Datexel DAT 4530 User Manual

DAT 4530

DAT 4530

Universal isolated converter

configurable by Dip-Switch or PC

double output & trip amplifier

TECHNICAL SPECIFICATIONS (Typical @ 25 °C and in nominal conditions)

Line resistance influence (1)

TC, mV <=0.8 uV/Ohm

RTD 3w (50W max balanced) 0.05%/W

RTD 4w (100W max balanced) 0.005%/W

Linearity (1)

TC, RTD ± 0.1 % f.s.

mV, V, mA ± 0.05 % f.s.

Thermal drift (1)

Full scale ± 0.01% / °C

CJC ± 0.01% / °C

RTD excitation current

RTD, Res 400 uA

CJC Comp. ± 0.5°C

Input impedance

TC, mV >= 10 MW

mA ~22 W

Aux. Voltage >18V @ 20mA

ALARM TRIP (SSR)

Contact SPST

Max Load (resistive) :

Voltage 48 Vdc / 30 Vac

Current 0.4 A

Aux. Voltage >12V @ 20mA

FEATURES

- Universal configurable input for:

mV, Tc, RTD, Res, Potentiometer, V and mA

- Two outputs configurable in current or voltage

- Trip alarm

- Configurable by dip-switch or PC

- High accuracy

- On-field reconfigurable

- Galvanic isolation among all the ways

- UL / CE mark

- Suitable for DIN rail mounting in compliance

with EN-50022 and EN-50035

GENERAL DESCRIPTION

The universal isolated converter DAT 4530 is able to measure and linearise voltage, current and resistance signals, potentiometers and the standard

thermocouples and RTDs with, if required, the cold junction compensation, the wires compensation. For mV, V and mA input it is possible to set an

option for the fast sampling (option HS) or to extract the square root of the measured signal (option SQRT). In function of programming, the measured

values are converted in a current or voltage signal on the two outputs. Moreover an output contact is available as trip alarm.

By dip-switches accessible opening the window on the side of the enclosure, it is possible to select the input type and range and the output type without

recalibrate the device.

By Personal Computer the user can set the two outputs with independent settings, the parameters of the Trip Alarm and the optional parameters for his

own necessity;

The galvanic isolation between input, outputs and power supply eliminates the effects of all ground loops eventually existing and allows the use of the

converter in heavy environmental conditions found in industrial applications. The device guarantees high accuracy and performances stability both

versus time and temperature.

The DAT 4530 is in compliance with the Directive UL 61010-1 for US market and with the Directive CSA C22.2 No 61010-1 for the Canadian market.

It is housed in a plastic enclosure of 12.5 mm thickness suitable for DIN rail mounting in compliance with EN-50022 and EN-50035 standards.

USER INSTRUCTIONS

The connections must be made as shown in the section "Connections".It is possible to configure the converter on field by dip-switch or Personal

Computer as shown in the section “ Programming ". The configuration by dip-switches can be made also if the device is powered (note: after the

configuration the device takes some seconds to provide the right output measure ).

Output type Min Max Min Span

Output resolution

Current 7 uA

Voltage 4 mV

Burn-out values

Max. output value 22 mA or 11 V

Min. output value 0 mA or -0.6 V

Current 0 mA 20 mA 4 mA

Voltage 0 V 10 V 1 V

Response time (10÷ 90%) about 400 ms

100 ms (option HS)

Output load Resistance - Rload

Current output < 500 W

Voltage output > 10 KW

Short circuit current 30 mA max.

OUTPUT (2 CHANNELS)

MECHANICAL SPECIFICATIONS

Material Self-extinguish plastic

IP Code IP20

Wiring wires with diameter

0.8÷2.1 mm2 /AWG 14-18

Tightening Torque 0.8 N m

Mounting in compliance with DIN

rail standard EN-50022

and EN-50035

Weight about 90 g.

Power supply voltage 20 .. 30 Vdc

Reverse polarity protection 60 Vdc max

Current consumption

Current output 90 mA max.

Voltage output 30 mA max.

ISOLATION

Among all the ways 1500 Vac,

50 Hz, 1 min

POWER SUPPLY

Input type Min Max Span min

Accuracy (1)

mV, TC the higher of ±0.1% and ±12 uV

RTD the higher of ±0.1% and ±0.2°C

Res. the higher of ±0.1% and ±0.15

Potentiometer ± 0.05 % f.s.

