Page 1

Intelligent Data Logging Products

DT80 Range

DT80/81/82/85

Series 1,2,3 & 4

Includes CEM20

User's Manual

A complete guide to:

• data acquisition

• data logging

• programming

• sensor wiring

• communications

Page 2

DT80 Range User’s Manual

Domain

Applicable Standards

IC

CFR47 FCC Part 15, Subpart B (Class A)

China RoHs 2 – models without WiFi / Modem

Refer to China RoHs table below

© Copyright 2005-2017 Thermo Fisher Scientific Australia Pty Ltd ABN 52 058 390 917

UM-0085-B10

Warranty

Thermo Fisher Scientific Australia Pty Ltd (“Thermo Fisher”) warrants the instruments it manufactures against defects in

either the materials or the workmanship for a period of three years from the date of delivery to the original customer.

This warranty is limited to, and purchaser’s sole remedy for a breach of this warranty is, the replacement or repair of

such defects, without charge, when the instrument is returned to Thermo Fisher or to one of its authorized dealers

pursuant to Thermo Fisher’s return policy procedures.

The obligations set forth above shall be void with respect to any damage to the instrument resulting from accident,

abuse, improper implementation or use, lack of reasonable care, loss of parts, force majeure, or any other third party

cause beyond Thermo Fisher’s control. Any installation, maintenance, repair, service, or alteration to or of, or other

tampering with, the instruments performed by any person or entity other than Thermo Fisher without its prior written

approval, or any use of replacement parts not supplied by Thermo Fisher, shall immediately void and cancel all

warranties with respect to the affected instruments.

Thermo Fisher shall not be liable for any incidental, indirect, special, punitive or consequential loss or damages resulting

from or arising out of the use of the instrument, In no event shall Thermo Fisher’s liability with respect to the instrument,

the use thereof, this warranty statement or any cause of action related thereto, under any circumstances exceed the

purchase price of the instrument actually paid by purchaser.

Where Thermo Fisher supplies to the customer equipment or items manufactured by a third party, then the warranty

provided by the third party manufacturer shall pass through to purchaser, but only to the extent allowed by the original

manufacturer or third party supplier.

EXCEPT AS EXPRESSLY PROVIDED IN THIS WARRANTY STATEMENT, THERMO FISHER DISCLAIMS ALL

OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED, ORAL OR WRITTEN, WITH RESPECT TO THE

INSTRUMENTS, INCLUDING WITHOUT LIMITATION ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE. THERMO FISHER DOES NOT WARRANT THAT THE INSTRUMENTS

ARE ERROR-FREE OR WILL ACCOMPLISH ANY PARTICULAR RESULT. ANY ADVICE OR ASSISTANCE

FURNISHED BY THERMO FISHER IN RELATION TO THE INSTRUMENTS SHALL NOT GIVE RISE TO ANY

WARRANTY OR GUARANTEE OF ANY KIND, AND SHALL NOT CONSTITUTE A WAIVER BY THERMO FISHER.

The Purchaser shall be solely responsible for complying with all applicable local, state and Federal laws with respect to

the installation, use and implementation of the equipment.

Trademarks

dataTaker is a registered trademark of Thermo Fisher Scientific Australia Pty Ltd

Adobe® Flash ® Player. Copyright © 1996 – 2006 Adobe Systems Incorporated. All Rights Reserved. Protected by U.S.

Patent 6,879,327; Patents Pending in the United States and other countries. Adobe and Flash are either trademarks or

registered trademarks in the United States and/or other countries.

All other brand and product names are trademarks or registered trademarks of their respective holders.

Regulatory Notices

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Please refer to the following table and information for compliance requirements of the DT80 Series, CEM20 and internal

devices.

Safety (Product with Integrated Modem)

EMC

EN 60950.1:2006 +Amdt 11(2009), A1(2010), A12(2011) & A2(2013)

AS/NZS 60950.1:2011 +Amdt 1(2012)

EN 55022:2010 + AC:2011

EN 55024:2010

EN 61000-3-2: Ed. 4.0 (2014)

EN 61000-3-3: Ed. 3.0 (2013)

ETSI EN 301 489-1 V1.9.2 (2011-09)

FCC CFR47 FCC Part 15, Subpart B (Class A)

