Page 1

12

Note:

Non-Isolate

Output

Gate In

Gate Out

ZCS

Boost

Converter

Inrush

& Short

Circuit

Protection

High Frequency

Control

Voltage

Waveform

Current

Sense

AC

Line

Control

& House-

keeping

Circuitry

Output Voltage

Module Enable

Power OK

DC

Out

Recti-

fier

Aux. Supply

+

–

NOTE: No input to output isolation.

1-800-735-6200

VI-HAM

Harmonic Attenuator

Modules

Features

■ Unity Power Factor

■ Safety Agency Approvals:

UL, CSA, TÜV, BABT

■ Meets IEC 6100-3-2 for Line

Current Harmonic Content

■ Reduces Peak and RMS Line

Currents

■ Universal Input: 85-264Vac:

50/60 Hz

■ Up to 600W of Power

■ Power Density Up to100W/in

■ Adaptive Output Voltage Control

■ Short-Circuit Protection

■ Input Surge Current Limiting

■ Converter Enable

■ Power OK Output

■ Size: 4.6" x 2.4" x 0.5"

(116,8mm x 61,0mm x 12,7mm)

■ Efficiency: 90-94% Typical

■ CE Marked

3

Unity Power Factor

Conventional capacitive-input front ends draw

energy from the AC line in short bursts of current

at the peaks of the line voltage waveform. These

current bursts are characterized by high peak currents

and high harmonic content. The effect of the

distorted line current can be appreciated by

measuring the rms line current drawn by a

conventional front end: the product of the

measured rms current and the rms line voltage —

the "apparent power" being delivered by the line

— will be significantly greater (typically 1.6X)

than the DC power delivered by the front end.

The "extra" rms current at the input is circulating

harmonic currents which deliver no power to the

load but which flow in the delivery system and

contribute to losses. Only the fundamental

component of the line current contributes to "real"

power flow. Power factor — the ratio of "real" to

"apparent" power — is a measure of the

effectiveness with which an AC load can extract

usable power from an AC source.

The VI-HAM (see Fig. 2) consists of a

full-wave rectifier, a proprietary high-frequency zerocurrent switching (ZCS) boost regulator (patents

applied for), active inrush, short-circuit protection,

control and housekeeping circuitry. The incoming

AC line is rectified and fed to the ZCS boost

converter. The control circuitry varies the operating

frequency of the ZCS boost converter so as to

simultaneously maintain the output voltage of the

HAM at a DC voltage value above the peak of the

incoming line, while forcing the input current to

the ZCS converter to follow the waveshape of the

rectified line. By this means, the AC input current

follows the AC voltage waveform and a power

factor better than 0.99 is achieved. Operating

efficiency of the ZCS boost converter is optimized

at any incoming line voltage by a patented

adaptive output voltage control scheme.

The HAM also includes active circuitry which

controls inrush currents when power is applied and

active short circuit protection circuitry — features

not normally found in conventional power factor

correctors.

