Datasheet BPB-12-1.65-Q48, BPB-12-1.65-Q12, BPB-12-1.65-D48, BPB-12-1.65-D24, BPB-5-4-Q48 Datasheet (DATEL)

...

DATEL, Inc., Mansfield, MA 02048 (USA) • Tel: (508)339-3000, (800)233-2765 Fax: (508)339-6356 • Email: sales@datel.com • Internet: www.datel.com

INNOVATION and EX C ELL E N C E

®

®

Dual Output

BPB Models

High-Efficiency, Smaller-Package

25-40 Watt, DC/DC Conver ters

Features DATEL’s new BPB Model, 25-40 Watt, dual-output DC/DC con verters bring you

efficient "on-board" power processing in a cost-effective smaller package with a

standard pinout. The 2" x 3" BPB "footprint" conforms to the industry-standard pinout

and pin geometries of most 3" x 3" devices (a 33% space savings) while delivering as

much as 60% more power (40W vs. 25W).

Applicable to a wide range of telecom, computer and other OEM applications, BPB

Model DC/DC’s off er ±5V , ±12V or ±15V outputs. They operate from four diff erent input

voltage ranges with total available output power being a function of the selected input

range. "Q12" models operate from 10-36V and deliver 25W .

"Q48" models operate from 18-72V and deliver 30W . For "D24" and "D48" models, the

input voltage ranges and rated output powers are 18-36V at 35W and 36-72V

at 40W, respectiv ely .

For improved reliability and aff ordability , BPB Models exploit modern, high-speed,

automatic assembly to construct their field-proven, SMT-on-pcb designs. Devices

employ corrosion-resistant steel cases with heavy zinc top plates (traditionally referred

to as baseplates). Heat-generating transformer cores and power semiconductors are

mounted directly to the cases, which have threaded inserts for optional add-on heat

sinks and/or pcb mounting.

All devices feature input pi filters, input overvoltage shutdown, output overvoltage

protection, output current limiting, and thermal shutdown. UL, CSA, EN and IEC

compliance testing is currently in progress as are EMI/EMC characterizations.

