Page 1

Synchronous Step-Down MOSFET Drivers

ZL1505

ZL1505

The ZL1505 is an integrated high-speed, high-current

N-channel MOSFET driver for synchronous step-down

DC-DC conversion applications. When used with Zilker

Labs Digital-DC™ PWM controllers, the ZL1505 enables

dynamically adaptive dead-time control that optimizes

efficiency under all operating conditions. A dual input

PWM configuration enables this efficiency optimization

while minimizing complexity within the driver.

Operating from a 4.5V to 7.5V input, the ZL1505

combines a 5A, 0.5W low-side driver and a 3A, 0.8W

high-side driver to support high step-down buck

applications. A unique adjustable gate drive current

scheme allows the user to adjust the drive current on

both drivers to optimize performance for a wide rage of

input/output voltages, load currents, power MOSFET s

and switching frequencies up to 1.4MHz. An integrated

30V bootstrap Schottky diode is used to charge the

external bootstrap capacitor. An internal w atchdog circuit

prevents excessive shoot-through currents and protects

the external MOSFET switches.

The ZL1505 is specified over a wide -40°C to +125°C

junction temperature range and is available in an

exposed pad DFN-10 package.

Features

• High-speed, high-current drivers for synchronous

N-channel MOSFETs

• Adaptive dead-time control optimizes efficiency

when used with Digital-DC controllers

• Integrated 30V bootstrap Schottky diode

• Capable of driving 40A per phase

• Supports switching frequency up to 1.4MHz

- >4A source, >5A sink low-side driver

- >3A source/sink high-side driver

- <10ns rise/fall times, low propagation delay

• Adjustable gate drive strength optimizes efficiency

, V

, I

for different V

combinations

• Internal non-overlap watchdog prevents

shoot-through currents

IN

OUT

, FSW and MOSFET

OUT

Applications*(see page 12)

