Datawell BV Hippy 40-MkII User Manual

March 20, 2019

Datawell Heave Pitch Roll Sensor

Manual

Hippy 40-MkII

from serial no. 18181

Service & Sales

Voltastr aat 3

1704 RP Heerhugowaard

The Neth erlands

+31 72 534 5298

+31 72 572 6406

www.datawell. nl

2

Contents

1 Introduction ................................................................................................... 5

2 Principle of operation.................................................................................... 6

2.1 Acceleration measurement ....................................................................... 6

2.2 High pass filter for heave measurement ................................................... 6

2.3 Pitch-roll measurement ............................................................................ 7

3 Connections ................................................................................................. 10

4 Position ........................................................................................................ 11

5 Outputs......................................................................................................... 12

5.1 Pitch (p) .................................................................................................. 12

5.2 Roll (r) .................................................................................................... 12

5.3 Heave and acceleration ......................................................................... 12

6 Platform offset ............................................................................................. 13

6.1 Influence of platform offset ..................................................................... 13

6.2 Amount of platform offset ....................................................................... 13

6.3 Platform orientation ................................................................................ 13

7 Transportation ............................................................................................. 14

8 Specifications .............................................................................................. 15

8.1 General .................................................................................................. 15

8.2 Pitch-roll ................................................................................................. 16

8.3 Heave ..................................................................................................... 17

8.4 Acceleration ........................................................................................... 18

9 System check and calibration (heave) ...................................................... 19

9.1 Simple System check ............................................................................. 19

9.2 Calibration .............................................................................................. 19

10 System check and calibration pitch and roll ........................................... 20

11 Alignment ................................................................................................... 22

12 Maintenance and repair ............................................................................ 24

12.1 Location of components (see fig. 6 and 8) ........................................... 24

12.2 Humidity ............................................................................................... 24

12.3 Repair and pcb check........................................................................... 26

12.3.1 Repair ........................................................................................... 26

12.3.2 Pcb check ..................................................................................... 27

12.4 Coils ..................................................................................................... 28

12.5 Accelerometer check ............................................................................ 28

12.6 Exchange of pcb .................................................................................. 29

13 Check of fluid level .................................................................................... 31

14 Modifications ............................................................................................. 32

15 Dimensions and connections ................................................................... 33

Appendix ........................................................................................................ A-1

3

4

fig. 1

1 Introduction

The Hippy measures pitch, roll and heave.

Reference plane for the pitch-roll measurements is a gravity stabilised platform with a natural

period time of 40 seconds.

An accelerometer is mounted on this stabilised platform.

The sensor can accept any voltage between 10 and 30 V DC.

Output and supply are floating with regard to each other as well as to the housing of the sensor.

5

ibaai 1.211

2

8.30Ta

170Tb

timeperiodT

2 Principle of operation

Acceleration measurement 2.1

The deflection of the tip of a clamped cantilever is a measure for the acceleration. (Vertical

acceleration since the accelerometer is mounted on a gravity stabilised platform).

The cantilever is placed in a fluid in which an electric field is present.

So the potential of the cantilever is a measure for this deflection.

No static friction is involved; the acceleration measurement is without hysteresis.

High pass filter for heave measurement 2.2

The heave is obtained by double integrating the acceleration.

Temporary offset of the platform caused by horizontal acceleration (varying ship's speed) leads

to false acceleration outputs; in order to minimise the resulting false heave outputs a high pass

filter is used.

The remaining false output caused by a 180° reversal of ship's direction is proportional to the

square of the ship's speed, and amounts to approx.0.15 m at ship's speed of 1 m/sec.

The resulting transfer of high pass filter is:

Resulting amplitude transfer and phase shift is given under the specifications for some

frequencies.

