Page 1

(

查询DMS-20PC供应商

www.datel.com

®®

DMS-20PC Series

3½ Digit, LED Displa y

Actual Size

Features

••

•

Lowest-cost LED meters

••

••

•

Subminiature size:

••

1.38" x 0.88" x 0.48"

35mm x 22mm x 12mm

••

•

Large (0.37"/9.4mm) LED display

••

••

•

Choice of 5 LED colors

••

••

•

High-intensity or low-power (7mA) red

••

LED's optional

••

•

Epoxy-encapsulated, 12-pin DIP package

••

with built-in color filter and bezel

••

•

4 differential input voltage ranges

••

••

•

Factory calibrated, ±1 count accuracy

••

••

•

Single +5V power supply

••

••

•

User-selectable decimal point placement

••

••

•

DISPLAY ENABLE function for

••

"power-down" mode

••

•

DISPLAY TEST and HOLD (optional)

••

functions

••

•

0 to +60°C temperature range

••

Low-Cost, Subminiature

Digital Panel Voltmeters

DMS-20PC Series, 3½ Digit, LED Display, Digital Panel Voltmeters combine a

precision A/D converter; a factory-trimmed, highly stable, voltage reference; and a

large (0.37"/9.4mm), easy-to-read LED display in a single package that is only

slightly larger than the display itself. Displays are offered in either red, orange,

amber, yellow or green colors. High-intensity and low-power (35mW total) red LED's

are also optional.

These low-cost meters are fully self-contained and fully functional. Their

subminiature (1.38" x 0.88" x 0.48"), epoxy-encapsulated cases incorporate built-in

color filters and bezels; are moisture and vibration proof; and function well in the

harshest environments. Their 12-pin, dual-in-line configuration offers component-like,

plug-in convenience and maximum versatility. Operating temperature range is 0 to

+60°C.

The meters come with one of four, differential, input voltage ranges: ±200mV, ±2V

±20V or ±200V. Input impedance is a minimum 800kΩ. CMRR is typically 86dB (dc

to 60Hz), and CMV is ±2V. Input over voltage protection (on the non-inverting input)

is ±250V. Devices are fully calibrated at the factory to an accuracy of ±1 count

(±0.05% of full scale range) and never require calibration or adjustment.

A DISPLAY ENABLE function permits the display to be disabled for "powerdown" operation. All models have a DISPLAY TEST function. Standard red LED

models offer an optional DISPLAY HOLD function.

Small size, low cost and adjustment-free reliability make the DMS-20PC Series

the best choice for all your 3½ digit, LED, DPM applications.

