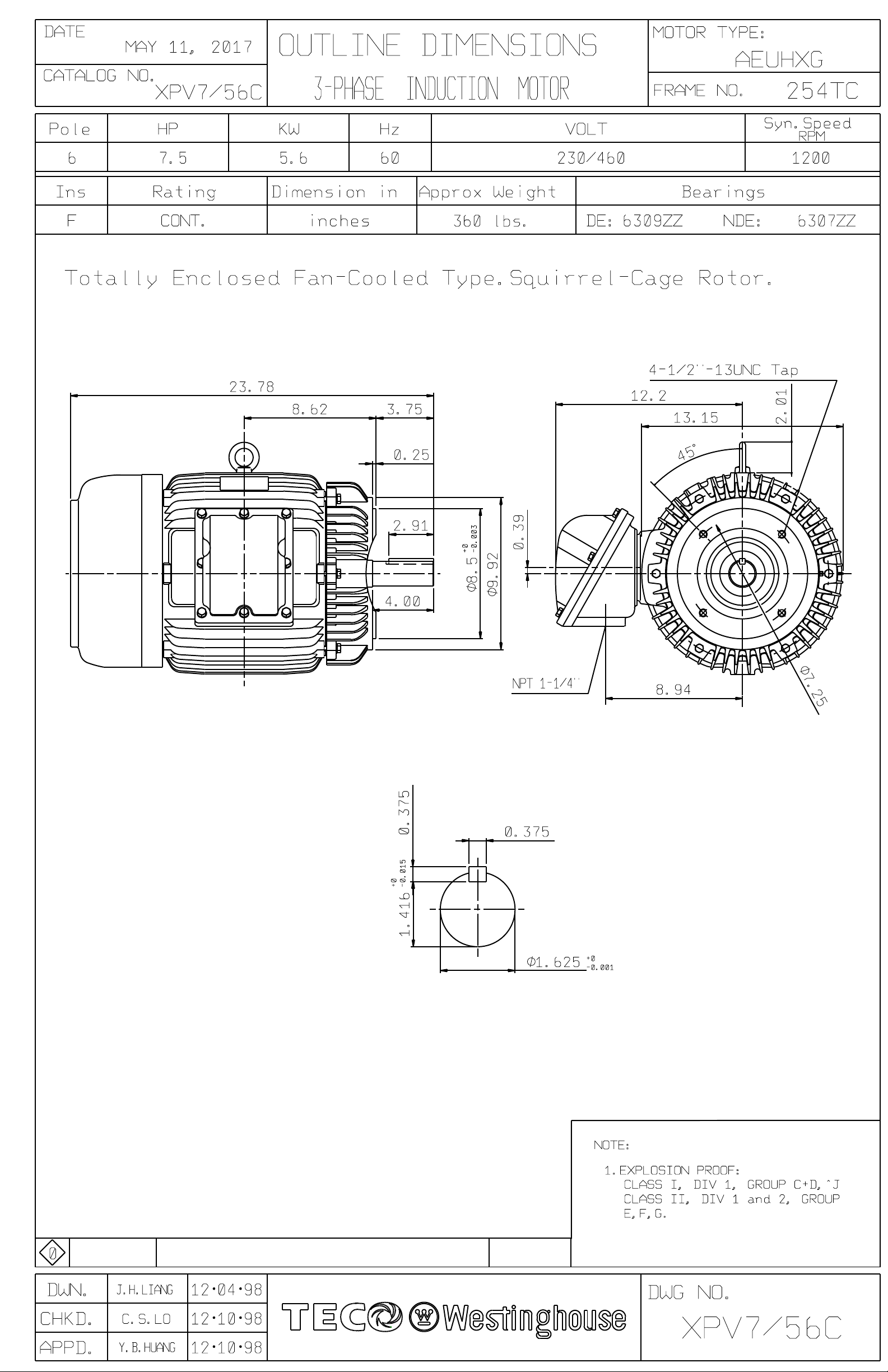

Page 1

Page 2

NAMEPLATE INFORMATION

HP KW

7.5 5.6 60

TYPICAL PERFORMANCE

0

ALLOWABLE

STARTS

PER HOUR

COLD

HOT

2

1

APPROVED:

REVISION

COLD

HOT

36

25

M. PRATER

DRAWING NO.

