Page 1

DS082 (v1.2) November 5, 2001 www.xilinx.com 1

Preliminary Product Specification 1-800-255-7778

© 2001 Xilinx, Inc. All rights reserved. All Xilinx trademarks, registered trademarks, patents, and disclaimers are as listed at http://www.xilinx.com/legal.htm.

All other trademarks and registered trademarks are the property of their respective owners. All specifications are subject to change without notice.

Features

• In-system programmable 3.3V PR OMs for

configuration of Xilinx FPGAs

- Endurance of 2,000 program/erase cycles

- Program/erase over full military temperature range

• IEEE Std 1149.1 boundary-scan (JTAG) support

• Cascadable for storing longer or multiple bitstreams

• Dual configuration modes

- Serial Slow/Fast configuration (up to 33 MHz)

- Parallel (up to 264 Mbps at 33 MHz)

• Low-power advanced CMOS FLASH process

• 5V tolerant I/O pins accept 5V, 3.3V and 2.5V signals.

• 3.3V or 2.5V output capability

• Available in CC44 and VQ44 packages.

• Design suppor t using the Xilinx Alliance™ and

Foundation™ series software packages.

• JTAG command initiation of standard FPGA

configuration.

• Available to Standard Microcircuit Drawing

5962-01525.

- For more information contact Defense Supply

Center Columbus (DSCC) at

http://www.dscc.dla.mil

Radiation Hardenned XQR18V04

• Fabricated on Epitaxial Substrate

• Latch-Up Immune to >120 LET

• Guaranteed TID of 40 kRad(Si)

• Supports SEU Scrubbing

Description

Xilinx introduces the QPro™ XQ18V04 and XQR18V04

series of QML in-system programmable and radiation hardened configuration PROMs. Initial devices in this 3.3V family are a 4-megabit PROM that provide an easy-to-use,

cost-effective method for re-programming and storing large

Xilinx FPGA configuration bitstreams.

When the F PGA is in Master S erial mode, it generates a

configuration clock that drives the PROM. A short access

time after the r ising CCLK, data is available on the PROM

DATA (D0) pin that is connect ed to the FPGA D

IN

pin. The

FPGA generates the appropri ate number of clock pulses to

complete the configuration. When the FPGA is in Slave

Serial mode, the PROM and the FPGA are c locked by an

external clock.

When the FPGA is in Express or SelectMAP Mode, an

external oscillator will generate t he configuration c lock that

drives the PROM and the FPGA. After the rising CCLK

edge, data are available on the PROMs D ATA (D0-D7) pins.

The data will be clocked into the FPGA on the following rising edge of the CCLK. Neither Express nor SelectMAP utilize a Length Count, so a free-running oscillator may be

used. See Figure 6.

0

QPro XQ18V04 (XQR18V04) QML

In-System Programmable

Configuration PROMs

DS082 (v1.2) November 5, 2001

05

Preliminary Product Specification

R

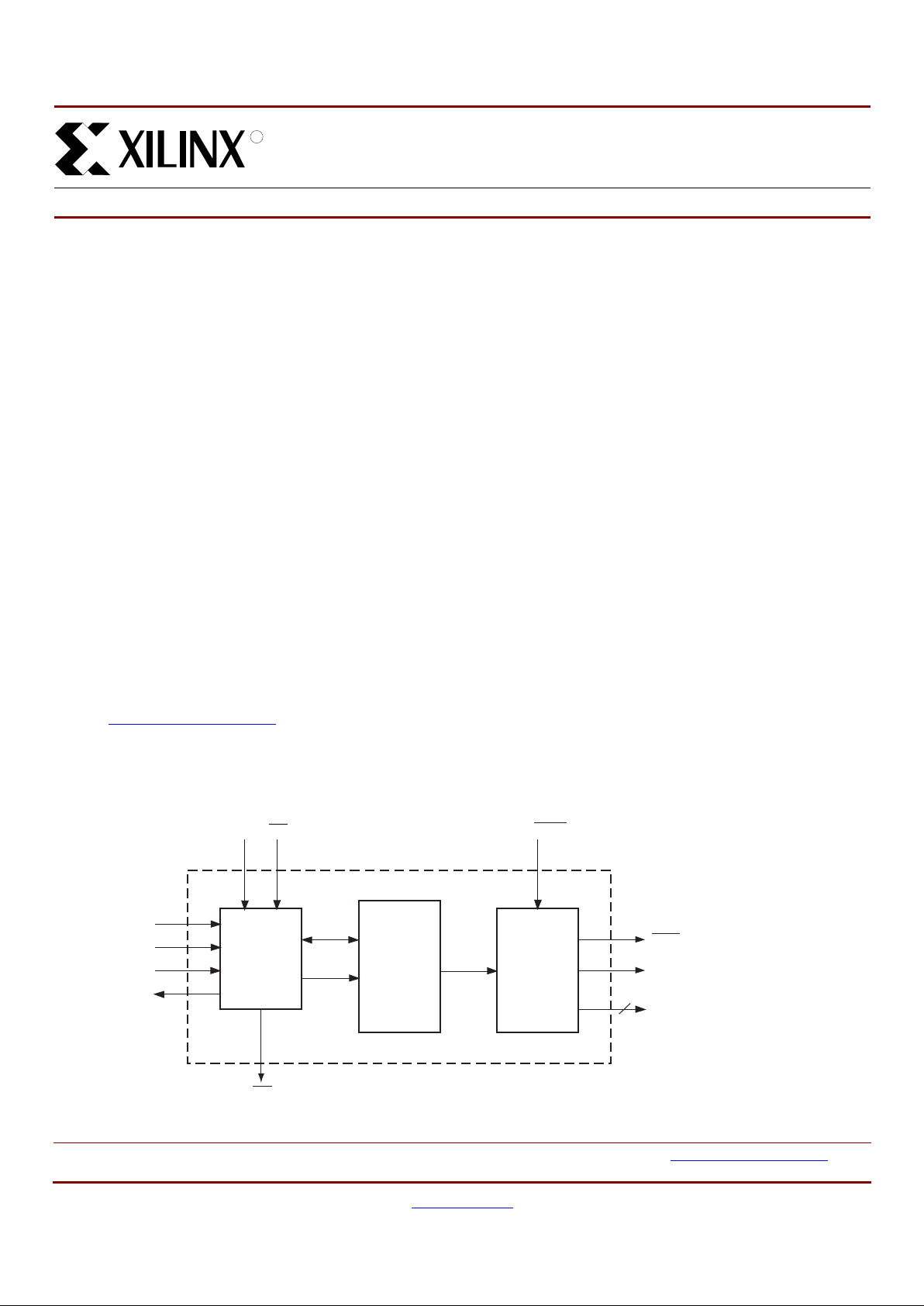

Figure 1: XQ18V04 Series Block Diagram

Control

and

JTAG

Interface

Memory

Serial

or

Parallel

Interface

D0 DATA

(Serial or Parallel

[Express/SelectMAP] Mode)

D[1:7]

Express Mode and

SelectMAP Interface

Data

Address

CLK

CE

TCK

TMS

TDI

TDO

OE/Reset

CEO

Data

DS026_01_021000

7

CF

Page 2

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

2 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Multiple devices can be concatenated by using the CEO

output to drive the CE input of the following device. The

clock inputs and the DATA outputs of all PROMs in this

chain are interconnected. All devices are compatible and

can be cascaded with other members of the family or with

the XC1700L one-time programmable Serial PROM family.