Voltage the higher of ±0.1% and ± 2 mV

mA the higher of ±0.1% and ± 6 uA

mV, V, mA ± 0.5 % f.s (opt. HS)

RTD (2, 3, 4 wires)

Pt100 -200°C 850°C 50°C

Pt1000 -85°C 185°C 30°C

Ni100 -60°C 180°C 50°C

Ni1000 -60°C 150°C 30°C

RES. (2, 3, 4 wires) 0 W 500 W 50 W

0 W 2000 W 50 W

INPUT

Voltage -10 V 10 V 1 V

TC (CJC int./ext.)

J -200°C 1200°C 100°C

K -200°C 1300°C 100°C

S 0°C 1750°C 400°C

R 0°C 1750°C 400°C

B 0°C 1850°C 400°C

E -200°C 1000°C 100°C

T -200°C 400°C 100°C

N -200°C 1300°C 100°C

Voltage

mV -100 mV +90 mV 5 mV

mV -100 mV +200 mV 10 mV

mV -100 mV +800 mV 20 mV

(1) referred to the input Span (difference between max. and min.)

Pot. (Rnom.< 50KW) 0 % 100 % 10 %

Current 0 mA 20 mA 1 mA

RTD/RES

V

mA

V

mA

TcmV

mA

V

Pot

Alarm

DC SUPPLY

+

-

ENVIRONMENTAL CONDITIONS

Operative Temperature -20°C .. +60°C

UL Operative Temperature -10°C .. +60°C

Storage Temperature -40°C.. +85°C

Humidity (not condensed) 0 .. 90 %

Maximum Altitude 2000 m

Installation Indoor

Category of installation II

Pollution Degree 2

CERTIFICATIONS

EMC ( for industrial environments)