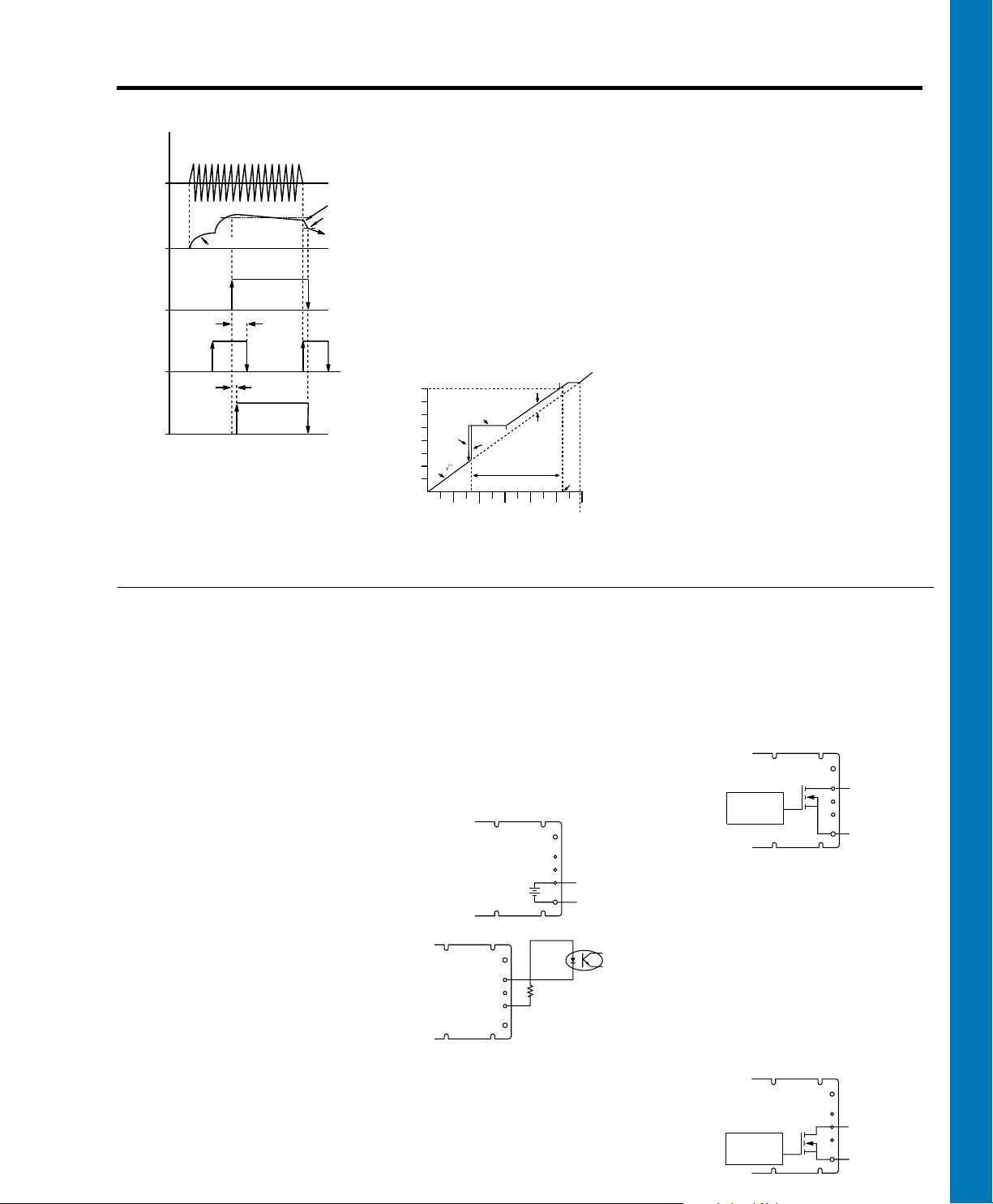

Housekeeping circuitry provides two signals of use

to the system designer (see Fig. 2): Module Enable

and Power OK. Referencing the timing diagram

(see Fig. 3), the Module Enable signal, which is

connected to the Gate In inputs of the Vicor DCDC converters powered by the HAM, will come

high and enable the DC-DC converters when the

HAM output voltage exceeds 240Vdc. The

DC-DC converter voltage outputs will be up

approximately 10 ms after Module Enable goes

high. Typically, 20 ms after Module Enable goes

high the HAM Power OK signal, which can be

used by the system designer to enable circuitry

powered by the DC-DC converter modules, goes

low. On loss of power or brownout, the Power OK

signal will go high when the HAM DC output

voltage drops below 230V, signaling an impending

loss of input power to the converter modules.

When the DC output dips below 195V, the Module

Enable signal will toggle low, disabling the

converter modules and unloading the HAM.

The HAM will provide at least 16 ms of

ride-through or holdup time, and at least 5 ms of

AC fail warning time with a 1000 µF output

capacitor.

