Page 1

Preliminary Information

New Features

Repetitive Alarms &

Temperature Compensation

Real Time Clock/Calendar

FEATURES

• Real Time Clock/Calendar

—Tracks time in Hours, Minutes, and Seconds

—Day of the Week, Day, Month, and Year

• 2 Polled Alarms (Non-volatile)

—Settable on the Second, Minute, Hour, Day of

the Week, Day, or Month

—Repeat Mode (periodic interrupts)

• Oscillator Compensation on chip

—Internal feedback resistor and compensation

capacitors

—64 position Digitally Controlled Trim Capacitor

—6 digital frequency adjustment settings to

±30ppm

• Battery Switch or Super Cap Input

• 2-Wire™ Interface interoperable with I2C*

—400kHz data transfer rate

• Low Power CMOS

—1.25µA Operating Current (Typical)

• Small Package Options

—8-Lead SOIC and 8-Lead TSSOP

APPLICATIONS

• Utility Meters

• HVAC Equipment

• Audio / Video Components

• Set Top Box / Television

X1205

• Modems

• Network Routers, Hubs, Switches, Bridges

• Cellular Infrastructure Equipment

• Fixed Broadband Wireless Equipment

• Pagers / PDA

• POS Equipment

• Test Meters / Fixtures

• Office Automation (Copiers, Fax)

• Home Appliances

• Computer Products

• Other Industrial / Medical / Automotive

DESCRIPTION

The X1205 device is a Real Time Clock with clock/

calendar, two polled alarms, oscillator compensation,

and battery backup switch.

The oscillator uses an external, low-cost 32.768kHz

crystal. All compensation and trim components are

integrated on the chip. This eliminates several external

discrete components and a trim capacitor, saving

board area and component cost.

The Real-Time Clock keeps track of time with separate

registers for Hours, Minutes, and Seconds. The

Calendar has separate registers for Date, Month, Year

and Day-of-week. The calendar is correct through

2099, with automatic leap year correction.

2-Wire

™

RTC

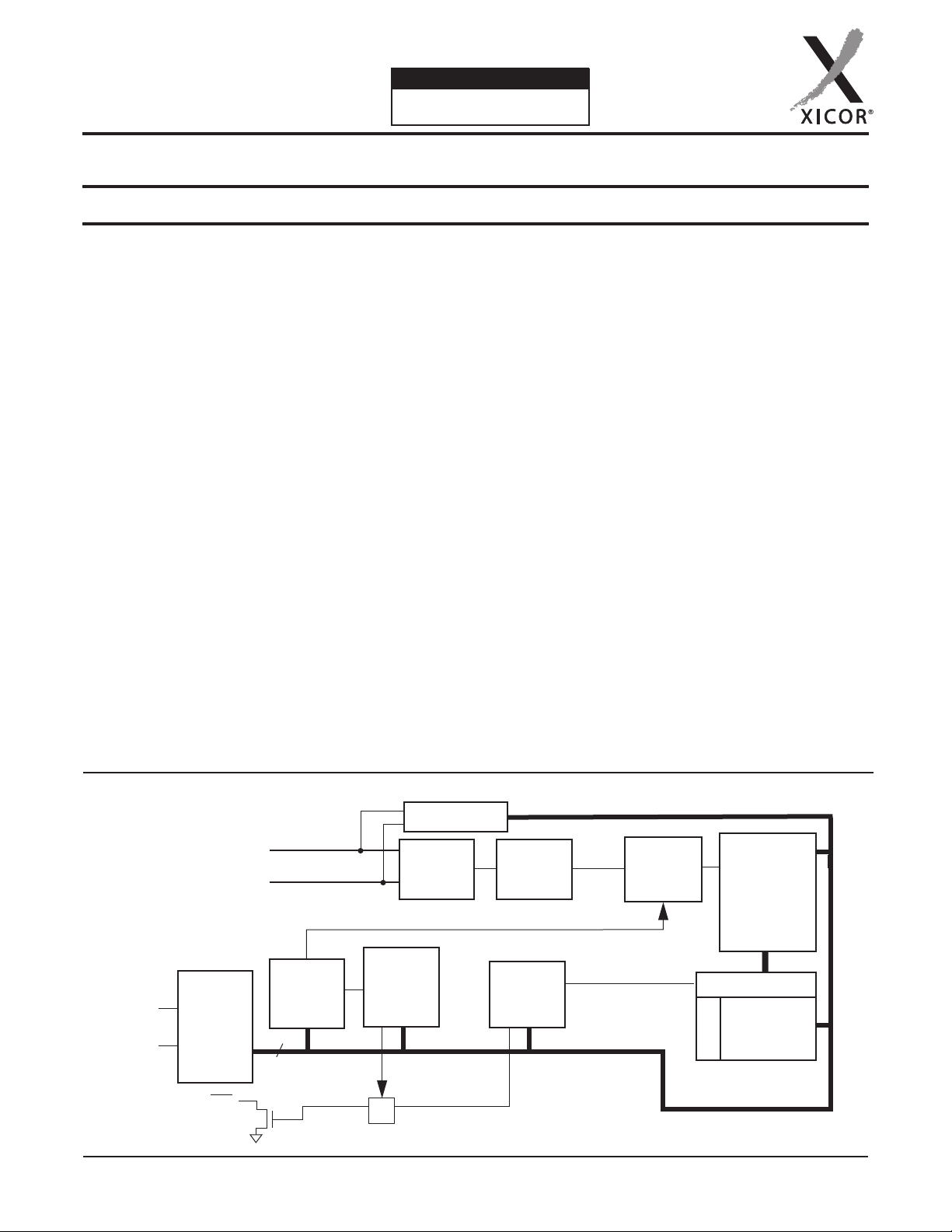

BLOCK DIAGRAM

32.768kHz

SCL

SDA

*I2C is a Trademark of Philips.

REV 1.0.9 8/29/02

Serial

Interface

Decoder

IRQ

OSC

Compensation

X1

X2

Oscillator

Frequency

Divider

1Hz

PRELIMINARY

Control

Decode

Logic

8

Control

Registers

(EEPROM)

Interrupt Enable

www.xicor.com

Status

Registers

(SRAM)

Alarm

Timer

Calendar

Logic

Alarm

Alarm

Characteristics subject to change without notice.

Keeping

Registers

(SRAM)

Compare

Alarm Regs

(EEPROM)

Mask

Time

1 of 22

Page 2

.

X1205 – Preliminary Information

DESCRIPTION (continued)

The powerful Dual Alarms can be set to any Clock/

Calendar value for a match. For instance, every

minute, every Tuesday, or 5:23 AM on March 21. The

alarms can be polled in the Status Register or provide

a hardware interrupt (IRQ Pin). There is a repeat

mode for the alarms allowing a periodic interrupt.

The device offers a backup power input pin. This

V

pin allows the device to be backed up by battery

BACK

or SuperCap. The entire X1205 device is fully

operational from 2.7 to 5.5 volts and the clock/calendar

portion of the X1205 device remains fully operational

down to 1.8 volts (Standby Mode).