Immunity EN 61000-6-2

Emission EN 61000-6-4

UL

US Standard UL 61010-1

Canadian Standard CSA C22.2 No 61010-1

CCN NRAQ/NRAQ7

Typology Open Type device

Classification Industrial Control

Equipment

File Number E352854

4-20mA Current Splitter

Phone: +1 561 779 5660 E-mail : Info@datexel.com - Web Site www.datexel.com

87654321

87654321

SW1

SW2

Input type

Out B

Full scale

Zero

OFF

ON

- Input type Pt100

- Option 3 wires

- Out A 4-20 mA

- Out B 0-10 V

- Full scale 200 °C

- Zero -50 °C

EX. of configuration

SW1 =

SW2 =

SW3 =

4321

SW3

Out AOpt

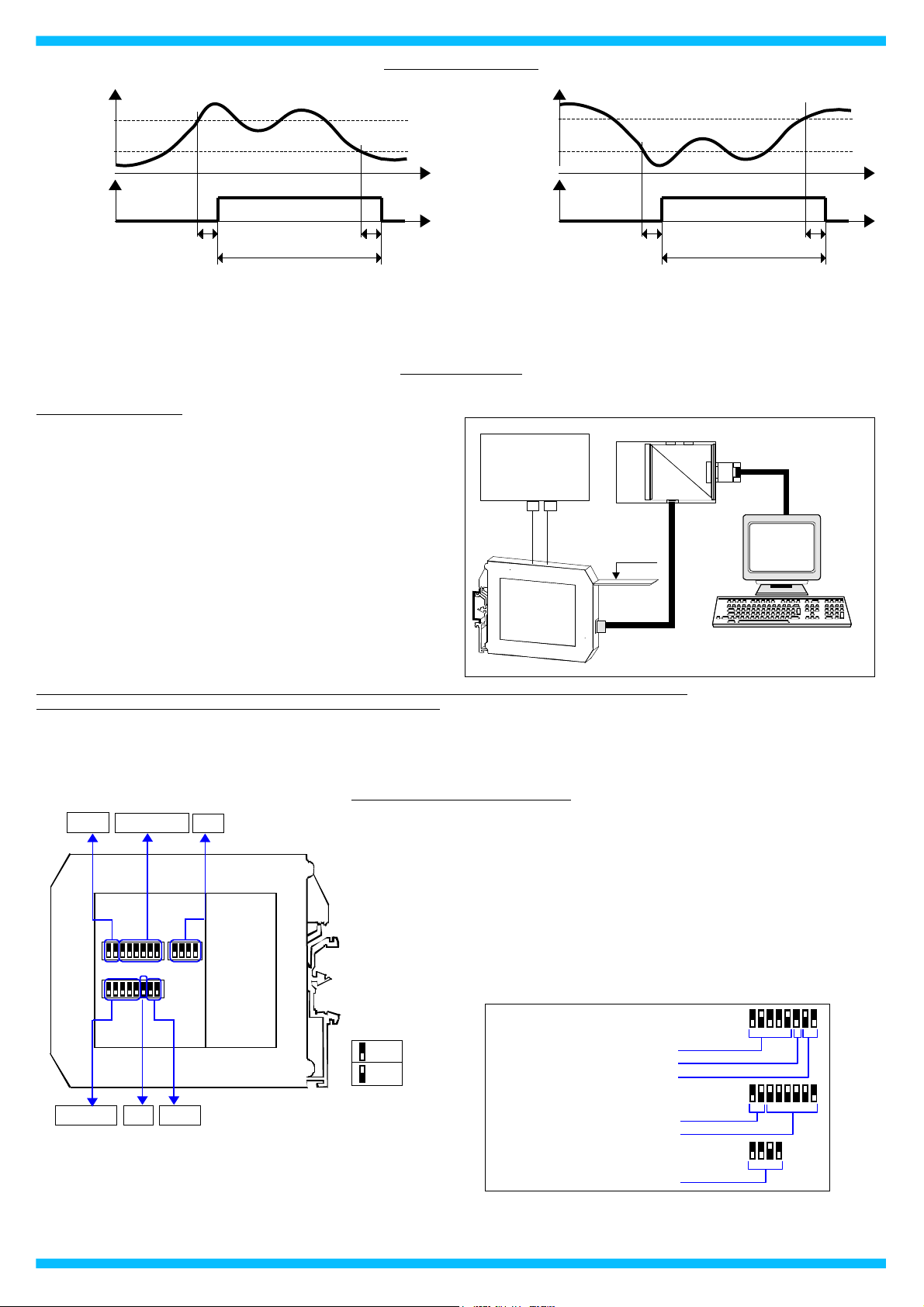

CONFIGURATION BY PC

By software DATESOFT it is possible to:

- set the default programming of the device;

- program the options not available with the dip-switch;

(burn-out level, CJC offset, trip alarm settings, fast sampling, etc...);

- read, in real time, the input and output measures;

- follow the dip-switches configuration wizard.

To configure the device follow the next steps:

1) Power-on the device.

2) Open the protection plastic label on the front of the device.

3) Connect the interface PRODAT to the PC (COM port)

and to the device (PGRM connector).

4) Open DATESOFT.

5) Select the COM port in use.

6) Click on “Open COM”.

7) Click on the icon “Program”.

8) Set the programming data.

9) Click on the icon “Write” to send the programming data to the device.

Warning: during these operations the device must always be powered and the TX/RX cable always connected.

For information about DATESOFT refer to the software's user guide.

J1

TX/RX CABLE

PRODAT

COM PORT

P.C.

V+ V-

U

V

PGRM

Plastic label protection

DAT

POWER SUPPLY

UNIT

PROGRAMMING

CONFIGURATION BY DIP-SWITCHES

1) Open the suitable door on the side of the device.

2) Set the input type by the dip-switch SW1 [1..5] (see TAB.1)

3) Set the output A type by the dip-switch SW1 [7..8] and SW2 [1..2] (see TAB.2)

4) Set, if available, the input option by the dip-switch SW1 [6] (see TAB.3)

5) Set the minimum input scale value (Zero) by the dip-switch SW3 [1..4] (see TAB.4)*

6) Set the maximum input value (Full scale) by the dip-switch SW2 [3..8] (see TAB.4)*

NOTE:

- It is also possible to set the dip-switches using the wizard of the

configuration software following the procedure described in the section

”Configuration by PC” until the step 6 and clicking on icon “Switch”.

THRESHOLD OPERATION

For the high alarm the relay goes on when the input signal is higher than

the trip level and after the delay time. The relay goes off only when the

input signal is lower than the trip level minus the hysteresis value or when

reaches the minimum value of the input scale and after the delay time.

For the low alarm the relay goes on when the input signal is lower than the

trip level and after the delay time. The relay goes off only when the input

signal is higher than the trip level plus the hysteresis value or when

reaches the maximum value of the input scale and after the delay time.

T(delay) T(delay)

Active relay

Trip level

Trip level - hyst.

T(delay) T(delay)

Active relay

Trip level

Trip level + hyst.

HIGH ALARM THRESHOLD

LOW ALARM THRESHOLD

Loading...

Loading...