INTEGRATED CIRCUITS

DATA SH EET

TDA4800

Vertical deflection circuit for monitor

applications

Preliminary specification

File under Integrated Circuits, IC02

February 1992

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

FEATURES

• Fully integrated, few external components

• RC oscillator with wide sync range of 1:3 (e.g. 50 Hz to

150 Hz)

• Preamplifier

• Power output stage with thermal and SOAR protection

• Flyback generator

• Internal voltage stabilizer

• Synchronization by positive or negative going sync

pulse

• Blanking pulse duration is determined externally

• Dual frequency criterion for automatic amplitude

switch-over (e.g. 50 Hz to 60 Hz)

• Guard circuit for screen protection

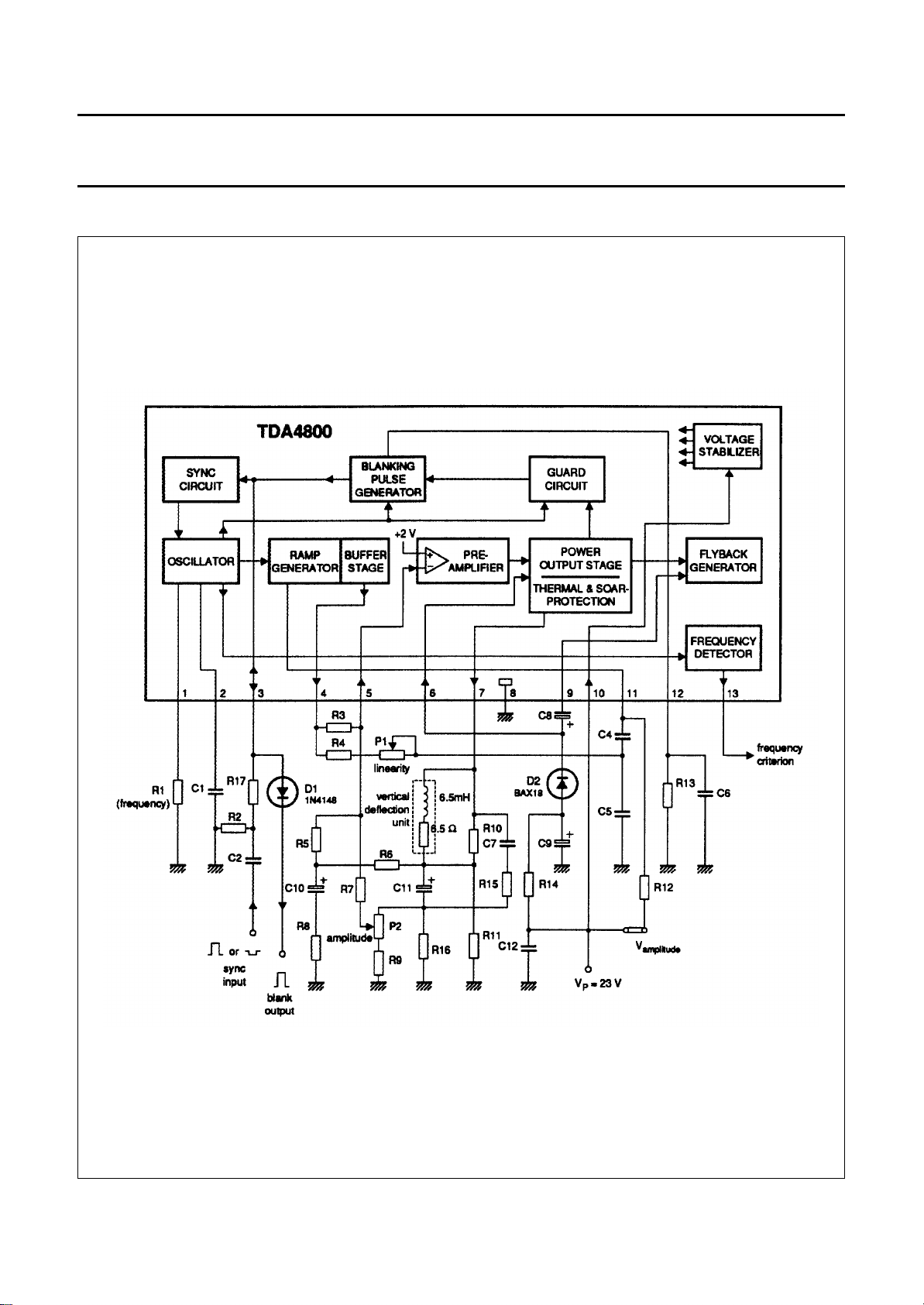

GENERAL DESCRIPTION

The TDA4800 is a monolithic integrated circuit for vertical

deflection primarily in monitors (and TV receivers). The

complete circuit consists of 11 main functional blocks as

shown in Fig.1.

