Page 1

1

Universal Input

8

264Vac o 110-340dc

e

sal Inut

85-264Vac or 110-340Vdc

OBSOLETE PRODUCT

Contact Factory for Replacement Model

FEATURES

N

Up to 80% efficient single, dual, and triple-

output model

N

Individual, fully-isolated outputs:

3000Vac on main

4000V double-isolation on auxiliaries

N

Available with +5V, +12V, and +24V outputs

N

Low noise: 40mVp-pk on main, 8mVp-pk on

auxiliaries; Ideal for sensitive instrumentation

N

Universal input: 85-264Vac @ 47-63Hz or

110-340Vdc

N

Choice of 5, 10, or 16W models for minimal

system power-consumption

N

Standby power consumption as low as 0.6W

N

Short-circuit protection on all outputs;

OVP on main output

N

Built-in ac mains fuse & ‘Power On’ indicator

N

5W models operate up to 5 LED-display DPM’s

N

Vibration-resistant, chassis-mount

modular packages

N

EMC compliant; UL/CSA recognized

N

Low cost!

Murata Power Solution’s DMS-PS-CM Series

of high-efficiency, chassis mount AC/DC

power supplies feature low noise (40mV on

main, 8mV on auxiliaries), fully-isolated +24,

+12V, and +5V outputs, making them perfect

for powering today’s complex instrumentation. A high-current main output is isolated

from the AC line by 3000Vac. In dual- and

triple-output models, the low-current auxiliary

outputs are isolated from the main output by

1000Vdc, and from each other by 2000Vdc,

effectively providing double isolation from the

AC line! This unprecedented isolation eliminates ground loop problems in complex,

multiple-instrument applications.

Full-load efficiencies of up to 80% and

output-power ratings of 5, 10 or 16 Watts,

combine to ensure minimal ac power consumption. For intermittent use or low-power

applications, the 5-Watt model’s no-load

quiescent consumption with a nominal

120Vac input is a mere 0.6 Watts---that’s

nearly seven times less than a standard 4W

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

C

®

night light! These low cost, high-efficiency

power supplies can significantly reduce

long-term electricity costs in low (<5Watts)

to medium (<16Watts) power applications.

All DMS-PSX-CM power supplies feature universal inputs of 85-264Vac 50/60Hz,

built-in line fuses, and on-board ‘Power On’

LED indicators. At full rated load, hold-up

time is typically 20ms at 120Vac, and 80ms

at 230Vac. All outputs provide indefinite

short-circuit protection and, for added reliability, the main high-current output also

includes overvoltage protection. A rugged,

vibration-proof, chassis mount package

incorporates large, shock-resistant terminal

blocks for all I/O connections.

Multiple outputs, low noise, low cost,

high efficiency, double isolation, and rugged

construction combine to make DMS-PSXCM Series AC/DC power supplies the

ideal choice for powering today’s sensitive

instrumentation, and any electronic device

that requires a reliable dc voltage!

US E15693

TB4

AC(L)

85-264V

50/60Hz

or

110-340Vdc

110-340Vdc

For full details go to

www.murata-ps.com/rohs

AC(N)

or

FG

F1

1A/250V

+

+

LDO

Regulator

IN

OUT

GND

LDO

Regulator

IN

OUT

GND

*

TB3

TB2

TB1

+

V3

–

+

V2

–

+

V1

–

(Auxilliary)

(Auxilliary)

(Main)

+

+

+

AC/DC Converter

Drive

Circuitry

DC/DC

**

Converter

+

––

DC/DC

Converter

+

––

+

**

+

+

*Not used on single-output models

Used only on dual and triple-output models

**

Figure 1. Simplified Schematic

Figure 1. DMS-PS-CM Series Simplified Schematic

www.murata-ps.com Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000

MPM_DMS-PS-CM.B02 Page 1 of 8

Page 2

Performance/Functional Specifications

Typical at TA = +25°C and VIN = 85-264V @47-63Hz

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

AC Input

Input Voltage Range, All models ~ 85-264V @47-63Hz

Input Current (115V/230V, typ.):

5-Watt Models 0.15A/0.07A

10-Watt Models 0.3A/0.13A

16-Watt Models 0.33A/0.16A

Inrush Current (All models, typical peak):

@115Vac 14.1A

@230Vac 32.5A

Isolation (Min.):