• High efficiency, high-current DC/DC buck converters

with digital control and PMBus™

• Multi-phase digital DC/DC converters with phase

adding/dropping

•Power train modules

• Synchronous rectification for secondary side isolated

power converters

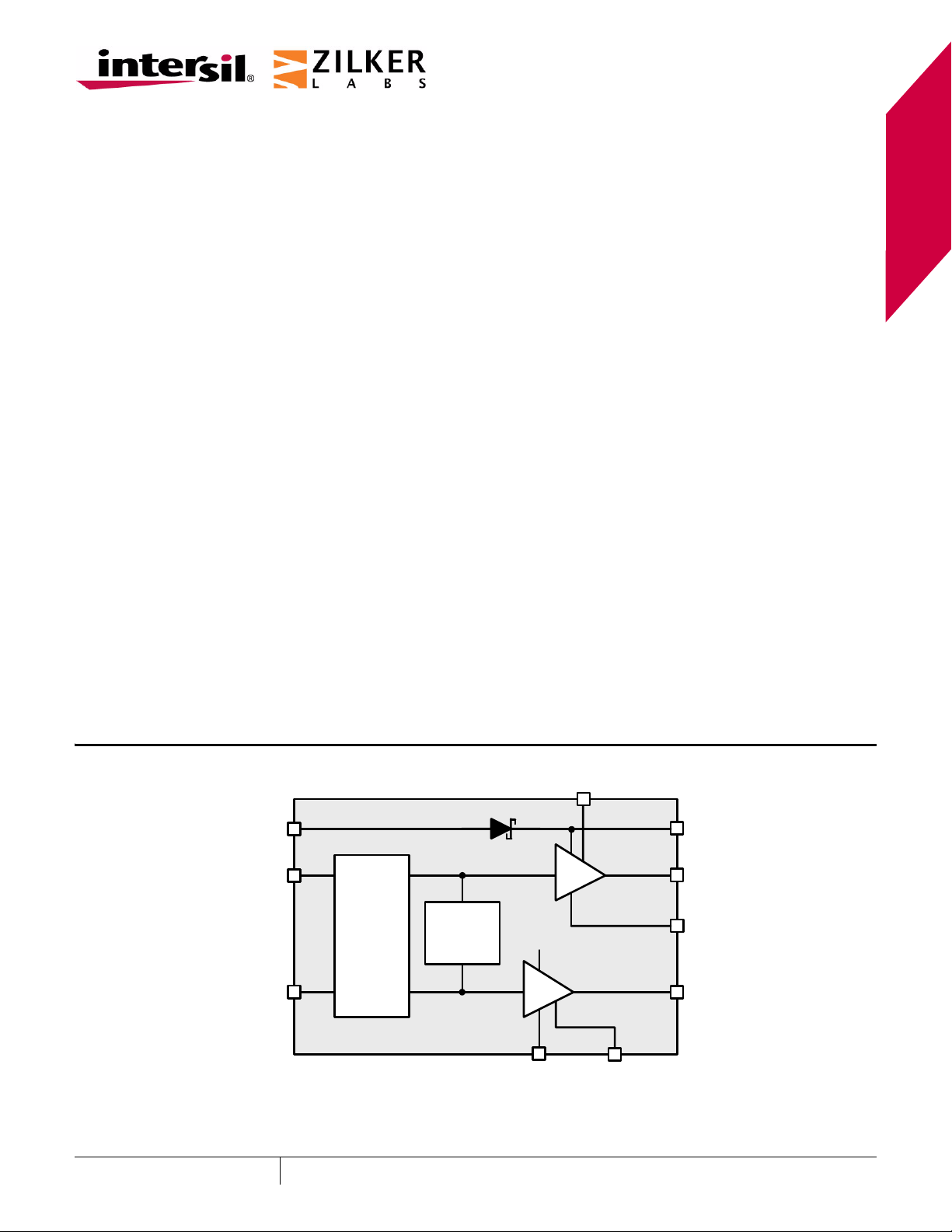

VDD

PWMH

PWML

Related Literature*(see page 12)

• FN6846 ZL2004 Data Sheet

HSEL

Level

shift

Shoot-

through

Protection

VDD

ZL1505

GND

FIGURE 1. ZL1505 BLOCK DIAGRAM

BST

GH

SW

GL

LSEL

December 4, 2009

FN6845.1

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Amer ic as Inc .

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2009. All Rights Reserved

Page 2

ZL1505

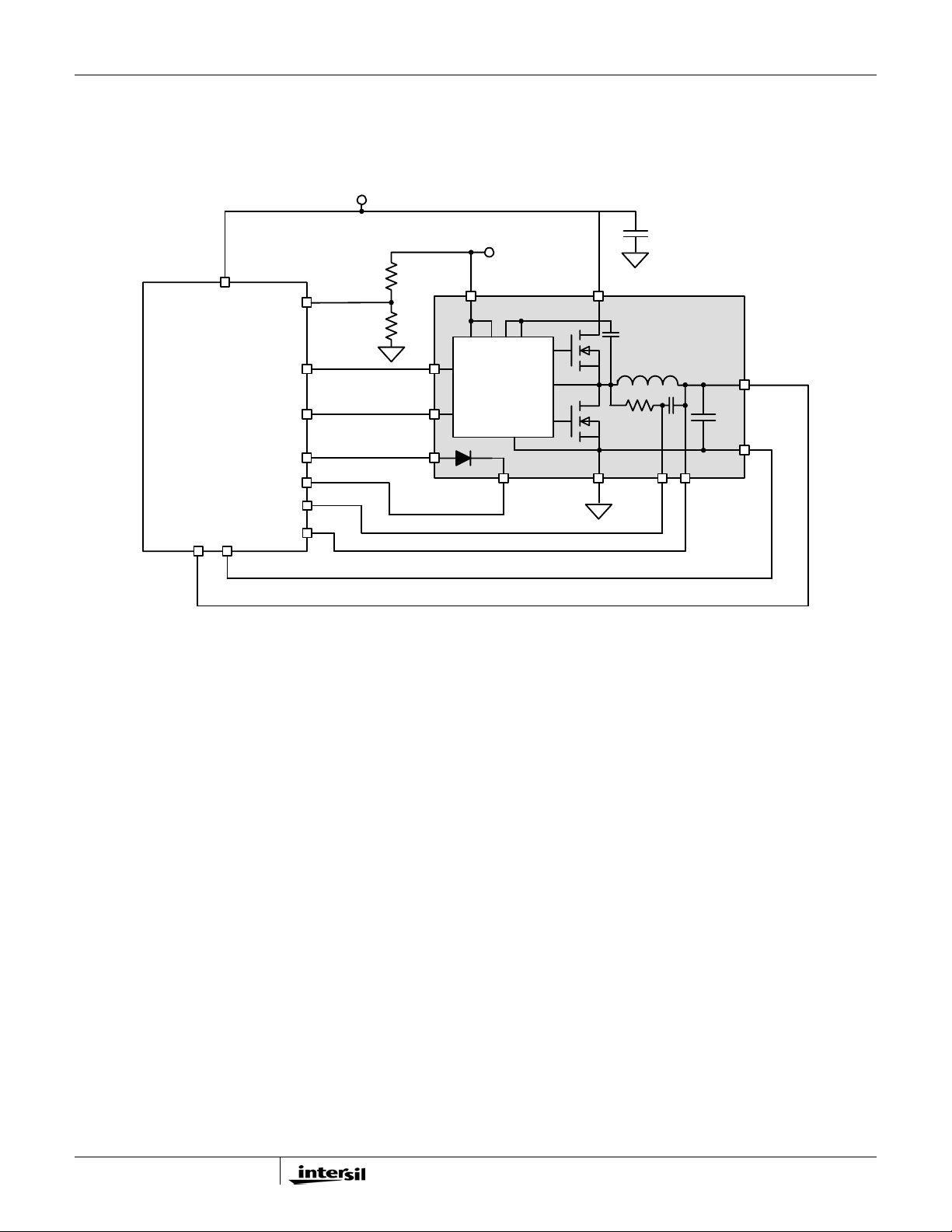

Typical Application Circuit

The following application circuit represents the typical implementation of the ZL1505 (Notes 1, 2).