UM-0085-B09 DT80 Range User Manual Page 2

RG

Page 3

FCC / IC Statements

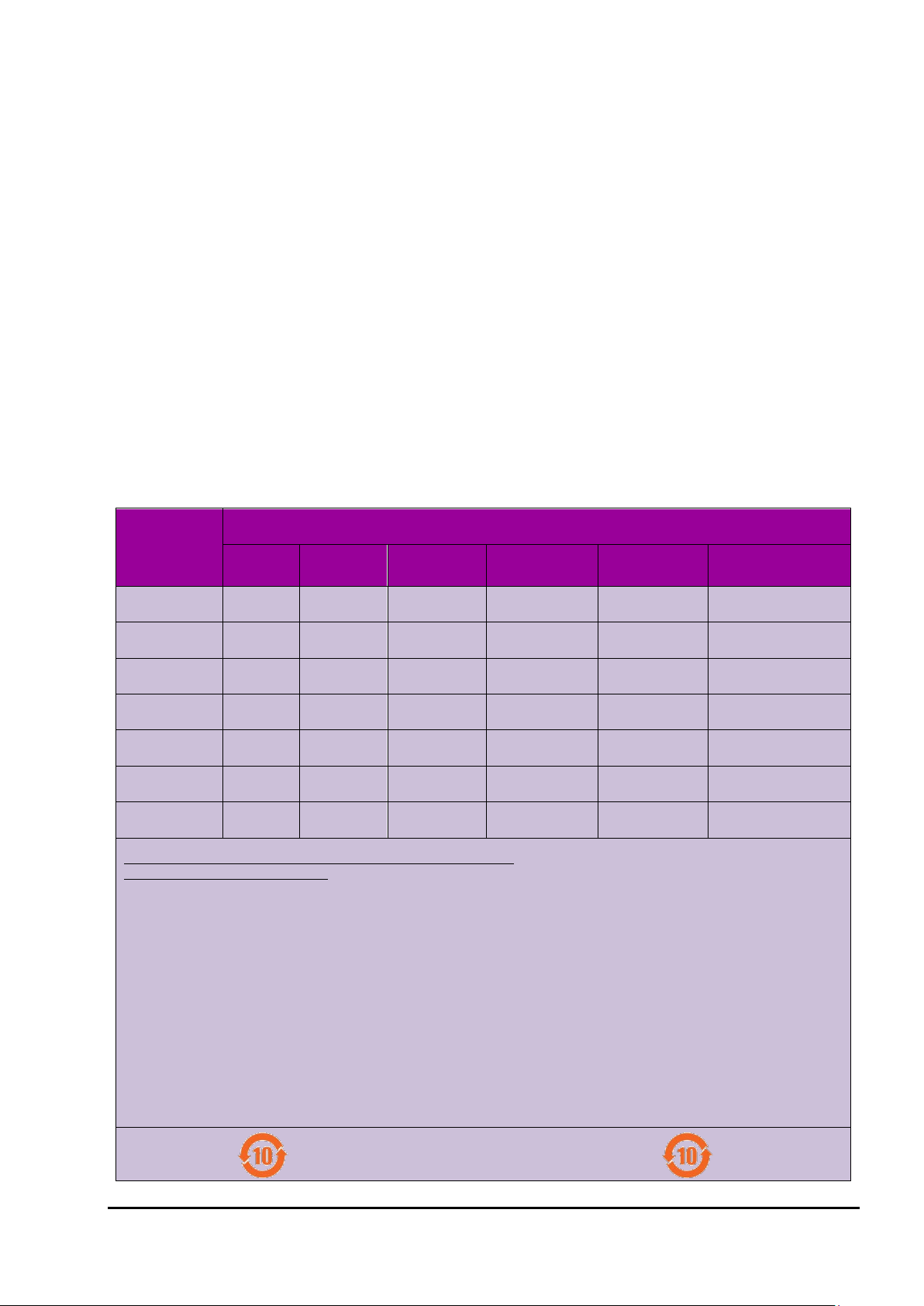

零件或部件名称

有害物质或元素

铅

汞

镉

Hexavalent

六价铬

Polybrominated

多溴联苯

Polybrominated

多溴二苯醚

0.1

0.01)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority

to operate the equipment.

Cet équipement a été testé et reconnu co nforme aux limites d'un appareil numérique de classe A, conformément à la

partie 15 des règles de la FCC. Ces limit es sont conçues pour fournir une prot ec tion raisonnable contre les interférences

nuisibles lorsque l'équipemen t est utilisé dans un environnement c ommercial. Cet équipement génère, utilise et peut

émettre de l'énergie radiofréquenc e et, s'il n'est pas installé et utilisé conformément au manuel d'instr uctions, peut

causer des interférences nuisibles aux communications radio. Le fonctionnement de cet équipement dans une zone

résidentielle est susceptible de causer des interférences nuisibles , auquel cas l'utilisateur devr a c orriger l'interférence à

ses propres frais.

Les changements ou modifications non expressément approuvés par la par tie responsable de la conformité pourraient

annuler l'autorisation de l'utilisateur d'utiliser l'équipement.

Dependent on model the product may contain

• Modem (DT80LM3, DT82EM3, DT85M3, DT85GLM3) – FCC ID: RI7HE910 / IC ID: 5131A-HE910

• WiFi Module (DT80W, DT80GW, DT85W, DT85GW) – FCC ID: XF6-RS9113SB / IC ID: 8407A-RS9113SB

China RoHs

Part or

Component

Name

Resistors

电阻

Standoffs

支座

Connectors

连接器

Fasteners

紧固件

Potentiometers

电位器

Memory Stick

记忆棒

Integrated Circuits

集成电路

Lead (Pb)

X O O O O O

X O O O O O

X O O O O O

X O O O O O

X O O O O O

X O O O O O

X O O O O O

Mercury (Hg)

Cadmium (Cd)

Hazardous Substances

Chromium (Cr(VI))

Biphenyls (PBB)

Diphenyl Ethers (PBDE)

This table is prepared in accordance with the provisions of SJ/T 11364.

本表格依据SJ/T 11364 的规定编制。

O : Indicates that the concentration of the hazardous substance in all homogeneous materials of the part is below the relevant

threshold of the GB/T 26572 standard.

O : 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X : Indicates that the concentration of the hazardous substance in at least one homogeneous material of the part is above the

relevant threshold of the GB/T 26572 standard.

X : 表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

Marking Standard SJ/T 11364 requires this chart format for listed parts or components that exceed a maximum concentrated limit.

As a service to our customers, we are using the chart format to provide information regarding these part or components.

标识标准SJ / T 11364要求此图表格式列出超过最大浓度限制的零件或组件。作为对我们客户的服务,我们使用此图表格式提供有关

这些零件或组件的信息。

(Concentration limits are 0.1% for Lead, Mercury, Hexavalent Chromium, Polybrominated Biphenyls, Polybrominated Diphenyl

Ethers (excluding decaBDE), and 0.01% for Cadmium)

(铅,汞,六价铬,多溴联苯,多溴二苯醚(不包含十溴二苯醚)的浓度限制为

%,以及镉为

Environment Friendly Use Period (EFUP)

环保使用期限(EFUP)

UM-0085-B09 DT80 Range User Manual Page 3

RG

Page 4

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority

to operate the equipment.

Disposal of Product and Batteries

This product is subject to the EU Directive 2012/19/EU for Waste Electrical and Electronic Equipment

(WEEE). As such product must not be disposed of in general waste facilities. Please refer to local

regulations or contact your distributor on he to dispose this product in an environmentally friendly

manner.

Dispose of used batteries via an appropriate recycling facility only.

Warning

dataTaker products are not authorized for use as critical components in any life support system where failure of the

product is likely to affect the system’s safety or effectiveness.

Important: Firmware Version Covered in This Manual

This version of the dataTaker DT80 Range User’s Manual (UM-0085-B10) applies to the DT80 range of data loggers

(DT80, DT80G, DT80L, DT80LM3, DT80GL, DT80W, DT82E, DT82EM3, DT82I, DT85, DT85G, DT85L, DT85LM3,

DT85GL, DT85W, DT85GW, and DT85GLM3, Series 1, 2, 3 and 4) running Version 9.20 firmware.