Output V1 to AC Input 3000Vac

Outputs V2 & V3 to AC Input 3000Vac + 1000Vdc

AC Input to Frame Ground 1500Vac

Output V1 to Frame Ground 500Vac

Outputs V2 & V3 to Frame Ground 500Vac + 1000Vdc

Outputs V2 & V3 to Output V1 1000Vdc

Output V2 to Output V3 2000Vdc

Frame Ground Leakage Current (Max.):

@115Vac 0.5mA

@230Vac 3.5mA

Switching Frequency (Typical):

V1 (5W and 10W models) 75kHz

V1 (16W models) 83kHz

V2 & V3 (All models) 100kHz

Line Fuse (Built-in) 1A/250Vac, 5 x 20mm, meeting

IEC60127-2, sheet 3 specification for time lag fuses

(slow-blow)

AC Mains Terminal Block (TB4):

Wire Size & Type 14-20AWG (2.5 to 0.5mm

solid or stranded

Insulation Strip Length 0.25 inches (6.4mm)

Screw Tightening Torque 4.4 pound-inches (0.5Nm)

Rated Voltage 630V (VDE 0110-V. Group 2);

250V (VDE 0110-V. Group 3)

EMI (All models) Meets CISPR Pub. 22 & FCC

Class B

Safety Approvals Pending

DC Outputs

Line Regulation (All outputs) ±0.1% (max)

Load Regulation:

V1 (All models) ±2%

V2 & V3 (All models) ±0.2% (max)

Output Accuracy (Max.):

V1 (All models) ±2.0%

V2 & V3 (All models) ±2.5%

Hold-Up Time (47-63Hz):

@115Vac 20mSec. typ.

@230Vac 80mSec. typ.

Noise & Ripple

(All models, 20MHz bandwidth): See Noise & Ripple graphs

V1 40mVp-pk (typ.)

V2 & V3 8mVp-pk (typ.)

Transient Response See Transient Response graphs

2

),

DC Outputs (continued)

Efficiency (Typ.@ 120Vac, full load):

Single Output Models 75%

Dual Output Models 73%

Triple Output Models 71%

DC-Output Terminal Blocks (TB1, TB2, TB3):

Wire Size &Type 16-20AWG (1.5 to 0.5mm

solid or stranded

Insulation Strip Length 0.25 inches (6.4mm)

Screw Tightening Torque 3.6 pound-inches (0.4Nm)

Short Circuit Protection (All outputs) Foldback, self-recovering

Overvoltage Protection V1 (max.) 134% x Vout

Environmental

Operating Temperature 0 to +50°C @ full rated power;

–25 to +70°C @ 50% rated power (see Figure 3)

Storage Temperature –40 to +85°C

Cooling Free air convection with derating

(see Figure 3 and Technical

Notes)

Humidity (Non-condensing) 0 to 85%

Physical

Dimensions See Mechanical Specifications

Weight:

5 Watt Models 5.8 ounces (165 grams)

10 Watt Models 6.9 ounces (195 grams)

16 Watt Models 7.9 ounces (223 grams)

Case Materials:

Outer Case ABS, UL94 5VA

DC/DC Modules Phenolic, UL94 V-0

AC/DC Modules Plastic, UL94 V-1

~ All models will also operate from a regulated and filtered 110 to 340Vdc input.

Unless otherwise specified, load regulation is measured with the output under

test undergoing a load change of 100% to 50% at nominal line input and,

when applicable, with all other outputs operating at 50% of rated load.

Transient response is defined as the output returning to within its specified

tolerance in 10ms or less, following a 90% load change.