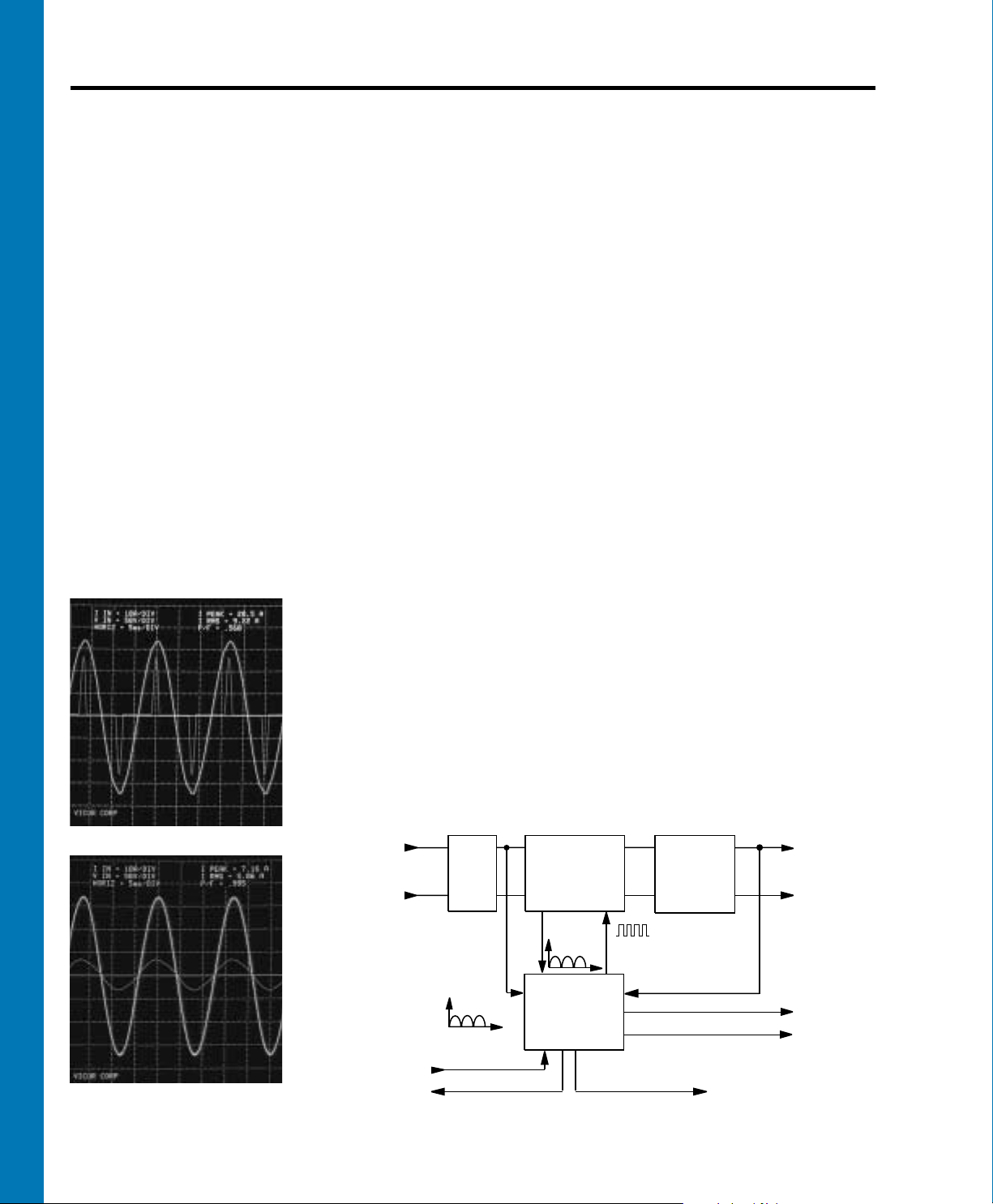

Figure 1a.

Figure 1b.

Above: Oscilloscope photos showing input

voltage and current without power factor

correction (A) and with power factor correction

as provided by the VI-HAM (B).

Figure 2 • VI-HAM Block Diagram

Page 2

12

Outputs

VI-200

DC-DC

Converter(s)

Rectified Line

Module

Enable

DC

Output

of HAM

Power OK

AC

Mains

120V

RMS

Boost Voltage

195

Vdc

240

Vdc

Off at

195

Vdc

Off at

230

Vdc

230

Vdc

25 ms

10 ms

50 100 150 200 250

300

Output Voltage

as a Function

of Input Voltage

Vac

400 Vdc

350 Vdc

300 Vdc

250 Vdc

200 Vdc

150 Vdc

100 Vdc

50 Vdc

25

75 125

175 225

275

80 Vac

85 Vac

260 Vdc

152 Vac

Operating Region

250 Vac

264

Vac

46V

Boost

296

Vin x

2

1-800-735-6200

Figure 3 • Functional Timing Diagram

Active power factor correctors incorporate a

boost regulator which must operate over a range

of incoming AC line voltages. Conventionally,

the output voltage of the boost regulator is set

to a value greater than the maximum anticipated

peak value of the incoming AC line.