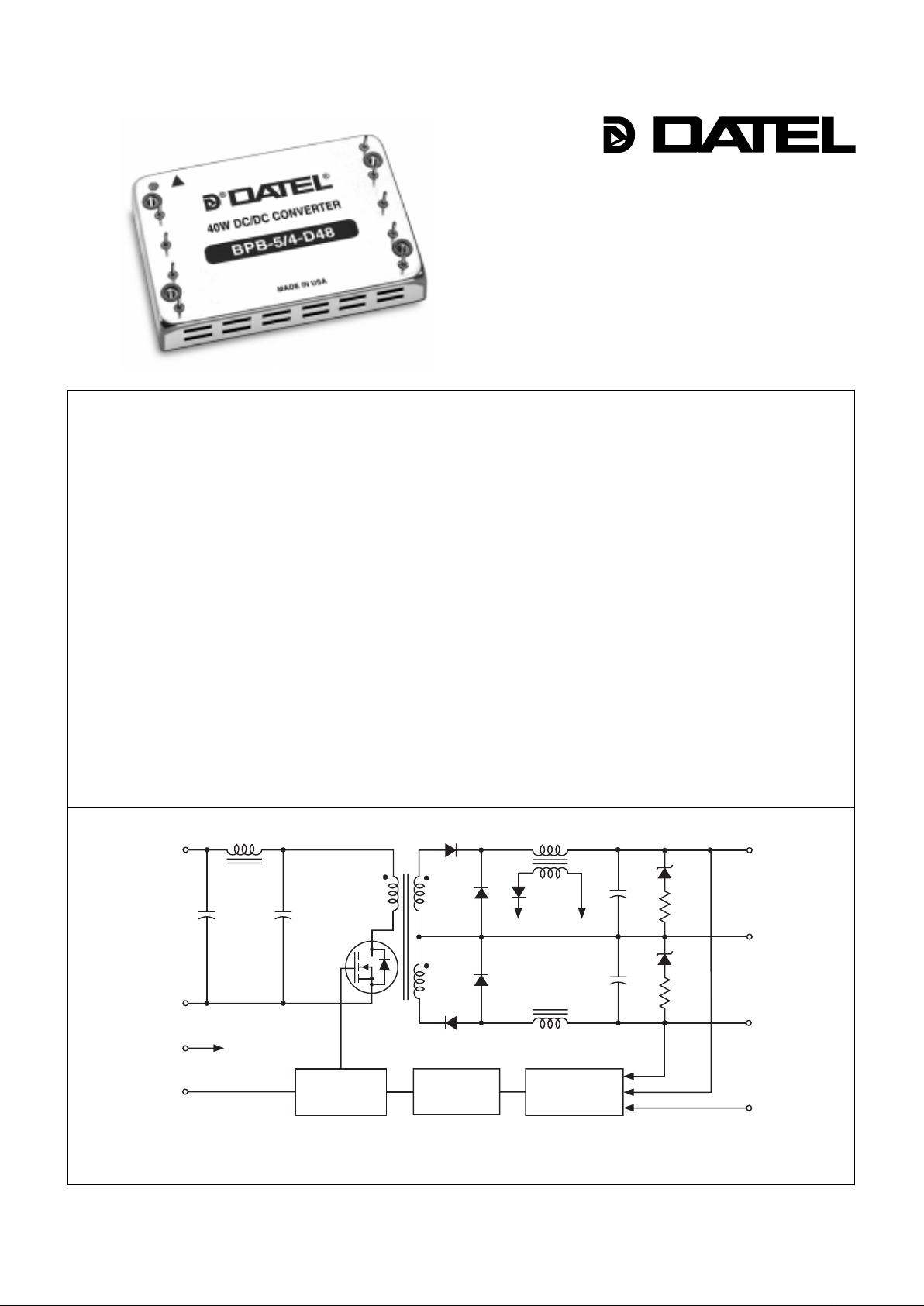

Figure 1. Simplified Schematic

OPTO

FEEDBACK

REFERENCE &

ERROR

AMPLIFIER

PWM

CONTROLLER

+V

IN

–

V

IN

ON/OFF

CONTROL

(SYNC)

TRIM

COMMON

+V

OUT

–

V

OUT

CASE

–

V

IN

PWM

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

25/30/35/40W output power

Standard pinout! Smaller size!

New 2" x 3" package fits 3" x 3" footprint

±5V, ±12V or ±15V outputs

Four input voltage ranges:

10-36V , 18-36V

18-72V , 36-72V

High efficiencies (to 88%)

