Page 1

Smart Sensors (Inductive Displacement Type)

ZX-E Series

Smart Sensors that use the

eddy current method are now

available. Develop new applications with sub-micron sensing

technology.

Ordering Information

■ Sensors

.

Sensor Heads

Shape Dimensions Sensing distance Resolution *1 Model

Cylindrical 3 dia. x 18 mm 0.5 mm 1 μm ZX-EDR5T

5.4 dia. x 18 mm 1 mm ZX-ED01T *2

8 dia. x 22 mm 2 mm ZX-ED02T *2

Screw-shaped M10 x 22 mm ZX-EM02T *2

M18 x 46.3 mm 7 mm ZX-EM07MT *2

Flat 30 x 14 x 4.8 mm 4 mm ZX-EV04T *2 *3

Heat-resistant, cylindrical M12 x 22 mm 2 mm ZX-EM02HT *4

*1: For an average count of 4,096.

*2: Models with Protective Spiral Tubes are also available. Add a suffix of “-S” to the above model numbers when ordering.

(Example: ZX-ED01T-S)

*3: Be sure to use ZX-EDA Amplifier Unit version 1,200 or later with the ZX-EV04.

*4: Be sure to use ZX-EDA Amplifier Unit version 1,300 or later with the ZX-EM02H.

Amplifier Units

Appearance Power supply Output type Model

DC NPN ZX-EDA11

PNP ZX-EDA41

Note: Compatible connection with the Sensor Head.

ZX-E Series Smart Sensors (Inductive Displacement Type) 1

Page 2

Accessories (Order Separately)

Calculating Unit

Appearance Model

ZX-CAL2

Amplifier Mounting Brackets

Appearance Model Remarks

ZX-XBE1 Attached to

ZX-XBE2 For DIN track

Logging Tool for Personal Computers

Appearance Name Model

Communications

Interface Unit

Smart Monitor (Logging Software

+ Function Setting Software)

RS-232C ZX-SF11

USB ZX-SF21

each Sensor

Head

mounting

ZX-SW11EV3

(See note 1.)

Setup Tool for Personal Computer

Appearance Name Model

Communications Interface

+

Note 1. The ZX-SFW11EV3 or ZX-SW11EV3 is required to use the

Smart Monitor with the ZX-LDA11-N/41-N. Earlier versions

cannot be used.

2. The Smart Monitor Basic does not have a logging function.

Other than the logging function, the Smart Monitor Basic supports the same functions as the Smart Monitor.

Unit (RS-232C) + Smart

Monitor Basic*2 (Function

Setting Software)

ZX-SFW11EV3

(See note 1.)

Cables with Connectors on Both Ends (for

Extension)*

Cable length Model Quantity

1 m ZX-XC1A 1

4 m ZX-XC4A

8 m ZX-XC8A

* Robot cable models are also available.

The model numbers are ZX-XC@R.

Bank Unit

Appearance Model

ZX-SB11

Specifications

■ Sensor Heads

Model ZX-EDR5T ZX-ED01T ZX-ED02T/

Measurement range 0 to 0.5 mm 0 to 1 mm 0 to 2 mm 0 to 7 mm 0 to 4 mm 0 to 2 mm

Sensing object Magnetic metals (Measurement ranges and linearities are different for non-magnetic metals. Refer to En-

Standard reference object 18×18×3 mm 30×30×3 mm 60×60×3 mm 45×45×3 mm

Resolution *1 1 μm

Linearity *2 ±0.5% F.S. ±1.0% F.S. *5

Linear output range Same as measurement range.

Temperature characteristic *3

(including Amplifier Unit)

Ambient

temperature

Ambient humidity Operating and storage: 35% to 85% (with no condensation)

Insulation resistance 50 MΩ min. (at 500 DC)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between charged parts and case

Vibration resistance (destruction) 10 to 55 Hz with 1.5-mm double amplitude for 2 h each in X, Y, and Z directions

Shock resistance (destruction) 500 m/s

Degree of protection (Sensor Head) IEC60529, IP65 IEC60529, IP67

Connection method Connector relay (standard cable length: 2 m)

Weight (packed state) Approx. 120 g Approx. 140 g Approx. 160 g Approx. 130 g Approx. 160 g

Materials

Accessories Amplifier Mounting Brackets (ZX-XBE1), Instruction Manual

Operating *4

Storage *4

Sensor

Head

Preamplifier

Case

Sensing surface

Tightening nut

Toothed washer

gineering Data on page 4.)

Material: ferrous (S50C)

0.15% F.S./°C 0.07% F.S./°C0.1% F.S./°C

0 to 50°C (with

no icing or condensation)

2

, 3 times each in X, Y, and Z directions

Brass Stainless steel Brass

Heat-resistant ABS PEEK

PES

−10 to 60°C (with no icing or condensation) −10 to 200°C

−20 to 70°C (with no icing or condensation) −20 to 200°C

---

---

EM02T

Brass (nickel-plated) (except ZX-ED02T)

Iron (zinc-plated) (except ZX-ED02T)

ZX-EM07MT ZX-EV04T ZX-EM02H

IEC60529, IP60 *6

Zinc (nickel-plated)

---

---

Brass

Brass (nickel-plated)

Iron (zinc-plated)

2 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 3

*1:Resolution: The resolution is the deviation (±3σ) in the linear output when connected to the ZX-EDA Amplifier Unit. The above values indicate

the deviations observed 30 minutes after the power is turned ON.

