Page 1

UM-21336-C

DT9816

User’s Manual

Page 2

Third Edition

March, 2006

Copyright © 2006 by Data Translation, Inc.

All rights reserved.

Information furnished by Data Translation, Inc.

is believed to be accurate and reliable; however,

no responsibility is assumed by Data

Translation, Inc. for its use; nor for any

infringements of patents or other rights of third

parties which may result from its use. No license

is granted by implication or otherwise under any

patent rights of Data Translation, Inc.

Use, duplication, or disclosure by the United

States Government is subject to restrictions as set

forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer software clause at

48 C.F.R, 252.227-7013, or in subparagraph (c)(2)

of the Commercial computer Software Registered Rights clause at 48 C.F.R., 52-227-19 as

applicable. Data Translation, Inc., 100 Locke

Drive, Marlboro, MA 01752

Data Translation® is a registered trademark of

Data Translation, Inc. DT-Open Layers

DataAcq SDK

TM

Link

, and DTx-EZTM are trademarks of Data

TM

, DataAcq OMNI CDTM, DT-LV

TM

,

Translation, Inc.

Data Translation, Inc.

100 Locke Drive

Marlboro, MA 01752-1192

(508) 481-3700

www.datatranslation.com

Fax: (508) 481-8620

E-mail: info@datx.com

All other brand and product names are

trademarks or registered trademarks of their

respective companies.

Page 3

Radio and Television Interference

This equipment has been tested and found to comply with CISPR

EN55022 Class A, and EN50082-1 (CE) requirements and also with

the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own

expense.

Changes or modifications to this equipment not expressly approved

by Data Translation could void your authority to operate the

equipment under Part 15 of the FCC Rules.

Note: This product was verified to meet FCC requirements under

test conditions that included use of shielded cables and connectors

between system components. It is important that you use shielded

cables and connectors to reduce the possibility of causing

interference to radio, television, and other electronic devices.

Canadian Department of Communications Statement

This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la class

A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le Ministère des Communications du Canada.

Page 4

Page 5

Table of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How this Manual is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . 11

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Where To Get Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Key Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Simultaneous Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . 14

Counter/Timer Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clocks and Triggers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Getting Started Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Part 1: Getting Started . . . . . . . . . . . . . . . . . . . . 19

Chapter 2: Preparing to Use a Module. . . . . . . . . . . . . . . . . 21

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checking the System Requirements . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3: Setting Up and Installing

the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Attaching Modules to the Computer . . . . . . . . . . . . . . . . . . . . . . 27

Connecting Directly to the USB Ports . . . . . . . . . . . . . . . . . . 28

Connecting to an Expansion Hub. . . . . . . . . . . . . . . . . . . . . . 29

Changing the Name of a Module (Optional) . . . . . . . . . . . . . . . . 31

5

Page 6

Contents

Chapter 4: Wiring Signals to the Module. . . . . . . . . . . . . . . 33

Preparing to Wire Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Wiring Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting Single-Ended Analog Input Signals . . . . . . . . . . . . . 37

Connecting Digital I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connecting Counter/Timer Signals . . . . . . . . . . . . . . . . . . . . . . . 39

Connecting Signals for Event Counting . . . . . . . . . . . . . . . . 39

Connecting Signals for Frequency Measurement . . . . . . . . 41

Connecting Signals for Rate Generation . . . . . . . . . . . . . . . . 42

Chapter 5: Verifying the Operation

of a Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using the Oscilloscope Function . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Using the Chart Recorder Function . . . . . . . . . . . . . . . . . . . . . . . 48

Using the Voltmeter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Using the File Viewer Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using the Digital Input Function . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using the Digital Output Function . . . . . . . . . . . . . . . . . . . . . . . . 52

Using the Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Using the Rate Generator Function . . . . . . . . . . . . . . . . . . . . . . . 54

Part 2: Using Your Module . . . . . . . . . . . . . . . . . 55

Chapter 6: Principles of Operation . . . . . . . . . . . . . . . . . . . 57

Analog Input Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Input Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Analog Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Specifying a Single Analog Input Channel . . . . . . . . . 60

Specifying One or More Analog Input Channels . . . . 60

6

Page 7

Input Ranges and Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Input Sample Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Analog Input Conversion Modes . . . . . . . . . . . . . . . . . . . . . 61

Single-Value Operations . . . . . . . . . . . . . . . . . . . . . . . . . 61

Continuous Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Input Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Data Format and Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Digital I/O Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Digital I/O Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Counter/Timer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C/T Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

C/T Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Gate Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Pulse Duty Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Counter/Timer Operation Modes . . . . . . . . . . . . . . . . . . . . . 69

Event Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rate Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Contents

Chapter 7: Supported Device Driver Capabilities. . . . . . . . 73

Data Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Buffering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DMA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Triggered Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Synchronous Digital I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7

Page 8

Contents

Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Clocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Counter/Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 8: Programming Flowcharts. . . . . . . . . . . . . . . . . . 87

Single-Value Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Continuous A/D Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Event Counting Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Frequency Measurement Operations . . . . . . . . . . . . . . . . . . . . . . 95

Pulse Output Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 9: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 107

General Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

If Your Module Needs Factory Service . . . . . . . . . . . . . . . . . . . . 112

Appendix A: Specifications . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix B: Screw Terminal Assignments . . . . . . . . . . . 119

Appendix C: Reading from or Writing to the Digital Registers

121

8

Page 9

The first part of this manual describes how to install and set up your

DT9816 module and software, and verify that your module is

working properly.

The second part of this manual describes the features of the DT9816

module and device driver, and how to program these modules using

the DT-Open Layers™ software. It also provides troubleshooting

information. Unless otherwise specified, all references to the DT9816

module refer to both the DT9816 and DT9816-A model numbers.

Intended Audience

This document is intended for engineers, scientists, technicians, or

others responsible for using and/or programming the DT9816

module for analog input, digital I/O, or counter/timer operations in

the Microsoft® Windows® 2000 or Windows XP operating system. It

is assumed that you have some familiarity with data acquisition

principles and that you understand your application.

About this Manual

How this Manual is Organized

This manual is organized as follows:

• Chapter 1, “Overview,” describes the major features of the

DT9816 module, as well as the supported software and

accessories for the module.

• Chapter 2, “Preparing to Use a Module,” describes how to

unpack the module, check the system requirements, and install

the software.

• Chapter 3, “Setting Up and Installing the Module,” describes

how to install the module and how to configure the device driver.

9

Page 10

About this Manual

• Chapter 4, “Wiring Signals to the Module,” describes how to

wire signals to the module.

• Chapter 5, “Verifying the Operation of a Module,” describes

how to verify the operation of the module with the GO!

application.

• Chapter 6, “Principles of Operation,” describes all of the features

of the DT9816 module and how to use them in your application.

• Chapter 7, “Supported Device Driver Capabilities,” lists the

supported subsystems and the associated capabilities accessible

using the device driver for the DT9816 module.

• Chapter 8, “Programming Flowcharts,” describes the processes

you must follow to program the subsystems of a DT9816 module

using DT-Open Layers-compliant software.

• Chapter 9, “Troubleshooting,” provides information that you can

use to resolve problems with a DT9816 module, should they

occur.

• Appendix A, “Specifications,” lists the specifications of the

DT9816 module.

10

• Appendix B, “Screw Terminal Assignments,” shows the screw

terminal assignments of the DT9816 module.

• Appendix C, “Reading from or Writing to the Digital Registers,”

describes how to access the module’s registers directly.

• An index completes this manual.

Page 11

Conventions Used in this Manual

The following conventions are used in this manual:

• Notes provide useful information or information that requires

special emphasis, cautions provide information to help you avoid

losing data or damaging your equipment, and warnings provide

information to help you avoid catastrophic damage to yourself or

your equipment.

• Items that you select or type are shown in bold.

Related Information

Refer to the following documents for more information on using the

DT9816 module:

• Benefits of the Universal Serial Bus for Data Acquisition. This white

paper describes why USB is an attractive alternative for data

acquisition. It is available on the Data Translation web site

(www.datatranslation.com).

About this Manual

• DT Measure Foundry Getting Started Manual (UM-19298) and

online help. These documents describe how to use DT Measure

Foundry™ to build drag-and-drop test and measurement

applications for Data Translation® data acquisition devices

without programming.

• DataAcq SDK User’s Manual (UM-18326). For programmers who

are developing their own application programs using the

Microsoft C compiler, this manual describes how to use the

DT-Open Layers DataAcq SDK™ to access the capabilities of

Data Translation data acquisition devices.