Fully isolated, 750Vdc guaranteed

Fully I/O protected

Thermal shutdown

V

OUT trim and on/off control

Safety approvals pending

Modifications and customs for OEM’ s

25-40W, DUAL OUTPUT DC/DC CONVERTERS

XPB Series

2

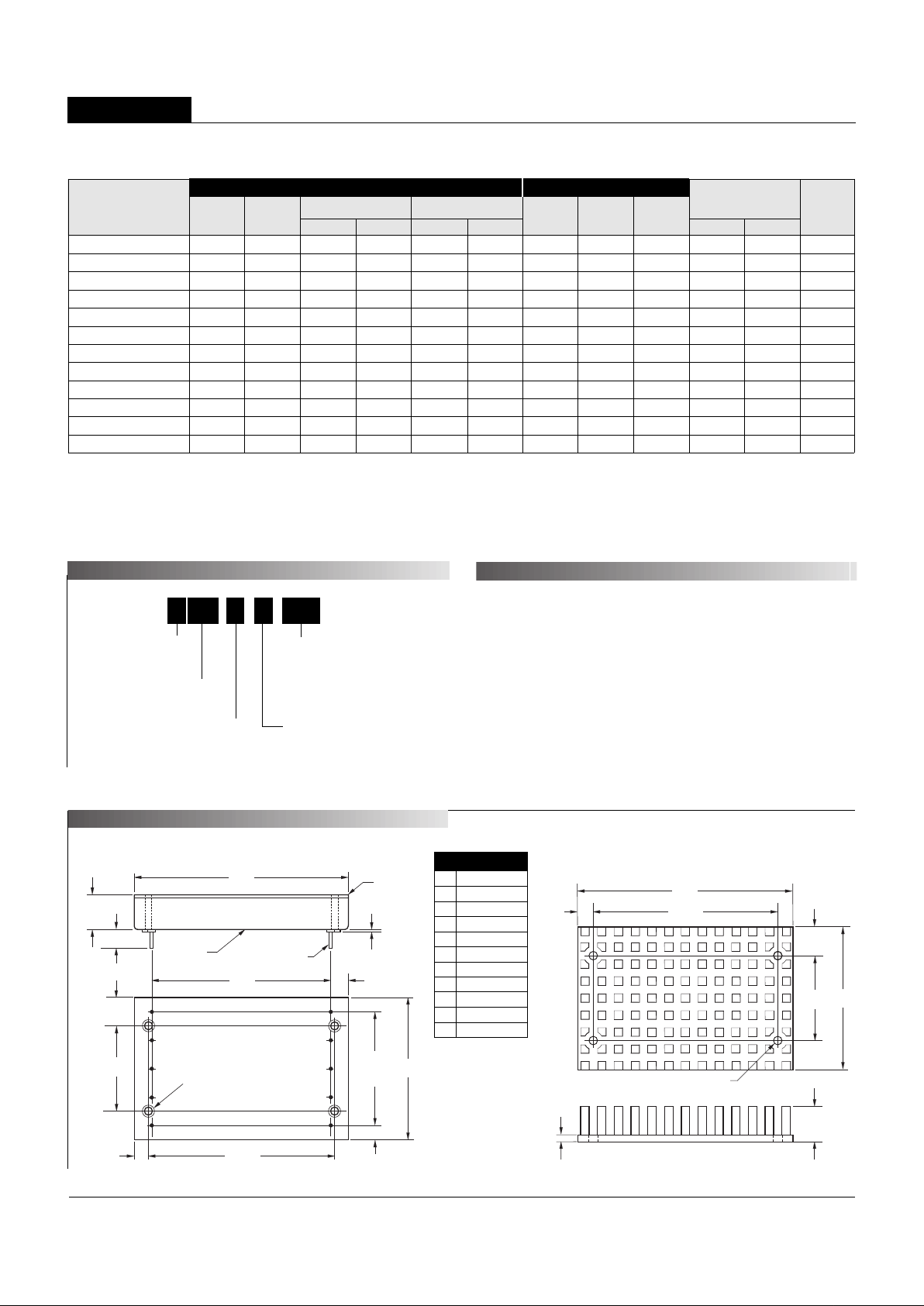

As shown below, BPB Model DC/DC Converters are classified by output

power. For dual-output devices, the total output power from the two outputs

can not exceed the rated power. For example, "Q48" models have a

maximum output power of 30W. Therefore, if the +Output is sourcing 20

Watts, the –Output is limited to sourcing 10 Watts ensuring the total output

power does not exceed 30 Watts.

Output Configuration:

B = Bipolar

Nominal Output Voltages:

±5, ±12 or ±15 Volts

5B PB 4-

/

D48-

Input Volta ge Range:

Q12 = 10-36 Volts (24V nominal)

D24 = 18-36 Volts (24V nominal)

Q48 = 18-72 Volts (48V nominal)

D48 = 36-72 Volts (48V nominal)

Maximum Output Current

in Amps from each output

Power Package with

Metal Baseplate

➀

T ypical at TA = +25°C under nominal line voltage and balanced "full-load" conditions unless otherwise noted.

For BPB devices, "full load" is a function of each de vice's input voltage range. See Output Po wer Considerations and T echnical Notes f or more details .

➁

Ripple/Noise (R/N) measured over a 20MHz bandwidth.

➂

Balanced loads, 10% to 100% load.

➃

Nominal line voltage, no-load/full-load conditions.

Performance Specifications and Ordering Guide

R/N (mVp-p)

➁

Load

➂

VOUT

(Volts)

Package

(Case,

Pinout)

Efficiency

Regulation (Max.)

Line

VIN Nom.

(Volts)

Range

(Volts)Model

IIN ➃

(mA)

➀

Max.

Typ.

Typ.

Min.