31057XPV7/56C

SOUND

PRESSURE

LEVEL @ 3 FT

dB(A)

15.66

NEMA

LOAD

WK

2

Sec

MAX

ALLOWABLE

WK

2

Sec

SAFE STALL

TIME IN

SECONDS

33.66

240

195

260

NEMA

LOAD

WK

2

lb-ft

2

PULL

UP

%FLT

9.05

8.18

AT

460

VOLT

AT

208

VOLT

AT

208

VOLT

AT

230

VOLT

AT

230

VOLT

AT

460

VOLT

63.50

20.81

4.09

9.41

18.82

127.00

BREAK

DOWN

%FLT

NEMA

KVA

CODE

LETTER

H

140.43

ACCEL TIME

INERTIA

2.158

ROTOR

WR

2

lb-ft

2

TORQUE

FULL LOAD

lb-ft

LOCKED

ROTOR

%FLT

312.31

1170

FULL

LOAD

RPM

POWER FACTOR

3/4 LOAD

%

1/2 LOAD

%

F. L.

%

829191.5

FULL LOAD

MIN. %

NOM. %

3/4 LOAD

%

104

MAX

ALLOWABLE

WK

2

lb-ft

2

CURRENTS

NO LOAD

FULL LOAD

LOCKED ROTOR

5.29

AT

208

VOLT

AT

230

VOLT

AT

460

VOLT

TIME

RATING

CONT.

SERVICE

FACTOR

1.15

77

66.5

MAXIMUM

POWER FACTOR

CORRECTION

KVAR

3.3

INS.

CLASS

F

NEMA

DESIGN

B

VOLTAGE

230/460

HZ

RATED

AMBIENT

40oC

ISSUED

December 12, 2018

TYPE

AEUHXG

ENCLOSURE

EXPLOSION PROOF

CATALOG#

XPV7/56C

PERFORMANCE DATA

3-PHASE INDUCTION MOTOR

57

OUTPUT

POLE

6

FRAME

SIZE

254TC

EFFICIENCY

1/2 LOAD

%

89.5

91

Page 3

DATE: CATALOG NO.:

LINE

LINE

LINE

LINE

July 14, 2011 XPV7/56C

CONNECTION DIAGRAM

SCHEMATIC - Δ / Y CONNECTION

ACROSS THE LINE CONNECTION

LINE

230 VOLT CONNECTION

460 VOLT CONNECTION

LINE

WYE START-DELTA RUN CONNECTION

230 VOLT START 230 VOLT RUN 460 VOLT START 460 VOLT RUN

DWG NO.

DAC-1565-4

Page 4

Page 5

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

FOR THREE PHASE

INDUCTION MOTORS

Frames 143T - 449TZ

Page 6

RECEIVING

1. Check nameplate data.

2. Check whether any damage has occurred during transportation.

3. After removal of shaft clamp, turn shaft by hand to check that it turns freely.

4. If motor is to be reshipped (alone or installed to anotherpiece of equipment)the shaft must again

be clamped to prevent axial movement.

Note: Remove the bearing clamp before turning the shaft on 284T-449TZ frame motors.

WARNING

THE FOLLOWING SAFETY PRECAUTIONS MUST BE OBSERVED:

1. Electric rotating machinery and high voltage can cause serious or fatal injuryif improperly

installed, operated or maintained. Responsible personnel should be familiarized with

NEMA MG-1; Safety Standards for Construction and Guide Selection. Installation and Use of

Electric Motors and Generators; National Electric Code and all local safety requirements.

2. Whenservicing, all power sources to the motor and to the accessorydevicesshould be

de-energized and disconnected and all rotating parts should be at standstill.

3. Lifting means, when supplied, are intendedfor lifting the motor only. When two lifting

devices are supplied with the motor a dual chain must be used.

4. Suitable protection must be used when working near machinery with high noise levels.

5. Safeguard or protective devices must not be by-passed or rendered inoperative.

6. The frame of this machine must be grounded in accordance with the National Electric Code and

applicable local codes.

7. A suitable enclosure should be provided to prevent access to the motor by other than

authorized personnel. Extra caution should be observed around motors that are

automatically or have automatic re-setting relays as they may restart unexpectedly.

8. Shaft key must be fully captive or removed before motor is started.

9. Provide proper safeguards for personnel against possible failure of motor-mounted brake,

particularly on applications involving overhauling loads.

10.Explosion proof motors are constructed to comply with the label service procedure manual, repair

of these motors must be made by or U/L listed service

center in order to maintain U/L listing.

LOCATION

1. Drip-proof motors are intended for use where atmosphere is relatively clean, dry, well

ventilated and non-corrosive.

2. Totallyenclosed motors maybeinstalled where dirt, moisture, or dustare present and in outdoor

locations.

3. Explosion-proof motors are built for use in hazardous locations as indicated by

Underwriters’ label on the motor.