• DTx-EZ Getting Started Manual (UM-15428). This manual

describes how to use the ActiveX controls provided in DTx-EZ™

to access the capabilities of Data Translation data acquisition

devices in Microsoft Visual Basic® or Visual C++®.

11

Page 12

About this Manual

Where To Get Help

• DT-LV Link Getting Started Manual (UM-15790). This manual

describes how to use DT-LV Link™ with the LabVIEW™

graphical programming language to access the capabilities of

Data Translation data acquisition devices.

• DAQ Adaptor for MATLAB (UM-22024). This document describes

how to use Data Translation’s DAQ Adaptor to provide an

interface between the MATLAB Data Acquisition subsystem

from The MathWorks and Data Translation’s DT-Open Layers

architecture.

• Microsoft Windows 2000 or Windows XP documentation.

• USB web site (http://www.usb.org).

Should you run into problems installing or using a DT9816 module,

the Data Translation Technical Support Department is available to

provide technical assistance. Refer to Chapter 9 for more information.

If you are outside the United States or Canada, call your local

distributor, whose number is listed on Data Translation’s web site

(www.datatranslation.com).

12

Page 13

1

Overview

Key Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Getting Started Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13

Page 14

Chapter 1

Key Hardware Features

The DT9816 module is part of the ECONseries of economy,

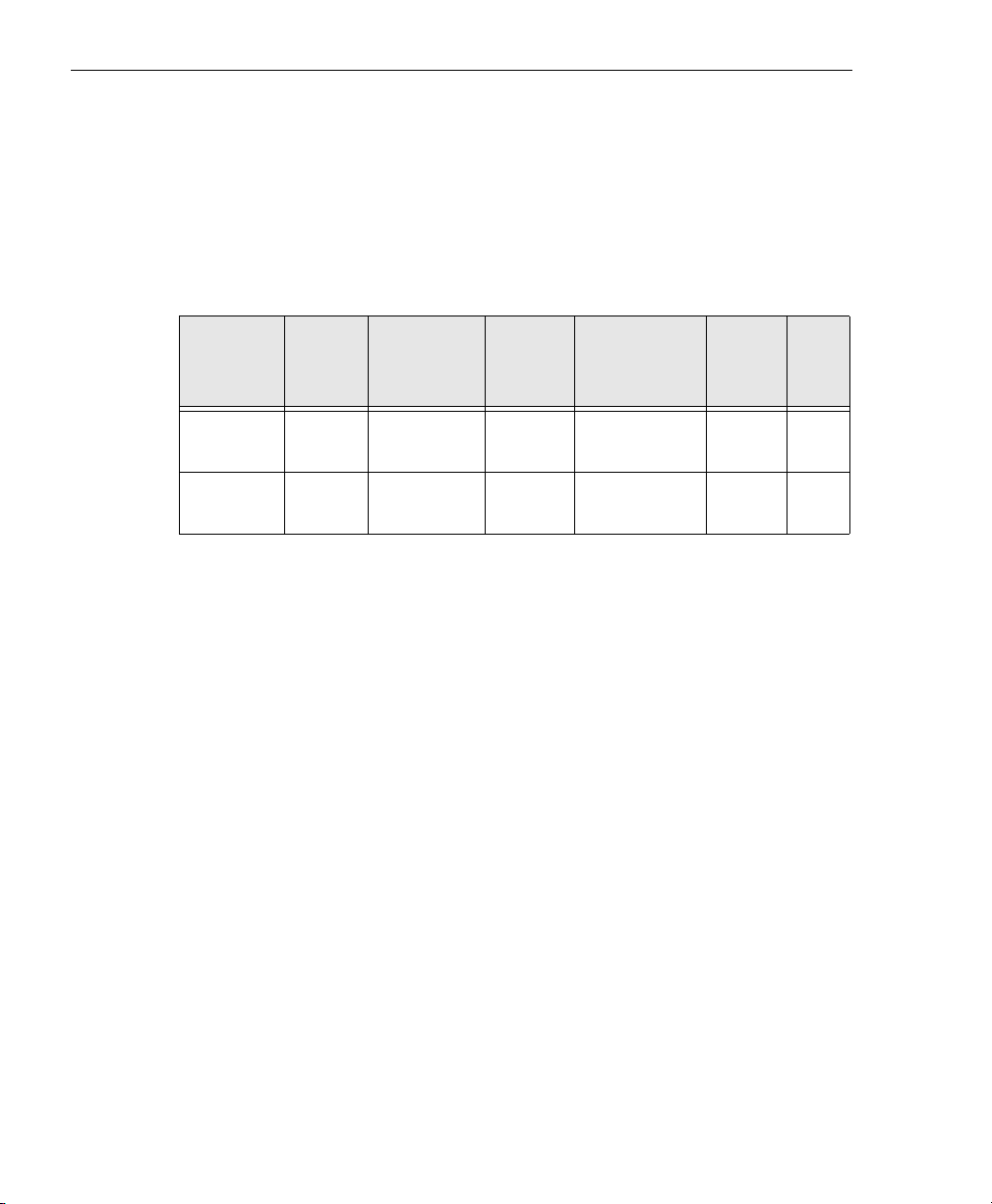

multifunction mini-instruments. Tab le 1 lists the key features of the

module.

Table 1: Key Features of the DT9816 Module

Analog

Analog

Module

DT9816 6 SE 16-bit ±10 V

DT9816-A 6 SE 16-bit ±10 V

a. Actual maximum is 153.846 kHz. If you use the olDaSetClockFrequency function to set

150 kHz, the olDaGetClockFrequency function will not return the true value (153.846

kHz) until after you invoke the olDaConfig function.

Inputs

Input

Resolution

I/O

Range

or ± 5 V

or ± 5 V

Analog Input

Sample Rate

50 kS/s per

channel

150 kS/s per

channel

a

Digital

I/O

8 in/

8 out

8 in/

8 out

The DT9816 is a low-power device (less than 100 mA draw).

Simultaneous Analog Inputs

The DT9816 module features six independent, 16-bit,

successive-approximation A/D converters with track-and-hold

circuitry. Each converter uses a common clock and trigger for

simultaneous sampling of all six analog input signals at up to 50 kHz

per channel (DT9816) or up to 150 kHz per channel (DT9816-A). All

channels in the channel-gain list are read simultaneously on a single

pulse of the internal clock.

C/T

1

1

14

The DT9816 module provides gains of 1 and 2, for effective full-scale

input signal ranges of

±10 V and ±5 V.

Page 15

Counter/Timer Channel

Overview

The DT9816 module supports one 16-bit counter/timer channel. This

counter/timer allows you to perform event counting, frequency

measurement, and continuous pulse output (rate generation)

operations.

Clocks and Triggers

The DT9816 modules supports an internal trigger and clock or an

external trigger and clock.

Use the internal trigger to start an analog input operation based on a

software command, or use the external trigger to start an analog

input operation based on an external event.

Use the external clock signal to pace an analog input operation at a

rate not available with the internal clock or when you want to pace at

uneven intervals.

Supported Software

The following software is available for use with the DT9816 module,

and is provided on the ECON CD:

1

1

1

1

1

1

• Device Driver – The DT9816 Device Driver allows you to use a

DT9816 module with any of the supported software packages or

utilities. Refer to Chapter 2 for more information on loading the

device driver.

• GO! application − The GO! application provides a quick way to

measure and control data from a DT9816 module right out of the

box. The following instrument views make acquiring data and

controlling signals easy: oscilloscope, chart recorder, file viewer,

digital voltmeter, digital input, digital output, frequency counter,

1

1

1

15

Page 16

Chapter 1

and rate generator. Refer to Chapter 5 for more information on

this application.

• DT Measure Foundry – An evaluation version of this software is

included or provided via a link on the ECON CD. DT Measure

Foundry is drag-and-drop test and measurement application

builder designed to give you top performance with ease-of-use

development. Order the full development version of this

software package to develop your own application using real

hardware.

• DataAcq SDK – Use the Data Acq SDK if you want to develop

your own application software for the DT9816 module using the

Microsoft C compiler; the DataAcq SDK complies with the

DT-Open Layers standard.

• DTx-EZ – Use this optional software package if you want to use

ActiveX controls to access the capabilities of the DT9816 module

using Microsoft Visual Basic or Visual C++; DTx-EZ complies

with the DT-Open Layers

standard.

• DAQ Adaptor for MATLAB – Data Translation’s DAQ Adaptor

provides an interface between the MATLAB Data Acquisition

(DAQ) subsystem from The MathWorks and Data Translation’s

DT-Open Layers architecture.