6

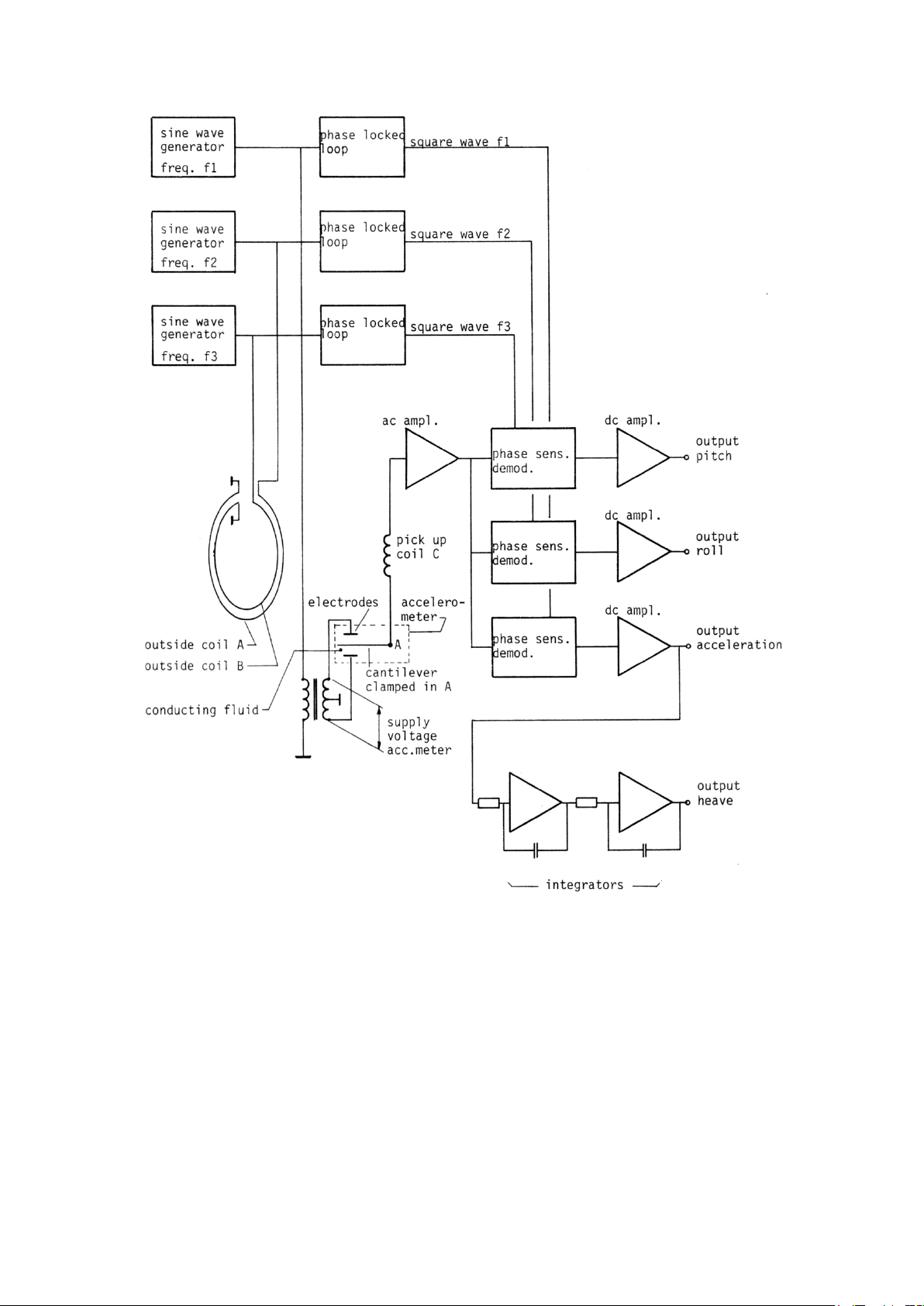

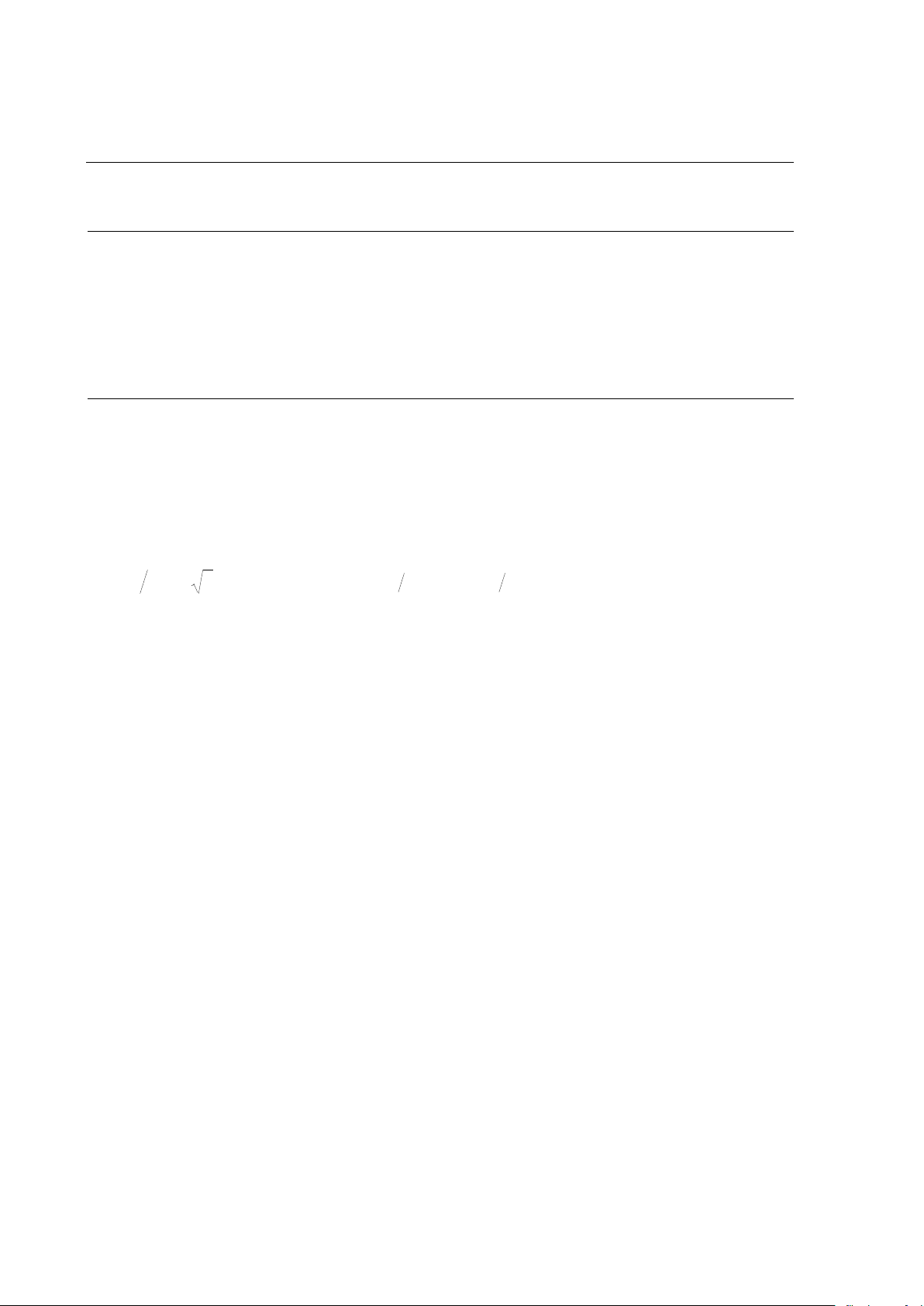

Pitch-roll measurement 2.3

An alternating magnetic field H1 is generated parallel to pitch axis and another field H2 at

different frequency parallel to roll axis (by means of coils A and B, fixed to housing and

perpendicular to each other).

A pickup coil C, mounted on the stabilised platform (horizontal plane) measures the vertical

components of H1 and H2 (fig. 2 and 3).

The induced voltage in coil C is amplified, phase sensitive demodulated and amplified again.

The pickup coil is placed in series with the output of the accelerometer.

See block diagram fig. 1.