BPB-5/4-Q12 ±5 ±4 100 150 ±0.5% ±1% 24 10-36 15/1225 82% 85% C10, P15

BPB-5/4-D24 ±5 ±4 100 150 ±0.5% ±1% 24 18-36 15/1696 84% 86% C10, P15

BPB-5/4-Q48 ±5 ±4 100 150 ±0.5% ±1% 48 18-72 25/735 82% 85% C10, P15

BPB-5/4-D48 ±5 ±4 100 150 ±0.5% ±1% 48 36-72 20/980 83% 85% C10, P15

BPB-12/1.65-Q12 ±12 ±1.65 100 150 ±0.5% ±1% 24 10-36 15/1224 82% 85% C10, P15

BPB-12/1.65-D24 ±12 ±1.65 100 150 ±0.5% ±1% 24 18-36 15/1667 85% 87% C10, P15

BPB-12/1.65-Q48 ±12 ±1.65 100 150 ±0.5% ±1% 48 18-72 15/727 84% 86% C10, P15

BPB-12/1.65-D48 ±12 ±1.65 100 150 ±0.5% ±1% 48 36-72 15/948 85% 87% C10, P15

BPB-15/1.3-Q12 ±15 ±1.3 100 150 ±0.5% ±1% 24 10-36 20/1225 83% 85% C10, P15

BPB-15/1.3-D24 ±15 ±1.3 100 150 ±0.5% ±1% 24 18-36 15/1648 85% 88% C10, P15

BPB-15/1.3-Q48 ±15 ±1.3 100 150 ±0.5% ±1% 48 18-72 15/735 83% 85% C10, P15

BPB-15/1.3-D48 ±15 ±1.3 100 150 ±0.5% ±1% 48 36-72 20/923 85% 88% C10, P15

IOUT

(Amps)

PART NUMBER STRUCTURE

Model Maximum Output Power

"Q12" 25 W atts

"Q48" 30 W atts

"D24" 35 Watts

"D48" 40 Watts

I/O Connections

Function P15

No Pin

–Input

+Input

Case

On/Off Control*

–Output

No Pin

Common

+Output

Trim

Pin

1

2

3

4

5

6

7

8

9

10

* See note 4 on next page.

MECHANICAL SPECIFICATIONS

BOTTOM VIEW

2.500

(63.50)

0.25

(6.35)

2.00

(50.80)

7

6

8

9

1.600

(40.64)

4 EQ. SP. @

0.400 (10.16)

4

1

2

0.20

(5.08)

1.200

(30.48)

2.600

(66.04)

0.40

(10.16)

3.00

(76.20)

(4) THREADED INSERTS

#4-40 THD THRU

WITH 0.025 (0.64)

STANDOFFS

0.20

(5.08)

3

5

10

0.50

(12.70)

0.20 MIN.

(5.08)

0.040 ±0.002 DIA.

(1.016 ±0.051)

0.025

(0.64)

METAL CASE

METAL

BASEPLATE

Case C10

2.600

(66.04)

0.20

(5.08)

2.00

(50.80)

1.200

(30.48)

3.00

(76.20)

0.50

(12.70)

0.40

(10.16)

0.10

(2.54)

0.120 DIA. (3.048)

(4 PLACES)

MATERIAL: BLACK ANODIZED ALUMINUM

4 MOUNTING SCREWS AND 0.009 (0.229) THERMAL PAD INCLUDED

TOP VIEW

Optional Heat Sink (Part Number HS-23)

OUTPUT POWER CONSIDERATIONS

Output Input

BPB Models

25-40W, DUAL OUTPUT DC/DC CONVERTERS

3

Floating Outputs

Since these are isolated DC/DC converters, their outputs are "floating." Any

BPB model may be configured to produce an output of 10V, 24V or 30V (for

±5V, ±12V or ±15V models, respectively) by applying the load across the

+Output and –Output (pins 9 and 6), with either output grounded. The

Common (pin 8) should be left open. Minimum 20% loading is recommended under these conditions. The total output voltage span may be

externally trimmed as described below.

Performance/Functional Specifications

T ypical @ TA = +25°C under nominal line voltage and "full-load" conditions, unless noted.

