Page 1

®

www.BDTIC.com/Intersil

X93254

Data Sheet February 4, 2008

Dual Digitally Controlled Potentiometers

(XDCPs™)

The Intersil X93254 is a dual digitally controlled

potentiometer (XDCP). The device consists of two resistor

arrays, wiper switches, a control section, and nonvolatile

memory. The wiper positions are controlled by individual

Up/Down interfaces.

A potentiometer is implemented by a resistor array

composed of 31 resistive elements and a wiper switching

network. The position of each wiper element is controlled by

a set of independent CS

, U/D, and INC inputs. The position

of the wiper can be stored in nonvolatile memory and then

be recalled upon during a subsequent power-up operation.

Each potentiometer is connected as a two-terminal variable

resistor and can be used in a wide variety of applications

including:

• Bias and Gain control

• LCD Contrast Adjustment

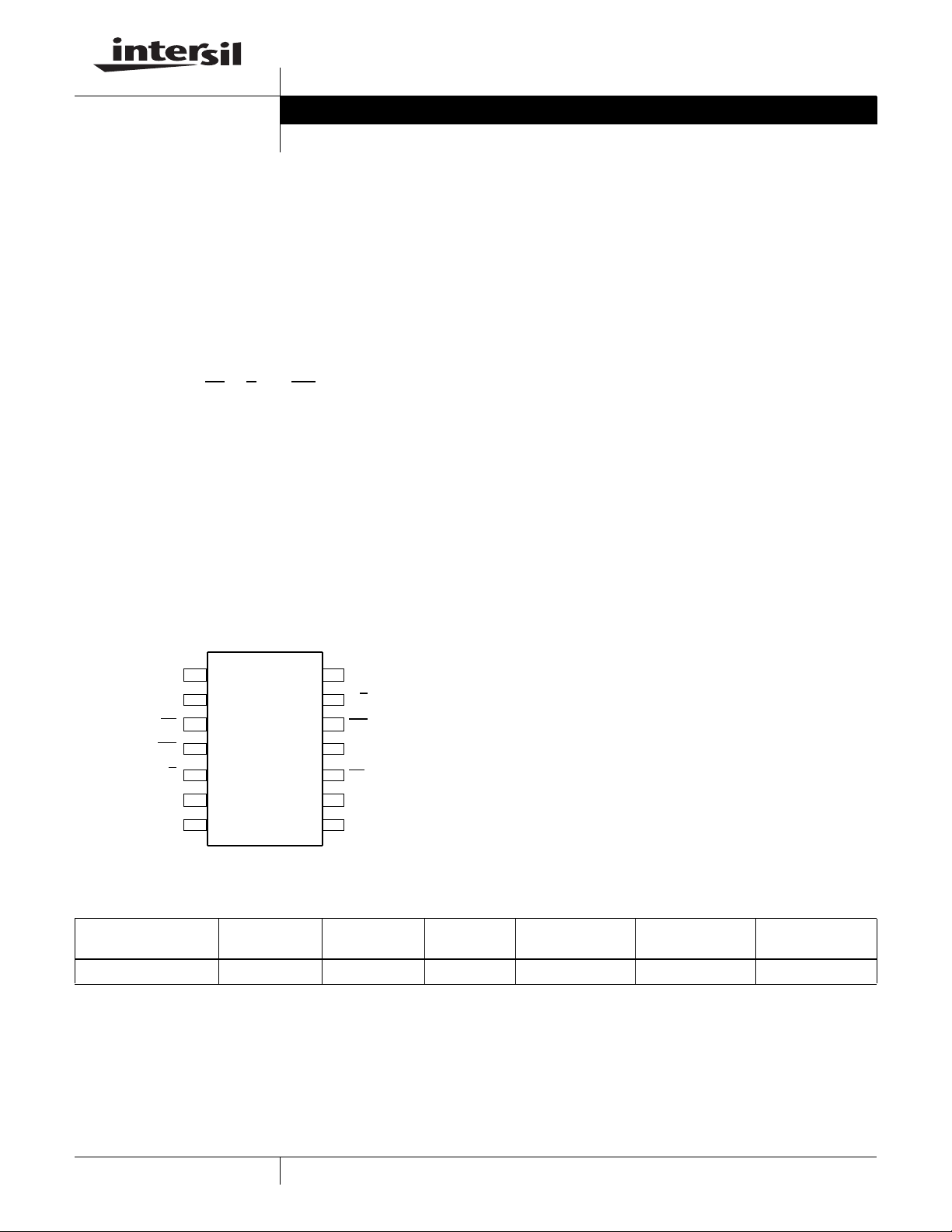

Pinout

X93254

(14 LD TSSOP)