2

),

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 2 of 8

Page 3

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

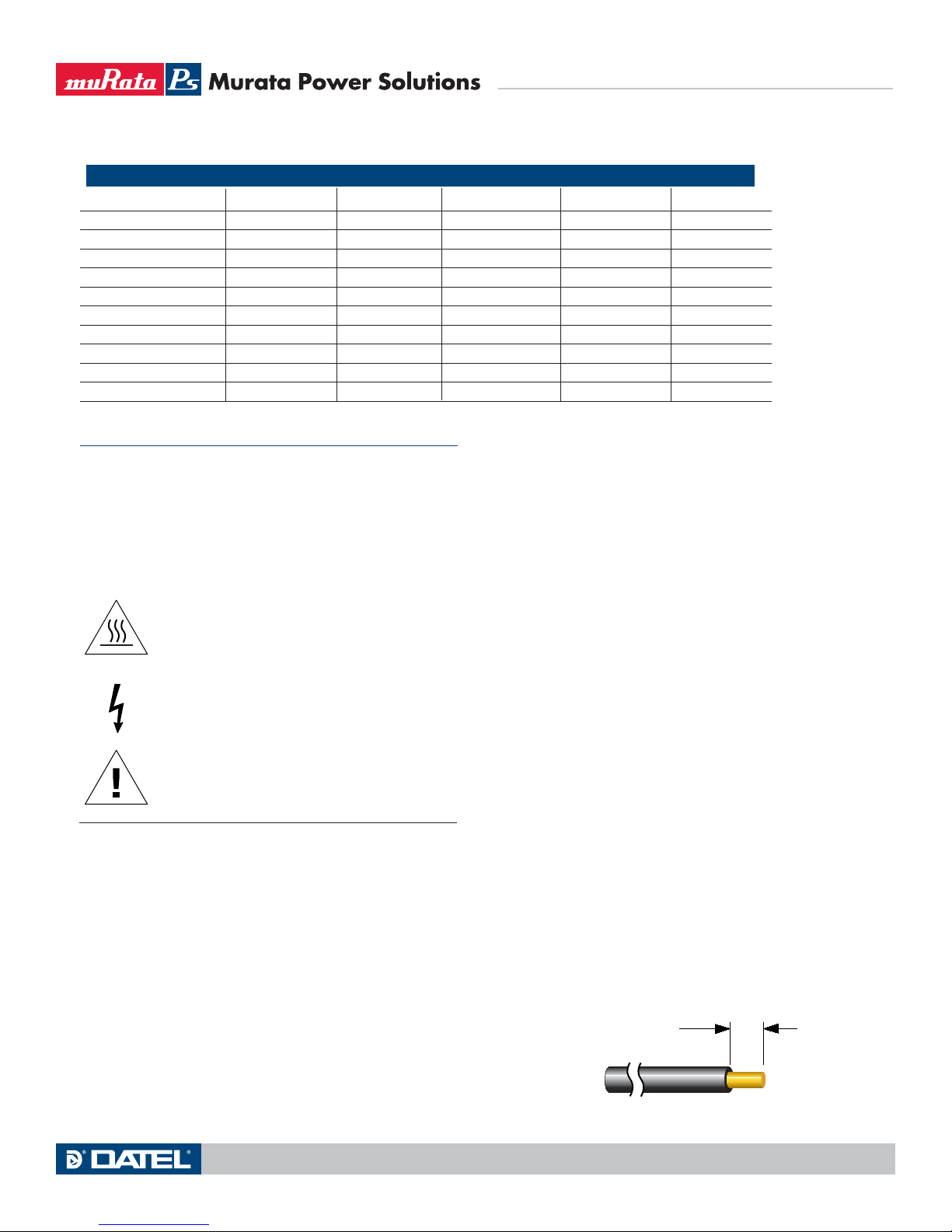

Ordering Information and Selection Guide

MPS Part No. Rated Power Efficiency ~ V1 Output V2 Output V3 Output

DMS-PS1-CM 5 Watts 75% 5Vdc/1A — —

DMS-PS2-CM 5 Watts 73% 5Vdc/0.65A 4.85Vdc/0.2A —

DMS-PS3-CM 5 Watts 71% 5Vdc/0.35A 4.85Vdc/0.2A 4.85Vdc/0.2A

DMS-PS4-CM 10 Watts 80% 24Vdc/0.45A — —

DMS-PS5-CM 10 Watts 75% 24Vdc/0.35A 4.85Vdc/0.2A —

DMS-PS6-CM 10 Watts 73% 24Vdc/0.30A 4.85Vdc/0.2A 4.85Vdc/0.2A

DMS-PS7-CM 16 Watts 82% 24Vdc/0.70A — —

DMS-PS8-CM 16 Watts 76% 24Vdc/0.60A 4.85Vdc/0.2A —

DMS-PS9-CM 16 Watts 74% 24Vdc/0.55A 4.85Vdc/0.2A 4.85Vdc/0.2A

DMS-PS10-CM 16 Watts 82% 12Vdc/1.35A — —

~Efficiency typical @120V/60Hz

TECHNICAL NOTES

IMPORTANT! To ensure safe and reliable operation, DMS-PS-CM

power supplies must be installed and serviced by qualified

personnel. Contact Murata Power Solutions if there is any doubt

regarding their installation and/or operation. Please read all of the

following technical and application notes BEFORE installing or

making connections to DMS-PS-CM power supplies.