16

• DT-LV Link – Use this optional software package if you want to

use the LabVIEW graphical programming language to access the

capabilities of the DT9816 module.

Page 17

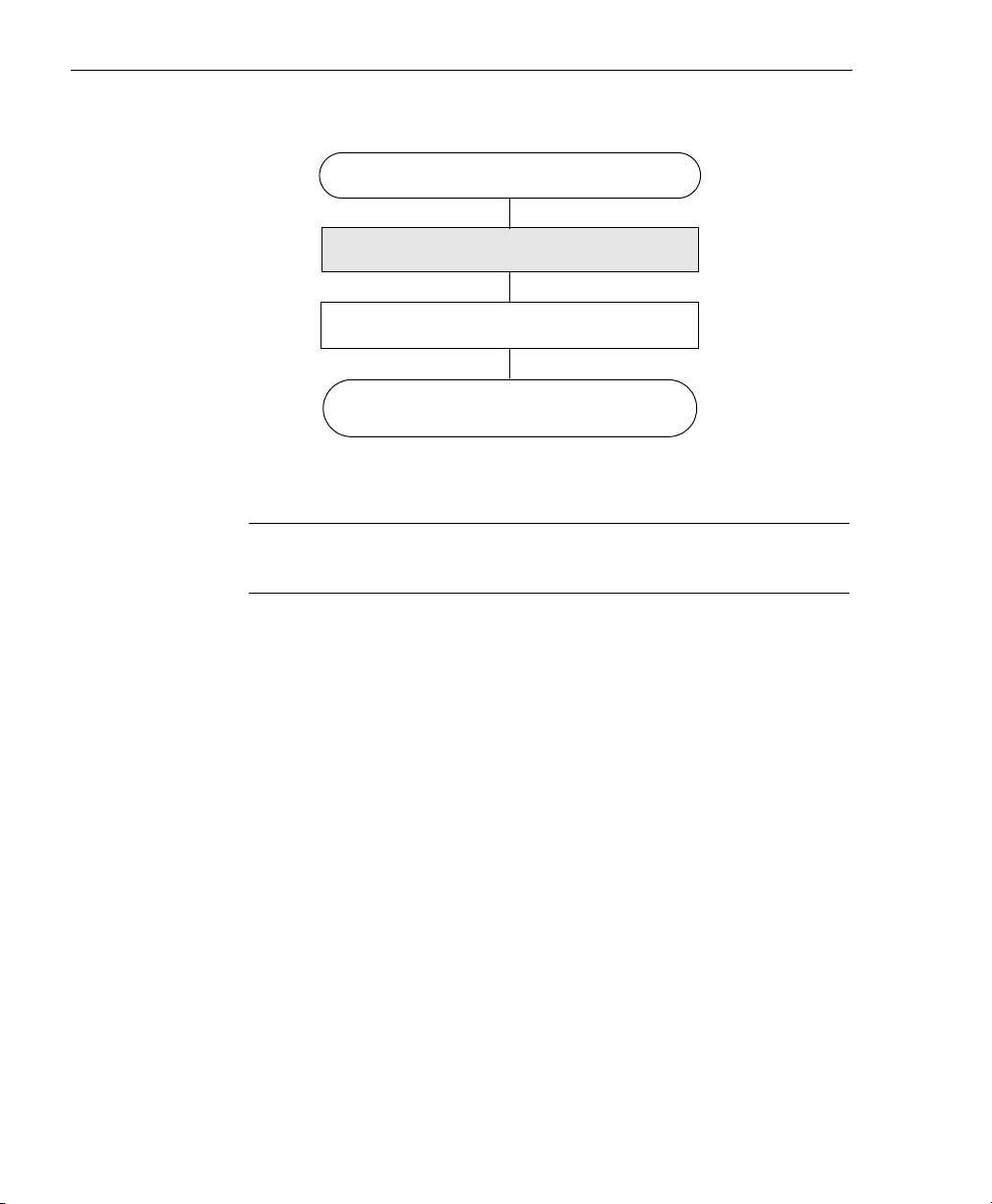

Getting Started Procedure

The flow diagram shown in Figure 1 illustrates the steps needed to

get started using the DT9816 module. This diagram is repeated in

each chapter; the shaded area in the diagram shows you where you

are in the getting started procedure.

Prepare to Use the Module

(see Chapter 2 starting on page 21)

Set Up and Install the Module

(see Chapter 3 starting on page 25)

Overview

1

1

1

Wire Signals to the Module

(see Chapter 4 starting on page 33)

Verify the Operation of the Module

(see Chapter 5 starting on page 43)

Figure 1: Getting Started Flow Diagram

1

1

1

1

1

1

17

Page 18

Chapter 1

18

Page 19

Part 1: Getting Started

Page 20

Page 21

2

Preparing to Use a Module

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checking the System Requirements . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

21

Page 22

Chapter 2

Prepare to Use the Module

(this chapter)

Set Up and Install the Module

(see Chapter 3 starting on page 25)

Wire Signals to the Module

(see Chapter 4 starting on page 33)

Verify the Operation of the Module

(see Chapter 5 starting on page 43)

Unpacking

Open the shipping box and verify that the following items are

present:

22

• DT9816 module

• ECON CD

•USB cable

If an item is missing or damaged, contact Data Translation. If you are

in the United States, call the Customer Service Department at (508)

481-3700. An application engineer will guide you through the

appropriate steps for replacing missing or damaged items. If you are

located outside the United States, call your local distributor (see Data

Translation’s web site (www.datatranslation.com) for contact

information).

Once you have unpacked your module, check the system

requirements, as described in the next section.

Page 23

Preparing to Use a Module

Checking the System Requirements

For reliable operation, your DT9816 module requires the following:

• Windows 2000 or Windows XP (Professional Edition) operating

system.

For USB Ver. 2.0 support, make sure that you install Service Pack

2 (for Windows XP) or Service Pack 4 (for Windows 2000). In

addition, for some systems, you may have to disable standby

mode. If you are not sure whether you are using USB Ver. 1.1 or

Ver. 2.0, run the Open Layers Control Panel applet, described on

page 27.

• One or more USB ports (Ver. 2.0 or Ver. 1.1). USB Ver. 2.0 is

recommended for optimal performance.

•One CD-ROM drive.

Once you have verified that your system meets the system

requirements, install the software, as described in the next section.

2

2

2

2

2

2

2

2

2

23

Page 24

Chapter 2

Installing the Software

To install the device driver, Data Acq SDK, DTx-EZ, and the GO!

application, do the following:

1. Insert the ECON CD into your CD-ROM drive.

If the software runs automatically (the default condition),

continue with step 4.

2. If the software does not run automatically, click Start from the

Task Bar, and then click Run.

The Run dialog box appears.

3. In the Command Line edit box, enter D:\Setup.Exe.

If your CD-ROM is not in drive D:, enter the letter of the drive where

your CD-ROM is located. The welcome screen appears.

4. Click Install Drivers and GO!

5. Click Install now!

The installation wizard appears.

6. Click Next.

The wizard prompts you for the destination location.

24

7. Either change the directory path and/or name using Browse or

accept the default directory (C:\Program Files\Data Translation),

and then click Next.

8. Click Next to copy the files.

9. Click Finish.

10. If you want to install DT-LV Link, click Install Additional

Software, click Install now! under the LabVIEW Link section,

and follow the installation prompts.

11. When you have finished the installation process, click Quit

Installer.

Continue with the instructions in Chapter 3 starting on page 25.

Page 25

3

Setting Up and Installing

the Module

Attaching Modules to the Computer. . . . . . . . . . . . . . . . . . . . . . . 27

Changing the Name of a Module (Optional) . . . . . . . . . . . . . . . . 31

25

Page 26

Chapter 3

Prepare to Use the Module

(see Chapter 2 starting on page 21)

Set Up and Install the Module

(this chapter)

Wire Signals to the Module

(see Chapter 4 starting on page 33)

Verify the Operation of the Module

(see Chapter 5 starting on page 43)

Note: The DT9816 module is factory-calibrated and requires no

further adjustment.

26

Page 27

Setting Up and Installing the Module

Attaching Modules to the Computer

This section describes how to attach a DT9816 module to the host

computer.

Note: Most computers have several USB ports that allow direct

connection to USB devices. If your application requires more DT9816

modules than you have USB ports for, you can expand the number

of USB devices attached to a single USB port by using expansion

hubs. For more information, refer to page 29.

You can unplug a module, and then plug it in again, if you wish,

without causing damage. This process is called hot-swapping. Your

application may take a few seconds to recognize a module once it is

plugged back in.