➀ ➁

Input

Input Voltage Range:

"Q12" Models 10-36 Volts (24V nominal)

"D24" Models 18-36 Volts (24V nominal)

"Q48" Models 18-72 Volts (48V nominal)

"D48" Models 36-72 Volts (48V nominal)

Input Current See Ordering Guide

Input Filter Type

➂

Pi

Overvoltage Shutdown:

"Q12" and "D24" Models 40 Volts

"Q48" and "D48" Models 80 Volts

Reverse-Polarity Protection Yes (Instantaneous, 6A maximum)

On/Off Control (Pin 5)

➃

TTL high (or open) = on, low = off

Output

VOUT Accuracy (50% load) ±1%, maximum

Temperature Coefficient ±0.02% per °C

Ripple/Noise (20MHz BW)

➂

See Ordering Guide

Line/Load Regulation See Ordering Guide

Efficiency See Ordering Guide

Isolation Voltage 750Vdc, minimum

Isolation Capacitance 620pF

Current Limiting Continuous, auto-recovery

Overvoltage Protection Zener/transorb clamps, magnetic feedback

Dynamic Characteristics

Transient Response (50% load step) 300µsec max. to ±1.5% of final value

Switching Frequency 125kHz (±10%)

Environmental

Operating Temperature (ambient):

Without Derating –25 to +50°C (Model dependent)

With Derating to +90°C (See Derating Curves)

Maximum Baseplate Temperature +90°C

Storage Temperature –40 to +105°C

Physical

Dimensions 2" x 3" x 0.5" (50.8 x 76.2 x 12.7mm)

Shielding 6-sided

Case Connection Pin 4

Case Material Tin-plated steel

Baseplate Material Zinc with black enamel finish

Pin Material Brass, solder coated

Weight 4 ounces (113 grams)

➀

These converters require a minimum 10% loading on each output to maintain

specified regulation. Operation under no-load conditions will not damage these devices;

however they ma y not meet all listed specifications.

➁

"Full load" varies by part number and is determined by the input voltage range as indicated by

the part number suffix. See Technical Notes and Output Power Considerations .

➂

Application-specific input/output filtering can be recommended or perhaps added internally

upon request. Contact DATEL Applications Engineering for details.

➃

Applying a voltage to the On/Off Control pin when no input power is applied to the converter

can cause permanent damage to the converter. If desired, the On/Off Control function can be

replaced with a Sync function. See page 6 of this data sheet for more details.

Filtering and Noise Reduction

All BPB 25-40 Watt DC/DC Converters achieve their rated ripple and noise

specifications without the use of external input/output capacitors. In critical

applications, input/output ripple and noise may be further reduced by

installing electrolytic capacitors across the input terminals and/or low-ESR

tantalum or electrolytic capacitors across the output terminals. Output

capacitors should be connected between their respective output pin (pin 6 or

9) and Common (pin 8). See Figure 7. The caps should be located as close

to the power converters as possible. Typical values are listed in the tables

below. In many applications, using values greater than those listed will yield

better results.

To Reduce Input Ripple

"Q12, D24" Models 47µF, 50V

"Q48, D48" Models 10µF, 100V

To Reduce Output Ripple

±5V Outputs 47µF, 10V, Low ESR

±12/15V Outputs 22µF, 20V, Low ESR

In critical, space-sensitive applications, DATEL may be able to tailor the

internal input/output filtering of these devices to meet your specific requirements. Contact our Applications Engineering Group for additional details.

Input Voltage:

"Q12/D24" Models 44 Volts

"Q48/D48" Models 88 Volts

Input Reverse-Polarity Protection Current must be <6A. Brief

duration only . Fusing recommended.

Output Overvoltage Protection

±5V Outputs 6.8 Volts, limited duration

±12V Outputs 15 Volts, limited duration

±15V Outputs 18 Volts, limited duration

Output Current Current limited. Max. current and

short-circuit duration are model

dependent.

Storage Temperature –40 to +105°C

Lead Temperature (soldering, 10 sec.) +300°C

These are stress ratings. Exposure of de vices to an y of these conditions ma y adv ersely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifications Table is not implied.