Vicor varies the output voltage of the HAM as

a function of incoming AC line voltage

(see Fig. 4, patent applied for). On a nominal

120Vac line the output voltage of the HAM is

260Vdc — well within the input operating

voltage range of standard Vicor converters.

As input line increases, so does the HAM

output voltage; at 220Vac the delivered voltage

will be about 350V. For any given input line

voltage, the HAM maintains enough headroom

between the output voltage and peak input

voltage to ensure high quality active power

factor correction without unnecessarily

sacrificing operating efficiency.

Figure 4 • Input Voltage vs. Output Voltage

VI-HAM Protection Features

Overtemperature Shutdown

The HAM incorporates overtemperature

shut-down, and is designed to shut down when

the temperature of the baseplate exceeds

90–100°C. It is not safe to run the HAM for

extended periods above its maximum operating

temperature of 85°C.

Short Circuit Protection

The HAM contains a short circuit shutdown

function. Operation of this function does not

clear the input fuse and the output will resume

normal operation after removal of the short. A

small period of time may be required to allow

for cooling of an internal PTC. Overcurrent

protection is provided by the Vicor DC-DC

converters.

Output Overvoltage Protection

The HAM contains output overvoltage

protection. In the event the output voltage

exceeds approximately 420Vdc, the boost will

decrease to maintain 420Vdc on the output.

When the peak of the AC line exceeds 420V

(approximately 293Vac) the boost will have

been reduced to zero. Beyond this the protection

circuit will be enabled and the output voltage

will decrease.

Pin Function Description

• L1 and L2/N (VI-HAM):

These pins are to be connected to the AC mains

output of a suitable EMI/RFI filter (Vicor

P/N 07818 or equivalent). Do not connect an

X capacitor across these pins as power factor

correction will be slightly degraded.

• +IN, –IN (VI-HAMD, VI-BAMD):

These pins are connected to the output of the external

bridge rectifier.

• Gate Input (VI-HAM):

This pin disables the boost converter only. Rectified

line current may still be present on the output. This pin

does not provide the same function as the gate input

pin of VI-200/VI-J00 modules. The user should not

make any connection to this pin.

• Gate Input (VI-HAMD):

This pin serves as a rectified AC following pin for

power factor correction synchronization to line. This

connection must be made through the synchronization

diodes between the line filter and bridge rectifier (see

Fig. 10, page 84).

• Gate Input (VI-BAMD):

The Gate Input pin is an interface pin to the Gate Out

pin of a VI-HAM, VI-HAMD or VI-BAMD depending

on configuration. The user should not make any other

connection to this pin.

• Gate Output:

The Gate Output pin is an interface pin to BAMDs;

the user should not make any other connection to

this pin.

• +Output and -Output and Holdup Capacitor:

These outputs should be connected to the respective

inputs of Vicor DC/DC converters. In addition, an

external holdup capacitor of 1000 µF with a minimum

voltage rating of 450Vdc, is required across the

output for 16 ms ride through time at 600W (500 µF

for 300W, etc). Do not exceed 3000 µF of total

output capacitance. Lower values of capacitance may

be used for reduced holdup requirements, but not less

than 330 µF. Lower capacitance values may degrade

power factor specifications.

• Auxiliary Supply (A/S):

The VI-HAM and VI-BAMD contain an internal low

voltage output (A/S) that may be used to power

primary side logic. This output is 19-23Vdc,

referenced to -OUT, at 3 mA max. Do not overload or

short this output as the HAM will fail. A typical use for

A/S is to power an optical coupler that isolates the

Power OK signal.