3

3

3

3

3

3

3

3

3

27

Page 28

Chapter 3

Connecting Directly to the USB Ports

To connect DT9816 modules directly to the USB ports of your

computer, do the following:

1. Attach one end of the USB cable to the USB port on the module.

2. Attach the other end of the USB cable to one of the USB ports on

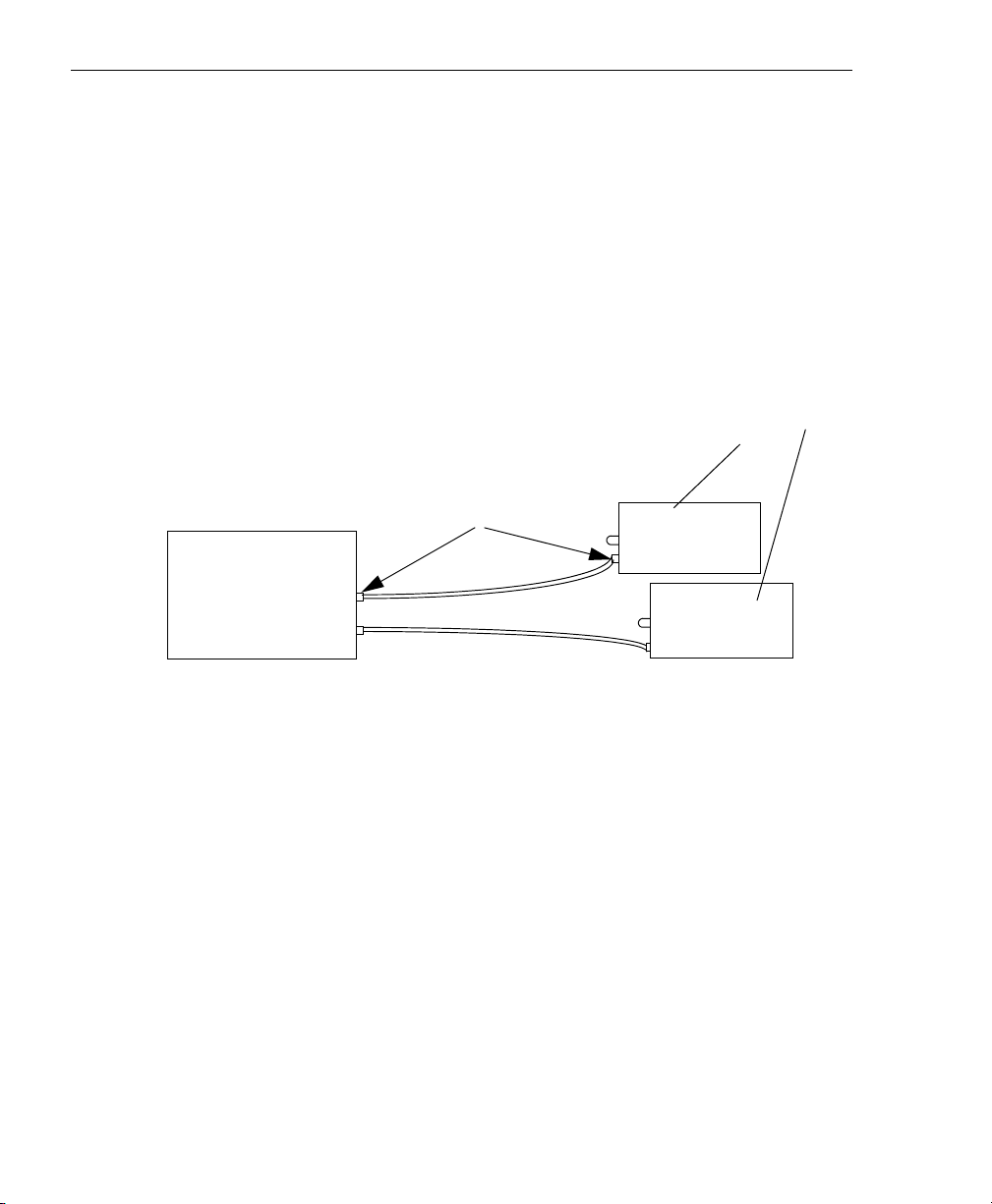

the host computer, as shown in Figure 2.

The operating system automatically detects the USB module and starts

the Found New Hardware wizard.

DT9816 Modules

USB Ports

Host Computer

28

USB Cable

Figure 2: Attaching the Module to the Host Computer

3. Click Next and/or Finish in the wizard. Once the firmware is

loaded, the wizard restarts to initiate the firmware to accept

commands. Click Next and/or Finish again.

If the power supply and module are attached correctly, the LED turns

green.

4. Repeat the steps to attach another DT9816 module to the host

computer, if desired.

Page 29

Connecting to an Expansion Hub

Setting Up and Installing the Module

Expansion hubs are powered by their own external power supply.

Theoretically, you can connect up to five expansion hubs to a USB

port on the host computer. However, the practical number of DT9816

modules that you can connect to a single USB port depends on the

throughput you want to achieve. Each of the hubs supports up to

four modules.

To connect multiple DT9816 modules to an expansion hub, do the

following:

1. Attach one end of the USB cable to the module and the other end

of the USB cable to an expansion hub.

2. Connect the power supply for the expansion hub to an external

power supply.

3. Connect the expansion hub to the USB port on the host computer

using another USB cable.

The operating system automatically detects the USB module and starts

the Found New Hardware wizard.

4. Click Next and/or Finish in the wizard. Once the firmware is

loaded, the wizard restarts to initiate the firmware to accept

commands. Click Next and/or Finish again.

If the power supply and module are attached correctly, the LED turns

green.

3

3

3

3

3

3

5. Repeat these steps until you have attached the number of

expansion hubs (up to five) and modules (up to four per hub)

that you require. Refer to Figure 3.

The operating system automatically detects the USB devices as they are

installed.

3

3

3

29

Page 30

Chapter 3

Host Computer

DT9816 Module

USB Cables

USB Cable

Power Supply

for Hub

DT9816 Module

USB Cables

DT9816 Module

USB Cable

Expansion Hubs

DT9816 Module

Figure 3: Attaching Multiple DT9816 Modules

Using Expansion Hubs

Power Supply

for Hub

30

Page 31

Setting Up and Installing the Module

Changing the Name of a Module (Optional)

To change the name of a DT9816 module, configure the device driver

as follows:

1. From the Windows Start menu, select Settings|Control Panel.

2. From the Control Panel, double-click Open Layers Control

Panel.

The Data Acquisition Control Panel dialog box appears.

3. If you want to rename the module, click the DT9816 module that

you want to rename, and then click Edit Name.

3

3

3

4. Enter a new name for the module, and then click OK. The name

is used to identify the module in all subsequent applications.

5. When you are finished configuring the module, click Close.

6. Repeat steps 3 to 5 for the other modules that you want to

configure.

7. Close the Data Acquisition Control Panel dialog box.

Continue with the instructions on wiring in Chapter 4 starting on

page 33.

3

3

3

3

3

3

31

Page 32

Chapter 3

32

Page 33

4

Wiring Signals to the Module

Preparing to Wire Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting Single-Ended Analog Input Signals . . . . . . . . . . . . . 37

Connecting Digital I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connecting Counter/Timer Signals . . . . . . . . . . . . . . . . . . . . . . . 39

33

Page 34

Chapter 4

Prepare to Use a Module

(see Chapter 2 starting on page 21)

Set Up and Install the Module

(see Chapter 3 starting on page 25)

Wire Signals to the Module

(this chapter)

Verify the Operation of the Module

(see Chapter 5 starting on page 43)

34

Page 35

Preparing to Wire Signals

CAUTION:

Wiring Signals to the Module

4

To avoid electrostatic sensitivity, unplug your DT9816 module from

the computer before wiring signals.

This section provides recommendations and information about

wiring signals to a DT9816 module.

Wiring Recommendations

Keep the following recommendations in mind when wiring signals to

a DT9816 module:

• Use individually shielded twisted-pair wire (size 16 to 26 AWG)

in highly noisy electrical environments.

• Separate power and signal lines by using physically different

wiring paths or conduits.

• To avoid noise, do not locate the box and cabling next to sources

that produce high electromagnetic fields, such as large electric

motors, power lines, solenoids, and electric arcs, unless the

signals are enclosed in a mumetal shield.

• Prevent electrostatic discharge to the I/O while the box is

operational.

4

4

4

4

4

4

• Connect all unused analog input channels to analog ground.