V

IN

4.5-14V

V

BIAS

4.5-7.5V

VMON

VIN

PWMH

PWMH

PWMH

ZL2004

PWML

XTEMP

VSEN+

SGND

VSEN-

PWML

TEMP+

ISENA

ISENB

FIGURE 2. POWER TRAIN MODULE USING ZL2004 PWM CONTROLLER

NOTES:

1. For V

specified in Figure 2.

2. V

of 4.5V to 7.5V, the maximum VIN of the ZL1505 is 22.5V to 25.5V. ZL1505 input supply voltage range (VIN) is

DD

for this application circuit is limited by the ZL2004 VIN of 4.5V to 14V.

IN

PWML

TEMP-

VDD

HSEL

LSEL

ZL1505

VINVDD

Power Train

Module

GH

BST

SW

GL

GND

GND

CS-CS+

VOUT

GND

2

FN6845.1

December 4, 2009

Page 3

Pin Configuration

ZL1505

ZL1505

(10 LD DFN)

TOP VIEW

HSEL

GH

SW

PWMH

PWML

1

2

*EPAD

3

4

5

*CONNECT TO GND

BST

10

VDD

9

GL

8

7

GND

LSEL

6

Pin Descriptions

PIN NUMBER PIN NAME TYPE (Note 3) DESCRIPTION

1 HSEL I High-side gate drive current selector. Connect to BST for maximum gate

drive current; Connect to SW for 50% of maximum gate drive current.

2 GH O Output of high-side gate driver. Connect to the gate of high-side FET.

3 SW I/O Phase node. Return path for high-side driver. Connect to source of high-side

4 PWMH I High-side PWM control input.

5 PWML I Low-side PWM control input.

6 LSEL I Low-side gate drive current selector. Connect to VDD for maximum gate

FET and drain of low-side FET.

drive current; Connect to GND for 50% of maximum gate drive current.

7 GND PWR Ground. All signals return to this pin.

8 GL O Output of low-side gate driver. Connect to the gate of low-side FET.

9 VDD PWR Gate drive bias supply . Connect a high quality bypass capacitor from this pin

to GND.

10 BST PWR Bootstrap supply. Connect external capacitor to SW node.

ePad GND PWR Ground.

NOTE:

3. I = Input, O = Output, PWR = Power OR Ground.

Ordering Information

PACKAGE

PART NUMBER

(Notes 4, 5, 6)

PART

MARKING

TEMP RANGE

(°C)

Tape and Reel

(Pb-free)

ZL1505ALNNT 1505 -40 to +125 10 Ld 3x3 DFN L10.3x3D

ZL1505ALNNT1 1505 -40 to +125 10 Ld 3x3 DFN L10.3x3D

NOTES:

4. Please refer to TB347

for details on reel specifications.

5. These Intersil Pb-free plastic packaged products employ special Pb-free material sets; molding compounds/die attach

materials and NiPdAu plate - e4 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free

soldering operations. Intersil Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J STD-020.

6. For Moisture Sensitivity Level (MSL), please see device information page for ZL1505

techbrief TB363

.

. For more information on MSL please see

PKG.

DWG. #

3

FN6845.1

December 4, 2009

Page 4

ZL1505

Absolute Maximum Ratings Thermal Information

Voltage Measured with Respect to GND

DC Supply Voltage for VDD Pin . . . . . . . . . . . . .-0.3V to 8V

High-Side Supply Voltage for BST Pin . . . . . . . . -0.3V to 30V

High-Side Drive Voltage for

GH Pin . . . . . . . . . . . . . . . (V

Low-Side Drive Voltage for

GL Pin . . . . . . . . . . . . . . . .(GND - 0.3V) to (V

Boost to Switch Differential (V

BST, SW Pins . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 8V

SW

- VSW) for

BST

- 0.3V) to (V

BST

DD

+ 0.3V)

+ 0.3V)

Switch Voltage for SW Pin

Continuous . . . . . . . . . . . . . . . . . . . (GND - 0.3V) to 30V

<100ns . . . . . . . . . . . . . . . . . . . . . . .(GND - 5V) to 30V

Logic I/O Voltage for PWMH, PWML, LSEL Pins. . .-0.3V to 8V

HSEL Pin . . . . . . . . . . . . . (V

ESD Rating

- 0.3V) to (V

SW

BST

+ 0.3V)

Human Body Model . . . . . . . . . . . . . . . . . . . . . . . . . 2kV

GL Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5kV

Machine Model . . . . . . . . . . . . . . . . . . . . . . . . . . . 500V

Latch Up . . . . . . . . . . . . . . . . . . . . . . . . Tested to JESD78

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact

product reliability and result in failures not covered by warranty.

NOTES:

7. θJA is measured in free air with the component mounted on a high effective thermal conductivit y test board with “direct attach”

features. See Tech Brief TB379.

8. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

Thermal Resistance (Typical) θ

(°C/W) θJC (°C/W)

JA

10 Ld DFN (Notes 7, 8). . . . . . . . . 50 7

Junction Temperature Range . . . . . . . . . . -55°C to +150°C

Storage Temperature Range . . . . . . . . . . . -55°C to +150°C

Pb-Free Reflow Profile . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Recommended Operating Conditions

Gate Drive Bias Supply Voltage Range

VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.5V to 7.5V

Input Supply Voltage Range, V

Operating Junction Temperature Range, TJ. . -40°C to +125°C

. . . . . . . . 3V to 30V - V

IN

DD

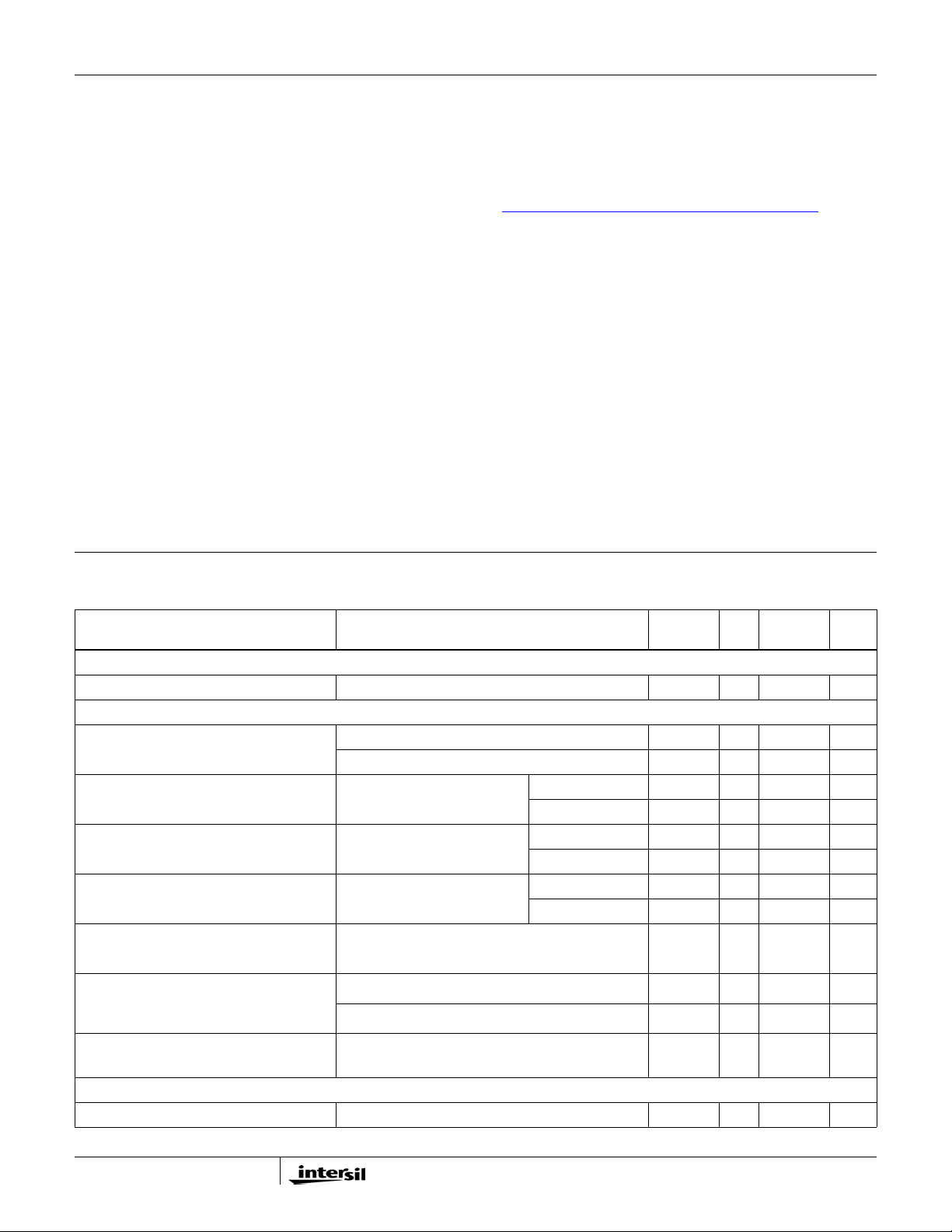

Electrical Specifications V

PARAMETER CONDITIONS

= 6.5V, TJ = -40°C to +125°C unless otherwise noted. Typica l values are at

DD

T

=+25°C. Boldface limits apply over the operating temperature range,

A

-40°C to +125°C.

