Page 1

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Laser Diode Driver with Automatic Power Control

SONET/SDH 3.125Gb/s

Features Applications

• Power Supply: 3.3V or 5V ±5%

• AC-Coupled to Laser Diode

• Programmable Modulation Current: 5mA to 60mA

• Programmable Bias Current: 1mA to 100mA

• Enable /Disable Control

• Typical Rise/Fall Times of 60ps

• Automatic Optical Average Power Control

• Supply Current of 33mA at 3.3V

• SONET/SDH at 622Mb/s, 1.244Gb/s,

2.488Gb/s, 3.125Gb/s

• Full-Speed Fibre Channel (1.062Gb/s)

General Description

The VSC7939 is a single 3.3V or 5V supply l aser diode driv er special ly desig ned for S ONET/SDH appli cations up to 3.125Gb/s. External resistors set a wide range of bias and modulation currents for driving the laser.

Data and clock inputs accept differential PECL signals. The autom atic power control (APC) loop maintains a

constant average optical power over temperature and lifetime. The dominant pole of the APC loop can be controlled with an external capacitor. Other features include enable/disable control, short-circuit protection for the

modulation and bias inputs, short rise and fall times, programmable slow-start circuit to set laser turn-on delay,

and failure-monitor output to indicate when the APC loop is unable to maintain the average optical power. The

VSC7939 is available in die form or in a 32-pin TQFP package.