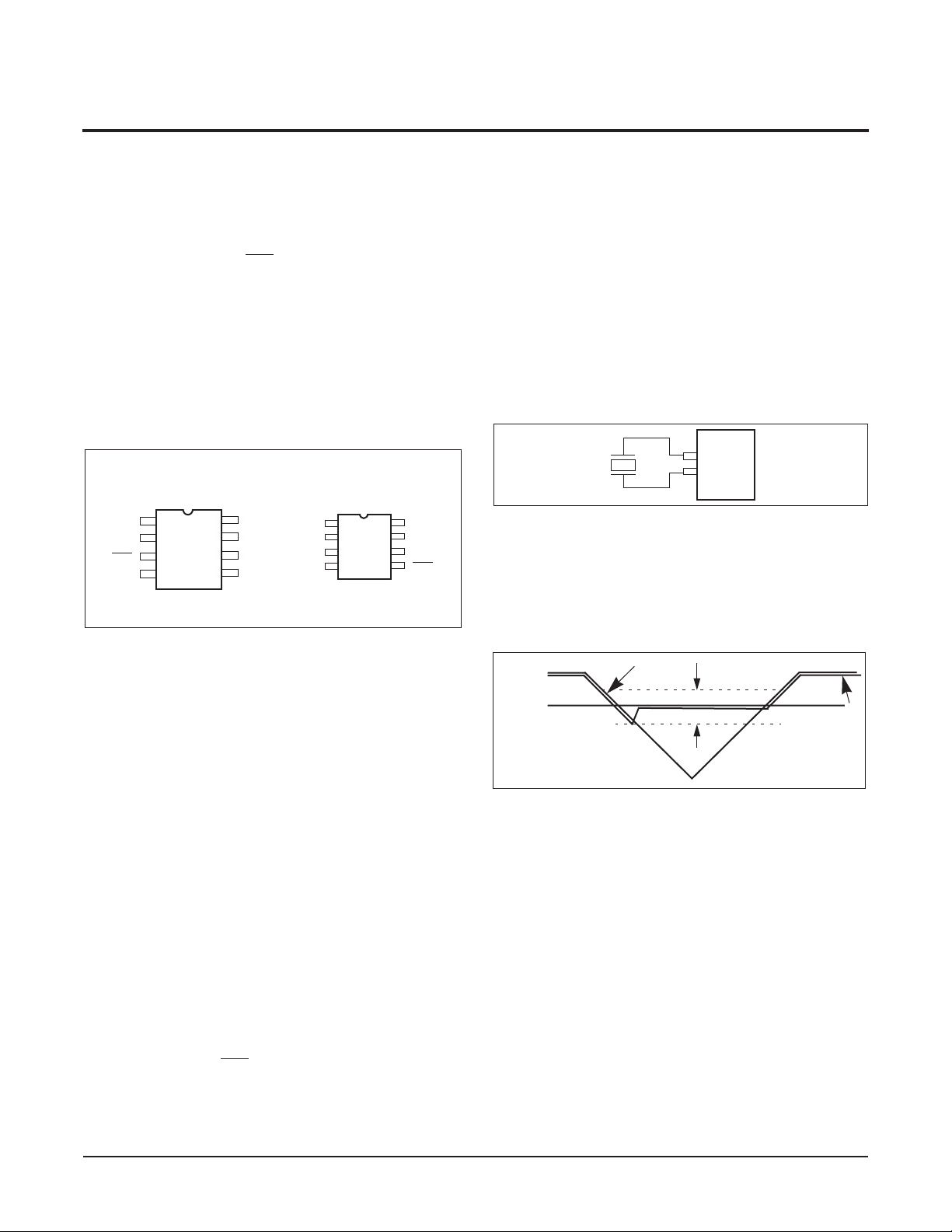

PIN DESCRIPTIONS

X1205

8-Pin SOIC

1

X1

2

X2

IRQ

V

NC = No internal connection

SS

3

4

8

7

6

5

V

CC

V

BACK

SCL

SDA

V

BACK

V

CC

X1

X2

8-Pin TSSOP

1

8

2

7

3

6

4

5

SCL

SDA

V

SS

IRQ

Serial Clock (SCL)

The SCL input is used to clock all data into and out of

the device. The input buffer on this pin is always active

(not gated).

Serial Data (SDA)

SDA is a bidirectional pin used to transfer data into and

out of the device. It has an open drain output and may

be wire ORed with other open drain or open collector

outputs. The input buffer is always active (not gated).

An open drain output requires the use of a pull-up

resistor. The output circuitry controls the fall time of the

output signal with the use of a slope controlled pulldown. The circuit is designed for 400kHz 2-wire inter-

PRELIMINARY

face speeds.

V

BACK

This input provides a backup supply voltage to the

device. V

event the V

supplies power to the device in the

BACK

supply fails. This pin can be connected

CC

to a battery, a Supercap or tied to ground if not used.

Interrupt Output – IRQ

This is an interrupt signal output. This signal notifies a

host processor that an alarm has occurred and

requests action. It is an open drain active low output.

REV 1.0.9 8/29/02

www.xicor.com

X1, X2

The X1 and X2 pins are the input and output,

respectively, of an inverting amplifier. An external

32.768kHz quartz crystal is used with the X1205 to

supply a timebase for the real time clock. The

recommended crystal is a Citizen CFS206-32.768KDZF.

Internal compensation circuitry is included to form a

complete oscillator circuit. Care should be taken in the

placement of the crystal and the layout of the circuit.

Plenty of ground plane around the device and short

traces to X1 and X2 are highly recommended. See

Application section for more recommendations.

Figure 1. Recommended Crystal connection

X1

X2

POWER CONTROL OPERATION

The power control circuit accepts a V

and a V

CC

BACK

input. The power control circuit powers the clock from

V

when V

BACK

power the device from V

CC

< V

- 0.2V. It will switch back to

BACK

CC

when V

exceeds V

CC

BACK

Figure 2. Power Control

V

V

CC

BACK

Off

Voltage

On

In

REAL TIME CLOCK OPERATION

The Real Time Clock (RTC) uses an external

32.768kHz quartz crystal to maintain an accurate internal representation of second, minute, hour, day, date,

month, and year. The RTC has leap-year correction.

The clock also corrects for months having fewer than

31 days and has a bit that controls 24 hour or AM/PM

format. When the X1205 powers up after the loss of

both V

CC

and V

, the clock will not operate until at

BACK

least one byte is written to the clock register.

Reading the Real Time Clock

The RTC is read by initiating a Read command and

specifying the address corresponding to the register of

the Real Time Clock. The RTC Registers can then be

read in a Sequential Read Mode. Since the clock runs

continuously and a read takes a finite amount of time,

there is the possibility that the clock could change during

Characteristics subject to change without notice.

2 of 22

Page 3

X1205 – Preliminary Information

the course of a read operation. In this device, the time is

latched by the read command (falling edge of the clock

on the ACK bit prior to RTC data output) into a separate

latch to avoid time changes during the read operation.

The clock continues to run. Alarms occurring during a

read are unaffected by the read operation.

Writing to the Real Time Clock

The time and date may be set by writing to the RTC

registers. To avoid changing the current time by an

uncompleted write operation, the current time value is

loaded into a separate buffer at the falling edge of the

clock on the ACK bit before the RTC data input bytes,

the clock continues to run. The new serial input data

replaces the values in the buffer. This new RTC value

is loaded back into the RTC Register by a stop bit at

the end of a valid write sequence. An invalid write

operation aborts the time update procedure and the

contents of the buffer are discarded. After a valid write

operation the RTC will reflect the newly loaded data

beginning with the next “one second clock cycle” after

the stop bit is written. The RTC continues to update

the time while an RTC register write is in progress and

the RTC continues to run during any nonvolatile write

sequences. A single byte may be written to the RTC

without affecting the other bytes.

Accuracy of the Real Time Clock

The accuracy of the Real Time Clock depends on the

frequency of the quartz crystal that is used as the time

base for the RTC. Since the resonant frequency of a

crystal is temperature dependent, the RTC performance will also be dependent upon temperature. The

frequency deviation of the crystal is a function of the

turnover temperature of the crystal from the crystal’s

nominal frequency. For example, a >20ppm frequency

deviation translates into an accuracy of >1 minute per

month. These parameters are available from the

crystal manufacturer. Xicor’s RTC family provides onchip crystal compensation networks to adjust loadcapacitance to tune oscillator frequency from +116

ppm to –37 ppm when using a 12.5 pF load crystal.

For more detail information see the Application

section.

