Page 1

3V 32M-BIT

SERIAL FLASH MEMORY WITH

DUAL/QUAD SPI & QPI

W25Q32FV

Publication Release Date: Sept 16, 2013

Revision H

Page 2

1.

2.

3.

4.

5.

6.

7.

W25Q32FV

Table of Contents

GENERAL DESCRIPTIONS ............................................................................................................. 5

FEATURES ....................................................................................................................................... 5

PACKAGE TYPES AND PIN CONFIGURATIONS ........................................................................... 6

3.1 Pin Configuration SOIC 208-mil / VSOP 208-mil .................................................................. 6

3.2 Pad Configuration WSON 6x5-mm / 8x6-mm ...................................................................... 6

3.3 Pin Description SOIC / VSOP 208-mil, WSON 6x5-mm / 8x6-mm ...................................... 6

3.4 Pin Configuration SOIC 300-mil ........................................................................................... 7

3.5 Pin Description SOIC 300-mil ............................................................................................... 7

3.6 Ball Configuration TFBGA 8x6-mm (5x5 or 6x4 Ball Array) ................................................. 8

3.7 Ball Description TFBGA 8x6-mm ......................................................................................... 8

3.8 Pin Configuration PDIP 300-mil ............................................................................................ 9

3.9 Pin Description PDIP 300-mil ............................................................................................... 9

PIN DESCRIPTIONS ...................................................................................................................... 10

4.1 Chip Select (/CS) ................................................................................................................ 10

4.2 Serial Data Input, Output and IOs (DI, DO and IO0, IO1, IO2, IO3) ................................... 10

4.3 Write Protect (/WP) ............................................................................................................ 10

4.4 HOLD (/HOLD) ................................................................................................................... 10

4.5 Serial Clock (CLK) .............................................................................................................. 10

4.6 Reset (/RESET) .................................................................................................................. 10

BLOCK DIAGRAM .......................................................................................................................... 11

FUNCTIONAL DESCRIPTIONS ..................................................................................................... 12

6.1 SPI / QPI Operations .......................................................................................................... 12

6.1.1 Standard SPI Instructions .................................................................................................... 12

6.1.2 Dual SPI Instructions ............................................................................................................ 12

6.1.3 Quad SPI Instructions .......................................................................................................... 13

6.1.4 QPI Instructions .................................................................................................................... 13

6.1.5 Hold Function ....................................................................................................................... 13

6.1.6 Software Reset & Hardware /RESET pin ............................................................................. 14

6.2 Write Protection .................................................................................................................. 15

6.2.1 Write Protect Features ......................................................................................................... 15

STATUS AND CONFIGURATION REGISTERS ............................................................................ 16

7.1 Status Registers ................................................................................................................. 16

7.1.1 Erase/Write In Progress (BUSY) – Status Only ................................................................... 16

7.1.2 Write Enable Latch (WEL) – Status Only ............................................................................. 16

7.1.3 Block Protect Bits (BP2, BP1, BP0) – Volatile/Non-Volatile Writable ................................... 16

- 1 -

Page 3

W25Q32FV

8.

7.1.4 Top/Bottom Block Protect (TB) – Volatile/Non-Volatile Writable .......................................... 17

7.1.5 Sector/Block Protect Bit (SEC) – Volatile/Non-Volatile Writable .......................................... 17

7.1.6 Complement Protect (CMP) – Volatile/Non-Volatile Writable ............................................... 17

7.1.7 Status Register Protect (SRP1, SRP0) – Volatile/Non-Volatile Writable .............................. 17

7.1.8 Erase/Program Suspend Status (SUS) – Status Only ......................................................... 18

7.1.9 Security Register Lock Bits (LB3, LB2, LB1) – Volatile/Non-Volatile OTP Writable ............. 18

7.1.10 Quad Enable (QE) – Volatile/Non-Volatile Writable ........................................................... 18

7.1.11 Write Protect Selection (WPS) – Volatile/Non-Volatile Writable ........................................ 19

7.1.12 Output Driver Strength (DRV1, DRV0) – Volatile/Non-Volatile Writable ............................ 19

7.1.13 HOLD or /RESET Pin Function (HOLD/RST) – Volatile/Non-Volatile Writable .................. 19

7.1.14 Reserved Bits – Non Functional ......................................................................................... 20

7.1.15 W25Q32FV Status Register Memory Protection (WPS = 0, CMP = 0) .............................. 21

7.1.16 W25Q32FV Status Register Memory Protection (WPS = 0, CMP = 1) .............................. 22

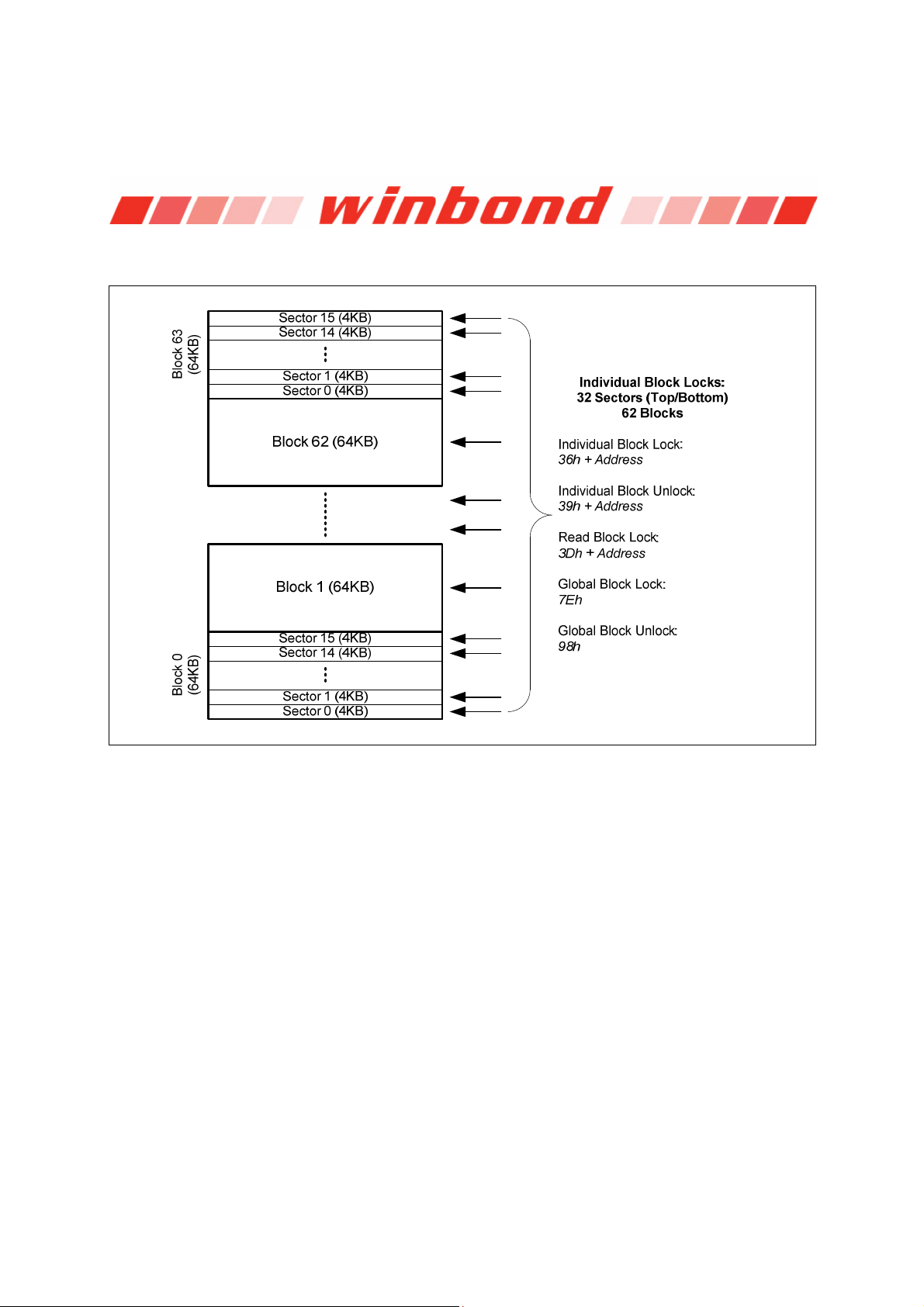

7.1.17 W25Q32FV Individual Block Memory Protection (WPS=1) ............................................... 23

INSTRUCTIONS ............................................................................................................................. 24

8.1 Device ID and Instruction Set Tables ................................................................................. 24

8.1.1 Manufacturer and Device Identification ................................................................................ 24

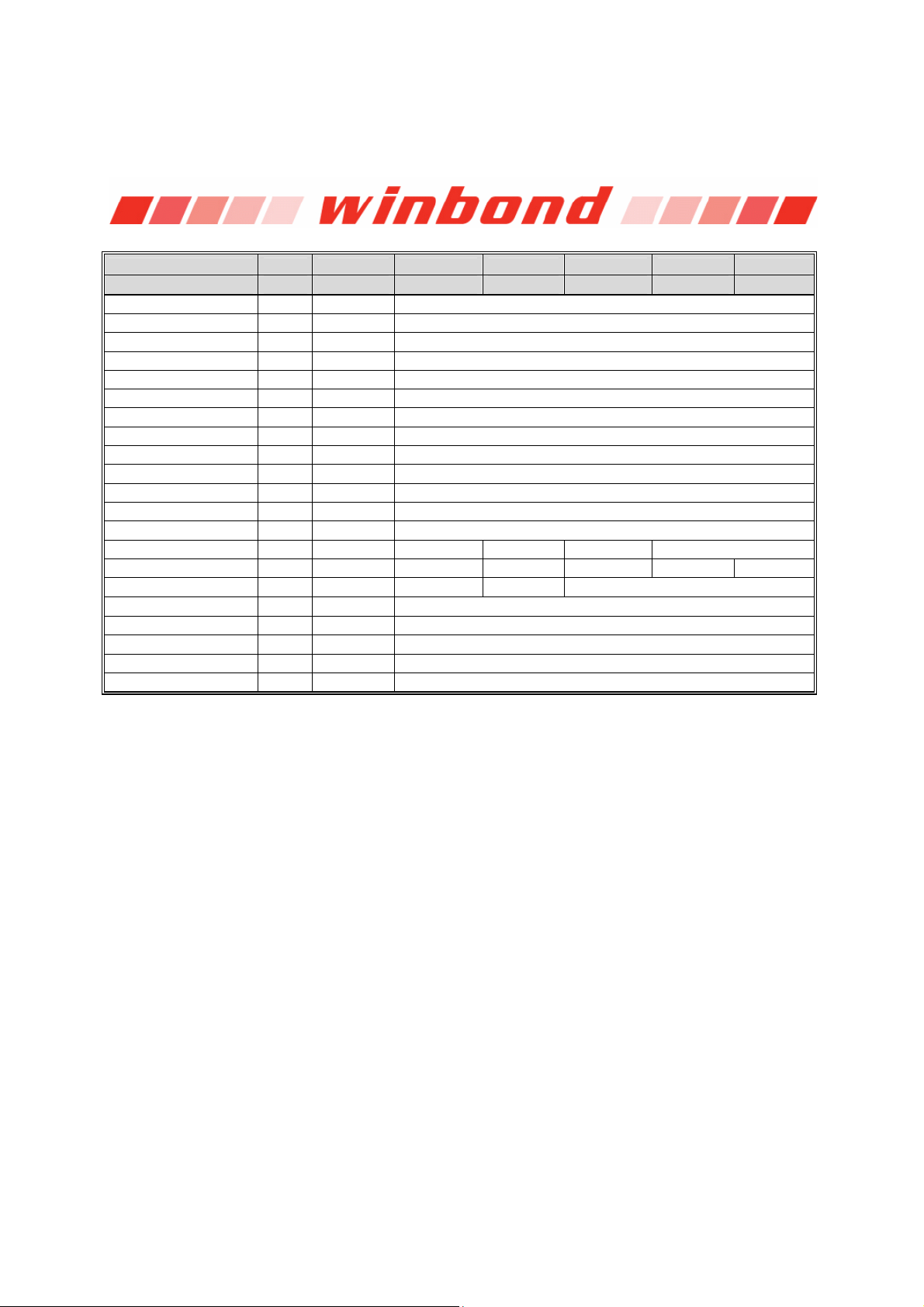

8.1.2 Instruction Set Table 1 (Standard/Dual/Quad SPI Instructions)

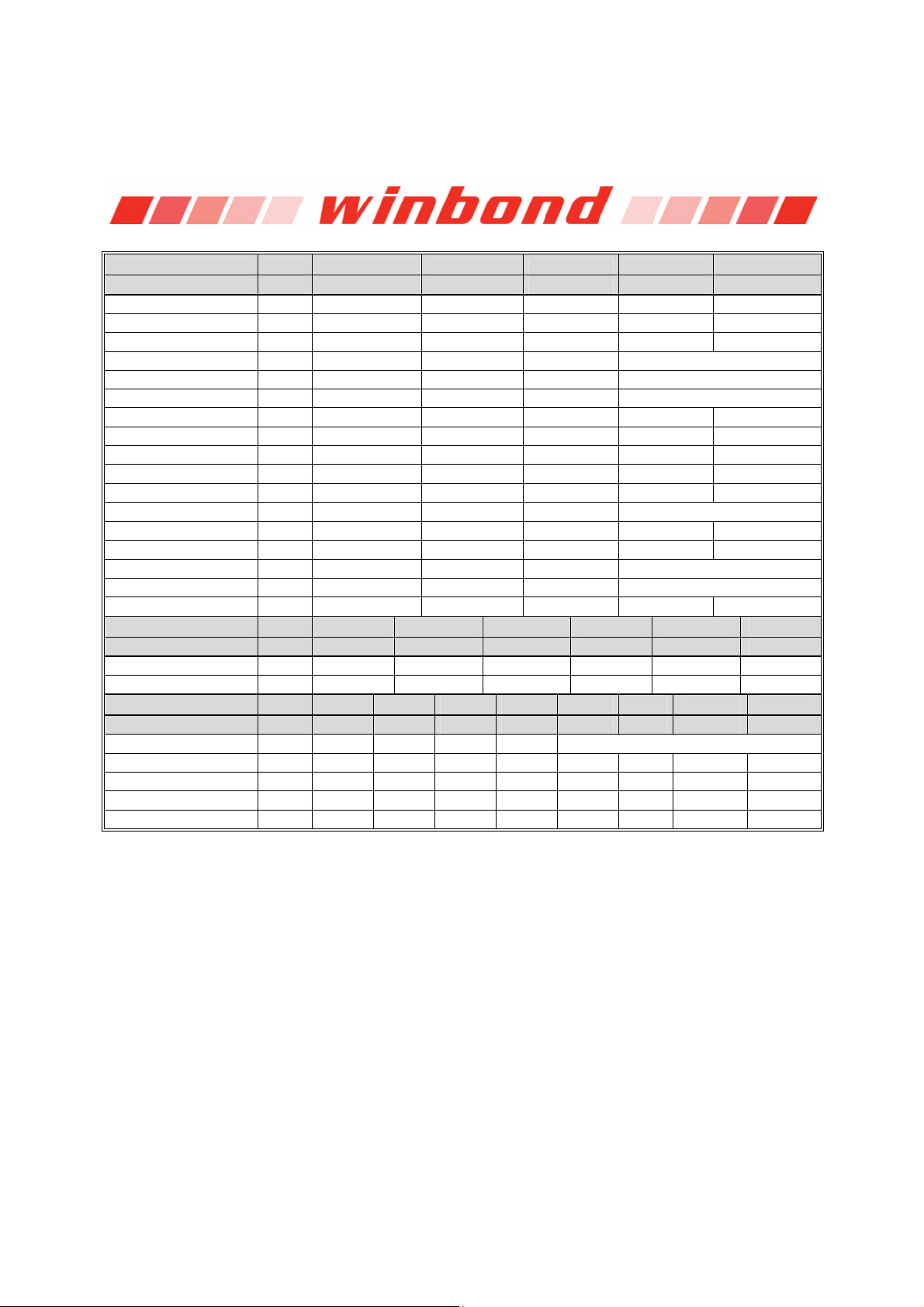

8.1.3 Instruction Set Table 2 (Standard/Dual/Quad SPI Instructions)

8.1.4 Instruction Set Table 3 (QPI Instructions)

8.2 Instruction Descriptions ...................................................................................................... 29

8.2.1 Write Enable (06h) ............................................................................................................... 29

8.2.2 Write Enable for Volatile Status Register (50h) ................................................................... 29

8.2.3 Write Disable (04h) .............................................................................................................. 30

8.2.4 Read Status Register-1 (05h), Status Register-2 (35h) & Status Register-3 (15h) .............. 30

8.2.5 Write Status Register-1 (01h), Status Register-2 (31h) & Status Register-3 (11h) .............. 31

8.2.6 Read Data (03h) ................................................................................................................... 34

8.2.7 Fast Read (0Bh) ................................................................................................................... 35

8.2.8 Fast Read Dual Output (3Bh) ............................................................................................... 37

8.2.9 Fast Read Quad Output (6Bh) ............................................................................................. 38