Wiring Locations

You wire signals to the DT9816 module using the screw terminals on

the module. Tabl e 2 lists the screw terminal assignments.

4

4

35

Page 36

Chapter 4

Table 2: DT9816 Screw Terminal Assignments

Terminal Signal Terminal Signal

20 USB +5 V Out 40 Ext Trigger

19 Ground 39 Ext Clock

18 Counter 0 In 38 Ground

17 Counter 0 Out 37 Digital Output 7

16 Counter 0 Gate 36 Digital Output 6

15 Ground 35 Digital Output 5

14 Reserved 34 Digital Output 4

13 Reserved 33 Digital Output 3

12 Reserved 32 Digital Output 2

11 Reserved 31 Digital Output 1

10 2.5 V Reference 30 Digital Output 0

36

9 Analog Ground 29 Ground

8 Reserved 28 Digital Input 7

7 Reserved 27 Digital Input 6

6 Analog Input CH5 26 Digital Input 5

5 Analog Input CH4 25 Digital Input 4

4 Analog Input CH3 24 Digital Input 3

3 Analog Input CH2 23 Digital Input 2

2 Analog Input CH1 22 Digital Input 1

1 Analog Input CH0 21 Digital Input 0

Page 37

Wiring Signals to the Module

Connecting Single-Ended Analog Input Signals

The DT9816 supports 6 single-ended analog input channels. Figure 4

shows how to connect single-ended voltage input signals (channels 0

and 1, in this case) to the screw terminals of a DT9816 module.

4

4

Analog Ground

-

source 1

V

-

Vsource 0

Signal Source

Figure 4: Connecting Single-Ended Inputs

+

+

Analog In 1

Analog In 0

9

2

1

DT9816 Module

4

4

4

4

4

4

4

37

Page 38

Chapter 4

Connecting Digital I/O Signals

Figure 5 shows how to connect digital input signals (lines 0 and 1, in

this case) to the screw terminals of a DT9816 module.

29

22

21

DT9816 Module

Ground

Digital Input 1

Digital Input 0

TTL Inputs

Figure 5: Connecting Digital Inputs

Figure 6 shows how to connect digital output signals (line 0, in this

case) to the screw terminals of a DT9816 module.

38

30

DT9816 Module

Ground

8 Out = LED On

Digital Output 0

500 Ω

+

5 V

-

38

Figure 6: Connecting Digital Outputs

Page 39

Wiring Signals to the Module

Connecting Counter/Timer Signals

The DT9816 module provides one counter/timer that you can use for

the following operations:

• Event counting

• Frequency measurement

• Continuous pulse output (rate generation)

4

4

This section describes how to connect counter/timer signals for these

operation modes. Refer to Chapter 6 for more information about

using the counter/timers.

Connecting Signals for Event Counting

Figure 7 shows how to connect counter/timer signals to the screw

terminals on the DT9816 module to perform an event counting

operation using an external gate.

In this example, the counter counts the number of rising edges that

occur on the Counter 0 In signal when the Counter 0 Gate signal is in

the active state (as specified by software). Refer to Chapter 6 for more

information.

4

4

4

4

4

4

4

39

Page 40

Chapter 4

Signal

Source

Ground

19

Counter 0 In

External

Gating

Switch

Counter

0 Gate

Ground

18

16

DT9816 Module

Figure 7: Connecting Counter/Timer Signals for an Event Counting

Operation Using an External Gate

Figure 8 shows how to connect counter/timer signals to the screw

terminals on the DT9816 module to perform an event counting

operation without using a gate (also called a software gate). The

counter counts the number of rising edges that occur on the Counter

0 In signal.

Ground

Signal

Source

19

40

Counter 0 In

18

DT9816 Module

Figure 8: Connecting Counter/Timer Signals for an Event Counting

Operation Without Using a Gate

Page 41

Wiring Signals to the Module

Connecting Signals for Frequency Measurement

Signal

Source

One way to measure frequency is to use the same wiring as a

standard event counting application that does not use a gate (see

Figure 8), and then use software (if using the SDK, call the

olDaMeasureFrequency function) to determine the duration over

which to count the number of pulses connected to the Counter 0 In

signal. The frequency of the Counter 0 In signal is the number of

counts divided by the duration of the olDaMeasureFrequency

function.

If you need more accuracy than the olDaMeasureFrequency function

provides, you can connect a pulse of a known duration to the Counter

0 Gate signal, as shown in Figure 9. In this case, the frequency of the

Counter 0 In signal is the number of counts divided by the period of

the signal connected to the Counter 0 Gate input.

Ground

Counter 0 In

(Number of pulses counted

during gate period)

Counter 0 Gate

Known Signal

Source

(Determines period

for count)

19

18

16

DT9816 Module

4

4

4

4

4

4

4

Figure 9: Connecting Counter/Timer Signals for a Frequency Measurement

Operation Using an External Pulse

4

4

41

Page 42

Chapter 4

Connecting Signals for Rate Generation

Figure 10 shows how to connect counter/timer signals to the screw

terminals of a DT9816 module to perform a rate generation

(continuous pulse output) operation.

Ground

Heater

Controller

19

Counter 0 Out

17

DT9816 Module

Figure 10: Connecting Counter/Timer Signals for a Rate Generation

Operation

42

Page 43

5

Verifying the Operation

of a Module

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using the Oscilloscope Function . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Using the Chart Recorder Function. . . . . . . . . . . . . . . . . . . . . . . . 48

Using the Voltmeter Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Using the File Viewer Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using the Digital Input Function . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using the Digital Output Function . . . . . . . . . . . . . . . . . . . . . . . . 52

Using the Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Using the Rate Generator Function . . . . . . . . . . . . . . . . . . . . . . . . 54

43

Page 44

Chapter 5

Prepare to Use a Module

(see Chapter 2 starting on page 21)

Set Up and Install the Module

(see Chapter 3 starting on page 25)

Wire Signals to the Module

(see Chapter 4 starting on page 33)

Verify the Operation of the Module

(this chapter)

44

Page 45

Overview

The GO! application allows you to measure and control signals from

your DT9816 module right out of the box. Simply install the

ECONseries software, connect your module to the PC, connect your

signals to the module, and run the GO! application from the Data

Translation, Inc|ECONseries program group.

The GO! application provides the following instrument-like functions

for data acquisition, control, and display (the software shows only

those functions that are supported by your module):

• Oscilloscope

Verifying the Operation of a Module

5

5

5

− Stream, plot, and analyze data from up to six analog input

channels

− Zoom in or out of live signals

− Select the trigger type, level, and channel

− Print your data or save it to an Excel file

• Chart Recorder

− Record up to 31,990 data points from up to six analog input

channels

− Log data to an Excel file

• Voltmeter

− Measure data from up to six analog input channels and view

it in a 5-digit digital display

− Display the maximum or true root mean square (RMS) value

• File Viewer

− Load a previously saved Excel file

− Scroll, zoom, or print your data

• Digital Input − Monitor the status of the digital inputs using

LEDs

5

5

5

5

5

5

45

Page 46

Chapter 5

• Digital Output − Control the state of the digital outputs using

switches

• Counter − Count pulses from the counter/timer for 1, 2, or 5

seconds or for an unlimited time

• Rate Generator − Control the frequency of a continuous pulse

output signal from the counter/timer

The GO! application automatically detects and configures the first

installed ECONseries module. If you have multiple ECONseries

modules installed, you can select the module to use.

Notes: If no module is connected, a message box is displayed. If you

want to continue with the GO! application, plug a DT9816 module

into any USB port of your PC, and then click Rescan. Otherwise,

click Quit to exit from the GO! application.

If you have multiple DT9816 modules, you can run multiple

instances of the GO! application, if you wish. Each instance of the

application detects the available (not already in use) modules for

your convenience.

46

Press F1 at any time to get help on any of the functions of the GO!

application.

Page 47

Verifying the Operation of a Module

Using the Oscilloscope Function

The verify the analog input operation of your DT9816 module using

the Oscilloscope function of the GO! application, do the following:

1. Connect a known voltage source, such as the output of a function

generator, to analog input channel 0 on the DT9816 module

(single-ended mode). Refer to page 37 for an example of how to

connect a single-ended analog input.

5

5

2. Under Visible Channels on the Oscilloscope tab, ensure that only

channel 0 is selected.

The analog input data from channel 0 is continuously displayed.

3. Zoom in on your data by using your left mouse button to create a

zoom rectangle around the region that you are interested in.

4. When you are finished, snap back to the standard voltage range

of the module by clicking the Unzoom button.