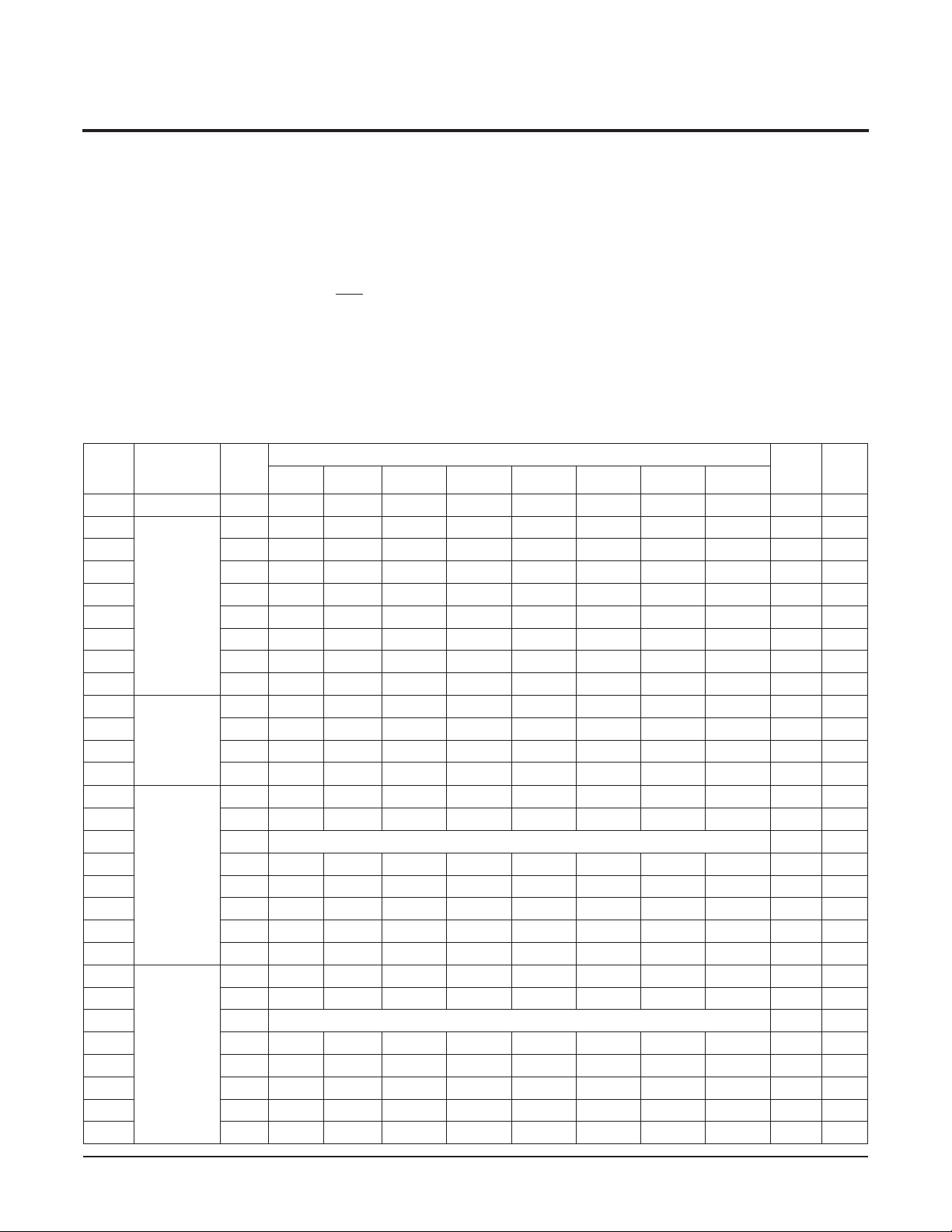

CLOCK/CONTROL REGISTERS (CCR)

The Control/Clock Registers are located in an area

accessible following a slave byte of “1101111x” and

reads or writes to addresses [0000h:003Fh]. The

clock/control memory map has memory addresses

from 0000h to 003Fh. The defined addresses are

described in the Table 1. Writing to and reading from

the undefined addresses are not recommended.

PRELIMINARY

CCR access

The contents of the CCR can be modified by performing a byte or a page write operation directly to any

address in the CCR. Prior to writing to the CCR

(except the status register), however, the WEL and

RWEL bits must be set using a two step process (See

section “Writing to the Clock/Control Registers.”)

The CCR is divided into 5 sections. These are:

1. Alarm 0 (8 bytes; non-volatile)

2. Alarm 1 (8 bytes; non-volatile)

3. Control (4 bytes; non-volatile)

4. Real Time Clock (8 bytes; volatile)

5. Status (1 byte; volatile)

Each register is read and written through buffers. The

non-volatile portion (or the counter portion of the RTC) is

updated only if RWEL is set and only after a valid write

operation and stop bit. A sequential read or page write

operation provides access to the contents of only one

section of the CCR per operation. Access to another section requires a new operation. Continued reads or writes,

once reaching the end of a section, will wrap around to

the start of the section. A read or write can begin at any

address in the CCR.

It is not necessary to set the RWEL bit prior to writing

the status register. Section 5 supports a single byte

read or write only. Continued reads or writes from this

section terminates the operation.

The state of the CCR can be read by performing a random read at any address in the CCR at any time. This

returns the contents of that register location. Additional registers are read by performing a sequential

read. The read instruction latches all Clock registers

into a buffer, so an update of the clock does not

change the time being read. A sequential read of the

CCR will not result in the output of data from the memory array. At the end of a read, the master supplies a

stop condition to end the operation and free the bus.

After a read of the CCR, the address remains at the

previous address +1 so the user can execute a current

address read of the CCR and continue reading the

next Register.

ALARM REGISTERS

There are two alarm registers whose contents mimic the

contents of the RTC register, but add enable bits and

exclude the 24 hour time selection bit. The enable bits

specify which registers to use in the comparison between

the Alarm and Real Time Registers. For example:

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice.

3 of 22

Page 4

X1205 – Preliminary Information

– Setting the Enable Month Bit (EMOn*) bit in combi-

nation with other enable bits and a specific alarm

time, the user can establish an alarm that triggers at

the same time once a year.

*n = 0 for Alarm 0: N = 1 for Alarm 1

When there is a match, an alarm flag is set. The occurrence of an alarm can be determined by polling the

AL0 and AL1 bits or by enabling the IRQ output, using

it as hardware flag.

The alarm enable bits are located in the MSB of the

particular register. When all enable bits are set to ‘0’,

there are no alarms.

Table 1. Clock/Control Memory Map

Addr. Type

003F Status SR BAT AL1 AL0 0 0 RWEL WEL RTCF 01h

0037 RTC (SRAM) Y2K 0 0 Y2K21 Y2K20 Y2K13 0 0 Y2K10 20h

0036 DW 0 0 0 0 0 DY2 DY1 DY0 0-6 00h

0035 YR Y23 Y22 Y21 Y20 Y13 Y12 Y11 Y10 0-99 00h

0034 MO 0 0 0 G20 G13 G12 G11 G10 1-12 00h

0033 DT 0 0 D21 D20 D13 D12 D11 D10 1-31 00h

0032 HR MIL 0 H21 H20 H13 H12 H11 H10 0-23 00h

0031 MN 0 M22 M21 M20 M13 M12 M11 M10 0-59 00h

0030 SC 0 S22 S21 S20 S13 S12 S11 S10 0-59 00h

0013 Control

(NONVOLATILE)

0012 ATR 0 0 ATR5 ATR4 ATR3 ATR2 ATR1 ATR0 00h

0011 INT IM AL1E AL0E 0 0 X X X 00h

0010 0 0 0 000000 00h

000F Alarm1

(NONVOLATILE)

000E DWA1 EDW1 0 0 0 0 DY2 DY1 DY0 0-6 00h

000D YRA1 Unused – Default = RTC Year value – Future expansion

000C MOA1 EMO1 0 0 A1G20 A1G13 A1G12 A1G11 A1G10 1-12 00h

000B DTA1 EDT1 0 A1D21 A1D20 A1D13 A1D12 A1D11 A1D10 1-31 00h

000A HRA1 EHR1 0 A1H21 A1H20 A1H13 A1H12 A1H11 A1H10 0-23 00h

0009 MNA1 EMN1 A1M22 A1M21 A1M20 A1M13 A1M12 A1M11 A1M10 0-59 00h

0008 SCA1 ESC1 A1S22 A1S21 A1S20 A1S13 A1S12 A1S11 A1S10 0-59 00h

0007 Alarm0

(NONVOLATILE)

0006 DWA0 EDW0 0 0 0 0 DY2 DY1 DY0 0-6 00h

0005 YRA0 Unused – Default = RTC Year value – Future expansion

0004 MOA0 EMO0 0 0 A0G20 A0G13 A0G12 A0G11 A0G10 1-12 00h

0003 DTA0 EDT0 0 A0D21 A0D20 A0D13 A0D12 A0D11 A0D10 1-31 00h

0002 HRA0 EHR0 0 A0H21 A0H20 A0H13 A0H12 A0H11 A0H10 0-23 00h

0001 MNA0 EMN0 A0M22 A0M21 A0M20 A0M13 A0M12 A0M11 A0M10 0-59 00h

0000 SCA0 ESC0 A0S22 A0S21 A0S20 A0S13 A0S12 A0S11 A0S10 0-59 00h

Reg

Name

DTR 0 0 0 0 0 DTR2 DTR1 DTR0 00h

Y2K1 0 0 A1Y2K21 A1Y2K20 A1Y2K13 0 0 A1Y2K10 20h

76543210

PRELIMINARY

Y2K0 0 0 A0Y2K21 A0Y2K20 A0Y2K13 0 0 A0Y2K10 19/20 20h

– The user can set the X1205 to alarm every Wednes-

day at 8:00 AM by setting the EDWn*, the EHRn*

and EMNn* enable bits to ‘1’ and setting the DWAn*,

HRAn* and MNAn* Alarm registers to 8:00AM

Wednesday.

– A daily alarm for 9:30PM results when the EHRn*

and EMNn* enable bits are set to ‘1’ and the HRAn*

and MNAn* registers are set to 9:30PM.

*n = 0 for Alarm 0: N = 1 for Alarm 1

Bit

Range

Default

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice.

4 of 22

Page 5

X1205 – Preliminary Information

REAL TIME CLOCK REGISTERS

Clock/Calendar Registers (SC, MN, HR, DT, MO, YR)

These registers depict BCD representations of the

time. As such, SC (Seconds) and MN (Minutes) range

from 00 to 59, HR (Hour) is 1 to 12 with an AM or PM

indicator (H21 bit) or 0 to 23 (with MIL=1), DT (Date) is

1 to 31, MO (Month) is 1 to 12, YR (Year) is 0 to 99.

Date of the Week Register (DW)

This register provides a Day of the Week status and

uses three bits DY2 to DY0 to represent the seven

days of the week. The counter advances in the cycle

0-1-2-3-4-5-6-0-1-2-… The assignment of a numerical

value to a specific day of the week is arbitrary and may

be decided by the system software designer. The

default value is defined as ‘0’.

24 Hour Time

If the MIL bit of the HR register is 1, the RTC uses a

24-hour format. If the MIL bit is 0, the RTC uses a 12hour format and H21 bit functions as an AM/PM indicator with a ‘1’ representing PM. The clock defaults to

standard time with H21=0.

