DATASONICS SIS-1500 System Manual

DATASONICS

SIS-1500

Seafloor Imaging System

System Manual

June 1998

Datasonics, Inc.

1400 Route 28A

Cataumet, MA 02534

U.S.A.

Tel: (01) 508-563-5511

Fax: (01) 508-563-9312

ii DATASONICS

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System iii

Notices

Proprietary Information

The information, descriptions, photos and illustrations in this manual are the

property of Datasonics, Inc. Materials may not be reproduced or

disseminated without the prior written consent of Datasonics.

Warranty

On standard catalog products, Seller warrants the products delivered under

this contract to be free from defects in material and workmanship at the time

of delivery to the F.O.B. point specified in the order, its liability under this

warranty being limited to repairing or replacing, at Seller’s option, items which

are returned to it FREIGHT PREPAID within one (1) year from delivery to the

Buyer and found to Seller’s satisfaction, to have been so defective. Items

shall be returned to the Buyer FREIGHT PREPAID.

On services, Seller warrants that all work performed by the employees will be

done in a workmanlike manner. Seller’s liability under this warranty is limited

to remedying at its expense any work found to Seller’s satisfaction not so

performed, provided however, Seller is notified of any claims within three (3)

months from the date the work is performed.

In no event shall Seller be liable for consequential damages. NO PRODUCT

IS WARRANTED AS BEING FIT FOR A PARTICULAR PURPOSE AND

THERE IS NO WARRANTY OF MERCHANTABILITY. This warranty applies

only if: (i) the items are used solely under the operating conditions and in the

manner recommended in Seller’s instruction manual, specifications, or other

literature; (ii) the items have not been missed or abused in any manner or

repairs attempted thereon; (iii) written notice of the failure within the warranty

period is forwarded to Seller and the directions for properly identifying items

returned under warranty are followed; and (iv) with return notice authorizing

Seller to examine and disassemble returned products to the extent Seller

deems necessary to ascertain the cause of failure. The warranties stated

herein are exclusive. THERE ARE NO OTHER WARRANTIES, EITHER

EXPRESSSED OR IMPLIED, BEYOND THOSE SET FORTH HEREIN, and

Seller does not assume any other obligation or liability in connection with the

sale or use of said products.

Any product or service repaired or replaced under this warranty shall be

warranted for the unexpired portion of the original warranty period only.

Notices

iv DATASONICS

Liability

Datasonics assumes no liability for damages, losses or costs incurred

consequentially through operation or malfunction of Datasonics products.

Title

Title shall pass to the Buyer on delivery to the carrier at Cataumet,

Massachusetts, U.S.A. Risk of damage or loss following such delivery shall

be the Buyer's, and Datasonics shall in no way be responsible for safe arrival

of the shipment. Title shall so pass to the Buyer regardless of any provision

for payment of freight or insurance by Datasonics, and regardless of the form

of the shipping documents. If shipment is consigned to Datasonics, it shall be

for the purpose of securing the Buyer's obligations under contract.

Changes

Datasonics reserves the right to make changes in design or specifications at

any time without incurring any obligation to modify previously installed units.

This manual is provided for informational and reference purpose only and is

subject to change without notice.

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System v

Preface

Congratulations on your purchase of the SIS-1500 Seafloor Imaging System!

The SIS-1500 delivers high resolution sidescan imagery using advanced

Chirp technology.

This manual is divided into six sections:

Section 1 - Overview describes the major system components and

explains Chirp sonar technology.

Section 2 - Specifications lists the specifications for the shipboard and

subsea components of the system.

Section 3 - Setup and Deployment covers the unpacking and setup of

the hardware, configuration of system parameters, and a system startup

procedure that includes predeployment checks and tow vehicle

deployment.

Section 4 - Theory of Operation describes the circuit functions and

signal flows for both the shipboard and subsea components of the

system.