TOP VIEW

Features

• Dual solid-state potentiometers

• Independent Up/Down interfaces

• 32 wiper tap points per potentiometer

- Wiper position stored in nonvolatile memory and

recalled on power-up

• 31 resistive elements per potentiometer

- Temperature compensated

- Maximum resistance tolerance of ± 30%

- Terminal voltage, 0 to V

• Low power CMOS

-V

= 3V ±10%

CC

- Active current, 250µA max

- Standby current, 1µA max

• High reliability

- Endurance 200,000 data changes per bit

- Register data retention, 100 years

TOTAL

value = 50kΩ

•R

• 14 Ld TSSOP package

CC

FN8186.1

DNC*

R

CS

INC

U/D

R

V

*Do not connect.

L1

H2

SS

1

2

1

3

2

4

5

2

6

7

14

13

12

11

10

R

H1

U/D

1

INC

1

V

CC

CS

2

R

9

8

L2

DNC*

Ordering Information

PART NUMBER PART MARKING VCC LIMITS (V) R

X93254UV141-3 X9325 4UVE 3 ±10% 50 -40 to +85 14 Ld TSSOP M14.173

TOTAL

(kΩ)

TEMP

RANGE (°C) PACKAGE PKG DWG. #

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or1-888-468-3774

XDCP is a trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2005, 2008. All Rights Reserved

