Page 1

VRE402

Precision

Dual Reference

DESCRIPTION

FEATURES

The VRE402 is a low cost, high precision, ±2.5V

reference. Packaged in 14 pin DIP or SMT

packages, the device is ideal for new designs that

need a high performance reference.

The device provides ultrastable ±2.500V output

with ±0.250 mV (.01%) initial accuracy and a

temperature coefficient of 0.6 ppm/°C. This

improvement in accuracy is made possible by a

unique, patented multipoint laser compensation

technique developed by Thaler Corporation.

Another key feature of this reference is the 0.3 mV

maximum tracking error between the positive and

negative output voltages over the operating

temperature range. This is extremely important in

high performance systems for reducing overall

system errors.

For designs which use the DIP package in a

socket, there is a reference ground pin to

eliminate reference ground errors.

The VRE402 is recommended for use as a

reference for high precision A/D and D/A

converters which require an external precision

reference. The device is ideal for calibrating

scale factor on high resolution A/D converters.

The VRE402 offers superior performance over

monolithic references.

• ±2.500 V OUTPUT ± 0.250 mV (.01%)

• TEMPERATURE DRIFT: 0.6 ppm/°C

• LOW NOISE: 1.5µVpp (0.1-10Hz)

• TRACKING ERROR: 0.2 mV max.

• EXCELLENT LINE REGULATION: 6ppm/V Typ.