Absolute Maximum Ratings

TECHNICAL NOTES

Input Fusing

VIN Range "Q12" "D24" "Q48" "D48"

Fuse Value 4A 4A 3A 2A

25-40W, DUAL OUTPUT DC/DC CONVERTERS

XPB Series

4

Temperature Derating and Electrical Performance Curves

Q12 Models (25 Watts)

Output Power (Watts)

Ambient Temperature (°C)

25

20

15

10

5

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Output Power (Watts)

Ambient Temperature (°C)

25

20

15

10

5

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 9

0

Figure 2a. Temperature Derating Without Heat Sink

Figure 2b. Temperature Derating With Heat Sink

Output Power (Watts)

Ambient Temperature (°C)

30

25

20

15

10

5

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Output Power (Watts)

Ambient Temperature (°C

)

30

25

20

15

10

5

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 9

0

Figure 3a. Temperature Derating Without Heat Sink

Figure 3b. Temperature Derating With Heat Sink

Q48 Models (30 Watts)

Output Power (Watts)

Ambient Temperature (°C)

35

30

25

20

15

10

5

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90

Output Power (Watts)

Ambient Temperature (°C)

35

30

25

20

15

10

5

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 9

0

Figure 4a. Temperature Derating Without Heat Sink

Figure 4b. Temperature Derating With Heat Sink

D24 Models (35 Watts)

BPB Models

25-40W, DUAL OUTPUT DC/DC CONVERTERS

5

40

35

30

25

20

15

10

5

0

Output Power (Watts)

Ambient Temperature (°C)

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 9

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

Figure 5a. Temperature Derating Without Heat Sink

Figure 5b. Temperature Derating With Heat Sink

D48 Models (40 Watts)

Output Power (Watts)

Ambient Temperature (°C)

40

35

30

25

20

15

10

5

0

–25 0 20 25 30 35 40 45 50 55 60 65 70 75 80 85 9

0

Natural Convection Cooling

150 Linear Feet Per Minute

300 Linear Feet Per Minute

Temperature Derating and Electrical Performance Curves

Voltage Output

Model Number Range Power ±5V Currents ±12V Currents ±15V Currents

BPB-5/4-Q12 10-36V 25 Watts ±2.5A (25W) – –

BPB-5/4-Q48 18-72V 30 Watts ±3A (30W) – –

BPB-5/4-D24 18-36V 35 Watts ±3.5A (35W) – –

BPB-5/4-D48 36-72V 40 Watts ±4A (40W) – –

BPB-12/1.65-Q12 10-36V 25 Watts – ±1.04A (24.96W) –

BPB-12/1.65-Q48 18-72V 30 Watts – ±1.25A (30W) –

BPB-12/1.65-D24 18-36V 35 Watts – ±1.46A (35W) –

BPB-12/1.65-D48 36-72V 40 Watts – ±1.67A (40.1W) –

BPB-15/1.3-Q12 10-36V 25 Watts – – ±833mA (24.99W)

BPB-15/1.3-Q48 18-72V 30 Watts – – ±1A (30W)

BPB-15/1.3-D24 18-36V 35 Watts – – ±1.17A (35.1W)

BPB-15/1.3-D48 36-72V 40 Watts – – ±1.33A (39.9W)

Definition of "Full Load" for Specification Purposes

Output Power

BPB Model, dual-output DC/DC converters incorporate a design tradeoff

between total available output power and input voltage range. The total

available power is a function of both the nominal input voltage and the

"width" of the input voltage range. For a given nominal input (24V or 48V),

narrower ranges (2:1 vs. 4:1) have more available power. For a given "width"

of input range (2:1 or 4:1), higher nominal inputs (48V vs. 24V) have more

available power. Each device, as indicated by its part-number suffix (Q12, Q48,

D24 or D48) has a total output power limitation of 25, 30, 35 or 40 Watts,

respectively. Observing these power limitations is the user's responsibility.

As indicated by its Part Number Structure, each ±5V, ±12V or ±15V BPB

device is capable of sourcing up to ±4, ±1.65 or ±1.3 Amps, respectively.

Users have the flexibility of loading either output up to these limits; however

you must be extremely careful not to exceed the total output power rating of

any given device. If, for example, a ±5V device with a 30W power rating

(BPB-5/4-Q48) is sourcing 4A from its +5V output (representing 20W of

+Output power), that device can only supply an additional 10W (2 Amps)

from its –Output.

As a consequence of this "power-allocation" flexibility, the definition of "full

load," as the condition under which performance specifications are tested and

listed, is ambiguous. The following table lists the positive and negative output

currents that DATEL uses to define each device’s "full load."