8.2.10 Fast Read Dual I/O (BBh) .................................................................................................. 39

8.2.11 Fast Read Quad I/O (EBh) ................................................................................................. 41

8.2.12 Word Read Quad I/O (E7h) ................................................................................................ 44

8.2.13 Octal Word Read Quad I/O (E3h) ...................................................................................... 46

8.2.14 Set Burst with Wrap (77h) .................................................................................................. 48

8.2.15 Page Program (02h) ........................................................................................................... 49

8.2.16 Quad Input Page Program (32h) ........................................................................................ 51

8.2.17 Sector Erase (20h) ............................................................................................................. 52

8.2.18 32KB Block Erase (52h) ..................................................................................................... 53

8.2.19 64KB Block Erase (D8h) .................................................................................................... 54

8.2.20 Chip Erase (C7h / 60h) ...................................................................................................... 55

(14)

........................................................................ 27

(1)

........................................ 25

(1)

........................................ 26

Publication Release Date: Sept 16,, 2013

- 2 - Revision H

Page 4

W25Q32FV

8.2.21 Erase / Program Suspend (75h) ........................................................................................ 56

8.2.22 Erase / Program Resume (7Ah) ......................................................................................... 58

8.2.23 Power-down (B9h) .............................................................................................................. 59

8.2.24 Release Power-down / Device ID (ABh)............................................................................. 60

8.2.25 Read Manufacturer / Device ID (90h) ................................................................................. 62

8.2.26 Read Manufacturer / Device ID Dual I/O (92h) .................................................................. 63

8.2.27 Read Manufacturer / Device ID Quad I/O (94h) ................................................................. 64

8.2.28 Read Unique ID Number (4Bh) .......................................................................................... 65

8.2.29 Read JEDEC ID (9Fh) ........................................................................................................ 66

8.2.30 Read SFDP Register (5Ah) ................................................................................................ 67

8.2.31 Erase Security Registers (44h) .......................................................................................... 68

8.2.32 Program Security Registers (42h) ...................................................................................... 69

8.2.33 Read Security Registers (48h) ........................................................................................... 70

8.2.34 Set Read Parameters (C0h) ............................................................................................... 71

8.2.35 Burst Read with Wrap (0Ch) .............................................................................................. 72

8.2.36 Enter QPI Mode (38h) ........................................................................................................ 73

8.2.37 Exit QPI Mode (FFh) .......................................................................................................... 74

8.2.38 Individual Block/Sector Lock (36h) ..................................................................................... 75

8.2.39 Individual Block/Sector Unlock (39h) ................................................................................. 76

8.2.40 Read Block/Sector Lock (3Dh) ........................................................................................... 77

8.2.41 Global Block/Sector Lock (7Eh) ......................................................................................... 78

8.2.42 Global Block/Sector Unlock (98h) ...................................................................................... 78

8.2.43 Enable Reset (66h) and Reset Device (99h)...................................................................... 79

9.

ELECTRICAL CHARACTERISTICS ............................................................................................... 80

9.1 Absolute Maximum Ratings

9.2 Operating Ranges............................................................................................................... 80

9.3 Power-Up Power-Down Timing and Requirements

9.4 DC Electrical Characteristics

9.5 AC Measurement Conditions

9.6 AC Electrical Characteristics

9.7 Serial Output Timing ........................................................................................................... 86

9.8 Serial Input Timing .............................................................................................................. 86

9.9 HOLD Timing ...................................................................................................................... 86

9.10 WP Timing .......................................................................................................................... 86

10. PACKAGE SPECIFICATIONS ........................................................................................................ 87

10.1 8-Pin SOIC 208-mil (Package Code SS) ............................................................................ 87

10.2 8-Pin VSOP 208-mil (Package Code ST) ........................................................................... 88

10.3 8-Pad WSON 6x5-mm (Package Code ZP) ....................................................................... 89

10.4 8-Pad WSON 8x6-mm (Package Code ZE) ....................................................................... 90

(1)(2)

................................................................................... 80

(1)

....................................................... 81

(1)

.......................................................................................... 82

(1)

......................................................................................... 83

(6)

........................................................................................... 84

- 3 -

Page 5

W25Q32FV

10.5 16-Pin SOIC 300-mil (Package Code SF) .......................................................................... 91

10.6 8-Pin PDIP 300-mil (Package Code DA) ............................................................................ 92

10.7 24-Ball TFBGA 8x6-mm (Package Code TB, 5x5-1 ball array) .......................................... 93

10.8 24-Ball TFBGA 8x6-mm (Package Code TC, 6x4 ball array) ............................................. 94

11. ORDERING INFORMATION .......................................................................................................... 95

11.1 Valid Part Numbers and Top Side Marking ........................................................................ 96

12. REVISION HISTORY ...................................................................................................................... 97

Publication Release Date: Sept 16,, 2013

- 4 - Revision H

Page 6

W25Q32FV

1. GENERAL DESCRIPTIONS

The W25Q32FV (32M-bit) Serial Flash memory provides a storage solution for systems with limited space,

pins and power. The 25Q series offers flexibility and performance well beyond ordinary Serial Flash

devices. They are ideal for code shadowing to RAM, executing code directly from Dual/Quad SPI (XIP)

and storing voice, text and data. The device operates on a single 2.7V to 3.6V power supply with current

consumption as low as 4mA active and 1µA for power-down. All devices are offered in space-saving

packages.

The W25Q32FV array is organized into 16,384 programmable pages of 256-bytes each. Up to 256 bytes

can be programmed at a time. Pages can be erased in groups of 16 (4KB sector erase), groups of 128

(32KB block erase), groups of 256 (64KB block erase) or the entire chip (chip erase). The W25Q32FV

has 1,024 erasable sectors and 64 erasable blocks respectively. The small 4KB sectors allow for greater

flexibility in applications that require data and parameter storage. (See Figure 2.)

The W25Q32FV support the standard Serial Peripheral Interface (SPI), Dual/Quad I/O SPI as well as 2clocks instruction cycle Quad Peripheral Interface (QPI): Serial Clock, Chip Select, Serial Data I/O0 (DI),

I/O1 (DO), I/O2 (/WP), and I/O3 (/HOLD). SPI clock frequencies of up to 104MHz are supported allowing

equivalent clock rates of 208MHz (104MHz x 2) for Dual I/O and 416MHz (104MHz x 4) for Quad I/O

when using the Fast Read Dual/Quad I/O and QPI instructions. These transfer rates can outperform

standard Asynchronous 8 and 16-bit Parallel Flash memories. The Continuous Read Mode allows for

efficient memory access with as few as 8-clocks of instruction-overhead to read a 24-bit address, allowing

true XIP (execute in place) operation.

A Hold pin, Write Protect pin and programmable write protection, with top or bottom array control, provide

further control flexibility. Additionally, the device supports JEDEC standard manufacturer and device ID

and SFDP Register, a 64-bit Unique Serial Number and three 256-bytes Security Registers.

2. FEATURES

• New Family of SpiFlash Memories

– W25Q32FV: 32M-bit / 4M-byte

– Standard SPI: CLK, /CS, DI, DO, /WP, /Hold

– Dual SPI: CLK, /CS, IO0, IO1, /WP, /Hold

– Quad SPI: CLK, /CS, IO0, IO1, IO2, IO

– QPI: CLK, /CS, IO0, IO1, IO2, IO3

– Software & Hardware Reset

• Highest Performance Serial Flash

– 104MHz Single, Dual/Quad SPI clocks

– 208/416MHz equivalent Dual/Quad SPI

– 50MB/S continuous data transfer rate

– More than 100,000 erase/program cycles

– More than 20-year data retention

• Efficient “Continuous Read” and QPI Mode

– Continuous Read with 8/16/32/64-Byte Wrap

– As few as 8 clocks to address memory

– Quad Peripheral Interface (QPI) reduces

instruction overhead

– Allows true XIP (execute in place) operation

– Outperforms X16 Parallel Flash

• Low Power, Wide Temperature Range

– Single 2.7 to 3.6V supply

3

– 4mA active current, <1µA Power-down (typ.)

– -40°C to +85°C operating range

• Flexible Architecture with 4KB sectors

– Uniform Sector/Block Erase (4K/32K/64K-Byte)

– Program 1 to 256 byte per programmable page

– Erase/Program Suspend & Resume

• Advanced Security Features

– Software and Hardware Write-Protect

– Power Supply Lock-Down and OTP protection

– Top/Bottom, Complement array protection

– Individual Block/Sector array protection

– 64-Bit Unique ID for each device

– Discoverable Parameters (SFDP) Register

– 3X256-Bytes Security Registers with OTP locks

– Volatile & Non-volatile Status Register Bits

• Space Efficient Packaging

– 8-pin SOIC 208-mil / VSOP 208-mil

– 8-pad WSON 6x5-mm / 8x6-mm

– 16-pin SOIC 300-mil (additional /RESET pin)

– 8-pin PDIP 300-mil

– 24-ball TFBGA 8x6-mm (6x4/5x5 ball array)

– Contact Winbond for KGD and other options

- 5 -

Page 7

3. PACKAGE TYPES AND PIN CONFIGURATIONS

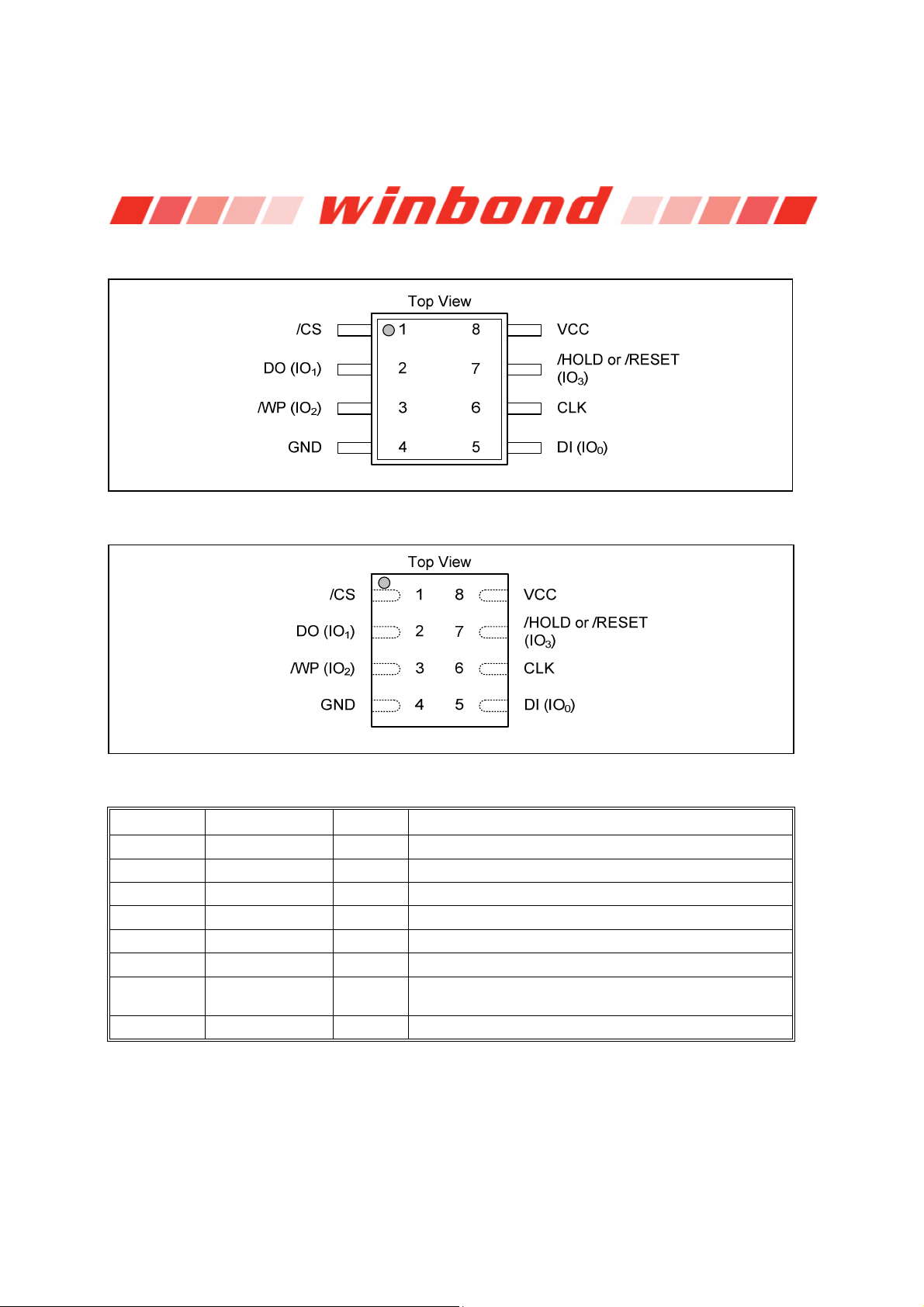

3.1 Pin Configuration SOIC 208-mil / VSOP 208-mil

Figure 1a. W25Q32FV Pin Assignments, 8-pin SOIC / VSOP 208-mil (Package Code SS / ST)

3.2 Pad Configuration WSON 6x5-mm / 8x6-mm

W25Q32FV

Figure 1b. W25Q32FV Pad Assignments, 8-pad WSON 6x5-mm / 8x6-mm (Package Code ZP / ZE)

3.3 Pin Description SOIC / VSOP 208-mil, WSON 6x5-mm / 8x6-mm

PIN NO. PIN NAME I/O FUNCTION

1 /CS I Chip Select Input

2 DO (IO1) I/O

3 /WP (IO2) I/O

4 GND Ground

5 DI (IO0) I/O

6 CLK I Serial Clock Input

7

8 VCC Power Supply

Notes:

1. IO0 and IO1 are used for Standard and Dual SPI instructions

2. IO0 – IO3 are used for Quad SPI instructions, /WP & /HOLD (or /RESET) functions are only available for Standard/Dual SPI.

/HOLD or /RESET

(IO3)

I/O

Data Output (Data Input Output 1)

Write Protect Input ( Data Input Output 2)

Data Input (Data Input Output 0)

Hold or Reset Input (Data Input Output 3)

Publication Release Date: Sept 16,, 2013

- 6 - Revision H

(1)

(2)

(1)

(2)

Page 8

W25Q32FV

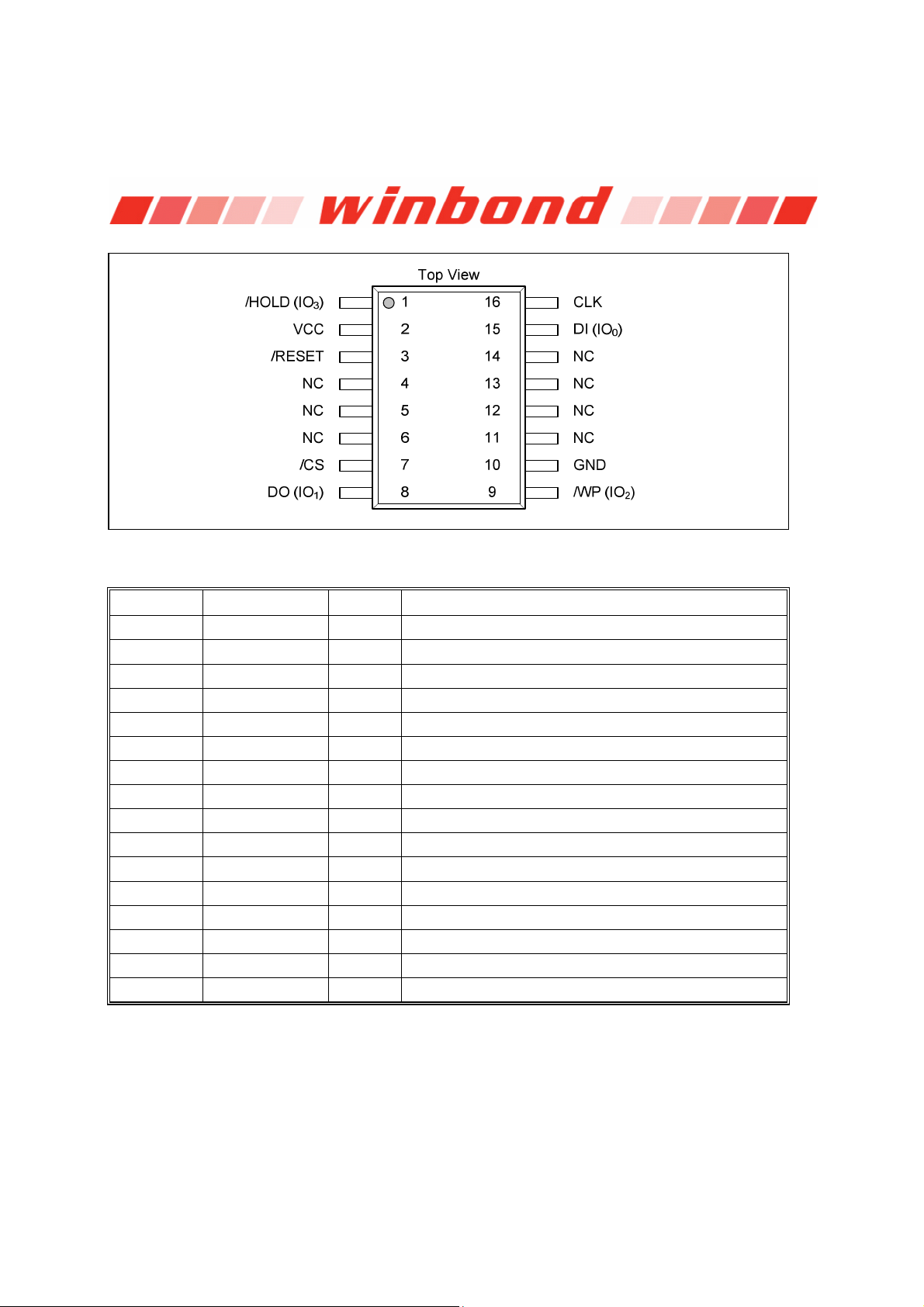

3.4 Pin Configuration SOIC 300-mil

Figure 1c. W25Q32FV Pin Assignments, 16-pin SOIC 300-mil (Package Code SF)

3.5 Pin Description SOIC 300-mil

PIN NO. PIN NAME I/O FUNCTION

1 /HOLD (IO3) I/O Hold Input (Data Input Output 3)

2 VCC Power Supply

3 /RESET I Reset Input

(3)

4 N/C No Connect

5 N/C No Connect

6 N/C No Connect

7 /CS I Chip Select Input

8 DO (IO1) I/O Data Output (Data Input Output 1)

9 /WP (IO2) I/O Write Protect Input (Data Input Output 2)

10 GND Ground

11 N/C No Connect

12 N/C No Connect

13 N/C No Connect

14 N/C No Connect

15 DI (IO0) I/O Data Input (Data Input Output 0)

16 CLK I Serial Clock Input

Notes:

1. IO0 and IO1 are used for Standard and Dual SPI instructions

2. IO0 – IO3 are used for Quad SPI instructions, /WP & /HOLD (or /RESET) functions are only available for Standard/Dual SPI.