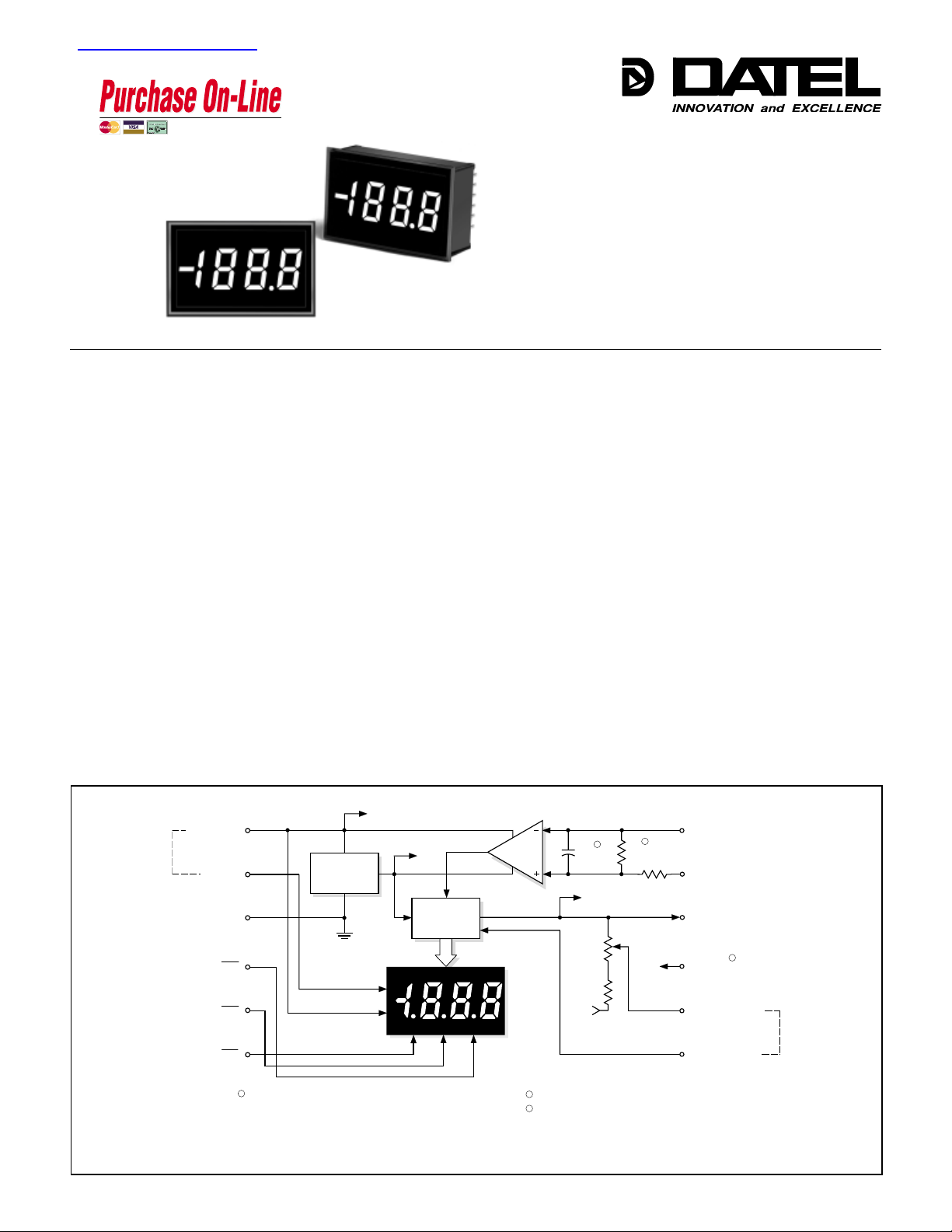

DC/DC

0 Vdc

+5V

–5V

CONVERTER

DATA

A/D

1

909k

12

11

11

R1

10

V+

2

»

R2

+2.0V

0.01

µF

V–

+5V

2

Only used on ±200mV (-0) and ±2V (-1) models.

3

Pin 9 is DISPLAY TEST on all but eight models. On those models

-H option), it is DISPLAY HOLD.

(–) INPUT LO

(+) INPUT HI

ANALOG

COMMON

9

DISPLAY

TEST/HOLD

8

REFERENCE OUT

7

REFERENCE IN

3

+5V SUPPLY

DISPLAY

ENABLE

5V RETURN

DP 3

DP 2

DP 1

1

2

3

4

5

6

1

R2 is not used on ± 2 00 mV (-0) models or ±2V (-1) mode ls .

R2 = 100k on ±20V (-2) models and 9.1k on ±200V (-3) models.

CONVERTER

Figure 1. DMS-20PC Series Simplified Schematic

DATEL, Inc., Mansfield, MA 02048 (USA) • Tel: (508)339-3000, (800) 233-2765 Fax: (508)339-6356 • E-mail: sales@datel.com • Internet: www.datel.com

Page 2

DMS-20PC

3½ DIGIT, LED DISPLAY DIGITAL PANEL VOLTMETERS

Performance/Functional Specifications

Typical at TA = +25°C and supply voltage = +5V using the single-ended input circuit,

unless otherwise noted.