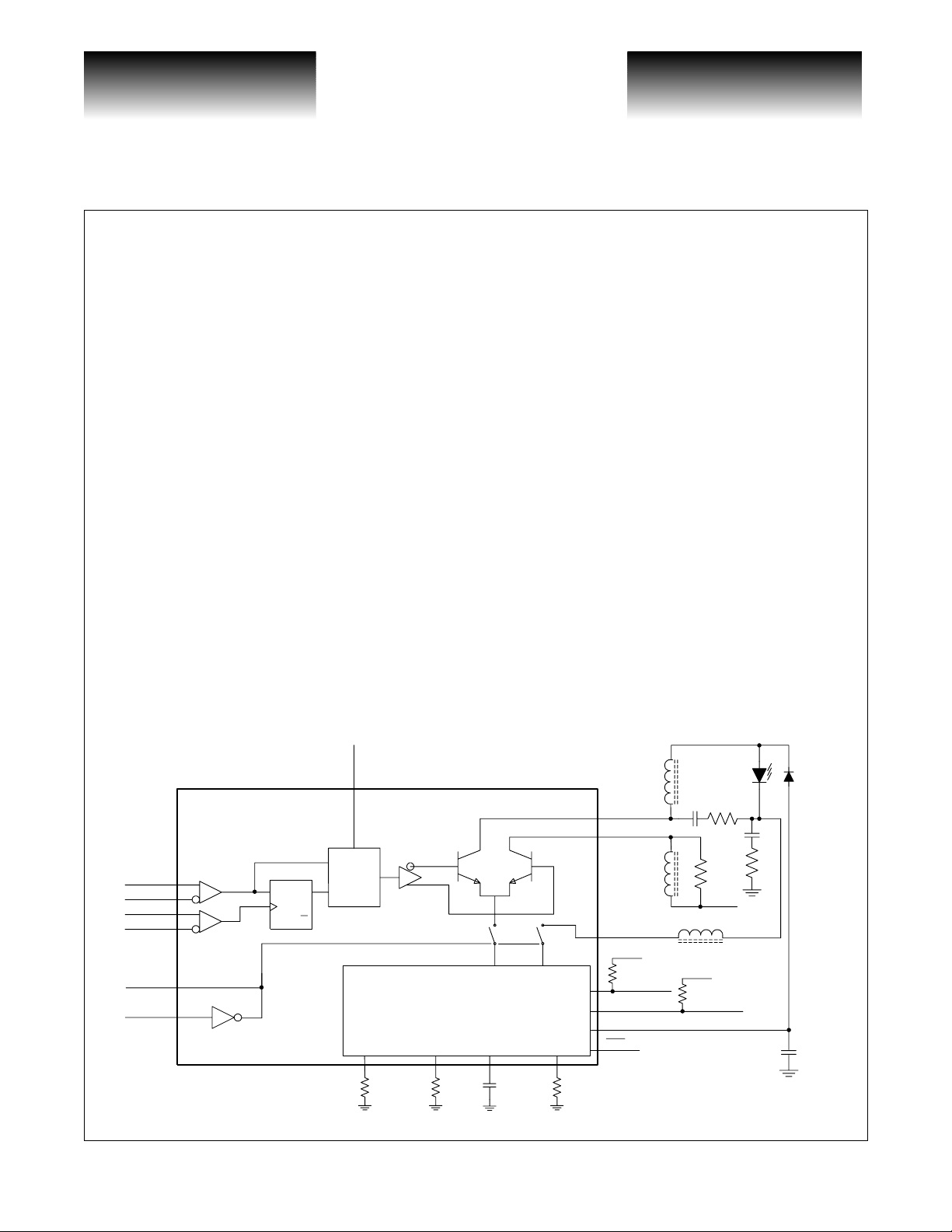

Block Diagram

V

P

L

C

D

P

L

V

CC

BIASMON

CC

C

F

R

F

V

CC

1nF

3.3V Operation

LATCH

IOUT+

IOUT-

MUX

DATA+

DATA-

CLK+

CLK-

ENABLE

DISABLE

G52350-0, Rev 3.2 Page 1

02/26/01

SET

D

Q

Q

CLR

APC

MODSET

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

BIASMAX

Internet: www.vitesse.com

CAPC

APCSET

V

MODMON

MD

FAIL

BIAS

CC

Page 2

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Preliminary Data Sheet

Laser Diode Driver with Automatic Power Control

Electrical Characteristics

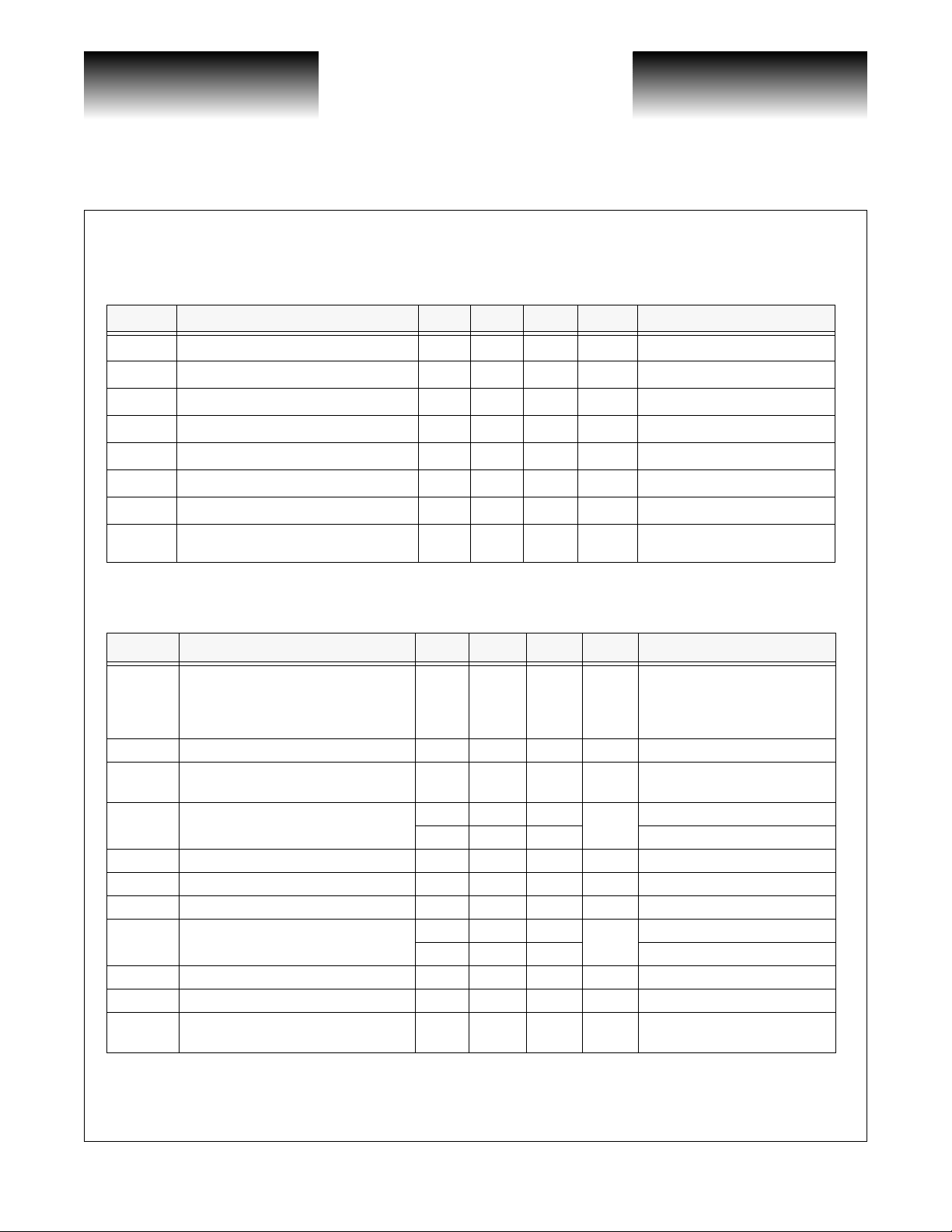

Table 1: AC Specifications

AC specifications are guaranteed by design an d characterization. Typical values are for 3.3V.

Symbol Parameter Min Typ Max Units Conditions

t

SU

t

H

t

R

t

F

PWD Pulse Width Distortion 10 50 ps See Notes 1, 2

CID

t

J

NOTES: (1) Measured with 622Mb/s 0-1 pattern , LATCH=high. (2) P WD = (wi der pulse - narrower pulse) / 2).

Input Latch Setup Time 100 ps LATCH=high

Input Latch Hold Time 100 ps LATCH=high

Enable/Start-up Delay 250 ns

Output Rise Time 60 80 ps 20% to 80%

Output Fall Time 60 80 ps 20% to 80%

Maximum Consecu tive Identical D igits 80 bits

MAX

Jitter Generation 7 20 ps

p-p

Jitter BW=12kHz to 20MHz,

0-1 pattern.

VSC7939

Table 2: DC Specifications

Symbol Parameter Min Typ Max Units Conditions

I

CC

I

BIAS

I

BIAS-OFF

S

BIAS

VR

MD

I

MD

I

MOD

I

MOD-OFF

R

Supply Current TBD 45 mA

Bias Current Range 1 100 mA Voltage at BIAS pin=(VCC-1.6)

Bias Off Current 100 µA

Bias Current Stability

Bias Current Absolute Accuracy ±15 % Refers to part-to-part variation

Monitor Diode Reverse Bias Voltage 1.5 V

Monitor Diode Reverse Current Range 18 1000 µA

Monitor Diode Bias Setpoint Stability

Monitor Diode Bias Absolute Accuracy -15 15 % Refers to part-to-part variation

Modulation Curren t Rang e 5 60 mA

Modulation Off Cu rr ent 200 µA

-480 -50 480

230

900 APC open loop. I

90 IMD=18µA

ppm/°C

ppm/°C

R

I

BIAS

V

ENABLE=low or

DISABLE=high

APC open loop. I

I

MD

ENABLE=low or

DISABLE=high

MODSET

BIASMAX

and I

=5V

CC

=1mA

=7.3kΩ

=4.8kΩ

MOD

(2)

(2)

excluded

(1)

BIAS

BIAS

(1)

=100mA

=1mA

Page 2 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 3

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Laser Diode Driver with Automatic Power Control

SONET/SDH 3.125Gb/s

Symbol Parameter Min Typ Max Units Conditions

Modulation Current Absolute Accuracy ±15 % See Note 2

Modulation Current Stability

A

BIAS

A

MOD

NOTES: (1) Both I

BIASMON to I

MODMON to I

tion does not change with temperature.