Pinout and Pin Description

Table 1: Pin Names and Descriptions (pins not listed are “no connect”)

Pin

Name

Boundary

Scan

Order Function Pin Description

44-pin

VQFP

44-pin

CLCC

D0 4 DAT A OUT D0 is the DAT A output pin to provide data for c onfiguring an

FPGA in serial mode.

40 2

3OUTPUT

ENABLE

D1 6 DATA OUT D0-D7 are the output pins to provide parallel data for

configuring a Xilinx FPGA in Express/SelectMap mode.

29 35

5OUTPUT

ENABLE

D2 2 DATA OUT 42 4

1OUTPUT

ENABLE

D3 8 DATA OUT 27 33

7OUTPUT

ENABLE

D4 24 DATA OUT 9 15

23 OUTP UT

ENABLE

D5 10 DATA OUT 25 31

9OUTPUT

ENABLE

D6 17 DATA OUT 14 20

16 OUTP UT

ENABLE

D7 14 DATA OUT 19 25

13 OUTP UT

ENABLE

CLK 0 DATA IN Each rising edge on the CLK input increments the internal

address counter if both CE

is Low a n d OE/RESET is High.

43 5

OE/

RESET

20 DATA IN When Low, this input holds the address counter reset and

the DATA output is in a high-impedance state. This is a

bidirectional open-drain pin that is held Low while the

PROM is reset. Polarity is NOT programmable.

13 19

19 DATA OUT

18 OUTP UT

ENABLE

CE

15 DATA IN When CE is High, this pin puts the device into standby

mode and resets the address counter. The DA T A output pin

is in a high-impedance state, and the device is in low power

standby mode.

15 21

Page 3

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 3

Preliminary Product Specification 1-800-255-7778

R

CF 22 DATA OUT Allows JTAG CONFIG instruction to initiate FPGA

configuration without powering down FPGA. This is an

open-drain output that is pulsed Lo w by the JTAG CONFIG

command.

10 16

21 OUTP UT

ENABLE

CEO 13 DATA OUT Chip Enable Output (CEO

) is connected to the CE input of

the next PROM in the chain. This output is Low when CE

is

Low and OE/RESET

input is High, AND the internal

address counter has been incremented beyond its

Terminal Count (TC) value. When OE/RESET

goes Low,

CEO

stays High until the PROM is brought out of reset by

bringing OE/RESET

High.

21 27

14 OUTP UT

ENABLE

GND GND is the ground connection. 6, 18,

28 &

41

3, 12,

24 &

34

TMS MODE SELECT The state of TMS on the rising edge of TCK determines the

state transitions at the Test Access Port (TAP) controller.

TMS has an internal 50K ohm resistive pull-up on it to

provide a logic "1" to the device if the pin is not driven.

511

TCK CLOCK This pin is the JTAG test clock. It sequences the TAP

controller and all the JTAG test and programming

electronics.

713

TDI DATA IN This pin is the serial input to all JTAG instruction and data

registers. TDI has an internal 50K ohm resistive pull-up on

it to provi de a l ogi c "1" to th e syste m if the pin is not driv en.

39

TDO DAT A OUT This pin is the serial output f or all JTAG instruction and data

registers. TDO has an internal 50K ohm resistive pull-up on

it to provide a logic "1" to the system if the pin is not driven.

31 37

V

CC

Positive 3.3V supply voltage for internal logic and input

buffers.

17, 35

& 38

23, 41

& 44

V

CCO

Positive 3.3V or 2.5V supply voltage connected to the

output voltage drivers.

8, 16,

26 &

36

14, 22,

32 &

42

Table 1: Pin Names and Descriptions (pins not listed are “no connect”) (Continued)

Pin

Name

Boundary

Scan

Order Function Pin Description

44-pin

VQFP

44-pin

CLCC

Page 4

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

4 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Xilinx FPGAs and Compatible PROMs

Capacity

In-System Programming

In-System Programmable PROMs can be programmed individually, or two or more can be daisy-chained together and

programmed in-system via the standard 4-pin JTAG protocol as shown in Figure 2. In-system programming offers

quick and efficient design iterations an d eliminates unnecessary package handling or socketing of devices. The Xilinx

development system provides the programming data

sequence using either Xilinx JTAG Programmer software

and a download cable, a third-party JTAG dev elopment system, a JTAG-compatible board tester, or a simple microprocessor interface that emulates the JTAG instruction

sequence. The JTAG Programmer software also outputs

serial vector format (SVF) files for use with any tools that

accept SVF format and with automatic test equipment.

All outputs are held i n a high-impedance state or held at

clamp levels during in-system programming.

OE/RESET

The ISP programming algorithm requires issuance of a

reset that w ill c au s e OE to go Low.

External Programming

Xilinx reprogrammable PROMs can also be programmed by

the Xilinx HW-130 device programmer. This provides the

added flexibility of using pre-programmed d evices in board

design and boundary-scan manufacturing tools, with an

in-system programmable option for future enhancements

and design changes.

Reliability and Endurance

Xilinx in-system programmable p roducts provide a guaranteed endurance level of 2,000 in-system program/erase

cycles and a minimum data retention of ten years. Each

device meets all functional, performance, and data retention

specifications within this endurance limit.

Design Security

The Xilinx in-syst em programmab le PROM de vices incorporate advanced data security features to fully protect the programming data against unauthorized reading. Table 2

shows the security setting available.

The read security bit can be set by the user to prevent the

internal programming pattern f rom bei ng read or copied via

JTAG. When set, it a llows device erase. Erasing the entire

device is the only way to reset the read security bit.