UM-0085-B09 DT80 Range User Manual Page 4

RG

Page 5

Content

Content ...................................................................................................................... 5

Part A – The DT80 ...................................................................................... 14

DT80 Concepts ........................................................................................................ 14

What is the DT80? ...................................................................................................................................... 14

The DT80 Product Family ........................................................................................................................... 14

DT80-Friendly Software .............................................................................................................................. 18

About This Manual ...................................................................................................................................... 18

A Tour of the DT80's Interfaces .................................................................................................................. 18

Getting Started ............................................................................................................................................ 19

Sending Commands.................................................................................................................................... 20

Getting Help ................................................................................................................................................ 21

Designing Your Data Logging System ........................................................................................................ 21

Measurements ......................................................................................................... 22

What can the DT80 Measure? .................................................................................................................... 22

Analog Channels – Introduction .................................................................................................................. 22

Digital Channels – Introduction ................................................................................................................... 25

Serial Channels – Introduction .................................................................................................................... 25

Programming the DT80 ........................................................................................... 26

Typical Workflow ......................................................................................................................................... 26

USB memory devices .................................................................................................................................. 28

Format of Returned Data ........................................................................................ 30

Real-time data ............................................................................................................................................. 30

Logged Data ............................................................................................................................................... 31

Part B – Channels ...................................................................................... 33

Channel Definitions ................................................................................................ 33

Channel Numbers ................................................................................................... 33

Channel Number Sequence ........................................................................................................................ 34

Channel Types ......................................................................................................... 34

Internal Channel Types ............................................................................................................................... 37

Channel Options ..................................................................................................... 41

Overview ..................................................................................................................................................... 41

A Special Channel Option — Channel Factor ............................................................................................. 42

Multiple Reports .......................................................................................................................................... 42

Mutually Exclusive Options ......................................................................................................................... 42

Order of Application .................................................................................................................................... 43

Default Channel Options ............................................................................................................................. 43

Channel Option Table ................................................................................................................................. 44

Part C – Schedules .................................................................................... 48

Schedule Concepts ................................................................................................. 48

What are Schedules? .................................................................................................................................. 48

Schedule Syntax ......................................................................................................................................... 48

Types of Schedules ................................................................................................ 51

UM-0085-B09 DT80 Range User Manual Page 5

RG

Page 6

General-Purpose Report Schedules ........................................................................................................... 51

Immediate Report Schedules ...................................................................................................................... 56

Statistical Report Schedules ....................................................................................................................... 57

Working with Schedules ......................................................................................... 58

Entering Schedules into the DT80 (BEGIN–END) ...................................................................................... 58

Triggering and Schedule Order ................................................................................................................... 58

Changing a Schedule Trigger ..................................................................................................................... 59

Halting & Resuming Schedules ................................................................................................................... 59

Executing Commands in Schedules ........................................................................................................... 59

Time Triggers — Synchronizing to Midnight ............................................................................................... 60

Part D – Jobs .............................................................................................. 61

What is a Job? ............................................................................................................................................ 61

Entering a Job ............................................................................................................................................. 61

Loading an Existing Job .............................................................................................................................. 62

Job Structure ............................................................................................................................................... 62

Job Commands ........................................................................................................................................... 63

Startup Job .................................................................................................................................................. 64

ONINSERT Job ........................................................................................................................................... 64

Part E – Manipulating Data ....................................................................... 65

Scaling ..................................................................................................................... 65

Channel Factor ........................................................................................................................................... 65

Spans (Sn) .................................................................................................................................................. 65

Polynomials (Yn) ......................................................................................................................................... 66

Thermistor Scaling (Tn) ............................................................................................................................... 66

Intrinsic Functions (Fn) ................................................................................................................................ 67

Combining Scaling Options ......................................................................................................................... 67

Calculations ............................................................................................................. 67

Channel Variables (nCV) ............................................................................................................................ 67

Calculation Only Channels .......................................................................................................................... 69

Reference Channels ................................................................................................................................... 69

Expressions ................................................................................................................................................ 70

Running Average ........................................................................................................................................ 74

Derived Quantities .................................................................................................. 75

Rates and Integrals ..................................................................................................................................... 75

Edge Timing ................................................................................................................................................ 75

Statistical Channel Options .................................................................................... 76

Overview ..................................................................................................................................................... 76

Statistical Functions .................................................................................................................................... 77

Multi Value Statistical Options ............................................................................... 78

Histogram (Hx:y:m..nCV) ............................................................................................................................ 78

Rainflow Cycle Counting ............................................................................................................................. 79

Part F – Alarms .......................................................................................... 82

Alarm Concepts ....................................................................................................... 82

Alarm Commands ................................................................................................... 82

Alarm Number ............................................................................................................................................. 83

Alarm Condition .......................................................................................................................................... 83

Alarm Digital Action Channels ..................................................................................................................... 85

Alarm Action Text ........................................................................................................................................ 85

Alarm Communication Actions .................................................................................................................... 87

UM-0085-B09 DT80 Range User Manual Page 6

RG

Page 7

Alarm Action Processes .............................................................................................................................. 88

Alarm Records ......................................................................................................... 92

Real Time Alarm Return .............................................................................................................................. 92

Logging Alarms ........................................................................................................................................... 92

Polling Alarm Inputs ............................................................................................... 93

Part G – Logging and Retrieving Data ..................................................... 94

Logging Data ........................................................................................................... 94

Enabling and Disabling Data Logging ......................................................................................................... 94

How Data and Alarms are Stored ............................................................................................................... 94

Logging Options .......................................................................................................................................... 96

Factors Which May Prevent Logging .......................................................................................................... 96

Checking Logging Status ............................................................................................................................ 97

Retrieving Logged Data .......................................................................................... 98

Overview ..................................................................................................................................................... 98

LISTD – List Available Data ........................................................................................................................ 98

COPYD – Unload Data ............................................................................................................................. 101

DELD - Delete Logged Data ..................................................................................................................... 111

Background Commands ............................................................................................................................ 112

Obsolete Commands ................................................................................................................................ 113

The DT80 File System ........................................................................................... 114

Internal File System (B:) ............................................................................................................................ 114

External USB Devices (A:) ........................................................................................................................ 114

File Commands ......................................................................................................................................... 116

Data Recovery .......................................................................................................................................... 116

Part H – DT80 Front Panel ...................................................................... 118

Display ................................................................................................................... 118

Displaying Channels and Alarms .............................................................................................................. 118

Bar Graph ................................................................................................................................................. 119

Controlling what is shown on the display .................................................................................................. 119

Auto-scrolling ............................................................................................................................................ 120

Auto-acknowledge .................................................................................................................................... 120

Pop-up Messages ..................................................................................................................................... 120

Interactive Screens ................................................................................................................................... 120

Display Backlight ....................................................................................................................................... 120

User Defined Functions ........................................................................................ 121

Defining Functions .................................................................................................................................... 121

Selecting Functions ................................................................................................................................... 121

Default Functions ...................................................................................................................................... 121

Keypad operation .................................................................................................. 122

Special Key Sequences ............................................................................................................................ 122

Status Indicator Lights ......................................................................................... 122

Sample Indicator ....................................................................................................................................... 122

Disk Indicator ............................................................................................................................................ 122

Power Indicator ......................................................................................................................................... 122

Attn Indicator ............................................................................................................................................. 122

Part I – dEX ............................................................................................. 124