Analog Inputs Min. Typ. Max. Units

Full Scale Input Range:

DMS-20PC-0 -- ±200 -- m V

DMS-20PC-1 -- ±2 -- Volts

DMS-20PC-2 -- ±20 -- Volts

DMS-20PC-3 -- ±200 -- Volts

Input Impedance:

DMS-20PC-0, -1 100 1000 -- M

DMS-20PC-2, -3 0.8 1 -- M

Overvoltage Protection

Common Mode Voltage Range -- -- ±2 Volts

CMRR (dc to 60Hz) -- 86 -- dB

Control Inputs ➁ ➂

Decimal Point Placement (Pins 4-6) Tie to pin 3 to activate

Display Test (Pin 9) Tie to pin 1 to activate all segments

Display Hold (Pin 9)

Performance

Sampling Rate 2.5 samples per second

Accuracy (3 minute warm-up):

DMS-20PC-0 (VIN = +0.19V) -- ±1 ±3 Counts

DMS-20PC-1 (VIN = +1.9V) -- ±1 ±3 Counts

DMS-20PC-2 (VIN = +19V) -- ±2 ±3 Counts

DMS-20PC-3 (VIN = +190V) -- ±2 ±3 Counts

Zero Reading (VIN = 0 Volts) "–001" "000" "001"

Temperature Drift (0 to +60°C) -- ±0.2 ±0.4 Cnts/°C

Power Supply Requirements

Supply Voltage + 4.75 +5.00 +5.25 Volts

Supply Current:

DMS-20PC-X-RS -- +60 +90 mA

DMS-20PC-X-RL -- +7 +12 mA

DMS-20PC-X-AS -- +90 +120 mA

DMS-20PC-X-GS -- +90 +120 mA

DMS-20PC-X-OS -- +90 +120 mA

DMS-20PC-X-YS -- +90 +120 mA

DMS-20PC-X-RS-H -- +60 +90 mA

DMS-20PC-X-GS-H -- +90 +120 mA

DMS-20PC-X-RH -- + 6 0 +90 mA

Display

Display Type and Size 3½ Digit LED, 0.37"/9.4mm high

Polarity Indication Autopolarity ("–" for negative VIN)

Overrange Indication "–1___" for negative VIN

Physical/Environmental

Operating Temperature 0--+60°C

Storage Temperature –40 -- +75 °C

Humidity (Non-condensing) 0 -- 95 %

Case Material Polycarbonate

Weight 0.4 ounces (11 grams)

➀

Applies for transient or continuous overvoltages applied to (+) INPUT HI (pin 11)

with (–) INPUT LO (pin 12) properly connected. Pin 12 is not overvoltage protected

(see Figure 1). Voltages applied to pin 12 should not exceed the supply voltage.

➁

See Technical Notes.

➂

The DISPLAY HOLD function is optional on standard red and green LED models only.

See Ordering Information.

➀

➂

-- -- ±250 Volts

Tie to pin 1 to hold last reading

"1___" for positive VIN

Ordering Information

DMS-20PC-1- RS

Input Range:

0 = ±200mV

Ω

Ω

1 = ±2V

2 = ±20V

3 = ±200V

LED Color:

AS = Standard Amber

GS = Standard Green

OS = Standard Orange

RS = Standard Red

Accessories:

DMS-20-CP Panel cutout punch

DMS-BZL3 DMS-20 bezel assembly

DMS-BZL4 DMS-20 bezel assembly with sealing gasket

DMS-EB2 Application/evaluation board with standard

MOLEX connector, decimal point solder pads

and attenuation resistor pads.

A panel-mount retaining clip is supplied with each model.

Leave blank for standard

models.

Add -H for DISPLAY

HOLD option (available on

standard red and green

LED models only).

YS = Standard Yellow

RH = High-Intensity Red

RL = Low-Power Red

Order on-line at www.datel.com

T echnical Notes

1. REFERENCE OUTPUT (Pin 8) and INPUT (Pin 7): Pin 8 is a

precision reference actively trimmed at the factory. In normal

operation, pin 8 must be tied to pin 7 to achieve all listed accuracy

and drift specifications.

2. ANALOG COMMON (Pin 10): This pin is connected to an internal,

low-noise, "relative" ground. It is used in certain differential and

"floating" measurements as described in the Applications section

of this data sheet and Ap Note 3 of the DATEL Panel Meter Catalog.

Pin 10 should not be connected to pin 3 (5V RETURN) or to

your system’s analog ground.

