was responsible for doing the test. Other

information can be optionally input to further identify the DUT.

Overview/Chapter 2 # Page 13

vPad-TI OPERATING MANUAL

2.7 Incubator Primer

Infant Incubators are a controlled temperature environment which are used to maintain the

body temperature of newborns who, for various reasons, are unable to regulate their own body

temperature. Incubators generally work in one of two modes: 1) air temperature control, or 2)

body temperature control.

In air temperature control, the heater in the incubator is used to control the temperature of the

air at a location close to the heater. The air is forced to flow through the incubator chamber by

means of a fan. The air circulates through the main chamber of the incubator where the infant

lies on a mattress. The air returns to the heating chamber, which normally is located in a

mechanical structure below the main chamber. The incubator is designed to create an airflow

which is reasonably consistent in the main chamber, normally from back to front. In addition,

the main chamber is designed to reduce temperature loss as much as possible through the use

of double walls of acrylic.

In many circumstances, keeping the infant surrounded by a blanket of air at a constant

temperature is sufficient to keep the infant warm. However, under certain circumstances the

infant may continue to lose heat. In these cases it may be more effective to control the

temperature of the air by monitoring the baby skin temperature directly and adjusting the air

temperature to maintain the skin temperature at the desired temperature. When operating in

this mode, the incubator will generally have an air temperature slightly above the skin

temperature of the infant.

In addition to controlling the temperature of the air, incubators will also support a number of

other features, including but not limited to: alarms for high temperature, humidity control and

independent, non-electronic, temperature indicators.

Overview/Chapter 2 # Page 14

Loading...

Loading...