Leap Years

Leap years add the day February 29 and are defined

as those years that are divisible by 4. Years divisible by

100 are not leap years, unless they are also divisible

by 400. This means that the year 2000 is a leap year,

the year 2100 is not. The X1205 does not correct for

the leap year in the year 2100.

STATUS REGISTER (SR)

The Status Register is located in the CCR memory

map at address 003Fh. This is a volatile register only

and is used to control the WEL and RWEL write

enable latches, read two power status and two alarm

bits. This register is separate from both the array and

the Clock/Control Registers (CCR).

PRELIMINARY

Table 2. Status Register (SR)

Addr 7 6 5 4 3 2 1 0

003Fh BAT AL1 AL0 0 0 RWEL WEL RTCF

Default 0 0 0 0 0 0 0 1

BAT: Battery Supply—Volatile

This bit set to “1” indicates that the device is operating

BACK

, not V

from V

reset by hardware (X1205 internally). Once the device

begins operating from V

“0”.

. It is a read-only bit and is set/

CC

, the device sets this bit to

CC

AL1, AL0: Alarm bits—Volatile

These bits announce if either alarm 0 or alarm 1 match

the real time clock. If there is a match, the respective

bit is set to ‘1’. The falling edge of the last data bit in a

SR Read operation resets the flags. Note: Only the AL

bits that are set when an SR read starts will be reset.

An alarm bit that is set by an alarm occurring during an

SR read operation will remain set after the read operation is complete.

RWEL: Register Write Enable Latch—Volatile

This bit is a volatile latch that powers up in the LOW

(disabled) state. The RWEL bit must be set to “1” prior

to any writes to the Clock/Control Registers. Writes to

RWEL bit do not cause a nonvolatile write cycle, so the

device is ready for the next operation immediately after

the stop condition. A write to the CCR requires both

the RWEL and WEL bits to be set in a specific

sequence.

WEL: Write Enable Latch—Volatile

The WEL bit controls the access to the CCR and

memory array during a write operation. This bit is a

volatile latch that powers up in the LOW (disabled)

state. While the WEL bit is LOW, writes to the CCR or

any array address will be ignored (no acknowledge will

be issued after the Data Byte). The WEL bit is set by

writing a “1” to the WEL bit and zeroes to the other bits

of the Status Register. Once set, WEL remains set

until either reset to 0 (by writing a “0” to the WEL bit

and zeroes to the other bits of the Status Register) or

until the part powers up again. Writes to WEL bit do

not cause a nonvolatile write cycle, so the device is

ready for the next operation immediately after the stop

condition.

RTCF: Real Time Clock Fail Bit—Volatile

This bit is set to a ‘1’ after a total power failure. This is

a read only bit that is set by hardware (X1205 internally) when the device powers up after having lost all

power to the device. The bit is set regardless of

whether V

one of the supplies does not result in setting the RTCF

bit. The first valid write to the RTC after a complete

power failure (writing one byte is sufficient) resets the

RTCF bit to ‘0’.

Unused Bits:

This device does not use bits 3 or 4 in the SR, but

must have a zero in these bit positions. The Data Byte

output during a SR read will contain zeros in these bit

locations.

CC

or V

is applied first. The loss of only

BACK

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice.

5 of 22

Page 6

X1205 – Preliminary Information

INTERRUPT CONTROL REGISTER (INT)

Interrupt Control and Status Bits (IM, AL1E, AL0E)

There are two Interrupt Control bits, Alarm 1 Interrupt

Enable (AL1E) and Alarm 0 Interrupt Enable (AL0E) to

specifically enable or disable the alarm interrupt signal

output (IRQ). The interrupts are enabled when either the

AL1E and AL0E bits are set to “1”, respectively.

Two volatile bits (AL1 and AL0), associated with the two

alarms respectively, indicate if an alarm has happened.

These bits are set on an alarm condition regardless of

whether the IRQ interrupt is enabled. The AL1 and AL0

bits in the status register are reset by the falling edge of

the eighth clock of a read of the register containing the

bits.

Pulse Interrupt Mode

The pulsed interrupt mode allows for repetitive or

recurring alarm functionality. Hence an repetitive or

recurring alarm can be set for every n

minute, or n

the week. The pulsed interrupt mode can be considered a repetitive interrupt mode, with the repetition

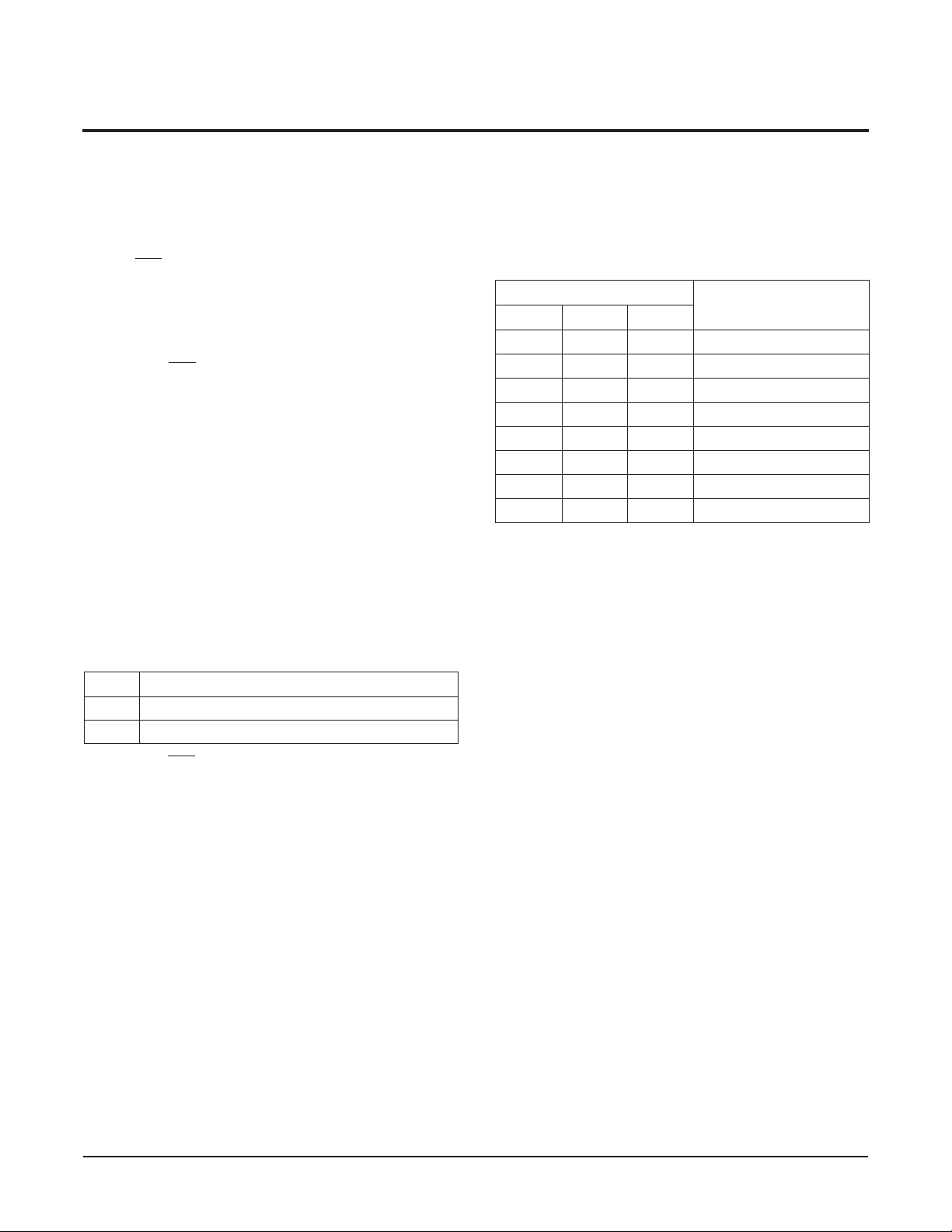

rate set by the time setting fo the alarm.

The Pulse Interrupt Mode is enabled when the IM bit is

set.

IM Bit Interrupt / Alarm Frequency

0 Single Time Event Set By Alarm

1 Repetitive / Recurring Time Event Set By Alarm

The Alarm IRQ output will output a single pulse of

short duration (approximately 10-40ms) once the

alarm condition is met. If the interrupt mode bit (IM bit)

is set, then this pulse will be periodic.

ON-CHIP OSCILLATOR COMPENSATION

Digital Trimming Register (DTR) — DTR2, DTR1

and DTR0 (Non-Volatile)

The digital trimming Bits DTR2, DTR1 and DTR0

adjust the number of counts per second and average

the ppm error to achieve better accuracy.

