INTEGRATED CIRCUITS

DATA SH EET

TDA1319T

DCC write amplifier (write 2)

Preliminary specification

File under Integrated Circuits, IC01

April 1994

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

FEATURES

• Bidirectional high current output

drivers

• Single point current setting

• Extra erase current for the auxiliary

channel

• Increased current for auxiliary data

• Low standby power consumption

• Short-circuit protection to ground

• Serial data input

GENERAL DESCRIPTION

The TDA1319T has been designed to

drive an inductive recording head

which is suitable for DCC (Digital

Compact Cassette) systems.

The bidirectional current outputs are

controlled by a two-wire serial bus.

The amplitude of the write current can

be set using an external resistor. The

circuit can be switched to the standby

mode to minimize supply current

consumption.

• Reduced RF emission due to slope

control of write current.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

V

I

DD

I

DDO

DD

DDO

supply voltage 4.75 5.0 5.5 V

supply voltage (write outputs) 4.75 5.0 5.5 V

supply current note 1 − 7.5 11 mA

supply current (write outputs) note 2 −−255 mA

note 3 −−365 mA

note 4 −−285 mA

I

sb

T

amb

total standby current note 5 − 23mA

operating ambient temperature −30 − +85 °C

Notes

1. 1 kΩ erase adjust resistor connected between pins 5 and 6, no load at pin 9.

2. Momentary maximum value during write data; see Table 1; IO= 225 mA.

3. Momentary maximum value during erase AUX; see Table 1 and Fig.5; resistor Re connected between pins 5 and 6

(see Fig.7).

4. Momentary maximum value during write AUX; see Table 1; IO= 255 mA.

5. Standby mode; see Table 1; Isb=IDD+I

DDO+Iclamp

.