3. The /RESET pin on SOIC-16 package is independent of the HOLD/RST bit and QE bit settings in the Status Register. This pin

can be left floating, if Rest function is not needed.

(2)

(1)

(2)

(1)

- 7 -

Page 9

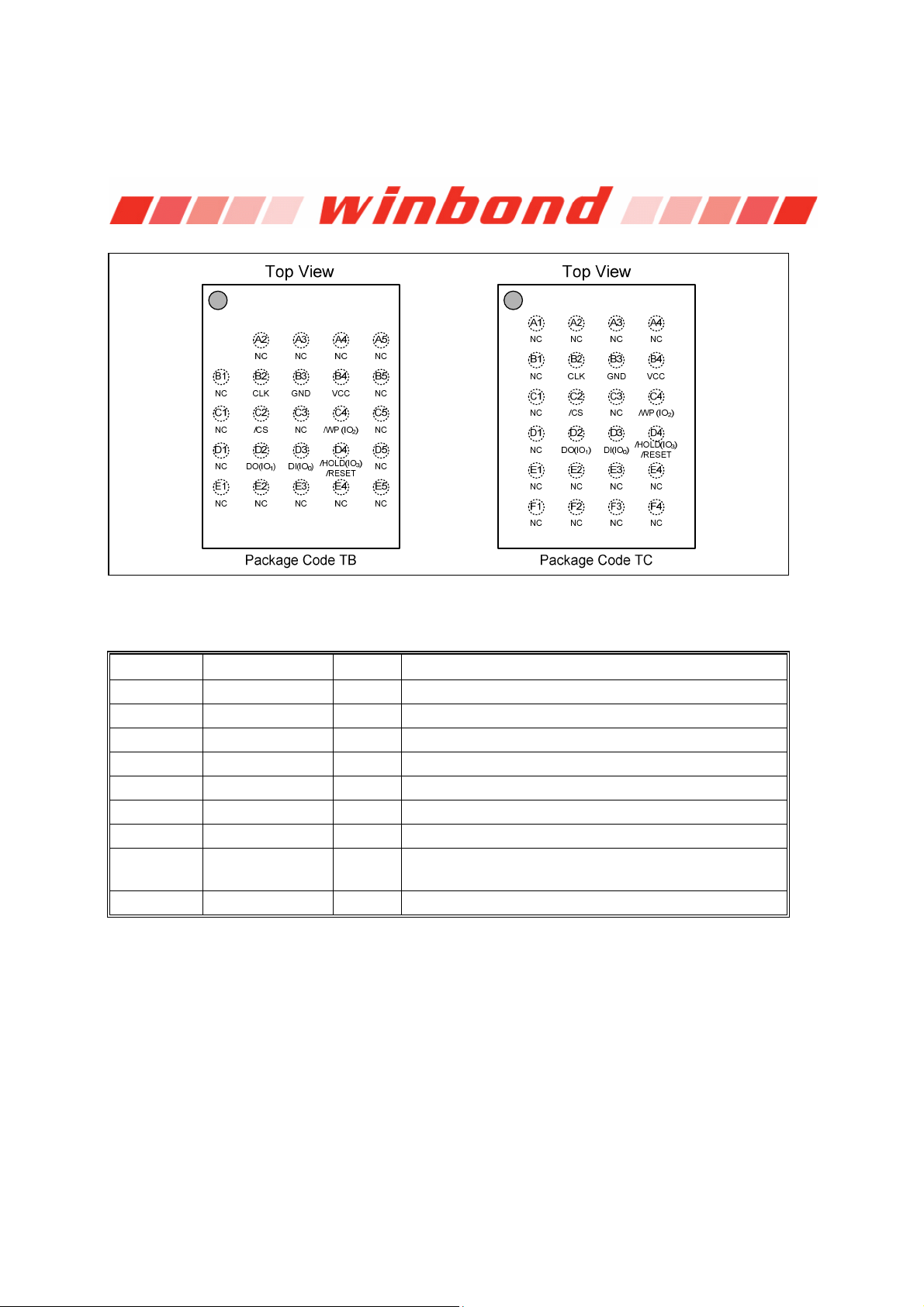

3.6 Ball Configuration TFBGA 8x6-mm (5x5 or 6x4 Ball Array)

Figure 1d. W25Q32FV Ball Assignments, 24-ball TFBGA 8x6-mm (Package Code TB & TC)

W25Q32FV

3.7 Ball Description TFBGA 8x6-mm

BALL NO.

B2 CLK I Serial Clock Input

B3 GND Ground

B4 VCC Power Supply

C2 /CS I Chip Select Input

C4 /WP (IO2) I/O Write Protect Input (Data Input Output 2)

D2 DO (IO1) I/O Data Output (Data Input Output 1)

D3 DI (IO0) I/O Data Input (Data Input Output 0)

D4

Multiple NC No Connect

Notes:

1. IO0 and IO1 are used for Standard and Dual SPI instructions

2. IO0 – IO3 are used for Quad SPI instructions, /WP & /HOLD (or /RESET) functions are only available for Standard/Dual SPI.

PIN NAME I/O FUNCTION

/HOLD or /RESET

(IO3)

I/O Hold or Reset Input (Data Input Output 3)

(2)

(1)

(1)

(2)

Publication Release Date: Sept 16,, 2013

- 8 - Revision H

Page 10

W25Q32FV

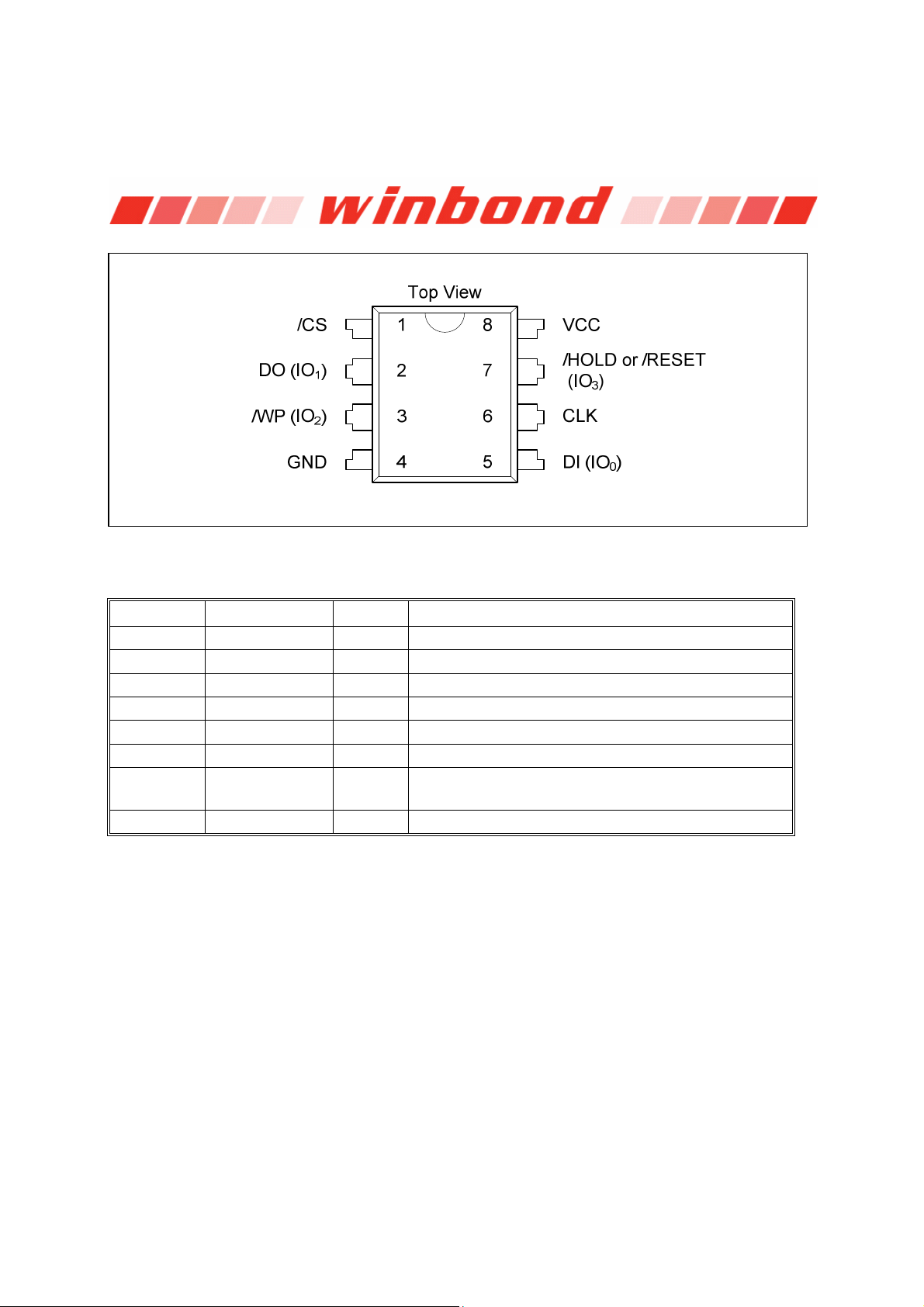

3.8 Pin Configuration PDIP 300-mil

Figure 1e. W25Q32FV Pin Assignments, 8-pin PDIP (Package Code DA)

3.9 Pin Description PDIP 300-mil

PIN NO. PIN NAME I/O FUNCTION

1 /CS I Chip Select Input

2 DO (IO1) I/O

3 /WP (IO2) I/O

4 GND Ground

5 DI (IO0) I/O

6 CLK I Serial Clock Input

7

8 VCC Power Supply

Notes:

1. IO0 and IO1 are used for Standard and Dual SPI instructions

2. IO0 – IO3 are used for Quad SPI instructions, /WP & /HOLD (or /RESET) functions are only available for Standard/Dual SPI.

/HOLD or /RESET

(IO3)

I/O

Data Output (Data Input Output 1)

Write Protect Input ( Data Input Output 2)

Data Input (Data Input Output 0)

Hold or Reset Input (Data Input Output 3)

(1)

(2)

(1)

(2)

- 9 -

Page 11

W25Q32FV

4. PIN DESCRIPTIONS

4.1 Chip Select (/CS)

The SPI Chip Select (/CS) pin enables and disables device operation. When /CS is high the device is

deselected and the Serial Data Output (DO, or IO0, IO1, IO2, IO3) pins are at high impedance. When

deselected, the devices power consumption will be at standby levels unless an internal erase, program or

write status register cycle is in progress. When /CS is brought low the device will be selected, power

consumption will increase to active levels and instructions can be written to and data read from the device.

After power-up, /CS must transition from high to low before a new instruction will be accepted. The /CS

input must track the VCC supply level at power-up and power-down (see “Write Protection” and Figure

58). If needed a pull-up resister on the /CS pin can be used to accomplish this.

4.2 Serial Data Input, Output and IOs (DI, DO and IO0, IO1, IO2, IO3)

The W25Q32FV supports standard SPI, Dual SPI and Quad SPI operation. Standard SPI instructions use

the unidirectional DI (input) pin to serially write instructions, addresses or data to the device on the rising

edge of the Serial Clock (CLK) input pin. Standard SPI also uses the unidirectional DO (output) to read

data or status from the device on the falling edge of CLK.

Dual and Quad SPI instructions use the bidirectional IO pins to serially write instructions, addresses or

data to the device on the rising edge of CLK and read data or status from the device on the falling edge

of CLK. Quad SPI instructions require the non-volatile Quad Enable bit (QE) in Status Register-2 to be

set. When QE=1, the /WP pin becomes IO2 and /HOLD pin becomes IO3.

4.3 Write Protect (/WP)

The Write Protect (/WP) pin can be used to prevent the Status Register from being written. Used in

conjunction with the Status Register’s Block Protect (CMP, SEC, TB, BP2, BP1 and BP0) bits and Status

Register Protect (SRP) bits, a portion as small as a 4KB sector or the entire memory array can be

hardware protected. The /WP pin is active low. When the QE bit of Status Register-2 is set for Quad I/O,

the /WP pin function is not available since this pin is used for IO2. See Figure 1a-c for the pin

configuration of Quad I/O operation.

4.4 HOLD (/HOLD)

The /HOLD pin allows the device to be paused while it is actively selected. When /HOLD is brought low,

while /CS is low, the DO pin will be at high impedance and signals on the DI and CLK pins will be ignored

(don’t care). When /HOLD is brought high, device operation can resume. The /HOLD function can be

useful when multiple devices are sharing the same SPI signals. The /HOLD pin is active low. When the

QE bit of Status Register-2 is set for Quad I/O, the /HOLD pin function is not available since this pin is

used for IO3. See Figure 1a-e for the pin configuration of Quad I/O operation.

4.5 Serial Clock (CLK)

The SPI Serial Clock Input (CLK) pin provides the timing for serial input and output operations. ("See SPI

Operations")

4.6 Reset (/RESET)

The /RESET pin allows the device to be reset by the controller. For 8-pin packages, when QE=0, the IO3

pin can be configured either as a /HOLD pin or as a /RESET pin depending on Status Register setting.

When QE=1, the /HOLD or /RESET function is not available for 8-pin configuration. On the 16-pin SOIC

package, a dedicated /RESET pin is provided and it is independent of QE bit setting.