DTR2 is a sign bit. DTR2=0 means frequency

compensation is > 0. DTR2=1 means frequency

compensation is < 0.

th

hour, or n

th

date, or for the same day of

PRELIMINARY

th

second, or n

DTR1 and DTR0 are scale bits. DTR1 gives 10 ppm

adjustment and DTR0 gives 20 ppm adjustment.

A range from -30ppm to +30ppm can be represented

by using three bits above.

Table 3. Digital Trimming Registers

DTR Register

0 0 0 0 (default)

0 1 0 +10

0 0 1 +20

0 1 1 +30

100 0

1 1 0 -10

1 0 1 -20

th

1 1 1 -30

Analog Trimming Register (ATR) (Non-volatile)

Six analog trimming Bits from ATR5 to ATR0 are pro-

vided to adjust the on-chip loading capacitance range.

The on-chip load capacitance ranges from 3.25pF to

18.75pF. Each bit has a different weight for capacitance adjustment. In addition, using a Citizen CFS-206

crystal with different ATR bit combinations provides an

estimated ppm range from +116ppm to -37ppm to the

nominal frequency compensation. The combination of

digital and analog trimming can give up to +146ppm

adjustment.

The on-chip capacitance can be calculated as follows:

C

= [(ATR value, decimal) x 0.25pF] + 11.0pF

AT R

Note that the ATR values are in two’s complement,

with ATR(000000) = 11.0pF, so the entire range runs

from 3.25pF to 18.75pF in 0.25pF steps.

The values calculated above are typical, and total load

capacitance seen by the crystal will include approximately 2pF of package and board capacitance in addition to the ATR value.

See Application section and Xicor’s Application Note

AN154 for more information.

Estimated frequency

PPMDTR2 DTR1 DTR0

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice.

6 of 22

Page 7

X1205 – Preliminary Information

WRITING TO THE CLOCK/CONTROL REGISTERS

Changing any of the nonvolatile bits of the clock/control register requires the following steps:

– Write a 02h to the Status Register to set the Write

Enable Latch (WEL). This is a volatile operation, so

there is no delay after the write. (Operation preceeded by a start and ended with a stop).

– Write a 06h to the Status Register to set both the

Register Write Enable Latch (RWEL) and the WEL

bit. This is also a volatile cycle. The zeros in the data

byte are required. (Operation preceeded by a start

and ended with a stop).

– Write one to 8 bytes to the Clock/Control Registers

with the desired clock, alarm, or control data. This

sequence starts with a start bit, requires a slave byte

of “11011110” and an address within the CCR and is

terminated by a stop bit. A write to the CCR changes

nonvolatile register values so these initiate a nonvolatile write cycle and will take up to 10ms to complete. Writes to undefined areas have no effect. The

RWEL bit is reset by the completion of a nonvolatile

write cycle, so the sequence must be repeated to

again initiate another change to the CCR contents.

If the sequence is not completed for any reason

(by sending an incorrect number of bits or sending a

start instead of a stop, for example) the RWEL bit is

not reset and the device remains in an active mode.

– Writing all zeros to the status register resets both the

WEL and RWEL bits.

– A read operation occurring between any of the previ-

ous operations will not interrupt the register write

operation.

SERIAL COMMUNICATION

Interface Conventions

The device supports a bidirectional bus oriented protocol. The protocol defines any device that sends data

onto the bus as a transmitter, and the receiving device

as the receiver. The device controlling the transfer is

called the master and the device being controlled is

called the slave. The master always initiates data

transfers, and provides the clock for both transmit and

receive operations. Therefore, the devices in this family operate as slaves in all applications.

PRELIMINARY

Clock and Data

Data states on the SDA line can change only during

SCL LOW. SDA state changes during SCL HIGH are

reserved for indicating start and stop conditions. See

Figure 3.

Start Condition

All commands are preceded by the start condition,

which is a HIGH to LOW transition of SDA when SCL

is HIGH. The device continuously monitors the SDA

and SCL lines for the start condition and will not

respond to any command until this condition has been

met. See Figure 4.

Stop Condition

All communications must be terminated by a stop

condition, which is a LOW to HIGH transition of SDA

when SCL is HIGH. The stop condition is also used to

place the device into the Standby power mode after a

read sequence. A stop condition can only be issued

after the transmitting device has released the bus. See

Figure 4.

Acknowledge

Acknowledge is a software convention used to indicate

successful data transfer. The transmitting device,

either master or slave, will release the bus after transmitting eight bits. During the ninth clock cycle, the

receiver will pull the SDA line LOW to acknowledge

that it received the eight bits of data. Refer to Figure 5.

The device will respond with an acknowledge after recognition of a start condition and if the correct Device

Identifier and Select bits are contained in the Slave

Address Byte. If a write operation is selected, the

device will respond with an acknowledge after the

receipt of each subsequent eight bit word. The device

will acknowledge all incoming data and address bytes,

except for:

– The Slave Address Byte when the Device Identifier

and/or Select bits are incorrect

– All Data Bytes of a write when the WEL in the Write

Protect Register is LOW

– The 2nd Data Byte of a Status Register Write

Operation (only 1 data byte is allowed)

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 7 of 22

Page 8

X1205 – Preliminary Information

Figure 3. Valid Data Changes on the SDA Bus

SCL

SDA

Data Stable Data Change Data Stable

Figure 4. Valid Start and Stop Conditions

SCL

SDA

Start Stop

Figure 5. Acknowledge Response From Receiver

SCL from

Master

Data Output

from Transmitter

Data Output

from Receiver

Start Acknowledge

In the read mode, the device will transmit eight bits of

data, release the SDA line, then monitor the line for an

acknowledge. If an acknowledge is detected and no

stop condition is generated by the master, the device

will continue to transmit data. The device will terminate

further data transmissions if an acknowledge is not

detected. The master must then issue a stop condition

to return the device to Standby mode and place the

device into a known state.

PRELIMINARY

81 9

DEVICE ADDRESSING

Following a start condition, the master must output a

Slave Address Byte. Slave bits ‘1101’ access the CCR.

Bit 3 through Bit 1 of the slave byte specify the device

select bits. These are set to ‘111’.

The last bit of the Slave Address Byte defines the operation to be performed. When this R/W bit is a one, then

a read operation is selected. A zero selects a write

operation. Refer to Figure 6.

REV 1.0.9 8/29/02

After loading the entire Slave Address Byte from the

SDA bus, the X1205 compares the device identifier

and device select bits with ‘1101111’. Upon a correct

compare, the device outputs an acknowledge on the

SDA line.

www.xicor.com

Characteristics subject to change without notice. 8 of 22

Page 9

X1205 – Preliminary Information

Following the Slave Byte is a two byte word address.

The word address is either supplied by the master

device or obtained from an internal counter. On power

up the internal address counter is set to address 0H,

so a current address read of the CCR array starts at

address 0. When required, as part of a random read,

the master must supply the 2 Word Address Bytes as

shown in Figure 6.

Figure 6. Slave Address, Word Address, and Data Bytes

1

1011

00 00000

A6 A5

0

1

In a random read operation, the slave byte in the

“dummy write” portion must match the slave byte in the

“read” section. For a random read of the Clock/Control

Registers, the slave byte must be 1101111x in both

places.

1

R/W

Slave Address Byte

Byte 0

Word Address 1

Byte 1

Word Address 0

A0A7 A2A4 A3 A1

Byte 2

D7 D6 D5 D2D4 D3 D1 D0

Write Operations

Byte Write

For a write operation, the device requires the Slave

Address Byte and the Word Address Bytes. This gives

the master access to any one of the words in the CCR.

(Note: Prior to writing to the CCR, the master must

write a 02h, then 06h to the status register in two preceding operations to enable the write operation. See

“Writing to the Clock/Control Registers.” Upon receipt

PRELIMINARY

Figure 7. Byte Write Sequence

S

Signals from

the Master

SDA Bus

Signals From

The Slave

t

a

r

t

Slave

Address

0

1111

A

C

K

Data Byte

Byte 3

of each address byte, the X1205 responds with an

acknowledge. After receiving both address bytes the

X1205 awaits the eight bits of data. After receiving the

8 data bits, the X1205 again responds with an

acknowledge. The master then terminates the transfer

by generating a stop condition. The X1205 then begins

an internal write cycle of the data to the nonvolatile

memory. During the internal write cycle, the device

inputs are disabled, so the device will not respond to

any requests from the master. The SDA output is at high

impedance. See Figure 7.

S

Word

Address 1

00000000101

Address 0

A

C

K

Word

Data

A

C

K

t

o

p

A

C

K

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 9 of 22

Page 10

X1205 – Preliminary Information

Stop and Write Modes

Stop conditions that terminate write operations must

be sent by the master after sending at least 1 full data

byte and it’s associated ACK signal. If a stop is issued

in the middle of a data byte, or before 1 full data byte +

ACK is sent, then the X1205 resets itself without performing the write. The contents of the array are not

affected.

Acknowledge Polling

Disabling of the inputs during nonvolatile write cycles

can be used to take advantage of the typical 5mS write

cycle time. Once the stop condition is issued to indicate the end of the master’s byte load operation, the

X1205 initiates the internal nonvolatile write cycle.

