Page 1

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 1 of 12

Set your site on VICOR at www.vicorpower.com

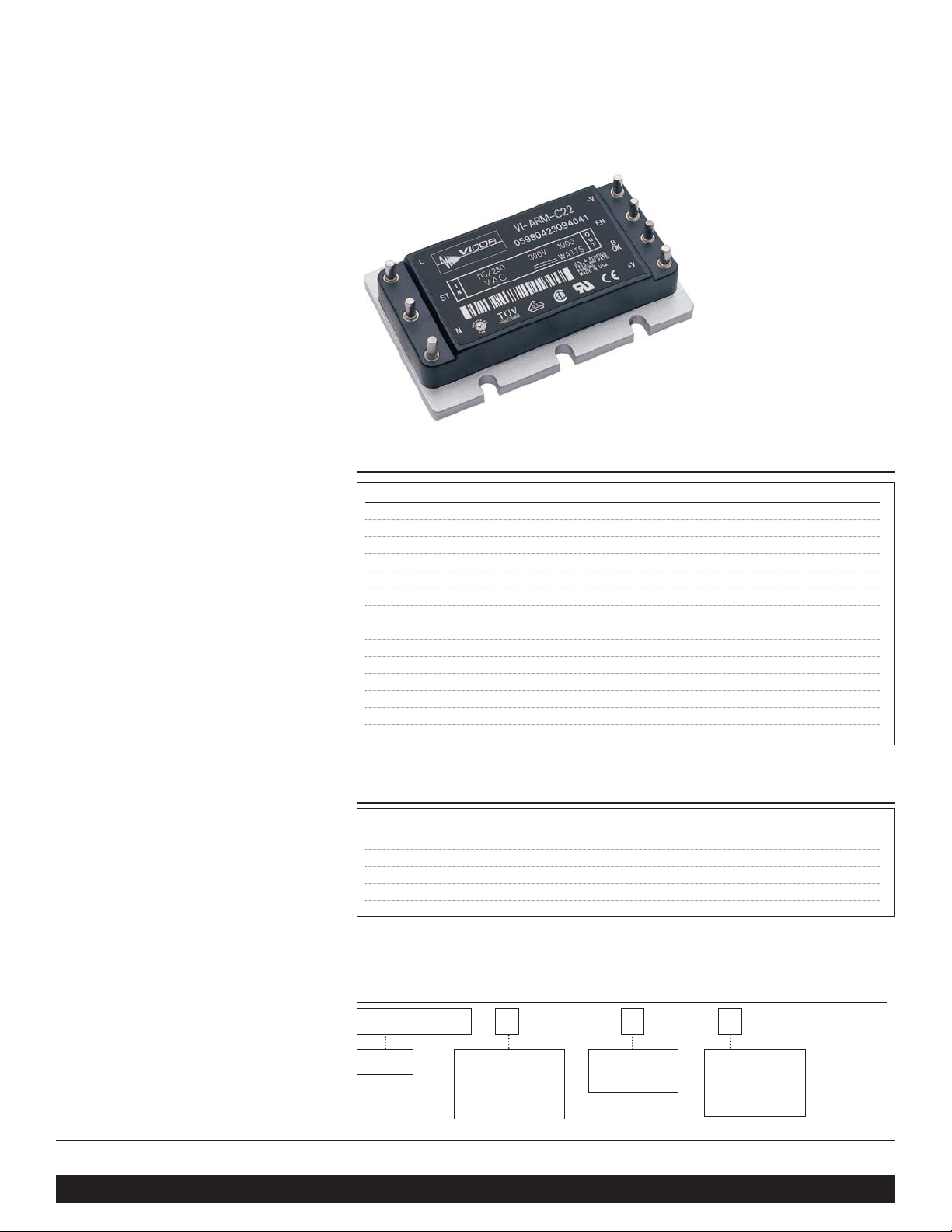

VI-ARM

TM

Autoranging Rectifier Modules

Up to 1500 Watts

45

Features

• Autoranging input

• Microprocessor controlled

• VI-ARM-1

500 Watts @ 90-132Vac

750 Watts @ 180-264Vac

• VI-ARM-2

1000 Watts @ 90-132Vac

1500 Watts @ 180-264Vac

• 96-98% Efficiency

• 100˚C baseplate (no derating)

• UL, CSA, TÜV, VDE, BABT

• AC Bus OK, module enable

• Inrush limiting (no external circuitry)

• CE Marked

Typical Applications: systems requiring a

rugged, full featured interface to the AC

mains in the smallest possible package.