BIAS

and I

-480 -50 480

250 I

Gain 37 A/A I

BIAS

Gain 29 A/A I

MON

will turn off if any of the current set pins are grounded. (2) Assume s l ase r di ode t o monitor diode transfer func-

MOD

ppm/°C

I

=60mA

MOD

=5mA

MOD

BIAS/IBIASMON

MOD/IMODMON

Table 3: PECL and TTL/CMOS Inputs and Outputs Specifications

Symbol Parameter Min Typ Max Units Conditions

V

ID

V

ICM

I

IN

V

IH

V

IL

Differential Input Voltage 100 1600 mV

-

V

Common-Mode Input V oltage

Clock and Data Input Current -1 10 µA

TTL Input High Voltage

(ENABLE, LATCH)

TTL Input Low Voltage

(ENABLE, LATCH)

TTL Output High Voltage (FAIL

TTL Output Low Vo ltage (FAIL

)2.4

) 0.1 0.44 V Sinking 100µA

CC

1.49

2.0 V

VCC -

1.32

V

0.3

CC

-

VCC V

/4

ID

0.8 V

V

CC

V PECL-compatible

V Sourcin g 50µA

(DATA+)-(DATA-)

p-p

G52350-0, Rev 3.2 Page 3

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

Page 4

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

Absolute Maximum Ratings

Power Supply Voltage (VCC).............................................................................................................-0.5V to +7V

Current into BIAS.....................................................................................................................-20mA to +150mA

Current into OUT+, OUT-...............................................................................................................................TBD

Current into MD.............................................................................................................................-5mA to +5mA

Current into FAIL

Voltage at DATA+, DATA-, CLK+, CLK-, ENABLE, LATCH.........................................-0.5V to (V

Voltage at APCFILT, MODSET, BIASMAX, APCSET, MD, FAIL

Voltage at OUT+, OUT-..................................................................................................... -0.5V to (V

Voltage at BIAS..................................................................................................................-0.5V to (V

Continouous Power Dissipation (T

Operating Junction Temperature Range...................................................................................... -55°C to +150°C

Storage Temperature Range ........................................................................................................ -65 °C to +165°C

NOTE: (1) CAUTION: Stresses listed under “Absolute Maximum Ratings” may be applied to devices one at a time without caus-

ing permanent damage. Functionality at or above the values listed is not implied. Exposure to these values for extended

periods may affect device reliability.

......................................................................................................................... -10mA to 30mA

= +85°C, TQFP derate 20.8mW/°C above +85°C) .......................1350mW

A

(1)

.............................................-0.5V to +3.0V

Preliminary Data Sheet

VSC7939

CC

CC

CC

+ 0.5V)

+ 1.5V)

+ 0.5V)

Recommended Operating Conditions

Positive Voltage Rail (VCC).....................................................................................................+3.135V to +5.25V

Negative Voltage Rail (GND) ............................................................................................................................0V

Modulation Current (I

Ambient Temperature Range (T

NOTE: (1) VCC = 3.3V, I

MOD

BIAS

(1)

)

.......................................................................................................................30mA

).................................................................................................-40°C to +85°C

A

= 60mA.