Warnings (Marking)

Caution, unit may become hot in normal operation, thereby creating a potential burn hazard. Disconnect ac mains and then allow

unit to cool before servicing.

Reference document: IEC 417, No. 5041.

Dangerous, potentially lethal voltages are present during normal

operation. Disconnect ac mains before servicing.

Reference document: IEC 417, No. 5036.

Caution, refer to accompanying documents for more information. Reference document: ISO 3864, No. B.3.1.

1. Shock Hazard: DMS-PS-CM Series power supplies feature touch-proof

terminals blocks and fully-isolated plastic construction, thereby greatly reduc-

ing the risk of electrical shock. However, these are mains-powered devices

whose operation is derived from hazardous and potentially lethal voltages.

All service and installation must be performed by qualified personnel, with

the ac supply voltage de-energized. Before making connections to any of

the unit’s terminal blocks, use a digital voltmeter to verify that the ac supply is

de-energized (off).

2. AC Supply Fuse (F1): All DMS-PS-CM Series power supplies are equipped

with a built-in 1A/250V time-lag fuse. Replacement fuses must be of the

same type and rating; please refer to the Functional Specifications section

of this datasheet for more information. F1 is conservatively rated in order

to reduce nuisance tripping which might occur during power-up or output

overload conditions. However, F1 is primarily intended to provide protection in

the event of catastrophic failure in the DMS-PS-CM’s ac/dc converter.

3. Fuse Replacement: If any dc-output drops to zero volts, and no fault

conditions exist within the external load circuitry or the ac mains, F1 may

have failed. F1 is located on the circuit (etch) side of the pc-board. Fuse

replacement is performed by first de-energizing and then disconnecting

the ac mains from TB4. Next, disconnect all load wiring from TB1, TB2,

and TB3. Lastly, remove the four screws that secure the pc-board to the

plastic case. After making sure that the new fuse is securely attached to its

mounting clips, re-assemble the unit using all four screws. Reconnect all

input and output wiring and re-apply ac power.

If the unit still does not operate properly, and the ac supply at TB4 is

measured to be within its specified operating range, the power supply

is defective and must be replaced. Except for F1, DMS-PS-CM supplies

contain no other user-serviceable components.

4. Wire Gauges and Fusing: All wiring connected to the DMS-PS-CM’s

terminal blocks must meet the requirements specified in the Functional

Specifications section. All ac supply and load wiring must be rated for the

voltages and currents they will conduct and must comply with any code

or application-mandated requirements pertaining to the user’s specific

installation. Applications subject to vibration should include adequate strain

reliefs on both input and output wiring. Install the strain reliefs within 2-3

inches (5-7.5cm) of the terminal blocks.

It is recommended that all wiring be rated for 600V and 105°C operation

(UL1015 type, for example). Also, wire insulation must be stripped to within

±10% of the dimensions shown in Figure 2. All wires must be inserted

into their respective terminal blocks such that the screw terminal does not

pinch their insulation. No more than two wires should be connected to

any single terminal on TB1 through TB4. If two wires are attached to a

single terminal, be sure to use only two 20AWG (0.5mm

TB2, and TB3, and only two 18 or 20AWG (0.75 or 0.5mm

0.25"

(6.4mm)

Figure 2. Insulation Strip Length

2

) wires on TB1,

2

) wires on TB4.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 3 of 8

Page 4

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

The ac-mains circuit supplying power to DMS-PS-CM supplies must be fused

according to the current rating of the wire gauge used, in accordance with

applicable regulatory codes. The built-in 1ampere line fuse (F1) only protects

the module itself from destructive over currents.

5. AC Mains Connections (TB4): To ensure EMI-compliant operation, all three

ac-supply inputs must be properly connected to TB4. Never operate any DMS-

PS-CM power supply without a ground connection to TB4’s ‘FG’ terminal.

On 120Vac 50/60Hz mains, connect the black or "hot" lead to ‘AC(L)’, the

white or “neutral” lead to ‘AC(N)’, and the supply ground (earth) to ‘FG’ (Frame

Ground). On 220V 50/60Hz ac mains with line and neutral conductor-designa-

tions, connect the line to AC(L), the neutral to AC(N), and the ground to ‘FG’.