MIN

(Note 9) TYP

MAX

(Note 9) UNIT

BIAS CURRENT CHARACTERISTICS

I

supply current Not switching – 110 180 µA

DD

PWM INPUT CHARACTERISTICS

PWM input bias current V

PWM input logic low, V

PWM input logic high, V

IL

IH

= 5 V –5–µA

PWM

V

= 0 V ––1µA

PWM

PWMH or PWML VDD = 6.5V 1.7 2 2.2 V

V

= 5.0 V 1.5 1.7 1.9 V

DD

PWMH or PWML VDD = 6.5V 2.8 3.1 3.4 V

VDD = 5.0V 2.2 2.5 2.7 V

Hysteresis PWMH or PWML V

Minimum PWMH On-time to Produce GH

Pulse, t

PWMH,ON

Minimum GH On-time pulse, t

(Note 11)

(Note 10)

GH,ON

= 0 – 8.5 12 ns

C

GH

CGH = 0 – 10 14 ns

C

GH

= 3 nF, V

HSEL

= V

BST

= 6.5V - 1.1 - V

DD

V

= 5.0V - 0.8 - V

DD

-1420 ns

Minimum PWMH Off-time to Produce

Valid GH Pulse, t

PWMH,OFF

BOOTSTRAP DIODE CHARACTERISTICS

Forward Voltage (V

) Forward bias current 100 mA – 0.8 – V

F

4

CGH = 0 – 13 17 ns

FN6845.1

December 4, 2009

Page 5

ZL1505

Electrical Specifications V

PARAMETER CONDITIONS

= 6.5V, TJ = -40°C to +125°C unless otherwise noted. Typica l values are at

DD

T

=+25°C. Boldface limits apply over the operating temperature range,

A

-40°C to +125°C. (Continued)

MIN

(Note 9) TYP

MAX

(Note 9) UNIT

THERMAL PROTECTION

Thermal trip point –150– °C

Thermal reset point –134– °C

UPPER GATE DRIVER CHARACTERISTICS

Driver Voltage (V

High-side Driver Peak Gate Drive

Current (Pull-up)

– VSW) –6– V

BST

(VGH – VSW) = 2.5V HSEL connected

2.0 3.2 – A

to BST

HSEL connected

1.0 1.7 - A

to SW

High-side Driver Peak Gate Drive

Current (Pull-down)

– VSW) = 2.5V HSEL connected

(V

GH

to BST

HSEL connected

2.0 3.2 – A

1.0 1.6 - A

to SW

High-side Driver Pull-up Resistance (V

– VGH) = 50mV HSEL connected

BST

to BST

HSEL connected

–0.70.9 Ω

-0.91.2 Ω

to SW

High-side Driver Pull-down Resistance (V

– VSW) = 50mV HSEL connected

GH

to BST

HSEL connected

–0.81.1 Ω

1.1 1.5 Ω

to SW

LOWER GATE DRIVER CHARACTERISTICS

Driver voltage (V

Low-side Driver Peak Gate Drive Current

(Pull-up)

) -6.5- V

DD

(V

GL

- V

) = 2.5V LSEL connected

GNG

to VDD

LSEL connected

3.0 4.5 – A

1.5 2.4 - A

to GND

Low-side Driver Peak Gate Drive Current

(Pull-down)

(V

GL

– V

) = 2.5V LSEL connected

GND

to VDD

LSEL connected

3.5 5.4 – A

1.8 2.8 - A

to GND

Low-side Driver Pull-up Resistance (V

- VGL) = 50mV LSEL connected

DD

–0.70.9 Ω

to VDD

LSEL connected

-1.01.3 Ω

to GND

Low-side Driver Pull-down Resistance (V

– GND) = 50mV LSEL connected

GL

to VDD

LSEL connected

–0.50.7 Ω

-0.71.0 Ω

to GND

SWITCHING CHARACTERISTICS

GH rise time, t

RH

CGH = 3nF HSEL connected

–5.38.5 ns

to BST

HSEL connected

-10.516.5 ns

to SW

5

FN6845.1

December 4, 2009

Page 6

ZL1505

Electrical Specifications V

PARAMETER CONDITIONS

GH fall time, t

GL rise time, t

GL fall time, t

GH turn-on propagation delay, t

GH turn-off propagation delay, t

GL turn-on propagation delay, t

GL turn-off propagation delay, t

NOTES:

9. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise specified. T emper ature limits established

by characterization and are not production tested.

10. The minimum PWMH on-time pulse (t

edge.

11. The minimum GH on-time pulse (t

FH

RL

FL

DLR

DLF

= 6.5V, TJ = -40°C to +125°C unless otherwise noted. Typica l values are at

DD

T

=+25°C. Boldface limits apply over the operating temperature range,

A

-40°C to +125°C. (Continued)

MIN

(Note 9) TYP

DHR

DHF

CGH = 3nF HSEL connected

to BST

HSEL connected

to SW

CGL = 3nF LSEL connected

CGL = 3nF LSEL connected

HSEL connected to BST –30.0– ns

HSEL connected to SW - 31.5 - ns

HSEL connected to BST –37.5– ns

HSEL connected to SW - 39.0 - ns

LSEL connected to V

LSEL connected to GND - 28.0 - ns

LSEL connected to V

LSEL connected to GND - 31.5 - ns

PWMH,ON

GH,ON

) is specified from VPWM = 2.5V on the rise edge to VPWM = 2.5V on the falling

) is specified at VGH = 2.5V.

