Page 1

APPLICATION NOTE

AVAILABLE

AN63

X88C64

8051 Microcontroller Family Compatible

SLIC

64K X88C64 8192 x 8 Bit

E2 Micro-Peripheral

FEATURES

• CONCURRENT READ WRITE

™

—Dual Plane Architecture

—Isolates Read/Write Functions

Between Planes

—Allows Continuous Execution of Code

From One Plane While Writing in

the Other Plane

• Multiplexed Address/Data Bus

—Direct Interface to Popular 8051 Family

• High Performance CMOS

—Fast Access Time, 120ns

—Low Power

—60mA Active Maximum

—500µA Standby Maximum

• Software Data Protection

• Block Protect Register

—Individually Set Write Lock Out in 1K Blocks

• Toggle Bit Polling

—Early End of Write Detection

• Page Mode Write

—Allows up to 32 Bytes to be Written in

One Write Cycle

• High Reliability

—Endurance: 100,000 Write Cycle

—Data Retention: 100 Years

DESCRIPTION

The X88C64 is an 8K x 8 E2PROM fabricated with

advanced CMOS Textured Poly Floating Gate Technology. The X88C64 features a Multiplexed Address

and Data bus allowing a direct interface to a variety of

popular single-chip microcontrollers operating in expanded multiplexed mode without the need for additional interface circuitry.

The X88C64 is internally configured as two independent 4K x 8 memory arrays. This feature provides the

ability to perform nonvolatile memory updates in one

array and continue operation out of code stored in the

other array; effectively eliminating the need for an

auxiliary memory device for code storage.

To write to the X88C64, a three-byte command

sequence must precede the byte(s) being written. The

X88C64 also provides a second generation software

data protection scheme called Block Protect. Block

Protect can provide write lockout of the entire device

or selected 1K blocks. There are eight 1K x 8 blocks

that can be write protected individually in any combination required by the user. Block Protect, in addition

to Write Control input, allows the different segments

of the memory to have varying degrees of alterability

in normal system operation.