Publication Release Date: Sept 16,, 2013

- 10 - Revision H

Page 12

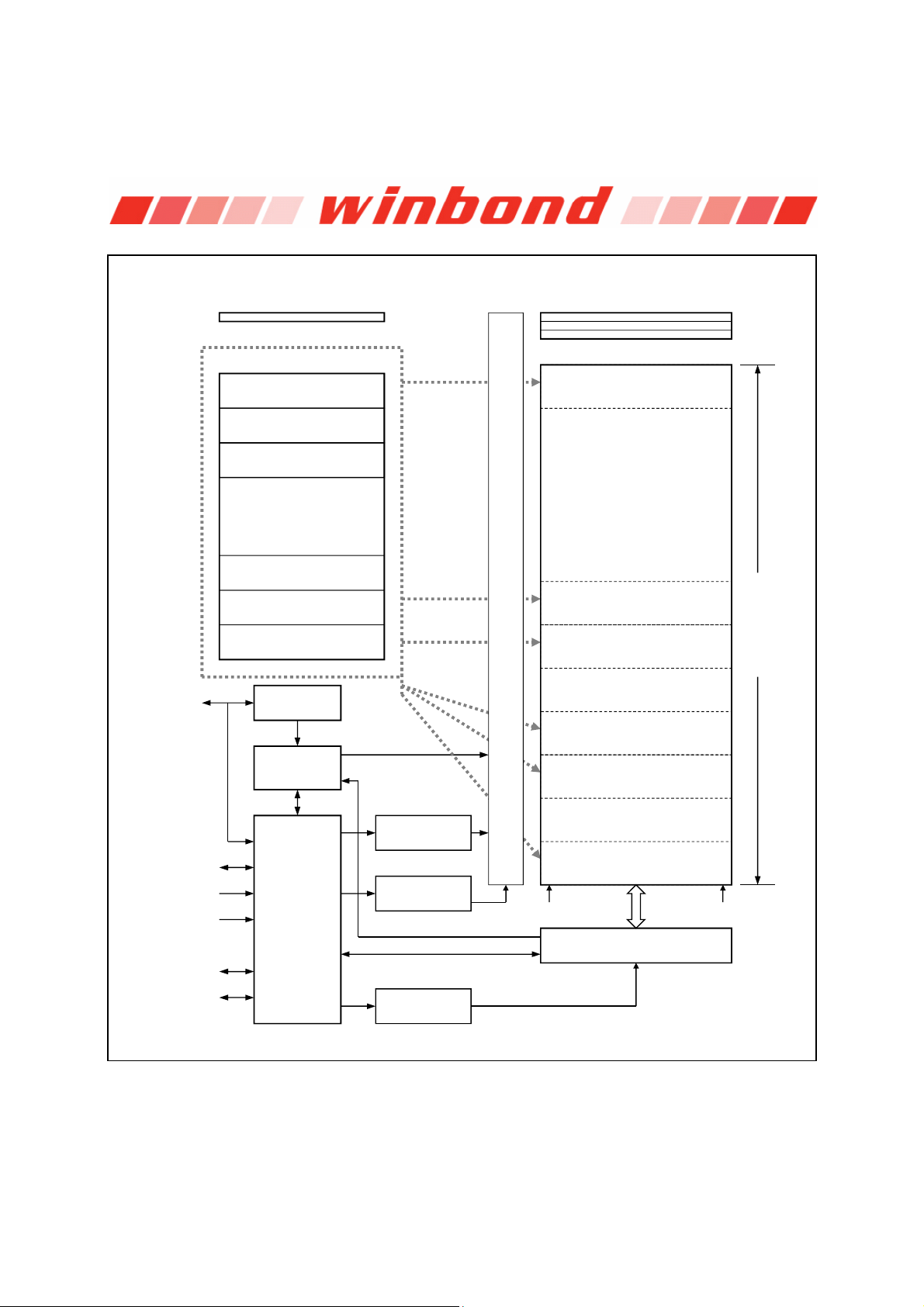

5. BLOCK DIAGRAM

W25Q32FV

/WP (IO2)

/HOLD (IO3) or

/RESET (IO3)

CLK

/CS

DI (IO0)

DO (IO1)

SFDP Register

000000h 0000FFh

Block Segmentation

xxFF00h xxFFFFh

• Sector 15 (4KB) •

xxF000h xxF0FFh

xxEF00h xxEFFFh

• Sector 14 (4KB) •

xxE000h xxE0FFh

xxDF00h xxDFFFh

• Sector 13 (4KB) •

xxD000h xxD0FFh

•

•

•

xx2F00h xx2FFFh

• Sector 2 (4KB) •

xx2000h xx20FFh

xx1F00h xx1FFFh

• Sector 1 (4KB) •

xx1000h xx10FFh

xx0F00h xx0FFFh

• Sector 0 (4KB) •

xx0000h xx00FFh

Write Control

Logic

Status

Register

SPI

Command &

Control Logic

High Voltage

Generators

Page Address

Latch / Counter

Data

Byte Address

Latch / Counter

Security Register 1 - 3

003000h 0030FFh

002000h 0020FFh

001000h 0010FFh

3FFF00h 3FFFFFh

• Block 63 (64KB) •

3F0000h 3F00FFh

•

•

•

20FF00h 20FFFFh

• Block 32 (64KB) •

200000h 2000FFh

1FFF00h 1FFFFFh

• Block 31 (64KB) •

1F0000h 1F00FFh

Write Protect Logic and Row Decode

10FF00h 10FFFFh

• Block 16 (64KB) •

100000h 1000FFh

0FFF00h 0FFFFFh

• Block 15 (64KB) •

0F0000h 0F00FFh

00FF00h 00FFFFh

• Block 0 (64KB) •

000000h 0000FFh

Beginning

Page Address

And 256-Byte Page Buffer

•

•

•

•

•

•

Column Decode

Ending

Page Address

W25Q32FV

Figure 2. W25Q32FV Serial Flash Memory Block Diagram

- 11 -

Page 13

6. FUNCTIONAL DESCRIPTIONS

6.1 SPI / QPI Operations

W25Q32FV

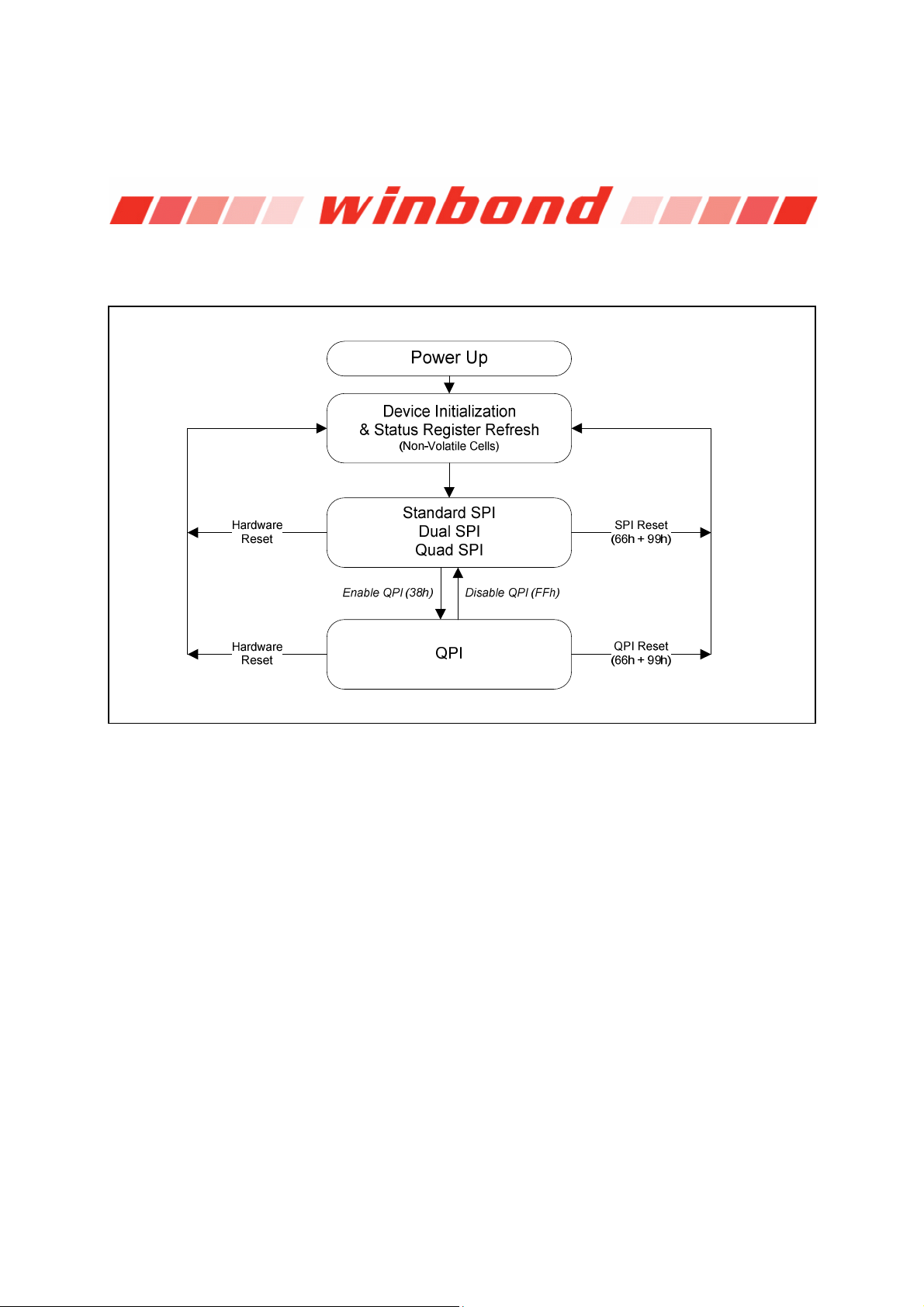

Figure 3. W25Q32FV Serial Flash Memory Operation Diagram

6.1.1 Standard SPI Instructions

The W25Q32FV is accessed through an SPI compatible bus consisting of four signals: Serial Clock (CLK),

Chip Select (/CS), Serial Data Input (DI) and Serial Data Output (DO). Standard SPI instructions use the

DI input pin to serially write instructions, addresses or data to the device on the rising edge of CLK. The

DO output pin is used to read data or status from the device on the falling edge of CLK.

SPI bus operation Mode 0 (0,0) and 3 (1,1) are supported. The primary difference between Mode 0 and

Mode 3 concerns the normal state of the CLK signal when the SPI bus master is in standby and data is

not being transferred to the Serial Flash. For Mode 0, the CLK signal is normally low on the falling and

rising edges of /CS. For Mode 3, the CLK signal is normally high on the falling and rising edges of /CS.

6.1.2 Dual SPI Instructions

The W25Q32FV supports Dual SPI operation when using instructions such as “Fast Read Dual Output

(3Bh)” and “Fast Read Dual I/O (BBh)”. These instructions allow data to be transferred to or from the

device at two to three times the rate of ordinary Serial Flash devices. The Dual SPI Read instructions are

ideal for quickly downloading code to RAM upon power-up (code-shadowing) or for executing non-speedcritical code directly from the SPI bus (XIP). When using Dual SPI instructions, the DI and DO pins

become bidirectional I/O pins: IO0 and IO1.

Publication Release Date: Sept 16,, 2013

- 12 - Revision H

Page 14

W25Q32FV

6.1.3 Quad SPI Instructions

The W25Q32FV supports Quad SPI operation when using instructions such as “Fast Read Quad Output

(6Bh)”, “Fast Read Quad I/O (EBh)”, “Word Read Quad I/O (E7h)” and “Octal Word Read Quad I/O

(E3h)”. These instructions allow data to be transferred to or from the device four to six times the rate of

ordinary Serial Flash. The Quad Read instructions offer a significant improvement in continuous and

random access transfer rates allowing fast code-shadowing to RAM or execution directly from the SPI

bus (XIP). When using Quad SPI instructions the DI and DO pins become bidirectional IO0 and IO1, and

the /WP and /HOLD pins become IO2 and IO3 respectively. Quad SPI instructions require the nonvolatile Quad Enable bit (QE) in Status Register-2 to be set.

6.1.4 QPI Instructions

The W25Q32FV supports Quad Peripheral Interface (QPI) operations only when the device is switched

from Standard/Dual/Quad SPI mode to QPI mode using the “Enter QPI (38h)” instruction. The typical SPI

protocol requires that the byte-long instruction code being shifted into the device only via DI pin in eight

serial clocks. The QPI mode utilizes all four IO pins to input the instruction code, thus only two serial

clocks are required. This can significantly reduce the SPI instruction overhead and improve system

performance in an XIP environment. Standard/Dual/Quad SPI mode and QPI mode are exclusive. Only

one mode can be active at any given time. “Enter QPI (38h)” and “Exit QPI (FFh)” instructions are used to

switch between these two modes. Upon power-up or after a software reset using “Reset (99h)” instruction,

the default state of the device is Standard/Dual/Quad SPI mode. To enable QPI mode, the non-volatile

Quad Enable bit (QE) in Status Register-2 is required to be set. When using QPI instructions, the DI and

DO pins become bidirectional IO0 and IO1, and the /WP and /HOLD pins become IO2 and IO3

respectively. See Figure 3 for the device operation modes.

6.1.5 Hold Function

For Standard SPI and Dual SPI operations, the /HOLD signal allows the W25Q32FV operation to be

paused while it is actively selected (when /CS is low). The /HOLD function may be useful in cases where

the SPI data and clock signals are shared with other devices. For example, consider if the page buffer

was only partially written when a priority interrupt requires use of the SPI bus. In this case the /HOLD

function can save the state of the instruction and the data in the buffer so programming can resume where

it left off once the bus is available again. The /HOLD function is only available for standard SPI and Dual

SPI operation, not during Quad SPI or QPI. The Quad Enable Bit QE in Status Register-2 is used to

determine if the pin is used as /HOLD pin or data I/O pin. When QE=0 (factory default), the pin is /HOLD,

when QE=1, the pin will become an I/O pin, /HOLD function is no longer available.

To initiate a /HOLD condition, the device must be selected with /CS low. A /HOLD condition will activate on

the falling edge of the /HOLD signal if the CLK signal is already low. If the CLK is not already low the

/HOLD condition will activate after the next falling edge of CLK. The /HOLD condition will terminate on the

rising edge of the /HOLD signal if the CLK signal is already low. If the CLK is not already low the /HOLD

condition will terminate after the next falling edge of CLK. During a /HOLD condition, the Serial Data

Output (DO) is high impedance, and Serial Data Input (DI) and Serial Clock (CLK) are ignored. The Chip

Select (/CS) signal should be kept active (low) for the full duration of the /HOLD operation to avoid

resetting the internal logic state of the device.

- 13 -

Page 15

W25Q32FV

6.1.6 Software Reset & Hardware /RESET pin

The W25Q32FV can be reset to the initial power-on state by a software Reset sequence, either in SPI

mode or QPI mode. This sequence must include two consecutive commands: Enable Reset (66h) &

Reset (99h). If the command sequence is successfully accepted, the device will take approximately 30uS

(

t

RST

)

to reset. No command will be accepted during the reset period.

For the WSON-8 and TFBGA package types, W25Q32FV can also be configured to utilize a hardware

/RESET pin. The HOLD/RST bit in the Status Register-3 is the configuration bit for /HOLD pin function or

RESET pin function. When HOLD/RST=0 (factory default), the pin acts as a /HOLD pin as described

above; when HOLD/RST=1, the pin acts as a /RESET pin. Drive the /RESET pin low for a minimum period

of ~1us (tRESET*) will reset the device to its initial power-on state. Any on-going Program/Erase operation

will be interrupted and data corruption may happen. While /RESET is low, the device will not accept any

command input.

If QE bit is set to 1, the /HOLD or /RESET function will be disabled, the pin will become one of the four

data I/O pins.

For the SOIC-16 package, W25Q32FV provides a dedicated /RESET pin in addition to the /HOLD (IO3)

pin as illustrated in Figure 1b. Drive the /RESET pin low for a minimum period of ~1us (tRESET*) will

reset the device to its initial power-on state. The HOLD/RST bit or QE bit in the Status Register will not

affect the function of this dedicated /RESET pin.

Hardware /RESET pin has the highest priority among all the input signals. Drive /RESET low for a

minimum period of ~1us (tRESET*) will interrupt any on-going external/internal operations, regardless the

status of other SPI signals (/CS, CLK, IOs, /WP and/or /HOLD).

Note:

1.While a faster /RESET pulse (as short as a few hundred nanoseconds) will often reset the device, a 1us minimum is

recommended to ensure reliable operation.

2.There is an internal pull-up resistor for the dedicated /RESET pin on the SOIC-16 package. If the reset function is not needed, this

pin can be left floating in the system.

Publication Release Date: Sept 16,, 2013

- 14 - Revision H

Page 16

W25Q32FV

6.2 Write Protection

Applications that use non-volatile memory must take into consideration the possibility of noise and other

adverse system conditions that may compromise data integrity. To address this concern, the W25Q32FV

provides several means to protect the data from inadvertent writes.

6.2.1 Write Protect Features

• Device resets when VCC is below threshold

• Time delay write disable after Power-up

• Write enable/disable instructions and automatic write disable after erase or program

• Software and Hardware (/WP pin) write protection using Status Registers

• Additional Individual Block/Sector Locks for array protection

• Write Protection using Power-down instruction

• Lock Down write protection for Status Register until the next power-up

• One Time Program (OTP) write protection for array and Security Registers using Status Register*

* Note: This feature is available upon special order. Please contact Winbond for details.

Upon power-up or at power-down, the W25Q32FV will maintain a reset condition while VCC is below the

threshold value of VWI, (See Power-up Timing and Voltage Levels and Figure 43). While reset, all

operations are disabled and no instructions are recognized. During power-up and after the VCC voltage

exceeds VWI, all program and erase related instructions are further disabled for a time delay of t

includes the Write Enable, Page Program, Sector Erase, Block Erase, Chip Erase and the Write Status

Register instructions. Note that the chip select pin (/CS) must track the VCC supply level at power-up until

the VCC-min level and t

down to prevent adverse command sequence. If needed a pull-up resister on /CS can be used to

accomplish this.

After power-up the device is automatically placed in a write-disabled state with the Status Register Write

Enable Latch (WEL) set to a 0. A Write Enable instruction must be issued before a Page Program, Sector

Erase, Block Erase, Chip Erase or Write Status Register instruction will be accepted. After completing a

program, erase or write instruction the Write Enable Latch (WEL) is automatically cleared to a writedisabled state of 0.

Software controlled write protection is facilitated using the Write Status Register instruction and setting the

Status Register Protect (SRP0, SRP1) and Block Protect (CMP, SEC, TB, BP[2:0]) bits. These settings

allow a portion or the entire memory array to be configured as read only. Used in conjunction with the

Write Protect (/WP) pin, changes to the Status Register can be enabled or disabled under hardware

control. See Status Register section for further information. Additionally, the Power-down instruction offers

an extra level of write protection as all instructions are ignored except for the Release Power-down

instruction.