6. Connector Torque Ratings: It is extremely important to tighten all input and

output terminal blocks securely. TB4’s screw terminals must be torqued to

4.4 pound-inches (0.5Nm). TB1, TB2, and TB3 must be torqued to 3.6 pound-

inches (0.4Nm). Proper tightening will minimize losses and ensure safe,

reliable operation.

7. ‘Power On’ LED: The Power On LED indicates that the unit has ac-power

applied and its V1 dc-output is operational. However, the power-on LED’s

illumination does not imply nor guarantee that the unit’s dc-outputs are within

their specified accuracy.

8. Output Adjustment: The main output, V1, on all 5, 10, and 16W models is

adjustable by approximately –10% to +15%. V1’s adjustment potentiometer

is accessed via a small hole located next to the Power-On LED. While not

recommended, field adjustment of single-output models can be performed

within the tolerance window noted above. However, keep in mind that the

unit’s maximum output power capability must not be exceeded. For example,

increasing V1’s output voltage by 10% produces a corresponding 10% reduc-

tion in V1’s maximum output current.

On dual-and triple-output units, V1 is factory calibrated with all outputs

simultaneously loaded to 100% of their rated current. On all dual- and

triple output models, adjusting V1 under any condition other than

those just noted (i.e., all outputs loaded to their full rated current) will

adversely affect the operation and stability of auxiliary outputs V2 and

V3. On these models, V1 must be adjusted to within ±2 % of its nominal

value (+5.0V, +12.0V, or +24.0V, depending on model).