What is dEX? ............................................................................................................................................ 124

dEX vs. Classic Web Interface .................................................................................................................. 124

UM-0085-B09 DT80 Range User Manual Page 7

RG

Page 8

Connecting to the Web Interface ............................................................................................................... 124

dEX Home Page ....................................................................................................................................... 124

Starting dEX .............................................................................................................................................. 125

Browser Requirements .............................................................................................................................. 126

Back to the Main Menu (Home) ................................................................................................................ 126

dEX Configuration Builder ................................................................................... 126

Configure the logger ................................................................................................................................. 126

About Configurations................................................................................................................................. 126

Using the Configuration Builder ................................................................................................................ 126

Defining Schedules ................................................................................................................................... 128

Defining Channels ..................................................................................................................................... 130

Global Settings .......................................................................................................................................... 136

Managing Configurations .......................................................................................................................... 143

Logger Controls ........................................................................................................................................ 144

Preventing Configuration Changes ........................................................................................................... 144

dEX Web Interface ................................................................................................. 145

Using the Web Interface ............................................................................................................................ 145

Status Screens .......................................................................................................................................... 146

Data Retrieval ........................................................................................................................................... 148

Displaying Real-Time Measurements ....................................................................................................... 150

Command Window .................................................................................................................................... 157

Help ........................................................................................................................................................... 159

Customising the Web Interface ............................................................................ 160

Overview ................................................................................................................................................... 160

The Web Interface Configuration Tool ...................................................................................................... 160

Preventing Configuration Changes ........................................................................................................... 163

Enabling dEX User Level Authentication................................................................................................... 163

dEX Languages ........................................................................................................................................ 166

Classic Web Interface ........................................................................................... 167

Browser Requirements .............................................................................................................................. 167

Navigating the Web Interface .................................................................................................................... 167

Home Page ............................................................................................................................................... 167

Channels Page ......................................................................................................................................... 168

Status Page .............................................................................................................................................. 168

Files Page ................................................................................................................................................. 169

Help Page ................................................................................................................................................. 169

Customising the Classic Interface ....................................................................... 170

Web Application Programming Interface (API) .......................................................................................... 170

Server-Side Include (SSI) Directives ......................................................................................................... 170

Building A Custom Web Page ................................................................................................................... 173

Part J – Modbus Interface ...................................................................... 175

About Modbus ........................................................................................................................................... 175

Connecting to a Modbus Network ............................................................................................................. 175

Modbus Registers ..................................................................................................................................... 176

Putting It All Together ................................................................................................................................ 179

Part K – Communications ....................................................................... 182

Overview ................................................................................................................ 182

Services .................................................................................................................................................... 182

Protocols ................................................................................................................................................... 182

Physical Ports ........................................................................................................................................... 183

About the Communications Diagram ........................................................................................................ 183

UM-0085-B09 DT80 Range User Manual Page 8

RG

Page 9

The Command Interface ....................................................................................... 186

Connecting to the Command Interface...................................................................................................... 186

Command Interface Operation .................................................................................................................. 186

Detecting DT80 Presence ......................................................................................................................... 186

Password Protection ................................................................................................................................. 186

USB Port ................................................................................................................ 187

Configuring the USB Port .......................................................................................................................... 187

About DtUsb .............................................................................................................................................. 187

Installing DtUsb ......................................................................................................................................... 188

Using DtUsb .............................................................................................................................................. 191

USB Direct Serial Mode ............................................................................................................................ 192

Sleep Mode ............................................................................................................................................... 193

RS-232 Communications ...................................................................................... 193

Direct RS-232 Connection ........................................................................................................................ 193

RS-232 Flow Control ................................................................................................................................. 193

Sleep Mode ............................................................................................................................................... 194

Host RS-232 Port ................................................................................................... 195

Configuring the Host RS-232 Port ............................................................................................................. 195

Serial Sensor Port ................................................................................................. 196

Connecting to the Serial Sensor Port ........................................................................................................ 197

Configuring the Serial Sensor Port ............................................................................................................ 198

External Modem .................................................................................................... 200

Modem (Remote) RS 232 Connection ...................................................................................................... 200

Automatic Modem Detection ..................................................................................................................... 200

DT80-to-Modem Cable .............................................................................................................................. 200

Modem Initialisation .................................................................................................................................. 201

Powering the DT80’s Modem .................................................................................................................... 203

Modem Communications Operation .......................................................................................................... 203

Setting Up a Remote Connection .............................................................................................................. 204

Part L – Network Communications ........................................................ 205

TCP/IP Concepts ................................................................................................... 205

About TCP/IP ............................................................................................................................................ 205

About This Section .................................................................................................................................... 205

TCP/IP Parameters ................................................................................................................................... 206

Integrated Modem ................................................................................................. 207

Mobile Plans ............................................................................................................................................. 208

Getting Started .......................................................................................................................................... 210

Configuring the Integrated Modem ............................................................................................................ 211

Verifying Modem Operation ...................................................................................................................... 215

Troubleshooting and Advanced Configuration .......................................................................................... 217

Communications Sessions .................................................................................. 222

Session Timing ......................................................................................................................................... 222

Error handling ........................................................................................................................................... 224

Session Diagnostics .................................................................................................................................. 227

Ethernet Sessions ..................................................................................................................................... 229

Ethernet Communications.................................................................................... 231

Connecting to the DT80 Ethernet Port ...................................................................................................... 231

Ethernet Commands ................................................................................................................................. 233

How to set up Ethernet .............................................................................................................................. 235

Accessing the DT80 via the Internet ......................................................................................................... 238

WiFi Communications .......................................................................................... 240

UM-0085-B09 DT80 Range User Manual Page 9

RG

Page 10

WiFi Interface ............................................................................................................................................ 240

WiFi Commands ....................................................................................................................................... 240

Setting up WiFi Connection ....................................................................................................................... 244

PPP Communications ........................................................................................... 246

About PPP ................................................................................................................................................ 246

Setting up PPP .......................................................................................................................................... 246

Using PPP ................................................................................................................................................. 253

Network Services .................................................................................................. 254

Using the Network Command Interface .................................................................................................... 254

Using the DT80 FTP Server ...................................................................................................................... 255

Security .................................................................................................................. 257

Basic Security ........................................................................................................................................... 257

dEX Security ............................................................................................................................................. 258

Part M – Configuration ............................................................................ 260

Configuring the DT80 ............................................................................................ 260

Parameters ............................................................................................................................................... 260

Switches .................................................................................................................................................... 262

Profile Settings .......................................................................................................................................... 264

Command Server Timeout Profile ............................................................................................................. 269

Setting the System Time ........................................................................................................................... 269