The W25Q32FV also provides another Write Protect method using the Individual Block Locks. Each 64KB

block (except the top and bottom blocks, total of 510 blocks) and each 4KB sector within the top/bottom

blocks (total of 32 sectors) are equipped with an Individual Block Lock bit. When the lock bit is 0, the

corresponding sector or block can be erased or programmed; when the lock bit is set to 1, Erase or

Program commands issued to the corresponding sector or block will be ignored. When the device is

powered on, all Individual Block Lock bits will be 1, so the entire memory array is protected from

Erase/Program. An “Individual Block Unlock (39h)” instruction must be issued to unlock any specific sector

or block.

The WPS bit in Status Register-3 is used to decide which Write Protect scheme should be used. When

WPS=0 (factory default), the device will only utilize CMP, SEC, TB, BP[2:0] bits to protect specific areas of

the array; when WPS=1, the device will utilize the Individual Block Locks for write protection.

VSL

time delay is reached, and it must also track the VCC supply level at power-

PUW

. This

- 15 -

Page 17

W25Q32FV

7. STATUS AND CONFIGURATION REGISTERS

Three Status and Configuration Registers are provided for W25Q32FV. The Read Status Register-1/2/3

instructions can be used to provide status on the availability of the flash memory array, whether the

device is write enabled or disabled, the state of write protection, Quad SPI setting, Security Register lock

status, Erase/Program Suspend status, output driver strength, power-up and current Address Mode.

The Write Status Register instruction can be used to configure the device write protection features, Quad

SPI setting, Security Register OTP locks, Hold/Reset functions, output driver strength and power-up

Address Mode. Write access to the Status Register is controlled by the state of the non-volatile Status

Register Protect bits (SRP0, SRP1), the Write Enable instruction, and during Standard/Dual SPI

operations, the /WP pin.

7.1 Status Registers

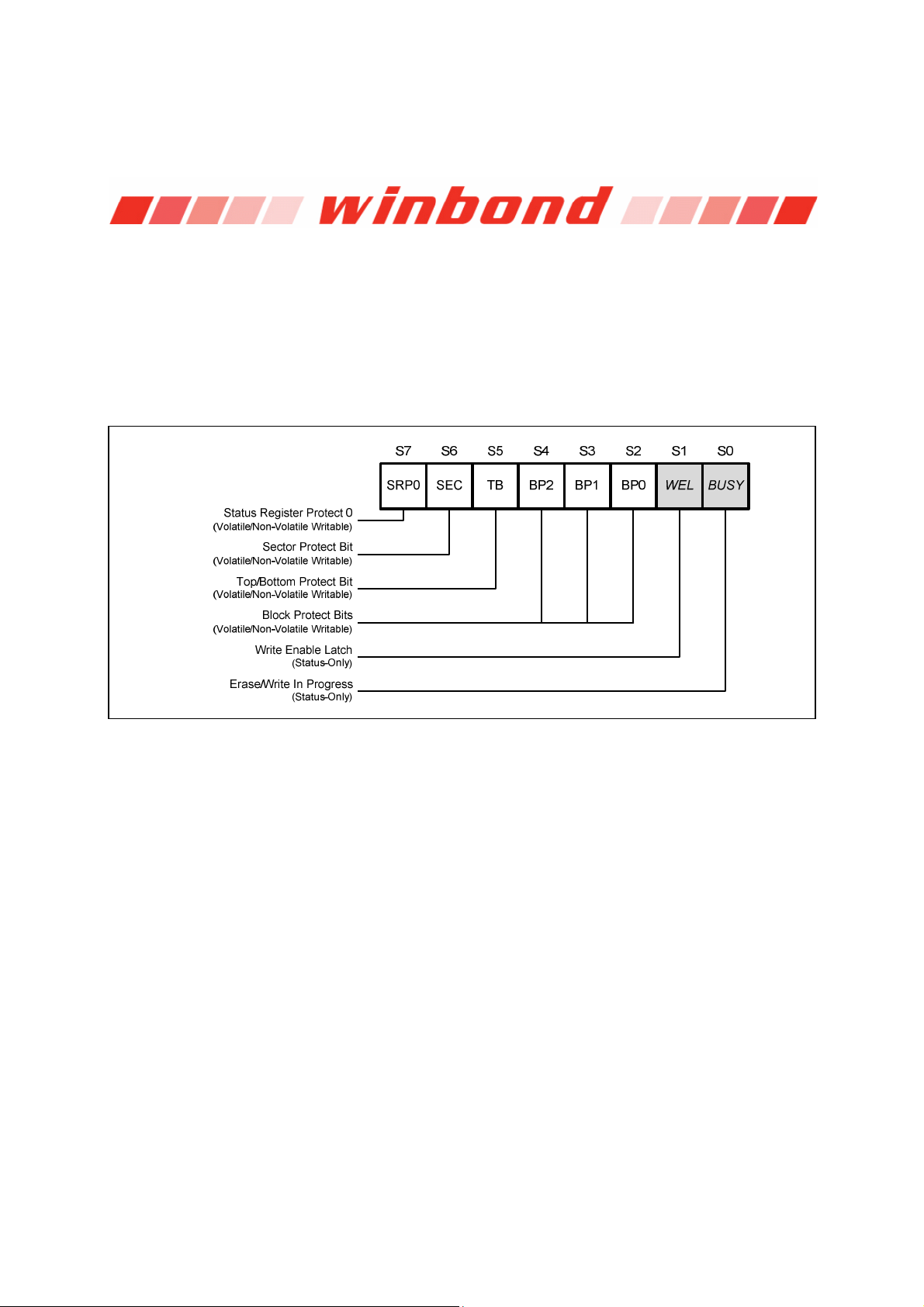

Figure 4a. Status Register-1

7.1.1 Erase/Write In Progress (BUSY) – Status Only

BUSY is a read only bit in the status register (S0) that is set to a 1 state when the device is executing a

Page Program, Quad Page Program, Sector Erase, Block Erase, Chip Erase, Write Status Register or

Erase/Program Security Register instruction. During this time the device will ignore further instructions

except for the Read Status Register and Erase/Program Suspend instruction (see tW, tPP, tSE, tBE, and

tCE in AC Characteristics). When the program, erase or write status/security register instruction has

completed, the BUSY bit will be cleared to a 0 state indicating the device is ready for further instructions.

7.1.2 Write Enable Latch (WEL) – Status Only

Write Enable Latch (WEL) is a read only bit in the status register (S1) that is set to 1 after executing a

Write Enable Instruction. The WEL status bit is cleared to 0 when the device is write disabled. A write

disable state occurs upon power-up or after any of the following instructions: Write Disable, Page

Program, Quad Page Program, Sector Erase, Block Erase, Chip Erase, Write Status Register, Erase

Security Register and Program Security Register.

7.1.3 Block Protect Bits (BP2, BP1, BP0) – Volatile/Non-Volatile Writable

The Block Protect Bits (BP2, BP1, BP0) are non-volatile read/write bits in the status register (S4, S3, and

S2) that provide Write Protection control and status. Block Protect bits can be set using the Write Status

Register Instruction (see tW in AC characteristics). All, none or a portion of the memory array can be

protected from Program and Erase instructions (see Status Register Memory Protection table). The

factory default setting for the Block Protection Bits is 0, none of the array protected.

Publication Release Date: Sept 16,, 2013

- 16 - Revision H

Page 18

W25Q32FV

7.1.4 Top/Bottom Block Protect (TB) – Volatile/Non-Volatile Writable

The non-volatile Top/Bottom bit (TB) controls if the Block Protect Bits (BP2, BP1, BP0) protect from the

Top (TB=0) or the Bottom (TB=1) of the array as shown in the Status Register Memory Protection table.

The factory default setting is TB=0. The TB bit can be set with the Write Status Register Instruction

depending on the state of the SRP0, SRP1 and WEL bits.

7.1.5 Sector/Block Protect Bit (SEC) – Volatile/Non-Volatile Writable

The non-volatile Sector/Block Protect bit (SEC) controls if the Block Protect Bits (BP2, BP1, BP0) protect

either 4KB Sectors (SEC=1) or 64KB Blocks (SEC=0) in the Top (TB=0) or the Bottom (TB=1) of the

array as shown in the Status Register Memory Protection table. The default setting is SEC=0.

7.1.6 Complement Protect (CMP) – Volatile/Non-Volatile Writable

The Complement Protect bit (CMP) is a non-volatile read/write bit in the status register (S14). It is used in

conjunction with SEC, TB, BP2, BP1 and BP0 bits to provide more flexibility for the array protection. Once

CMP is set to 1, previous array protection set by SEC, TB, BP2, BP1 and BP0 will be reversed. For

instance, when CMP=0, a top 64KB block can be protected while the rest of the array is not; when

CMP=1, the top 64KB block will become unprotected while the rest of the array become read-only. Please

refer to the Status Register Memory Protection table for details. The default setting is CMP=0.

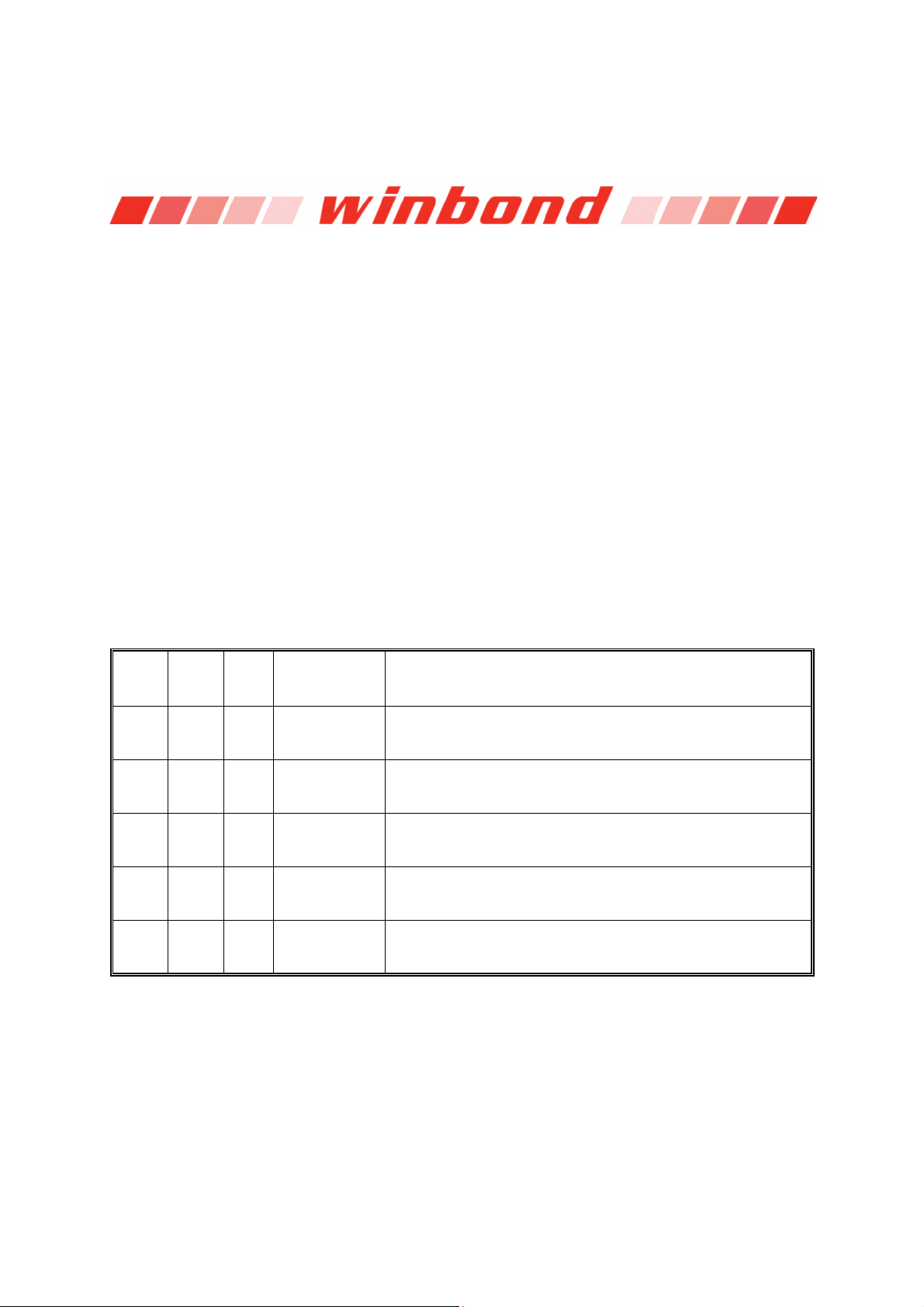

7.1.7 Status Register Protect (SRP1, SRP0) – Volatile/Non-Volatile Writable

The Status Register Protect bits (SRP1 and SRP0) are non-volatile read/write bits in the status register

(S8 and S7). The SRP bits control the method of write protection: software protection, hardware

protection, power supply lock-down or one time programmable (OTP) protection.

SRP1 SRP0 /WP

Status

Register

Description

0 0 X

0 1 0

0 1 1

1 0 X

1 1 X

Notes:

1. When SRP1, SRP0 = (1, 0), a power-down, power-up cycle will change SRP1, SRP0 to (0, 0) state.

2. This feature is available upon special order. Please contact Winbond for details.

Software

Protection

Hardware

Protected

Hardware

Unprotected

Power Supply

Lock-Down

One Time

Program

/WP pin has no control. The Status register can be written to

after a Write Enable instruction, WEL=1. [Factory Default]

When /WP pin is low the Status Register locked and cannot

be written to.

When /WP pin is high the Status register is unlocked and can

be written to after a Write Enable instruction, WEL=1.

Status Register is protected and cannot be written to again

until the next power-down, power-up cycle.

Status Register is permanently protected and cannot be

(2)

written to.

- 17 -

(1)

Page 19

W25Q32FV

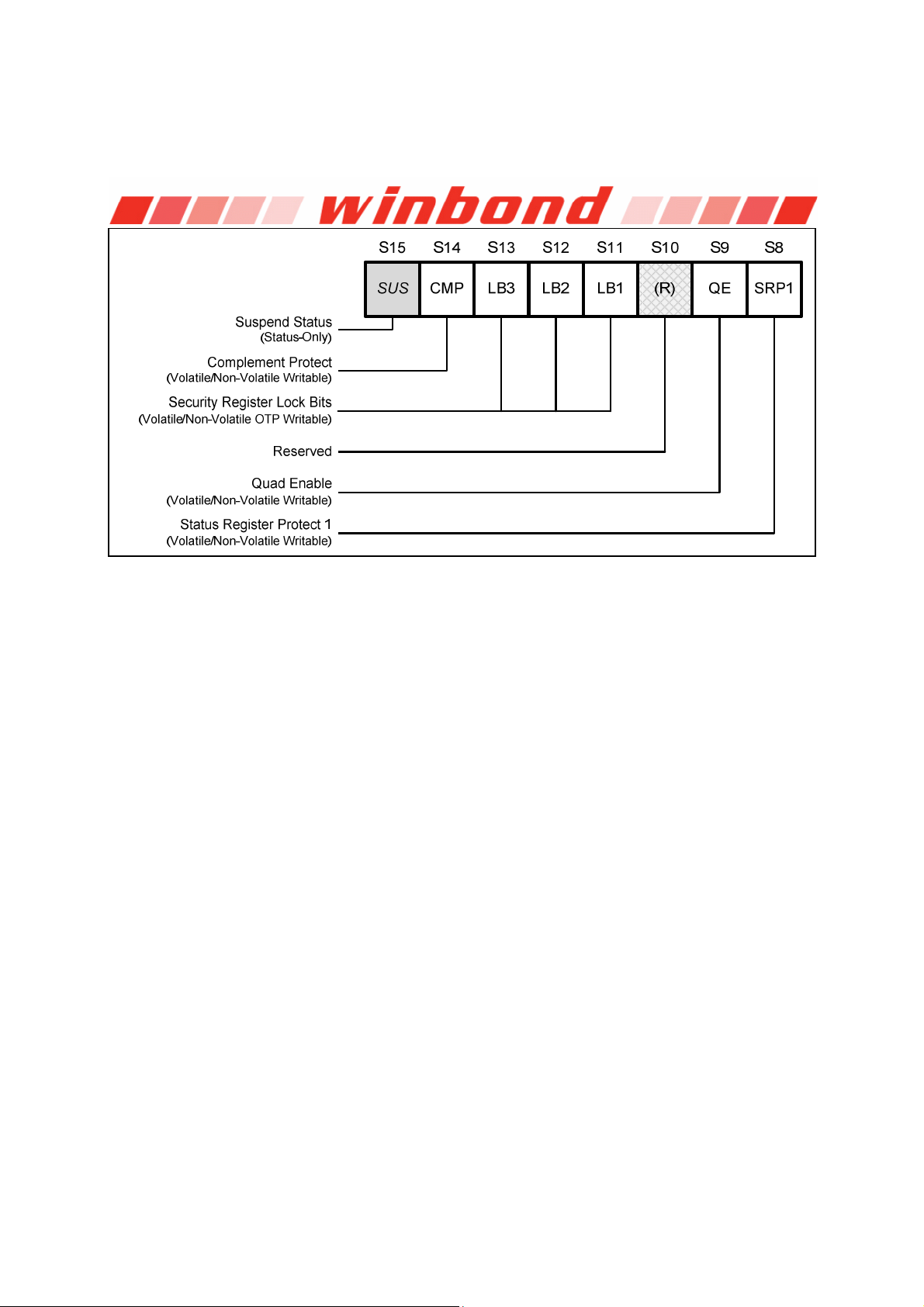

Figure 4b. Status Register-2

7.1.8 Erase/Program Suspend Status (SUS) – Status Only

The Suspend Status bit is a read only bit in the status register (S15) that is set to 1 after executing a

Erase/Program Suspend (75h) instruction. The SUS status bit is cleared to 0 by Erase/Program Resume

(7Ah) instruction as well as a power-down, power-up cycle.