Section 5 - Maintenance covers routine maintenance and includes

troubleshooting guides, recommended test equipment, test and

calibration procedures, and tables of downlink commands and uplink

data.

Section 6 - Drawings includes the circuit board assembly drawings and

the wiring diagrams for the shipboard and subsea hardware components

of the system.

Notes and Warnings

Where applicable, special notes and warnings are presented as follows:

NOTE A referral to another part of this manual or to another reference; a

recommendation to check that certain criteria are met before proceeding

further in a step or sequence; or general information applicable to the setup

and operation of the SIS-1500 Seafloor Imaging System.

Preface

vi DATASONICS

WARNING A reminder that dangerous or damaging consequences could

result if certain recommended procedures are not followed.

Comments

We welcome your comments and suggestions for improving our products and

documentation as well as developing better ways of serving you with acoustic

technology. Therefore, please contact Customer Service should you have

any comments or suggestions about this manual or the SIS-1500 Seafloor

Imaging System, or if you require service or support.

Please contact us at:

DATASONICS, INC.

Attention: Customer Service

1400 Route 28A

Cataumet, MA 02534

U.S.A.

Telephone: (01) 508-563-5511

FAX: (01) 508-563-9312

E-mail: sales@datasonics.com

http:\\www.datasonics.com

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System vii

Contents

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Proprietary Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Title . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Notes and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

SECTION 1

SIS-1500 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Main System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Advantages of Chirp Sonar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

SIP-150 Sonar Image Processor . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

SIP-150 Sonar Image Processor Workstation . . . . . . . . . . . . . . . . . .1-7

Chirpscan3 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Data Fusion and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Realtime Display and Image Processing . . . . . . . . . . . . . . . . . . . .1-8

Post-Processing of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Chirplink II Digital Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

TTV-195 Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Sidescan Sonar Transducer Arrays . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Sonar Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Optional Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Chirp Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Across-Track Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Along-Track Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Signal-to-Noise Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Chirp Pulse Transmission and Reception . . . . . . . . . . . . . . . . . . . .1-14

Contents

viii DATASONICS

SECTION 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SIP-150 Sonar Image Processor . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Downlink Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Downlink Responder Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Downlink Sonar Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Uplink Vehicle Status and Sensor Data . . . . . . . . . . . . . . . . . . . . . . 2-6

Uplink Sonar Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

TTV-195 Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Sidescan Sonar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

SECTION 3

Setup and Deployment . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Processor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Processor Hardware Connections . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Workstation Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Digital Multiplexer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Processor Operator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Workstation Operator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Digital Multiplexer Operator Functions . . . . . . . . . . . . . . . . . . . . . 3-11

Tow Vehicle Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Installing the Tail Fins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Connecting the Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Adjusting the Down-Look Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System ix

System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Starting Chirpscan3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Configuring the Navigation Parameter Settings . . . . . . . . . . . . .3-19

Configuring the Sonar Parameter Settings . . . . . . . . . . . . . . . . .3-20

Configuring the Display Parameter Settings . . . . . . . . . . . . . . .3-22

Saving Setup Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Loading Setup Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Activating the Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Predeployment Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Rub Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Chirp Pattern Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Data Telemetry and Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Launching the Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

SECTION 4

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Topside Processor Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Digital Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Subsea Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Sonar Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Transducer Arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Standard and Optional Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

SECTION 5

Maintenance and Troubleshooting . . . . . . . . . . . . . . . . 5-1

Processor Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Backups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Hard Disk Maintenance Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Tow Vehicle Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . .5-4

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Tow Vehicle Disassembly and Reassembly . . . . . . . . . . . . . . . . . . .5-5

Electronics Housing Disassembly . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Electronics Housing Reassembly . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Sonar Transducer Housing Disassembly . . . . . . . . . . . . . . . . . . .5-7