Page 4 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 5

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

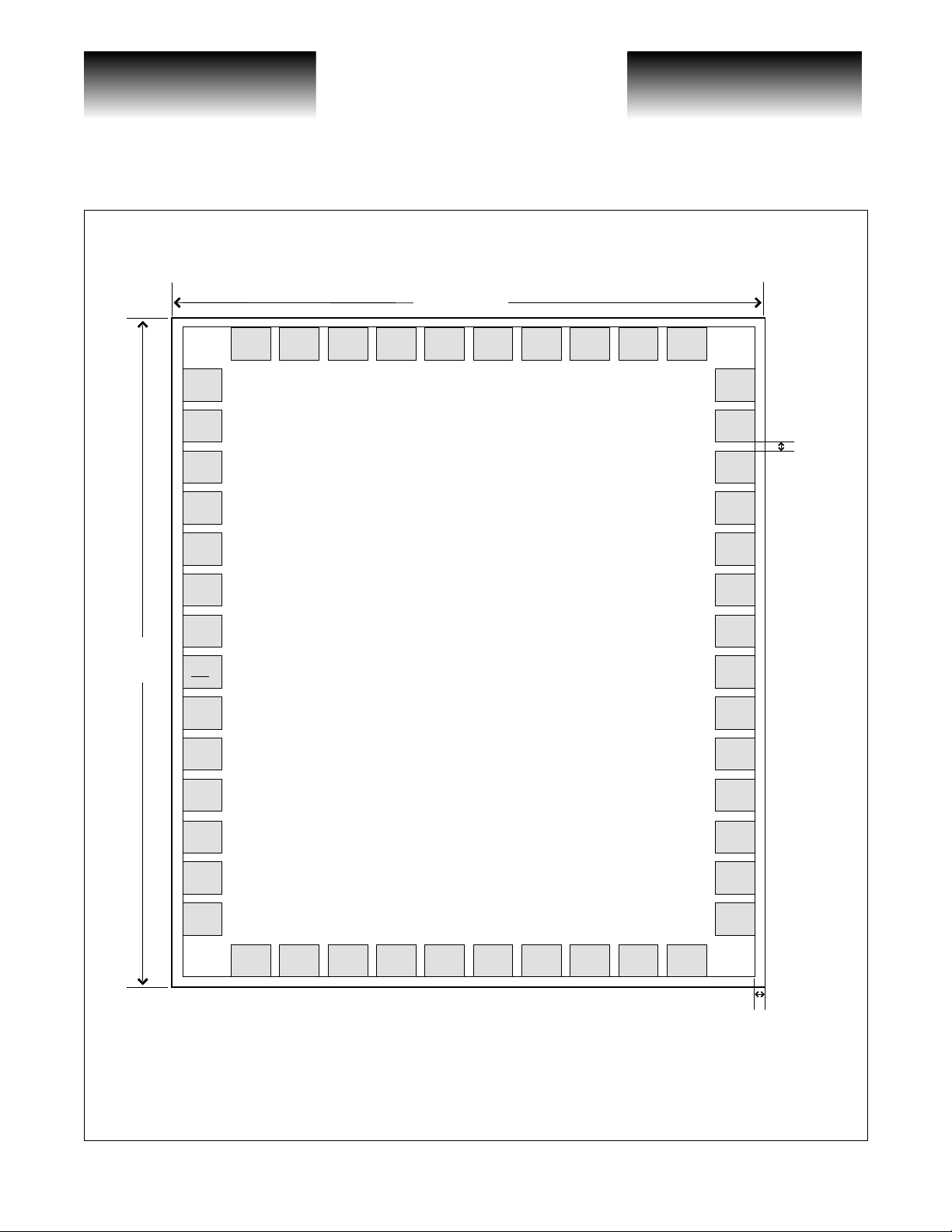

Bare Die Pad Descriptions

Pad 10

Pad 12

GND1

Pad 13

LATCH

Pad 14

ENABLE

Pad 15

DISABLE

Pad 16

GND1

Pad 17

BIASMON

Pad 11

VCC1

(Pin 7)

(Pin 8)

(Pin 9)

(Pin 10)

(Pin 11)

CLK-

Laser Diode Driver with Automatic Power Control

Figure 1: Pad Assignments

1773

µm (0.0698")

Pad 9

CLK+

Pad 8

VCC1

Pad 7

GND1

Pad 6

VCC1

Pad 5

DATA-

Pad 4

DATA+

SONET/SDH 3.125Gb/s

Pad 3

VCC1

(Pin 1)(Pin 2)(Pin 3)(Pin 4)(Pin 5)(Pin 6)

Pad 2

GND1

(Pin 32)

(Pin 31)

(Pin 30)

(Pin 29)

Pad 1

GND2

Pad 48

VCC2

Pad 47

BIASMAX

Pad 46

MODSET

Pad 45

GND2

Pad 44

APCSET

20

µm

(0.0008")

2233

µm

(0.0879")

Pad 18

(Pin 12)

MODMON

Pad 19

FAIL

Pad 20

GND4

Pad 21

PB_GND

Pad 22

APCFILT

Pad 23

GND4

Pad 24

VCC4

Pad 25

BIAS

(Pin 13)

(Pin 14)

(Pin 15)

(Pin 16)

(Pin 17)

Pad 26

PB_GND1

(Pin 18) (Pin 19) (Pin 20) (Pin 21) (Pin 22) (Pin 23) (Pin 24)

Pad 27

VCC4

Pad 28

DB_OUT+

Pad 29

OUT+

VSC7939

Pad 30

OUT-

Pad 31

DB_OUT-

Die Size: 1773µm x 2233µm (0.0698" x 0.0879")

Die Thickness: 625

µm (0.0246")

Pad Pitch: 115µm (0.0045")

Pad Size: 95µm x 95µm (0.0037" x 0.0037")

Pad to Pad Clearance: 20µm (0.0008

")

Pad Passivation Opening: 95µm x 95µm (0.0037" x 0.0037")

Scribe Size: 75µm (0.0030")

Pad 32

VCC4

Pad 33

GND4

Pad 34

GND3

(Pin 28)

(Pin 27)

(Pin 26)

(Pin 25)

Pad 35

MD

Pad 43

RESERVED

Pad 42

GND3

Pad 41

PB_GND

Pad 40

GND3

Pad 39

PB_GND

Pad 38

CAPC

Pad 37

VCC3

Pad 36

GND3

75

(0.0030")