3. Decimal Point Placement: The location of the decimal point is

user-selectable, and the decimal point control pins (DP1-DP3) are

active low functions. Select the appropriate decimal point by tying

the appropriate pin (pin 4, 5 or 6) to pin 3 (5V RETURN). Unused

decimal point location pins should be left open.

Hard wiring is preferable, however, you can use logic gates to

exercise dynamic control over the location of the decimal point if the

following drive conditions are met:

Model Applied "0" Voltage Load Current*

DMS-20PC-X-RL +0.05V max. 0.7mA max.

All Others +0.4V max. 6mA max.

* The driving gates must be able to sink this much current

OL) with a logic "0" output.

(I

2

Page 3

3½ DIGIT, LED DISPLAY DIGITAL PANEL VOLTMETERS

DMS-20PC

4. DISPLAY TEST/HOLD (Pin 9) Function: Pin 9 is a dual-function

pin. On all standard models (without "-H" suffix), tying pin 9 to pin

1 (+5V SUPPLY) activates the meter's DISPLAY TEST feature.

All display segments, except the decimal points, will be

illuminated. The display will show "1888" ("–1888" if a negative

input signal is present). Do not leave the meter in the test

mode for more than 10 seconds as this will cause the

meter's operating temperature to rise and possibly affect its

performance. Pin 9 must be left open when the test function is

not being used.

On models with the "-H" suffix (DMS-20PC-1-RS-H for example),

pin 9 serves as a DISPLAY HOLD control pin. Tying pin 9 to +5V

SUPPLY (pin 1) on these models will hold or "freeze" the current

display reading indefinitely. Pin 9 must also be left open when the

hold function is not being used. After disabling DISPLAY HOLD,

allow the meter a full 10 seconds to resume normal calibrated

operation before holding a new reading.

The DISPLAY TEST or DISPLAY HOLD pin should normally be

connected, via a selector switch, to pin 1 (+5V SUPPLY). If

automatic, logic-controlled operation is desired, only PNP or

MOSFET transistors should be used. The base or gate of these

transistors should be driven sufficiently hard to bring pin 9 within

0.05V of +5V SUPPLY.

5. DISPLAY ENABLE (Pin 2) Function: On all models, tying pin 2

to pin 1 (+5V SUPPLY) applies full power to the LED display. This

is the normal mode of operating the meter. Leaving DISPLAY

ENABLE open (no connection), only turns off the LED display.

The meter's analog-to-digital converter continues to sample the

input signal. Total current consumption with the display off is

approximately 400µA (0.4mA). This is a very useful feature if the

meter is used in battery-powered equipment.

With the exception of the low-power red LED models (DMS20PC-X-RL), a regulated voltage lower than +5V SUPPLY can be

used to dim the display intensity. Display intensity control is best

performed with the high brightness, red LED, DMS-20PC-X-RH

model. All low-power red LED models must have DISPLAY

ENABLE tied directly to pin 1 (+5V SUPPLY). Voltages applied to

DISPLAY ENABLE must never be greater than +5V SUPPLY.

6. Gain Adjust: There is a gain-adjust potentiometer on the back

of each meter. It has approximately ±50 counts (±2.5%) range of

adjustment. Since these devices essentially have no zero/offset

errors, a gain adjustment is effectively an overall accuracy

adjustment. Though they may be performed at any point (except

zero), accuracy adjustments are most effectiv e when performed

with higher level input signals. The circuit shown in Figure 10

provides ±10% range of adjustment.

7. Soldering Methods: All models in the DMS-20PC Series easily

withstand most common wave soldering operations. We

recommend, however, that you evaluate the effects your

particular soldering techniques may have on the meter’s plastic

case and high-precision electrical performance. We recommend

the use of water-soluble solders and thorough cleaning

procedures.