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

PINS PIN POSITION MATERIAL CODE

PACKAGE

TDA1319T 24 SO24L plastic SOT137-1

April 1994 2

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

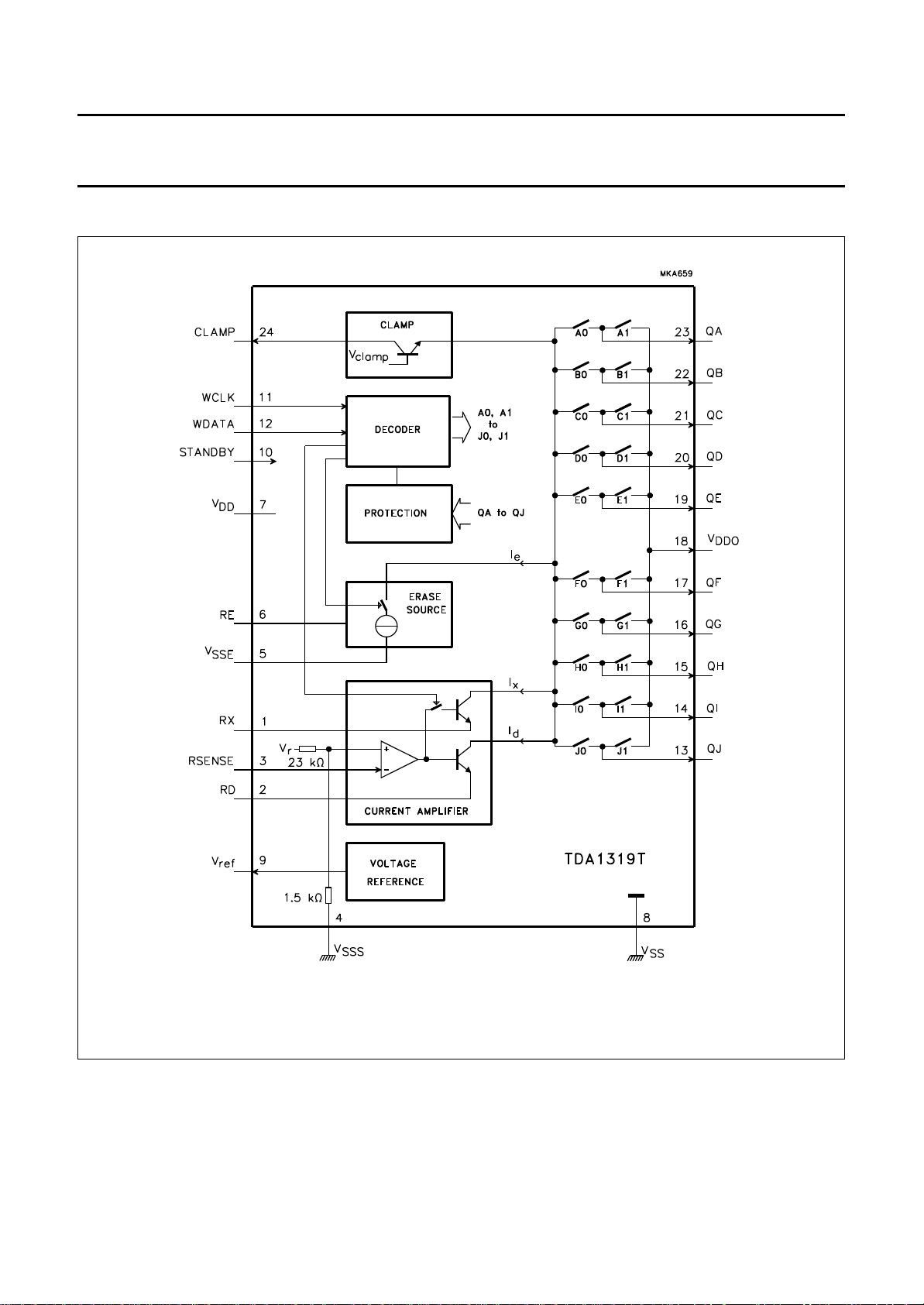

BLOCK DIAGRAM

April 1994 3

Fig.1 Block diagram.