7.1.9 Security Register Lock Bits (LB3, LB2, LB1) – Volatile/Non-Volatile OTP Writable

The Security Register Lock Bits (LB3, LB2, LB1) are non-volatile One Time Program (OTP) bits in Status

Register (S13, S12, S11) that provide the write protect control and status to the Security Registers. The

default state of LB3-1 is 0, Security Registers are unlocked. LB3-1 can be set to 1 individually using the

Write Status Register instruction. LB3-1 are One Time Programmable (OTP), once it’s set to 1, the

corresponding 256-Byte Security Register will become read-only permanently.

7.1.10 Quad Enable (QE) – Volatile/Non-Volatile Writable

The Quad Enable (QE) bit is a non-volatile read/write bit in the status register (S9) that allows Quad SPI

and QPI operation. When the QE bit is set to a 0 state (factory default for part numbers with ordering

options “IG”, “IP” and “IF”), the /WP pin and /HOLD are enabled. When the QE bit is set to a 1(factory

default for Quad Enabled part numbers with ordering option “IQ”),, the Quad IO2 and IO3 pins are

enabled, and /WP and /HOLD functions are disabled.

QE bit is required to be set to a 1 before issuing an “Enter QPI (38h)” to switch the device from

Standard/Dual/Quad SPI to QPI, otherwise the command will be ignored. When the device is in QPI

mode, QE bit will remain to be 1. A “Write Status Register” command in QPI mode cannot change QE bit

from a “1” to a “0”.

WARNING: If the /WP or /HOLD pins are tied directly to the power supply or ground during

standard SPI or Dual SPI operation, the QE bit should never be set to a 1.

Publication Release Date: Sept 16,, 2013

- 18 - Revision H

Page 20

W25Q32FV

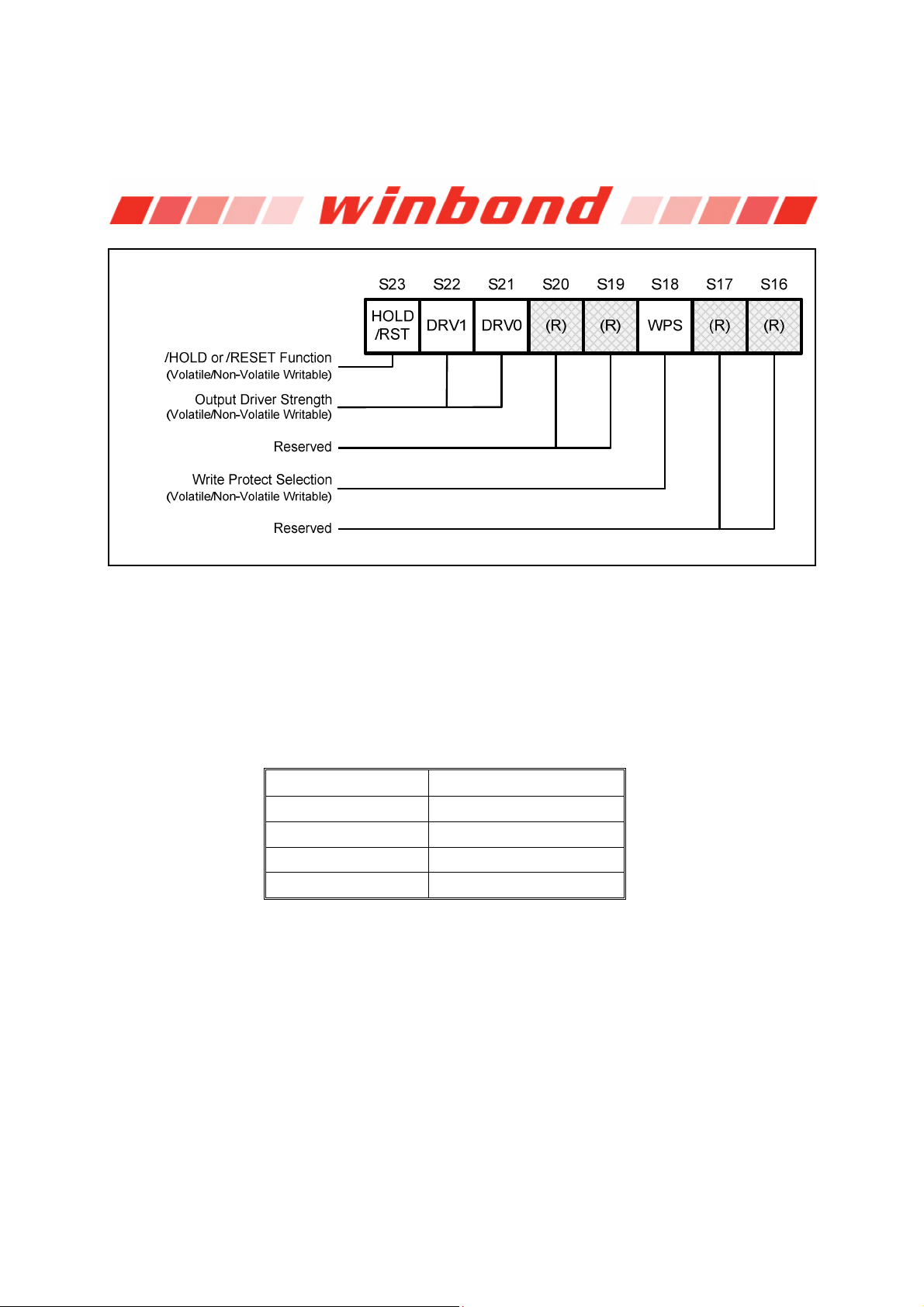

Figure 4c. Status Register-3

7.1.11 Write Protect Selection (WPS) – Volatile/Non-Volatile Writable

The WPS bit is used to select which Write Protect scheme should be used. When WPS=0, the device will

use the combination of CMP, SEC, TB, BP[2:0] bits to protect a specific area of the memory array. When

WPS=1, the device will utilize the Individual Block Locks to protect any individual sector or blocks. The

default value for all Individual Block Lock bits is 1 upon device power on or after reset.

7.1.12 Output Driver Strength (DRV1, DRV0) – Volatile/Non-Volatile Writable

The DRV1 & DRV0 bits are used to determine the output driver strength for the Read operations.

DRV1, DRV0 Driver Strength

0, 0 100%

0, 1 75%

1, 0 50%

1, 1 25% (default)

7.1.13 /HOLD or /RESET Pin Function (HOLD/RST) – Volatile/Non-Volatile Writable

The HOLD/RST bit is used to determine whether /HOLD or /RESET function should be implemented on

the hardware pin for 8-pin packages. When HOLD/RST=0 (factory default), the pin acts as /HOLD; when

HOLD/RST=1, the pin acts as /RESET. However, /HOLD or /RESET functions are only available when

QE=0. If QE is set to 1, the /HOLD and /RESET functions are disabled, the pin acts as a dedicated data

I/O pin.

- 19 -

Page 21

W25Q32FV

7.1.14 Reserved Bits – Non Functional

There are a few reserved Status Register bits that may be read out as a “0” or “1”. It is recommended to

ignore the values of those bits. During a “Write Status Register” instruction, the Reserved Bits can be

written as “0”, but there will not be any effects.

Publication Release Date: Sept 16,, 2013

- 20 - Revision H

Page 22

W25Q32FV

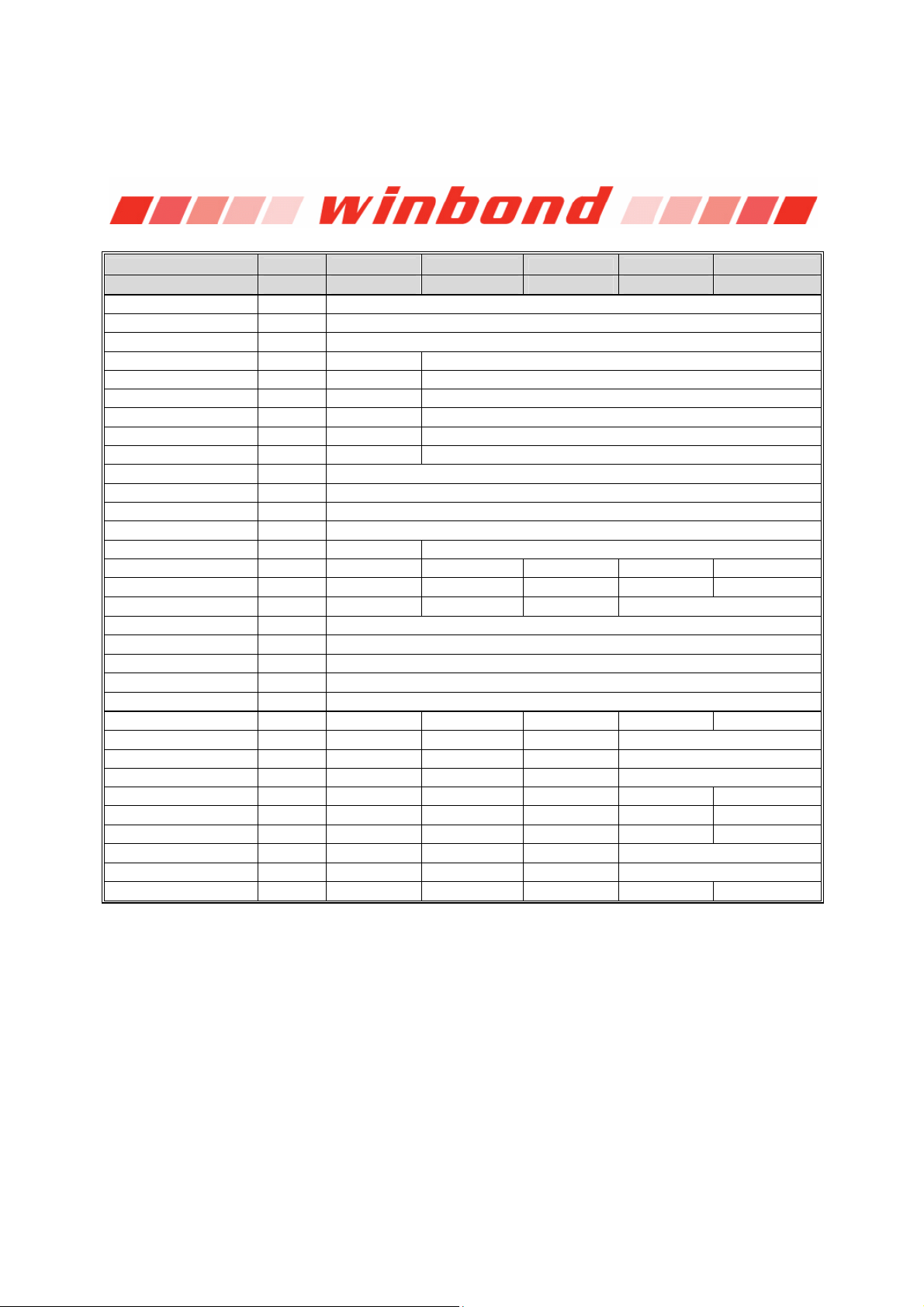

7.1.15 W25Q32FV Status Register Memory Protection (WPS = 0, CMP = 0)

STATUS REGISTER

SEC TB BP2 BP1 BP0

(1)

W25Q32FV (32M-BIT) MEMORY PROTECTION

PROTECTED

BLOCK(S)

PROTECTED

ADDRESSES

PROTECTED

DENSITY

(3)

PROTECTED

PORTION

X X 0 0 0 NONE NONE NONE NONE

0 0 0 0 1 63 3F0000h – 3FFFFFh

0 0 0 1 0 62 and 63 3E0000h – 3FFFFFh

0 0 0 1 1 60 thru 63 3C0000h – 3FFFFFh

0 0 1 0 0 56 thru 63 380000h – 3FFFFFh

0 0 1 0 1 48 thru 63 300000h – 3FFFFFh

0 0 1 1 0 32 thru 63 200000h – 3FFFFFh

0 1 0 0 1 0 000000h – 00FFFFh

0 1 0 1 0 0 and 1 000000h – 01FFFFh

0 1 0 1 1 0 thru 3 000000h – 03FFFFh

0 1 1 0 0 0 thru 7 000000h – 07FFFFh

0 1 1 0 1 0 thru 15 000000h – 0FFFFFh

64KB Upper 1/64

128KB Upper 1/32

256KB Upper 1/16

512KB Upper 1/8

1MB Upper 1/4

2MB Upper 1/2

64KB Lower 1/64

128KB Lower 1/32

256KB Lower 1/16

512KB Lower 1/8

1MB Lower 1/4

(2)

0 1 1 1 0 0 thru 31 000000h – 1FFFFFh

X X 1 1 1 0 thru 63 000000h – 3FFFFFh

1 0 0 0 1 63 3FF000h – 3FFFFFh

1 0 0 1 0 63 3FE000h – 3FFFFFh

1 0 0 1 1 63 3FC000h – 3FFFFFh

1 0 1 0 X 63 3F8000h – 3FFFFFh

1 1 0 0 1 0 000000h – 000FFFh

1 1 0 1 0 0 000000h – 001FFFh

1 1 0 1 1 0 000000h – 003FFFh

1 1 1 0 X 0 000000h – 007FFFh

Notes:

1. X = don’t care

2. L = Lower; U = Upper

3. If any Erase or Program command specifies a memory region that contains protected data portion, this command

will be ignored

2MB Lower 1/2

4MB ALL

4KB U - 1/1024

8KB U - 1/512

16KB U - 1/256

32KB U - 1/128

4KB L - 1/1024

8KB L - 1/512

16KB L - 1/256

32KB L - 1/128

- 21 -

Page 23

W25Q32FV

7.1.16 W25Q32FV Status Register Memory Protection (WPS = 0, CMP = 1)

STATUS REGISTER

SEC TB BP2 BP1 BP0

X X 0 0 0 0 thru 63 000000h – 3FFFFFh

0 0 0 0 1 0 thru 62 000000h – 3EFFFFh

0 0 0 1 0 0 and 61 000000h – 3DFFFFh

0 0 0 1 1 0 thru 59 000000h – 3BFFFFh

0 0 1 0 0 0 thru 55 000000h – 37FFFFh

0 0 1 0 1 0 thru 47 000000h – 2FFFFFh

0 0 1 1 0 0 thru 31 000000h – 1FFFFFh

0 1 0 0 1 1 thru 63 010000h – 3FFFFFh

0 1 0 1 0 2 and 63 020000h – 3FFFFFh

0 1 0 1 1 4 thru 63 040000h – 3FFFFFh

0 1 1 0 0 8 thru 63 080000h – 3FFFFFh

0 1 1 0 1 16 thru 63 100000h – 3FFFFFh

(1)

W25Q32FV (32M-BIT) MEMORY PROTECTION

PROTECTED

BLOCK(S)

PROTECTED

ADDRESSES

PROTECTED

DENSITY

4MB ALL

4,032KB Lower 63/64

3,968KB Lower 31/32

3,840KB Lower 15/16

3,584KB Lower 7/8

3MB Lower 3/4

2MB Lower 1/2

4,032KB Upper 63/64

3,968KB Upper 31/32

3,840KB Upper 15/16

3,584KB Upper 7/8

3MB Upper 3/4

(3)

PROTECTED

PORTION

(2)

0 1 1 1 0 32 thru 63 200000h – 3FFFFFh

2MB Upper 1/2

X X 1 1 1 NONE NONE NONE NONE

1 0 0 0 1 0 thru 63 000000h – 3FEFFFh

1 0 0 1 0 0 thru 63 000000h – 3FDFFFh

1 0 0 1 1 0 thru 63 000000h – 3FBFFFh

1 0 1 0 X 0 thru 63 000000h – 3F7FFFh

1 1 0 0 1 0 thru 63 001000h – 3FFFFFh

1 1 0 1 0 0 thru 63 002000h – 3FFFFFh

1 1 0 1 1 0 thru 63 004000h – 3FFFFFh

1 1 1 0 X 0 thru 63 008000h – 3FFFFFh

Notes:

4. X = don’t care

5. L = Lower; U = Upper

6. If any Erase or Program command specifies a memory region that contains protected data portion, this command

will be ignored

4,092KB L - 1023/1024

4,088KB L - 511/512

4,080KB L - 255/256

4,064KB L - 127/128

4,092KB U - 1023/1024

4,088KB U - 511/512

4,080KB U - 255/256

4,064KB U - 127/128

Publication Release Date: Sept 16,, 2013

- 22 - Revision H

Page 24

W25Q32FV

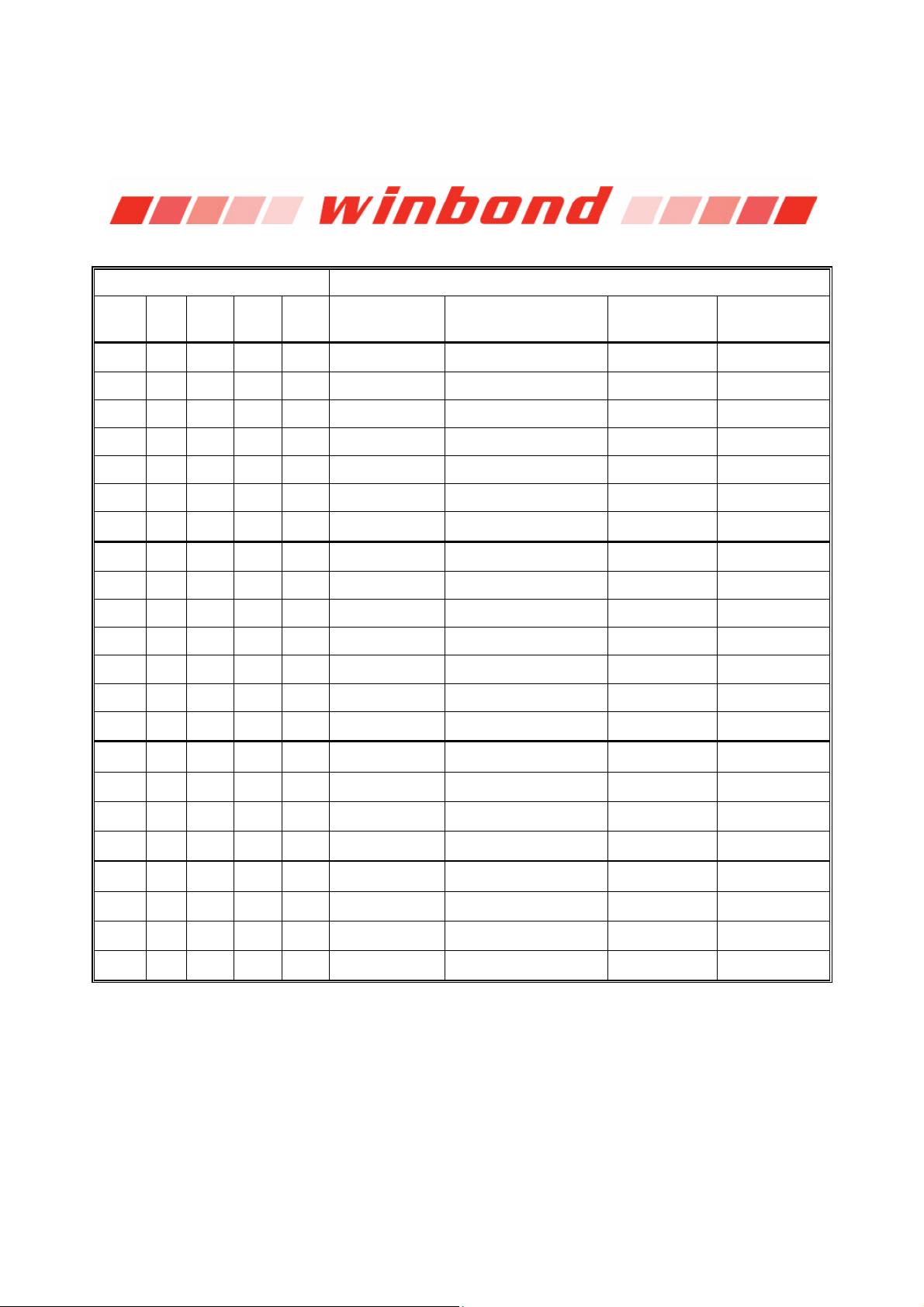

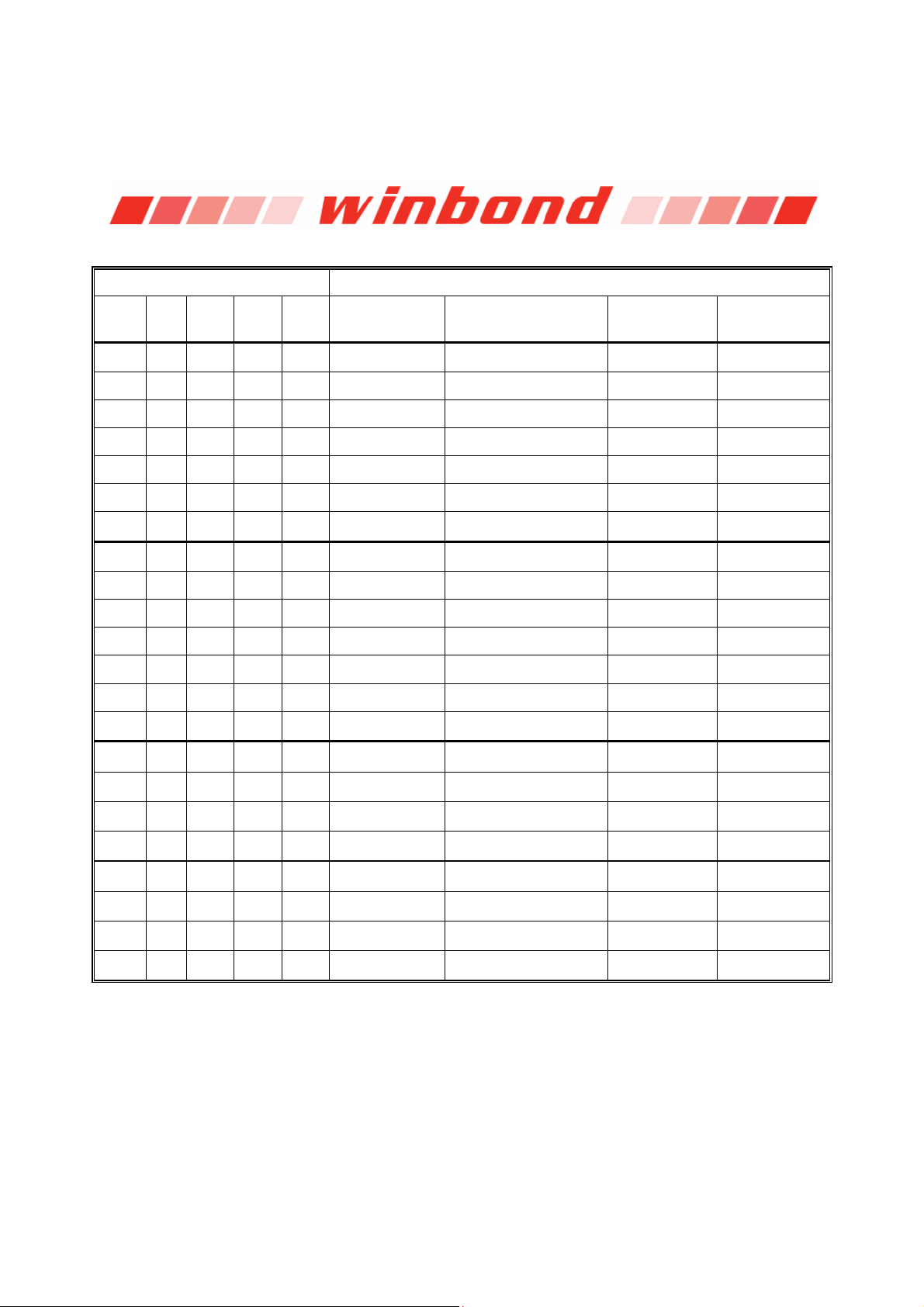

7.1.17 W25Q32FV Individual Block Memory Protection (WPS=1)

Figure 4d. Individual Block/Sector Locks

Notes:

1. Individual Block/Sector protection is only valid when WPS=1.

2. All individual block/sector lock bits are set to 1 by default after power up, all memory array is protected.

- 23 -

Page 25

W25Q32FV

8. INSTRUCTIONS

The Standard/Dual/Quad SPI instruction set of the W25Q32FV consists of 45 basic instructions that are

fully controlled through the SPI bus (see Instruction Set Table1-2). Instructions are initiated with the falling

edge of Chip Select (/CS). The first byte of data clocked into the DI input provides the instruction code.

Data on the DI input is sampled on the rising edge of clock with most significant bit (MSB) first.

The QPI instruction set of the W25Q32FV consists of 32 basic instructions that are fully controlled

through the SPI bus (see Instruction Set Table 3). Instructions are initiated with the falling edge of Chip

Select (/CS). The first byte of data clocked through IO[3:0] pins provides the instruction code. Data on all

four IO pins are sampled on the rising edge of clock with most significant bit (MSB) first. All QPI

instructions, addresses, data and dummy bytes are using all four IO pins to transfer every byte of data

with every two serial clocks (CLK).

Instructions vary in length from a single byte to several bytes and may be followed by address bytes, data

bytes, dummy bytes (don’t care), and in some cases, a combination. Instructions are completed with the

rising edge of edge /CS. Clock relative timing diagrams for each instruction are included in Figures 5

through 57. All read instructions can be completed after any clocked bit. However, all instructions that

Write, Program or Erase must complete on a byte boundary (/CS driven high after a full 8-bits have been

clocked) otherwise the instruction will be ignored. This feature further protects the device from inadvertent

writes. Additionally, while the memory is being programmed or erased, or when the Status Register is

being written, all instructions except for Read Status Register will be ignored until the program or erase

cycle has completed.

8.1 Device ID and Instruction Set Tables

8.1.1 Manufacturer and Device Identification

MANUFACTURER ID (MF7 - MF0)

Winbond Serial Flash

Device ID (ID7 - ID0)

Instruction ABh, 90h, 92h, 94h

W25Q32FV (SPI Mode) 15h 4016h

W25Q32FV (QPI Mode) 15h 6016h

EFh

(ID15 - ID0)

9Fh

Publication Release Date: Sept 16,, 2013

- 24 - Revision H

Page 26

W25Q32FV

8.1.2 Instruction Set Table 1 (Standard/Dual/Quad SPI Instructions)

Data Input Output Byte 1

Clock Number (0 – 7)

Write Enable 06h

Volatile SR Write Enable 50h

Write Disable 04h

Read Status Register-1 05h (S7-S0)

Write Status Register-1

Read Status Register-2 35h (S15-S8)

Write Status Register-2 31h (S15-S8)

Read Status Register-3 15h (S23-S16)

Write Status Register-3 11h (S23-S16)

Chip Erase C7h/60h

Erase / Program Suspend 75h

Erase / Program Resume 7Ah

Power-down B9h

Release Power-down / ID ABh Dummy Dummy Dummy (ID7-ID0)

Manufacturer/Device ID 90h Dummy Dummy 00h (MF7-MF0) (ID7-ID0)

JEDEC ID 9Fh (MF7-MF0) (ID15-ID8) (ID7-ID0)

Global Block Lock 7Eh

Global Block Unlock 98h

Enter QPI Mode 38h

Enable Reset 66h

Reset Device 99h

(4)

01h (S7-S0)

Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

(8 – 15) (16 – 23) (24 – 31) (32 – 39) (40 – 47) (48 – 55)

(2)

(4)

(2)

(2)

(1)

(2)

- 25 -

Page 27

W25Q32FV

8.1.3 Instruction Set Table 2 (Standard/Dual/Quad SPI Instructions)

Data Input Output Byte 1

Clock Number (0 – 7)

Read Unique ID 4Bh Dummy Dummy Dummy Dummy (UID63-UID0)

Page Program 02h A23-A16 A15-A8 A7-A0 D7-D0 D7-D0

Quad Page Program 32h A23-A16 A15-A8 A7-A0 D7-D0, …

Sector Erase (4KB) 20h A23-A16 A15-A8 A7-A0

Block Erase (32KB) 52h A23-A16 A15-A8 A7-A0

Block Erase (64KB) D8h A23-A16 A15-A8 A7-A0

Read Data 03h A23-A16 A15-A8 A7-A0 (D7-D0)

Fast Read 0Bh A23-A16 A15-A8 A7-A0 Dummy (D7-D0)

Fast Read Dual Output 3Bh A23-A16 A15-A8 A7-A0 Dummy (D7-D0, …)

Fast Read Quad Output 6Bh A23-A16 A15-A8 A7-A0 Dummy (D7-D0, …)

Read SFDP Register 5Ah A23-A16 A15-A8 A7-A0 Dummy (D7-D0)

Erase Security Register

Program Security Register

Read Security Register

Individual Block Lock 36h A23-A16 A15-A8 A7-A0

Individual Block Unlock 39h A23-A16 A15-A8 A7-A0

Read Block Lock 3Dh A23-A16 A15-A8 A7-A0 (L7-L0)

Data Input Output Byte 1

Clock Number (0 – 7)

Fast Read Dual I/O BBh A23-A16 A15-A8 A7-A0 Dummy (D7-D0)

Mftr./Device ID Dual I/O 92h A23-A16 A15-A8 A7-A0 Dummy (MF7-MF0) (ID7-ID0)

Data Input Output Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Clock Number (0 – 7) (8, 9) (10, 11) (12, 13) (14, 15) (16, 17) (18, 19) (20, 21) (22, 23)

Set Burst with Wrap 77h Dummy Dummy Dummy W8-W0

Fast Read Quad I/O EBh A23-A16 A15-A8 A7-A0 M7-M0 Dummy Dummy (D7-D0) (D7-D0)

Word Read Quad I/O

Octal Word Read Quad I/O

Mftr./Device ID Quad I/O 94h A23-A16 A15-A8 A7-A0 M7-M0 Dummy Dummy (MF7-MF0) (ID7-ID0)

(5)

44h A23-A16 A15-A8 A7-A0

(5)

42h A23-A16 A15-A8 A7-A0 D7-D0 D7-D0

(5)

48h A23-A16 A15-A8 A7-A0 Dummy (D7-D0)

(12)

E7h A23-A16 A15-A8 A7-A0 M7-M0 Dummy (D7-D0) (D7-D0) (D7-D0)

(13)

E3h A23-A16 A15-A8 A7-A0 M7-M0 (D7-D0) (D7-D0) (D7-D0) (D7-D0)

Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

(8 – 15) (16 – 23) (24 – 31) (32 – 39) (40 – 47)

Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

(8 – 11) (12 – 15) (16 – 19) (20 – 23) (24 – 27) (28 – 31)

(1)

Byte 7

(9)

D7-D0, …

Byte 7

Byte 8 Byte 9

(3)

(3)

(7)

(9)

(3)

Publication Release Date: Sept 16,, 2013

- 26 - Revision H

Page 28

W25Q32FV

8.1.4 Instruction Set Table 3 (QPI Instructions)

Data Input Output Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

Clock Number (0, 1) (2, 3) (4, 5) (6, 7) (8, 9) (10, 11)

Write Enable 06h

Volatile SR Write Enable 50h

Write Disable 04h

Read Status Register-1 05h (S7-S0)

Write Status Register-1

Read Status Register-2 35h (S15-S8)

Write Status Register-2 31h (S15-S8)

Read Status Register-3 15h (S23-S16)

Write Status Register-3 11h (S23-S16)

Chip Erase C7h/60h

Erase / Program Suspend 75h

Erase / Program Resume 7Ah

Power-down B9h

Set Read Parameters C0h P7-P0

Release Powerdown / ID ABh Dummy Dummy Dummy (ID7-ID0)

Manufacturer/Device ID 90h Dummy Dummy 00h (MF7-MF0) (ID7-ID0)

JEDEC ID 9Fh (MF7-MF0) (ID15-ID8) (ID7-ID0)

Global Block Lock 7Eh

Global Block Unlock 98h

Exit QPI Mode FFh

Enable Reset 66h

Reset Device 99h

Page Program 02h A23-A16 A15-A8 A7-A0 D7-D0

Sector Erase (4KB) 20h A23-A16 A15-A8 A7-A0

Block Erase (32KB) 52h A23-A16 A15-A8 A7-A0

Block Erase (64KB) D8h A23-A16 A15-A8 A7-A0

Fast Read 0Bh A23-A16 A15-A8 A7-A0 Dummy

Burst Read with Wrap

Fast Read Quad I/O EBh A23-A16 A15-A8 A7-A0 M7-M0

Individual Block Lock 36h A23-A16 A15-A8 A7-A0

Individual Block Unlock 39h A23-A16 A15-A8 A7-A0

Read Block Lock 3Dh A23-A16 A15-A8 A7-A0 (L7-L0)

(4)

01h (S7-S0)

(16)

0Ch A23-A16 A15-A8 A7-A0 Dummy

(2)

(4)

(2)

(2)

(14)

(2)

(9)

D7-D0

(15)

(D7-D0)

(15)

(D7-D0)

(15)

(D7-D0)

(3)

- 27 -

Page 29

W25Q32FV

Notes:

1. Data bytes are shifted with Most Significant Bit first. Byte fields with data in parenthesis “( )” indicate data

output from the device on either 1, 2 or 4 IO pins.