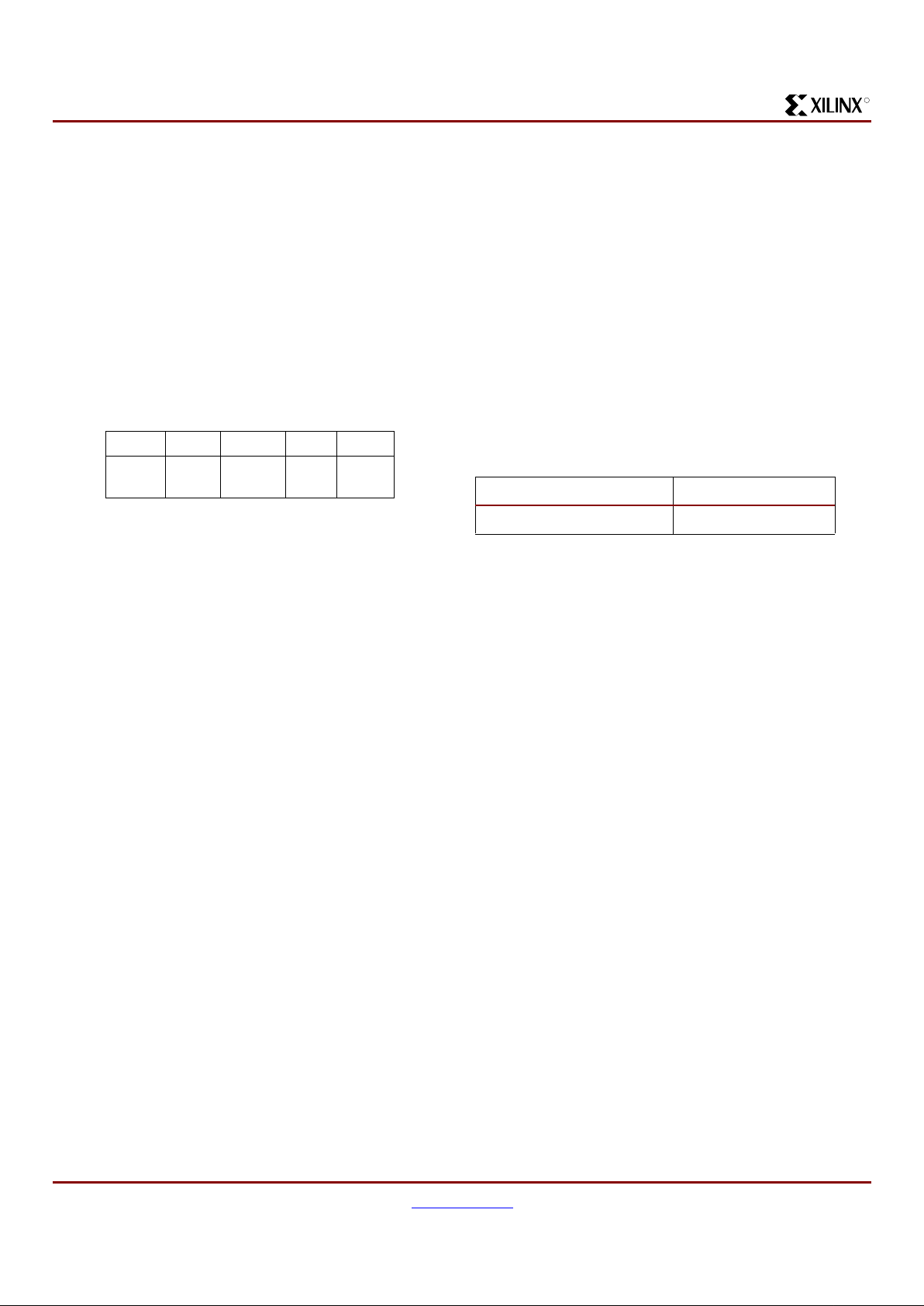

Table 2: Data Security Options

Device

Configuration

Bits

XQ(R)18VO4

PROMs

XQV100 781,216 1

XQV(R)300 1,751,808 1

XQV(R)600 3,607,968 1

XQV(R)1000 6,127,744 2

XQV(R)600E 3,961,632 1

XQV(R)1000E 6,587,520 2

XQV(R)2000E 10,159,648 3

Devices Configuration Bits

XQ(R)18V04 4,194,304

Default = Reset Set

Read Allowed

Program/Erase Allowed

Read Inhibited via JTAG

Erase Allowed

Page 5

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 5

Preliminary Product Specification 1-800-255-7778

R

IEEE 1149.1 Boundary-Scan ( JTAG)

The XQ(R)18V0 4 famil y is fully com pliant wit h the IEEE Std.

1149.1 Boundary-Scan, also known as JTAG. A Test

Access Port (TAP) and regi sters are provided to s uppo rt all

required boundary scan instructions, as well as many of the

optional instructions specified by IEEE Std. 1149.1. In addition, the JTAG interf ace is used to imp lement in-syst em programming (ISP) to facilitate configuration, erasure, and

verification operations on the XQ(R)18V04 device.

Table 3 lists the required and optional boundary-scan

instructions supported in the XQ(R)18V04. Refer to the

IEEE Std. 1149.1 specificati o n for a complete descrip tion of

boundary-scan architecture and the required and optional

instructions.

Figure 2: In-System Programming Operation (a) Solder Device to PCB and (b) Program Using Download Cable

DS026_02_011100

G

N

D

V

CC

(a) (b)