(The resolution is measured with OMRON's standard reference object at 1/2 of the measurement range with the ZX-EDA set for the maximum average count of 4,096 per period.)

The resolution is given at the repeat accuracy for a stationary workpiece, and is not an indication of the distance accuracy. The resolution

may be adversely affected under strong electromagnetic fields.

*2: Linearity: The linearity is given as the error in an ideal straight line displacement output when measuring the standard reference object. The

linearity and measurement values vary with the object being measured.

*3: Temperature characteristic: The temperature characteristic is measured with OMRON's standard reference object at 1/2 of the measure-

ment range.

*4: The ambient temperature given is only for the sensor head. It is -10 to 60°C for the preamp.

*5: The value given is for an ambient temperature of 25°C.

*6: Do not use in moist environments because the case is not waterproof.

■ Amplifier Units

Model ZX-EDA11 ZX-EDA41

Measurement period *1 150 µs

Possible average count settings 1, 2, 4, 8, 16, 32, 64, 128, 256, 512, 1,024, 2,048, or 4,096

Linear output *2 Current output: 4 to 20 mA/F.S., Max. load resistance: 300 Ω

Voltage output: ±4 V (± 5 V, 1 to 5 V *3), Output impedance: 100 Ω

Judgement outputs

(3 outputs: HIGH/PASS/LOW)

Zero reset input, timing input, reset

input, judgement output hold input

Function - Measurement value display - Set value/output value/resolution display

Indications Judgement indicators: High (orange), pass (green), low (yellow), 7-segment main digital display (red),

Voltage influence

(including Sensor)

Power supply voltage 12 to 24 VDC ±10%, Ripple (p-p): 10% max.

Current consumption 140 mA max. with power supply voltage of 24 VDC (with Sensor connected)

Ambient temperature Operating and storage: 0 to 50°C (with no icing or condensation)

Ambient humidity Operating and storage: 35% to 85% (with no condensation)

Insulation resistance 20 MΩ min. (at 500 DC)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min

Vibration resistance (destruction) 10 to 150 Hz with 0.7-mm double amplitude for 80 min each in X, Y, and Z directions

Shock resistance (destruction) 300 m/s

Connection method Prewired (standard cable length: 2 m)

Weight (packed state) Approx. 350 g

Materials Case: PBT (polybutylene terephthalate), Cover: Polycarbonate

Accessories Instruction Manual

*1:The response time for the first linear output or judgment output is calculated as follows (with fixed sensitivity): Measurement period × (Aver-

age count setting + 1). The response time for the second and later outputs is the measurement period specified in the table.

*2: The output can be switched between a current output and voltage output using a switch on the bottom of the Amplifier Unit.

*3: Setting is possible via the monitor focus function.

*4: A Calculating Unit (ZX-CAL2) is required.

NPN open-collector outputs, 30 VDC, 50 mA max.

Residual voltage: 1.2 V max.

ON: Short-circuited with 0-V terminal or 1.5 V or

less

OFF: Open (leakage current: 0.1 mA max.)

- Linearity adjustment (materials selection) - Scaling

- Display reverse - Display OFF mode - ECO mode

- Number of display digit changes - Sample hold - Peak hold

- Bottom hold, peak-to-peak hold - Self-peak hold - Self-bottom hold

- Average hold - Delay hold - Zero reset

- Initial reset - Linearity initialization - ON-delay timer

- OFF-delay timer - One-shot timer - Previous value comparison

- Non-measurement setting - Direct threshold value setting - Position teaching

- Automatic teaching - Hysteresis width setting - Timing inputs

- Reset input - Judgement output hold input - Monitor focus

- Linear output correction - (A-B) calculations *4 - (A+B) calculations *4

- K-(A+B) calculation *4 - Mutual interference prevention *4

- Sensor disconnection detection - Zero reset memory - Zero reset indicator

- Key lock

7-segment sub-digital display (yellow), power ON (green), zero reset (green), enable (green)

0.5% F.S. of linear output value at ±20% of power supply voltage

2

, 3 times each in 6 directions (up, down, left, right, forward, backward)

PNP open-collector outputs, 30 VDC, 50 mA max.

Residual voltage: 2 V max.

ON: Supply voltage short-circuited or supply volt-

age within 1.5 V

OFF: Open (leakage current: 0.1 mA max.)