8. Suggested Mating Connectors:

Panel mounted:

Connector housing DATEL P/N 39-2079400

Terminal type DATEL P/N 39-2099090

Crimping tool DATEL P/N 39-2099000

Wire size 22 to 26 AWG

Insulation diameter 0.062" (1.57mm) maximum

Stripping length 0.100 to 0.125" (2.54 to 3.17mm)

Board mounted:

Socket DATEL P/N 39-2359625

Applications

DMS-20PC meters are highly versatile devices that can be used in

hundreds of applications. The application circuits chosen for this

section are ones that have historically received man y inquiries.

The schematic in Figure 1 shows that the meter's high-impedance

input consists of an op amp powered from a ±5Vdc power supply

(the –5V is internally generated). One can easily see why input

signals applied to (–) INPUT LO and (+) INPUT HI have to be kept

within the power supply rails of ±5V. Also note that only pin 11 has a

Ω

current-limiting 909k

a common ground with pin 3 (5V RETURN) should only be applied

to pin 11 ((+) INPUT HI) and never to pin 12. In these high-voltage

cases, pin 12 should always be tied to pin 3 (5V RETURN).

The schematic also shows that pin 3 is the meter's zero-volt

reference point — regardless of the type of power or signal source

used. This is an important point to keep in mind when a digital or

analog multimeter is used to make system measurements. The

multimeter's negative lead (usually the black one) must be

connected to pin 3 (5V RETURN).

1. Single-Ended Input Configurations: Tr ue single-ended

measurements can be made with any DMS-20PC meter. The

circuit of Figure 2 avoids problems normally associated with

ground-loop currents. Separate ground runs should be used

for 5V RETURN (pin 3) and (–) INPUT LO (pin 12).

+

V

IN

–

120 VAC

Figure 2. Single-Ended Input Configuration

series resistor. High input voltages that have

DMS-20PC-1

11

(+) IN HI

12

(–) IN LO

6

2

+5V SUP

DATEL

UPA-5/500

AC to DC Converte r

1

DISPLAY

ENABLE

DP1

8

REF OUT

7

REF IN

3

5V RET

3

Page 4

DMS-20PC

C

3½ DIGIT, LED DISPLAY DIGITAL PANEL VOLTMETERS

Applications

2. Differential Input Configurations: Differential measurements

can be made with all DMS-20PC meters. Figure 3, though not a

practical real-world application, uses a voltage divider to

demonstrate the concept of a differential input signal. Be careful

not to exceed the ±2V common mode voltage limitation for 5Vpowered meters.

R1

1k

R2

1k

R3

1k

120 VAC

3

5V RET

11

(+) IN HI

12

(–) IN LO

REF OUT

8

REF IN

7

DP1

6

+5V SUP

DATEL

UPA-5/500

AC to DC Converte r

DMS-20PC-1

1

2

DISPLAY

ENABLE

Figure 3. Differential Input Configuration

3. Engineering Scaling: For measuring voltages greater than the

full scale input range of a given meter, the input signal must be

attenuated. A simple voltage divider (similar to that shown in

Figure 4) will scale the input to within the range of the selected

meter. R1 and R2 should be precision, ±1%, metal-film resistors

with absolute TCR's less than 50ppm/°C. See Ap Note 4 for more

information on engineering scaling.

Ω

< R1 + R2 < 10M

50k

R2

x VIN = Reading

Ω

R1 + R2

+

120 VAC

R1

R2

DATEL

UPA-5/500

(+) IN HI

(–) IN LO

+5V SUP 5V RET

V

IN

–

AC to DC Converte r

Figure 4. Input Attenuation Circuit

11

12

1

DMS-20PC-1

2

DISPLAY

ENABLE

8

REF OUT

7

REF IN

3

to (–) INPUT LO (pin 12) provides the reference point for the

meter’s input.

A "floating" input is a signal that has no galvanic connection

to the meter's power supply. In the figures below, the 1.5V

battery illustrates a true floating input.