µm

G52350-0, Rev 3.2 Page 5

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

Page 6

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

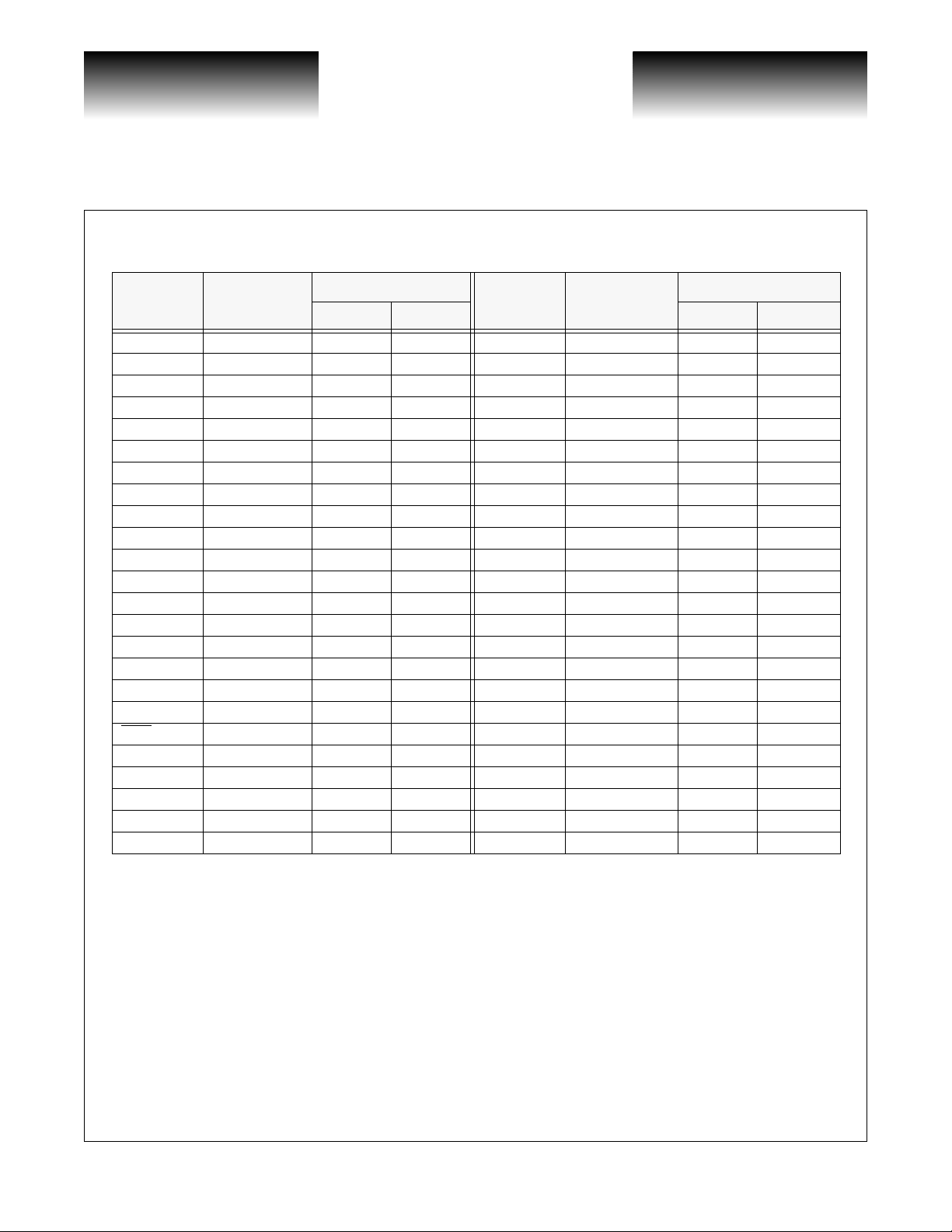

Table 4: Pad Coordinates

Signal

Name

GND2 1 1613.55 1863.475 BIAS 25 (Pin 17) 159.45 368.475

GND1 2 1414.525 2073.55 PB_GND 26 369.525 159.45

VCC1 3 (Pin 1) 1289.525 2073.55 VCC4 27 (Pin 18) 484.525 159.45

DATA+ 4 (Pin 2) 1174.525 2073.55 DB_OUT+ 28 599.525 159.45

DATA- 5 (Pin 3) 1059.525 2073.55 OUT+ 29 (Pin 19 ) 714.525 159.45

VCC1 6 (Pin 4) 944.525 2073.55 OUT– 30 (Pin 20) 829.525 159.45

GND1 7 829.525 2073.55 DB_OUT– 31 944.525 159.45

VCC1 8 714.525 2073.55 VCC4 32 (Pin 21) 1059.525 159.45

CLK+ 9 (Pin 5) 599.525 2073.55 GND4 33 (Pin 22) 1174.525 159.45

CLK- 10 (Pin 6) 484.525 2073.55 GND3 34 (Pin 23) 1289.525 159.45

VCC1 11 (Pin 7) 369.525 2073.55 MD 35 (Pin 24) 1404.525 159.45

GND1 12 159.45 1863.475 GND3 36 1613.55 368.475

LATCH 13 (Pin 8) 159.45 1748.475 VCC3 37 (Pin 25) 1613.55 483.475

ENABLE 14 (Pin 9) 159.45 1633.475 CAPC 38 (Pin 26 ) 1613.55 598.475

DISABLE 15 (Pin 10) 159.45 1518.475 PB_GND 39 1613.55 713 .475

GND 16 159.45 1403.4 GND3 40 (Pin 27) 1613.55 828.475

BIASMON 17 ( Pin 11) 159.45 1288.475 PB_GND 41 1613.55 943.475

MODMON 18 (Pin 12) 159.45 1058.475 GND3 42 1613.55 1058.475

FAIL

GND4 20 159.45 943.475 APCSET 44 (Pin 29) 1613.55 1288.475

PB_GND 21 159.45 828.475 GND2 45 1613.55 1403.475

APCFILT 22 (Pin 14) 159.45 713.475 MODSET 46 (Pin 30) 1613.55 1518.475

GND4 23 (Pin 15) 159.45 598.475 BIASMAX 47 (Pin 31) 1613.55 1633.475

VCC4 24 (Pin 16) 159.45 483.475 VCC2 48 (Pin 32) 1613.55 1748.475

Pad

No.

19 (Pin 13) 159.45 1058.475 RESERVED 43 (Pin 28) 1613.55 1173.475

Coordinates (µm)

X Y X Y

Signal

Name

Preliminary Data Sheet

VSC7939

Pad

No.