2. The Status Register contents and Device ID will repeat continuously until /CS terminates the instruction.

3. At least one byte of data input is required for Page Program, Quad Page Program and Program Security

Registers, up to 256 bytes of data input. If more than 256 bytes of data are sent to the device, the

addressing will wrap to the beginning of the page and overwrite previously sent data.

4. Write Status Register-1 (01h) can also be used to program Status Register-1&2, see section 8.2.5.

5. Security Register Address:

Security Register 1: A23-16 = 00h; A15-8 = 10h; A7-0 = byte address

Security Register 2: A23-16 = 00h; A15-8 = 20h; A7-0 = byte address

Security Register 3: A23-16 = 00h; A15-8 = 30h; A7-0 = byte address

6. Dual SPI address input format:

IO0 = A22, A20, A18, A16, A14, A12, A10, A8 A6, A4, A2, A0, M6, M4, M2, M0

IO1 = A23, A21, A19, A17, A15, A13, A11, A9 A7, A5, A3, A1, M7, M5, M3, M1

7. Dual SPI data output format:

IO0 = (D6, D4, D2, D0)

IO1 = (D7, D5, D3, D1)

8. Quad SPI address input format: Set Burst with Wrap input format:

IO0 = A20, A16, A12, A8, A4, A0, M4, M0 IO0 = x, x, x, x, x, x, W4, x

IO1 = A21, A17, A13, A9, A5, A1, M5, M1 IO1 = x, x, x, x, x, x, W5, x

IO2 = A22, A18, A14, A10, A6, A2, M6, M2 IO2 = x, x, x, x, x, x, W6, x

IO3 = A23, A19, A15, A11, A7, A3, M7, M3 IO3 = x, x, x, x, x, x, x, x

9. Quad SPI data input/output format:

IO0 = (D4, D0, …..)

IO1 = (D5, D1, …..)

IO2 = (D6, D2, …..)

IO3 = (D7, D3, …..)

10. Fast Read Quad I/O data output format:

IO0 = (x, x, x, x, D4, D0, D4, D0)

IO1 = (x, x, x, x, D5, D1, D5, D1)

IO2 = (x, x, x, x, D6, D2, D6, D2)

IO3 = (x, x, x, x, D7, D3, D7, D3)

11. Word Read Quad I/O data output format:

IO0 = (x, x, D4, D0, D4, D0, D4, D0)

IO1 = (x, x, D5, D1, D5, D1, D5, D1)

IO2 = (x, x, D6, D2, D6, D2, D6, D2)

IO3 = (x, x, D7, D3, D7, D3, D7, D3)

12. For Word Read Quad I/O, the lowest address bit must be 0. (A0 = 0)

13. For Octal Word Read Quad I/O, the lowest four address bits must be 0. (A3, A2, A1, A0 = 0)

14. QPI Command, Address, Data input/output format:

CLK # 0 1 2 3 4 5 6 7 8 9 10 11

IO0 = C4, C0, A20, A16, A12, A8, A4, A0, D4, D0, D4, D0

IO1 = C5, C1, A21, A17, A13, A9, A5, A1, D5, D1, D5, D1

IO2 = C6, C2, A22, A18, A14, A10, A6, A2, D6, D2, D6, D2

IO3 = C7, C3, A23, A19, A15, A11, A7, A3, D7, D3, D7, D3

15. The number of dummy clocks for QPI Fast Read, QPI Fast Read Quad I/O & QPI Burst Read with Wrap is

controlled by read parameter P7 – P4.

16. The wrap around length for QPI Burst Read with Wrap is controlled by read parameter P3 – P0.

Publication Release Date: Sept 16,, 2013

- 28 - Revision H

Page 30

W25Q32FV

8.2 Instruction Descriptions

8.2.1 Write Enable (06h)

The Write Enable instruction (Figure 5) sets the Write Enable Latch (WEL) bit in the Status Register to a

1. The WEL bit must be set prior to every Page Program, Quad Page Program, Sector Erase, Block

Erase, Chip Erase, Write Status Register and Erase/Program Security Registers instruction. The Write

Enable instruction is entered by driving /CS low, shifting the instruction code “06h” into the Data Input (DI)

pin on the rising edge of CLK, and then driving /CS high.

/CS

Mode 3 0 1 2 3 4 5 6 7

CLK

(IO0)

Mode 0

Instruction (06h)

DI

/CS

Mode 3

Mode 0

CLK

IO

IO

0

1

Mode 3 0 1

Mode 0

Instruction

06h

Mode 3

Mode 0

DO

(IO1)

High Impedance

IO

2

IO

3

Figure 5. Write Enable Instruction for SPI Mode (left) or QPI Mode (right)

8.2.2 Write Enable for Volatile Status Register (50h)

The non-volatile Status Register bits described in section 7.1 can also be written to as volatile bits. This

gives more flexibility to change the system configuration and memory protection schemes quickly without

waiting for the typical non-volatile bit write cycles or affecting the endurance of the Status Register nonvolatile bits. To write the volatile values into the Status Register bits, the Write Enable for Volatile Status

Register (50h) instruction must be issued prior to a Write Status Register (01h) instruction. Write Enable

for Volatile Status Register instruction (Figure 6) will not set the Write Enable Latch (WEL) bit, it is only

valid for the Write Status Register instruction to change the volatile Status Register bit values.

/CS

/CS

CLK

DI

(IO0)

DO

(IO1)

Mode 3 0 1

CLK

Mode 3 0 1 2 3 4 5 6 7

Mode 0

Instruction (50h)

High Impedance

Mode 3

Mode 0

Mode 0

IO

0

IO

1

IO

2

IO

3

Instruction

50h

Figure 6. Write Enable for Volatile Status Register Instruction for SPI Mode (left) or QPI Mode (right)

Mode 3

Mode 0

- 29 -

Page 31

W25Q32FV

8.2.3 Write Disable (04h)

The Write Disable instruction (Figure 7) resets the Write Enable Latch (WEL) bit in the Status Register to

a 0. The Write Disable instruction is entered by driving /CS low, shifting the instruction code “04h” into the

DI pin and then driving /CS high. Note that the WEL bit is automatically reset after Power-up and upon

completion of the Write Status Register, Erase/Program Security Registers, Page Program, Quad Page

Program, Sector Erase, Block Erase, Chip Erase and Reset instructions.

/CS

/CS

CLK

DI

(IO0)

DO

(IO1)

Mode 3 0 1 2 3 4 5 6 7

Mode 0

Instruction (04h)

High Impedance

Mode 3

Mode 0

Mode 3 0 1

CLK

Mode 0

Instruction

04h

IO

0

IO

1

IO

2

IO

3

Mode 3

Mode 0

Figure 7. Write Disable Instruction for SPI Mode (left) or QPI Mode (right)

8.2.4 Read Status Register-1 (05h), Status Register-2 (35h) & Status Register-3 (15h)

The Read Status Register instructions allow the 8-bit Status Registers to be read. The instruction is

entered by driving /CS low and shifting the instruction code “05h” for Status Register-1, “35h” for Status

Register-2 or “15h” for Status Register-3 into the DI pin on the rising edge of CLK. The status register bits

are then shifted out on the DO pin at the falling edge of CLK with most significant bit (MSB) first as shown

in Figure 8. Refer to section 7.1 for Status Register descriptions.

The Read Status Register instruction may be used at any time, even while a Program, Erase or Write

Status Register cycle is in progress. This allows the BUSY status bit to be checked to determine when

the cycle is complete and if the device can accept another instruction. The Status Register can be read

continuously, as shown in Figure 8. The instruction is completed by driving /CS high.

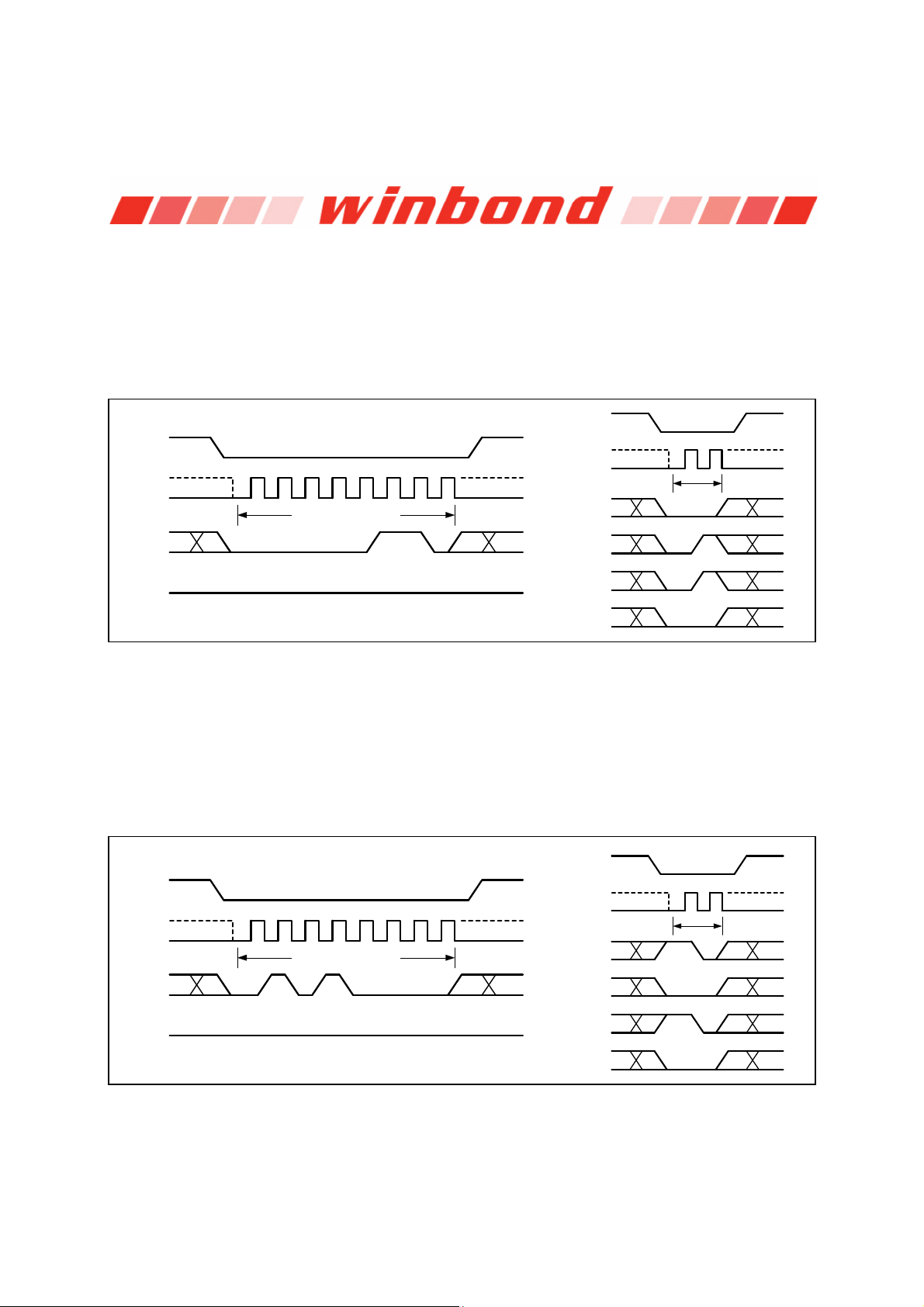

Figure 8a. Read Status Register Instruction (SPI Mode)

Publication Release Date: Sept 16,, 2013

- 30 - Revision H

Page 32

W25Q32FV

Figure 8b. Read Status Register Instruction (QPI Mode)

8.2.5 Write Status Register-1 (01h), Status Register-2 (31h) & Status Register-3 (11h)

The Write Status Register instruction allows the Status Registers to be written. The writable Status

Register bits include: SRP0, SEC, TB, BP[2:0] in Status Register-1; CMP, LB[3:1], QE, SRP1 in Status

Register-2; HOLD/RST, DRV1, DRV0, WPS & ADP in Status Register-3. All other Status Register bit

locations are read-only and will not be affected by the Write Status Register instruction. LB[3:1] are nonvolatile OTP bits, once it is set to 1, it cannot be cleared to 0.

To write non-volatile Status Register bits, a standard Write Enable (06h) instruction must previously have

been executed for the device to accept the Write Status Register instruction (Status Register bit WEL

must equal 1). Once write enabled, the instruction is entered by driving /CS low, sending the instruction

code “01h/31h/11h”, and then writing the status register data byte as illustrated in Figure 9a & 9b.

To write volatile Status Register bits, a Write Enable for Volatile Status Register (50h) instruction must

have been executed prior to the Write Status Register instruction (Status Register bit WEL remains 0).

However, SRP1 and LB[3:1] cannot be changed from “1” to “0” because of the OTP protection for these

bits. Upon power off or the execution of a Software/Hardware Reset, the volatile Status Register bit

values will be lost, and the non-volatile Status Register bit values will be restored.

During non-volatile Status Register write operation (06h combined with 01h/31h/11h), after /CS is driven

high, the self-timed Write Status Register cycle will commence for a time duration of tW (See AC

Characteristics). While the Write Status Register cycle is in progress, the Read Status Register

instruction may still be accessed to check the status of the BUSY bit. The BUSY bit is a 1 during the

Write Status Register cycle and a 0 when the cycle is finished and ready to accept other instructions

again. After the Write Status Register cycle has finished, the Write Enable Latch (WEL) bit in the Status

Register will be cleared to 0.

- 31 -

Page 33

W25Q32FV

During volatile Status Register write operation (50h combined with 01h/31h/11h), after /CS is driven high,

the Status Register bits will be refreshed to the new values within the time period of t

SHSL2

(See AC

Characteristics). BUSY bit will remain 0 during the Status Register bit refresh period.

The Write Status Register instruction can be used in both SPI mode and QPI mode. However, the QE bit

cannot be written to when the device is in the QPI mode, because QE=1 is required for the device to

enter and operate in the QPI mode.

Refer to section 7.1 for Status Register descriptions.

Figure 9a. Write Status Register-1/2/3 Instruction (SPI Mode)

Figure 9b. Write Status Register-1/2/3 Instruction (QPI Mode)

Publication Release Date: Sept 16,, 2013

- 32 - Revision H

Page 34

W25Q32FV

The W25Q32FV is also backward compatible to Winbond’s previous generations of serial flash memories,

in which the Status Register-1&2 can be written using a single “Write Status Register-1 (01h)” command.

To complete the Write Status Register-1&2 instruction, the /CS pin must be driven high after the sixteenth

bit of data that is clocked in as shown in Figure 9c & 9d. If /CS is driven high after the eighth clock, the

Write Status Register-1 (01h) instruction will only program the Status Register-1, the Status Register-2

not be affected (Previous generations will clear CMP and QE bits).

/CS

Mode 3 0 1 2 3 4 5 6 7

CLK

Mode 0

Instruction (01h)

DI

(IO0)

DO

(IO1)

*

= MSB

Figure 9c. Write Status Register-1/2 Instruction (SPI Mode)

/CS

Mode 3 0 1

CLK

Mode 0

IO

0

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Status Register 1 in Status Register 2 in

7 6 5 4 3 2 1 0 15 14 13 12 11 10 9 8

* *

High Impedance

Instruction

01h

2 3 4 5

SR1 in SR2 in

4 0 12 8

Mode 3

Mode 0

Mode 3

Mode 0

IO

1

IO

2

IO

3

5 1

6 2

7 3

13 9

14 10

15 11

Figure 9d. Write Status Register-1/2 Instruction (QPI Mode)

- 33 -

Page 35

W25Q32FV

8.2.6 Read Data (03h)

The Read Data instruction allows one or more data bytes to be sequentially read from the memory. The

instruction is initiated by driving the /CS pin low and then shifting the instruction code “03h” followed by a

24-bit address (A23-A0) into the DI pin. The code and address bits are latched on the rising edge of the

CLK pin. After the address is received, the data byte of the addressed memory location will be shifted out

on the DO pin at the falling edge of CLK with most significant bit (MSB) first. The address is automatically

incremented to the next higher address after each byte of data is shifted out allowing for a continuous

stream of data. This means that the entire memory can be accessed with a single instruction as long as

the clock continues. The instruction is completed by driving /CS high.

The Read Data instruction sequence is shown in Figure 14. If a Read Data instruction is issued while an

Erase, Program or Write cycle is in process (BUSY=1) the instruction is ignored and will not have any

effects on the current cycle. The Read Data instruction allows clock rates from D.C. to a maximum of fR

(see AC Electrical Characteristics).

The Read Data (03h) instruction is only supported in Standard SPI mode.

/CS

Mode 3 0 1 2 3 4 5 6 7

CLK

Mode 0

Instruction (03h)

DI

(IO0)

DO

(IO1)

*

= MSB

High Impedance

8 9 10 28 29 30 31 32 33 34 35 36 37 38 39

24-Bit Address

23 22 21 3 2 1 0

*

Data Out 1

7 6 5 4 3 2 1 0 7

*

Figure 14. Read Data Instruction (SPI Mode only)

Publication Release Date: Sept 16,, 2013

- 34 - Revision H

Page 36

W25Q32FV

8.2.7 Fast Read (0Bh)

The Fast Read instruction is similar to the Read Data instruction except that it can operate at the highest

possible frequency of FR (see AC Electrical Characteristics). This is accomplished by adding eight