DMS-20PC-1

1.5V

CELL

120 VAC

(+) IN HI

+

–

(–) IN LO

DATEL

UPA-5/500

AC to DC Converter

11

12

+5V SUP

2

1

DISPLAY

ENABLE

3

5V

RET

8

REF OUT

7

REF IN

6

DP1

Figure 5. Floating Input Measurements

DMS-20PC-1

1.5V

ELL

120 VAC

(+) IN HI

+

ANA COMM

–

(–) IN LO

DATEL

UPA-5/500

AC to DC Converte r

11

10

12

+5V SUP

2

1

DISPLAY

ENABLE

3

5V

RET

8

REF OUT

7

REF IN

6

DP1

Figure 6. Floating Input Measurements

(Alternate Configuration)

5. Process Control (4-to-20mA) Measurements: In many

common process-control applications, a 4-to-20mA current loop is

used to transmit information. Because DMS-20PC meters have

such high input impedance, a simple shunt resistor across the

meter's input can be used to convert the loop current to a voltage.

See Figure 7. The value of the shunt resistor is a function of the

scaling requirements of the particular application and can be

calculated using the following equation:

RShunt = R1 = VFsr /IFsr

4. Floating Signal Source Measurements: Floating signals can

be measured using the circuits shown in Figures 5 and 6.

Where: VFsr = Full scale reading (in Volts)

I

Fsr = Relative full scale current (in Amps)

Connecting pin 10 (ANALOG COMMON) or pin 3 (5V RETURN)

4

Page 5

3½ DIGIT, LED DISPLAY DIGITAL PANEL VOLTMETERS

T

12

VOLTAGE

CALIBRATOR

OUT

10

(+) IN HI

(–) IN LO

ANA

COMM

= 10 to 20 Turns

7

REF

IN

11

732, 1%

8.06k, 1%

5V RET

Connections

for ±2V, ±20V

and ±200V models

Connections

for ±200mV

models

COM

17.4k, 1%

2k

24.3k, 1%

3

12

DMS-20PC-1

8

NC

200

+5V IN

1

1

1

1

Applications

DMS-20PC

Example: For a meter with a 2V full scale input (1.999 full scale

reading) and a desired display reading of "1000" (with an input

of 20mA), V

Fsr = 1.000 Volts

R

Shunt = 1.000V/(0.020 – 0.004)A

RShunt = 1.000V/0.016A = 62.5 Ohms

To calibrate the circuit of Figure 7, perform the following:

1. With 4mA applied, adjust the 50kΩ potentiometer (R2) to

display a reading of "000" (assuming that is the desired

reading).

2. With 20mA applied, adjust the gain-adjust potentiometer on

the back of the meter to display a reading of "1000". For different

full scale readings, alter the value of R

11

ANA COMM

DATEL

UPA-5/500

(+) IN HI

10

12

(–) IN LO

+5V SUP 5V RET

R2

50k

+

R1

4-20mA

–

120 VAC

AC to DC Converte r

Figure 7. 4-to-20mA Current Loop Operation

Shunt accordingly.

DMS-20PC-1

13

2

DISPLAY

ENABLE

8

REF OUT

7

REF IN

The LM-2931 was chosen because it has the following on-chip

protection features: reverse polarity, short circuit and thermal

runaway. When using other, higher-power, DMS-20PC models

with three-terminal regulators, be sure to consult the regulator

manufacturer's data sheet to ensure the regulator is being

utilized safely and correctly.

7. Digital Ammeter: Digital ammeters are finding ever-increasing

usage because analog-style ammeters (moving-vane types) now

cost roughly the same as their digital counterparts. Additionally,

analog ammeters are not nearly as rugged as modern digital

panel voltmeters. Figure 9 illustrates a typical ammeter

application. The circuit uses a ±200mV input meter — the

preferred range for most ammeters — to measure the voltage

Ω

developed across a 0.1

current shunt. The circuit shown

represents a basic ammeter connection diagram. A detailed

application note describing digital dc ammeters is included in

DATEL's new Digital Panel Meter Databook.

1

2

3

6

(–) IN LO

DMS-20PC-0

12

0.150V

W

0.1

R

Shunt

11

(+) IN HI

Load

(3.3 )

W

8

REF OU

7

REF IN

+5V SUP

+

–

DISP EN

5Vdc

5V RET

DP1

1.5 Amp (Load Current)

Figure 9. DC Ammeter Circuit

6. Power Supply Monitoring: One of the most common digital

panel meter applications involves monitoring the output voltage

of the system power supply — often this supply also powers the

meter itself. The low-power, red LED DMS-20PC-2-RL can be

configured to allow power supply monitoring over the range of

4.5-18Vdc. The circuit in Figure 8 uses a low-drop-out, threeterminal regulator (LM-2931Z-5, available from National

Semiconductor) to provide regulated 5V-power to the meter.