Acknowledge polling can begin immediately. To do this,

the master issues a start condition followed by the

Slave Address Byte for a write or read operation. If the

X1205 is still busy with the nonvolatile write cycle then

no ACK will be returned. When the X1205 has completed the write operation, an ACK is returned and the

host can proceed with the read or write operation.

Refer to the flow chart in Figure 9.

Read Operations

There are three basic read operations: Current

Address Read, Random Read, and Sequential Read.

Figure 9. Acknowledge Polling Sequence

Byte load completed

by issuing STOP.

Enter ACK Polling

Issue START

Issue Slave

Address Byte

(Read or Write)

ACK

returned?

YES

nonvolatile write

Cycle complete. Continue

command sequence?

YES

Continue normal

Read or Write

command

sequence

Issue STOP

NO

NO

Issue STOP

Current Address Read

Internally the X1205 contains an address counter that

maintains the address of the last word read incremented by one. Therefore, if the last read was to

address n, the next read operation would access data

from address n+1. Upon receipt of the Slave Address

Byte with the R/W bit set to one, the X1205 issues an

acknowledge, then transmits eight data bits. The master terminates the read operation by not responding

with an acknowledge during the ninth clock and issuing

a stop condition. Refer to Figure 8 for the address,

acknowledge, and data transfer sequence.

PRELIMINARY

Figure 8. Current Address Read Sequence

S

Signals from

the Master

SDA Bus

Signals from

the Slave

t

a

r

t

PROCEED

It should be noted that the ninth clock cycle of the read

operation is not a “don’t care.” To terminate a read

operation, the master must either issue a stop condition during the ninth cycle or hold SDA HIGH during

the ninth clock cycle and then issue a stop condition.

Slave

Address

101

11111

A

C

Data

K

S

t

o

p

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 10 of 22

Page 11

X1205 – Preliminary Information

Random Read

Random read operations allow the master to access

any location in the X1205. Prior to issuing the Slave

Address Byte with the R/W bit set to zero, the master

must first perform a “dummy” write operation.

The master issues the start condition and the slave

address byte, receives an acknowledge, then issues

the word address bytes. After acknowledging receipt of

each word address byte, the master immediately

issues another start condition and the slave address

byte with the R/W bit set to one. This is followed by an

acknowledge from the device and then by the eight bit

data word. The master terminates the read operation

by not responding with an acknowledge and then issuing a stop condition. Refer to Figure 10 for the address,

acknowledge, and data transfer sequence.

In a similar operation called “Set Current Address,” the

device sets the address if a stop is issued instead of

the second start shown in Figure 10. The X1205 then

goes into standby mode after the stop and all bus

Figure 10. Random Address Read Sequence

activity will be ignored until a start is detected. This

operation loads the new address into the address

counter. The next Current Address Read operation will

read from the newly loaded address. This operation

could be useful if the master knows the next address it

needs to read, but is not ready for the data.

Sequential Read

Sequential reads can be initiated as either a current

address read or random address read. The first data

byte is transmitted as with the other modes; however,

the master now responds with an acknowledge, indicating it requires additional data. The device continues

to output data for each acknowledge received. The master terminates the read operation by not responding with

an acknowledge and then issuing a stop condition.

The data output is sequential, with the data from

address n followed by the data from address n + 1.

Refer to Figure 11 for the acknowledge and data transfer sequence.

S

Signals from

the Master

SDA Bus

Signals from

the Slave

t

a

r

t

Slave

Address

101

Figure 11. Sequential Read Sequence

Signals from

the Master

SDA Bus

Signals from

the Slave

Slave

Address

PRELIMINARY

1

A

C

K

0

1111

A

C

K

Data

Word

Address 1

0000000

C

K

(1)

S

Word

Address 0

A

C

K

A

Data

(2)

t

Slave

a

r

Address

t

101

1

1111

A

C

K

A

C

K

Data

(n-1)

(n is any integer greater than 1)

A

C

K

A

C

K

Data

Data

(n)

S

t

o

p

S

t

o

p

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 11 of 22

Page 12

X1205 – Preliminary Information

ABSOLUTE MAXIMUM RATINGS

Temperature Under Bias ................... -65°C to +135°C

Storage Temperature......................... -65°C to +150°C

Voltage on VCC, V

BACK

and IRQ

pin (respect to ground) ............................-0.5V to 7.0V

Voltage on SCL, SDA, X1 and X2

pin (respect to ground) ............... -0.5V to 7.0V or 0.5V

above VCC or V

(whichever is higher)

BACK

DC Output Current .............................................. 5 mA

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and the functional operation

of the device at these or any other conditions above

those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Lead Temperature (Soldering, 10 sec) ...............300°C

DC OPERATING CHARACTERISTICS (Temperature = -40°C to +85°C, unless otherwise stated.)

Symbol Parameter Conditions Min Typ Max Unit Notes

V

V

V

V

CC

BACK

CB

BC

Main Power Supply 2.7 5.5 V

Backup Power Supply 1.8 5.5 V

Switch to Backup Supply V

Switch to Main Supply V

-0.2 V

BACK

BACK

BACK

V

BACK

-0.1 V

+0.2 V

OPERATING CHARACTERISTICS

Symbol Parameter Conditions Min Typ Max Unit Notes

= 2.7V 400 µA

I

CC1

I

CC2

I

CC3

I

BACK

I

LI

I

LO

V

V

V

HYS

V

OL

IH

Read Active Supply

Current

Program Supply Current

(nonvolatile)

Main Timekeeping

Current

Timekeeping Current

Input Leakage Current 10 µA 10

Output Leakage Current 10 µA 10

IL

Input LOW Voltage -0.5

Input HIGH Voltage

Schmitt Trigger Input

Hysteresis

Output LOW Voltage for

SDA/IRQ

PRELIMINARY

V

CC

= 5.5V 800 µA

V

CC

= 2.7V 2.5 mA

V

CC

= 5.5V 3.0 mA

V

CC

= 2.7V 5 µA

V

CC

= 5.5V 10 µA

V

CC

V

= 1.8V 1.25 µA 3, 6, 9, 14, 15

BACK

V

= 3.3V 1.5 µA

BACK

V

CC

V

BACK

x 0.7 or

V

CC

BACK

x 0.7

or

CC

BACK

V

related level

V

CC

VCC = 2.7V 0.4

= 5.5V 0.4

V

CC

.05 x V

.05 x V

V

CC

V

BACK

x 0.2 or

x 0.2

+ 0.5 or

+ 0.5

1, 5, 7, 14

2, 5, 7, 14

3, 7, 8, 14, 15

“See Perfor-

mance Data”

V13

V13

V13

V11

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 12 of 22

Page 13

X1205 – Preliminary Information

Notes: (1) The device enters the Active state after any start, and remains active: for 9 clock cycles if the Device Select Bits in the Slave

Address Byte are incorrect or until 200nS after a stop ending a read or write operation.

(2) The device enters the Program state 200nS after a stop ending a write operation and continues for tWC.

(3) The device goes into the Timekeeping state 200nS after any stop, except those that initiate a nonvolatile write cycle; tWC after a

stop that initiates a nonvolatile write cycle; or 9 clock cycles after any start that is not followed by the correct Device Select Bits in

the Slave Address Byte.

(4) For reference only and not tested.

(5) VIL = VCC x 0.1, VIH = VCC x 0.9, f

(6) VCC = 0V

(7) V

(8) V

(9) V

(10) V

(11) IOL = 3.0mA at 5V, 1mA at 2.7V

(13) Threshold voltages based on the higher of Vcc or Vback.

(14) Using recommended crystal and oscillator network applied to X1 and X2 (25°C).

(15) Typical values are for TA = 25°C

= 0V

BACK

= V

SDA

SCL=VCC

SDA =VSCL=VBACK

= GND or VCC, V

SDA

, Others = GND or V

, Others = GND or V

= GND or V

SCL

Capacitance TA = 25°C, f = 1.0 MHz, VCC = 5V

Symbol Parameter Max. Units Test Conditions

(1)

C

OUT

(1)

C

IN

Notes: (1) This parameter is not 100% tested.

(2) The input capacitance between x1 and x2 pins can be varied between 5pF and 19.75pF by using analog trimming registers

Output Capacitance (SDA, IRQ)10pFV

Input Capacitance (SCL) 10 pF VIN = 0V

= 400KHz

SCL

CC

CC

BACK

OUT

= 0V

AC CHARACTERISTICS

AC Test Conditions

Input Pulse Levels V

x 0.1 to VCC x 0.9

CC

Input Rise and Fall Times 10ns

Input and Output Timing

Levels

x 0.5

V

CC

Output Load Standard Output Load

Figure 14. Standard Output Load for testing the device with VCC = 5.0V

Equivalent AC Output Load Circuit for VCC = 5V

5.0V

PRELIMINARY

1533Ω

SDA

100pF

For VOL= 0.4V

and I

= 3 mA

OL

IRQ

5.0V

1316Ω

806Ω

100pF

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 13 of 22

Page 14

X1205 – Preliminary Information

AC Specifications (TA = -40°C to +85°C, VCC = +2.7V to +5.5V, unless otherwise specified.)