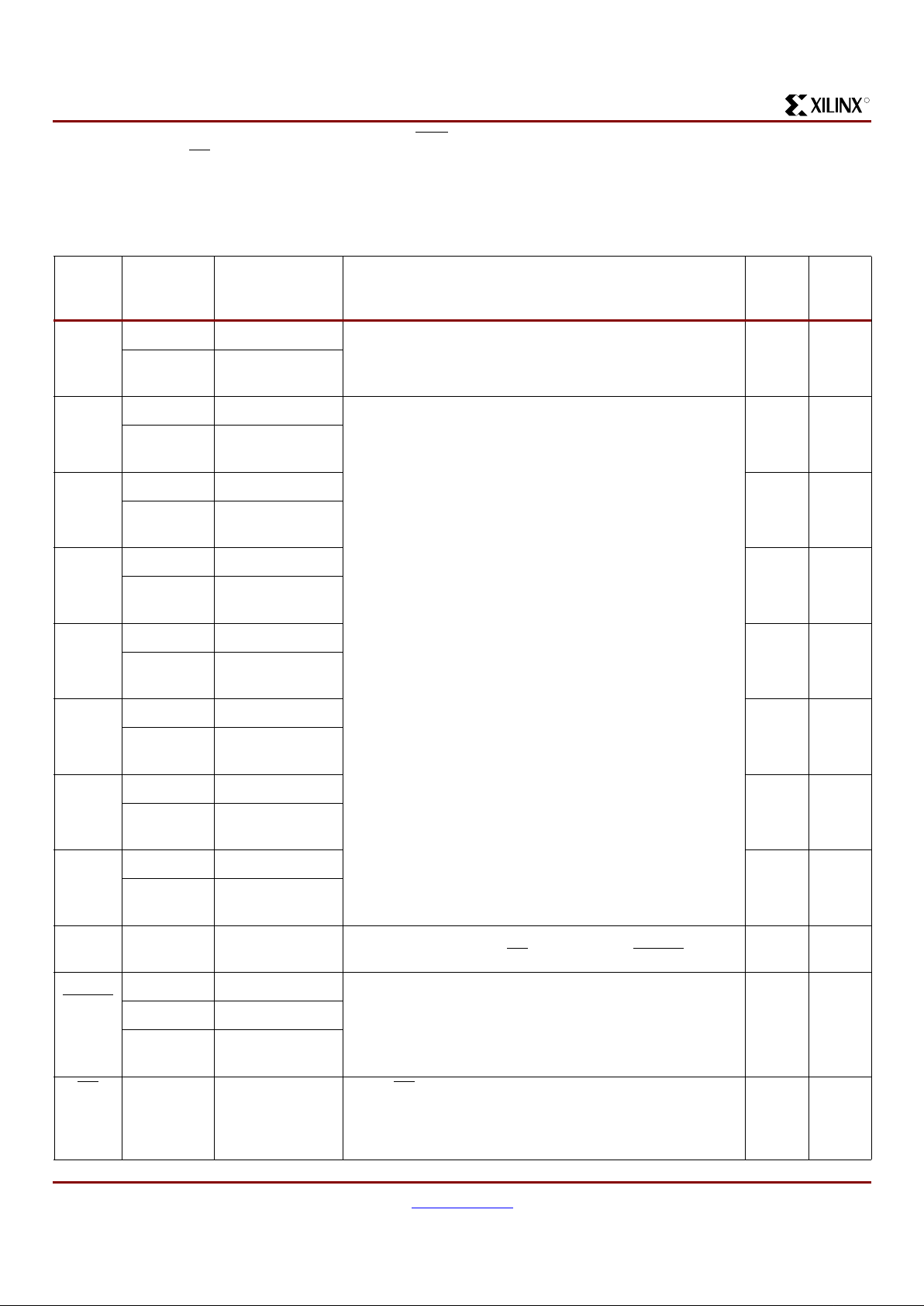

Table 3: Boundary Scan Instructions

Boundary-Scan

Command

Binary

Code [7:0] Description

Requ ired In s truc ti o ns

BYPASS 11111111 Enables BYP ASS

SAMPLE/

PRELOAD

00000001 Enables boundary-scan

SAMPLE/PRELOAD

operation

EXTEST 00000000 Enables boundary-scan

EXTEST operation

Optional Instructions

CLAMP 11111010 Enables boundary-scan

CLAMP operation

HIGHZ 11111100 All outputs in

high-impedance state

simultaneously

IDCODE 11111110 Enables shifting out

32-bit IDCODE

USERCODE 11111101 Enables shifting out

32-bit USERCODE

XQ(R)18V04 Specific Instructions

CONFIG 11101110 Initiates FPGA

configuration by pulsing

CF

pin Low

Page 6

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

6 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Instruction Register

The Instruction Register (IR) for the XQ(R)18V04 is eight

bits wide and is connected between TDI and TDO during an

instruction scan sequence. In preparation for an instruction

scan sequence, the instruction register is parallel loaded

with a fixed instruction capture pattern. This pattern is

shifted out onto TDO (LSB first), while an instruction is

shifted into the instructi on register from TDI. The detailed

compos ition of the instructi on captur e pattern is illustrat ed

in Figure 3.

The ISP Status field, IR(4), contains logic "1" if the device is

currently in ISP mode; otherwise, it will contain logic "0".

The Security field, IR(3 ), will contain logic "1" if th e device

has been programmed with the security option turned on;

otherwise, it will contain logic "0".

Boundary Scan Register

The boundary -s can register is used t o control and observe

the state of the device pins during the EXTEST, SAMPLE/PRELOAD, and CLAMP instructions. Each output pin

on the XQ(R)18V00 has two register stages that contribute

to the boundary-scan register, while each input pin only has

one register stage.

For each output pin, the register stage nearest to TDI c ontrols and observes the output state, and the second stage

closest to TDO controls and obser ves the High-Z enable

state of the pin.

For each input pin, the register stage controls and observes

the input state of the pin.

Identification Registers

The IDCODE is a fixed, vendor-assigned value that is used

to electrically identify the manufacturer and type of the

device being addressed. The IDCODE register is 32 bits

wide. The IDCODE register can be shifted out for examina-

tion by using the IDCODE instruction. The IDCODE is available to any other system component via JTAG.

The IDCODE register has the following binary format:

vvvv:ffff:ffff:aaaa:aaaa:cccc:cccc:ccc1

where

v = the die version number

f = the family code (50h for XQ(R)18V04 family)

a = the ISP PROM product ID (26h for the XQ(R)18V04)

c = the company code (49h for Xilinx)

Note: The LSB of the IDCODE register is always read as

logic "1" as defined by IEEE Std. 1149.1

Table 4 lists the IDCODE register values for the

XQ(R)18V00 devices. 0

The USERCODE instr uction gives access to a 32-bit user

programmable scratch pad typically used to supply information about the device’s programmed contents. By using t he

USERCODE instruction, a user-programmable identification code can be shifted out for exam ination. This code is

loaded into the USERCODE register during programming of

the XQ(R)18V04 device. If the device is blank or was not

loaded during programming, the USERCODE register will

contain FFFFFFFFh.

XQ(R)18V04 TAP Characteristics

The XQ(R)18V04 family performs both in-system programming and IEEE 1149.1 boundar y-sc an (JTAG) testing via a

single 4-wire Test Access P ort (TAP). This simplifies sys tem

designs and allows standard Automatic Test Equi pment to

perform both functions. The AC characteristics of the

XQ(R)18V04 TAP are descr ibed as follows.

TAP Timing

Figure 4 shows the timing relationships of the TAP signals.

These TAP timing characteristics are identical for both

boundary-s can and ISP operations.