Sonar Transducer Housing Reassembly . . . . . . . . . . . . . . . . . . . .5-8

Contents

x DATASONICS

System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Troubleshooting Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Cable Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Arcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Short Circuit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Transducer Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Arcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Tap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Short Circuit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Transmit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Heading Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Downlink Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Range Command (TLF x) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Receiver Gain Command (G x y) . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Power ON/OFF Command (Pxy) . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Chirp Pattern Diagnostics Enable/Disable Command (D x) . . . 5-22

Trigger Mode Command (TRIGx) . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Uplink Vehicle Status and Sensor Data . . . . . . . . . . . . . . . . . . . . . 5-23

SECTION 6

Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Topside Processor Electronics Drawings . . . . . . . . . . . . . . . . . 6-3

Sonar Electronics Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System xi

List of Figures

Figure 1-1 SIP-150 Sonar Image Processor . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-2 TTV-195 Tow Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-3 TTV-195 Tow Vehicle Breaking Away from Obstruction . . 1-11

Figure 3-1 SIP-150 Sonar Image Processor Recommended Setup . . . 3-5

Figure 3-2 SIP-150 Sonar Image Processor Operator Functions . . . . 3-11

Figure 3-3 Tow Vehicle Tail Fin Retaining Screw Locations . . . . . . . . 3-13

Figure 3-4 Installing the Tow Vehicle Tail Fins . . . . . . . . . . . . . . . . . . 3-14

Figure 3-5 Tow Vehicle Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Figure 3-6 Transducer Array Down-Look Angle Adjustment . . . . . . . 3-16

Figure 3-7 The Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Figure 3-8 The Setup Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Figure 3-9 The Comm Setup Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Figure 3-10 The Sonar Setup Dialog Box . . . . . . . . . . . . . . . . . . . . . . . 3-21

Figure 3-11 The Attitude Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Figure 3-12 The Save As Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Figure 3-13 The Open Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Figure 3-14 Pitch/Roll, Heading/Course, Altitude,

and Sonar Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Figure 3-15 Location of the Port and Starboard Transducer Arrays . 3-26

Figure 3-16 Rub Test Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Figure 3-17 The Sonar Diagnostics Box . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Figure 3-18 Chirp Pattern Test Display . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Figure 3-19 Displayed Pitch and Roll Data . . . . . . . . . . . . . . . . . . . . . . 3-29

Figure 3-20 Displayed Heading and Course Data . . . . . . . . . . . . . . . . 3-30

Figure 3-21 Example of SIS-1500 Sonar Images . . . . . . . . . . . . . . . . . 3-31

Figure 4-1 Topside Processor Electronics Block Diagram . . . . . . . . . . 4-4

List of Figures

xii DATASONICS

Figure 4-2 Chirplink II Digital Multiplexer Chassis . . . . . . . . . . . . . . . . . 4-7

Figure 4-3 Subsea Electronics Block Diagram . . . . . . . . . . . . . . . . . . . . 4-9

Figure 4-4 Sonar Electronics Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 5-1 Tow Vehicle Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System xiii

List of Tables

Table 5-1 Processor Startup Problems . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Table 5-2 Tow Vehicle Activation Problems . . . . . . . . . . . . . . . . . . . . . 5-11

Table 5-3 Predeployment Checks Problems . . . . . . . . . . . . . . . . . . . . . 5-16

Table 5-4 Operation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Table 5-5 Uplink Telemetry Data Format . . . . . . . . . . . . . . . . . . . . . . . . 5-23

List of Tables

xiv DATASONICS

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-1

SECTION 1

SIS-1500 Overview

SECTION 1 SIS-1500 Overview

1-2 DATASONICS

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-3

T

he Datasonics SIS-1500 Seafloor Imaging System is a fully

integrated sonar system that uses advanced Chirp technology to

produce high resolution sidescan sonar images. The system consists

of two main components: the Datasonics SIP-150 Sonar Image Processor

shown in Figure 1-1 and the Datasonics TTV-195 Tow Vehicle shown in

Figure 1-2. This section provides a general description of the system and

identifies some of its important features. A review of Chirp technology is also

presented and how the system makes use of its important advantages.