• SURFACE MOUNT AND DIP PACKAGES

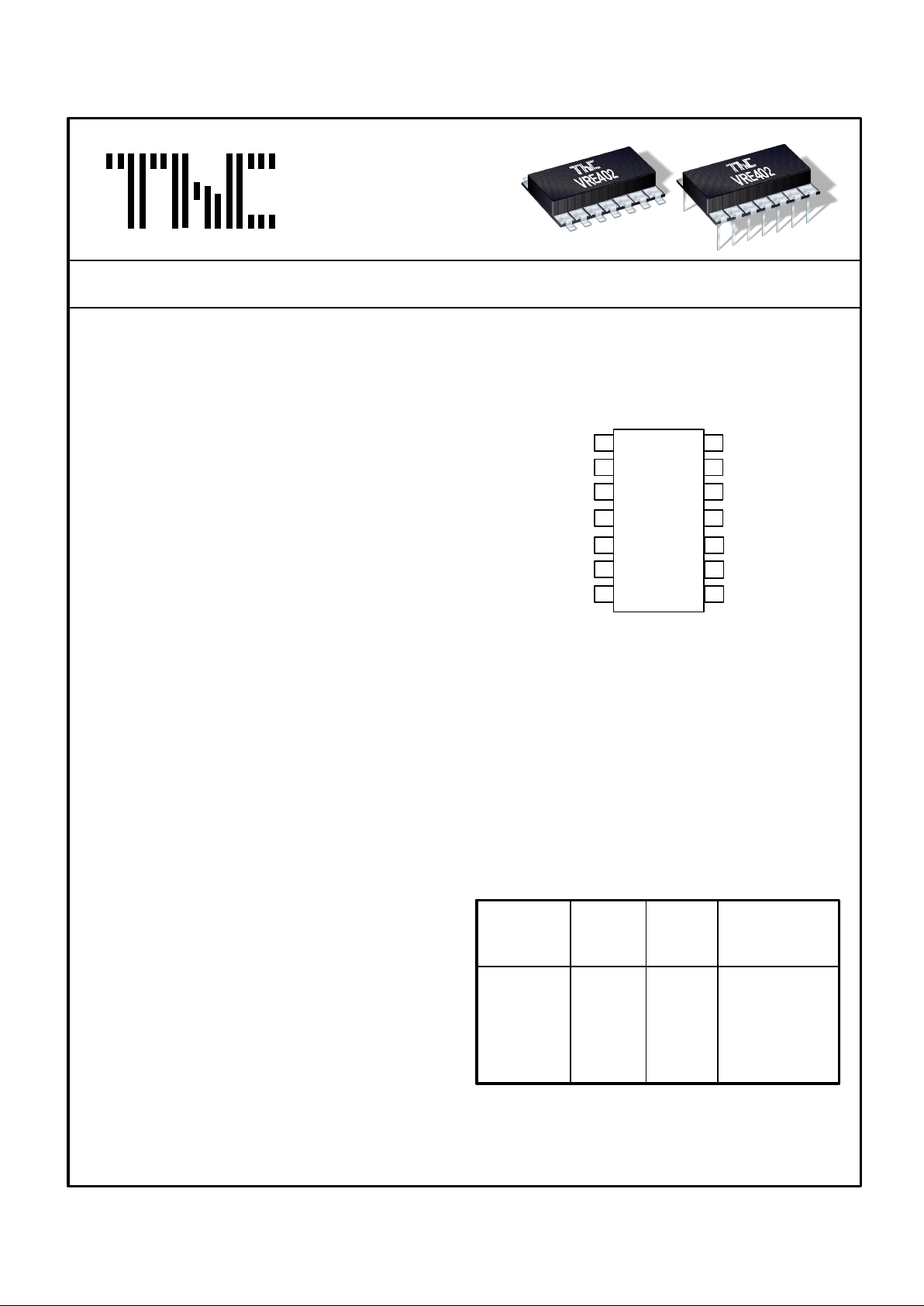

FIGURE 1

VRE402DS REV. A MAY 1996

SELECTION GUIDE

Model

Temp.

Range

°C

Temp.

Coeff.

ppm/

°C

VRE402A 0.25 0.6 0°C to +70°C

VRE402B 0.40 1.0 0°C to +70°C

VRE402C 0.50 2.0 0°C to +70°C

VRE402J 0.25 0.6 -40°C to +85°C

VRE402K 0.40 1.0 -40°C to +85°C

VRE402L 0.50 2.0 -40°C to +85°C

For package option add D for DIP or S for Surface

Mount to end of model number.