IR[7:5] IR[4] IR[3] IR[2] IR[1:0]

TDI-> 0 0 0 ISP

Status

Security 0 0 1

->TDO

Notes:

1. IR(1:0) = 01 is specified by IEEE Std. 1149.1

Figure 3: Instruction Register Values Loaded into IR as

Part of an Instruction Scan Sequence

Table 4: IDCODES Assigned to XQ(R)18V04 Devices

ISP-PROM IDCODE

XQ(R)18V04 05026093h

Page 7

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 7

Preliminary Product Specification 1-800-255-7778

R

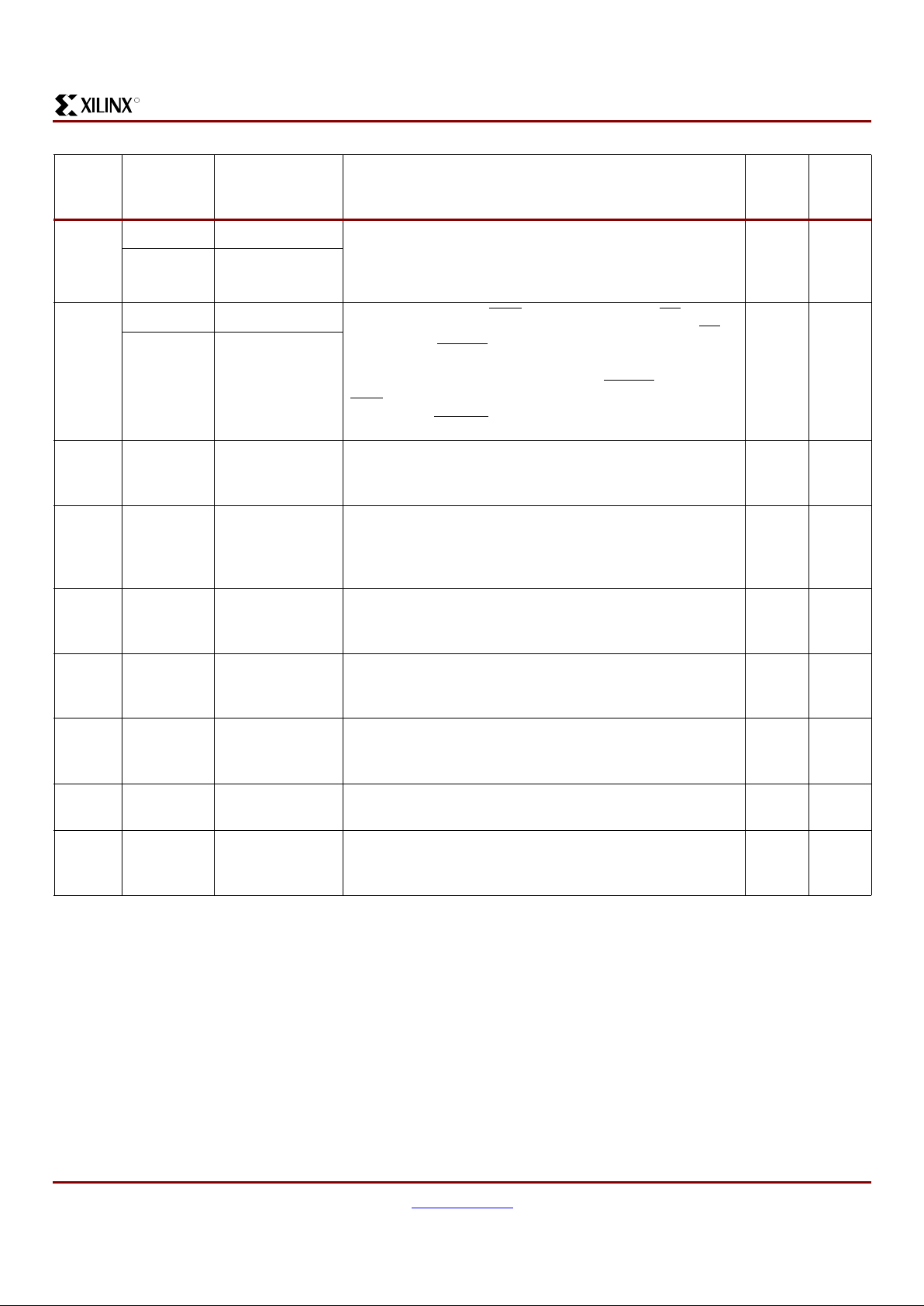

TAP AC Parameters

Table 5 shows the timing parameters f or the TAP wavef orms

shown in Figure 4

Figure 4: Test Access Port Timing

TCK

T

CKMIN

T

MSS

TMS

TDI

TDO

T

MSH

T

DIH

T

DOV

T

DIS

DS026_04_020300

Table 5: T est Access Port Timing Parameters

Symbol Parameter Min Max Units

T

CKMIN1

TCK minimum clock period 100 - ns

T

CKMIN2

TCK minimum clock period, Bypass mode 50 - ns

T

MSS

TMS setup time 10 - ns

T

MSH

TMS hold time 25 - ns

T

DIS

TDI setup time 10 - ns

T

DIH

TDI hold time 25 - ns

T

DOV

TDO valid delay - 25 ns

Page 8

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

8 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Connecting Configuration PROMs

Connecting the FPGA device with th e configuration PROM

(see Figure 6).

• The DATA output(s) of the PROM(s) drives the D

IN

input of the lead FPGA device.

• The Master FPGA CCLK output drives the CLK input(s)

of the PROM(s) (in Master Serial mode only).

• The CEO

output of a PROM drives the CE input of the

next PROM in a daisy chain (if any).

• The OE/RESET

input of all PROMs is best dr iven by

the INIT

output of the lead FPGA device. This

connection assures that the PROM address counte r is

reset before the start of any (re)configuration, even

when a reconfiguration is initiated by a V

CC

glitch.

• The PROM CE

input can be driven from the DONE pin.

The CE

input of the first (or only) PROM can be driven

by the DONE output of the first FPGA device, provided

that DONE is not permanently grounded. CE

can also

be permanently tied Low, but this keeps the DATA

output active and causes an unnecessary supply

current of 20 mA maximum.

• Express/SelectMap mode is similar to slave serial

mode. The DATA is clocked out of the PROM one by te

per CCLK instead of one bit per CCLK cycle. See

FPGA data sheets for special configuration

requirements.

Initiating FPGA Configuration

The XQ(R)18V04 devices incorporate a pin nam ed CF that

is controllable through the JTAG CONFIG instruction. Executing the CONFIG instruction through JTAG pulses the CF

low for 300-500 ns, which resets the FPGA and initiates

configuration.