4. Chemical duty enclosed motors aredesigned for installation in highcorrosion or excessive

moisture locations.

Note: in all cases, no surrounding structure should obstruct normal flow or

ventilating air through or over the motor.

Page 7

MOUNTING

2/82537

1/26090

5/8

120

180

1. Mount motor securely on a firm, flat base. All ball bearing normal thrust motors up to and

including 256T frame size may be side-wall or ceiling mounted; all others check nearest

TECO-Westinghouse office for mounting recommendations.

2. Align motoraccurately, using a flexiblecoupling if possible.For drive recommendations,

consult with drive or equipment manufacturer, or TECO-Westinghouse.

3. Mounting bolts must be carefully tightened to prevent changes in alignment and possible

damageto the equipment. The recommended tighteningtorque’s for medium carbon steel bolts,

identified by three radial lines at 120 degrees on the head, are:

Bolt Size

Recommended Torque (Ft-lb.)

Minimum Maximum

3/4 210 320

4. V-beltsSheavePitchDiameters should not be lessthanthose shown in Table1 (NEMA

recommended values)

5. Tighten belts only enough to prevent slippage. Belt speed should not exceed 5000 ft. per

min.

TABLE 1. V-Belt Sheave Pitch Diameters (MG1-14.42)

V-Belt Sheave

Conventional

A, B, C, D AND E

Minimum

Horsepower at

Frame

Number 3600 1800 1200 900

143T 1.5 1 .75 .5 2.2 4.25 2.2 2.25

145T 2-3 1.5-2 1 .75 2.4 4.25 2.4 2.25

182T 3 3 1.5 1 2.4 5.25 2.4 2.75

182T 5 ... ... ... 2.6 5.25 2.4 2.75

184T ... ... 2 1.5 2.4 5.25 2.4 2.75

184T 5 ... ... ... 2.6 5.25 2.4 2.75

184T 7.5 5 ... ... 3.0 5.25 3.0 2.75

213T 7.5-10 7.5 3 2 3.0 6.5 3.0 3.375

215T 10 ... 5 3 3.0 6.5 3.0 3.375

215T 15 10 ... ... 3.8 6.5 3.8 3.375

254T 15 ... 7.5 5 3.8 7.75 3.8 4

254T 20 15 ... ... 4.4 7.75 4.4 4

256T 20-25 ... 10 7.5 4.4 7.75 4.4 4

256T ... 20 ... ... 4.6 7.75 4.4 4

284T ... ... 15 10 4.6 9 4.4 4.625

284T ... 25 ... ... 5.0 9 4.4 4.625

286T ... 30 20 15 5.4 9 5.2 4.625

Synchronous Speed, RPM

Pitch

Diameter

Inches

*Maximum

Width

Inches

Minimum

Outside

Diameter

Inches

Narrow

3V, 5V, AND 8V

**Maximum

Width

Inches

Page 8

TABLE 1. V-Belt Sheave Pitch Diameters (MG1-14.42)

V-Belt Sheave

Conventional

A, B, C, D AND E

Minimum

Horsepower at

Frame

Number 3600 1800 1200 900

324T ... 40 25 20 6.0 10.25 6.0 5.25

326T ... 50 30 25 6.8 10.25 6.8 5.25

364T ... ... 40 30 6.8 11.5 6.8 5

364T ... 60 ... ... 7.4 11.5 7.4 5.785

365T ... ... 50 40 8.2 11.5 8.2 5.785

365T ... 75 ... ... 9.0 11.5 8.6 5.785

404T ... ... 60 ... 9.0 14.25 8.0 7.25

404T ... ... ... 50 9.0 14.25 8.4 7.25

404T ... 100 ... ... 10.0 14.25 8.6 7.25

405T ... ... 75 60 10.0 14.25 10.0 7.25

405T ... 100 ... ... 10.0 14.25 8.6 7.25

405T ... 125 ... ... 11.5 14.25 10.5 7.25

444T ... ... 100 ... 11.0 16.75 10.0 8.5

444T ... ... ... 75 10.5 16.75 9.5 8.5

444T ... 125 ... ... 11.0 16.75 9.5 8.5

444T ... 150 ... ... ... 16.75 10.5 8.5

445T ... ... 125 ... 12.5 16.75 12.0 8.5

445T ... ... ... 100 12.5 16.75 12.0 8.5

445T ... 150 ... ... ... 16.75 10.5 8.5

Synchronous Speed, RPM

Pitch

Diameter

Inches

*Maximum

Width

Inches

Minimum

Outside

Diameter

Inches

Narrow

3V, 5V, AND 8V

**Maximum

*Max. Sheave width = 2(N-W) - .25

**Max Sheave width = N-W

***Sheave ratios grater than 5:1 and center-to-center distance less than the diameter of the

large sheave should be referred to TECO-Westinghouse.