Table 1. Output Currents Comprising "Full Load"

25-40W, DUAL OUTPUT DC/DC CONVERTERS

XPB Series

66

DATEL makes no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein

do not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifications are s ubject to change without notice. The DATEL logo is a registered DATEL, Inc. trademark.

DATEL (UK) L TD. T adle y, England Tel: (01256)-880444

DATEL S.A.R.L. Montign y Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, J apan Tel: 3-3779-1031, Osaka Tel: 6-354-2025

DATEL, Inc. 11 Cabot Boulevard, Mansfield, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

Data Sheet Fax Back:(508) 261-2857

DS-0410 10/98

On/Off Control (Standard)

The On/Off Control pin (pin 5) may be used for remote on/off operation. As

shown in Figure 6, the control pin has an internal 10kΩ pull-up resistor to

approximately 10V. The converter is designed so that it is enabled when the

control pin is left open (normal mode) and disabled when the control pin is

pulled low (to less than +0.8V relative to –Input, pin 2).

Dynamic control of the on/off function is best accomplished with a mechanical relay or an open-collector/open-drain drive circuit (optically isolated if

appropriate). The drive circuit should obviously be able to sink approximately

1mA when activated and withstand more than 10 Volts when deactivated.

Applying an external voltage to pin 5 when no input power is applied to the

converter can cause permanent damage to the converter. The on/off control

function, however, is designed such that the converter can be disabled (pin 5

pulled low) while input power is ramping up and then "released" once the

input has stabilized. Under these circumstances, it takes approximately

30ms for the output of the fully loaded DC/DC to ramp up and settle to within

±1% of its final value after the converter has been turned on.

Synchronization (Optional)

In critical applications employing multiple switching DC/DC converters, it may

be desirable to intentionally synchronize the switching of selected converters

(so the system noise can be reduced with notch filtering) or to purposely

desynchronize the converters (to lessen the current-carrying requirements on

intermediate dc buses). BPB DC/DC Converters have been designed so that

the On/Off Control function on pin 5 can be replaced with a Sync function. This

change has to be implemented by DATEL during the product assembly

process. Contact our Applications Engineering Group for additional details.

To synchronize the switching of multiple BPB converters configured with the

Sync function, an external clock can be applied to pin 5 of each converter.

The clock should be a TTL square wave referenced to –Input (logic high =

+2 to +5 Volts, 250µA max.; logic low = 0 to +0.8 Volts, 70µA max.) with a

maximum 1µsec "high" duration. The frequency of the synchronizing clock

should be higher than that of any individual converter. Therefore, it should be

145kHz ±5kHz.

Output Trimming

The total o ut p u t vo l t age span, from +Output (pin 9) to –Output (pin 6) may

be trimmed ±5% via a single trimpot or fixed resistor. The trimpot should be

connected as shown in Figure 8 with its wiper connected to pin 10 (Trim). A

trimpot can also be used to determine the value of a single fixed resistor

which can be connected between pin 10 (Trim) and pin 9 (+Output) to trim

"down" the output voltages, or between pins 10 (Trim) and 6 (–Output) to

trim "up" the output voltages. Fixed resistors should be metal-film types with

absolute TCR's less than 100ppm/°C to ensure stability.

Figure 7. Using External Capacitors

to Reduce Input/Output Ripple/Noise

Figure 8. Trim Connections Using a Trimpot

–OUTPUT

+INPUT

–INPUT

+OUTPUT

3

2

9

6

COMMON

8

C

IN

C

OUT

C

OUT

+

+

+

20k

Ω

5-10

Turns

+INPUT

–INPUT

TRIM

COMMON

3

2

9

6

8

LOAD

LOAD

10

–OUTPUT

+OUTPUT

Case Connection

Unlike most other DC/DC converters, BMP DC/DC's do not have their metal

case connected to one of their input pins. The "uncommitted" case is

connected to pin 4 which, depending on your system configuration, should be

connected to either +Input (pin 3) or –Input (pin 2).

+INPUT

–INPUT

3

2

+10V

10kΩ

5

ON/OFF

CONTROL

Figure 6. Driving the On/Off Control Pin

INNOVATION and EX C ELL E N C

E

®

®

ISO 9001

I

SO 9001

REGISTERED

Loading...

Loading...