Automatic Time Adjustment (NTP) ............................................................................................................ 270

Resetting the DT80 ................................................................................................ 273

Soft Reset ................................................................................................................................................. 273

Hard Reset ................................................................................................................................................ 273

Safe Mode ................................................................................................................................................. 274

Factory Settings ........................................................................................................................................ 274

Diagnostic Commands ......................................................................................... 275

TEST Command ....................................................................................................................................... 275

Event Logs ................................................................................................................................................ 276

STATUS Command .................................................................................................................................. 276

CHARAC Command ................................................................................................................................. 277

SERVICEDATA Command ....................................................................................................................... 277

Part N – Hardware & Power .................................................................... 278

Inputs and Outputs ............................................................................................... 278

Wiring Panel .............................................................................................................................................. 278

Left Side Panel .......................................................................................................................................... 279

Right Side Panel (DT8xM only) ................................................................................................................. 280

Right Side Panel (DT8xW only) ................................................................................................................ 280

Front Panel ............................................................................................................................................... 281

Rear Panel (DT8xG only) .......................................................................................................................... 281

Inside the DT80 ...................................................................................................... 282

Accessing the main battery (if fitted) ......................................................................................................... 282

Accessing the lithium memory backup battery .......................................................................................... 283

Installation ............................................................................................................. 285

Dimensions ............................................................................................................................................... 285

Operating Environment ............................................................................................................................. 285

Grounding ................................................................................................................................................. 286

Powering the DT80 ................................................................................................ 286

Power Subsystem ..................................................................................................................................... 286

UM-0085-B09 DT80 Range User Manual Page 10

RG

Page 11

External Power .......................................................................................................................................... 287

Internal Power ........................................................................................................................................... 288

Power Outputs .......................................................................................................................................... 290

Signal Output ............................................................................................................................................ 291

Internal Memory-Backup Battery ............................................................................................................... 291

Monitoring DT80 Power ............................................................................................................................ 292

Power Consumption ............................................................................................. 292

Power Consumption .................................................................................................................................. 292

Battery Life ................................................................................................................................................ 297

Minimising Power Consumption ................................................................................................................ 298

Sleep Mode ............................................................................................................ 300

About Sleep Mode .................................................................................................................................... 300

Wake Events ............................................................................................................................................. 300

Controlling Sleep ....................................................................................................................................... 300

Forced Sleep Mode ................................................................................................................................... 301

Part O – Sensors & Channels ................................................................. 302

Analog Channels ................................................................................................... 302