5

5

5

5

5

5

5

47

Page 48

Chapter 5

Using the Chart Recorder Function

To verify the analog input operation of your DT9816 module using

the Chart Recorder function of the GO! application, do the following:

1. Connect a known voltage source, such as the output of a function

generator, to analog input channel 0 on the DT9816 module

(single-ended mode). Refer to page 37 for an example of how to

connect a single-ended analog input.

2. Under Visible Channels on the Chart Recorder tab, ensure that

only channel 0 is selected.

3. Click Start Recording, and enter Te st for the filename.

The analog input data from channel 0 is displayed on the screen and

logged to the Test.xls file.

4. After a few seconds, click Stop Recording.

5. Launch Excel and open the file called Test.xls to review the data

you just recorded.

48

Page 49

Using the Voltmeter Function

To verify the analog input operation of your DT9816 module using

the Voltmeter function of the GO! application, do the following:

1. Connect a known voltage source, such as the output of a function

generator, to analog input channel 0 on the DT9816 module

(single-ended mode). Refer to page 37 for an example of how to

connect a single-ended analog input.

Verifying the Operation of a Module

5

5

2. Under Visible Channels on the Voltmeter tab, ensure that only

channel 0 is selected.

3. Click Normal under Display Settings.

The analog input data from analog input channel 0 is converted into

digital format and displayed.

Note that the 5-digit display is refreshed twice per second.

5

5

5

5

5

5

5

49

Page 50

Chapter 5

Using the File Viewer Tab

To verify the analog input operation of your DT9816 module using

the File Viewer function of the GO! application, do the following:

1. Connect a known voltage source, such as the output of a function

generator, to analog input channel 0 on the DT9816 module

(single-ended mode). Refer to page 37 for an example of how to

connect a single-ended analog input.

2. Under Visible Channels on the Chart Recorder tab, ensure that

only channel 0 is selected.

3. Click Start Recording, and enter Te st for the filename.

The analog input data from channel 0 is displayed on the screen and

logged to the Test.xls file.

4. After a few seconds, click Stop Recording.

5. Click on the File Viewer tab, and click Open File.

6. Click on the filename Te s t .x l s .

7. Click Open.

50

8. Scroll through the data in the file using the slider at the bottom of

the File Viewer screen.

Page 51

Verifying the Operation of a Module

Using the Digital Input Function

To verify the digital input operation of your DT9816 module using

the Digital Input function of the GO! application, do the following:

1. Connect a digital input signal to a digital input line on the

module. Refer to page 38 for an example of how to connect a

digital input.

2. Read the status of the LEDs.

If digital input line 0 is high, the LED for line 0 turns green (on). If

digital input line 0 is low, the LED for line 0 turns gray (off).

The DT9816 module supports 8 digital input lines; the GO!

application supports all 8 lines.

5

5

5

5

5

5

5

5

5

51

Page 52

Chapter 5

Using the Digital Output Function

To verify the digital output operation of your DT9816 module using

the Digital Output function of the GO! application, do the following:

1. Connect a device to a digital output line on the module. Refer to

page 38 for an example of how to connect a digital output.

2. Click the switches to change the state of your device.

3. Check that the device has been changed as expected.

For example, if you connect a simple set of LEDs, the LED

corresponding to a line you switch on with the Digital Output function

should turn green (on).

The DT9816 module supports 8 digital output lines; the GO!

application supports all 8 lines.

52

Page 53

Using the Counter Function

To verify the event counting operation of your module using the

Counter function of the GO! application, do the following:

1. Wire an external clock source to the Counter 0 In signal on your

DT9816 module. (Refer to page 41 for an example of how to

connect an external clock to the counter/timer channel.)

2. Click 2 Seconds, and click Start Counting.

The number of counts is displayed on the screen.

When 2 seconds have elapsed, the operation stops automatically.

Verifying the Operation of a Module

5

5

5

5

5

5

5

5

5

53

Page 54

Chapter 5

Using the Rate Generator Function

To verify the rate generation operation of your module using the Rate

Generator function of the GO! application, do the following:

1. Connect a scope or similar device that accepts a pulse output

signal to the Counter 0 Out signal of your DT9816 module. (Refer

to page 42 for an example of how to connect signals for rate

generation.)

2. Use the slider to change the frequency of the continuous pulse

output signal.

If you are using a scope, you can see the frequency of the pulse output

signal change as you move the slider.

54

Page 55

Part 2: Using Your Module

Page 56

Page 57

6

Principles of Operation

Analog Input Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Digital I/O Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Counter/Timer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

57

Page 58

Chapter 6

Figure 11 shows a block diagram of the DT9816 module.

Reference

A/D Ch5

A/D Ch4

A/D Ch3

A/D Ch2

A/D Ch1

A/D Ch0

External

Clock

External

Trigger

ESD Buffered to 4000 V

A/D Clock

A/D Trigger

+2.5 V

16

16

16

16

16

16

From USB

Por t

Powe r

Supply

16-Bit

Counter/Timer

Digital

Out

Digital

In

ESD Buffered to 4000 V

+5 V

C/T Out 0

C/T Gate 0

C/T In 0

DOUT 7

DOUT 0

DIN 7

DIN 0

58

USB 2.0 Port

Input FIFO

Figure 11: Block Diagram of the DT9816 Module

Page 59

Analog Input Features

This section describes the following features of analog input (A/D)

operations on the DT9816 module:

• Input resolution, described below

• Analog input channels, described below

• Input ranges and gains, described on page 60

Principles of Operation

6

6

• Input sample clock sources, described on page 61

• Analog input conversion modes, described on page 61

• Input triggers, described on page 63

• Data format and transfer, described on page 63

• Error conditions, described on page 64

Input Resolution

The resolution of the A/D subsystem on the DT9816 module is

16-bits. This resolution is fixed; it cannot be programmed in software.

Analog Input Channels

The DT9816 provides six single-ended simultaneous analog input

channels. You can acquire data from a single analog input channel or

from a group of analog input channels on the module.

Note: To maintain simultaneous operation, all analog input

connections must have the same lead lengths.

6

6

6

6

6

6

The following subsections describe how to specify the channels.

6

59

Page 60

Chapter 6

Specifying a Single Analog Input Channel

The simplest way to acquire data from a single analog input channel

is to specify the channel for a single-value analog input operation

using software; refer to page 61 for more information about

single-value operations.

You can also specify a single channel using the analog input

channel-gain list, described in the next section.

Specifying One or More Analog Input Channels

You can read data from one or more analog input channels using an

analog input channel-gain list. Group the channels in the list

sequentially (starting either with 0 or with any other analog input

channel) in ascending order. You cannot specify the same channel

more than once in the list.

Using software, specify the channels you want to sample. You can

enter up to 6 entries in the channel-gain list for this module. Refer to

page 61 for more information about the supported conversion modes.

60

Input Ranges and Gains

The DT9816 provides an input range of -10 to +10 V or -5 to +5 V. Use

software to specify the range as -10 to +10 V with a gain of 1, or -5 to

+5 V with a gain of 2.

Note: This is the range for the entire analog input subsystem, not

the range per channel.

Page 61

Input Sample Clock Sources

Principles of Operation

You can pace an analog input operation on a DT9816 module using a

software clock source. Using software, specify the clock source as

internal, then specify the clock frequency at which to pace the

operation. The DT9816-A supports an A/D clock frequency of 60 Hz

to 150 MHz; the DT9816 supports an A/D clock frequency of 60 Hz to

50 MHz.

According to sampling theory (Nyquist Theorem), specify a

frequency that is at least twice as fast as the input’s highest frequency

component. For example, to accurately sample a 2 kHz signal, specify

a sampling frequency of at least 4 kHz. Doing so avoids an error

condition called aliasing, in which high frequency input components

erroneously appear as lower frequencies after sampling.

Analog Input Conversion Modes

The DT9816 supports the following conversion modes:

• Single-value operations

• Continuous scan operations

The following subsections describes the conversion modes in more

detail.

6

6

6

6

6

6

Single-Value Operations

Single-value operations are the simplest to use. Using software, you

specify the range, gain, and analog input channel. The module

acquires the data from the specified channel and returns the data

immediately. For a single-value operation, you cannot specify a clock

source, trigger source, scan mode, or buffer.

Single-value operations stop automatically when finished; you

cannot stop a single-value operation.

6

6

6

61

Page 62

Chapter 6

Continuous Scan Mode

Use continuous scan mode if you want to accurately control the

period between successive simultaneous conversions of all channels

in a channel-gain list.