The CF

pin must be connected to the PROGRAM pin on the

FPGA(s) to use this feature.

The JTAG Programmer software can also issue a JTAG

CONFIG command to initiate FPGA configuration through

the "Load FPGA" setting.

Selecting Configuration Modes

The XQ(R)18V04 accomm odates serial and parallel m ethods of configuration. The configuration modes are selectable through a user control register in the XQ(R)18V04

device. This control register is accessible through JTAG,

and is set using the "Parallel mode" setting on the Xilinx

JT A G Program mer software. Serial output is the default programming mode.

Master Serial Mode Summary

The I/O and logic func tions of the Configurable Log ic Block

(CLB) and their associated interconnections are established

by a configuration program. The program is loaded either

automatically upon power up, or on command, depending

on the state of the three FPGA mode pins. In Master Serial

mode, the FPGA automatically loads the configuration program from an external memory. Xilinx PROMs are designed

to accommodate the Master Serial mode.

Upon power-up or reconfiguration, an FPGA enters the

Master Serial mode whenever all three of the FPGA

mode-select pins are Low (M0=0, M1=0, M2=0). Data is

read from the PROM sequentially on a single data line. Synchronization is provided by the rising edge of the temporary

signal CCLK, which i s gene rated by the FPGA during configuration.

Master Serial Mode provides a simple configuration interface. Only a serial dat a line, a clock line, and two control

lines are required to configure an FPGA. Data from the

PROM is read sequentially, accessed via the internal

address and bit count ers which are increment ed on every

valid rising edge of CCLK. If the user-programmable,

dual-function D

IN

pin on the FPGA is used only for configuration, it m ust st ill be held at a de fined level dur ing n orma l

operation. The Xilinx FPGA families take care of this automatically with an on-chip pu ll-up resist or.

Cascading Configuration PROMs

For multiple FPGAs configured as a serial daisy-chain, or a

single FPGA requir ing larger configuration memories in a

serial or SelectMAP configuration mode, cascaded PROMs

provide additional memory (Figure 5). Multiple XQ(R)18V04

devices can be concatenated by using the CEO

output to

drive the CE

input of the downstream device. The clock

inputs and the data outputs of all XQ(R)18V04 devices in

the chain are interconnecte d. Afte r the last bit from the first

PROM is read, the next clock signal to the PROM asserts its

CEO

output Low and drives its DATA line to a high-impedance state. The second PROM recognizes the Low level on

its CE

input and enables its DATA output. See Figure 6.

After configuration is complete, the address counters of all

cascaded PROMs are reset if the PROM OE/RESET

pin

goes Low.

Page 9

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 9

Preliminary Product Specification 1-800-255-7778

R

Figure 5: JTAG Chain for Configuring Devices in Master Serial Mode

4.7K

**

1

2

3

4

TDO

DOUT

TDI

TMS

TCK

Vcc

Vcc

DIN

CCLK

DONE

INIT

Vcc MODE PINS*

Xilinx

FPGA

Master

Serial

Vcc

D0

Vcco

TDI CLK

TMS CE

TCK CEO

OE/RESET

PROGRAM

TDO

TDI

TMS

TCK

DIN

CCLK

DONE

INIT

Vcc MODE PINS*

Xilinx

FPGA

Slave

Serial

PROGRAMCF

TDO

GND

* For Mode pin connections, refer to appropriate FPGA data sheet.

** Virtex, Virtex-E is 300 ohms, all others are 4.7K.

XC18V00

Cascaded

PROM

TDI

TMS

TCK

TDO

J1

DS026_08_021000

VccVccoVcco

Vcc

D0

Vcco

TDI CLK

TMS CE

TCK CEO

OE/RESET

CF

TDO

GND

XC18V00

First

PROM

Vcc

Page 10

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

10 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Figure 6: (a) Master Serial Mode (b) Virtex Select MAP Mode (c) Spartan-XL Express Mode

(dotted lines indicates optional connection)

PROGRAM

DIN

CCLK

INIT

DONE

First

PROM

DATA

CEO

CLK

CE

OPTIONAL

Slave FPGAs

with identical

configurations

Vcc

FPGA

(Low Resets the Address Pointer)

VCCV

CCO

OPTIONAL

Daisy-chained

FPGAs with

different

configurations

OE/RESET

DOUT

Modes*

Vcco

CF

PROGRAM

VIRTEX

Select MAP

BUSY

CS

WRITE

INIT

D[0:7]

CCLK

DONE

CLK

Virtex Select MAP Mode

D[0:7]

CE

OE/RESET

XC18Vxx

Modes***

NC

CF

3.3V

External Osc

CEO

4.7K

V

CC

4.7K

V

CC

**

**

VCCV

CCO

VCCV

CCO

V

CC

4.7K

V

CC

4.7K

V

CC

1K

I/O*

M0

M1

CS1

PROGRAM

Spartan-XL,

XC4000

DOUT

DONE

INIT

XC18Vxx

CEO

CE

OE/RESET

Spartan-XL Express Mode

Master Serial Mode

8

CF

CLK

D[0:7]

D[0:7]

CCLK

M0

M1

CS1

PROGRAM

Optional

Daisy-chained

Spartan-XL,

XC4000

DOUT

DONE

INIT

D[0:7]

CCLK

8

To Additional

Optional

Daisy-chained

Devices

To Additional

Optional

Daisy-chained

Devices

External Osc

I/O*

1K

*CS and WRITE must be pulled down to be used as I/O. One option is shown.

**Virtex, Virtex-E is 300 ohms, all others are 4.7K.

***For Mode pin connections, refer to the appropriate FPGA data sheet.

DS026_05_031000

*For Mode pin connections, refer to the appropriate FPGA data sheet.

**Virtex, Virtex-E is 300 ohms, all others are 4.7K.

Cascaded

PROM

DATA

CLK

CE

OE/RESET

CF

VCCV

CCO

VCCV

CCO

V

CC

Page 11

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 11

Preliminary Product Specification 1-800-255-7778

R

5V Tolerant I/Os

The I/Os on each re-programmable PROM are fully 5 V tolerant even through the core power supply is 3.3V. This

allows 5V CMOS signals to connect directly to the PROM

inputs without damage. In addition, the 3.3V V

CC

power

supply can be applied before or after 5V signals are applied

to the I/Os. In mixed 5V/3.3V/2.5V system s, the user pins,

the core power supply (V

CC

), and the output power supply

(V

CCO

) may have power applied in any order. This makes

the PROM devices immune to power supply sequencing

issues.