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

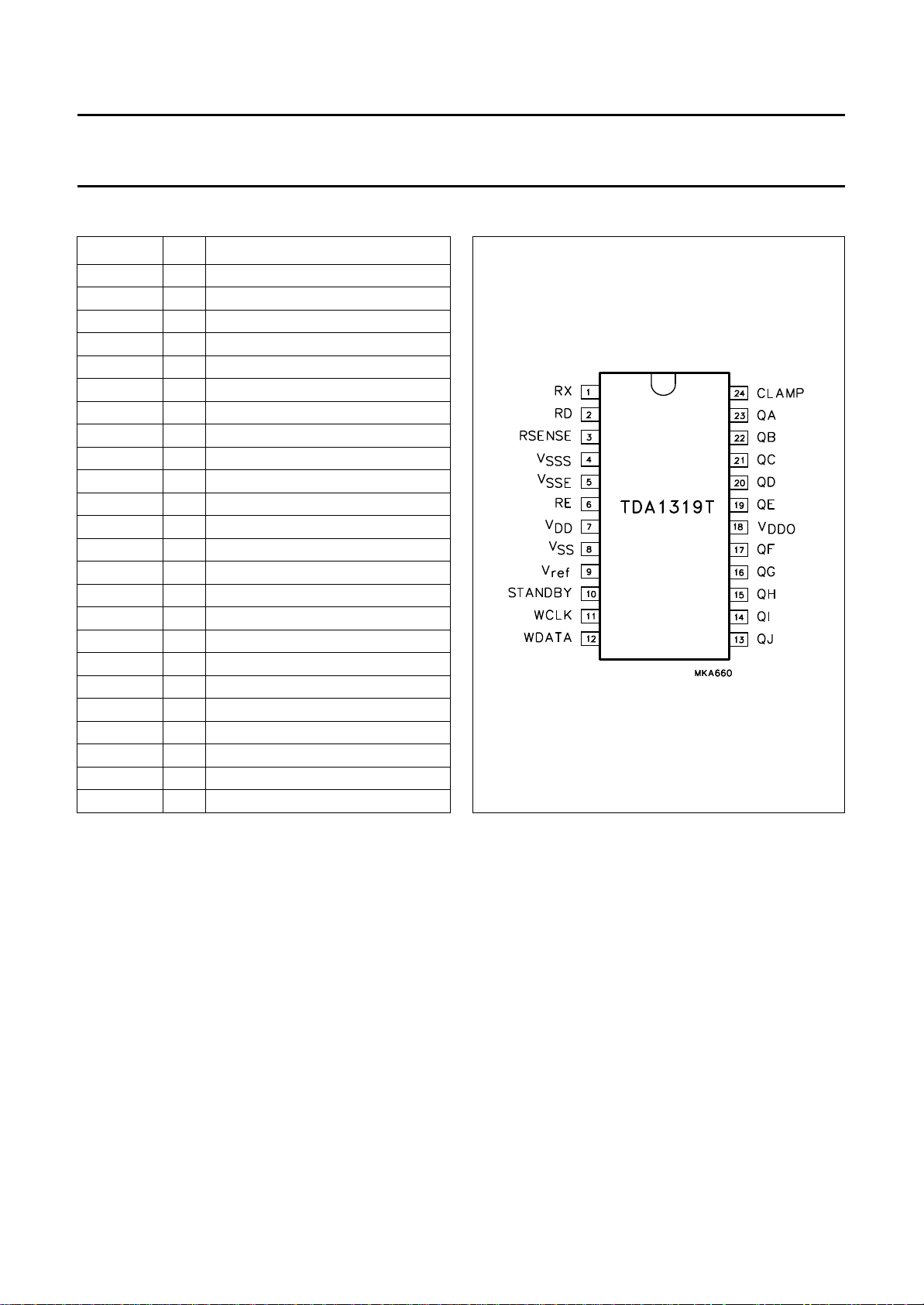

PINNING

SYMBOL PIN DESCRIPTION

RX 1 auxiliary current adjust resistor

RD 2 data current adjust resistor

RSENSE

V

SSS

V

SSE

RE 6 erase current adjust resistor

V

DD

V

SS

V

ref

STANDBY 10 standby mode control input

WCLK 11 write clock input

WDATA 12 write data input

QJ 13 write pulse output

QI 14 write pulse output

QH 15 write pulse output

QG 16 write pulse output

QF 17 write pulse output

V

DDO

QE 19 write pulse output

QD 20 write pulse output

QC 21 write pulse output

QB 22 write pulse output

QA 23 write pulse output

CLAMP 24 clamp current output

3 sense voltage positive input

4 sense voltage ground

5 erase current source ground

7 supply voltage

8 ground

9 reference voltage output

18 supply voltage (write outputs)

Fig.2 Pin configuration.

April 1994 4

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

FUNCTIONAL DESCRIPTION

The TDA1319T is designed to drive the nine elements of

the multichannel recording head (as used in a DCC

recorder) by forcing a current through the selected path. A

brief functional description of each block (see Fig.1) is

given below.

Decoder

The IC is controlled by the 32-bit wide serial dataword

which is clocked in at WDATA (pin 12). The clock

frequency (WCLK, pin 11) is 3.072 MHz with a clock

period of 325 ns. The write pulses are made available at

the outputs QA to QJ (see Fig.4). The timing sequence of

the write pulses is illustrated in Fig.5.

The operating mode of the IC can be set by the first 3 bits

of data (see Fig.5). The signals TCH0 to TCH7 and

TERAUX determine the direction of the write current.

When TCHn is HIGH, the current flows as indicated in

Fig.4. When TCHn is LOW current flows in the opposite

direction. The various modes of operation are given in

Table 1. The standby mode can also be forced by setting

the STANDBY input (pin 10) HIGH.

Current amplifier

The write current at the outputs is regulated by the current

amplifier. The value of the current I

external resistor Rd, connected between pin 2 and V

can be set using an

d

SS

(see Fig.9). The current through Rd also flows at the

outputs. The current amplifier regulates the voltage across

Rd, which is measured between RSENSE and V

SSS

(pins 3 and 4), to a value of 150 mV (see Chapter

“Characteristics”). This force-sense technique eliminates

the influence of parasitic series impedances.

The output of the current amplifier is internally switched to

the output pins QA to QJ. During AUX write (outputs QA

and QB active) an additional current Ix is added to the write

current. This current can be controlled by a resistor R

x

connected between RX (pin 1) and VSS. RX must be

6.7 × Rd for 1.2 dB current increase.

During the erase mode of the auxiliary channel

(TERAUX = HIGH; see Table 1) it is possible to let an

additional output current Ie flow through QA and QB

(pins 23 and 22). This extra current can be adjusted with

an external resistor Re connected between pins 6 and 5.

Pin 5 must be externally connected to ground. A typical

value of the extra current can be calculated from the

response curve of Fig.7.

Voltage reference

A reference voltage is available at pin 9. This voltage is

derived from a bandgap reference source and can be used

to modify the voltage sensed by the current amplifier, e.g.

for external temperature compensation.

Outputs

Each channel is selected in sequence. Depending on the

dataword, the current is directed forward or reversed

through the heads. The outputs that are not selected are

kept floating to prevent any incorrect current flow. A

simplified schematic of one output stage is illustrated in

Fig.3. In the HIGH state (one of the switches A1 to J1 is

closed) the output is internally connected to a fixed voltage

(see Chapter “Characteristics”). In the LOW state

V

OH

(one of the switches A0 to J0 is closed) the output is

connected to the current amplifier. The voltage developed

across the output pin pairs must not exceed a certain

value, otherwise the lower switch transistor (Fig.3) will

become saturated.