Main System Components

The SIP-150 Sonar Image Processor is the shipboard component of the

system and includes the following:

the Datasonics SIP-150 Sonar Image Processing Workstation that

processes, displays, and archives sidescan sonar data and monitors and

controls system performance;

the Datasonics Chirpscan3 software for Windows with matched-filter

digital signal processing that generates multiple views of the sidescan

sonar data as the information is collected and recorded on high density

storage media; and

the Datasonics Chirplink II Digital Multiplexer, an advanced digital

telemetry system that multiplexes tow vehicle power and data over

industry-standard coaxial cable.

The TTV-195 Tow Vehicle is the subsea component of the system and is

equipped with the following sensors and electronics:

sidescan sonar transducer arrays capable of operating at depths up to

1000 meters;

advanced sonar electronics that controls the performance of the sonar

equipment and sensors, and includes pitch, roll and heading sensors;

and

optional sensor analog and digital inputs for the addition of optional

oceanographic sensors, including a cesium magnetometer, a water

temperature sensor, a pressure sensor, and a responder.

SECTION 1 SIS-1500 Overview Main System Components

1-4 DATASONICS

Figure 1-1 SIP-150 Sonar Image Processor

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-5

SECTION 1 SIS-1500 Overview Main System Components

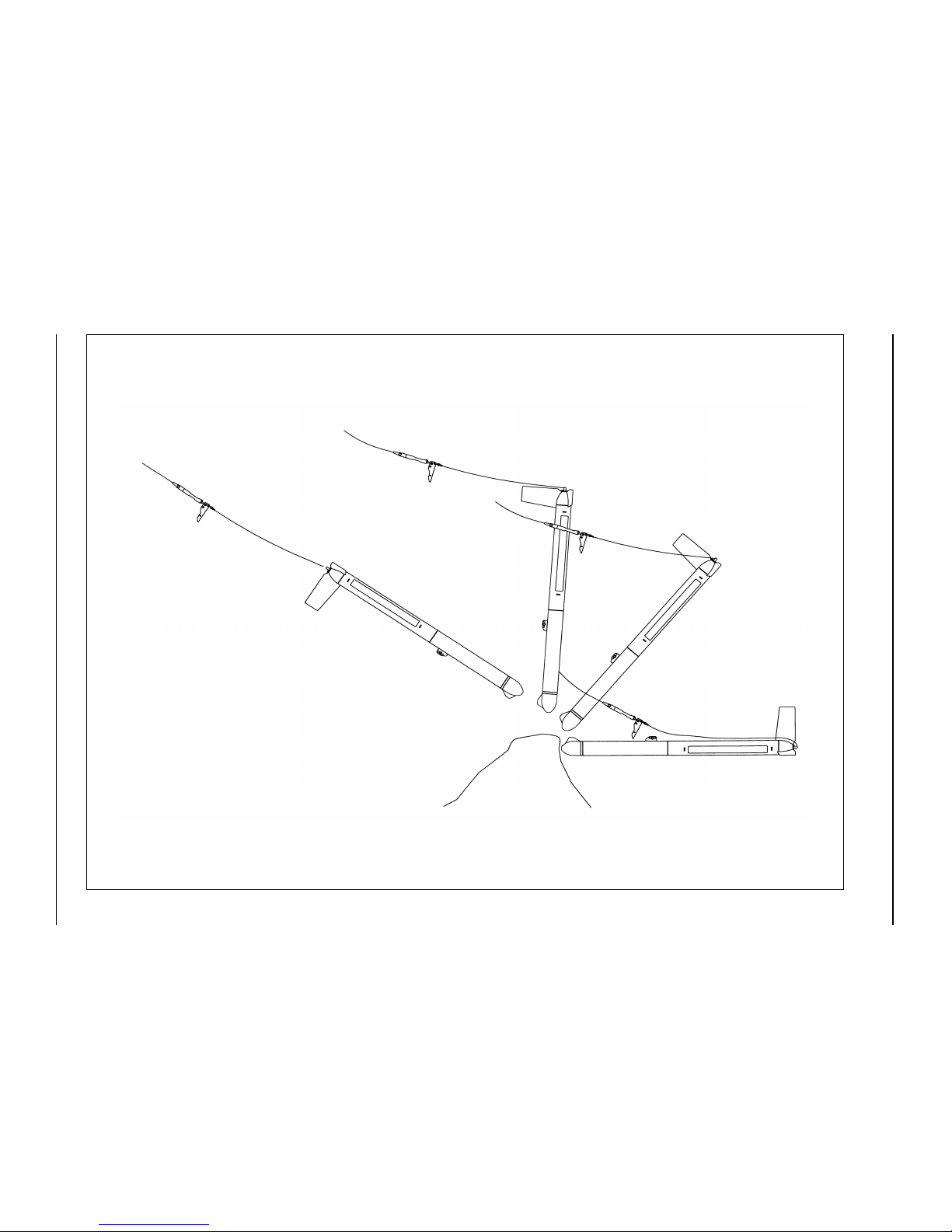

Figure 1-2 TTV-195 Tow Vehicle

1-6 DATASONICS

Advantages of Chirp Sonar

Chirp sonar technology employs swept FM transmitted signals along with

digital signal processing for matched-filter processing of reflected energy.

This delivers the following performance advantages:

a greater dynamic range is attained as long FM pulses provide an

additional 20 dB to 30 dB of dynamic range over conventional sidescan

sonar systems;

enhanced resolution is achieved with matched-filter processing, as

compared to systems using standard processing in the same frequency

band, by correlating the return signals with a replica of the outgoing

pulse;

transmitted waveforms are repeatable from pulse to pulse;

the temporal resolution is constant throughout the entire range;

the pulse characteristics are programmable, as the pulse length,