• Sawtooth generator with buffer stage supplied by

external voltage

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

V

I

P

I

7

f

sync

V

V

T

P

P

3

3

amb

supply voltage range (pin 10) 10 − 45 V

supply voltage range (pin 6) 10 − 30 V

supply current (pins 6 and 10) note 1 − 215 − mA

output current (peak-to-peak value) −−2.6 A

picture frequency note 1, 3 −−135 Hz

positive sync input pulse 1.0 − 6.0 V

negative sync input pulse −0.5 −−0.7 V

operating ambient temperature range note 2 −20 −+70 °C

Notes to the quick reference data

1. Measured in circuit Fig.4

2. P

3. fo= 45 Hz (f

= 3.6 W for R

tot

sync max

th j−a

=3f

= 20 K/W

o)

ORDERING INFORMATION

EXTENDED

TYPE NUMBER

PACKAGE

PINS PIN POSITION MATERIAL CODE

TDA4800 13 DBS plastic SOT141

Note

1. SOT141-6; 1996 November 15.

February 1992 2

(1)

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

BLOCK DIAGRAM

February 1992 3

Fig.1 Block diagram

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

FUNCTIONAL DESCRIPTION

The complete circuit consists of the following functional

blocks as shown in Fig.1:

1. Oscillator

2. Synchronization circuit

3. Blanking pulse generator

4. Frequency detector and storage

5. Ramp generator

6. Buffer stage

7. Preamplifier

8. Power output stage

9. Flyback generator

10. Guard circuit

11. Voltage stabilizer

1. Oscillator (pins 1, 2)

The oscillator is an RC-oscillator with a threshold value

switch, which ensures very good frequency stability.

The upper and lower threshold voltages are defined by an

internal voltage divider.

An external capacitor C1 at pin 2 is charged by a constant

current source. When the scan voltage of C1 reaches the

upper threshold voltage, oscillator flyback starts. Capacitor

C1 discharges via an internal resistor and transistor until

the lower threshold is reached.

The constant charge current and free-running frequency

are adjusted by an external resistor R1 at pin 1:

f

o

f

o

1

-------------------------------KR1C1××

with K = 0.68=

2. Synchronization circuit (pin 3)

A positive- or negative-going pulse fed to pin 3

synchronizes the oscillator by lowering the upper threshold

voltage. The synchronizing range is f

50 Hz f

f

o

→ 150 Hz.==

sync max

to 3 fo. For example:

o

3. Blanking pulse generator (pin 3)

Also at pin 3 a blanking pulse is available. Diode D1

separates the synchronization pulse from the blanking

pulse. During scanning, the external capacitor C6 at pin 12

is charged to an internal stabilized voltage V. The blanking

pulse starts with the beginning of oscillator flyback; then

capacitor C6 discharges via the external resistor R13 at

pin 12. The blanking pulse stops when the capacitor

voltage is V/2.

The blanking pulse duration is determined by the values of

external components R13 and C6 at pin 12:

R13C6Ln2××=

t

bl

4. Frequency detector with storage (pin 13)

At the end of the scanning period a frequency detector

detects the oscillator frequency (see

Note

). When this

frequency is above the threshold a flip-flop is set to store

this information. The output is an open collector output.

Note:

Frequency detector change-over at pin 13 from low ( = low

frequency) to high ( = high frequency) is determined by fo:

f

threshold

1.23 fo×=

5. Ramp generator (pin 11)

The ramp generator consists of two external series

capacitors C4 and C5, external charge resistor R12

(connected to pin 11), and an internal differential amplifier

which is synchronously-switched by the oscillator.

External capacitors C4 and C5 at pin 11 are charged by

the charging current via the external charge resistor R12

until oscillator flyback starts. C4 and C5 are then

discharged via pin 11 by an internal resistor and transistor.

This generates a positive-going ramp voltage.

6. Buffer stage (pin 4)

The buffer stage consists of two emitter followers. The

ramp voltage is fed via the buffer stage and is available at

pin 4 with a low ohmic output impedance. With R4 and P1

it generates a ramp function, which, together with the

feedback network of the deflection yoke, gives a high

degree of linearity at the picture tube. The linearity can be

adjusted by P1.