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Page 2

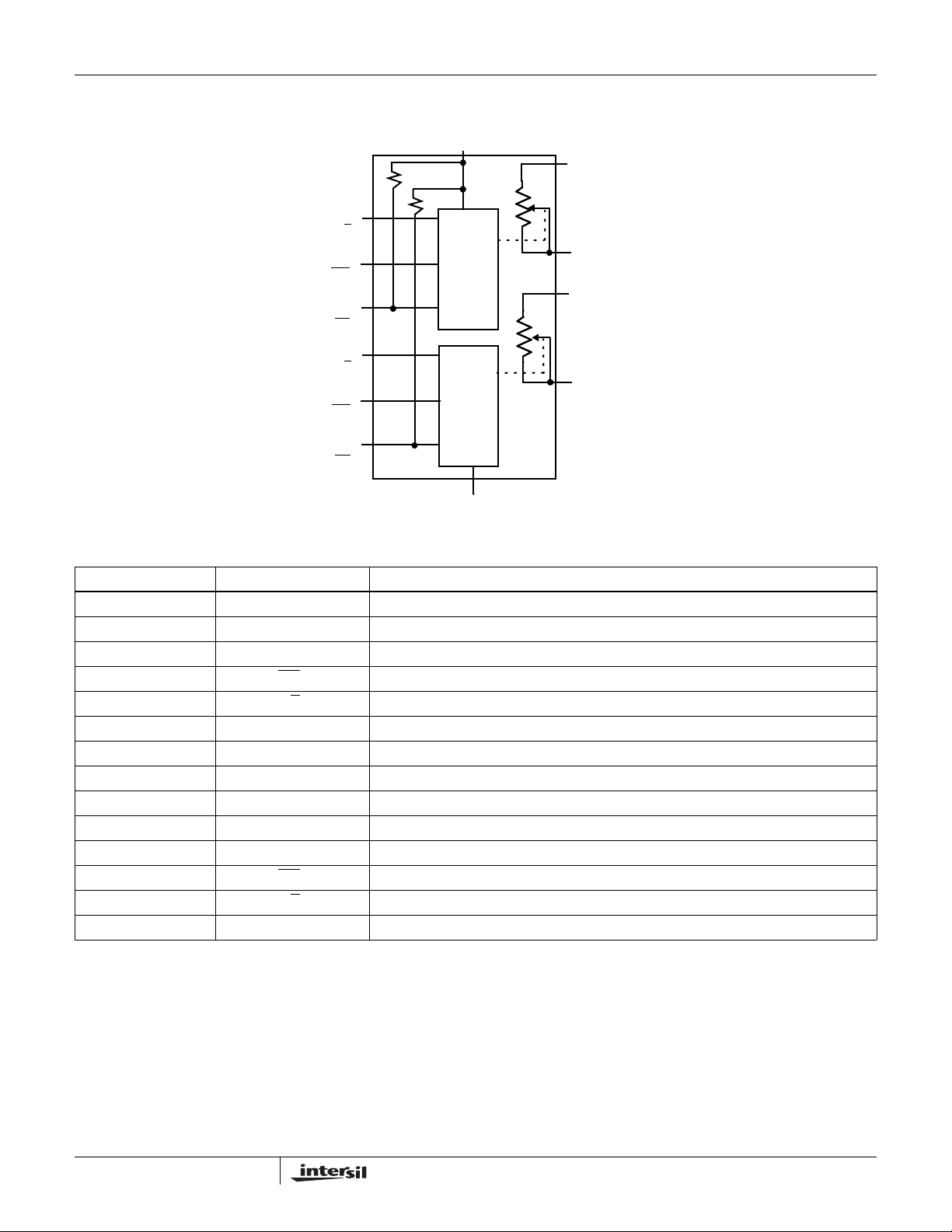

Block Diagram

www.BDTIC.com/Intersil

UP/DOWN

(U/D1)

INCREMENT

(INC

DEVICE SELECT

(CS

UP/DOWN

(U/D2)

INCREMENT

(INC

DEVICE SELECT

(CS

X93254

(SUPPLY VOLTAGE)

V

CC

R

30k

30k

CONTROL

)

1

)

1

)

2

)

2

AND

MEMORY

CONTROL

AND

MEMORY

V

(Ground)

SS

H1

R

L1

R

H2

R

L2

Pin Descriptions

TSSOP SYMBOL DESCRIPTION

1 DNC Do Not Connect

2R

3CS

4INC

5U/D

6R

7V

8 DNC Do Not Connect

9R

10 CS

11 V

12 INC

13 U/D

14 R

L1

H2

SS

L2

CC

H1

Low Terminal 1

1

2

2

Chip Select 1

Increment 2

Up/Down 2

High Terminal 2

Ground

Low Terminal 2

2

Chip Select 2

Supply Voltage

1

1

Increment 1

Up/Down 1

High Terminal 1

2

FN8186.1

February 4, 2008

Page 3

X93254

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Voltage on CS, INC, U/D, RH, RL and V

with respect to VSS . . . . . . . . . . . . . . . . . . . . . . . . . .-1V to +6.5V

Maximum resistor current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2mA

CC

Recommended Operating Conditions

Temperature Range

Industrial. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

Supply Voltage

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3V ±10% (Note 6)

V

CC

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTES:

1. Absolute linearity is utilized to determine actual wiper voltage versus expected voltage = (V

n = 1 .. 29 only

2. Relative linearity is a measure of the error in step size between taps = V

3. 1 Ml = Minimum Increment = R

4. Typical values are for T

5. Limits established by characterization and are not production tested.

6. When performing multiple write operations, V

7. Parts are 100% tested at +25°C. Over-temperature limits established by characterization and are not production tested.

= +25°C and nominal supply voltage.

A

TOT

/31.

must not decrease by more than 150mV from its initial value.

CC

Temperature under bias. . . . . . . . . . . . . . . . . . . . . .-65°C to +135°C

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Lead temperature (soldering 10s) . . . . . . . . . . . . . . . . . . . . .+300°C

Maximum reflow temperature (40s). . . . . . . . . . . . . . . . . . . .+240°C

H(n+1)

- [V

(actual) - V

H(n)

+ Ml] = ±0.5 Ml, n = 1 .. 29 only.

H(n)

(expected)) = ±1 Ml Maximum.

H(n)

Potentiometer Specifications Over recommended operating conditions, unless otherwise stated.