span of frequency sweep and phase/amplitude calibration of the transmit

waveform can be varied without hardware changes; and

the sidescan sonar data can be stored for off-line processing, on a

hard disk, a magneto-optical disk, or an Exabyte 8 mm cartridge tape.

SIP-150 Sonar Image Processor

The SIP-150 Sonar Image Processor comprises the SIP-150 Sonar Image

Processor Workstation, which includes the Chirpscan3 software, and the

Chirplink II Digital Multiplexer. Together the workstation, the Chirpscan3

software and the digital multiplexer serve to process, display and store the

sonar data, the tow vehicle status information and the sensor data that are

received from the tow vehicle. In addition, they monitor and control the tow

vehicle’s functions while sending commands and the sonar and responder

keys to the tow vehicle.

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-7

SIP-150 Sonar Image Processor Workstation

The SIP-150 Sonar Image Processor Workstation, which runs the Datasonics

Windows based Chirpscan3 software, serves as the operator interface for

monitoring and controlling the system. The workstation includes a Pentium

based processor, Windows 95/NT and the following components:

• 1280 X 1024 high resolution color monitor

• Dual channel digital signal processor

• Graphics processor

• Hard drive with a SCSI interface

• Optional magneto-optical drive or Exabyte 8 mm

cartridge tape drive

• CD ROM drive

• 1.44 megabyte floppy drive

• Drawer type integrated keyboard and pointing device

The workstation displays the port and starboard sidescan sonar data and the

pitch, roll, heading, course, and altitude data in separate display windows in

the Display area of the Main window. Also within the Main window is the

Parameter display, the Status display, the Sonar Controls box, and the

Auxiliary Controls box.

As the sonar data are received, the workstation processes the data using

matched-filter digital signal processing, applying continuous Short Time

Fourier Transforms (STFT) for each sweep or transmit cycle. In addition, the

full dynamic range of the processed data is recorded on digital storage media

while being displayed on a high resolution 1280 X 1024 monitor. An optional

printer or graphic recorder can be connected to print either the data currently

being recorded or previously recorded data.