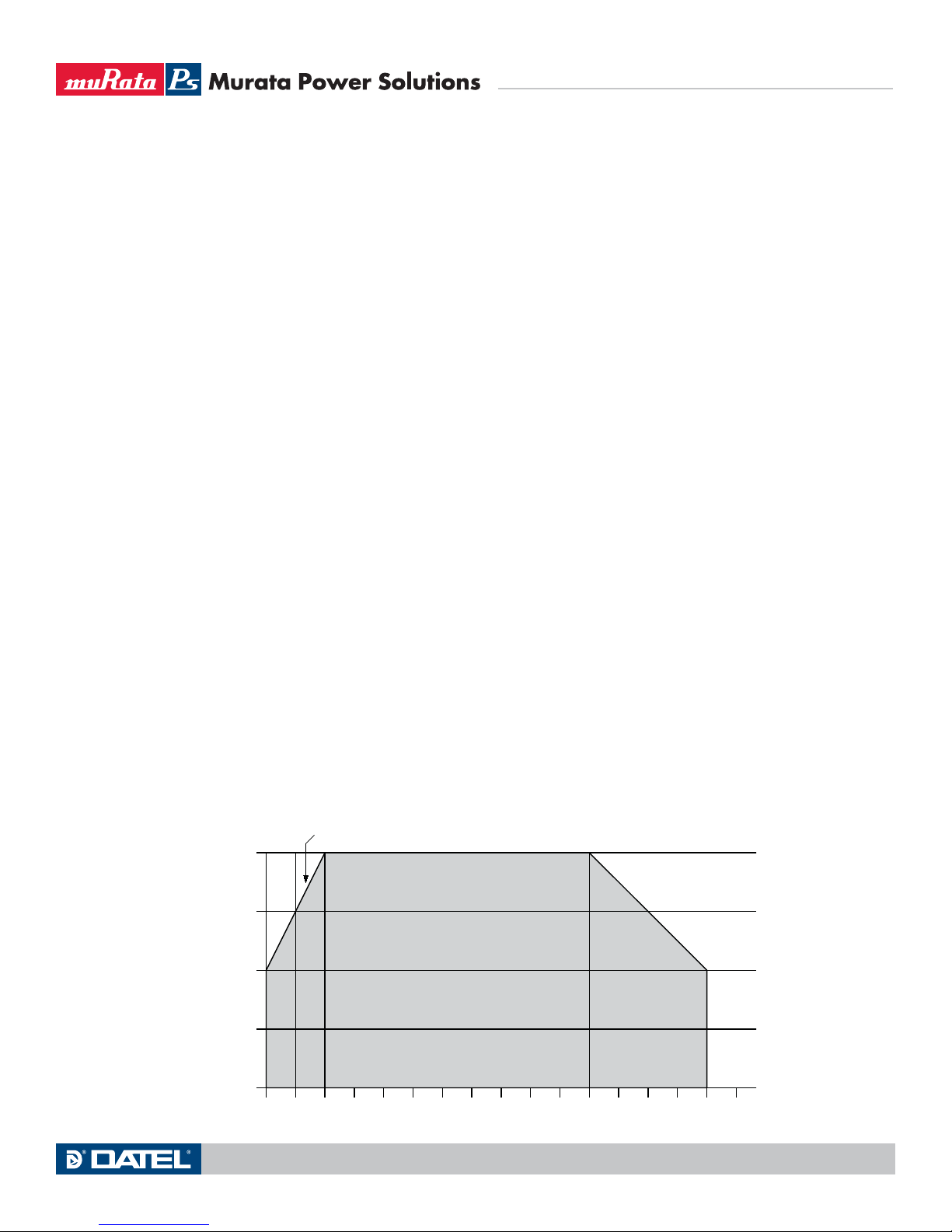

9. Temperature Derating (See Figure 3): All DMS-PS-CM supplies are speci-

fied to operate at their full rated power over the temp range of 0°C to +50°C

in still air (convection cooling) without any thermal derating. For operation

over +50°C in still air, derate the output power linearly by 2.5% per °C down

to 50% rated power at +70°C. To operate the units at full rated power between

+50°C and +70°C, a minimum forced-airflow of 100 LFM is required. For

operation below 0°C, derate the output power linearly by 2.0% per °C down

to 50% rated power at –25°C.

Unless forced air with the velocity noted above is employed, DMS-PS-CM

supplies should never be mounted upside down (terminal blocks facing

down). Also, always provide sufficient clearances in order to ensure adequate

airflow around the supply.

10. V1 Peak Capabilities: DMS-PS-CM power supplies have a maximum

continuous output-current rating that’s specified in the Ordering and Selection

Guide. In addition, each model’s V1 output can intermittently supply 120% of

its continuous rated current for short periods of time if the duty cycle is less

than 10%. Peak current ratings do not apply to the auxiliary outputs V2 or V3.

11. Isolated Outputs: Unlike the majority of competitive ac/dc power supplies,

all dual- and triple-output DMS-PS-CM power supplies feature fully-isolated

outputs. This is an important feature when, for reasons of high common mode

voltages, an instrument’s input circuit must be isolated from the system ground.

All V1 outputs are isolated from the ac mains by a minimum of 3000Vac, while

auxiliary outputs V2 and V3 are isolated from one another by 2000Vdc, and

fromV1 by 1000Vdc. The low noise, double-isolated auxiliaries are ideal for

powering sensitive instrumentation that requires low ac leakage-currents.

All ac/dc and dc/dc power components utilized in the construction of DMS-

PS-CM power supplies are 100% hi-pot tested during their manufacturing pro-

cesses. In addition, after final assembly by MPS, all models are subjected to an

additional hi-pot testing consisting of 1000Vac sequentially applied between the

ac mains input and each output, and between each output and all other outputs.

2.0% / ºC

100

75

50

Output Power (%)

25

0

–25–100 10152025303540455055606570

2.5% / ºC

70ºC

75

Figure 3. Temperature Derating

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 4 of 8

Page 5

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

Application Information

1. Chassis Mounting Considerations: In order to minimize self-heating,

DMS-PS-CM power supplies should always be mounted in either a

vertical or horizontal position. Avoid mounting units upside-down or in

close proximity to other heat-generating devices. Also, be sure to use

the mounting hardware described in Figure 4 below in order to ensure

a secure, vibration-resistant installation.

Screw,

Split Lock Washer,

Flat Washer

Panel/Chassis

Panel/Chassis

Hole

Figure 4. Chassis Mounting

Threaded

Hole

Screw,

Flat Washer

Flat Washer,

Split Lock Washer,

Nut

3. Model Selection & Energy Conservation: In order to achieve the lowest

possible energy consumption, be sure to determine your application’s total

current requirements. This is especially true when using DMS-PS-CM

supplies to power DATEL’s energy-efficient LED and/or LCD display digital

panel meters (DPMs) and process monitors. In general, choose a power

supply that will accommodate your maximum current consumption plus a

20% margin. Choosing the lowest-wattage model suitable for a given appli-

cation will provide lower procurement costs and lower long-term operating

costs.

When calculating total current requirements in installations employing

three or more DMS-Series meters, it is acceptable practice to use each

meter’s typical current consumption rating. However, be sure to consult

the relevant product datasheets for all instrumentation comprising your

application.