Symbol Parameter

f

SCL

t

IN

t

AA

t

BUF

t

LOW

t

HIGH

t

SU:STA

t

HD:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

DH

t

R

t

F

SCL Clock Frequency 400 kHz

Pulse width Suppression Time at inputs 50

SCL LOW to SDA Data Out Valid 0.9 µs

Time the bus must be free before a new transmission can start 1.3 µs

Clock LOW Time 1.3 µs

Clock HIGH Time 0.6 µs

Start Condition Setup Time 0.6 µs

Start Condition Hold Time 0.6 µs

Data In Setup Time 100 ns

Data In Hold Time 0 µs

Stop Condition Setup Time 0.6 µs

Data Output Hold Time 50 ns

SDA and SCL Rise Time 20 +.1Cb

SDA and SCL Fall Time 20 +.1Cb

Cb Capacitive load for each bus line 400 pF

Notes: (1) This parameter is not 100% tested.

(2) Cb = total capacitance of one bus line in pF.

Min. Max. Units

(1)

(1)(2)

(1)(2)

300 ns

300 ns

ns

TIMING DIAGRAMS

Bus Timing

SCL

t

SU:STA

SDA IN

SDA

OUT

t

HD:STA

t

F

t

SU:DAT

t

HIGH

t

LOW

t

HD:DAT

t

R

t

SU:STO

t

t

DH

AA

t

BUF

PRELIMINARY

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 14 of 22

Page 15

X1205 – Preliminary Information

Write Cycle Timing

SCL

SDA

8th Bit of Last Byte ACK

Stop

Condition

t

WC

Start

Condition

Power Up Timing

Symbol Parameter Min. Typ.

(1)

t

PUR

(1)

t

PUW

Notes: (1) Delays are measured from the time VCC is stable until the specified operation can be initiated. These parameters are not 100%

tested. VCC slew rate should be between 0.2mV/µsec and 50mV/µsec.

(2) Typical values are for TA = 25°C and VCC = 5.0V

Time from Power Up to Read 1 ms

Time from Power Up to Write 5 ms

(2)

Max. Units

Nonvolatile Write Cycle Timing

Symbol Parameter Min. Typ.

(1)

t

WC

Note: (1) tWC is the time from a valid stop condition at the end of a write sequence to the end of the self-timed internal nonvolatile write cycle.

It is the minimum cycle time to be allowed for any nonvolatile write by the user, unless Acknowledge Polling is used.

Write Cycle Time 5 10 ms

(1)

Max. Units

REV 1.0.9 8/29/02

PRELIMINARY

www.xicor.com

Characteristics subject to change without notice. 15 of 22

Page 16

X1205 – Preliminary Information

APPLICATION SECTION

CRYSTAL OSCILLATOR AND TEMPERATURE

COMPENSATION

Xicor has now integrated the oscillator compensation

circuity on-chip, to eliminate the need for external components and adjust for crystal drift over temperature

and enable very high accuracy timekeeping (<5ppm

drift).

The Xicor RTC family uses an oscillator circuit with onchip crystal compensation network, including adjustable load-capacitance. The only external component

required is the crystal. The compensation network is

optimized for operation with certain crystal parameters

which are common in many of the surface mount or

tuning-fork crystals available today. Table 6 summarizes these parameters.

Table 7 contains some crystal manufacturers and part

numbers that meet the requirements for the Xicor RTC

products.

The turnover temperature in Table 6 describes the

temperature where the apex of the of the drift vs. temperature curve occurs. This curve is parabolic with the

drift increasing as (T-T0)2. For an Epson MC-405

device, for example, the turnover temperature is typi-

cally 25 deg C, and a peak drift of >110ppm occurs at

the temperature extremes of –40 and +85 deg C. It is

possible to address this variable drift by adjusting the

load capacitance of the crystal, which will result in predictable change to the crystal frequency. The Xicor

RTC family allows this adjustment over temperature

since the devices include on-chip load capacitor trimming. This control is handled by the Analog Trimming

Register, or ATR, which has 6 bits of control . The load

capacitance range covered by the ATR circuit is

approximately 3.25pF to 18.75pF, in 0.25pf increments. Note that actual capacitance would also

include about 2pF of package related capacitance. Incircuit tests with commercially available crystals demonstrate that this range of capacitance allows frequency control from +116ppm to –37ppm, using a

12.5pF load crystal.

In addition to the analog compensation afforded by the

adjustable load capacitance, a digital compensation

feature is available for the Xicor RTC family. There are

three bits known as the Digital Trimming Register or

DTR, and they operate by adding or skipping pulses in

the clock signal. The range provided is ±30ppm in

increments of 10ppm. The default setting is 0ppm. The

DTR control can be used for coarse adjustments of

frequency drift over temperature or for crystal initial

accuracy correction.

Table 6. Crystal Parameters Required for Xicor RTC’s

Parameter Min Typ Max Units Notes

Frequency 32.768 kHz

Freq. Tolerance ±100 ppm Down to 20ppm if desired

Turnover Temperature 20 25 30 °C

Operating Temperature Range -40 85 °C

Parallel Load Capacitance 12.5 pF

Equivalent Series Resistance 50 kΩ For best oscillator performance

Typically the value used for most

crystals

PRELIMINARY

Table 7. Crystal Manufacturers

Manufacturer Part Number Temp Range +25°C Freq Toler.

Citizen CM201, CM202, CM200S -40 to +85°C ±20ppm

Epson MC-405, MC-406 -40 to +85°C ±20ppm

Raltron RSM-200S-A or B -40 to +85°C ±20ppm

SaRonix 32S12A or B -40 to +85°C ±20ppm

Ecliptek ECPSM29T-32.768K -10 to +60°C ±20ppm

ECS ECX-306/ECX-306I -10 to +60°C ±20ppm

Fox FSM-327 -40 to +85°C ±20ppm

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 16 of 22

Page 17

X1205 – Preliminary Information

A final application for the ATR control is in-circuit calibration for high accuracy applications, along with a

temperature sensor chip. Once the RTC circuit is powered up with battery backup, the PHZ output is set at

32.768kHz and frequency drift is measured. The ATR

control is then adjusted to a setting which minimizes

drift. Once adjusted at a particular temperature, it is

possible to adjust at other discrete temperatures for

minimal overall drift, and store the resulting settings in

the EEPROM. Extremely low overall temperature drift

is possible with this method. The Xicor evaluation

board contains the circuitry necessary to implement

this control.

For more detailed operation see Xicor’s application

note AN154 on Xicor’s website at www.xicor.com.

Layout Considerations

The crystal input at X1 has a very high impedance and

will pick up high frequency signals from other circuits

on the board. Since the X2 pin is tied to the other side

of the crystal, it is also a sensitive node. These signals

can couple into the oscillator circuit and produce double clocking or mis-clocking, seriously affecting the

accuracy of the RTC. Care needs to be taken in layout

of the RTC circuit to avoid noise pickup. Below in Figure 15 is a suggested layout for the X1205 SOIC

device.

Figure 15. Suggested Layout for Xicor RTC in SO-8

PRELIMINARY

The X1 and X2 connections to the crystal are to be

kept as short as possible. A thick ground trace around

the crystal is advised to minimize noise intrusion, but

ground near the X1 and X2 pins should be avoided as

it will add to the load capacitance at those pins. Keep in

mind these guidelines for other PCB layers in the vicinity of the RTC device. A small decoupling capacitor at

the Vcc pin of the chip is mandatory, with a solid connection to ground.

Assembly

Most electronic circuits do not have to deal with

assembly issues, but with the RTC devices assembly

includes insertion or soldering of a live battery into an

unpowered circuit. If a socket is soldered to the board,

and a battery is inserted in final assembly, then there

are no issues with operation of the RTC. If the battery

is soldered to the board directly, then the RTC device

Vback pin will see some transient upset from either soldering tools or intermittent battery connections which

can stop the circuit from oscillating. Once the battery is

soldered to the board, the only way to assure the circuit

will start up is to momentarily (very short period of

time!) short the Vback pin to ground and the circuit will

begin to oscillate.

Oscillator Measurements

When a proper crystal is selected and the layout guidelines above are observed, the oscillator should start up

in most circuits in less than one second. Some circuits

may take slightly longer, but startup should definitely

occur in less than 5 seconds. When testing RTC circuits, the most common impulse is to apply a scope

probe to the circuit at the X2 pin (oscillator output) and

observe the waveform. DO NOT DO THIS! Although in

some cases you may see a useable waveform, due to

the parasitics (usually 10pF to ground) applied with the

scope probe, there will be no useful information in that

waveform other than the fact that the circuit is oscillating. The X2 output is sensitive to capacitive impedance

so the voltage levels and the frequency will be affected

by the parasitic elements in the scope probe. Applying

a scope probe can possibly cause a faulty oscillator to

start up, hiding other issues (although in the Xicor

RTC’s, the internal circuitry assures startup when

using the proper crystal and layout).