DMS-20PC-2-RL

(+) IN HI

11

1

2

3

5

DP2

7

REF

IN

8

REF

OUT

12

(–) IN LO

LM2931Z-5

+

+5V SUP

DISP EN

5V RET

IN

OUT

+

–

4.5 - 18Vdc

GND

22µF

10V

Figure 8. 4.5V-18V Power Supply Monitor

8. External Gain Adjustment: Connect REFERENCE OUT

(pin 8) to REFERENCE IN (pin 7) for normal, factory calibrated,

operation. Use the circuit shown in Figure 10 for applications

needing external gain adjustment. Calibration is performed with

a precise, near-full-scale, input voltage.

Figure 10. External Gain Adjustment

5

Page 6

DMS-20PC

3½ DIGIT, LED DISPLAY DIGITAL PANEL VOLTMETERS

Mechanical Specifications

MECHANICAL DIMENSIONS: Inches (mm)

TOLERANCES: 2 PL DEC ±0.02 (±0.51)

LEAD DIMENSIONS: 0.025 (0.635) x 0.025 (0.635) NOMINAL

RECOMMENDED PC BOARD FINISHED HOLE DIAMETER:

3 PL DEC ±0.010 (±0.254)

0.042 ±0.003 (1.067 ±0.076)

CALIBRATION POTENTIOMETER HOLE LOCATION

PIN 1

0.170

(4.32)

PIN #1

IDENTIFIER

+5V SUPPLY

DISPLAY ENABLE

5V RETURN

DP3

DP2

DP1

DMS-20PC-X-XX

MADE IN USA

®®

FRONT VIEW

12

1

2

3

4

5

6

(–) INPUT LO

11

(+) INPUT HI

10

ANALOG COMMON

9

DISPLAY TEST/HOLD

8

REFERENCE OUT

7

REFERENCE IN

0.125 (3.175) DIAMETER

(USE ONLY WHEN

PC BOARD MOUNTING)

OPTIONAL BEZEL (DMS-BZL3 and DMS-BZL4)

0.187

(4.75)

FRONT VIEW

#2-56 INSERT

0.156 (3.96) DEEP

1.826 (46.38)

1.280

(32.51)

0.150

(3.81)

0.040

(1.02)

0.15

(3.8)

TYP.

0.88

(22.4)

0.80

(20.3)

0.50

(12.7)

0.040

(1.02)

0.10

(2.5)

TYP.

BEZEL INSTALLATION

DP1 DP2 DP3

1.38

(35.1)

1.30

(33.0)

1.10

(27.9)

0.040

(1.02)

0.475 (12.07)

0.25 (6.4) TYP.

0.10

(2.5)

TYP.

RECOMMENDED DRILL AND PANEL CUTOUT DIMENSIONS

INTERNAL CORNER RADII:

0.032 (0.81) MAX.

RETAINING CLIP INSTALLATION

1.07

(27.18)

1.336 (33.93)

1.626 (41.30)

0.093 (2.362) DIAMETER (4 REQUIRED)

ONLY WHEN USING OPTIONAL BEZEL ASSEMBLY

0.145

(3.68)

0.838

(21.29)

0.116

(2.95)

®®

ISO 9001

ISO 9001

REGISTERED

DATEL, Inc. 11 Cabot Boulevard, Mansfield, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

Data sheet fax back: (508) 261-2857

DATEL makes no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein

do not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifications are subject to change without notice. The DATEL logo is a registered DATEL, Inc. trademark.

DATEL (UK) LTD. Tadley, England Tel: (01256)-880444

DATEL S.A.R.L. Montigny Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, Japan Tel: 3-3779-1031, Osaka Tel: 6-354-2025

DS-0271B 1/98

Loading...

Loading...