MIN

SYMBOL PARAMETER TEST CONDITIONS/NOTES

R

TOT

V

R

I

W

C

H/CL/CW

R

W

End-to-End Resistance 37.5 50 62.5 kΩ

RH, RL Terminal Voltages 0 V

Power Rating R

Noise Ref: 1kHz -120 dBV

Wiper Resistance (Note 5) 1000 Ω

Wiper Current (Note 5) 0.6 mA

Resolution 3%

Absolute Linearity

Relative Linearity

Temperature Coefficient (Note 5) ±35 ppm/°C

R

TOTAL

Potentiometer Capacitances See “Circuit #2 SPICE Macro

(Note 1) V

(Note 2) V

= 50kΩ 1mΩ

TOTAL

- [V

H(n)+MI

- V

H(n)(expected)

H(n)(actual)

H(n+1)

Model” on page 4

(Note 7)

TYP

(Note 4)

10/10/25 pF

MAX

(Note 7) UNIT

CC

(Note 5)

(Note 5)

±1 MI

(Note 3)

±0.5 MI

(Note 3)

(Note 5)

V

3

FN8186.1

February 4, 2008

Page 4

X93254

www.BDTIC.com/Intersil

.

DC Operating Specifications

Over recommended operating conditions unless otherwise stated.

SYMBOL PARAMETER TEST CONDITIONS/NOTES

I

CC1

I

CC2

I

V

VCC Active Current (Increment) per DCP CS = VIL, U/D = VIL or VIH and

= 0.4V @ max. t

INC

VCC Active Current (Store) (EEPROM

Store) per DCP

Standby Supply Current CS = VCC - 0.3V, U/D and INC = VSS

SB

I

CS1 or CS

LI

CS1 or CS

I

LI

INC1, INC2, U/D1, U/D2 Input Leakage

I

LI

Current

CS1, CS2, INC1, INC2, U/D1, U/D2 Input

IH

2

2

CS = VIH, U/D = VIL or VIH and

INC

=V

@ max. t

IH

- 0.3V

or V

CC

VIN = V

CC

VCC = 3V, CS = 0 60 100 150 µA

VIN = V

SS

to V

)±1µA

CC

CY

WR

HIGH Voltage

V

C

Endurance and Data Retention

CS1, CS2, INC1, INC2, U/D1, U/D2 Input

IL

HIGH Voltage

CS1, CS2, INC1, INC2, U/D1, U/D2 Input

IN

Capacitance

VCC = 3V, VIN = VSS, TA= +25°C,

f = 1MHz (Note 5)

Circuit #2 SPICE Macro Model

PARAMETER MIN UNIT

Minimum endurance 200,000 Data changes per bit

Data retention 100 Years

Test Circuit #1

TEST POINT

VH/R

H

MIN

(Note 7)

TYP

(Note 4)

MAX

(Note 7) UNIT

50 250 µA

600 µA

1µA

±1 µA

V

x 0.7 VCC + 0.5 V

CC

-0.5 V

x 0.1 V

CC

10 pF

R

R

H

10pF

TOTAL

C

C

H

W

25pF

C

10pF

R

L

L

AC Conditions of Test

V

L

Input pulse levels 0V to 3V

Input rise and fall times 10ns

Input reference levels 1.5V

AC Operating Specifications Over recommended operating conditions, unless otherwise stated. CS, INC, U/D, R

refer to either CS

SYMBOL PARAMETER

t

t

t

t

t

t

CPH

t

CPH

Cl

lD

DI

t

lL

lH

lC

CS to INC Setup 100 ns

INC HIGH to U/D Change 100 ns

U/D to INC Setup 100 ns

INC LOW Period 1 µs

INC HIGH Period 1 µs

INC Inactive to CS Inactive 1 µs

CS Deselect time (No Store) 250 ns

CS Deselect time (Store) 10 ms

4

or CS2, etc.

1

MIN

(Note 7)

TYP

(Note 4)

MAX

(Note 7) UNIT

and RL are used to

H

FN8186.1

February 4, 2008

Page 5

X93254

www.BDTIC.com/Intersil

AC Operating Specifications Over recommended operating conditions, unless otherwise stated. CS, INC, U/D, R

refer to either CS

SYMBOL PARAMETER

t

CYC

t

R, tF

(Note 5)

t

R VCC

(Note 5)

t

WR

INC Cycle Time 2 µs

INC

input Rise and Fall Time 500 µs

Power-up Rate 1 50 V/ms

V

CC

Store Cycle 510ms

or CS2, etc. (Continued)

1

MIN

(Note 7)

TYP

(Note 4)

MAX

(Note 7) UNIT

AC Timing

CS

t

INC

U/D

CYC

t

CI

t

IL

t

ID

t

IH

t

IC

t

DI

(STORE)

t

CPH

t

F

90% 90%

10%

and RL are used to

H

t

R

Note: CS, INC, U/D, RH and RL are used to refer

to either CS

or CS2, etc.