Coordinates (µm)

Page 6 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 7

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Package Pin Description

VCC

DATA+

DATA-

VCC

CLK-

CLK+

VCC

LATCH

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

Figure 2: Pin Diagram

VCC

BIASMAX

MODSET

APCSET

RESERVED

GND

CAPC

VCC

32

31

30

29

28

27

26

25

1

2

3

4

5

6

7

8

VSC7939

24

23

22

21

20

19

18

17

MD

GND

GND

VCC

OUTOUT+

VCC

BIAS

9

10

11

12

13

14

15

16

FAIL

ENABLE

DISABLE

BIASMON

MODMON

G52350-0, Rev 3.2 Page 7

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

APCFILT

GND

VCC

Page 8

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Preliminary Data Sheet

Laser Diode Driver with Automatic Power Control

Table 5: Pin Identifications

Pin Name Pin Number Description

GND 15, 22, 23, 27 Ground

V

CC

DATA+ 2 Positive Data Input (PECL)

DATA- 3 Negative Data Input (PECL)

CLK+ 5 Positive Clock Input (PECL). Connect to V

CLK- 6 Negative Clock Input (PECL) . Leave unconnect ed if LATCH function is not used.

LATCH 8 Latch Input (TTL/CMOS). Connect to VCC for data retiming and GND for direct data.

ENABLE 9

DISABLE 10

BIASMON 11 Bias Current Monitor. Sink current source that is proportional to the laser bias current.

MODMON 12

FAIL

APCFILT 14 No effect on device operation..

BIAS 17 Laser Bias Current Output

OUT+ 19 Positive Modulation-Current Output. I

OUT- 20 Negative Modulation-Current Output. I

MD 24

CAPC 26 Capacitor to GND sets dominan t pole of the APC feedback loop.

RESERVED 28 Do not connect.

APCSET 29

MODSET 30 Connect resistor to GND to set desired modulation current.

BIASMAX 31

1, 4, 7, 16,

18, 21, 25, 32

13 Output (TTL/CMOS). When low indicates APC failure.

Power Suppl y

Enable Input (TTL/CMOS). If used, connect DISABLE to GND. Connect to VCC for

normal operation and GND to disable laser bias and modulation currents.

Disable Input (TTL/CMOS). If used, leave ENABLE pin floating. Connect to GND for

normal operation and V

Modulation Current Monitor. Sink current source that is proportional to the laser

modulation current.

Monitor Diode Input. Connect to monitor photodiode anode. Connect capacitor to GND to

filter high-speed AC monitor photocurrent.

Resistor to GND sets desired average optical power. If APC is not used, connect 100kΩ

resistor to GND.

Connect resistor to GND to set maximum bias current. The APC function can subtract from

this value, but cannot add to it.

to disable laser bias and modulation currents.

CC

MOD

MOD

if LATCH function is not used.

CC

flows when input data is high.

flows when input data is low.

VSC7939

Page 8 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 9

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Laser Diode Driver with Automatic Power Control

SONET/SDH 3.125Gb/s

Detailed Description

The VSC7939 is a high-speed l aser dri ver with Automatic Power Con trol. The device is desig ned to operate

up to 3.125Gb/s with a 3.3V or 5V supply. The data and clock inputs support PECL inputs as well as other

inputs that meet the common-mode voltage and differential voltage swing specif ications. The differential pair

output stage is capab le of sinking up to 60mA from the l aser with typical rise and fall times of 60ps. This output

may be DC-coupled for 5V operation. To allow for larger output swings during 3.3V operation, the VSC7939

was designed to be AC-coupled to the laser cathode with a pull-up inductor for DC-biasing. This configuration

will isolate laser forward voltage from the output circuitry and will allow the output at OUT+ to s wing above

and below the supply voltage V

supply current, and fast ri se and fall times. Th e VSC7938 is another Vitesse laser drivers with simi lar feat ures in

a 48-pin TQFP package. The VSC7938 does not have monitoring for modulation and bias currents. The

VSC7940 is a modified version of the VSC7939 capable of 100mA output currents.

Automatic Power Control

To ensure constant average optical power, the VSC7939 utilizes an Automatic Power Control loop. A photodiode mounted in the laser packa ge pr ov ide s optica l f eed back t o comp ensat e f or chang e s in average l aser ou tput power due to ch anges tha t affect laser performan ce such a s temper ature and laser life time. Th e laser bia s

current is adjusted by the APC loop according to the reference current set at APCSET by an external resistor.

An external capacitor at CAPC controls the time constant for the APC feedback loop. The recommended value

for CAPC is 0.1

guarantees stability. Because the APC loop noise is internally filtered, APCFIL T is not internally connected and

does not need to be connected to any external components. The device’s performance will not be affected if a

capacitor is connected to APCFILT. If the APC loop cannot adjust the bias current to track the desired monitor

current, FAIL

The device may be operated with or without APC. To utilize APC, a capacitor must be connected at CAPC

(0.1

µF) and a resistor must be connected at APCSET to set the average optical power. For open-loop operation

(no APC), a 10 0k

loop operation. In both mo des of o peratio n, resist ors to ground sho uld be p laced at BIASMAX and MODSET to

set the bias and modulation currents.

µF. This value reduces pattern-dependent jitter associated with the APC feedback loop and

is set low.

Ω resistor should be connected between APCSET and GND. CAPC has no effect on open-

. The key features of the VSC7939 are Automatic Power Control, low power

CC

Data Retiming

The VSC7939 provides inpu ts for differential PECL cl ock signals for data ret iming to minim ize jitter at

high speeds. To incorporate this function, LATCH shou ld be connected to V

CLK+ should be connected to V

GND.

Short-Circuit Protection

If BIASMAX or MODSET are shorted to ground, the output mo dulation and bias currents will be turned

off.