Clamp circuit

During the periods that the head elements are not

selected, the clamp circuit accommodates the write

current. This current is directed through an external

resistor from pin 24 to the supply, in order to have less

dissipation in the IC. The clamping results in a constant

current being drawn from the supply and therefore reduces

emission of interferences (the DC level at pin 24 must not

fall lower than 1.8 V).

Standby

The circuit is in the standby mode when TDAPLB = 1 and

TAUPLB = 1 (see Table 1 and Fig.6), or when a HIGH

level is applied to pin 10. After a HIGH-to-LOW transition

at pin 10, the IC will remain in the standby mode until

TDAPLB = 0 or TAUPLB = 0. When the IC is in the

standby mode, the current amplifier is switched off to

minimize the power consumption, switches A to J are

open-circuit and the voltage reference and the erase

source are switched off.

Protection

The IC is immediately switched to standby mode when a

short-circuit to ground at an output pin is detected

< 0.5 V; see Fig.6, “SHORT”). When the short-circuit

(V

o

condition is removed, the IC will resume operation. The

state of the decoder is not affected by a “SHORT”.

April 1994 5

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

Table 1 Modes of operation.

CONTROL BITS

DATA

CHANNELS

0 TO 7

AUXILIARY

CHANNELS

TDAPLB

(DATA

CHANNEL

PLAYBACK)

TAUPLB

(AUXILIARY

CHANNEL

PLAYBACK)

Read read 1 1 X standby mode

Write (Id) read 0 1 X

Write (I

Write (I

Read write (I

Read erase (I

) write (Id + Ix)0 0 0

d

) erase (Id + Ix + Ie)0 0 1

d

+ Ix)1 0 0

d

+ Ix + Ie)1 0 1

d

Note

1. X = don't care; 0 = LOW; 1 = HIGH.

(1)

TERAUX

(AUXILIARY

CHANNEL

ERASE)

REMARKS

Fig.3 Simplified schematic of ONE output stage. Fig.4 Output current definition.

April 1994 6

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

April 1994 7

Fig.5 Data format and timing sequence of write pulse.

(1) Erase pulses are inverted every other cycle of 32 clock pulses.

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

April 1994 8

Fig.6 Timing of the standby mode (via WDATA, STANDBY or “SHORT”).

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

Fig.7 Additional erase current as a function of Re (typ.).

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134); all voltages referenced to ground (pin 8); all

currents are positive into the IC.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

V

V

DD

DDO

I

supply voltage −0.3 +5.5 V

supply voltage (write outputs) −0.3 +5.5 V

input voltage (pins 1 to 6, 9 to 17

VDD+ 0.3 < 5.5 V −0.3 VDD+ 0.3 V

and 19 to 24)

I

n

maximum input current (pins 3, 4, 6

−10 +10 mA

and 9 to 12)

I

1

I

5

I

2

I

18

T

amb

T

stg

V

es

maximum input current (pin 1) −40 +40 mA

maximum input current (pin 5) −100 +40 mA

maximum input current (pin 2) −250 +40 mA

maximum input current (pin 18) −40 +400 mA

operating ambient temperature −30 +85 °C

storage temperature −55 +150 °C

electrostatic handling note 1 −2000 +2000 V

Note

1. Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

THERMAL RESISTANCE

SYMBOL PARAMETER THERMAL RESISTANCE

R

th j-a

from junction to ambient in free air 65 K/W

April 1994 9

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

CHARACTERISTICS

V

DD=VDDO

= 5 V; f

accordance with Fig.9; all voltages referenced to V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

DD

V

DDO

I

DD

I

DDO

I

sb

P

d(av)

Digital inputs (pins 10 to 12)

V

IH

V

IL

I

IL

t

su

t

h

Outputs (pins 9, 13 to 17 and 19 to 23)

V

ODATH

V

OAUXH

I

O(min)

I

ODAT(max)

I

OAUX(max)

∆I

O/IO

I

AUX

I

e

V

ref

Current amplifier (pins 1 to 4)

V

sense

, V

V

1

2

= 3.072 MHz; T

clk

=25°C; outputs QA to QJ resistively loaded; resistors connected in

amb

(pin 8); unless otherwise specified..