1

Power-up and Power-down Requirements

There are no restrictions on the power-up or power-down

conditions of V

potentiometer pins provided that V

positive than or equal to V

V

ramp rate specification is always in effect.

CC

and the voltages applied to the

CC

and VL, i.e., VCC ≥ VH,VL. The

H

is always more

CC

Pin Descriptions

In the text, CS, INC, U/D, RH and RL are used to refer to

either CS

independently or at the same time.

RH and R

The R

fixed terminals of a mechanical potentiometer. The minimum

voltage is V

R

H

relation to wiper movement direction selected by the U/D

input per potentiometer.

Up/Down (U/D)

The U/D input controls the direction of a single

potentiometer’s wiper movement and whether the counter is

incremented or decremented.

or CS2, etc. Note: These signals can be applied

1

L

and RL pins of the X93254 are equivalent to the

H

and the maximum is VCC. The terminology of

SS

and R

references the relative position of the terminal in

L

Increment (INC)

The INC input is negative-edge triggered. Toggling INC will

move the wiper and either increment or decrement the

corresponding potentiometer’s counter in the direction

indicated by the logic level on the corresponding

potentiometer’s U/D

input.

Chip Select (CS)

A potentiometer is selected when the corresponding C S input

is LOW. Its curren t counter value is store d in nonvo latile

memory when the corresponding CS

the corresponding INC

input is also HIGH. After the store

is returned HIGH while

operation is complete, the affected potentiometer will be

placed in the low power standby mode until the potentiometer

is selected once again.

Principles of Operation

There are multiple sections for each potentiometer in the

X93254: an input control, a counter and decode section; the

nonvolatile memory; and a resistor array. Each input control

section operates just like an up/down counter. The output of

this counter is decoded to turn on a single electronic switch

connecting a point on the resistor array to the wiper output.

Under the proper conditions, the contents of the counter can

be stored in nonvolatile memory and retained for future use.

Each resistor array is comprised of 31 individual resistors

5

FN8186.1

February 4, 2008

Page 6

X93254

www.BDTIC.com/Intersil

connected in series. At either end of the array and between

each resistor is an electronic switch that transfers the

connection at that point to the wiper.

Each wiper, when at either fixed terminal, acts like its

mechanical equivalent and does not move beyond the last

position. That is, the counter does not wrap around when

clocked to either extreme.

If the wiper is moved several positions, multiple taps are

connected to the wiper for t

(INC to VW change). The

IW

2-terminal resistance value for the device can temporarily

change by a significant amount if the wiper is moved several

positions.

When the device is powered-down, the last wiper position

stored will be maintained in the nonvolatile memory for each

potentiometer. When power is restored, the contents of the

memory are recalled and each wiper is set to the value last

stored.

Instructions and Programming

The INC, U/D and CS inputs control the movement of the

wiper along the resistor array. With CS

potentiometer is selected and enabled to respond to the U/D

and INC

inputs. HIGH to LOW transitions on INC will

increment or decrement (depending on the state of the U/D

input) a 5-bit counter. The output of this counter is decoded

to select one of thirty two wiper positions along the resistive

array.

The value of the counter is stored in nonvolatile memory

whenever each CS

transitions HIGH while the INC input is

also HIGH. In order to avoid an accidental store during

power-up, each CS

must go HIGH with VCC during initial

power-up. When left open, each CS

to V

by an internal 30k resistor.

CC

The system may select the X93254, move any wiper and

deselect the device without having to store the latest wiper

position in nonvolatile memory. After the wiper movement is

performed as previously described and once the new position

is reached, the system must keep INC

HIGH. The new wiper position will be maintained until

changed by the system or until a power-up/down cycle

recalled the previously stored data. In order to recall the

stored position of the wiper on power-up, the CS

held HIGH.