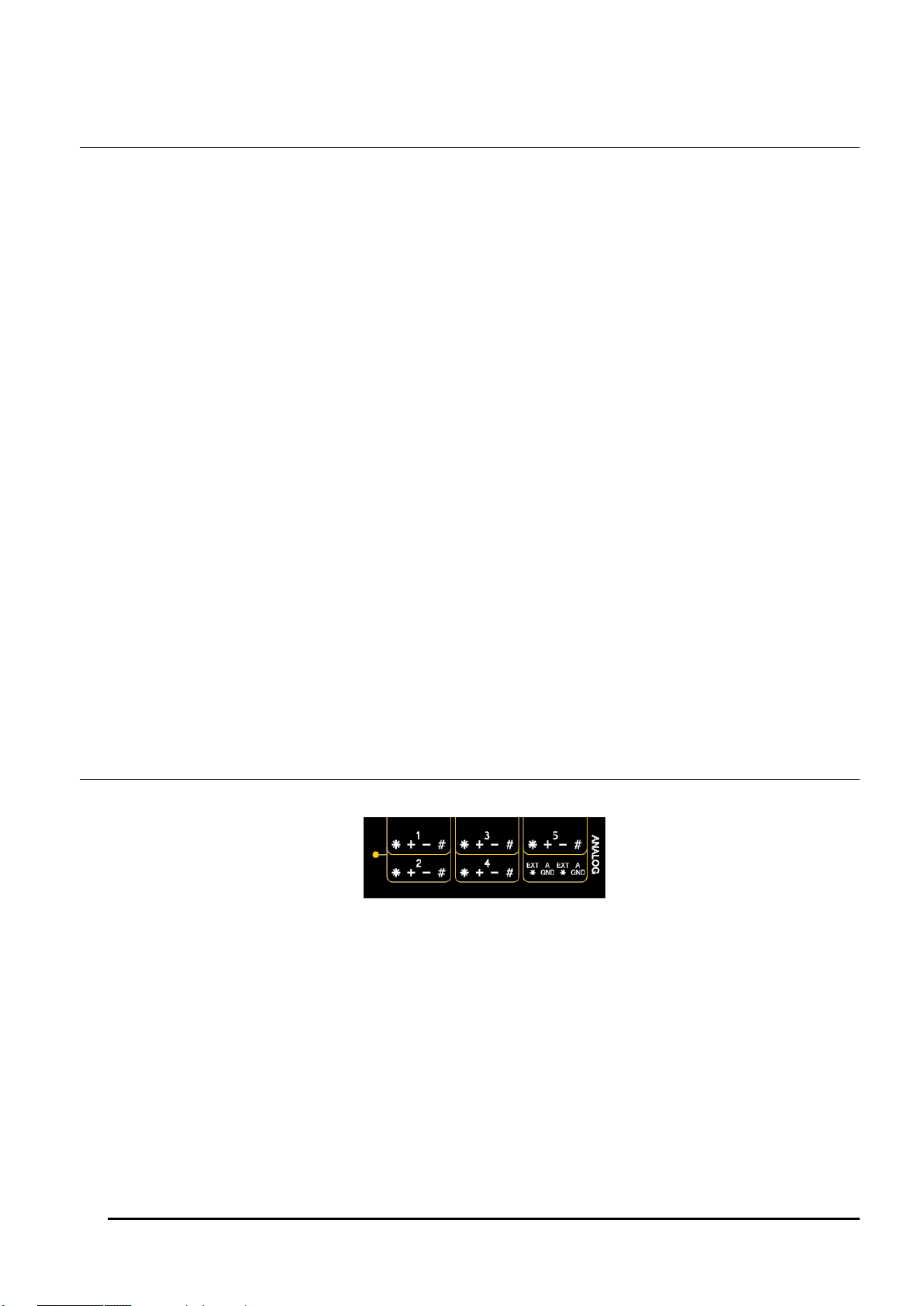

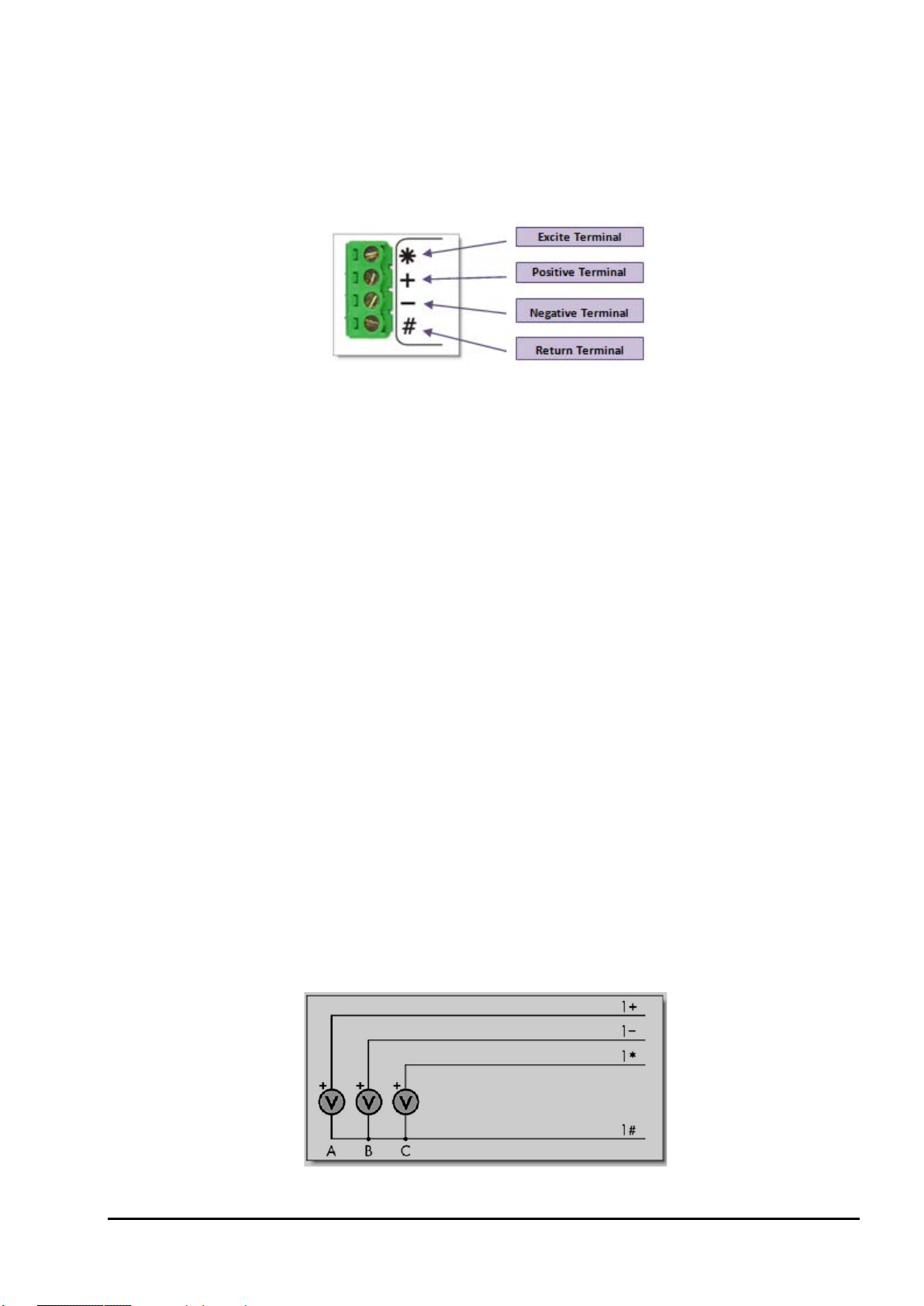

About the Analog Input Terminals ............................................................................................................. 302

Voltage ...................................................................................................................................................... 303

Current ...................................................................................................................................................... 306

4–20mA Current Loops ............................................................................................................................. 308

Resistance ................................................................................................................................................ 308

Bridges ...................................................................................................................................................... 311

Temperature – Thermocouples ................................................................................................................. 315

Temperature – Thermistors ....................................................................................................................... 317

Temperature – RTDs ................................................................................................................................ 319

Temperature – AD590 Series IC Sensors ................................................................................................. 319

Temperature – LM35 Series IC Sensors ................................................................................................... 321

Temperature – LM135 Series IC Sensors ................................................................................................. 322

Humidity Sensors ...................................................................................................................................... 323

Frequency ................................................................................................................................................. 323

Strain Gauges – Bridge ............................................................................................................................. 324

Strain Gauges – Vibrating Wire ................................................................................................................. 325

Strain Gauges – Carlson Meter ................................................................................................................. 327

Digital Channels .................................................................................................... 331