G52350-0, Rev 3.2 Page 9

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

, CLK- should be left unconnected, and LATCH should be connected to

CC

Internet: www.vitesse.com

. If this function is unused,

CC

Page 10

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

Modulation and Bias Current Monitors

Preliminary Data Sheet

VSC7939

The VSC7939 provides monitoring of the modulation and bias currents vias BIASMON and MODMON.

These pins sink a current proportiona l to the actual modu lation and bias curren ts. MODMON sinks approximately 1/28th of the amount of modulation current and BIASMON sink approximately 1/35th of the amount of

the bias current. These pins should be tied through a pull-up resistor to V

that the voltage at MODMON is greater than V

- 1.0V and the voltage at BIASMON is greater than VCC -

CC

. The resistors must be chosen such

CC

1.6V.

Enable/Disable

Two pins are provided to a llow either EN ABLE or DISABLE contr ol. If ENABLE is used, co nnect DISABLE to ground. Is DISABLE is used, leave ENABLE floating. Both modulation and bias currents are turned

off when ENABLE is low or DISABLE is high. Typically, ENABLE or DISABLE responds within approximately 250ns.

Controlling the Modulation Current

The output modulation current may be determined from the following equation where P

peak optical power, P

is the average power, r

AVE

I

MOD

= P

is the extinction ratio, and η is the laser slope efficiency:

e

/ η= 2 * P

p-p

* (re-1) / (re+1) / η

AVE

is the peak-to-

p-p

A resistor at MODSET controls the output bias current. Graphs of I

MODSET

vs. R

in Typical Operat-

MODSET

ing Characteristics for both 3.3V and 5V operation describe the relationship between the resistor at MODSET

and the output modulation current at 25

°C. After determining the desired outpu t modulatio n current, use the

graph to determine the appropriate resistor value at MODSET.

Controlling the Bias Current

A resistor at BIASMAX should be used to control the output bias current. Graphs of I

BIASMAX

vs. R

BIASMAX

in Typical Operating Characteristics for both 3.3V and 5V operation describe the relationship between the

resistor at BIASMAX and the output bias current at 25

°C. If the APC is not used, the appropriate resistor value

at BIASMAX is determined by first selecting the desired output bias current, and then using the graph to determine the appropriate resistor value at BIASMAX. When using APC, BIASMAX sets the maximum allowed

bias current. After determining the maximum end-of-life bias current at 85

I

BIASMAX

Controlling the APC Loop

vs. R

BIASMAX

To select the resistor at APCSET, use the graph of IMD vs. R

in Typical Operating Characteristics to select the appropriate resistor value.

APCSET

The graph relates the desired monitor current to the appropriate resistance value at APCSET. I

late from the desired optical average power, P

, and the laser-to-monitor transfer, ρ

AVE,

°C for the laser, refer to the graph of

in Typical Operating Characteristics.

may be calcu-

MD

, for a specific laser

MON

using the following equa tion:

I

MD

= P

AVE

* ρ

MON

Page 10 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 11

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Laser Diode Interface

Laser Diode Driver with Automatic Power Control

SONET/SDH 3.125Gb/s

An RC shunt network should be placed at the laser outpu t interface. Th e sum of the re sistor placed at the

output and the laser diode resistance should be 25

Ω resistor should be placed in series with the laser. For optimal performance, a bypass capacitor should be

20

Ω. For exam ple, if t he lase r diode ha s a resis tance of 5Ω, a

placed close to the laser anode.

A “snubber network” consisting of a capacitor C

and resistor RF should be placed at the laser output to

F

minimize reflections from the laser (see Block Diagram). Suggested values for these components are 80

2pF, respectively, however, these values should be adjusted until an optical output waveform is obtained.

Reducing Pattern-Dependent Jitter

Three design values significantly affect pattern-dependent jitter; the capacitor at CAPC, the pull-up inductor at the output (L

value for the capacitor at CAPC is 0.1

), and the AC-coupling c apaci t or at t he out put (CD). As previously stated, the recommended

P

µF. This results in a 10kHz loop bandwidth which makes the pattern-

dependent jitter from the APC loop negligible.

For 2.5Gb/s data rates, the recommended value for C

nated by L

. The variation in the peak vo ltage should be less that 12% of the average voltage over the maximum

P

is 0.056µF. The time constant at the output is domi-

D

consecutive identical digit (CID) period. The following equation approximates this time constant for a CID

period, t, of 100UI = 40ns:

τ

= -t / ln(1-12%) = 7.8t = LP / 25Ω

LP

Ω and

Therefore, the inductor LP should be a 7.8µH SMD ferrite bead inductor for this case.

Input/Output Considerations

Although the VSC7939 is PECL-compatible, this is not required to drive the device. The inputs must only

meet the common-mode voltage and differential voltage swing specifications.

Power Consumption

The following equation provides the device supply current (IS) in terms of quiescent current (IQ), modulation current (I

), and bias current (I

MOD

):

BIAS

I

= IQ + 0.47 * I

S

+ 0.15 * I

MOD

BIAS

For 3.3V operation, IQ is 15mA. For 5V operation, IQ is 20mA.

This equation may be used to determine the estimated power dissipation:

= VCC * I

P

DIS

S

For example, if the device were operated at 3.3V with a 30mA mod ulation current and a 10mA bias current ,

the supply current would be:

= 15mA + 0.47 * 30mA + 0.15 * 10mA = 31

I

S

This corresponds to a power dissipation of 3.3V * 31mA = 102mW.