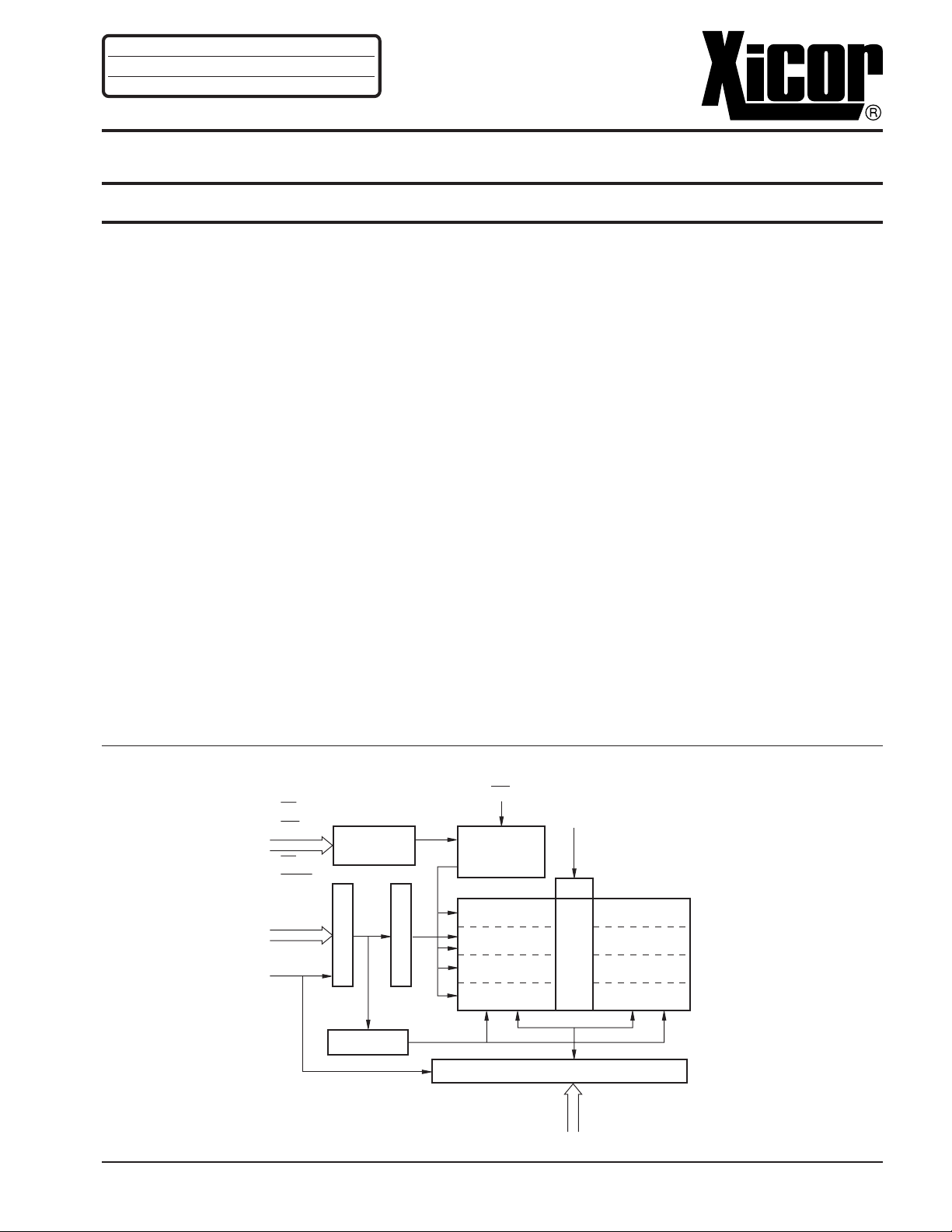

FUNCTIONAL DIAGRAM

WC

CE

WR

RD

PSEN

A8–A

ALE

CONCURRENT READ WRITE™ is a trademark of Xicor, Inc.

© Xicor, Inc. 1994, 1995, 1996 Patents Pending Characteristics subject to change without notice

3867-1.5 7/9/96 T0/C2/D0 NS

11

CONTROL

LOGIC

L

A

T

C

H

E

S

Y DECODE

SOFTWARE

DATA

PROTECT

X

D

E

C

O

D

E

1K BYTES

1K BYTES

1K BYTES

1K BYTES

I/O & ADDRESS LATCHES AND BUFFERS

1

A12

A

12

A

12

M

U

X

1K BYTES

1K BYTES

1K BYTES

1K BYTES

A/D0–A/D

7

3867 FHD F02

Page 2

X88C64

PIN DESCRIPTIONS

Address/Data (A/D0–A/D7)

Multiplexed low-order addresses and data. The Addresses flow into the device while ALE is HIGH. After

ALE transitions from a HIGH to LOW the addresses

are latched. Once the addresses are latched these

pins input data or output data depending on RD, WR,

PSEN, and CE.

Addresses (A8–A12)

High order addresses flow into the device when ALE

is HIGH and are latched when ALE goes LOW.

Chip Enable (CE)

The Chip Enable input must be LOW to enable all

read/write operations. When CE is HIGH and ALE is

LOW, the X88C64 is placed in the low power standby

mode.

Program Store Enable (PSEN)

When the X88C64 is to be used in a 8051 based

system, PSEN is tied directly to the microcontroller’s

PSEN output.

When WC is LOW (tied to VSS) the X88C64 will be

enabled to perform write operations. When WC is

HIGH normal read operations may be performed, but

all attempts to write to the device will be disabled.