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 17 of 22

Page 18

X1205 – Preliminary Information

The best way to analyze the RTC circuit is to power it

up and read the real time clock as time advances, or if

the chip has the PHZ output, look at the output of that

pin on an oscilloscope (after enabling it with the control

register, and using a pullup resistor for an open-drain

output). Alternatively, the X1226/1286/1205 devices

have an IRQ- output which can be checked by setting

an alarm for each minute. Using the pulse interrupt

mode setting, the once-per-minute interrupt functions

as an indication of proper oscillation.

Backup Battery Operation

Many types of batteries can be used with the Xicor

RTC products. 3.0V or 3.6V Lithium batteries are

appropriate, and sizes are available that can power a

Xicor RTC device for up to 10 years. Another option is

to use a supercapacitor for applications where Vcc may

disappear intermittently for short periods of time.

Depending on the value of supercapacitor used,

backup time can last from a few days to two weeks

(with >1F). A simple silicon or Schottky barrier diode

can be used in series with Vcc to charge the supercapacitor, which is connected to the Vback pin. Do not

use the diode to charge a battery (especially lithium

batteries!).

Figure 16. Supercapactor charging circuit

2.7-5.5V

Since the battery switchover occurs at Vcc=Vback-

0.1V (see Figure 16), the battery voltage must always

be lower than the Vcc voltage during normal operation

or the battery will be drained.

The summary of conditions for backup battery operation is given in Table 8:

V

CC

V

back

Supercapacitor

V

SS

Table 8. Battery Backup Operation

1. Example Application, Vcc=5V, Vback=3.0V

Condition Vcc Vback Vtrip Iback Notes

a. Normal Operation 5.00 3.00 4.38 <<1µA

b. Vcc on with no battery 5.00 0 4.38 0

c. Backup Mode 0–1.8 1.8-3.0 4.38 <2µA Timekeeping only

2. Example Application, Vcc=3.3V,Vback=3.0V

Condition Vcc Vback Vtrip Iback

a. Normal Operation 3.30 3.00 2.65 <<1µA

b. Vcc on with no battery 3.30 0 2.65 0

c. Backup Mode 0–1.8 1.8–3.0* 2.65 <2µA* Timekeeping only

d. UNWANTED - Vcc ON, Vback powering

*since Vback>2.65V is higher than Vtrip, the battery is powering the entire device

PRELIMINARY

2.65 - 3.30 > Vcc 2.65 up to 3mA

Internal

Vcc=Vback

REV 1.0.9 8/29/02

www.xicor.com

Characteristics subject to change without notice. 18 of 22

Page 19

X1205 – Preliminary Information

Referring to Figure 16, Vtrip applies to the “Internal

Vcc” node which powers the entire device. This means

that if Vcc is powered down and the battery voltage at

Vback is higher than the Vtrip voltage, then the entire

chip will be running from the battery. If Vback falls to

lower than Vtrip, then the chip shuts down and all outputs are disabled except for the oscillator and timekeeping circuitry. The fact that the chip can be powered

from Vback is not necessarily an issue since standby

current for the RTC devices is <2µA for this mode

(called “main timekeeping current” in the data sheet).

Only when the serial interface is active is there an

increase in supply current, and with Vcc powered

down, the serial interface will most likely be inactive.

One way to prevent operation in battery backup mode

above the Vtrip level is to add a diode drop (silicon

diode preferred) to the battery to insure it is below

Vtrip. This will also provide reverse leakage protection

which may be needed to get safety agency approval.

One mode that should always be avoided is the operation of the RTC device with Vback greater than both

Vcc and Vtrip (Condition 2d in Table 8). This will cause

the battery to drain quickly as serial bus communication and non-volatile writes will require higher supplier

current.

PERFORMANCE DATA

I

Performance

BACK

I

BACK

1.4

1.2

1.0

0.8

(µA)

0.6

BACK

I

0.4

0.2

0

Multi-Lot Process Variation Data

-40 25 60 85

Temperature °C

vs. Temperature

3.3V

1.8V

REV 1.0.9 8/29/02

PRELIMINARY

www.xicor.com

Characteristics subject to change without notice. 19 of 22

Page 20

X1205 – Preliminary Information

PACKAGING INFORMATION

8-Lead Plastic, SOIC, Package Code S8

Pin 1 Index

(4X) 7°

0.050 (1.27)

0.010 (0.25)

0.020 (0.50)

Pin 1

X 45°

0.014 (0.35)

0.019 (0.49)

0.188 (4.78)

0.197 (5.00)

0.150 (3.80)

0.158 (4.00)

0.004 (0.19)

0.010 (0.25)

0.228 (5.80)

0.244 (6.20)

0.053 (1.35)

0.069 (1.75)

0.050"Typical

0° - 8°

REV 1.0.9 8/29/02

0.050"

Typical

0.0075 (0.19)

0.010 (0.25)

0.016 (0.410)

PRELIMINARY

0.037 (0.937)

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

www.xicor.com

0.250"

0.030"

Typical

8 PlacesFOOTPRINT

Characteristics subject to change without notice. 20 of 22

Page 21

X1205 – Preliminary Information

PACKAGING INFORMATION

8-Lead Plastic, TSSOP, Package Code V8

.025 (.65) BSC

0° – 8°

.019 (.50)

.029 (.75)

Detail A (20X)

.114 (2.9)

.122 (3.1)

.0075 (.19)

.0118 (.30)

.010 (.25)

.169 (4.3)

.177 (4.5)

.002 (.05)

.006 (.15)

Gage Plane

Seating Plane

.252 (6.4) BSC

.047 (1.20)

(4.16)

(7.72)

See Detail “A”

REV 1.0.9 8/29/02

(1.78)

PRELIMINARY

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

.031 (.80)

.041 (1.05)

www.xicor.com

(0.42)

(0.65)

All Measurements Are Typical

Characteristics subject to change without notice. 21 of 22

Page 22

X1205 – Preliminary Information

ORDERING INFORMATION

VCC Range Package Operating Temperature Range Part Number

2.7-5.5V 8L SOIC 0–70°C X1205S8

-40–85°C X1205S8I

8L TSSOP 0–70°C X1205V8

-40–85°C X1205V8I

PART MARK INFORMATION

8-Lead TSSOP

YWW

XXXXX

1205 = 2.7 to 5.5V, 0 to +70°C

1205I = 2.7 to 5.5V, -40 to 85°C

LIMITED WARRANTY

Devices sold by Xicor, Inc. are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. Xicor, Inc. makes no warranty,

express, statutory, implied, or by description regarding the information set forth herein or regarding the freedom of the described devices from patent infringement.

Xicor, Inc. makes no warranty of merchantability or fitness for any purpose. Xicor, Inc. reserves the right to discontinue production and change specifications and prices

at any time and without notice.

Xicor, Inc. assumes no responsibility for the use of any circuitry other than circuitry embodied in a Xicor, Inc. product. No other circuits, patents, or licenses are implied.

COPYRIGHTS AND TRADEMARKS

Xicor, Inc., the Xicor logo, E

2

KEY, X24C16, SecureFlash, and SerialFlash are all trademarks or registered trademarks of Xicor, Inc. All other brand and product names mentioned herein are

E

used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

U.S. PATENTS

Xicor products are covered by one or more of the following U.S. Patents: 4,326,134; 4,393,481; 4,404,475; 4,450,402; 4,486,769; 4,488,060; 4,520,461; 4,533,846;

4,599,706; 4,617,652; 4,668,932; 4,752,912; 4,829,482; 4,874,967; 4,883,976; 4,980,859; 5,012,132; 5,003,197; 5,023,694; 5,084,667; 5,153,880; 5,153,691;

5,161,137; 5,219,774; 5,270,927; 5,324,676; 5,434,396; 5,544,103; 5,587,573; 5,835,409; 5,977,585. Foreign patents and additional patents pending.

LIFE RELATED POLICY

In situations where semiconductor component failure may endanger life, system designers using this product should design the system with appropriate error detection

and correction, redundancy and back-up features to prevent such an occurrence.

Xicor’s products are not authorized for use in critical components in life suppor t devices or systems.

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life, and whose failure to

perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or effectiveness.

REV 1.0.9 8/29/02

PRELIMINARY

2

POT, XDCP, XBGA, AUTOSTORE, Direct Write cell, Concurrent Read-Write, PASS, MPS, PushPOT, Block Lock, IdentiPROM,

www.xicor.com

8-Lead SOIC

X1205 X

Blank = 8-Lead SOIC

YWW XX

Blank = 2.7 to 5.5V, 0 to +70°C

I = 2.7 to 5.5V, -40 to 85°C

©Xicor, Inc. 2001 Patents Pending

Characteristics subject to change without notice. 22 of 22

Loading...

Loading...