When it receives a software trigger, the module cycles through the

channel-gain list, acquiring and converting the data for each entry in

the list (this process is defined as the scan). The module then wraps to

the start of the channel-gain list and repeats the process continuously

until either the allocated buffers are filled or until you stop the

operation. Refer to page 63 for more information about buffers.

The conversion rate is determined by the frequency of the internal

sample clock; refer to page 61 for more information about the internal

sample clock. The sample rate, which is the rate at which a single

entry in the channel-gain list is sampled, is the same as the

conversion rate due to the simultaneous nature of the module.

To select continuous scan mode, use software to specify the data flow

as continuous.

62

Figure 12 illustrates continuous scan mode using a channel-gain list

with three entries: channel 0, channel 1, and channel 2. In this

example, analog input data is acquired simultaneously on all

channels on each clock pulse of the input sample clock. Data is

acquired continuously.

Page 63

Principles of Operation

Chan 0

Chan 1

Chan 2

Internal

Sample

Clock

Software trigger occurs

Figure 12: Continuous Scan Mode

Input Triggers

The DT9816 supports a software trigger or an external TTL trigger for

starting an analog input operation. When the computer issues a write

to the DT9816 module, data acquisition begins. Acquisition stops

when the specified number of samples has been acquired (if the

buffer wrap mode is none, described on page 64), or when you stop

the operation. Note that when you stop the operation, the module

completes the reading of the channel-gain list.

Chan 0

Chan 1

Chan 2

Chan 0

Chan 1

Chan 2

Data is acquired continuously

Chan 0

Chan 1

Chan 2

Chan 0

Chan 1

Chan 2

Chan 0

Chan 1

Chan 2

Chan 0

Chan 1

Chan 2

6

6

6

6

6

6

Using software, specify the trigger source as a software trigger or an

external trigger. The external trigger is initiated by a high to low

transition on the A/D external TTL trigger input.

Data Format and Transfer

DT9816 modules use binary data encoding, where 0000 represents

negative full-scale, and FFFFh represents positive full-scale. Use

software to specify the data encoding as binary. The ADC outputs

FFFFh for above-range signals, and 0000 for below-range signals.

6

6

6

63

Page 64

Chapter 6

Before you begin acquiring data, you must allocate buffers to hold

the data. A Buffer Done message is returned whenever a buffer is

filled. This allows you to move and/or process the data as needed.

We recommend that you allocate a minimum of three buffers for

analog input operations, specifying one of the following buffer wrap

modes in software:

• None − Data is written to multiple allocated input buffers

continuously; when no more empty buffers are available, the

operation stops. If wrap mode is none, the module guarantees

gap-free data.

• Multiple − Data is written to multiple allocated input buffers

continuously; if no more empty buffers are available, the module

overwrites the data in the current buffer, starting with the first

location in the buffer. This process continues indefinitely until

you stop it. If wrap mode is multiple, the module does not

guarantee gap-free data.

Error Conditions

64

An overrun condition is reported if the A/D sample clock rate is too

fast. This error is reported if a new A/D sample clock pulse occurs

while the ADC is busy performing a conversion from the previous

A/D sample clock pulse. The host computer can clear this error. To

avoid this error, use a slower sampling rate or increase the buffer size

and/or number of buffers.

Page 65

Digital I/O Features

This section describes the following features of digital I/O operations

on the DT9816:

• Digital I/O lines

•Resolution

•Operation modes

Principles of Operation

6

6

Digital I/O Lines

The DT9816 module includes 8 digital input and 8 digital output

lines.

Using DT-Open Layers, you can specify the digital I/O line that you

want to read or write in a single-value digital I/O operation. Refer to

page 66 for more information about single-value operations.

A digital line is high if its value is 1; a digital line is low if its value is

0. On power up or reset, a low value (0) is output from each of the

digital output lines.

Note: You can also read or write to the digital I/O lines using

functions that access the hardware registers on the module directly.

Refer to Appendix C starting on page 121 for more information on

these functions.

Resolution

6

6

6

6

6

6

The DT9816 provides 16 digital lines that are dedicated, 8 each, to the

DIN and DOUT subsystems. By default, these lines are organized as

two 8-bit ports. Because these are dedicated lines, you cannot

combine the digital ports into one port to change resolution.

6

65

Page 66

Chapter 6

Operation Modes

The DT9816 supports single-value digital I/O operations only. For a

single-value operation, use software to specify the digital I/O port

(the gain is ignored). The DT9816 then reads data from or writes data

to the digital lines associated with that port (determined by the

resolution setting).

Single-value operations stop automatically when finished; you

cannot stop a single-value operation.

66

Page 67

Counter/Timer Features

This section describes the following features of counter/timer (C/T)

operations on the DT9816 module:

• C/T channel, described below

• C/T clock sources, described on page 68

• Gate types, described on page 68

Principles of Operation

6

6

• Pulse types and duty cycles, described on page 69

• C/T operation modes, described on page 69

C/T Channel

The DT9816 module provides one 16-bit counter/timer. The counter

accepts a clock input signal and gate input signal and outputs a pulse

(pulse output signal), as shown in Figure 13.

Clock Input Signal

(internal or external)

Counter

Gate Input Signal

(software or external input)

Figure 13: Counter/Timer Channel

6

6

6

Pulse Output Signal

6

6

6

6

67

Page 68

Chapter 6

C/T Clock Sources

The following clock sources are available for the counter/timer:

• Internal clock – Through software, specify the clock source as

internal, and specify the frequency at which to pace the

counter/timer operation. The frequency of the internal C/T clock

can range from 60 Hz to 6 MHz.

• External clock – An external clock is useful when you want to

pace counter/timer operations at rates not available with the

internal clock or if you want to pace at uneven intervals.

Connect an external clock with a maximum recommended

frequency of 6 MHz to the Counter 0 In signal on the DT9816

module. Using software, specify the C/T clock source as external,

and specify a clock divider between 2 and 65534 to determine the

actual frequency at which to pace the counter/timer operation.

For example, if you connect a 6 MHz external C/T clock and use

a clock divider of 2, the resulting C/T output frequency is 3 MHz.

Counter/timer operations start on the falling edge of the Counter

0 In signal.

68

Gate Types

The edge or level of the Counter 0 Gate signal determines when a

counter/timer operation is enabled. Using software, you can specify

one of the following gate types:

• None − A software command enables any counter/timer

operation immediately after execution.

• Logic-high level external gate input − Enables a counter/timer

operation when Counter 0 Gate is high, and disables a

counter/timer operation when Counter 0 Gate is low. Note that

this gate type is used for event counting and rate generation

modes; refer to page 69 for more information about these modes.

Page 69

Pulse Duty Cycles

Principles of Operation

Counter/timer output signals from the DT9816 module are

high-to-low going signals. The low portion of the total pulse output

period is the active portion of the counter/timer clock output signal.

The duty cycle (or pulse width) indicates the percentage of the total

pulse output period that is active. In rate generation mode, the duty

cycle is fixed at 50% for the DT9816 module. Figure 14 illustrates a

high-to-low going output pulse with a duty cycle of 50%.

Total Pulse Period

high pulse

low pulse

Active Pulse Width

Figure 14: Example of a Pulse Output SIgnal with a 50% Duty Cycle

(High-to-Low Going)

6

6

6

6

6

6

Counter/Timer Operation Modes

The DT9816 module supports the following counter/timer operation

modes:

• Event counting

• Frequency measurement

• Rate generation

6

6

6

69

Page 70

Chapter 6

Event Counting

Use event counting mode if you want to count the number of falling

edges that occur on Counter 0 In when the gate is active (high-level).

Refer to page 68 for information about specifying the active gate type.

You can count a maximum of 65,536 events before the counter rolls

over to 0 and starts counting again.

For event counting operations, use software to specify the

counter/timer mode as count, the C/T clock source as external, and

the active gate type as high-level.

Make sure that the signals are wired appropriately. Refer to

Chapter 4 for an example of connecting an event counting

application.

Frequency Measurement

Using software, specify the counter/timer mode as count, the clock

source as external, and then call the olDaMeasureFrequency function.

70

Our function uses the Windows timer (which has a resolution of 1

ms) to specify the duration. If you need more accuracy than the

Windows timer provides, you can connect a pulse of a known

duration to the Counter 0 Gate signal.

If you are using a known pulse connected to the gate pin for the

duration, specify the active gate in software (high level). When the

operation starts, read the number of counts that occurred when the

gate was active.