Reset Activation

On power up, OE/RESET is held low until the XQ(R)18V04

is active (1 ms) and able to supply data after receiving a

CCLK pulse from the FPGA. OE/RESET

is connected to an

external resistor to pull OE/RESET

HIGH releasing the

FPGA INIT

and allowing configuration to begin. OE/RESET

is held low until the XQ(R)18V04 voltage reaches the operating voltage range. If the power drops below 2.0V, the

PROM will res et. OE/RESET

polarity is NOT programma-

ble.

Standby Mode

The PROM enters a low-power standby mode whenever CE

is asserte d High. The output remains in a high-impedanc e

state regardless of the state of the OE input. JTAG pins

TMS, TDI and TDO c an be in a high-impedance state or

High.

Customer Control Pins

The XQ(R)18V04 PROMs have various control bits accessible by the customer. These can be set after the array has

been programmed using " Skip User Array" in Xilinx JTAG

Programmer Software.

Table 6: Truth Table for PROM Control Inputs

Cont ro l Inpu t s

Internal Address

Outputs

OE/RESET CE DATA CEO I

CC

High Low If address < TC

(1)

: increment

If address > TC

(1)

: don’t change

Active

High-Z

High

Low

Active

Reduced

Low Low Held reset High-Z High Act ive

High High Held reset High-Z High Standby

Low High Held reset High-Z High Standby

Notes:

1. TC = Terminal Count = highest add ress value. TC + 1 = address 0.

Page 12

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

12 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Absolute Maximum Ratings

(1,2)

Recommended Operating Conditions

Quality and Reliability Characteristics

Radiation Tolerances for XQR18V04

Symbol Description Value Units

V

CC

Supply voltage relative to GND –0.5 to +4.0 V

V

IN

Input voltage with respect to GND –0.5 to +5.5 V

V

TS

Voltage appl ied to High-Z output –0.5 to +5.5 V

T

STG

Storage temperature (ambient) –65 to +150 °C

T

J

Junction temperature Ceramic +150 °C

Plastic +125 °C

Notes:

1. Maximum DC under shoot be low G ND must be limi ted t o eit her 0.5 V or 10 mA, whi che v er is easi er t o achieve. During transiti ons, the

device pi ns may undershoot to –2.0V or overshoot to +7.0V, provided this over- or undershoot lasts less then 10 ns and with the

forcing current being limited t o 200 mA.

2. Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress

ratings on ly, and functional operat ion of the device at these or any other condit ions beyond those listed under Ope rating Conditions

is not implied. Exposure to Absolute Maximum Ratings conditions for ext ended periods of time may affect device reliabili ty.

Symbol Parameter Min Max Units

V

CCINT

Internal voltage supply (TC = –55°C to +125°C) Ceramic 3.0 3.6 V

Internal voltage supply (T

J

= –55°C to +125°C) Plastic 3.0 3.6 V

V

CCO

Supply voltage for output drivers for 3.3V operation 3.0 3.6 V

Supply voltage for output drivers for 2.5V operation 2.3 2.7 V

V

IL

Low-level input voltag e 0 0.8 V

V

IH

High-level input voltage 2.0 5.5 V

V

O

Output voltage 0 V

CCO

V

Symbol Description Min Max Units

T

DR

Data retention 10 - Years

N

PE

Program/erase cycles (Endurance) 2,000 - Cycles

V

ESD

Electrostatic discharge (ESD) 2,000 - Volts

Symbol Description Min Max Units

TID T otal Ionizing Dose - 40 krad(Si)

SEL Single Event Latch-Up

(No Latch-Up observed for LET > 120 MeV -mg/cm

2

)

-0cm

2

SEU Static Memo ry Cell Saturation Bit Cross-Section

(No Upset observed for LET > 120 MeV-m g/cm

2

)