Width

Inches

POWER SUPPLY & CONNECTIONS

1. Wiringof motor and control, overload protection and grounding should be in accordance with

National Electrical Code and all local safety requirements.

2. Nameplate voltage and frequency should agree with power supply. Motor will operate

satisfactorily on line voltage within ±10% of nameplatevoltage; or frequency with ±5% and

with a combined variation not to exceed ±10%. 230-volt motorscan be used on 208-volt

networksystems, but with slightly modified performance characteristics as shown on the

nameplate.

3. Dual voltage and single voltage motors can be connected for the desired voltage by

following connection diagram shown on the nameplate or inside of the conduit box.

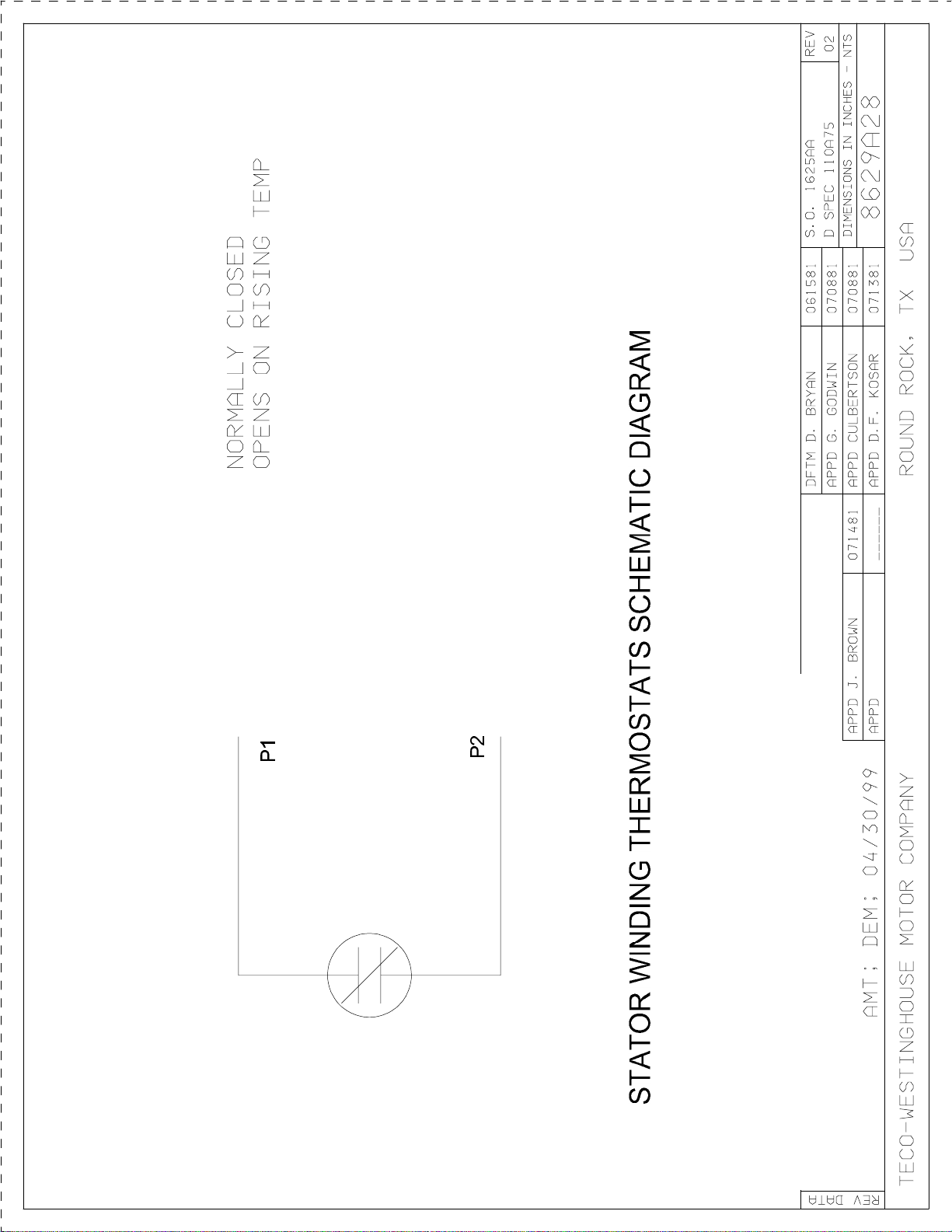

4. All Explosion Proof motorshave Temperature Limiting Devices in the motor enclosure to

preventexcessive external surface temperature of the motor in accordance with U/L

standards. Terminals of thermal protectors (P1 & P2) should be connected to the motor

control equipment, according to the connection diagram inside of the conduit box.