18 kΩ, 1/4W

A/S

≤ 3mA

-OUT

"Power OK" Status

Low = OK

+ OUT

P/OK

– OUT

E/O

A/S

19 - 23V

+

–

Figure 5 • Auxiliary Supply (A/S)

• Power OK (P/OK)

P/OK is a monitor signal that indicates the status of the

AC mains and the DC output voltage of the HAM.

P/OK, during normal operation, is an active low

(see Fig. 6). In the event AC mains or DC output fails,

this pin goes to an open circuit state. P/OK is asserted

when the output bus voltage is within normal operating

range and 20-25 ms after DC-DC converters are

enabled by the Module Enable output of the HAM.

This provides sufficient time for the converters to turn

on and their outputs to stabilize prior to P/OK being

asserted. When the AC mains is removed and the

output of the HAM drops below 230V, P/OK goes to

an open circuit state. When the output voltage drops

below 195V the converters are disabled via Module

Enable. P/OK will provide power fail warning at least

1 ms prior to converter shutdown.

P/OK

D

LOGIC

S

G

-OUT

Figure 6 • Power OK (P/OK)

• Module Enable (E/O)

The Module Enable output is used to disable the

DC-DC converters until there is sufficient energy in

the holdup capacitor (240V) to support normal

operation, while limiting inrush current. Module

Enable must be connected to the Gate Input of all

driver DC-DC converters. It is not necessary to

connect this pin to boosters as they are controlled by

their respective driver. If the AC mains fail, Module

Enable goes low when the DC output of the HAM

drops below 195V. Failure to connect Module Enable

may result in the output of the HAM latching low

during turn-on.

E/O

LOGIC

D

S

G

-OUT

Figure 7 • Enable/Output (E/O)

Page 3

12

VI-HAMD

Vac

VI-BAMD

Line Filter

VI-BAMD

1-800-735-6200

VI-HAM Protection Features

(continued)

Inrush Current Limit

The HAM contains inrush current protection

in the form of a PTC and a shunt device. The

same PTC is used for overcurrent protection

on the output.

Input Transient Overvoltage Surge Protection

This function is included in all HAM

compatible filters. If any other filter is used

this function must be provided externally,

typically by a transient suppressor.

• Safety Note •

All VI-HAM configurations must be

preceded by an appropriately rated fast-blow

3AG fuse ahead of the line filter. This fuse

would be a 10A for a single VI-HAM

connected to line. For fusing information on

other VI-HAM configurations, please contact

Vicor’s Application Engineering Department.

Compatible Modules

Over the full range of input voltages (85 to 264

Vac), the output varies from 260 to 415Vdc.

Therefore the modules used with the HAM are

from the VI-260 and VI-J60 families.

When ordering add the prefix VI- to the part

number below; i.e., VI-260-CU.

Filter Requirements for the VI-HAM

The VI-HAM requires an external filter to meet international standards for conducted

EMI/RFI emissions. P/N 07818 (for use up to 600W) incorporates transient protection

for compliance with IEC 61000-4-5 Level 3 and meets conducted emissions standards

EN55022 and FCC Part 15 Level A (minimum loading of 150W required).

VI-HAM Configurations

VI-HAM-CM Driver HAM: Fully configured power factor correcting front end.

VI-HAMD-CM Driver HAM: No internal bridge rectifier or synchronization diodes.

VI-BAMD-CM Booster HAM: Companion module to VI-HAMD-CM used for

additional output power. No internal bridge rectifier.

Use the VI-HAM-CM for applications requiring up to 600W from the front end.

For applications in excess of 600W, it is not possible to simply parallel two driver

HAMs due to conflicting control loops. Gate Out to Gate In connections on

respective driver/boosters are used to ensure that the power train of the HAMs

current-share. However, this does not ensure that the diodes in the lower half of the

bridge rectifier will current-share. A solution for this situation is illustrated (see Fig. 8).

VI-200 Family

5V 12V 15V 24V 48V Output

260-CU 261-CU 262-CU 263-CU 264-CU 200W

260-CV 261-CV 262-CV 263-CV 264-CV 150W

260-CW 261-CW 262-CW 263-CW 264-CW 100W

260-CX 261-CX 262-CX 263-CX 264-CX 75W

260-CY 261-CY 262-CY 263-CY 264-CY 50W

Framed area available as boosters.

Change VI-2XX-XX to VI-BXX-XX.