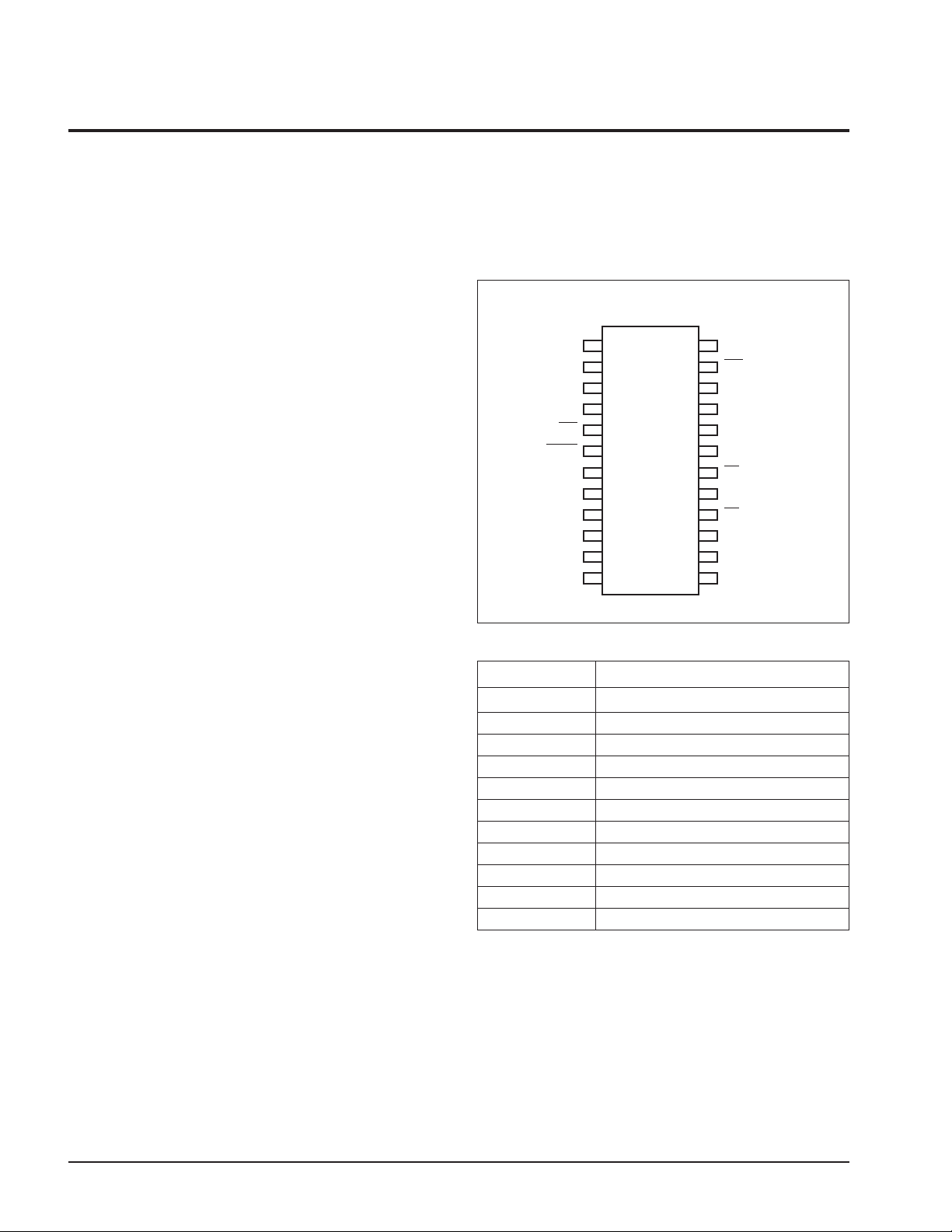

PIN CONFIGURATION

DIP/SOIC

NC

A12

NC

NC

WC

PSEN

A/D0

A/D1

A/D2

A/D3

A/D4

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

X88C64

24

23

22

21

20

19

18

17

16

15

14

13

V

CC

WR

ALE

A8

A9

A11

RD

A10

CE

A/D7

A/D6

A/D5

3867 FHD F01

Read (RD)

When the X88C64 is to be used in a 8051 based

system, RD is tied directly to the microcontroller’s RD

output.

Write (WR)

When the X88C64 is to be used in a 8051 based

system, WR is tied directly to the microcontroller’s

WR output.

Address Latch Enable (ALE)

Addresses flow through the latches to address decoders when ALE is HIGH and are latched when ALE

transitions from a HIGH to LOW.

Write Control (WC)

The Write Control allows external circuitry to abort a

page load cycle once it has been initiated. This input

is useful in applications in which a power failure or

processor RESET could interrupt a page load cycle.

In this case, the microcontroller might drive all signals

HIGH, causing bad data to be latched into the

E2PROM. If the Write Control input is driven HIGH

(before t

Max) after Write (WR) goes HIGH, the

BLC

write cycle will be aborted.

PIN NAMES

Symbol Description

ALE Address Latch Enable

A/D0–A/D

A8–A

12

7

Address Inputs/Data I/O

Address Inputs

RD Read Input

WR Write Input

PSEN Program Store Enable Input

CE Chip Enable

WC Write Control

V

SS

V

CC

Ground

Supply Voltage

NC No Connect

3867 PGM T01.1

2

Page 3

X88C64

PRINCIPLES OF OPERATION

The X88C64 is a highly integrated peripheral device for

a wide variety of single-chip microcontrollers. The

X88C64 provides 8K bytes of E2PROM which can be

used either for Program Storage, Data Storage, or a

combination of both in systems based upon Harvard

(80XX) architectures. The X88C64 incorporates the

interface circuitry normally needed to decode the control

signals and demultiplex the Address/Data bus to provide a “Seamless” interface.

The interface inputs on the X88C64 are configured such

that it is possible to directly connect them to the proper

interface signals of the appropriate single-chip

microcontroller. In the Harvard type system, the reading

of data from the chip is controlled either by the PSEN or

the RD signal, which essentially maps the X88C64 into

both the Program and the Data Memory address map.

The X88C64 is internally organized as two independent

planes of 4K bytes of memory with the A12 input selecting which of the two planes of memory are to be

accessed. While the processor is executing code out of

one plane, write operations can take place in the other

plane, allowing the processor to continue execution of

code out of the X88C64 during a byte or page write to the

device.

The X88C64 also features an advanced implementation

of the Software Data Protection scheme, called Block

Protect, which allows the device to be broken into 8

independent sections of 1K bytes. Each of these sections can be independently enabled for write operations;

thereby allowing certain sections of the device to be

secured so that updates can only occur in a controlled

environment (e.g. in an automotive application, only at

an authorized service center). The desired set-up configuration is stored in a nonvolatile register, ensuring the

configuration data will be maintained after the device is

powered down.

The X88C64 also features a Write Control input (WC),

which serves as an external control over the completion

of a previously initiated page load cycle.

The X88C64 also features the industry standard

E2PROM characteristics such as byte or page mode

write and Toggle Bit Polling.

DEVICE OPERATION

MODES

Mixed Program/Data Memory

By properly assigning the address spaces, a single

X88C64 can be used as both the Program and Data

Memory. This would be accomplished by connecting all

of the 8051 control outputs to the corresponding inputs

of the X88C64.

In this configuration, one plane of memory could be

dedicated to Program Storage and the other plane

dedicated to Data Storage. The Data Storage can be

fully protected by enabling block protect write lockout.