ZX-E Series Smart Sensors (Inductive Displacement Type) 3

Page 4

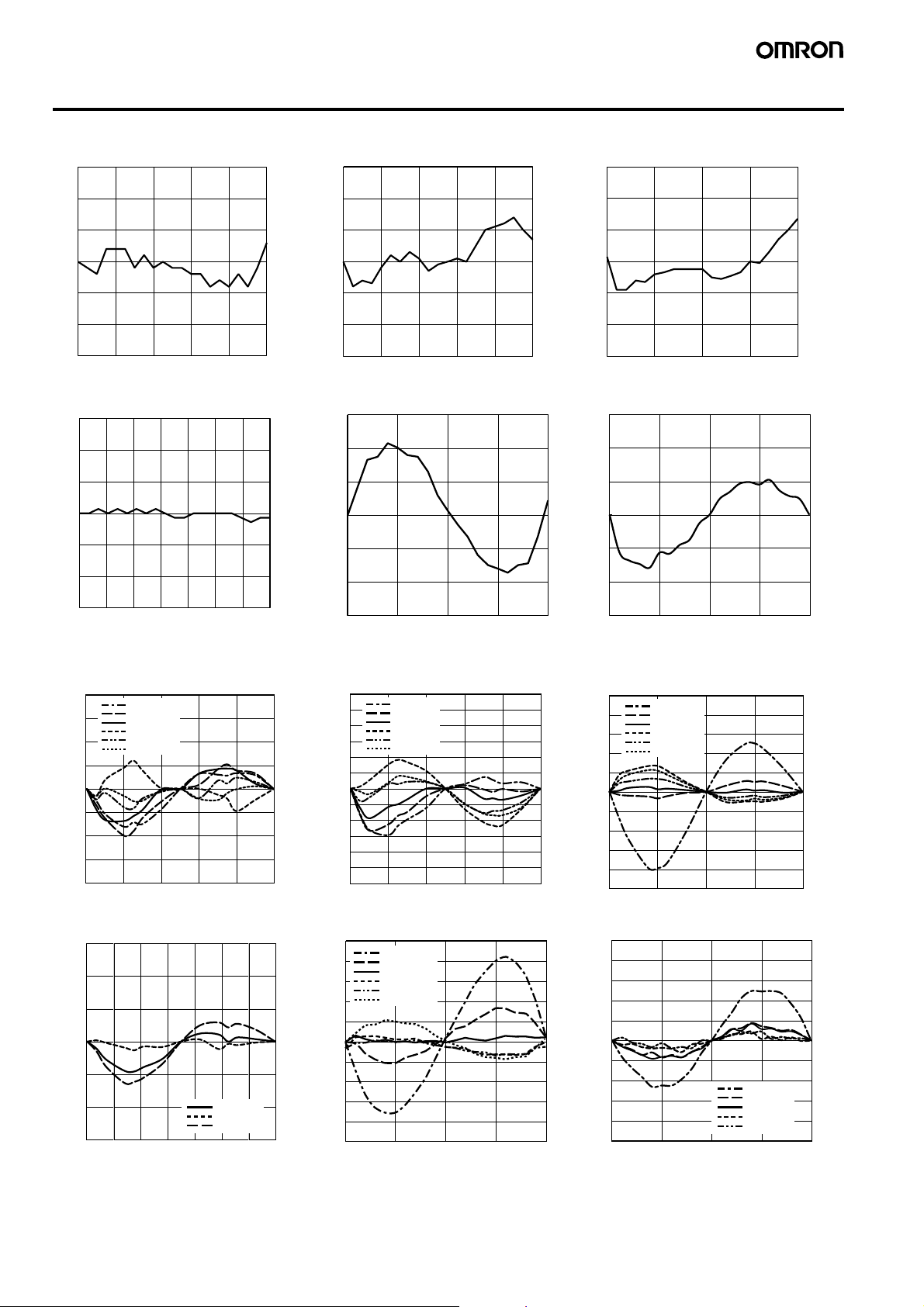

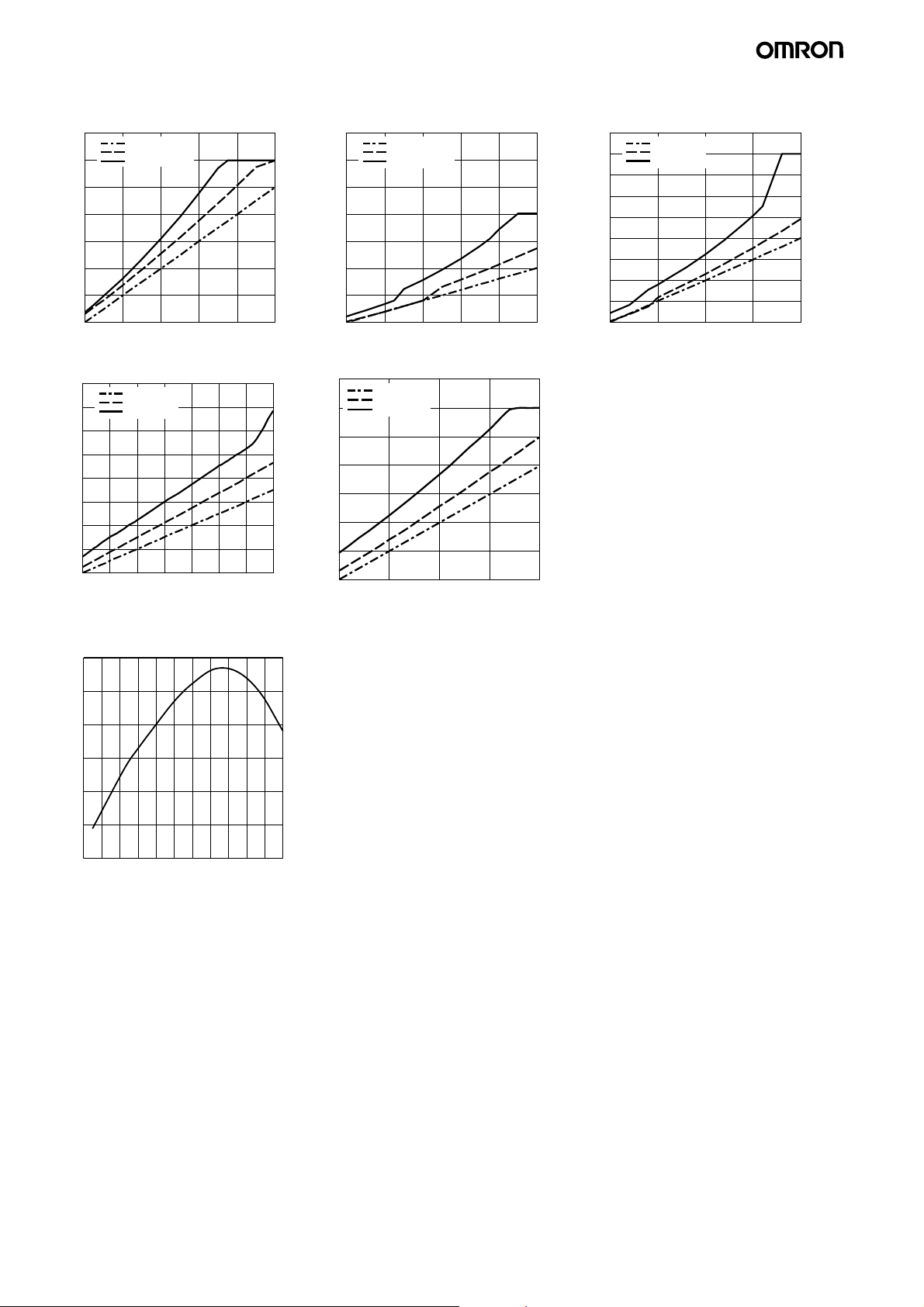

Engineering Data (Typical)

Measurement Distance vs. Linearity (with Linearity Adjusted for Standard Sensing Object)

ZX-EDR5T ZX-ED01T ZX-ED02T/ZX-EM02T

0.3

0.3

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

0

0.1 0.2 0.3 0.4 0.5

Measurement distance (mm)

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

0

0.2 0.4 0.6 0.8 1

Measurement distance (mm)

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

0

0.5 1 1.5 2

ZX-EM07MT ZX-EV04T ZX-EM02HT

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

1234 657

0

Measurement distance (mm)

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

0.0

1.0 2.0 3.0 4.0

Measurement distance (mm)

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

0

0.5 1 1.5 2

Size of Sensing Object vs. Linearity (with Linearity Adjusted for Each Sensing Object)

ZX-EDR5T ZX-ED01T ZX-ED02T/ZX-EM02T

0.4

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