G52350-0, Rev 3.2 Page 11

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

Page 12

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

Typical Operating Characteristics

I

MODSET

vs. R

MODSET

T=25°C VCC = 3.3V

Preliminary Data Sheet

VSC7939

I

MODSET

vs. R

MODSET

T=25°C VCC = 5V

I

BIASMAX

vs. R

T=25°C, VCC = 3.3V

BIASMAX

I

BIASMAX

vs. R

T=25°C, VCC = 5V

BIASMAX

Page 12 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 13

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

IMD vs. R

T=25°C, V

APCSET

CC

,

= 3.3V

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

IMD vs. R

T=25°C, V

APCSET

= 5V

CC

,

Rise and Fall Times

T=85°C, V=3.3V

Monte Carlo Si mulation of I

CC

G52350-0, Rev 3.2 Page 13

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

Page 14

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Preliminary Data Sheet

Laser Diode Driver with Automatic Power Control

Applications Information

The following is a typical design example for the VSC7939 assuming 3.3V operation with APC.

Select a Laser

The Table 7 provides specifications for a typical communication-grade laser capable of operating at

2.5Gb/s.

Table 6: Typical Laser Characteristics

Symbol Parameter Value Units

λ W avelength 1310 nm

P

AVE

I

th

ρ

MON

η Laser Slope Efficiency 0.4 mW/mA

T

C

Select Resistor for APCSET

The monitor diode current is estimated by IMD = P

vs. R

APCSET

Average Opti cal Output Power 6 mW

Threshold Current 6 mA

Laser to Monitor Transfer 0.04 mA/mW

Operating Temperature Range -40 to +85 °C

AVE

* ρ

= 6mW * 0.04mA/mW = 0.24mA. The IMD

MON

in Typical Operating Characteristics shows the resistor at APCSET should be 5kΩ.

VSC7939

Select Resistor for MODSET

T o ensure some minimum extinction ratio over temperature and lifetime, assume an optimal extinction ratio

of 20 (13dB) at 25

I

MOD

The graph of I

should be 8.5k

Select Resistor for BIASMAX

°C. The modulation current may be calculated from the following equation:

= P

/ η= 2 * P

p-p

MODSET

vs. R

* (re-1) / (re+1) / η = 2 * 6mA * (20-1) / (20 + 1) / 0.4 = 27.1mA

AVE

MODSET

in Typical Operating Characteristics shows the resistor for MODSET

Ω.

The maximum threshold current at +85°C and end of life must be determined. A graph of a typical laser’s

versus TC reveals a maximum threshold current of 30mA at 85°C. Therefore, the maxim um bias can be

I

th

approximated by:

vs. R

= I

BIASMAX

I

BIASMAX

The graph of I

should be 5k

Select Resistors for MODMON and BIASMON

BIASMAX

Ω.

TH-MAX

+ I

/ 2 = 30mA + 27.1mA / 2 = 43.6mA

MOD

in T ypi cal Operating Characteristics shows the resistor for BIASMAX

Assuming the modulation and bias currents never exceed 120mA, the following equations provide values

for the resistor at MODMON, RMODMON, and the resistor at BIASMON, RBIASMON:

R

MODMON

= 1V * 28 / 120mA = 233Ω

R

BIASMON

Page 14 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

= 1.6V * 35 / 120mA = 467Ω

Internet: www.vitesse.com

02/26/01

Page 15

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Standard values for these values are R

MODMON would indicate a modulation current of:

I

MOD

Wire Bonding

For best performance, gold ball-bonding techniques are recommended. Wedge bonding is not recommended. For best performance and to minimize inductance keep wire bond lengths short.

MODMON

= (5.2V - 4.8V) * 28 / 232mA = 48mA

Laser Diode Driver with Automatic Power Control

= 232Ω and R

BIASMON

SONET/SDH 3.125Gb/s

= 464Ω. A voltage of 4.8V at

PCB Layout Guidelines

Use high frequency PCB layout techniques with solid ground planes to minimize crosstalk and EMI. Keep

high speed traces as short as possible for signal integrity. The output traces to the laser diode must be short to

minimize inductance. Short output traces will provide best performance.

G52350-0, Rev 3.2 Page 15

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

Page 16

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

Package Information - 32 Pin TQFP

Preliminary Data Sheet

VSC7939

1. All dimensioning and tolerancing conform to ANSI Y14.5-1982

2. Controlling dimension: millimeter

3. This outline conforms to JEDEC Publication 95 Registration MS-026

Page 16 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Page 17

VITESSE

SEMICONDUCTOR CORPORATION

Preliminary Data Sheet

VSC7939

Ordering Informatio n

The order number for this product is formed by a combination of the device type and package type.

Device Type

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

VSC7939

xx

Package

RP: 32-Pin TQFP

W: Dice Waffle Pack

Notice

Vitesse Semiconductor Corporation (“Vitesse”) provides this document for informational purposes only. This document contains pre-production information

about Vitesse products in their co ncept , devel opmen t and/or te stin g phas e. All inf ormat ion in th is docu ment, inclu ding des cript ions of f eature s, functio ns,

performance, technical specifications and availability, is subject t o ch an g e without notice at any time. Nothing c ontained in this document shall be construed

as extending any war ranty or p romi se, e xpress or impl ied, that a ny Vitesse prod uct wi ll be a vail able a s de scrib ed or wi ll be suitable for or will accomplish

any particular task.

Vitesse products are not intended for use in life support appliances, devices or systems. Use of a Vitesse product in such applications without written consent

is prohibited.

G52350-0, Rev 3.2 Page 17

02/26/01

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

Page 18

VITESSE

SEMICONDUCTOR CORPORATION

SONET/SDH 3.125Gb/s

Laser Diode Driver with Automatic Power Control

Preliminary Data Sheet

VSC7939

Page 18 G52350-0, Rev 3.2

© VITESSE SEMICONDUCTOR CORPORATION • 741 Calle Plano • Camarillo, CA 93012

Tel: (800) VITESSE • FAX: (805) 987-5896 • Email: prodinfo@vitesse.com

Internet: www.vitesse.com

02/26/01

Loading...

Loading...