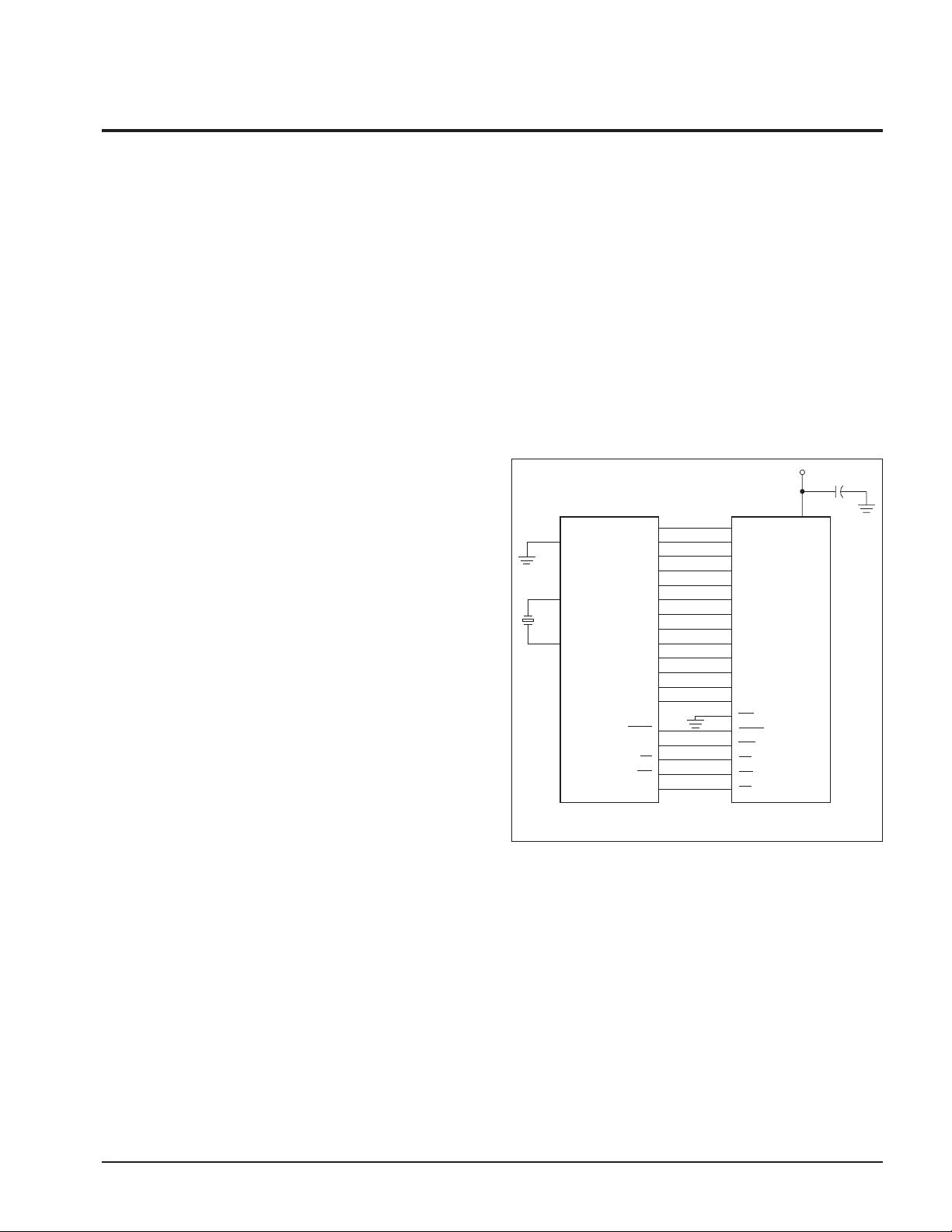

TYPICAL APPLICATION

X88C6480C31

24

V

CC

3867 FHD F03

39

31

EA/VP

19

X1

18

X2

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

P2.0

P2.1

P2.2

P2.3

P2.4

PSEN

ALE

RD

WR

P2.7

38

37

36

35

34

33

32

21

22

23

24

25

29

30

17

16

7

A/D0

8

A/D1

9

A/D2

10

A/D3

11

A/D4

13

A/D5

14

A/D6

15

A/D7

21

A8

20

A9

17

A10

19

A11

2

A12

5

WC

6

PSEN

22

ALE

18

RD

23

WR

16

CE

Program Memory Mode

This mode of operation is read-only. The PSEN and ALE

inputs of the X88C64 are tied directly to the PSEN and

ALE outputs of the microcontroller. The RD and WR

inputs are tied HIGH.

When ALE is HIGH, the A/D0–A/D7 and A8–A12 addresses flow into the device. The addresses, both low

and high order, are latched when ALE transitions LOW

(VIL). PSEN will then go LOW and after t

PLDV

, valid data

is presented on the A/D0–A/D7 pins. CE must be LOW

during the entire operation.

3

Page 4

X88C64

Data Memory Mode

This mode of operation allows both read and write

functions. The PSEN input is tied to VIH or to V

CC

through a pull-up resistor. The ALE, RD, and WR inputs

are tied directly to the microcontroller’s ALE, RD, and

WR outputs.

Read

This operation is quite similar to the Program Memory

read. A HIGH to LOW transition on ALE latches the

addresses and the data will be output on the AD pins

after RD goes LOW (t

RLDV

).

Write

A write is performed by latching the addresses on the

falling edge of ALE. Then WR is strobed LOW followed

by valid data being presented at the A/D0–A/D7 pins.