−0.4

0

S50C @5

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

0.1 0.2 0.3 0.4 0.5

Measurement distance (mm)

0.6

0.5

0.4

0.3

Linearity (% F.S.)

0.2

0.1

0

−0.1

−0.2

−0.3

−0.4

−0.5

−0.6

0

S50C @5

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

0.2 0.4 0.6 0.8 1

Measurement distance (mm)

1.0

0.8

0.6

Linearity (% F.S.)

0.4

0.2

0

−0.2

−0.4

−0.6

−0.8

−1.0

0

S50C @5

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

0.5 1 1.5 2

ZX-EM07MT ZX-EV04T ZX-EM02HT

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

0

S50C @30

S50C @45

S50C @60

1234 567

Measurement distance (mm)

1

0.8

0.6

0.4

Linearity (% F.S.)

0.2

0

−0.2

−0.4

−0.6

−0.8

−1

0.0

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

S50C @60

1.0 2.0 3.0 4.0

Measurement distance (mm)

0.5

0.4

0.3

Linearity (% F.S.)

0.2

0.1

0

−0.1

−0.2

−0.3

−0.4

−0.5

0

0.5 1 1.5 2

Measurement distance (mm)

Measurement distance (mm)

Measurement distance (mm)

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

Measurement distance (mm)