5. Standard connection diagram for three phase, not thermally protected, dual rotation motors

are shown in diagrams A through E. (Note: To change rotation, Interchange any two line

leads)

Page 9

Page 10

Page 11

*Important: For Part Winding Start, M2 contactor should be closed within two (2) seconds

after M1 contactor is closed.

Only 4 pole and above (e.g., 6P, 8P...) motors are satisfactory for Part WindingStart

at low voltage.

START UP

1. Disconnect load and start motor. Check direction of rotation. If rotation must be changed,

ALLOW THE MOTOR TO STOP COMPLETLEY. Interchange any two leads of a three-phase

motor.

2. Connect load. The motor should start quickly and run smoothly. If no, shut power off at once.

Recheck the assembly including all connections before restarting.

3. If excessive vibration is noted, check for loose mounting boltstoo flexible motorsupport

structure or transmitted vibration from adjacent machinery. Periodic vibration checks should

be made; foundations often settle.

4. Operate under load for short period of time and check operating current against nameplate.

TESTING

If themotor has beenin storagefor an extensiveperiodor has beensubjected to adversemoisture

conditions, it is bestto check the insulation resistance of the stator winding with a megometer.

Depending on the length and conditions of storageit may be necessary to regrease or change

rusted bearings.

If the resistance is lower than one megohm the windingsshould be dried in one of the following two

ways:

1. Bake in ovenat temperatures not exceeding 194°F until insulation resistancebecomes

constant.

2. With rotorlocked, apply low voltage and graduallyincrease the current through windings until

temperature measured with a thermometer reaches 194°F. Do not exceed this temperature.

Page 12

MAINTENANCE

1 Thru 30 Hp, 1800 rpm and below

7 years

3 years

180 days

1 Thru 20 Hp, 3600 rpm

5 years

2 years

90 days

INSPECTION

Inspect motor at regular intervals. Keep motor clean and ventilation openings clear.

LUBRICATION

1. Frame 143T-256T: Double shielded and pre-lubricated ball-bearing motors without grease

fittings and don’t need re-lubrication, except on MAX-E1®and MAX-E2®products which

have re-greasable features.

2. Frames 280TS, 320-449TZ(TS): Motors having grease fittings and grease discharge

devices at brackets. Motors are shipped with grease for initial running. It is necessary to

re-lubricate anti-friction bearingmotors periodically, depending on size and type of service. See

Table 2 to provide maximum bearing life. Excessive or too frequent lubrication may damage

the motor.

TABLE 2

Horsepower

40 Thru 75 Hp, 1800 rpm and below 210 days 70 days 30 days

100 Thru 150 Hp, 1800 rpm and below 90 days 30 days 15 days

25 Thru 75 Hp, 3600 rpm 180 days 60 days 30 days

100 Thru 150 Hp, 3600 rpm 90 days 30 days 15 days

Note:

A. Standard conditions: 8 hours operation per day, normal or light loading, clear and 40°C

ambient conditions.

B. Severe conditions: 24-hour operation per day or light shock loading, vibration or in dirty or

dusty conditions.

C. Extreme conditions: With heavy shock loading or vibration or dusty conditions.

D. For double shielded bearings, abovedata (lubricationfrequency) meansthat the

bearing must be replaced.

3. Be sure fittings are clean and free from dirt. Using a low-pressure grease gun, pump in the

recommended grease until new grease appears at grease discharge hole.

4. Use the POLYUREA grease unless special grease is specified on the nameplate.

5. If re-lubrication is to be performed with the motor running, stay clear of rotating parts. After

re-greasing, allow the motor to run for ten to thirty minutes.

Standard

Conditions

Severe

Conditions

Extreme

Conditions

Page 13

RENEWAL PARTS

1. Use only genuine TECO-Westinghouse renewal parts or as recommended by TECOWestinghouse Motor Company.

2. Whenyou order renewal parts please specify complete informationto TECO-Westinghouse

office/agent such as type, frame no., poles, horsepower, voltage, series no., quantity, etc.

FOR FURTHER INFORMATION PLEASE CONTACT

Loading...

Loading...