The data will be latched into the X88C64 on the rising

edge of WR. To write to the X88C64, a three-byte

command sequence must precede the byte(s) being

written. (See Software Data Protection.)

MODE SELECTION

CE PSEN RD WR Mode I/O Power

V

CC

X X X Standby High Z Standby (CMOS)

HIGH X X X Standby High Z Standby (TTL)

LOW LOW HIGH HIGH Program Fetch D

LOW HIGH LOW HIGH Data Read D

LOW HIGH HIGH Write D

OUT

OUT

IN

Active

Active

Active

3867 PGM T02.2

4

Page 5

X88C64

t

BLC

CE

ALE

A/D0–A/D

7

A8–A

12

WR

PSEN(RD)

A

IN

D

IN

A12=n

OPERATION

BYTE 0

BYTE 1

BYTE 2 LAST BYTE READ (1)(2) AFTER tWC READY FOR

NEXT WRITE OPERATION

t

WC

A

IN

D

IN

A12=n

A

IN

D

IN

A12=n

A

IN

D

IN

A12=n

A

IN

D

OUT

A12=x

A

IN

ADDR

A

IN

Next Address

PAGE WRITE OPERATION

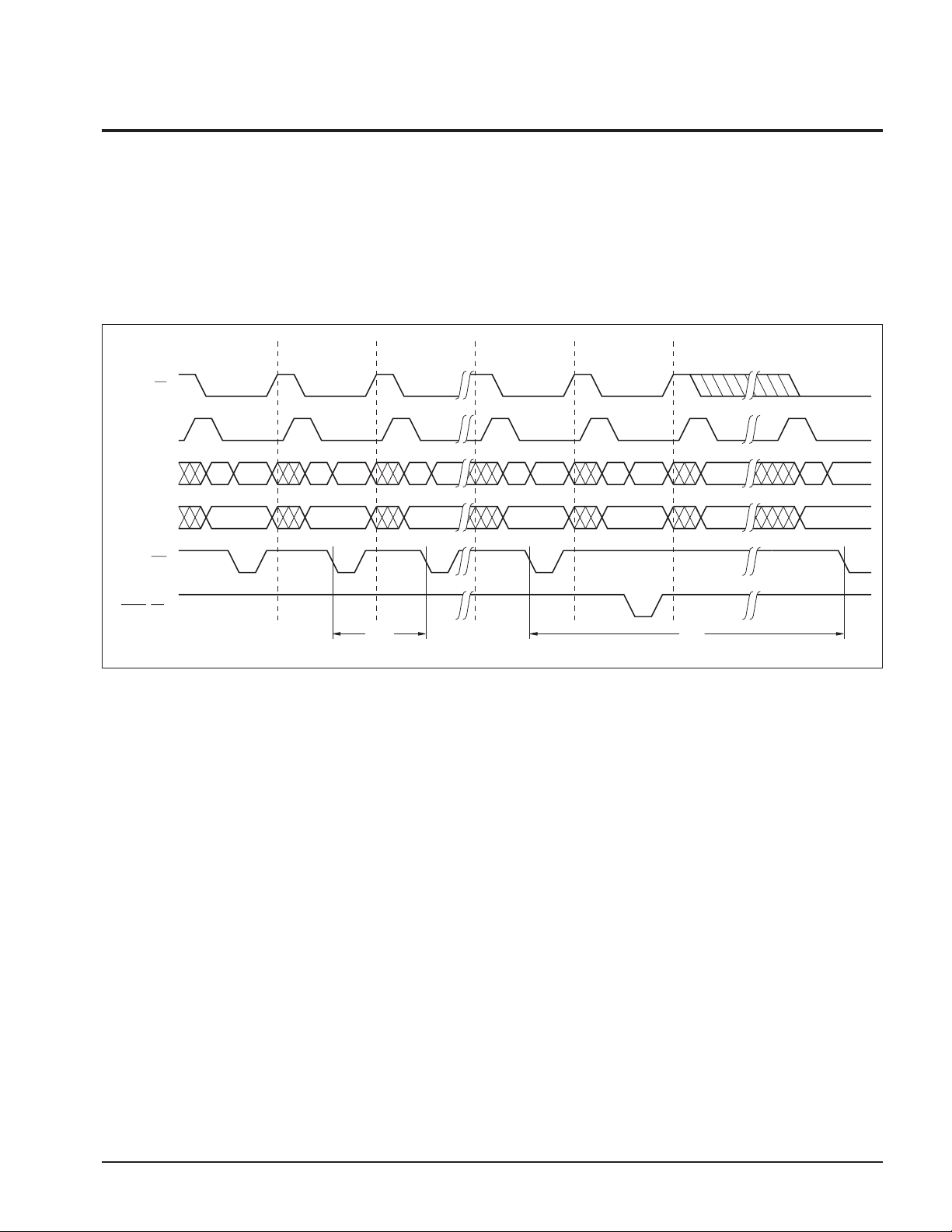

Regardless of the microcontroller employed, the X88C64

supports page mode write operations. This allows the

microcontroller to write from one to thirty-two bytes of

data to the X88C64. Each individual write within a page

write operation must conform to the byte write timing

requirements. The falling edge of WR starts a timer

delaying the internal programming cycle 100µs. Therefore, each successive write operation must begin within

100µs of the last byte written. The following waveforms

illustrate the sequence and timing requirements.