-0cm

2

Page 13

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 13

Preliminary Product Specification 1-800-255-7778

R

DC Characte ri sti cs Over Operat ing Con dit ions

Symbol Parameter Test Conditions Min Max Units

V

OH

High-level output voltage for 3.3V outputs IOH = –4 mA 2.4 - V

High-level output voltage for 2.5V outputs I

OH

= –500 µA 90% V

CCO

-V

V

OL

Low-lev el output voltage for 3.3V outputs IOL = 8 mA - 0.4 V

Low-lev el output voltage for 2.5V outputs I

OL

= 500 µA-0.4V

I

CC

Supply current, active mode 25 MHz - 50 mA

I

CCS

Supply current, standby mode - 20 mA

I

ILJ

JTAG pins TMS, TDI, and TDO V

CC =

MAX

V

IN

= GND

–100 - µA

I

IL

Input leakage current V

CC

= Max

V

IN

= GND or V

CC

–10 10 µA

I

IH

Input and output High-Z leakage current V

CC

= Max

V

IN

= GND or V

CC

–10 10 µA

C

IN

and

C

OUT

Input and output capacitance VIN = GND

f = 1.0 MHz

-10pF

Page 14

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

14 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

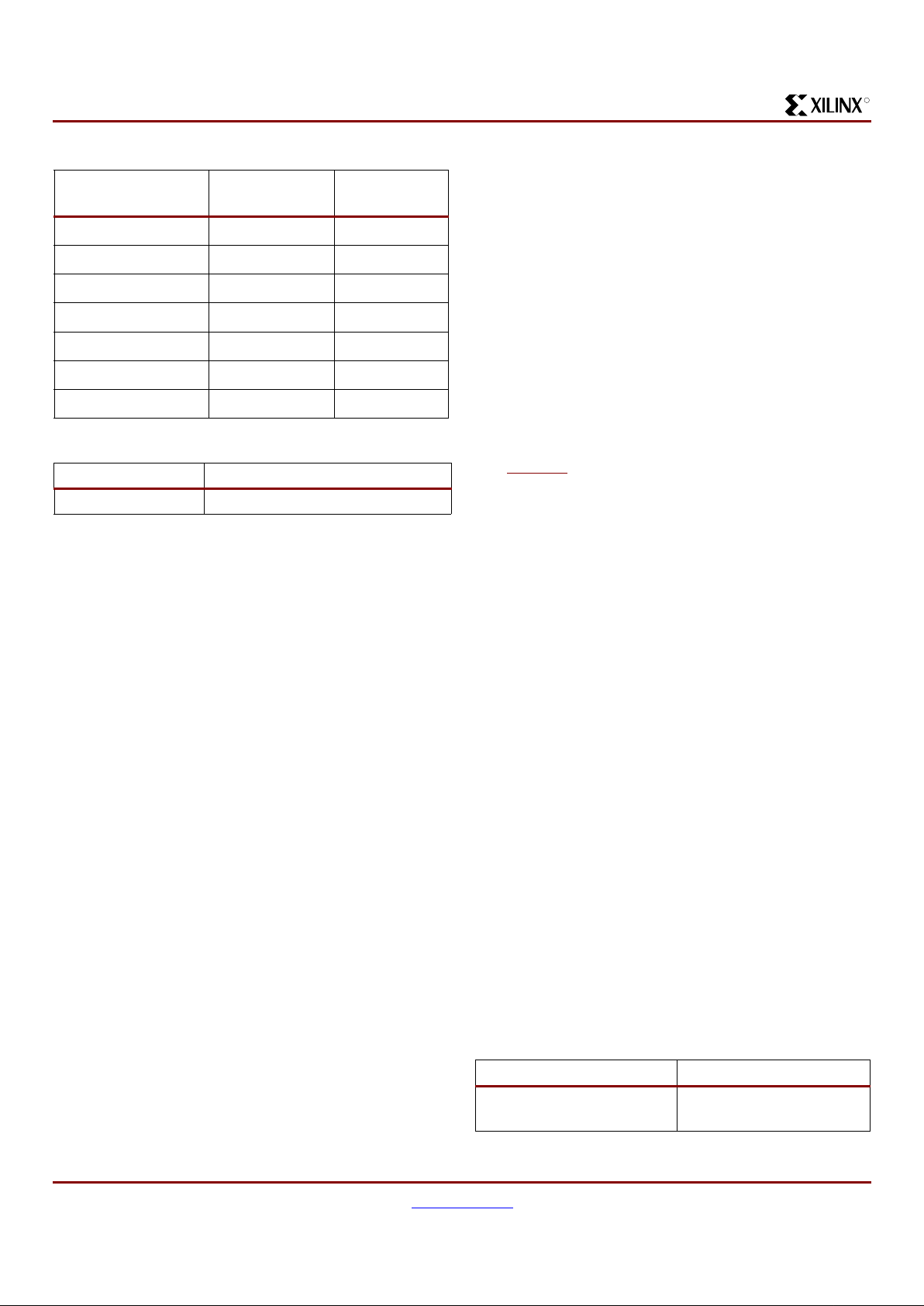

.AC Characteristics Over Operating Conditions for XC18V04 .

Symbol Description Min Max Units

T

OE

OE/RESET to data delay - 10 ns

T

CE

CE to data delay - 20 ns

T

CAC

CLK to data delay - 20 ns

T

OH

Data hold from CE, OE/RESET, or CLK 0 - ns

T

DF

CE or OE/RESET to data float delay

(2)

-25ns

T

CYC

Clock periods 50 - ns

T

LC

CLK Low time

(3)

10 - ns

T

HC

CLK High time

(3)

10 - ns

T

SCE

CE setup time to CLK (to guarantee proper counting)

(3)

25 - ms

T

HCE

CE High time (to guarantee proper counting) 2 - µs

T

HOE

OE/RESET hold time (guarantees counters are reset) 25 - ns

Notes:

1. AC test load = 50 pF.

2. Float dela ys are measured with 5 pF AC loads. Transition is measured at ±200 mV from steady state activ e levels.

3. Guaranteed by design, not tested.

4. All AC parameters are measured with V

IL

= 0.0V and VIH = 3.0V.

5. If T

HCE

High < 2 µs, TCE = 2 µs.

OE/RESET

CE

CLK

DATA

T

CE

T

OE

T

LC

T

SCE

T

HCE

T

HOE

T

CAC

T

OH

T

DF

T

OH

T

HC

DS026_06_012000

T

CYC

Page 15

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 15

Preliminary Product Specification 1-800-255-7778

R

AC Characteristics Over Operating Conditions When Cascading for XC18V04

Symbol Description Min Max Un its

T

CDF

CLK to data float delay

(2,3)

-25 ns

T

OCK

CLK to CEO delay

(3)

-20 ns

T

OCE

CE to CEO delay

(3)

-20 ns

T

OOE

OE/RESET to CEO delay

(3)

-20 ns

Notes:

1. AC test load = 50 pF.

2. Float dela ys are measured with 5 pF AC loads. Transition is measured at ±200 mV from steady

state active levels.

3. Guaranteed by design, not tested.

4. All AC parameters are measured with V

IL

= 0.0V and VIH = 3.0V.

CLK

DATA

CE

CEO

First Bit

Last Bit

T

CDF

DS026_07_020300

OE/RESET

T

OCK

T

OOE

T

OCE

Page 16

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

16 www.xilinx.com DS082 (v1.2) Nov em ber 5, 2001

1-800-255-7778 Preliminary Product Specification

R

Ordering Information

XQ18V04 CC44 V

Grade (Manufacturing Flow /

Temperature Range )

Device Number

Package Type

Device Ordering Options

Devi ce Type Package Grad e

XQ18V04 CC44 44-pin Ceramic Chip Carrier Package

M

Military Ceramic TC = –55°C to +125°C

XQR18V04

(1)

VQ44 44-pin Plastic Thin Quad Flat Package

N

Military Plastic TJ = –55°C to +12 5 °C

V

QPro-Plus TC = –55°C to +125°C

Notes:

1. Radiation Hardened.

5962 - 01525 Q Y A

Lead Finish

Generic Standard

Microcircuit Drawing (SMD)

Radiation Hardened

(1)

Package Type

QML Certified MIL-PRF-3 8535

SMD Ordering Options

Device Type QML

Package

Lead Finish

5962-01525 XQ18V04 - 44-pin Ceramic Chip Carrier Package Solder Dip

5962R01525 XQR18V04 - 44-pin Plastic Thin Quad Flat Package Solder Plate

Notes:

1. Type R designates Radiation Hardened.

Valid Ordering Combinations

Mil-Std SMD Rad Hard SMD

XQ18V04CC44M

-

XQR18V04CC44M

-

XQ18V04VQ44N - XQR18V04CC44V

Device Type

Page 17

QPro XQ18V04 (XQR18V04) QML In-System Programmable Configuration PROMs

DS082 (v1.2) November 5, 2001 www.xilinx.com 17

Preliminary Product Specification 1-800-255-7778

R

Revision History

The following table shows the revision history for this document.

Date Version Revision

5/1/01 1.0 First publication of this early access specification

7/23/01 1.1 Preliminary publication supporting Full Mil Temp range and corrected write cycles

11/05/01 1.2 Added Class V to ordering combinations for Rad Hard version. Updated format.

Loading...

Loading...