You can determine the frequency of the clock input signal using the

following equation:

Frequency Measurement = Number of Events

Measurement Period

Page 71

Make sure that the signals are wired appropriately. Refer to

Chapter 4 for an example of connecting a frequency measurement

application.

Rate Generation

Use rate generation mode to generate a continuous pulse output

signal from Counter 0 Out; this mode is sometimes referred to as

continuous pulse output or pulse train output.

Principles of Operation

6

6

The pulse output operation is enabled whenever the Counter 0 Gate

signal is active (high level or software gate). While the pulse output

operation is enabled, the counter outputs a high-to-low going pulse

with a pulse width of 50% continuously. As soon as the operation is

disabled, rate generation stops.

The frequency of the output is determined by the C/T clock source

(either internal or external) and, for an external clock source, the clock

divider used. You can generate an output signal from Counter 0 Out

with a frequency of 60 Hz to 6 MHz.

To specify rate generation mode, use software to specify the

counter/timer mode as rate, the C/T clock source as either internal or

external, the clock divider (2 to 65534) if external, and the active gate

type (low-level, high-level, or software gate). Refer to page 68 for

more information about gate types.

Make sure that the signals are wired appropriately. Refer to

Chapter 4 for an example of connecting a rate generation application.

6

6

6

6

6

6

6

71

Page 72

Chapter 6

72

Page 73

7

Supported Device Driver

Capabilities

Data Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Buffering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DMA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Triggered Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Synchronous Digital I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Clocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Counter/Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

73

Page 74

Chapter 7

The DT9816 Device Driver provides support for the analog input

(A/D), digital input (DIN), digital output (DOUT), and

counter/timer (C/T) subsystems on the DT9816 module.

Table 3: DT9816 Series Subsystems

DT9816 A/D D/A DIN DOUT C/T

Total Subsystems on Module 1 0 1 1 1

The tables in this chapter summarize the features available for use

with the DataAcq SDK and the DT9816 module. The DataAcq SDK

provides functions that return support information for specified

subsystem capabilities at run-time.

The first row in each table lists the subsystem types. The first column

in each table lists all possible subsystem capabilities. A description of

each capability is followed by the parameter used to describe that

capability in the DataAcq SDK.

74

Note: Blank fields represent unsupported options.

The DataAcq SDK uses the functions olDaGetSSCaps (for those

queries starting with OLSSC) and olDaGetSSCapsEx (for those

queries starting with OLSSCE) to return the supported subsystem

capabilities for a device.

For more information, refer to the description of these functions in

the DataAcq SDK online help. See the DataAcq User’s Manual for

information on launching this help file.

Page 75

Supported Device Driver Capabilities

Data Flow

Table 4: DT9816 Data Flow Options

DT9816 A/D D/A DIN DOUT C/T

Single-Value Operation Support

OLSSC_SUP_SINGLEVALUE Yes Yes Yes No

Continuous Operation Support

OLSSC_SUP_CONTINUOUS Yes Yes

Continuous Operation until Trigger Event Support

OLSSC_SUP_CONTINUOUS_PRETRIG

Continuous Operation before & after Trigger Event

OLSSC_SUP_CONTINUOUS_ABOUTTRIG

DT-Connect Support

OLSSC_SUP_DTCONNECT

Continuous DT-Connect Support

OLSSC_SUP_DTCONNECT_CONTINUOUS

Burst DT-Connect Support

OLSSC_SUP_DTCONNECT_BURST

7

7

7

7

7

7

7

7

7

75

Page 76

Chapter 7

Buffering

Table 5: DT9816 Buffering Options

DT9816 A/D D/A DIN DOUT C/T

Buffer Support

OLSSC_SUP_BUFFERING Yes

Single Buffer Wrap Mode Support

OLSSC_SUP_WRPSINGLE Yes

Multiple Buffer Wrap Mode Support

OLSSC_SUP_WRPMULTIPLE Yes

Inprocess Buffer Flush Support

OLSSC_SUP_INPROCESSFLUSH Yes

Waveform Generation Mode Support

OLSSC_SUP_WAVEFORM_MODE

DMA

76

Table 6: DT9816 DMA Options

DT9816 A/D D/A DIN DOUT C/T

Number of DMA Channels

OLSSC_NUMDMACHANS 0 0 0 0

Supports Gap Free Data with No DMA

OLSSC_SUP_GAPFREE_NODMA Yes

Supports Gap Free Data with Single DMA

OLSSC_SUP_GAPFREE_SINGLEDMA

Supports Gap Free Data with Dual DMA

OLSSC_SUP_GAPFREE_DUALDMA

Page 77

Supported Device Driver Capabilities

Triggered Scan Mode

Table 7: DT9816 Triggered Scan Mode Options

DT9816 A/D D/A DIN DOUT C/T

Triggered Scan Support

OLSSC_SUP_TRIGSCAN

Maximum Number of CGL Scans per Trigger

OLSSC_MAXMULTISCAN 0 0 0 0

Supports Scan per Trigger Event Triggered Scan

OLSSC_SUP_RETRIGGER_SCAN_PER_

TRIGGER

Supports Internal Retriggered Triggered Scan

OLSSC_SUP_RETRIGGER_INTERNAL

Extra Retrigger Support

OLSSC_SUP_RETRIGGER_EXTRA

Maximum Retrigger Frequency

OLSSCE_MAXRETRIGGER 0 0 0 0

Minimum Retrigger Frequency

OLSSCE_MINRETRIGGER 0 0 0 0

7

7

7

7

7

7

7

7

7

77

Page 78

Chapter 7

Gain

Table 8: DT9816 Gain Options

DT9816

Maximum Channel-Gain List Depth

OLSSC_CGLDEPTH 6

Sequential Channel-Gain List Support

OLSSC_SUP_SEQUENTIAL_CGL Yes

Zero Start Sequential Channel-Gain List Support

OLSSC_SUP_ZEROSEQUENTIAL_CGL Yes

Random Channel-Gain List Support

OLSSC_SUP_RANDOM_CGL Yes

Simultaneous Sample-and-Hold Support

OLSSC_SUP_SIMULTANEOUS_SH Yes

Channel List Inhibit Support

OLSSC_SUP_CHANNELLIST_INHIBIT

Programmable Gain Support

OLSSC_SUP_PROGRAMGAIN Yes

Number of Gains

OLSSC_NUMGAINS 2 1 1 0

Noncontiguous Channels in Channel-Gain List

OLSSC_NONCONTIGUOUS_CHANNELNUM 16 0 0 0

AutoRanging Support

OLSSC_SUP_SINGLEVALUE_AUTORANGE

A/D D/A DIN DOUT C/T

a

b

0 0 0

78

a. You cannot specify the same channel more than once in the list.

b. Place channels in your CGL in ascending order. All channels are sampled simultaneously

with data returned in ascending channel order; if your CGL does not match, you will have

unexpected results.

Page 79

Synchronous Digital I/O

Table 9: DT9816 Synchronous Digital I/O Options

Supported Device Driver Capabilities

7

DT9816

Synchronous Digital I/O Support

OLSSC_SUP_SYNCHRONOUS_DIGITALIO

Maximum Synchronous Digital I/O Value

OLSSC_MAX_DIGITALIOLIST_VALUE 1 0 0 0

A/D D/A DIN DOUT C/T

Channels

Table 10: DT9816 Channel Options

DT9816

Number of Channels

OLSSC_NUMCHANNELS 6

SE Support

OLSSC_SUP_SINGLEENDED Yes

SE Channels

OLSSC_MAXSECHANS 6 0 0 0

DI Support

OLSSC_SUP_DIFFERENTIAL Yes Yes Yes

DI Channels

OLSSC_MAXDICHANS 0 1 1 1

DT2896 Channel Expansion Support

OLSSC_SUP_EXP2896

DT727 Channel Expansion

OLSSC_SUP_EXP727

A/D D/A DIN DOUT C/T

a

1 1 1

7

7

7

7

7

7

7

a. The DT9816 provides analog input channels 0 to 5.

7

79

Page 80

Chapter 7

Filters

Table 11: DT9816 Filter Options

DT9816 A/D D/A DIN DOUT C/T

Filter/Channel Support

OLSSC_SUP_FILTERPERCHAN

Number of Filters

OLSSC_NUMFILTERS 1 1 1 0

Ranges

Table 12: DT9816 Range Options

DT9816 A/D D/A DIN DOUT C/T

80

Number of Voltage Ranges

OLSSC_NUMRANGES 1

Range per Channel Support

OLSSC_SUP_RANGEPERCHANNEL Yes

a. The input range for the module is -10 to +10 V.

a

000