Initial

Error

mV

THALER CORPORATION • 2015 N. FORBES BOULEVARD • TUCSON, AZ. 85745 • (520) 882-4000

11

12

13

14

VRE402

TOP

VIEW

1

2

3

4

N/C

+V

IN

GND

REF. GND

+V

OUT

PIN CONFIGURATION

5

6

7

10

9

8

- V

OUT

N/C

- V

IN

N/C

N/C

N/C

N/C

N/C

N/C

Page 2

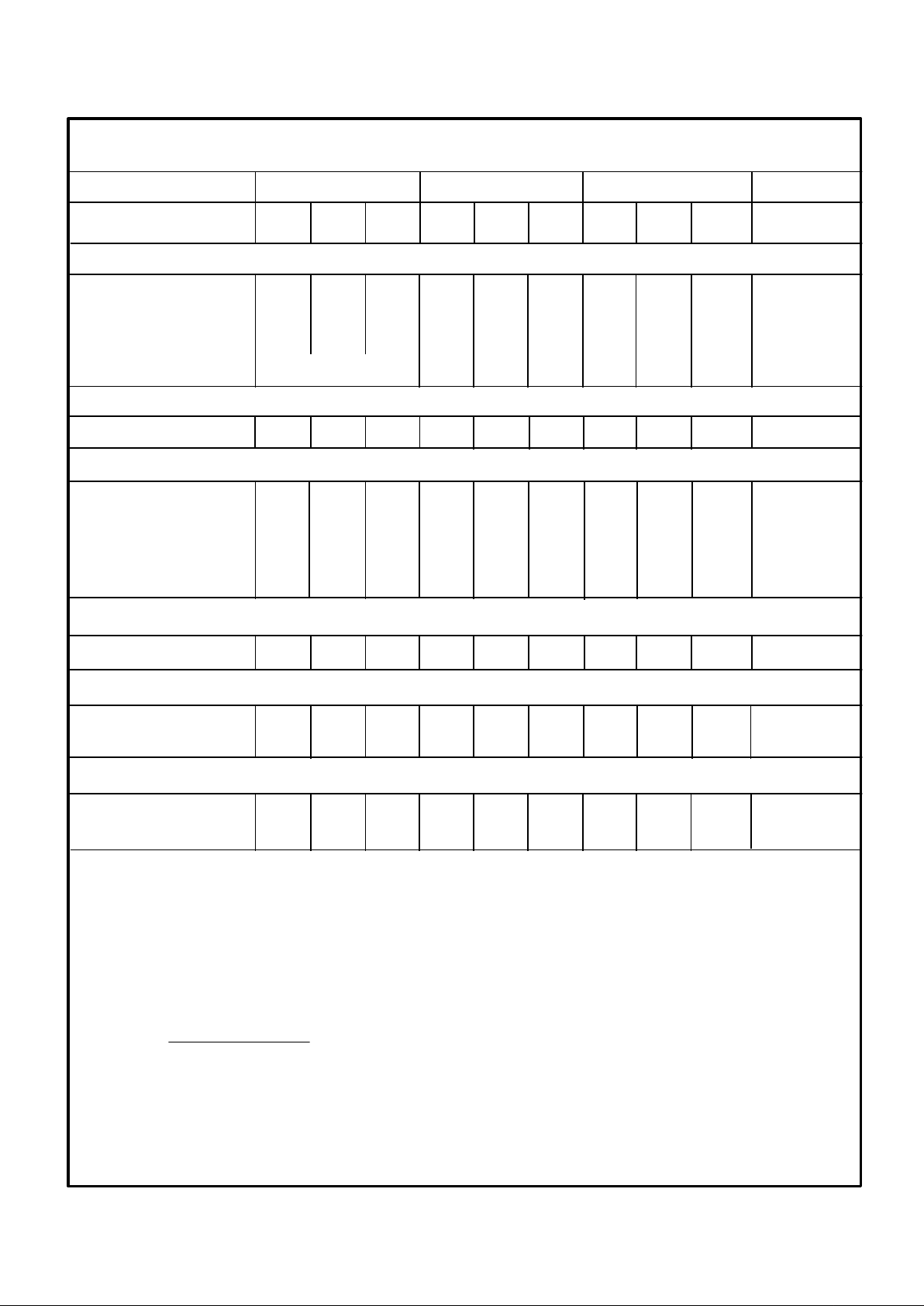

MODEL A/J B/K C/L

PARAMETER MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

ABSOLUTE RATINGS

Power Supply ±13.5 ±15 ±22 * * * * * * V

Operating Temp. (A,B,C) 0 +70 * * * * °C

Operating Temp. (J,K,L) -40 +85 * * * * °C

Storage Temperature -65 +150 * * * * °C

Short Circuit Protection Continuous * *

OUTPUT VOLTAGE

VRE402 ±2.5 * * V

OUTPUT VOLTAGE ERRORS

Initial Error 0.25 0.40 0.50 mV

Warmup Drift 1 2 3 ppm

T

min

- T

max

0.6 1.0 2.0 ppm/ °C

Tracking Error 0.2 0.3 0.4 mV

Long-Term Stability 6 * * ppm/1000hrs

Noise (.1-10Hz) 1.5 * * µVpp

OUTPUT CURRENT

Range ±10 * * mA

REGULATION

Line 3 10 * * * * ppm/V

Load 3 * * ppm/mA

POWER SUPPLY CURRENTS

+PS 7 9 * * * * mA

-PS 4 6 * * * * mA

VRE402

NOTES: *Same as A/J Models.

1. The specified values are without external trim.

2. The temperature coefficient (tc) is determined by the

box method using the following formula:

V

max

- V

min

tc = x 10

6

V

nominal

x (T

max-Tmin

)

3. The tracking error is the deviation between the

positive and negative output over the operating temp.

range.

(1)

(4)

(2)

(3)

VRE402DS REV. A MAY 1996

Vps =±15V, T = 25°C, RL = 10KΩ unless otherwise noted.