In addition to the sonar data, the workstation integrates the tow vehicle status

information, the sensor data and the navigation data, if available, into the

sidescan sonar data records. The status information also includes various

tow vehicle hardware settings. The sensor data are input from the tow

vehicle’s pitch, roll, heading, and optional sensors, and the navigation data

are input from the ship’s navigation system.

SECTION 1 SIS-1500 Overview SIP-150 Sonar Image Processor

1-8 DATASONICS

Chirpscan3 Software

The Chirpscan3 software has enabled the development of compact, low cost,

modular shipboard data acquisition and image processing systems.

Chirpscan3 supports the acquisition, processing and storage of multiple

channels of sidescan sonar data and also manages the acquisition and

storage of navigation, magnetic and environmental data. And as Chirpscan3

runs under Windows, it allows independent control of the processing. In

addition, a graphics engine drives the high resolution 1280 x 1024 color

monitor. The sonar records are stored on a hard disk, a magneto-optical disk,

or an Exabyte 8 mm cartridge tape.

Data Fusion and Storage

While sidescan sonar imagery are acquired and processed, other types of

data can be input to the workstation’s serial ports. For example, a navigation

device or an integrated navigation computer can be connected to a serial

port. Navigation data are merged into the standard data format in the

workstation and combined with the sonar data before being displayed and

recorded on the magneto-optical disk or the Exabyte 8 mm cartridge tape.

Although the sonar data can be saved to the workstation’s hard drive, the

higher density magneto-optical disk or tape cartridge is more appropriate for

storing the large files that are generated by the SIS-1500 Seafloor Imaging

System.

Realtime Display and Image Processing

Chirpscan3 runs under Windows 95/NT, which facilitates a standard and

familiar graphic user interface. The Windows environment also allows for

independent control of a number of data display windows. Several different

types of data display windows are available, each suited to a specific data

type. Windows also allows multiple applications of the software to run

simultaneously. This enables the viewing of a previously recorded file while

recording data in a new file.

The flexibility of the image processing features is a major advantage over

simple sonar video displays. These tools greatly enhance the power of the

workstation and the capabilities for manipulating and interpreting data.

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-9

Post-Processing of Data

Chirpscan3 enables both a record mode for data acquisition and real-time

image processing, and a playback mode for image processing and data

analysis after the sidescan sonar records have been collected and

processed. All the real-time image processing tools available with operation

in record mode are also available in playback mode.

Chirplink II Digital Multiplexer

The Chirplink II Digital Multiplexer is the communications interface between

the workstation and the tow vehicle. It provides full duplex communications

with the tow vehicle, allowing the workstation to send commands to the tow

vehicle while simultaneously receiving sonar data, tow vehicle status

information, and sensor data from the tow vehicle. In addition, the digital

multiplexer supplies power to the tow vehicle. Using a combination of

frequency division and time division multiplexing, the digital multiplexer

allows both the data and the power to be carried on a single coaxial cable,

which connects the digital multiplexer to the tow vehicle. Frequency division

multiplexing is used for transmitting all the downlink commands and uplink

vehicle status information and sensor data at a frequency of 9600 baud.

T1 telecommunications technology, an industry standard, is used for

transmitting all the sonar data at a data communications rate of

1.544 Mbits/sec. The digital multiplexer also contains the system’s main

power switch, and includes a front panel voltmeter and ammeter for

monitoring the power transmitted to the tow vehicle.

TTV-195 Tow Vehicle

The TTV-195 Tow Vehicle contains the sidescan sonar transducer arrays,

the sonar electronics and the standard pitch, roll and heading sensors.