VI-J00 Family

5V 12V 15V 24V 48V Output

J60-CW J61-CW J62-CW J63-CW J64-CW 100W

J60-CX J61-CX J62-CX J63-CX J64-CX 75W

J60-CY J61-CY J62-CY J63-CY J64-CY 50W

J60-CZ J61-CZ J62-CZ J63-CZ J64-CZ 25W

Prod. Baseplate Storage Model

Grade Temp. Temp.

E -10°C to +85°C -20°C to +100°C VI-HAM-EM

C -25°C to +85°C -40°C to +100°C VI-HAM-CM

I -40°C to +85°C -55°C to +100°C VI-HAM-IM

M -55°C to +85°C -65°C to +100°C VI-HAM-MM

Figure 8 • VI-HAMD with Booster HAMs (BAMDs) — No Internal Bridge Rectifier

A solution to bridge rectifier current sharing issues is to remove the bridge rectifier

from each HAM and use one diode bridge sized to handle the entire load.

Approximately 25% of the heat is removed from the HAM in this approach; use a

VI-HAMD-CM with one or more VI-BAMD-CMs. Note: Synchronization diodes

are required when using this approach (see Fig. 10, page 84).

Page 4

12

1-800-735-6200

Specifications

VI-HAM and VI-HAMD With External Bridge and Synchronization Diodes, 1000 µF Output Capacitor and Vicor Line Filter P/N 07818.

VI-BAMD When Operated with VI-HAM and VI-HAMD, Respectively.

(Unless otherwise indicated, specifications apply over operating input voltage and temperature range)

Parameter VI-HAM VI-HAMD VI-BAMD Remarks

Line Input 85V to 264V 85V to 264V 85V to 264V Unit will operate from 400 Hz, but

47–63 Hz (Volts AC) (Rectified AC) (Rectified AC) may not meet PF or THD specs

Output Power Up to 600W Up to 600W Up to 600W Derate from 110Vac to 85 Vac @

Efficiency 90–91% 90-91% (With ext. rectifier loss) 90–91% (With ext. rectifier loss) 120Vac, full load

Efficiency 93–94% 93-94% (With ext. rectifier loss) 93–94% (With ext. rectifier loss) 240Vac, full load

Power Factor 0.99 0.99 0.99 120/240Vac, 50-100% of full load

Total Har. Distortion (line current)* <7.5% <7.5% <7.5% Sinusoidal, 120Vac, full load

Total Har. Distortion (line current)* <8.5% <8.5% <8.5% Sinusoidal, 240Vac, full load

Output Ripple 7V p-p 7V p-p 7V p-p 120Vac, full load

Output Ripple 5V p-p 5V p-p 5V p-p 240Vac, full load

Inrush Current <13A peak <13A peak <13A peak 120Vac, full load

Inrush Current <20A peak <20A peak <20A peak 240Vac, full load

Output Capacitance 500-3000 µF 500-3000 µF 500-3000 µF External to HAM (for 600W load)

Ride Through/Holdup Time 16 ms 16 ms 16 ms 600W output with a 1000 µF hold-

Transient Surge Withstand, Included in the Included in the Included in the

Normal Mode external filter external filter external filter

Isolation Voltage

Input to Output None None None Isolation provided

Input to Baseplate 1,500 VRMS 1,500 VRMS 1,500 VRMS by DC-DC converters

Output to Baseplate 1,500 VRMS 1,500 VRMS 1,500 VRMS

Auxiliary Output 19-23Vdc 19-23Vdc 19-23Vdc Note: Not short circuit protected

Thermal Shutdown 90°C-100°C baseplate 90°C-100°C baseplate N/A

Baseplate Temperature -10°C to +85°C (E Grade) -25˚C to +85˚C (C Grade) -40˚C to +85˚C (I-Grade) -55˚C to +85˚C (M-Grade)

Storage Temperature -40˚C to +100˚C (C Grade) -55˚C to +100˚C (I-Grade) -65˚C to +100˚C (M-Grade)

Short Circuit Protection Yes Yes Yes

MTBF (GB, 25˚C) >420,000 hours >424,000 hours >818,000 hours

Size 4.6" x 2.4" x 0.5" 4.6" x 2.4" x 0.5" 4.6" x 2.4" x 0.5"

Weight 6 Ounces (170 Grams) 6 Ounces (170 Grams) 6 Ounces (170 Grams)

* I

= HAM

THD

– V

THD

THD

Line current total harmonic distortion = input voltage distortion plus 8.5% max.