Page Write Timing Sequence for WR Controlled Operation

Notes: (1) For each successive write within a page write cycle A5–A12 must be the same.

(2) Although it is not illustrated, the microcontroller may interleave read operations between the individual byte writes within the page

write operation. Two responses are possible:

a. Reading from the same plane being written (A12 of Read = A12 of Write) is effectively a Toggle Bit Polling operation.

b. Reading from the opposite plane being written (A12 of Read ≠ A12 of Write) true data will be returned, facilitating the use of a

single memory component as both program and data storage.

3867 FHD F08

5

Page 6

X88C64

TOGGLE BIT POLLING

Because the X88C64 typical nonvolatile write cycle time

is less than the specified 5ms, Toggle Bit Polling has

been provided to determine the early completion of

write. During the internal programming cycle I/O6 will

toggle from HIGH to LOW and LOW to HIGH on subse-

Toggle Bit Polling RD/WR Control

OPERATION

CE

ALE

A/D0–A/D

A8–A

7

12

WR

LAST BYTE

WRITTEN

A

IN

A12=n

I/O6=X

D

IN

A

IN

A12=n

D

OUT

I/O6=X I/O6=X I/O6=X

A

IN

A12=n

quent attempts to read the device. When the internal

cycle is complete, the toggling will cease and the device

will be accessible for additional read or write operations.

Due to the dual plane architecture, reads for polling

must occur in the plane that was written; that is, the state

of A12 during a write must match the state of A12 during

Toggle Bit Polling.

X88C64 READY FOR

NEXT OPERATION

D

OUT

A

IN

A12=n

D

OUT

A

IN

A12=x

D

OUT

A

IN

ADDR

RD

SYMBOL TABLE

WAVEFORM

INPUTS

Must be

steady

May change

from LOW

to HIGH

May change

from HIGH

to LOW

Don’t Care:

Changes

Allowed

N/A

3867 FHD F09

OUTPUTS

Will be

steady

Will change

from LOW

to HIGH

Will change

from HIGH

to LOW

Changing:

State Not

Known

Center Line

is High

Impedance

6

Page 7

X88C64

WRITE AA

TO X555

WRITE BPR

MASK VALUE TO

ANY ADDRESS

WAIT t

WC

EXIT ROUTINE

WRITE 55

TO XAAA

WRITE C0

TO XAAA

(BPR REGISTER SET)

WRITE AA

TO X555

WRITE A0

TO X555

X = A12:

A

12

= 1 IF PROGRAM BEING EXECUTED

RESIDES WITHIN ADDRESS 0000 TO 0FFF.

A

12

= 0 IF PROGRAM BEING EXECUTED

RESIDES WITHIN ADDRESS 1000 TO 1FFF.

DATA PROTECTION

The X88C64 provides two levels of data protection

through software control. There is a global software data

protection feature similar to the industry standard for

E2PROMs and a new Block Protect write lockout protection providing a secondary level of data security.

SOFTWARE DATA PROTECTION

Software Data Protection (SDP) is employed to protect

the entire array against inadvertent writes. To write to the

X88C64, a three-byte command sequence must precede

the byte(s) being written. All write operations, both the

command sequence and any data write operations, must

conform to the page write timing requirements.

Writing with SDP

WRITE AA

TO X555

WRITE 55

TO XAAA

Setting write lockout is accomplished by writing a fivebyte command sequence, opening access to the Block

Protect Register (BPR). After the fifth byte is written, the

user writes to the BPR, selecting which blocks to protect

or unprotect. All write operations, both the command

sequence and writing the data to the BPR, must conform

to the page write timing requirements.

Block Protect Register Format

MSB LSB

7

1 = Protect, 0 = Unprotect Block Specified

5

6

43

2

1

0

BLOCK

ADDRESS

0000–03FF

0400–07FF

0800–0BFF

0C00–0FFF

1000–13FF

1400–17FF

1800–1BFF

1C00–1FFF

3867 FHD F12

Setting BPR Sequence

WRITE A0

TO X555

PERFORM BYTE

OR PAGE WRITE

OPERATIONS

WAIT t

WC

Block Protect Write Lockout

The X88C64 provides a secondary level of data security

referred to as Block Protect write lockout. This is accessed through an extension of the SDP command

sequence. Block Protect allows the user to lockout

writes to any 1K x 8 blocks of memory. Unlike SDP which

EXIT ROUTINE

prevents inadvertent writes, but still allows easy system

access to writing the memory, Block Protect will lockout

all attempts unless it is specifically disabled by the host.

This could be used to set a higher level of protection in

a system where a portion of the memory is used for

Program Storage and another portion is used as Data

Storage.

X = A12 :

A12 = 1 IF DATA TO BE

WRITTEN IS WITHIN

ADDRESS 1000 TO 1FFF.

A12 = 0 IF DATA TO BE

WRITTEN IS WITHIN

ADDRESS 0000 TO 0FFF.