Available optional sensors include temperature and pressure sensors, a

cesium magnetometer and a responder. The tow vehicle, which is 4.5 inches

in diameter and 70 inches long, is constructed of 316 stainless steel and is

specifically designed to operate at depths up to 1000 meters. The nose of the

tow vehicle contains the optional temperature sensor and the optional

responder transducer, where both are encapsulated in a single urethane

mold. The temperature sensor is in direct contact with the water at all times,

providing a fast thermal time constant and a means of correlating any

observed anomalies in the sonar data with changes in sound velocity that are

due to temperature gradients. The responder transducer is positioned to

SECTION 1 SIS-1500 Overview TTV-195 Tow Vehicle

1-10 DATASONICS

provide the optimum beam pattern for tracking the tow vehicle with an

acoustic positioning system. The optional pressure sensor is contained within

the end cap and is exposed to ambient pressure through a port on the rim of

the end cap.

The nose is attached to the forward end of a pressure housing, the

electronics housing, which contains the sonar electronics. An end cap both

seals the opposite end of the housing and attaches to another housing, the

sonar transducer housing, which is free flooding and contains the sonar

transducers. The nose and end cap are secured to the electronics housing

with a closure bolt in the nose. The electronics housing also contains the

vehicle’s tow point, and the sonar transducer housing contains the vehicle’s

tail fin.

The tow vehicle’s towing arm, which is designed for rapid attachment and

detachment, contains a shear pin release mechanism, which is designed to

cause the towing arm to break away from the tow point should a collision

occur or should the tow vehicle become snagged. However, one end of a

recovery cable is attached to the towing arm. The cable runs back along the

top of the vehicle to its stern. Should an obstruction cause the tension on the

towing arm to exceed 200 lbs, the towing arm will break away and the tow

vehicle will cartwheel one-half of a revolution, with the nose moving

downward and then backward, clearing the tow vehicle from the obstruction.

This is shown in Figure 1-3. As the recovery cable remains attached, the tow

vehicle can be safely recovered. The tail fin will also break away should it

collide with an obstruction—and it is easily replaced.

Sidescan Sonar Transducer Arrays

The sidescan sonar, which operates in the 190 to 210 kHz band, utilizes two

transducer line arrays that are installed in the free flooding transducer

housing. The arrays are aligned end to end, with one along each side of the

tow vehicle. This arrangement provides a one-way horizontal beam width of

1° and a vertical beam width of 50°. In addition, the down-look angle of each

transducer array is adjustable from 0° to 20° in 10° increments.

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-11

SECTION 1 SIS-1500 Overview TTV-195 Tow Vehicle

Figure 1-3 TTV-195 Tow Vehicle Breaking Away from Obstruction

1-12 DATASONICS

Sonar Electronics

Contained within the electronics housing in the tow vehicle is the sonar

electronics, which controls the tow vehicle’s functions, generates and

transmits the Chirp waveforms, and processes the received signals. Included

with the sonar electronics in the electronics housing are the pitch, roll, and

heading sensors. The sonar electronics receives power, downlink

commands, and the sonar and responder keys from the Chirplink II Digital

Multiplexer, and transmits the sonar data, the tow vehicle status information,

and the sensor data to the digital multiplexer.

Optional Sensors

Spare RS-232 and analog inputs are available for connecting optional

sensors and oceanographic instruments, including a temperature sensor, a

pressure sensor, and a cesium magnetometer. In addition, a responder input

is included, which allows for the installation of a responder for tow vehicle

positioning.

Chirp Technology

Chirp technology uses digitally produced linear FM acoustic transmissions to

produce high resolution images of seafloor contours. In all sonar systems,

higher frequency content is invariably associated with an increase in

resolution, and in the case of a sidescan sonar, a decrease in range. Chirp

technology, as implemented in the SIS-1500 Seafloor Imaging System,

reduces this trade-off, providing both high resolution and extended range.