7. Preamplifier (pin 5)

The preamplifier is a differential amplifier. The

non-inverting input is fixed at about 2 V by an internal

voltage divider. The inverting input at pin 5 is connected to

the ramp voltage via R3 and feedback network

P2, R5 - R11, R15, R16, C7, C10 and C11.

8. Power output stage (pin 7)

The power output stage is an amplifier with a

quasi-complementary class-B output. The output is

connected to pin 7.

The power stage includes SOAR and thermal protection.

February 1992 4

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

9. Flyback generator (pin 9)

The flyback generator has an external capacitor C8 at

pin 9. During scanning, the internal circuit switches pin 9

almost to ground; thereby C8 is charged by the supply

voltage via external components R14 and D2.

During the flyback time pin 9 is switched almost to the

supply voltage, so that the supply voltage for the power

output stage (pin 6) is nearly doubled. This high flyback

voltage ensures a very short flyback time.

10. Guard circuit (pin 3)

When the vertical deflection current is absent (e.g.

short-circuit, or open-circuit of the yoke) the guard circuit

changes the blanking pulse at pin 3 into a DC signal which

blanks the beam current to protect the screen. Also an

oscillator defect (C1 short-circuited or R1 disconnected

from pin 1) switches on the guard circuit.

11. Voltage stabilizer

The voltage stabilizer circuit provides a stable operating

voltage of about 7.5 V for several circuits of the TDA4800.

February 1992 5

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

PINNING

SYMBOL PIN DESCRIPTION

OSC

OSC

SYB

R

C

O

1 oscillator resistor

2 oscillator capacitor

3 sync. input,

blanking pulse output

S

OUT

PRE

P

SUP

I

4 sawtooth output

5 preamplifier input

6 power supply

OUTP 7 deflection output

GND 8 ground

C

FLY

9 pin for the flyback generator

capacitor

V

P

S

GEN

BP

FRQ

DU

C

10 supply voltage

11 sawtooth generator

12 blanking pulse duration

13 frequency criterion

Fig.2 Internal circuits.

Fig.3 Pin configuration.

February 1992 6

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC 134)

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

2

V

11

V

12

V

13

V

10

V

9

V

7

V

6

V

5

V

4

V

3

I

1

I

3

I

4

, I7,I

I

6

I

9

I

11

T

stg

T

amb

T

j max

P

tot

V

ESD

voltages 0 6 V

024V

06V

050V

supply voltages (VP) 0 50 V

050V

060V

060V

06V

024V

−0.7 6 V

currents 0 −1mA

+3 −10 mA

0 −5mA

8

see note 1

−1.5 + 1.5 A

−0.1 + 30 mA

storage temperature range −25 +150 °C

operating ambient temperature range see note 2 −20 + 70 °C

maximum junction temperature see note 3 − 150 °C

total power dissipation see note 2 −−W

ESD sensitivity see note 4 −2000 +2000 V

Notes to the limiting values

, I7and I8are limited by SOAR protection circuit that ensures that a short-circuit between the output pin 7 and supply

1. I

6

voltage or ground does not destroy the output stage. A short-circuit may be soldered into the printed-circuit board or

may sometimes (non-periodically) occur in the applied circuit.

2. The maximum value for the operating ambient temperature range and the power dissipation depends on the

heatsink.

3. Internally limited by thermal protection: switching temperature point at Tj= 150 °C ±8 °C.

4. Human body model: 1.5 kΩ, 100 pF, 5 pulses.

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

R

th j-a

th j-mb

from junction to ambient 20 K/W

from junction to mounting base 5 K/W

February 1992 7

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

CHARACTERISTICS

All voltages are measured to V

GND

(pin 8); T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

P

V

P

I

10

I

6

I

6

V

7

V

7

V

9

I

7

I

9

I

5

V

1

V

3

R

3

I

3

t

bl

V

11

I

11

V

13

I

13

V

4

I

4

V

3

V

3

supply voltage.range (pin 10) 10 − 45 V

supply voltage range (pin 6) 10 − 30 V

supply current V10= 25 V; V5=3V

supply current V6=25V; V5=1V

supply current V6=25V; V5=3V

minimum output voltage I7=1A − 1.4 1.65 V

maximum output voltage I7= −1A V6−2.3 V6−2.0 − V

output voltage during flyback I9= −1A − V10−2.2 − V

output current −−±1.3 A

output current −−±1.3 A

preamplifier input current −−0.1 −µA

stabilized voltage 6.1 6.8 7.3 V

blanking pulse output voltage − 5.7 − V

blanking pulse output resistance − 300 −Ω

blanking pulse output current 0 −−3mA

blanking pulse duration R = 100 kΩ;