3867 FHD F10

3867 FHD F13

7

Page 8

X88C64

ABSOLUTE MAXIMUM RATINGS*

Temperature under Bias .................. –65°C to +135°C

Storage Temperature ....................... –65°C to +150°C

Voltage on any Pin with

Respect to VSS.................................. –1V to +7V

D.C. Output Current ............................................5 mA

Lead Temperature

(Soldering, 10 seconds).............................. 300°C

*COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and the functional operation of

the device at these or any other conditions above those

indicated in the operational sections of this specification is

not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

RECOMMENDED OPERATING CONDITIONS

Temperature Min. Max.

Commercial 0°C +70°C

Industrial –40°C +85°C

Supply Voltage Limits

X88C64 5V ±10%

3867 PGM T04.1

Military –55°C +125°C

3867 PGM T03.1

D.C. OPERATING CHARACTERISTICS (Over recommended operating conditions unless otherwise specified.)

Limits

Symbol Parameter Min. Max. Units Test Conditions

I

CC

I

SB1(CMOS)VCC

I

SB2(TTL)

I

LI

I

LO

VCC Current (Active) 60 mA CE = RD = VIL, All I/O’s =

Open,Other Inputs = V

Current (Standby) 500 µA CE = V

Open,Other Inputs = V

0.3V, ALE = V

– 0.3V, All I/O’s =

CC

IL

CC

CC

–

VCC Current (Standby) 6 mA CE = VIH, All I/O’s = Open, Other

Inputs = VIH, ALE = V

Input Leakage Current 10 µAV

Output Leakage Current 10 µAV

= VSS to V

IN

= VSS to VCC,

OUT

CC

IL

RD = VIH = PSEN

(3)

V

lL

(3)

V

IH

V

OL

V

OH

Input LOW Voltage –1 0.8 V

Input HIGH Voltage 2 VCC + 0.5 V

Output LOW Voltage 0.4 V IOL = 2.1 mA

Output HIGH Voltage 2.4 V IOH = –400 µA

3867 PGM T05.2

CAPACITANCE TA = +25°C, f = 1MHz, VCC = 5V

Symbol Test Max. Units Conditions

(4)

C

I/O

(4)

C

IN

Input/Output Capacitance 10 pF V

Input Capacitance 6 pF V

POWER-UP TIMING

Symbol Parameter Max. Units

(4)

t

PUR

(4)

t

PUW

Notes: (3) VIL min. and VIH max. are for reference only and are not tested.

(4) This parameter is periodically sampled and not 100% tested.

Power-Up to Read 1 ms

Power-Up to Write 5 ms

8

I/O

IN

= 0V

= 0V

3867 PGM T06

3867 PGM T07

Page 9

X88C64

A.C. CONDITIONS OF TEST

Input Pulse Levels 0V to 3V

EQUIVALENT A.C. TEST CIRCUIT

5V

Input Rise and

Fall Times 10ns

1.92KΩ

Input and Output

Timing Levels 1.5V

3867 PGM T08.1

OUTPUT

1.37KΩ

100pF

A.C. CHARACTERISTICS (Over the recommended operating conditions unless otherwise specified.)

PSEN Controlled Read Cycle

Symbol Parameter Min. Max. Units

t

LHLL

t

AVLL

t

LLAX

t

PLDV

t

PHDX

t

ELLL

PW

t

PS

t

PH

t

PHDZ

t

PLDX

PL

(5)

(5)

ALE Pulse Width 80 ns

Address Setup Time 20 ns

Address Hold Time 30 ns

PSEN Read Access Time 120 ns

Data Hold Time 0 ns

Chip Enable Setup Time 7 ns

PSEN Pulse Width 150 ns

PSEN Setup Time 30 ns

PSEN Hold Time 20 ns

PSEN Disable to Output in High Z 50 ns

PSEN to Output in Low Z 10 ns

PSEN Controlled Read Timing Diagram

3867 FHD F04.3

3867 PGM T09

CE

t

t

LHLL

ALE

t

AVLL

A/D0–A/D

Note: (5) This parameter is periodically sampled and not 100% tested.

A8–A

PSEN

7

12

A

IN

ELLL

t

LLAX

t

PS

t

PLDX

t

PLDV

PW

PL

9

D

OUT

t

PHDX

ADDRESS

t

PH

t

PH

t

PHDZ

3867 FHD F05

Page 10

X88C64

RD Controlled Read Cycle

Symbol Parameter Min. Max. Units

t

LHLL

t

AVLL

t

LLAX

t

RLDV

t

RHDX

t

ELLL

PW

t

RDS

t

RDH

t

RHDZ

t

RLDX

RL

(6)

(6)

ALE Pulse Width 80 ns

Address Setup Time 20 ns

Address Hold Time 30 ns

RD Read Access Time 120 ns

Data Hold Time 0 ns

Chip Enable Setup Time 7 ns

RD Pulse Width 150 ns

RD Setup Time 30 ns

RD Hold Time 20 ns

RD Disable to Output in High Z 50 ns

RD to Output in Low Z 0 ns

RD Controlled Read Timing Diagram

CE

t

ELLL

t

LLAX

t

RDS

ALE

A/D0–A/D

A8–A

12

RD

t

LHLL

t

AVLL

A

7

IN

t

RLDX

t

RLDV

PW

RL

D

OUT

t

RDH

t

RHDX

ADDRESS

t

RDH

t

RHDZ

3867 PGM T10

Note: (6) This parameter is periodically sampled and not 100% tested.