Across-Track Resolution

The resolution of a sidescan sonar is measured by its ability to discern closely

spaced objects that lie in the direction that is 90 degrees to the path of the

tow vehicle. This resolution is referred to as the across-track resolution. A

sidescan sonar system with an across-track resolution of 10 cm will detect

individual objects that are at least 10 cm apart. Objects spaced closer than

10 cm will be resolved by the sonar as a single object. In a conventional

sidescan sonar system, the limit of its resolution is determined by the pulse

length of the transmitted waveform. In the SIS-1500 Seafloor Imaging

System, which is a Chirp sidescan sonar system, it is the bandwidth of the

transmitted pulse that sets the system's theoretical resolution. The theoretical

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 1-13

across-track resolution of a conventional system is calculated by multiplying

the length of the pulse by the speed of sound, and then dividing the product

by 2 to account for the pulse’s round trip.

across-track resolution = pulse length x speed of sound / 2

In comparison the pulse length equivalent of a de-Chirped swept frequency

pulse equals the inverse of the bandwidth.

pulse length = 1 / bandwidth

For example, the duration of a pulse with a bandwidth of 20 kHz, which is the

bandwidth of a system configured to operate between 190 and 210 kHz, is

approximately 50 µs (1/20000 Hz = 0.00005 sec). Travelling at about

1500 m/sec, the sound will traverse approximately 7.5 cm in 50 µs. Allowing

for the round trip, this results is a one-way distance of 3.75 cm, which is the

across-track resolution.

Along-Track Resolution

In addition to the frequency and bandwidth of the transmitted sonar beam,

which affect the across-track resolution, the horizontal width of the beam

affects the sidescan sonar’s resolution in the direction that is parallel to the

path of the tow vehicle. This resolution is referred to as the along-track

resolution. To attain a high along-track resolution, narrow beam widths are

required. However, narrow beams produce side lobes, which contain energy

that produces undesired echoes from reflections not located in the primary

beam. In conventional sidescan sonar systems resolution is lost due to the

presence of these echoes. With Chirp technology the side lobes are greatly

reduced through matched-filter correlation processing, which attenuates

echoes that do not correlate well with the transmitted pulse.

Signal-to-Noise Ratio

Another factor that affects the image quality is the signal-to-noise ratio. As the

transmitted pulse travels through the water, its amplitude becomes

attenuated and falls below the noise level. The matched-filter correlation

processing used in the SIS-1500 Seafloor Imaging System improves the

signal-to-noise ratio, and hence the quality of the sonar images.

SECTION 1 SIS-1500 Overview Chirp Technology

1-14 DATASONICS

Chirp Pulse Transmission and Reception

The sequence of steps in the transmission and reception of the Chirp pulses

are summarized as follows:

1. A linear FM pulse is generated at fixed intervals.

2. The signal is sent to power amplifiers that drive the two sidescan sonar

transducer arrays. The sidescan’s port transducer array sweeps from a

low to a high frequency, while the starboard array sweeps from a high to

a low frequency. The counter-directional sweeps minimize cross-talk

between the sidescan channels.

3. The sidescan sonar transducer arrays transmit the pulse and the same

transducer arrays detect the reflected energy.

4. Reflections at the receiver array are amplified by a computer-controlled

amplifier and a user-programmable gain stage. In addition, the sidescan

receiver applies time varying gain to enhance attenuated signals

returning from greater distances.

5. The received sonar signals are digitized with a 16-bit A/D converter.

6. On the surface a dual channel digital signal processor in the workstation

de-Chirps (compresses the FM reflections using the matched-filter) the

return signals from the sidescan sonar. This correlates the received

reflections with a compensated replica of the outgoing pulse. Signals that

do not resemble the outgoing pulses are attenuated by this type of

processing. Compressed returns are further processed to correct for

amplitude losses from attenuation and absorption by the water.

Volume ISystem Manual June 1998

SIS-1500 Seafloor Imaging System 2-1

SECTION 2

Specifications

SECTION 2 Specifications

2-2 DATASONICS

Volume ISystem Manual June 1998

Loading...

Loading...