4 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 5

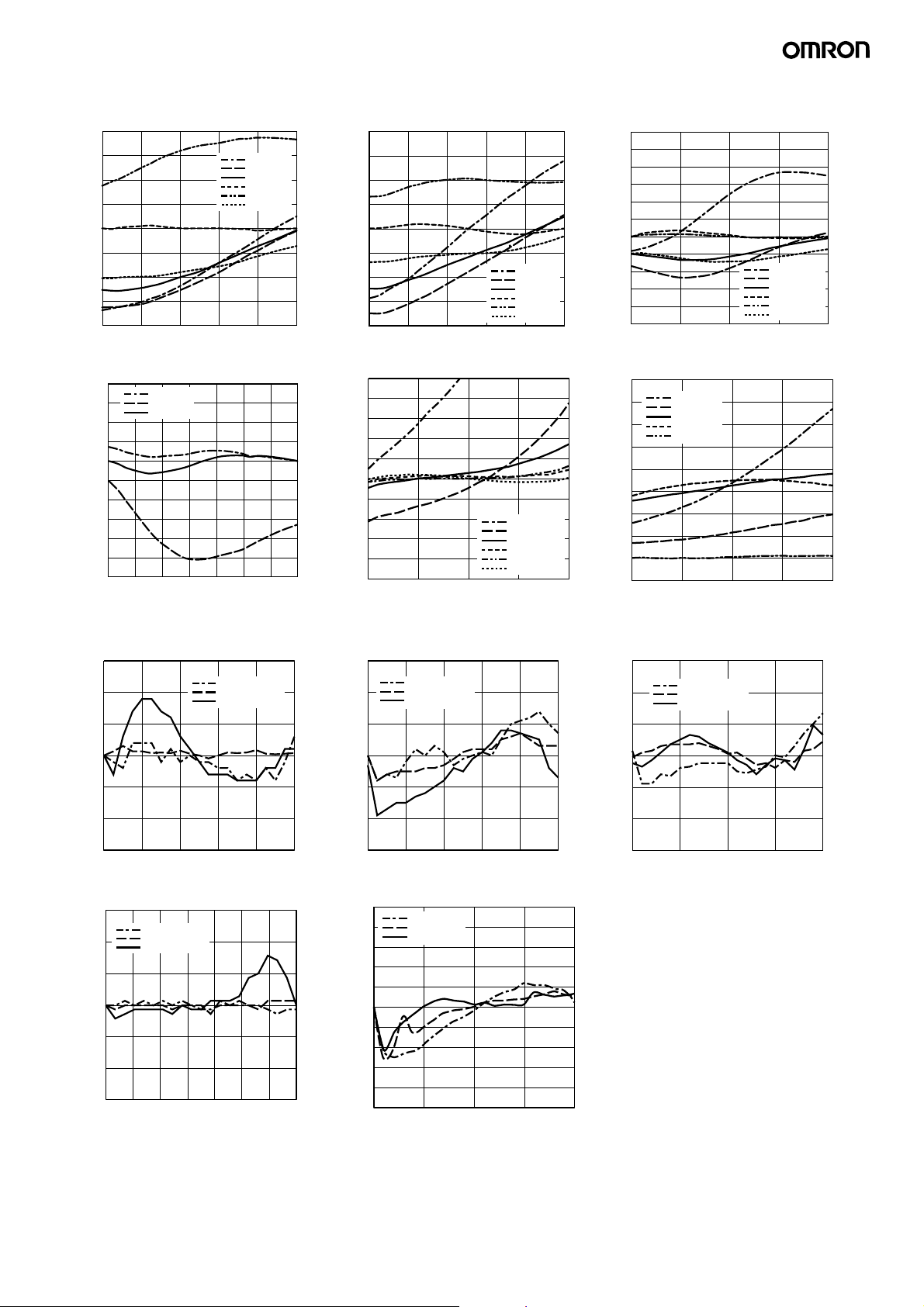

Size of Sensing Object vs. Linearity (with Linearity Adjusted for Standard Sensing Object)

ZX-EDR5T ZX-ED01T ZX-ED02T/ZX-EM02T

4

3

2

Linearity (% F.S.)

1

0

−1

−2

−3

−4

0.1 0.2 0.3 0.4 0.5

0

S50C @5

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

Measurement distance (mm)

4

3

2

Linearity (% F.S.)

1

0

−1

−2

−3

−4

0.2 0.4 0.6 0.8 1

0

S50C @5

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

Measurement distance (mm)

6

5

4

3

Linearity (% F.S.)

2

1

0

−1

−2

−3

−4

−5

0

0.5 1 1.5 2

ZX-EM07MT ZX-EV04T ZX-EM02HT

0.8

0.6

0.4

Linearity (% F.S.)

0.2

0

−0.2

−0.4

−0.6

−0.8

−1

−1.2

S50C @30

S50C @45

S50C @60

01234567

Measurement distance (mm)

Material of Sensing Object vs. Linearity (

5

4

3

2

Linearity (% F.S.)

1

0

−1

−2

−3

−4

−5

0.0

1.0 2.0 3.0 4.0

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

S50C @60

Measurement distance (mm)

with Linearity Adjusted for Each Sensing Object)

8

7

6

Linearity (% F.S.)

5

4

3

2

1

0

−1

0

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

0.5 1 1.5 2

ZX-EDR5T ZX-ED01T ZX-ED02T/ZX-EM02T

0.3

0.2

Linearity (% F.S.)

0.1

S50C @18

SUS304 @18

A5052 @18

0.3

0.2

Linearity (% F.S.)

0.1

S50C @18

SUS304 @18

A5052 @18

0.3

0.2

Linearity (% F.S.)

0.1

S50C @30

SUS304 @30

A5052 @30

S50C @5

S50C @8

S50C @12

S50C @18

S50C @30

S50C @45

Measurement distance (mm)

Measurement distance (mm)

−0.1

−0.2

−0.3

0

0.1 0.2 0.3 0.4 0.5

0

Measurement distance (mm)

−0.1

−0.2

−0.3

0

0

ZX-EM07MT ZX-EV04T

0.3

S50C @60

0.2

Linearity (% F.S.)

0.1

−0.1

−0.2

−0.3

SUS304 @60

A5052 @60

0

1234 657

0

Measurement distance (mm)

0.5

0.4

0.3

0.2

Linearity (% F.S.)

0.1

0

−0.1

−0.2

−0.3

−0.4

−5

0.0

ZX-E Series Smart Sensors (Inductive Displacement Type) 5

0.2 0.4 0.6 0.8 1

S50C @60

SUS304 @60

A5052 @60

Measurement distance (mm)

1.0 2.0 3.0 4.0

Measurement distance (mm)

−0.1

−0.2

−0.3

0

0.5 1 1.5 2

0

Measurement distance (mm)

Page 6

Material of Sensing Object vs. Linearity (with Linearity Adjusted for Standard Sensing Object and Iron)

ZX-EDR5T ZX-ED01T ZX-ED02T/ZX-EM02T

0.7

0.6

0.5

Display value (mm)

0.4

0.3

0.2

0.1

0

0.1 0.2 0.3 0.4 0.5

0

S50C @18

SUS304 @18

A5052 @18

Measurement distance (mm)

3.5

3

2.5

Display value (mm)

2

1.5

1

0.5

0

0.2 0.4 0.6 0.8 1

0

S50C @18

SUS304 @18

A5052 @18

Measurement distance (mm)

4.5

4

3.5

3

Display value (mm)

2.5

2

1.5

1

0.5

0

0

S50C @30

SUS304 @30

A5052 @30

0.5 1 1.5 2

ZX-EM07MT ZX-EV04T

16

14

12

Display value (mm)

10

8

6

4

2

0

S50C @60

SUS304 @60

A5052 @60

1234567

0

Measurement distance (mm)

7

S50C @60

SUS304 @60

6

A5052 @60

5

Display value (mm)

4

3

2

1

0

0.0

1.0 2.0 3.0 4.0

Measurement distance (mm)

Temperature Characteristics

ZX-EM02HT

1.0

Measurement distance (mm)

0.5

0

−0.5

−1

Rate of sensing distance change (%F.S.)