output voltage ramp generator 0.3 − 20 V

output current ramp generator −2 − 15× 103µA

output voltage frequency detector lower frequency

leakage current frequency detector higher frequency

output voltage buffer stage 0 − 20 V

output current buffer stage −−−4.0 mA

synchronizing input voltage positive sync 1.0 − 6.0 V

synchronizing input voltage negative sync −0.5 −−0.7 V

tolerance of free running oscillator without sync −3.0 −+3.0 %

∆f/f / ∆TCoscillator temperature dependency T

∆f/f / ∆VPoscillator voltage dependency VP= 10 V to 30 V − 4 × 10

f0/f

sync

synchronizing ratio 1:2.9 1:3 −−

=25°C; VP= 23 V; unless otherwise specified.

amb

− 12 − mA

without load

− 20 − mA

without load

− 5 − mA

without load

640 680 730 µs

C = 10 nF (pin 12)

−−1.0 V

I13=1mA

−−1.0 µA

V13=50V

=20°C to 100 °C − 10

case

−4

−4

− K

− K

−1

−1

February 1992 8

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

February 1992 9

Fig.4 Test and application circuit.

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

TDA4800 IN THE TEST AND APPLICATION CIRCUIT (see Fig.4)

SYMBOL PARAMETER CONDITIONS TYP. UNIT

V

P

I

P

V

7

V

7M

I

7

I

Y(p−p)

t

fb

t

bl

P

tot

f

o

supply voltage 23 V

supply current 215 mA

DC output voltage 11.8 V

peak output voltage 45 V

output current 0.8 A

vertical deflection current (peak to peak) 1.5 A

flyback time 0.3 ms

blanking pulse duration 1.25 ms

total power dissipation 3.3 W

free running oscillator frequency without sync 45 Hz

February 1992 10

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

PACKAGE OUTLINE

DBS13P: plastic DIL-bent-SIL power package; 13 leads (lead length 12 mm)

non-concave

x

D

E

h

view B: mounting base side

d

B

j

A

SOT141-6

D

h

2

E

A

113

e

Z

DIMENSIONS (mm are the original dimensions)

UNIT A e

mm

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

OUTLINE

VERSION

SOT141-6

A2bpcD

17.0

4.6

4.2

0.75

0.60

15.5

1

e

(1)

0.48

24.0

23.6

20.0

19.6

0.38

IEC JEDEC EIAJ

w M

b

p

0 5 10 mm

(1)

deD

E

h

12.2

10 3.4

11.8

REFERENCES

scale

1

1.7

e

5.08

L

3

L

E

2

h

6

Q

c

m

LL3m

3.4

12.4

3.1

11.0

e

2

2.4

1.6

PROJECTION

Qj

2.1

4.3

1.8

EUROPEAN

v M

v

0.8

x

0.25w0.03

ISSUE DATE

92-11-17

95-03-11

(1)

Z

2.00

1.45

February 1992 11

Philips Semiconductors Preliminary specification

Vertical deflection circuit for monitor applications TDA4800

SOLDERING

Introduction

There is no soldering method that is ideal for all IC packages. Wave soldering is often preferred when through-hole and

surface mounted components are mixed on one printed-circuit board. However, wave soldering is not always suitable for

surface mounted ICs, or for printed-circuits with high population densities. In these situations reflow soldering is often

used.

This text gives a very brief insight to a complex technology. A more in-depth account of soldering ICs can be found in our

“IC Package Databook”

Soldering by dipping or by wave

The maximum permissible temperature of the solder is 260 °C; solder at this temperature must not be in contact with the

joint for more than 5 seconds. The total contact time of successive solder waves must not exceed 5 seconds.

The device may be mounted up to the seating plane, but the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

be necessary immediately after soldering to keep the temperature within the permissible limit.

(order code 9398 652 90011).

). If the printed-circuit board has been pre-heated, forced cooling may

stg max

Repairing soldered joints

Apply a low voltage soldering iron (less than 24 V) to the lead(s) of the package, below the seating plane or not more

than 2 mm above it. If the temperature of the soldering iron bit is less than 300 °C it may remain in contact for up to

10 seconds. If the bit temperature is between 300 and 400 °C, contact may be up to 5 seconds.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

February 1992 12

Loading...

Loading...