DD

DD

to VDD

LSEL connected

to GND

to VDD

LSEL connected

to GND

-4.87.5 ns

-9.515 ns

–4.06.0 ns

-7.812 ns

-3.04.5 ns

-5.58.5 ns

–26.5– ns

–30.0– ns

MAX

(Note 9) UNIT

PWM

GH

2.5V 2.5V

t

PWMH,ON

t

DLF

t

DLR

90% 90%

2.5V 2.5V

t

10%

t

RH

FIGURE 3. TIMING DIAGRAM

GH,ON

6

10%

t

FH

FN6845.1

December 4, 2009

Page 7

Typical Performance Curves

)

)

130

ZL1505

155

120

110

100

IVDD (uA)

90

80

70

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 4. IVDD vs VDD WITH TEMPERATURE (NO

SWITCHING)

22

20

18

16

14

On-time (ns

12

10

8

4.5 5 5.5 6 6.5 7 7.5

CGH=0

CGH=3nF, HSEL=BST

CGH=3nF, HSEL=SW

VDD (V)

150

145

140

T (C)

135

130

125

120

4.555.566.577.5

VDD (V)

Trising

Tfalling

FIGURE 5. THERMAL PROTECTION THRESHOLDS

16

15

14

13

12

11

On-t ime (ns

10

9

8

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 6. MINIMUM GH ON-TIME, t

T

= +25°C)

A

GH,ON

(Note 12,

FIGURE 7. t

GH,ON

C

GH

WITH TEMPERATURE (Note 13,

= 0)

NOTES:

12. Performance curves with temperature are measured at ambient temperatures (T

13. t

timing is shown in Figure 3.

GH,ON

7

) of +85°C, +25°C and -25°C.

A

FN6845.1

December 4, 2009

Page 8

)

ZL1505

Typical Performance Curves (Continued)

16

14

12

10

30

26

22

-25 °C

25 °C

85 °C

8

On-ti me (ns

6

4

2

4.555.566.577.5

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 8. MINIMUM PWMH ON-TIME, t

(CGH= 0)

6.6

5.6

4.6

3.6

IGL (A)

2.6

1.6

0.6

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

LSEL=VDD

LSEL=GND

PWMH,ON

18

Off-time (ns)

14

10

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

FIGURE 9. MINIMUM PWMH OFF-TIME, t

(CGH= 0)

6.6

5.6

4.6

IGL (A)

3.6

2.6

1.6

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

-25 °C

25 °C

85 °C

PWMH,OFF

FIGURE 10. LOW-SIDE DRIVER PULL-UP CURRENT

(V

= 2.5V, TA = +25°C)

GL

8

7

6

5

IGL (A)

4

3

2

1

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

LSEL=VDD

LSEL=GND

FIGURE 12. LOW-SIDE DRIVER PULL-DOWN

CURRENT (V

= 2.5V, TA = +25°C)

GL

8

FIGURE 11. LS PULL-UP CURRENT WITH

TEMPERATURE (V

8

7

6

IGL (A)

5

4

3

4.555.566.577.5

VDD (V)

= 2.5V, LSEL = VDD)

GL

-25 °C

25 °C

85 °C

FIGURE 13. LS PULL-DOWN CURRENT WITH

TEMPERATURE (VGL = 2.5V, LSEL = VDD)

December 4, 2009

FN6845.1

Page 9

ZL1505

Typical Performance Curves (Continued)

12

11

10

9

8

7

trise (ns)

6

5

4

3

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

LSEL=VDD

LSEL=GND

6.5

6

5.5

5

4.5

trise (ns)

4

3.5

3

4.555.566.577.5

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 14. LOW-SIDE DRIVER RISE TIME, t

(CGL= 3nF, TA = +25°C)

7

6

5

tfall (ns)

4

3

2

4.555.566.577.5

VDD (V)

LSEL=VDD

LSEL=GND

FIGURE 16. LOW-SIDE DRIVER FALL TIME, t

(CGL=3nF, TA = +25°C)

5

4

RL

FL

FIGURE 15. t

4.5

4

3.5

tfall (ns)

3

2.5

2

4.5 5 5 .5 6 6 .5 7 7.5

FIGURE 17. t

5

4.5

4

WITH TEMPERATURE (CGL = 3nF,

RL

LSEL = VDD)

VDD (V)

WITH TEMPERATURE (CGL = 3nF,

FL

LSEL = VDD)

-25 °C

25 °C

85 °C

3

IGH (A)

2

1

0

4.555.566.577.5

VDD (V)

HSEL=BST

HSEL=SW

FIGURE 18. HIGH-SIDE DRIVER PULL-UP CURRENT

(V

- VSW = 2.5V, TA = +25°C)

GH

9

3.5

3

IGH (A)

2.5

2

1.5

1

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 19. HS PULL-UP CURRENT WITH