−1.5

−2

−20

200 40 60 80 180160140120100

Ambient sensor head temperature (°C)

200

6 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 7

I/O Circuit Diagrams

NPN Amplifier Unit: ZX-EDA11 PNP Amplifier Unit: ZX-EDA41

Brown: 12 to 24 VDC

Brown: 12 to 24 VDC

Load

Internal circuits

Current/voltage

switch

100 Ω

Current output

4 to 20 mA

Voltage output

±4V

White:

HIGH judgement output

Green:

PASS judgement output

Gray:

LOW judgement output

Blue: GND (0V)

Pink: Judgement output hold input

Purple: Timing input

Orange: Zero reset input

Red: Reset input

Black: Linear output

Shield: Linear GND

Load

Load

12 to 24 VDC

Current output: 300 Ω max.

Voltage output: 10 kΩ min.

Load

Connections: Amplifier Unit

Brown

12 to 24 VDC

Blue

GND (0V)

White

HIGH judgement output

Green

PASS judgement output

Gray

LOW judgement output

Black

Linear output

Shield

Linear output GND

Pink

Judgement output hold input

Orange

Zero reset input

Purple

Timing input

Red

Reset input

Note 1. Use a separate stabilized power supply for the Amplifier Unit,

particularly when high resolution is required.

2. Wire the Unit correctly. Incorrect wiring may result in damage

to the Unit. (Do not allow wiring, particularly the linear output,

to come into contact with other lines.)

3. Use the blue (0-V) line for the power supply and use the

shield wire (linear output ground) together with the black (linear output) line for linear output. Each of these grounds must

be used for the designed purpose. When not using the linear

output, connect the linear output ground to the 0-V ground.

Internal circuits

Current/voltage

switch

100 Ω

Current output

4 to 20 mA

Voltage output

±4V

White:

HIGH judgement output

Green:

PASS judgement output

Gray:

LOW judgement

output

Blue: GND (0V)

Pink: Judgement output hold input

Purple: Timing input

Orange: Zero reset input

Red: Reset input

Black: Linear output

Shield: Linear GND

Load

Load

Load

Current output:

300 Ω max.

Voltage output:

Load

10 kΩ min.

12 to

24 VDC

ZX-E Series Smart Sensors (Inductive Displacement Type) 7

Page 8

Part Names

Sensors

ZX-EDR5T

ZX-ED01T

ZX-ED02T

ZX-EM02T

ZX-EM07MT

ZX-EM02HT

Sensor head

ZX-EV04T

Sensor head

Preamplifier

Preamplifier

Output cable

(with connector)

Output cable

(with connector)

Amplifier Units

ZX-EDA11

ZX-EDA41

Controls

Display area

Input cable

(with connector)

Output cable

Connector

(Cover opens and closes)

Calculating Unit

ZX-CAL2

Display area

Connector

8 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 9

Precautions

■ Design Precautions

Conform to the specified ratings and performance. Refer to Specifications on page 2 for details.

Objects of certain materials or shapes may not be detectable, or the

detection accuracy may not be sufficiently high.

Environment

Do not operate the product in locations subject to flammable or explosive gases.

In order to ensure safe operation and maintenance, do not install the

product in the vicinity of high-voltage devices or power equipment.

■ Wiring

Do not use the product at voltages exceeding the rated values. Doing

so may result in damage.

Do not connect the product to an AC power supply or connect the

power supply in reverse.

Do not short-circuit the load for open-collector output.

■ Correct Use

Design Precautions

Power Supplies

Allow a warm-up period of approximately 30 minutes after turning ON

the power supply.

Mutual Interference

Up to 5 Sensor Heads can be used together by connecting the ZXCAL2 Calculating Unit between Amplifier Units.

When installing Sensor Heads facing each other or in parallel, separate them by the minimum distances given in the table below.

A

Mutual Interference

Model A B

ZX-EDR5T 5 mm 20 (3.1) mm

ZX-ED01T 10 mm 50 (5.4) mm

ZX-ED02T 20 mm 50 (8) mm

ZX-EM02T 20 mm 50 (10) mm

ZX-EM07MT 100 mm 150 (30) mm

ZX-EV04T 80 mm 50 (14) mm

ZX-EM02HT 20 mm 50 (12) mm

Note: The figures in parentheses apply when the mutual interfer-

ence prevention function is used.

Compatibility

Sensors and Amplifier Units are mutually compatible. Sensors can be

added or replaced individually.

Influence of High-frequency

Electromagnetic Fields

Using the product in the vicinity of devices that generate high-frequency electromagnetic fields, such as ultrasonic cleaning equipment, high-frequency generators, transceivers, mobile phones, and

inverters, may result in malfunction.

Calculating Unit

B

Do not lay the power cable for the product together with or in the same

duct as high-voltage lines or power lines. Doing so may result in incorrect operation or damage due to induction.

Do not connect or disconnect connectors while the power is ON. Doing so may result in damage.