@ ≤3 mA @ ≤3 mA @ ≤10 mA

(116,8 x 61,0 x 12,7) (116,8 x 61,0 x 12,7) (116,8 x 61,0 x 12,7)

8W/Volt

(1000 µF Nom.)

up capacitor (300W = 500 µF, etc.)

Application of the VI-HAM

The HAM must be used in conjunction with a

suitable line filter, such as Vicor’s P/N 07818**,

output holdup capacitor and Vicor DC-DC

converters (see Fig. 9). Connect single phase

AC mains to the input of the line filter via a

standard 10A AC fuse. Connect the output of

the filter to L1 and L2/N of the HAM. Do not

put an X capacitor across the input of the

HAM or use a line filter with an X capacitor

on its output as power factor correction may

be impacted. Connect the +Output of the

HAM to the +Input of the converters via a 3A

PC Tron DC fuse. Connect the -Output of the

HAM to the -Input of the converters. Connect

a 1000 µF electrolytic capacitor rated at a

minimum of 450Vdc across the + and -Output

of the HAM (or 500 µF for 300W, etc). This

capacitor must be in close proximity to the

HAM. Connect the Enable Output of the

HAM to the Gate Input of each driver

converter to disable the converters until the

output of the HAM is within normal operating

range. Please refer to Vicor's Applications

Manual for information on the proper

connection of the DC-DC converters.

The aforementioned connections are the

minimum required. In addition, there are

other features available.

• The Auxiliary Supply output is approximately

21V at 3 mA max

. This output is usually used

in conjunction with the Power OK signal.

Power OK provides an indication of the

status of the DC output and the AC mains.

• The Enable Output of the HAM must be

connected to the Gate Input of all driver

modules. The HAM will then disable the

module output until the input exceeds 85Vac

and the output has been boosted to 260Vdc.

If an external load is connected directly to

the output of the HAM, do not apply the load

until the output of the HAM is in boost mode.

• Although the efficiency of the HAM is

quite high, it still dissipates significantly

more power than a VI-200 DC-DC converter.

Care should be taken to cool it. Thermal

compound should be used between the

heatsink and baseplate of the VI-HAM,

VI-HAMD and VI-BAMD.

• When making any connections to the

VI-HAM for measurement purposes,

remember that it is not isolated from the

line — either input or output. A line

isolation transformer must be used when

making scope measurements.

• The input voltage range of the VI-HAM is

85 to 264Vac; however it may not start

boosting until the AC mains has exceeded

87Vac. Once the VI-HAM has started, it will

operate down to 85Vac. The VI-HAM

contains 2.5 to 6V of input hysteresis,

therefore if the AC line impedance is high,

i.e., when using a variable autotransformer,

the VI-HAM may start, but the AC line may

then fall enough to drop below undervoltage

lockout. When this happens the AC line will

go up, the HAM starts and the cycle repeats.

Therefore avoid soft AC lines at or near

low line.

Page 5

12

Module

Output

Voltage

+IN

Vicor 26X or J6X

Family Converters

GATE IN

GATE OUT

-IN

260-400 Vdc

Up to 600W

Driver

L2/N

GATE

OUT

GATE

IN

L1

– OUT

E/O

+ OUT

A/S

P/OK

VI-HAM

GATE IN

GATE OUT

-IN

Booster (n)

Y-Capacitor

Y-Capacitor

PC-Tron

3A

+

+IN

+OUT

+OUT

-OUT

-OUT

+S

T

-S

L1

GND

L2/N

L1

LOAD

L2/N

Vicor

Line Filter

P/N 07818

6.3A

LINE

10A

24V

Zener

(1N4709)

PC-Tron

3A

PC-Tron

0.5A

MOV

P/N 03040

270µF HUB270-P 150W max

470µF HUB470-P 300W

870µF HUB870-P 450W

1100µF HUB1100-P 600W

1000 µF

Holdup Box (HUB) available as

accessory product through Vicor Express

Line Filter

12.6A*

+IN

GATE IN

GATE OUT

-IN

+OUT

-OUT

P/OK

E/O

A/S

HAMD

GATE IN

GATE OUT

-IN

+IN

+OUT

-OUT

BAMD

1000 µF @

450 Vdc

+

+

1000 µF @

450 Vdc

Input

Bridge

Rectifier

+

–

L1

GND

L2/N

L1

L2/N

1N4006

1N4006

N/C

N/C

A/S

* Please consult Vicor's Application Engineering Department

for specific VI-HAMD/VI-BAMD filtering information.