This procedure allows the system to always power-up to a

preset value stored in nonvolatile memory; then during

system operation minor adjustments could be made. The

set LOW the

pin is internally pulled up

LOW while taking CS

pin must be

adjustments might be based on user preference, system

parameter changes due to temperature drift, or other system

trim requirements.

The state of U/D

may be changed while CS remains LOW.

This allows the host system to enable the device and then

move each wiper up and down until the proper trim is

attained.

Mode Selection

CS INC U/D MODE

L H Wiper Up

L L Wiper Down

H X Store Wiper Position

H X X Standby Current

L X No Store, Return to Standby

L H Wiper Up (not recommended)

L L Wiper Down (not recommended)

Symbol Table

WAVEFORM INPUTS OUTPUTS

Must be

steady

May change

from Low to

High

May change

from High to

Low

Don’t Care:

Changes

Allowed

N/A Center Line

Will be

steady

Will change

from Low to

High

Will change

from High to

Low

Changing:

State Not

Known

is High

Impedance

Applications Information

Electronic digitally controlled (XDCP) potentiometers provide

three powerful application advantages:

1. The variability and reliability of a solid-state potentiometer

2. The flexibility of computer-based digital controls

3. The retentivity of nonvolatile memory used for the storage

of multiple potentiometer settings or data

6

FN8186.1

February 4, 2008

Page 7

X93254

www.BDTIC.com/Intersil

.

V

R

I

Low Voltage High Impedance Instrumentation Amplifier

3.3V

+

V

IN

–

10k

10k

+

U1A

–

50k

1

/2 X93254 (R

50k

–

U1B

+

TOTAL

)

Two terminal variable resistor.

Variable current

10k 50k

–

U1C

+

10k

50k

GAIN =

U1 = LT1467

50k

10k

V

OUT

50k

R

TOTAL

)

(

1 +

Micro-Power LCD Contrast Control

3.3V

240k

100k

3.3V

+

U1A

–

100k

50k

1

/2 X93254 (R

TOTAL

Single Supply Variable Gain Amplifier

V

IN

20k

20k

)

10k

3.3V

100k

300k

1 +

100k

50k + R

V

= -3.88

–

U1B

+

–12V

3.3V

+

U1

–

1

/2 X93254

(R

TOTAL

V

U1 = LMC6042

V

OUT

GAIN =

U1 = LMC6042

)

OUT

= -2.75V TO -11.6V

OUT

R

(

TOTAL

10k

TOTAL

)

7

FN8186.1

February 4, 2008

Page 8

X93254

www.BDTIC.com/Intersil

Thin Shrink Small Outline Plastic Packages (TSSOP)

N

INDEX

AREA

123

0.05(0.002)

-AD

e

b

0.10(0.004) C AM BS

NOTES:

1. These package dimensions are within allowable dimensions of

JEDEC MO-153-AC, Issue E.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension “E1” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.15mm (0.006 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “b” does not include dambar protrusion. Allowable dambar

protrusion shall be 0.08mm (0.003 inch) total in excess of “b” dimension at maximum material condition. Minimum space between protrusion and adjacent lead is 0.07mm (0.0027 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact. (Angles in degrees)

E1

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

E

α

A1

0.10(0.004)

GAUGE

PLANE

0.25

0.010

A2

L

c

M14.173

14 LEAD THIN SHRINK SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.047 - 1.20 -

A1 0.002 0.006 0.05 0.15 -

A2 0.031 0.041 0.80 1.05 -

b 0.0075 0.0118 0.19 0.30 9

c 0.0035 0.0079 0.09 0.20 -

D 0.195 0.199 4.95 5.05 3

E1 0.169 0.177 4.30 4.50 4

e 0.026 BSC 0.65 BSC -

E 0.246 0.256 6.25 6.50 -

L 0.0177 0.0295 0.45 0.75 6

N14 147

o

α

0

o

8

o

0

o

8

NOTESMIN MAX MIN MAX

-

Rev. 2 4/06

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its sub sidi aries.

For information regarding Intersil Corporation and its products, see www.intersil.com

8

FN8186.1

February 4, 2008

Loading...

Loading...