TEMPERATURE (V

HSEL = BST)

- VSW = 2.5V,

GH

FN6845.1

December 4, 2009

Page 10

ZL1505

Typical Performance Curves (Continued)

5

4

3

IGH (A)

2

1

HSEL=BST

0

HSEL=SW

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

FIGURE 20. HIGH-SIDE DRIVER PULL-DOWN

17.5

15.5

13.5

11.5

CURRENT (V

T

=+25°C)

A

- VSW = 2.5V,

GH

HSEL=BST

HSEL=SW

5

4.5

4

3.5

IGH (A)

3

2.5

2

1.5

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 21. HS PULL-DOWN CURRENT WITH

TEMPERATURE (V

HSEL = BST)

8.5

7.5

6.5

- VSW = 2.5V,

GH

-25 °C

25 °C

85 °C

9.5

trise (ns)

7.5

5.5

3.5

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

FIGURE 22. HIGH-SIDE DRIVER RISE TIME, t

(CGH= 3nF, TA = +25°C)

11.5

9.5

7.5

tfall (ns)

5.5

3.5

4.5 5 5.5 6 6.5 7 7.5

VDD (V)

HSEL=BST

HSEL=SW

RH

trise (ns)

5.5

4.5

3.5

4.555.566.577.5

VDD (V)

FIGURE 23. t

7.5

6.5

5.5

tfall (ns)

4.5

3.5

4.5 5 5.5 6 6.5 7 7.5

WITH TEMPERATURE (CGH = 3nF,

RH

HSEL = BST)

VDD (V)

-25 °C

25 °C

85 °C

FIGURE 24. HIGH-SIDE DRIVER FALL TIME, t

(CGH= 3nF, TA = +25°C)

10

FH

FIGURE 25. t

WITH TEMPERATURE (CGH = 3nF,

FH

HSEL = BST)

December 4, 2009

FN6845.1

Page 11

ZL1505

ZL1505 Overview

Theory of Operation

The ZL1505 is a synchronous N-channel MOSFET driver

that is intended for use with Zilker Labs Digital-DC PWM

controllers to enable a high-efficiency DC/DC conversion

scheme. The patented Digital-DC control scheme utilizes

a closed-loop algorithm to optimize the dead-time

applied between the gate drive signals for the high-side

and low-side MOSFETs. By monitoring the duty cycle of

the resulting DC/DC converter circuit, this dynamic

routine continuously varies the MOSFET dead times to

optimize conversion efficiency in response to varying

circuit conditions. The ZL1505’s dual PWM input

configuration enables this optimization scheme to be

applied while minimizing the complexity within the driver

device. Please refer to the ZL2004 data sheet for details

on the dynamic dead-time optimization routine.

The ZL1505 integrates two powerful gate drivers that

have been optimized for step-down DC/DC con version

circuit configurations whose output current can exceed

40A per phase. The ZL1505 also integrates a 30V

bootstrap Schottky diode to minimize the external

components and provide a high drive voltage to the

high-side driver device.

condition ceases, allowing normal switching operation to

continue.

Start-up Requirements

During power-up, the ZL1505 maintains both GH and GL

outputs in the LOW state while the V

ramping up. Once the VDD supply is within specification,

the GH and GL pins may be oper ated using th e PWMH

and PWML logic inputs respectively.

In the case where the PWM controller is powered from a

supply other than the ZL1505’s V

controller is powered up first, the PWM controller gate

outputs should be kept in low or in high-impedance state

until the V

the ZL1505 begins its power-down sequence prior to the

PWM controller then the PWM controller gate outputs

should be set in low or in high-impedance state before

the V

DD

supply is within specification. Additionally , if

DD

voltage supply drops below its specified range.

voltage is

IN

supply , and the PWM

DD

Thermal protection

When the junction temperature exceeds +150°C the

high-side driver output GH is forced to logic low state.

The driver output is allowed to switch logic states again

once the junction temperature drops below +134°C.

Variable Gate Drive Current

The ZL1505 incorporates an innovative variable drive

current scheme that enables the user to optimize the

gate drive current levels to the requirements of the

external MOSFET s used ov er a wide r ange of oper ating

frequencies. Each of the gate drivers incorporates a logic

input (HSEL and LSEL) that allows the user to select the

gate drive strength to 50% or 100% of the total rated

drive current.

With the HSEL pin connected to the BST pin, the

high-side driver can deliver the full rated gate drive

current; with the HSEL pin connected to the SW pin, the

output current will be limited to 50% of the full rated

output capability. With the LSEL pin connected to VDD,

the low-side driver can deliver the full rated gate drive

current; with the LSEL pin connected to GND, the output

current will be limited to 50% of the full rated output

capability . Using HSEL and LSEL, the ZL1505 can be used

across a wide range of applications using only a simple

PCB layout change.

Also, the VDD pin is the gate drive bias supply for the

external MOSFET s. VDD can be used to vary the gate

drive strength as shown for the low-side driver in

Figures 9 thru 12 and for the high-side driver in

Figures 17 thru 20.