For applications where DMS-PS-CM power supplies will be powering only

Murata Power Solution’s DPM’s, a 5-Watt DMS-PS3-CM can power up

to four, standard intensity (‘-RS’ suffix) red-LED DMS-30PC meters: two

meters on V1, and one meter each on V2 and V3. The same DMS-PS3-CM

could also be used to power over 40 low-power red DMS-30PC meters

(‘-RL’ suffix), or over 800 DMS-30LCD non-backlit meters! Of course, these

statements are made without regard to ground-loop problems that may be

encountered when powering 800 DPM’s from a single power supply.

2. Bipolar Operation (See Figure 5): DMS-PS-CM power supplies’ fully

isolated outputs allow for the generation of bipolar (positive and nega-

tive) supply voltages. Bipolar outputs can be used to power dual-supply

operational amplifiers, as well as any other type of instrumentation that

requires bipolar supply voltages. However, please keep in mind that

when connecting and operating any two outputs in this fashion, each

output retains its maximum current rating.

DMS-PS6-CM

V1 V2

– + – + – +

+24V –5V +5V

COM

Figure 5. Bipolar Connections

V3

Scope Probe

V1

–

+

DMS-PS-CM

Figure 6. Measuring Ripple and Noise

Oscilloscope

BW = 20MHz

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 5 of 8

Page 6

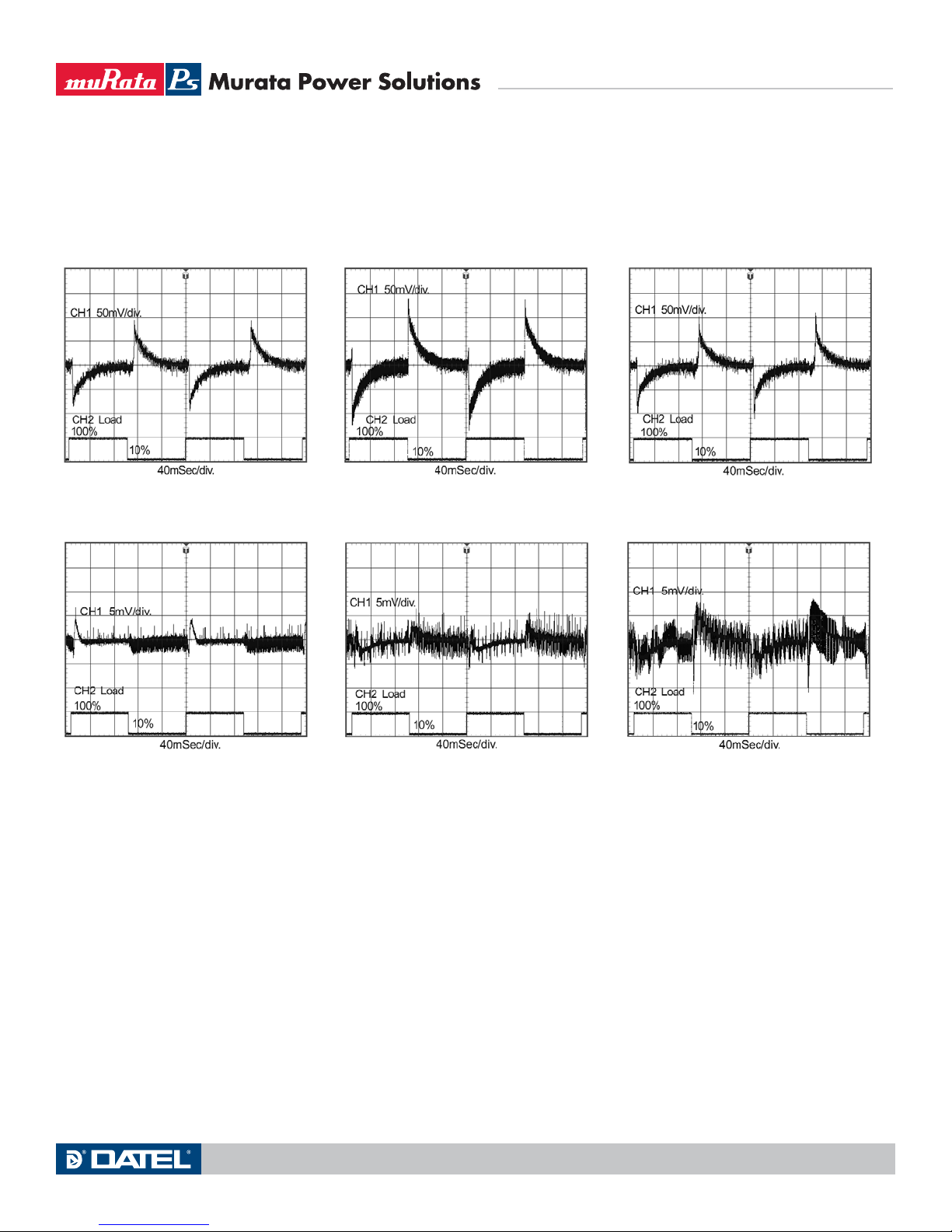

Typical Performance Curves TA = +25°C, VIN = 120V @60Hz

Noise and Ripple - 100% Load, 20MHz Bandwidth

DMS-PS3-CM V1 (+5V)

DMS-PS6-CM V1 (+24V) DMS-PS9-CM V1 (+24V)

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

DMS-PS3-CM V2 (+4.85V) DMS-PS6-CM V2 (+4.85V) DMS-PS9-CM V2 (+4.85V)

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 6 of 8

Page 7

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Supplies with Individually Isolated Outputs

Typical Performance Curves TA = +25°C, VIN = 120V @60Hz

Transient Response - 10% to 100% Load Step

DMS-PS3-CM V1 (+5V) DMS-PS6-CM V1 (+24V) DMS-PS9-CM V1 (+24V)

DMS-PS3-CM V2 (+4.85V) DMS-PS6-CM V2 (+4.85V) DMS-PS9-CM V2 (+4.85V)

Mechanical Dimensions: Inches (mm) Tolerances: 2 PL DEC ±0.02 (±0.51), 3 PL DEC ±0.010 (±0.254)