■ Adjustment

Setting

When setting threshold values, ensure that the Amplifier Unit’s judgement output hold input line is ON so that there is no judgement output

to external devices.

■ Other Precautions

Do not attempt to disassemble, repair, or modify the product.

Dispose of the product using standard procedures for industrial

waste.

These Sensors are not compatible with the ZX-L@@ Smart Sensors

(laser type). Do not connect combinations of ZX-E@@ Smart Sensors

and ZX-T@@ Smart Sensors.

Influence of Metallic Objects

When installing the product, separate it from metallic objects by the

distances shown below.

d dia.

D

Influence of Metallic Objects

Model d D

ZX-EDR5T 8 mm 9 mm

ZX-ED01T 10 mm

ZX-ED02T/EM02T 12 mm

ZX-EM07MT 55 mm 20 mm

ZX-EV04T 16 × 32 mm 4.8 mm

ZX-EM02HT 18 mm 9 mm

Wiring

Wiring Check

After wiring is completed, before turning ON the power, confirm that

the power supply is connected correctly, that there are no faulty connections, such as load short-circuits, and that the load current is correct. Incorrect wiring may result in failure.

Cable Extension

Do not extend the cable for the Sensor and the Amplifier Unit to a

length exceeding 10 m. Use a ZX-XC@A Extension Cable (sold separately) to extend the Sensor’s cable. Extend the Amplifier Unit’s cable using a shielded cable of the same type.

Power Supply

When using a commercially available switching regulator, ground the

FG (frame ground) terminal.

If the power supply line is subject to surges, connect a surge absorber

that meets the conditions of the operating environment.

When using a Calculating Unit, connect the linear output ground of

the corresponding Amplifier Unit.

ZX-E Series Smart Sensors (Inductive Displacement Type) 9

Page 10

Connectors

Do not connect or disconnect connectors while the power is ON.

Be sure hold to connectors by the cover when connecting or disconnecting.

Mounting

Handling

When mounting the Sensor Head, do not apply excessive shock by,

for example, using a hammer. Doing so may result in damage or a reduction in the level of water-proofing. Also, there are screw-shaped

models that require a toothed washer to allow for a tolerance in the

tightening torque for the nut.

When using a heat-resistant model like the ZX-EM02HT, develop designs that account for thermal expansion due to rising sensing object

temperature so the sensing object will never touch the sensing surface. Also note that any sudden rise in temperature will shorten the

service life of the product.

Tightening Torque

Do not apply excessive torque when tightening the nut. Use a toothed

washer if necessary.

Model Tightening torque

ZX-EM02T 15 N·m

ZX-EM07MT

ZX-EM02HT 59 N·m

Note: The above figure applies for use with a toothed washer.

Mounting Cylindrical Models:

Tighten set screws with a tightening torque of 0.2 N·m max.

Set screw hole

A

Mounting Bracket

Y92E-F5R4 (for 5.4-dia.

screws), sold separately

Model A

ZX-EDR5T 9 to 18 mm

ZX-ED01T

ZX-ED02T 11 to 22 mm

Installation Location

Do not install the product in the following locations.

• Locations subject to temperatures outside the specified range

• Locations subject to condensation due to sudden temperature

changes

• Locations subject to humidity levels outside range 35% to 85%

• Locations subject to corrosive or flammable gases

• Locations subject to dust, salts, or metallic powder.

• Locations directly subject to vibrations and shocks

• Locations subject to direct sunlight

• Locations subject to splashes of water, oil, or chemicals

• Locations subject to strong electromagnetic or electrical fields

Maintenance and Inspection

• Be sure to turn OFF the power supply before adjusting or removing

the Sensor Head.

• Cleaning:

Do not use thinners, benzine, acetone, or kerosene for cleaning.

10 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 11

Dimensions

Sensors

Sensor Heads

ZX-EDR5T

(15.5)

3 dia.

Dimensions with Mounting Bracket Attached

Vinyl-insulated round cable

Vinyl-insulated coaxial round cable

18

1.7 dia., 1 conductor, standard length: 2 m

15 dia.

72

5.1 dia., 9 conductors, standard length: 200 mm

13

(46)

Connector

(15 dia.)

ZX-ED01T

ZX-ED02T

(15.5)

(15.5)

(22.5)

15

7.8

2715.6

58.2

15.1

Mounting Hole Cutout Dimensions

Two, M3 holes

0.1

27±

Dimensions with Mounting Bracket Attached

Vinyl-insulated round cable

Vinyl-insulated coaxial round cable

18

5.4 dia.

(22.5)

15

7.8

2.5 dia., 1 conductor, standard length: 2 m

15 dia.

72

2715.6

58.2

5.1 dia., 9 conductors, standard length: 200 mm

13

(46)

Connectors

(15 dia.)

15.1

Mounting Hole Cutout Dimensions

Two, M3 holes

0.1

27±

Dimensions with Mounting Bracket Attached

Vinyl-insulated round cable

5.1 dia., 9 conductors, standard length: 200 mm

13

(46)

Connector

(15 dia.)

8 dia.

Vinyl-insulated coaxial round cable

22

2.5 dia., 1 conductor, standard length: 2 m

15 dia.

72

(22.5)

15

7.8

2715.6

58.2

15.1

Mounting Hole Cutout Dimensions

Two, M3 holes

0.1

27±

ZX-E Series Smart Sensors (Inductive Displacement Type) 11

Page 12

ZX-EM02T

18 dia.