SS

supply voltage 4.75 5.0 5.5 V

supply voltage (write outputs) 4.75 5.0 5.5 V

supply current note 1 − 7.5 11 mA

supply current (write outputs) note 2 −−255 mA

note 3 −−365 mA

note 4 −−285 mA

total standby current note 5 − 23mA

average power dissipation note 6 − 645 − mW

HIGH level input voltage 3.5 − 5.0 V

LOW level input voltage 0 − 1.5 V

input leakage current −10 − +10 µA

WDATA set-up time see Fig.8 30 −− ns

WDATA hold time see Fig.8 30 −− ns

HIGH level data output voltage note 7 − 3.7 − V

HIGH level auxiliary output voltage note 8 − 3.7 − V

minimum output current −−25 mA

maximum data output current 225 −− mA

maximum auxiliary output current note 9 335 −− mA

output current deviation between channels note 7 −−0.5 dB

relative auxiliary write current increase note 10 1 1.2 1.4 dB

additional output current note 3 −−80 mA

reference voltage (pin 9) IO< 3 mA 2.4 2.5 2.6 V

sense voltage regulation between pins 3 and 4 140 150 160 mV

maximum DC voltage level (pins 1 and 2) −−500 mV

April 1994 10

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

Notes

1. 1 kΩ erase adjust resistor connected between pins 5 and 6, no load at pin 9.

2. Momentary maximum value during write data; see Table 1; IO= 225 mA.

3. Momentary maximum value during erase AUX; see Table 1 and Fig.5; resistor Re connected between pins 5 and 6

(see Fig.7).

4. Momentary maximum value during write AUX; see Table 1; IO= 255 mA.

5. Standby mode; see Table 1; Isb=IDD+I

DDO+Iclamp

6. Auxiliary and data write mode; Id= 170 mA; RL=3Ω (between current outputs); R

7. Data channels (pins 13 to 17 and 19 to 22); maximum output load resistance is 5 Ω; IO= 225 mA. Deviation defined

as 20log {(I

O(max)

− I

O(min)

)/I

} for channels 0 to 7.

o(av)

8. Auxiliary channel (pins 22 and 23); auxiliary erase mode; IO= 335 mA.

9. Auxiliary channel (pins 22 and 23); auxiliary erase mode; maximum output load resistance is 4 Ω.

10. Defined as 20log {(Id+Ix)/Id} when Rx= 6.7 × Rd.

.

=12Ω.

clamp

Fig.8 Timing relationship between the edges of WCLK and WDATA.

April 1994 11

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

TEST AND APPLICATION INFORMATION

April 1994 12

Fig.9 Test circuit.

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

April 1994 13

Fig.10 Application circuit.

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

PACKAGE OUTLINE

handbook, full pagewidth

S

pin 1

index

112

0.9

0.4

(4x)

15.6

15.2

1.27

0.49

0.36

0.1 S

1324

0.25 M

(24x)

2.45

2.25

0.3

0.1

10.65

10.00

detail A

7.6

7.4

1.1

0.5

1.1

1.0

0.32

0.23

0 to 8

MBC235 - 1

A

2.65

2.35

o

Dimensions in mm.

Fig.11 24-lead small-outline; plastic (SOT137-1).

April 1994 14

Philips Semiconductors Preliminary specification

DCC write amplifier (write 2) TDA1319T

SOLDERING

Plastic small-outline packages

YWAVE

B

During placement and before soldering, the component

must be fixed with a droplet of adhesive. After curing the

adhesive, the component can be soldered. The adhesive

can be applied by screen printing, pin transfer or syringe

dispensing.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder bath is

10 s, if allowed to cool to less than 150 °C within 6 s.

Typical dwell time is 4 s at 250 °C.

A modified wave soldering technique is recommended

using two solder waves (dual-wave), in which a turbulent

wave with high upward pressure is followed by a smooth

laminar wave. Using a mildly-activated flux eliminates the

need for removal of corrosive residues in most

applications.

Y SOLDER PASTE REFLOW

B

Reflow soldering requires the solder paste (a suspension

of fine solder particles, flux and binding agent) to be

applied to the substrate by screen printing, stencilling or

pressure-syringe dispensing before device placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt, infrared, and

vapour-phase reflow. Dwell times vary between 50 and

300 s according to method. Typical reflow temperatures

range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 min at 45 °C.

EPAIRING SOLDERED JOINTS (BY HAND-HELD SOLDERING

R

IRON OR PULSE

-HEATED SOLDER TOOL)

Fix the component by first soldering two, diagonally

opposite, end pins. Apply the heating tool to the flat part of

the pin only. Contact time must be limited to 10 s at up to

300 °C. When using proper tools, all other pins can be

soldered in one operation within 2 to 5 s at between 270

and 320 °C. (Pulse-heated soldering is not recommended

for SO packages.)

For pulse-heated solder tool (resistance) soldering of VSO

packages, solder is applied to the substrate by dipping or

by an extra thick tin/lead plating before package

placement.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

April 1994 15

Loading...

Loading...