10

3867 FHD F06

Page 11

X88C64

WR Controlled Write Cycle

Symbol Parameter Min. Max. Units

t

LHLL

t

AVLL

t

LLAX

t

DVWH

t

WHDX

t

ELLL

t

WLWH

t

WRS

t

WRH

t

BLC

t

WC

(7)

ALE Pulse Width 80 ns

Address Setup Time 20 ns

Address Hold Time 30 ns

Data Setup Time 50 ns

Data Hold Time 30 ns

Chip Enable Setup Time 7 ns

WR Pulse Width 120 ns

WR Setup Time 30 ns

WR Hold Time 20 ns

Byte Load Time (Page Write) 0.5 100 µs

Write Cycle Time 5 ms

WR Controlled Write Timing Diagram

CE

t

ELLL

t

LLAX

ALE

A/D0–A/D

t

LHLL

t

AVLL

A

7

IN

D

t

DVWH

3867 PGM T11

t

WRH

t

WRH

IN

t

WHDX

A8–A

12

t

WRS

WR

Note: (7) tWC is the minimum cycle time to be allowed from the system perspective unless polling techniques are used. It is the maximum

time the device requires to automatically complete the internal write operation.

t

WLWH

11

ADDRESS

3867 FHD F07

Page 12

X88C64

PACKAGING INFORMATION

24-LEAD PLASTIC DUAL IN-LINE PACKAGE TYPE P

PIN 1 INDEX

PIN 1

1.265 (32.13)

1.230 (31.24)

1.100 (27.94)

REF.

0.557 (14.15)

0.530 (13.46)

0.080 (2.03)

0.065 (1.65)

SEATING

PLANE

0.150 (3.81)

0.125 (3.18)

0.110 (2.79)

0.090 (2.29)

0.065 (1.65)

0.040 (1.02)

0.625 (15.87)

0.600 (15.24)

TYP. 0.010 (0.25)

0°

15°

NOTE:

1. ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

2. PACKAGE DIMENSIONS EXCLUDE MOLDING FLASH

0.162 (4.11)

0.140 (3.56)

0.030 (0.76)

0.015 (0.38)

0.022 (0.56)

0.014 (0.36)

12

3926 FHD F03

Page 13

X88C64

PACKAGING INFORMATION

24-LEAD PLASTIC SMALL OUTLINE GULL WING PACKAGE TYPE S

PIN 1 INDEX

(4X) 7°

0.050 (1.27)

0.010 (0.25)

0.020 (0.50)

PIN 1

X 45°

0.014 (0.35)

0.020 (0.50)

0.598 (15.20)

0.610 (15.49)

0.290 (7.37)

0.299 (7.60)

0.003 (0.10)

0.012 (0.30)

0.050" TYPICAL

0.393 (10.00)

0.420 (10.65)

0.092 (2.35)

0.105 (2.65)

0° – 8°

0.009 (0.22)

0.013 (0.33)

0.015 (0.40)

0.050 (1.27)

0.420"

FOOTPRINT

0.030" TYPICAL

24 PLACES

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

13

0.050"

TYPICAL

3926 FHD F24

Page 14

X88C64

ORDERING INFORMATION

X88C64 X X

Device

Temperature Range

Blank = Commercial = 0°C to +70°C

I = Industrial = –40°C to +85°C

M = Military = –55°C to +125°C

MB = MIL-STD-883

Package

P = 24-Lead Plastic DIP

S = 24-Lead SOIC

LIMITED WARRANTY

Devices sold by Xicor, Inc. are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. Xicor, Inc. makes

no warranty, express, statutory, implied, or by description regarding the information set forth herein or regarding the freedom of the described

devices from patent infringement. Xicor, Inc. makes no warranty of merchantability or fitness tor any purpose. Xicor, Inc. reserves the right to

discontinue production and change specifications and prices at any time and without notice.

Xicor, Inc. assumes no responsibility for the use of any circuitry other than circuitry embodied in a Xicor, Inc. product. No other circuits, patents,

licenses are implied.

US. PATENTS

Xicor products are covered by one or more of the following U.S. Patents: 4,263,664; 4,274,012; 4,300,212; 4,314,265; 4,326,134; 4,393,481;

4,404,475; 4,450,402; 4,486,769; 4,488,060; 4,520,461; 4,533,846; 4,599,706; 4,617,652; 4,668,932; 4,752,912; 4,829,482; 4,874,967; 4,883,976;

4,980,859; 5,012,132; 5,003,197; 5,023,694. Foreign patents and additional patents pending.

LIFE RELATED POLICY

In situations where semiconductor component failure may endanger life, system designers using this product should design the system with

appropriate error detection and correction, redundancy and back-up features to prevent such an occurrence.

Xicor’s products are not authorized for use as critical components in life support devices or systems.

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life,

and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected

to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure

of the life support device or system, or to affect its satety or effectiveness.

14

Loading...

Loading...