10A

10A

20A

MOV

P/N 03040

410V Transorb

1.5 KE 130CA

1.5 KE 130CA

1.5 KE 150CA

Product ID

this surface

FULL R

5

6

7

8

9

4

3

2

1

.040 (1,0) Dia (7) places

Solder plate

over copper alloy

.080 (2,0) Dia.

Solder plate

over copper alloy

.30 (7,6)

±.015 (0,38)

1.80

(45,7)

4.60 (116,8)

.15

(3,8)

2.10

(53,3)

.40

(10,2)

.35 (8,9)

±.015 (0,38)

1.40

(35,6)

1.00

(25,4)

.70

(17,8)

3.60 (91,4)

.50

(12,7)

.15

(3,8)

Pin #

1

2

3

4

5

6

7

8

9

HAM

L1

Gate In

Gate Out

L2/N

+Out

P/OK

E/O

A/S

–Out

HAMD

+IN

Gate In

Gate Out

–IN

+Out

P/OK

E/O

A/S

–Out

BAMD

+IN

Gate In

Gate Out

–IN

+Out

N/C

N/C

A/S

–Out

(2) places

VI-HAM

+.030 (0,76)

-.000

.01

.50 (12,7)

(5,6) MIN

4.20 (106,7)

.22

.12 (3,0)

.30 (7,6)

Min

Aluminum Base

2.40 (61,0)

1.75 (44,5)

1-800-735-6200

Connection Diagram, VI-HAM/DC-DC Converters

Figure 9 • VI-HAM Connection Diagram

Connection Diagram, VI-HAMD/VI-BAMD

Figure 10 • VI-HAMD/BAMD Connection Diagram

VI-HAM /HAMD /BAMD Mechanical Diagram

Page 6

12

1-800-735-6200

Typical HAM Filter Applications

Operating voltage = 85 to 250Vac

Operating current = 6.3A

Operating frequency = 50/60 Hz

Operating temperature = 20 to 50˚C

Diel. withstanding (line - case) = 1500Vac

Diel. withstanding (line - line) = 1500Vac

Leakage current = 1.0 ma at 220Vac, 50 Hz

Max residual voltage after 1 sec. = 34V

Agency approvals = UL, CSA, TÜV

MOV

P/N 03040

LINE

R

Cx = 1.5uF(x2)SH Cy = .01uF SH LC = 6.9mH LD = .72mH

LD

C

x

HAM Filter P/N 07818

R = 235K OHM D1,2 = 1.5KE130CA D3 = 1.5KE150CA

LC

D1

C

y

D2

C

y

D3

LOAD

RATED CURRENT VS AMBIENT TEMPERATURE

90

80

70

60

50

OPERATING TEMP (DEG C)

40

1.0 2.0 3.0 4.0 5.0 6.0 7.0

CURRENT (AMPS)

HAM Filter Mechanical Diagram

4-40 INSERT

.25 DP 4 PL

4.60±.02

2.50

1.200

90

80

70

60

50

40

30

20

INSERTION LOSS (db)

10

0

.01 .04 .1 .4 1 4 10 40 100

.02 .07 .2 .7 2 7 20 70

ø.080 PIN

6 PLACES

DM

CM

FREQUENCY (MEGAHERTZ)

SEE

.060

NOTE 1

2.40

±.02

2.00

.100

LINE

.500 .500

1.45

2.800

LOAD

.900

1.800

.30±.02

FACE MAY BE

BOWED .04 MAX

.13±.02

'

'

1.00

MAX

VICOR

LABEL

SEE NOTE 2

Loading...

Loading...