fig. 2

7

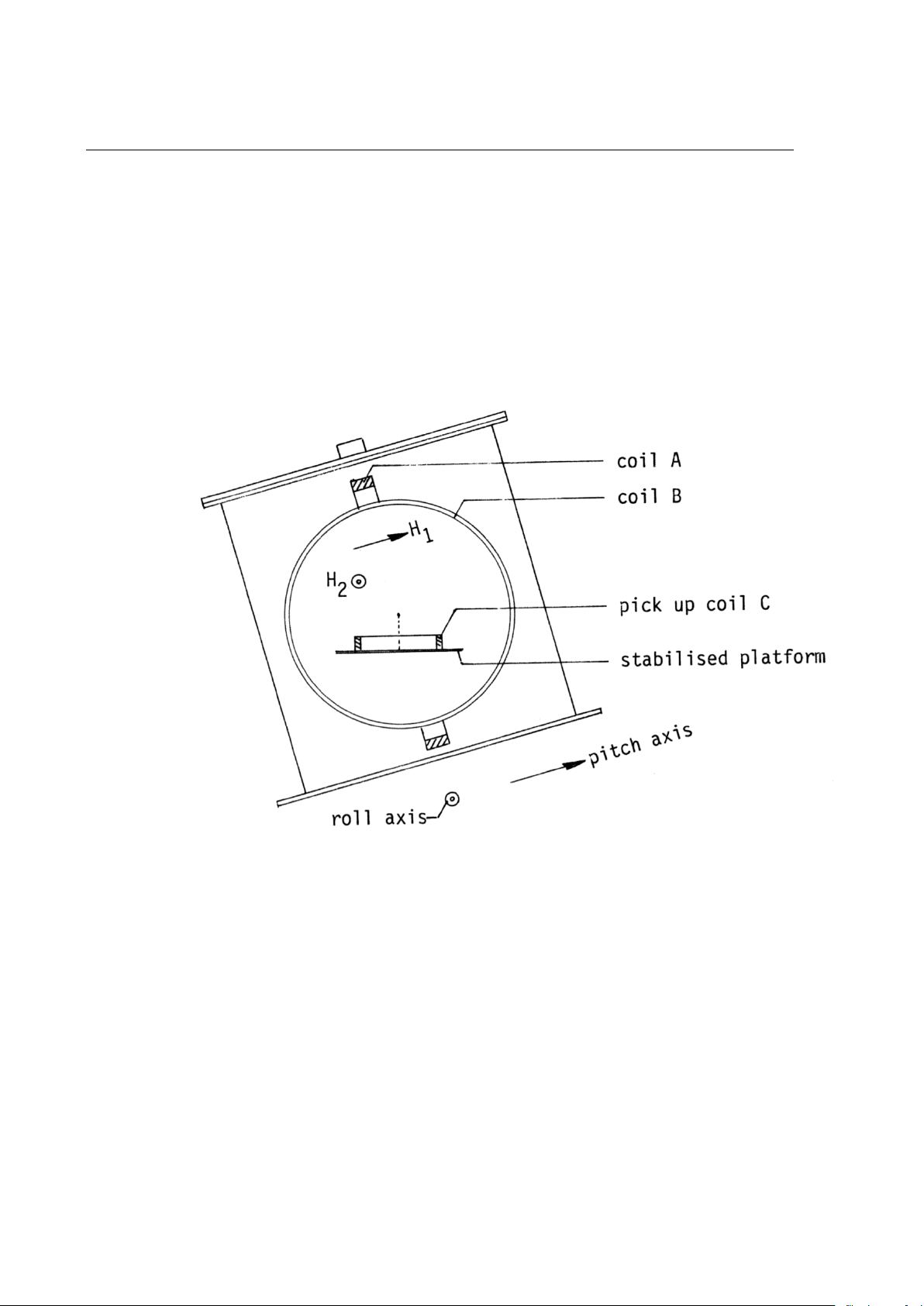

fig. 3

Calculation of induced voltage

Vi is base plane of instrument

Vh is horizontal plane (platform plane)

OL intersection of both planes

Angle between both planes is α

Be H1 = P the magnetic field vector generated parallel to the pitch axis.

OP1 the projection of OP on horizontal plane.

Component of H1 perpendicular to Vh = PP

1

So induced voltage in pickup coil on platform plane = ei;

ei = PP1/OP = sin ∠POP1 (roll output)

also is PP1/OP = PP1/PL . PL/OP = sinαsinβ

8

So roll output r = sin∠POP1 = sinαsinβ

Also pitch output p = sin∠ROR1 = sinαcosβ

For scale factor see specifications (8.2).

α = angle between instrument plane and horizontal plane

β = angle between pitch axis and rotation axis

∠POP1 = angle between pitch axis and horizontal plane

∠ROR1 = angle between roll axis and horizontal plane

9

3 Connections

+ junction box terminal no. 1

Supply

− junction box terminal no. 2

pitch junction box terminal no. 3

roll junction box terminal no. 4

Outputs heave junction box terminal no. 5

acceleration junction box terminal no. 6

common junction box terminal no. 7

For cable diameters see fig. 10.

10

4 Position

Pitch and roll axis are indicated by V formed cuttings in the rim of the bottom flange.

Mount the instrument with arrow (on text plate on lid) in the direction of the bow of the ship

(see fig. 10).

V formed cuttings in lid and top flange should coincide.

11

Loading...

Loading...