16

(5.4)

8 dia.

22

16.6

Dimensions with Mounting Bracket Attached

Vinyl-insulated round cable

Vinyl-insulated coaxial round cable

2.5 dia., 1 conductor, standard length: 2 m

5.1 dia., 9 conductors, standard length: 200 mm

13

(46)

(15 dia.)

ZX-EM07MT

29 dia.

24

(15.5)

10

15.7 dia.

(15.5)

4

(22.5)

15

7.8

M10×1

2 tightening nuts

2 toothed washers

15 dia.

72

2715.6

58.2

Connector

15.1

Mounting Hole Cutout Dimensions

Two, M3 holes

0.1

27±

Dimensions with Mounting Bracket Attached

46.3

25

4

(11.3)

9.8 dia.

M18×1

2 tightening nuts

2 toothed washers

Vinyl-insulated coaxial round cable

2.5 dia., 1 conductor, standard length: 2 m

15 dia.

72

Vinyl-insulated round cable

5.1 dia., 9 conductors, standard length: 200 mm

13

(46)

(15 dia.)

Connector

(22.5)

15

7.8

ZX-EV04T

14

(15.5)

(22.5)

15

7.8

Mounting Hole Cutout Dimensions

10±

7

4.8

Two, M3 holes

0.1

7

10

Sensing surface

10

30

2715.6

58.2

Mounting Hole Cutout Dimensions

Two, M3 holes

27±

Dimensions with Mounting Bracket Attached

Vinyl-insulated coaxial round cable

2.5 dia., 1 conductor, standard length: 2 m

Distance: 3 mm

Hole size: 3.3 dia. (2 holes)

15 dia.

1.5

72

2715.6

58.2

Mounting Hole Cutout Dimensions

Two, M3 holes

0.1

27±

15.1

0.1

13

(46)

(15 dia.)

15.1

Vinyl-insulated round cable

5.1 dia., 9 conductors,

standard length: 200 mm

Connector

12 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 13

ZX-EM02HT

21 dia.

17

(15.5)

(22.5)

15

7.8

Mounting Hole Cutout Dimensions

Two, M3 holes

Amplifier Units

ZX-EDA1 1

ZX-EDA4 1

27±

Dimensions with Mounting Bracket Attached

Fluororesin-insulated coaxial round cable

2.5 dia., single conductor

15 dia.

standard length: 2m

72

2715.6

58.2

13

Vinyl-insulated round cable

5.1 dia., 9 conductors,

standard length: 200 mm

(46)

15.1

Connector

22

0.1

10.5 dia.

M12×1

Two fastening nuts

Toothed washer

30

15.5 dia.

13.2

44

133

Vinyl-insulated round cable

5.1 dia., standard: 100 mm

3

13 36.8

11.7

64.3

2.2

29

Current/voltage switch

(Factory-set to voltage output.)

4.24.2

31.5

15.8

Vinyl-insulated round cable

5.2 dia., 10 conductors

(conductor cross-section: 0.09 mm

insulator diameter: 0.7 mm),

standard length: 2 m

11.7

Voltage output

2

,

ZX-E Series Smart Sensors (Inductive Displacement Type) 13

Page 14

Accessories (Sold Separately)

Preamplifier Mounting Bracket

ZX-XBE1 ZX-XBE2

0.1

27±

15.5

63.3

21.9

52

20

9.8

15.5

21.9

0.1

27±

15.5

M3×8 pan-head screw (with M3 spring washer)

63.3

52

20

9.8

6.2 10

31.9

15.5

Material: Stainless steel (SUS304)

Calculating Unit

ZX-CAL2

15.1

12

8

30

26

14.4

9.4

11.4

Operation

24.9

3

19.5

5

3.4

indicators

57

54.9

44.05

9.5

36.7

Connectors

15

1.8

35.3

58

Material: Stainless steel (SUS304)

1.8

10

14 ZX-E Series Smart Sensors (Inductive Displacement Type)

Page 15

ZX-series Communications Interface Unit

ZX-SF11

Sensor communications indicator (communications operation)

Sensor communications indicator (communications error)

Connector

30

(46)

15

13.2

(33.1)

Connector

(336)

Vinyl-insulation round cable, 5.23 dia.

Cables with Connectors on Both Ends (for Extension)

ZX-XC1A (1 m)

ZX-XC4A (4 m)

ZX-XC8A (8 m)

46

Power supply indicator

4.2

3

29

11.7

External terminal communications

indicator (communications operation)

External terminal communications

indicator (communications error)

64.3 4.2

36.813

2.2

44

31.5

4.3

11.7

6.5553

15 dia.

Vinyl-insulated round cable, 5.2 dia., 10 conductors

*ZX-XC1A: 1,000

ZX-XC4A: 4,000

ZX-XC8A: 8,000

15.5 dia.

12 pins (female)12 pins (male)

ZX-E Series Smart Sensors (Inductive Displacement Type) 15

Page 16

.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

This document provides information mainly for selecting suitable models. Please read the manual carefully for

information that the user must understand and accept before purchase, including information on warranty,

limitations of liability, and precautions.

CSM_2_1_0609

E331-E1

In the interest of product improvement, specifications are subject to change without notice

OMRON Corporation

Industrial Automation Company

Sensing Devices Division H.Q.

Application Sensors Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7068/Fax: (81)75-344-7107

Page 17

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified)

from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the

products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

•

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

•

Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or government regulations.

•

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the

result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2009 All Right Reserved.

2009.6

Loading...

Loading...