Overlap Protection Circuit

The ZL1505 includes an internal watchdog circuit that

prevents excessive shoot-through current from occurring

in the unlikely event that the PWM converter places both

switches in the ON position. If the overlap time between

the PWMH and PWML pulses exceeds 30ns, the PWMH

signal will be forced to the LOW state until the overlap

11

FN6845.1

December 4, 2009

Page 12

ZL1505

Revision History

The revision history provided is for informational purposes only and is believed to be accurate, but not warranted. Please go to

web to make sure you have the latest Rev.

DATE REVISION CHANGE

12/4/09 FN6845 .1 Converted to new Intersil template. Changed in Abs Max Ratings “Low- Side Driv e Voltage for

GL pin” from “(GND - 0.3) to (VIN + 0.3)” to “(GND - 0.3) to (VDD + 0.3)”. Removed Bullet

"Adjustable gate drive voltage: 4.5V to 7.5V" and "Exposed pad 3mmx3mm DFN -10 Package"

from Features. Intersil Standards applied are: Added Related Information, Updated ordering

information with Notes that includes MSL. Updated Abs Max Ratings with notes, added ESD

Ratings and Latchup, added Boldface text in Electrical Spec Table. Added POD

2/14/09 FN6845.0 Assigned file number FN6845 to datasheet as this will be the first release with an Intersil fil e

number. Replaced header and footer with Intersil header and footer. Updated disclaimer

information to read “Intersil and it’s subsidiaries including Zilker Labs, Inc.” No changes to

datasheet content

Products

Intersil Corporation is a leader in the design and manufacture of high-performance analog semiconductors. The

Company's products address some of the industry's fastest growing markets, such as, flat panel displays, cell phones,

handheld products, and notebooks. Intersil's product families address power management and analog signal

processing functions. Go to www.intersil.com/products

*For a complete listing of Applications, Related Documentation and Related Parts, please see the respective device

information page on intersil.com: ZL1505

To report errors or suggestions for this datasheet, please go to www.intersil.com/askourstaff

FIT s are available from our website at http://rel.intersil.com/reports/search.php

for a complete list of Intersil product families.

For additional products, see www.intersil.com/product_tree

Intersil products are manufactured, assembled and tested utilizing ISO9000 quality systems as noted

in the quality certifications found at www.intersil.com/design/quality

Intersil products are sold by description o nly . In tersil Corporation reserves the right to make change s in c irc uit design, software and/or specifications

at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by

Intersil is believed to be accurate and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any

infringements of patents or other rights of third parties which may result from its use. No license is granted by implication or otherwise under any

patent or patent rights of Intersil or its s ub si di arie s .

For information regarding Intersil Corporation and its products, see www.intersil.com

12

FN6845.1

December 4, 2009

Page 13

Dual Flat No-Lead Plastic Package (DFN)

ZL1505

8.

0.20 DIA TYP

0.10 C

2X

2X

9.

PIN #1 ID

E2

K

SEE DETAIL "A"

0.10 C

0.10 C

0.05 C

SEATING PLANE

(DATUM A)

R0.20

E2/2

5.

L

e

D

N N-1

2

1

TOP VIEW

A

A1

SIDE VIEW

D2

D2/2

2

1

N N-1

e

(ND-1) X e

BOTTOM VIEW

DATUM A OR B

11. 11.

L1

e/2

TERMINAL TIP

A

B

L10.3x3D

10 LEAD DUAL FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

E

A 0.80 0.85 0.90 -

A1 0.00 0.02 0.05 -

NOTESMIN NOMINAL MAX

A3 0.20 REF -

θ 0-122

K 0.20 MIN

D 3.00 BSC -

D2 2.20 2.30 2.40 -

E 3.00 BSC -

E2 1.50 1.60 1.70 -

C

L 0.35 0.40 0.45 12

L1 0.15mm MAX 11

b 0.18 0.25 0.30 4

e 0.50 BSC N103

ND 5 5

Rev. 0 3/09

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

NX L

(DATUM B)

2. All dimensions are in millimeters. θ is in degrees.

3. N is the number of terminals.

4. Dimension b applies to the metallized terminal and is measured

9.

between 0.15mm and 0.30mm from the terminal tip. If the

terminal has optional radius on the other end of the terminal, the

dimension b should not be measured in that radius area.

NX b

0.10 M

0.05 M C

4.

C A B

5. ND refers to the number of terminals on D side.

6. Max package warpage is 0.05m.

7. Maximum allowable burrs is 0.076mm in all directions.

8. Pin #1 ID on top will be laser marked

9. Bilatteral coplaniarity zone applies to the exposed heat sink slug

as well as the terminals.

10. This drawing conforms to JEDEC registered outline M0-229.

11. Depending on the method of lead termination at the edge of the

package, pullback (L1) may be present.

12. Pullback design option is for 0.50mm nominal landlength only.

L

4.

L1

e

DETAIL “A”

13

FN6845.1

December 4, 2009

Loading...

Loading...