ELECTRICAL SPECIFICATIONS

4. The specified values are unloaded.

Page 3

TYPICAL PERFORMANCE CURVES

VRE402DS REV. A MAY 1996

QUIESCENT CURRENT VS. TEMP

Temperature oC

JUNCTION TEMP. RISE VS. OUTPUT CURRENT

Output Current (mA)

PSRR VS. FREQUENCY

Frequency (Hz)

QUIESCENT CURRENT VS. TEMP

Temperature oC

JUNCTION TEMP. RISE VS. OUTPUT CURRENT

Output Current (mA)

PSRR VS. FREQUENCY

Frequency (Hz)

Temperature oC

VRE402A

V

OUT

vs. TEMPERATURE

Temperature oC

VRE402B

V

OUT

vs. TEMPERATUREV

OUT

vs. TEMPERATURE

Temperature oC

VRE402C

Temperature oC

VRE402J

V

OUT

vs. TEMPERATURE

Temperature oC

VRE402K

V

OUT

vs. TEMPERATURE

Temperature oC

VRE402L

V

OUT

vs. TEMPERATURE

POSITIVE OUTPUT (TYP)

NEGATIVE OUTPUT (TYP)

Page 4

DISCUSSION OF PERFORMANCE

VRE402DS REV. A MAY 1996

VRE402

FIGURE 2

THEORY OF OPERATION

The following discussion refers to the schematic in

figure 2 below. A FET current source is used to bias

a 6.3V zener diode. The zener voltage is divided by

the resistor network R1 and R2. This voltage is then

applied to the noninverting input of the operational

amplifier which amplifies the voltage to produce a

2.500V output. The gain is determined by the

resistor networks R3 and R4: G=1 + R4/R3. The

6.3V zener diode is used because it is the most

stable diode over time and temperature.

The current source provides a closely regulated

zener current, which determines the slope of the

references’ voltage vs. temperature function. By

trimming the zener current a lower drift over

temperature can be achieved. But since the voltage

vs. temperature function is nonlinear this

compensation technique is not well suited for wide

temperature ranges.

Thaler Corporation has developed a nonlinear

compensation network of thermistors and resistors

that is used in the VRE series voltage references.

This proprietary network eliminates most of the

nonlinearity in the voltage vs. temperature function.

By adjusting the slope, Thaler Corporation produces

a very stable voltage over wide temperature ranges.

This network is less than 2% of the overall network

resistance so it has a negligible effect on long term

stability.

The VRE402 reference has it’s ground brought out

on two pins (pin 6 and 7) which are connected

internally. This allows the user to achieve greater

accuracy when using a socket. Voltage references

have a voltage drop across their power supply

ground pin due to quiescent current flowing through

the contact resistance. If the contact resistance was

constant with time and temperature, this voltage

drop could be trimmed out. When the reference is

plugged into a socket, this source of error can be as

high as 20ppm. By connecting pin 7 to the power

supply ground and pin 6 to a high impedance

ground point in the measurement circuit, the error

due to the contact resistance can be eliminated. If

the unit is soldered into place, the contact

resistance is sufficiently small that it does not effect

performance.

Page 5

DIM MIN MAX MIN MAX DIM MIN MAX MIN MAX

A .114 .136 2.90 3.45 E .410 .435 10.4 11.0

B .018 .027 .460 .690 E1 .390 .415 9.91 10.5

B1 .047 .056 1.19 1.42 E2 .265 .270 6.73 6.86

B2 .097 .103 2.46 2.62 G1 .285 .315 7.24 8.00

C .009 .020 0.22 0.51 L .195 .225 4.95 5.72

D .690 .715 17.5 18.1 P .090 .110 2.29 2.79

D 1 .666 .680 16.9 17.2 Q .050 .070 1.27 1.79

S .040 .060 1.02 1.52

INCHES MILLIMETER

INCHES MILLIMETER

VRE402DS REV. A MAY 1996

MECHANICAL

FIGURE 4

FIGURE 3

DIM MIN MAX MIN MAX DIM MIN MAX MIN MAX

A .114 .136 2.90 3.45 E .495 .526 12.5 13.3

B .098 .103 2.48 2.62 E1 .390 .415 9.91 10.5

B1 .047 .056 1.19 1.42 E2 .265 .270 6.73 6.86

C .103 .118 2.62 3.00 P .090 .110 2.29 2.79

C1 .009 .020 0.22 0.51 Q .024 .035 0.61 .890

C2 .054 .062 1.37 1.57 S .040 .060 1.02 1.52

D .690 .715 17.5 18.1

D1 .666 .680 16.9 17.2

INCHES MILLIMETER

INCHES MILLIMETER

Loading...

Loading...