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 7 of 8

Page 8

DMS-PS-CM Series

High Efficiency, AC/DC Instrumentation Power

Mechanical Specifications

MECHANICAL DIMENSIONS: Inches (mm)

TOLERANCES: 2 PL DEC ±0.02 (±0.51)

3 PL DEC ±0.010 (±0.254)

0.188

(4.8)

AC(L)

AC(N)

FG

TB4

See detail

® ®

DMS-PSX-CM

AC/DC POWER SUPPLY

4.625 (117.5)

5.125 (130.2)

Supplies with Individually Isolated Outputs

5 Watt &

10 Watt Models 16 Watt Models

Power On

V1 Adjust

TB3

TB2

® ®

TB1

Adjust

Detail

+

V3

–

+

V2

–

+

V1

–

Power

V1

On

2.835

(72.0)

1.42

(36.1)

1.000 (25.4)

4.165 (105.8)

Murata Power Solutions, Inc.

11 Cabot Boulevard, Mansfield, MA 02048-1151 U.S.A.

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

www.murata-ps.com email: sales@murata-ps.com ISO 9001 and 14001 REGISTERED

Murata Power Solutions, Inc. makes no representation that the use of its products in the circuits described herein, or the use of other

technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein do not imply

the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifications are subject to change without

notice. © 2008 Murata Power Solutions, Inc.

11/24/08

5W models: 0.77 (19.6)

10W models: 0.87 (22.1)

16W models: 0.93 (23.6)

0.125

(3.2)

USA: Mansfield (MA), Tel: (508) 339-3000, email: sales@murata-ps.com

Canada: Toronto, Tel: (866) 740-1232, email: toronto@murata-ps.com

UK: Milton Keynes, Tel: +44 (0)1908 615232, email: mk@murata-ps.com

France: Montigny Le Bretonneux, Tel: +33 (0)1 34 60 01 01, email: france@murata-ps.com

Germany: München, Tel: +49 (0)89-544334-0, email: munich@murata-ps.com

Japan: Tokyo, Tel: 3-3779-1031, email: sales_tokyo@murata-ps.com

Osaka, Tel: 6-6354-2025, email: sales_osaka@murata-ps.com

China: Shanghai, Tel: +86 215 027 3678, email: shanghai@murata-ps.com

Guangzhou, Tel: +86 208 221 8066, email: guangzhou@murata-ps.com

Singapore: Parkway Centre, Tel: +65 6348 9096, email: singapore@murata-ps.com

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MPM_DMS-PS-CM.B02 Page 8 of 8

Loading...

Loading...