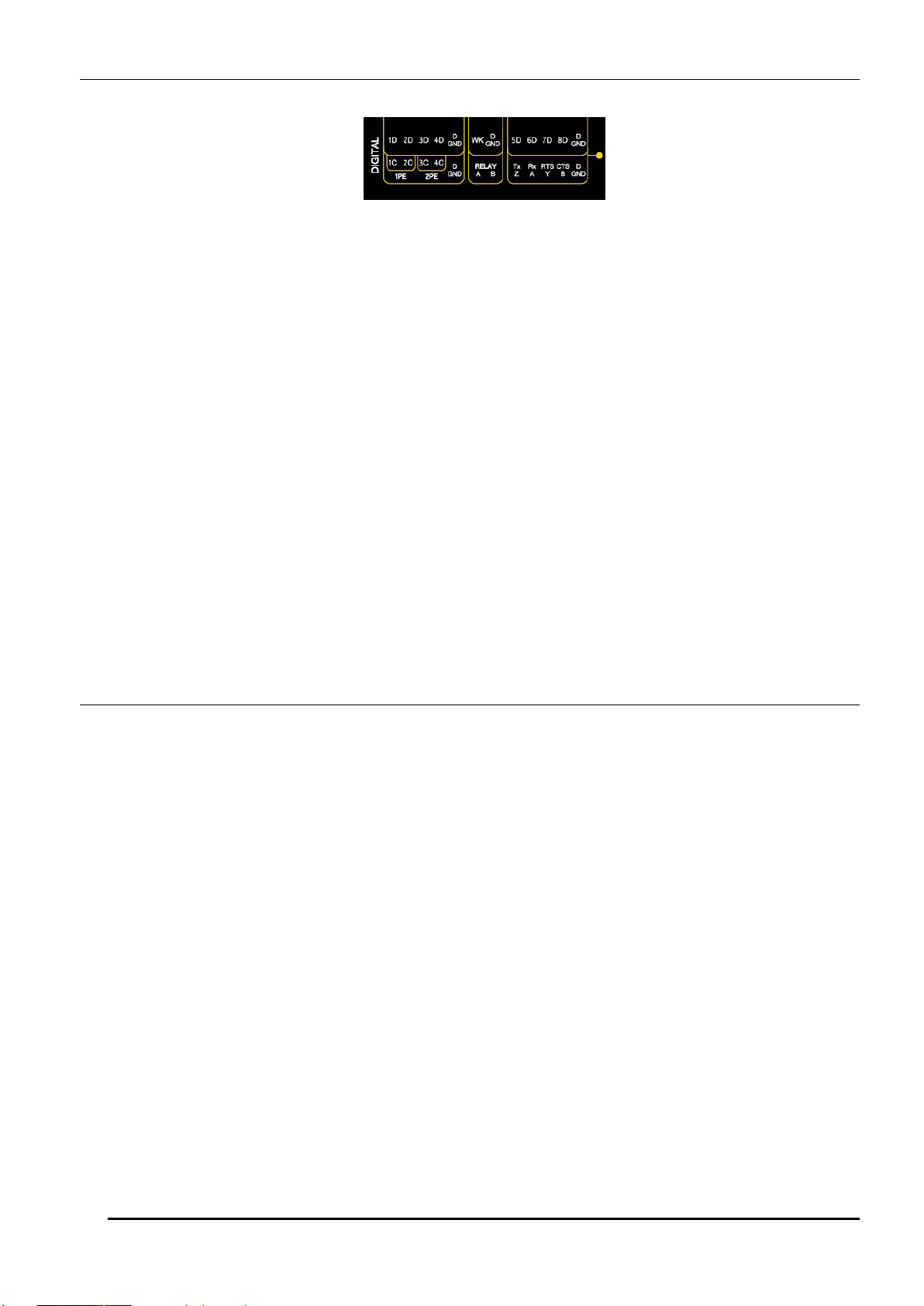

About the Digital I/O Channels .................................................................................................................. 331

Digital Inputs ............................................................................................................................................. 332

Digital Outputs .......................................................................................................................................... 333

Counters – Low Speed .............................................................................................................................. 337

Counters – High Speed ............................................................................................................................. 338

Phase Encoders ........................................................................................................................................ 340

Examples – Digital and Counters .............................................................................................................. 341

SDI-12 Channel ...................................................................................................... 342

About SDI-12 ............................................................................................................................................ 342

Testing and Configuring an SDI-12 Device ............................................................................................... 343

Reading Data from SDI-12 Devices .......................................................................................................... 343

Example .................................................................................................................................................... 345

Other Considerations ................................................................................................................................ 346

Troubleshooting ........................................................................................................................................ 346

Generic Serial Channel ......................................................................................... 348

Connecting to and Configuring the Serial Port .......................................................................................... 348

Serial Channel Commands ....................................................................................................................... 348

Serial Channel Operation .......................................................................................................................... 349

UM-0085-B09 DT80 Range User Manual Page 11

RG

Page 12

Control String – Output Actions ................................................................................................................. 351

Control String – Input Actions ................................................................................................................... 353

Control String – Example .......................................................................................................................... 355

Schedules ................................................................................................................................................. 355

Serial Sensor Direct Mode ........................................................................................................................ 356

Serial Interface Power Control .................................................................................................................. 357

Serial Channel Debugging Tools .............................................................................................................. 357

Serial Channel Examples .......................................................................................................................... 358

Modbus Channel ................................................................................................... 361

About Modbus ........................................................................................................................................... 361

Connecting Serial Modbus Sensors .......................................................................................................... 361

Connecting Network Modbus Sensors ...................................................................................................... 362

Reading Data from Modbus Devices ........................................................................................................ 363

MODBUS Channel Options ....................................................................................................................... 364

Block Transfers ......................................................................................................................................... 365

Examples .................................................................................................................................................. 366

Troubleshooting ........................................................................................................................................ 366

Technical Details & Troubleshooting .................................................................. 368

DT80 Analog Sub-System ......................................................................................................................... 368

Grounds, Ground Loops and Isolation ...................................................................................................... 372

Noise Pickup ............................................................................................................................................. 373

Self-Heating of Sensors ............................................................................................................................ 373

Getting Optimal Speed from Your DT80 ................................................................................................... 374

Part P – The CEM20 ................................................................................. 375

What is the CEM20? ................................................................................................................................. 375

Connecting CEM20s ................................................................................................................................. 375

CEM20 Addresses .................................................................................................................................... 377

Powering the CEM20 ................................................................................................................................ 377

Accessing CEM20 Channels ..................................................................................................................... 377

CEM20 Temperature Reference ............................................................................................................... 378

Troubleshooting ........................................................................................................................................ 378

Part Q – Reference ................................................................................... 379

DT80 Series Specifications .................................................................................. 379

Analog Inputs ............................................................................................................................................ 379

Digital Inputs and Outputs ......................................................................................................................... 380

High Speed Counter Inputs ....................................................................................................................... 381

Serial Channels ......................................................................................................................................... 381

Data Manipulation and Logging ................................................................................................................ 382

Communication Interfaces ........................................................................................................................ 382

Network (TCP/IP) Services ....................................................................................................................... 383

System ...................................................................................................................................................... 384

CEM20 Specifications ........................................................................................... 385

Command Summary ............................................................................................. 386

ASCII-Decimal Table ............................................................................................. 389

RS-232 .................................................................................................................... 392

Signals ...................................................................................................................................................... 392

Cables ....................................................................................................................................................... 392

Upgrading DT80 Firmware ................................................................................... 394

Recommended Preparation ...................................................................................................................... 394

Firmware Upgrade – USB Flash Device ................................................................................................... 395

UM-0085-B09 DT80 Range User Manual Page 12

RG

Page 13

Firmware Upgrade – Host USB or RS232 Port ......................................................................................... 395

Firmware Upgrade – Remote TCP/IP ....................................................................................................... 396

Reverting Back to Old Firmware ............................................................................................................... 396

In Case of Failed Upgrade ........................................................................................................................ 396

Upgrading Modem Firmware ..................................................................................................................... 396

Error Messages ..................................................................................................... 397

Standard Messages .................................................................................................................................. 397

Data Errors ................................................................................................................................................ 401

DT80 Abnormal Resets ............................................................................................................................. 402

Glossary ................................................................................................................. 403

Safety Information ................................................................................................. 414

General ..................................................................................................................................................... 414

Models with Internal Lead Acid Battery ..................................................................................................... 414

Models with Integrated Modem/ Integrated WiFi ....................................................................................... 414

Index ....................................................................................................................... 415

UM-0085-B09 DT80 Range User Manual Page 13

RG

Page 14

Part A – The DT80

Figure 1: The dataTaker DT80, DT80W (left); DT85W, DT85GM, CEM20 (centre), DT82EM, DT82I (right)

DT80 Concepts

What is the DT80?

The dataTaker DT80 range of data acquisition and logging instruments are tools to measure and record a wide variety of

quantities and values in the real world.

The web based dEX graphical user interface makes it quick and easy to define basic measurement tasks. Logged data

can then be easily extracted via a USB "memory stick", or downloaded using the web interface into files ready for import

into spreadsheets and data analysis tools.

The DT80 range of loggers also include a powerful programming language which allows complex systems to be

developed and monitored.

Extensive sensor support and communications options, and a rugged and low-power design, make the DT80 a very

flexible data logger.

The DT80 Product Family

Models

The DT80 product family includes the following models:

• The DT80 is a full-featured data logger,

• The DT82E is a low cost, low power logger designed for environmental applications.

UM-0085-B09 DT80 Range User Manual Page 14

RG

Page 15

• The DT82I is designed for industrial applications.

• The DT85 is an expanded and enhanced version of the DT80.

• The DT80L and DT85L are low power variants of the DT80 and DT85.

• The DT80W and DT85W are WiFi variant of the DT80 and DT85.

• The DT80G and DT85G GeoLoggers are designed for Geotechnical applications

• The DT80GW and DT85GW are WiFi variant of the DT80G and DT85G.

• The DT80GL and DT85GL are low power variants of the DT80G and DT85G.

• The DT82EM3, DT80LM3, DT85LM3 and DT85GLM3 contain an inbuilt GSM/EDGE/WCDMA cellular modem.

• The DT82EM2, DT80LM2, DT85LM2 and DT85GLM2 contain an inbuilt GSM/EDGE cellular modem.

• The CEM20 (Channel Expansion Module) is a 20-channel analog multiplexer which can be used to expand the

number of analog input channels on a DT80 or DT85.

All of these models operate in a similar way; the differences are mainly to do with the number of input channels and other

hardware features. Table 1 (P16) and Table 2 (P17) lists the main differences between each model.

Series 1, 2, 3 and 4

In January 2008, the original DT80, DT81 and DT85 models were superseded by enhanced Series 2 models. These

offered an all-new web based interface (dEX), additional power outputs, and more flexible analog input switching.

Series 3 models were introduced from October 2010. These supersede Series 2 and include enhanced resistance

measurement options and an isolated switched 5V power output.

Series 4 were launched from February 2017 and include increased voltage and resistance measurement ranges, flexible

12/ 5V power outputs and integrating with DAC converter to produce voltage/ current outputs as well as WiFi connectivity

support.

Along with DT80 Series 4 launch the new CEM20 Series 2 has also been released. In CEM20 Series 2 all mechanical

relays has been replaced by opto-relays . As result all audible noise from the mechanical relay switching was eliminated.

Series 2, 3 and 4 units are clearly labelled as such on the front panel.When a logger model number is displayed, the

series is shown as a suffix, e.g. "DT85L-3" is a Series 3 DT85L.

GeoLoggers

The DT80G/GL and DT85G/GL "GeoLoggers" are equivalent to the DT80 and DT85, but also include direct support for

vibrating wire strain gauges, which are widely used in geotechnical applications; see Strain Gauges – Vibrating Wire

(P325). Throughout this manual, references to the DT80 and DT85 also refer to the DT80G and DT85G respectively,

unless otherwise noted.

Low Power Models

Most DT80 models include an internal 6V lead acid battery. However the low power "L" and "E" models do not include

an internal battery and are instead optimised for operation with an external battery (often solar charged). Throughout this

manual, references to the DT80 and DT85 also refer to the DT80L and DT85L respectively, unless otherwise noted.

Modem Models

The "M" models (DT82EM, DT80LM, DT85LM, DT85GLM) include an integrated cellular modem, which provides a

convenient wireless solution for control of the DT80 and data retrieval. The "M3" models support 2G and 3G networks

(GSM/ GPRS/ EDGE/ WCDMA), while the "M2" models support 2G only (GSM/ GPRS/ EDGE). Apart from this

difference, the M2 and M3 variants operate identically.

WiFi Models

The "W" models (DT80W, DT80GW, DT85W, DT85GW) include an integrated WiFi interface, which provides a

convenient wireless solution for control of the DT80 and data retrieval. See WiFi Communications (P240).

Channel Expansion Module

The CEM20 is an analog multiplexer designed to work with a DT80 or DT85 Series 2 logger and later revisions. It

provides an easy way to expand the number of input channels. Up to 16 CEM20 modules can be connected to a DT85,

giving a total of 320 input channels. See The CEM20 (P375).

Note: In this manual, the term DT80 (italics) is used to refer to all products (DT80, DT81, DT82 and DT85; Series 1, 2, 3 and 4). If a

feature or behaviour is specific to a particular model, this will be made clear in the text.

UM-0085-B09 DT80 Range User Manual Page 15

RG

Page 16

Feature

discontinued models

current models

Analog input channels

1 5 16 1 2 2 5 5 16

16 2 2 2 2 5 5 5 5 5 5

16

16

16

16

16

16

16

16

Fully isolated analog input pairs (+- and *#

terminals switched independently)

2-wire resistance measurements on *#, +# and # terminal pairs

Vibrating wire strain gauge support

- - - - - - - - - - - - - - - - - - - -

CEM20 modules supported

- - - - - - 5 5 16

16 - - - - 5 5 5 5 5 5

16

16

16

16

16

16

16

16

Digital I/O channels (open-drain outputs)

3 4 4 3 3 4 4 4 4 4 3 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4

4

Digital I/O channels (logic outputs / SDI-12)

1 4 4 1 1 - 4 4 4 4 1 1 1 - 4 4 4 4 4 4 4 4 4 4 4 4 4 4 High speed counter inputs

4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 7 4 7 7 7 4 7

7

Phase encoder inputs

1 2 2 1 - 2 2 2 2 2 - - - 2 2 2 2 2 2 2 3 2 3 3 3 2 3

3

RS232/422/485 communications port

-

-

-

- - -

RS232 communications port

-

-

-

-

-

- -

-

USB communications port

-

-

- - -

-

Ethernet port

Integrated GSM/GPRS/EDGE/WCDMA modem

- - - - - - - - - - -

- - - - - - - - - - - -

-

Integrated GSM/GPRS/EDGE modem

- - - - - - - - - - -

- - - - -

- - - - -

-

-

-

USB memory device port

Switched 12V power output

-

-

Unswitched external power output

-

-

- - - - -

- - - - - - - - -

-