Product Highlights

The ARM (Autoranging Rectifier Module)

is an AC front end module which provides

autoranging line rectification and inrush

current limiting. The ARM is available in

either 500/750W or 750/1000W models in a

mini sized package measuring only 2.28" x

1.45" x 0.5".

The ARM interfaces directly with

worldwide AC mains and may be used with

Vicor 1st or 2nd Generation 300V input

DC-DC converters to realize an

autoranging, high density, low profile

switching power supply. The ARM includes

a microcontroller that continuously

monitors the AC line to control

bridge/doubler operation. The user need

only provide external capacitance to satisfy

system hold-up requirements.

Vicor 2nd Generation packaging technology

offers flexible mounting options for various

manufacturing processes. The ARM may be

installed as a conventional leaded device

for on-board applications, in-board for low

profile, height restricted applications,

socketed or surface mounted with optional

ModuMate interconnect products.

Actual size:

2.28 x 1.45 x 0.5 in

57,9 x 36,8 x 12,7 mm

Parameter Rating

VI-ARM-1/VI-ARM-2 Unit Notes

L to N 264 Vac

L to N 280 Vac 100ms

+Out to –Out 400 Vdc

B OK to –Out 16 Vdc

EN to –Out 16 Vdc

Output power 500/1000 Watts 90-132Vac

750/1500 Watts 180-264Vac

Mounting torque 4 - 6 (0.45 -0.68) in- lbs (N-m) 6 each, 4-40 screw

Pin soldering temperature 500 (260) °F (°C) <5 sec; wave solder

Pin soldering temperature 750 (390) °F (°C) <7 sec; hand solder

Storage temperature, C–,& T– Grade –40 to +125 °C Baseplate

Operating temperature, C–Grade –20 to +100 °C Baseplate

Operating temperature, T– Grade –40 to +100 °C Baseplate

Parameter Typ Unit

Baseplate to sink; flat, greased surface 0.24 °C/Watt

Baseplate to sink; with thermal pad (P/N 16495) 0.3 °C/Watt

Baseplate to ambient- free convection 15 °C/Watt

Baseplate to ambient; 1000 LFM- forced air 2.7 °C/Watt

Thermal capacity 48 Watt-sec/°C

Product

Type

1 = 500/1000W

2 = 750/1500W

Pin Style*

1 = Short

2 = Long

S=Short Modumate

N=Long Modumate

Product Grade

C = –20°C to +100°C

T = –40°C to +100°C

H = –40°C to +100°C

M = –55°C to +100°C

Thermal Resistance and Capacity

Absolute Maximum Ratings

Part Numbering

*Pin styles S & N are compatible with the ModuMate interconnect system for socketing and surface mounting.

VI-ARM- C 1 2

Page 2

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 2 of 12

Set your site on VICOR at www.vicorpower.com

VI-ARM - 1 VI-ARM - 2

Parameter Min Typ Max Min Typ Max Unit Notes

Operating input voltage 90 132 90 132 Vac Autoranging (doubler mode)

Operating input voltage 180 264 180 264 Vac Autoranging (bridge mode)

Input undervoltage 90 90 Vac No damage

Input surge withstand 280 280 Vac 100ms

AC line frequency 47 63 47 63 Hz C-Grade

AC line frequency 47 880 47 880 Hz T-Grade

Input current, rms 0 7.4 0 14.8 Amps 120Vac

Input current, rms 0 5.4 0 10.8 Amps 240Vac

Power factor 0.60 0.60 Typical line voltage condition

Inrush current 30 60 Amps 264Vac peak line, cold start

Holdup capacitance 1600 3300 µF

SAFETY SPECIFICATIONS

MODULE INPUT SPECIFICATIONS

MODULE OUTPUT SPECIFICATIONS

Electrical Characteristics

Electrical characteristics apply over the full operating range of input voltage, output load (resistive) and baseplate temperature,

unless otherwise specified. All temperatures refer to the operating temperature at the center of the baseplate. Specifications apply

for AC mains having up to 5% total harmonic distortion.

VI-ARM - 1 VI-ARM - 2

Parameter Min Typ Max Min Typ Max Unit Notes

Output power 0 500 0 1000 Watts 90-132Vac

Output power 0 750 0 1500 Watts 180-264Vac

Efficiency, 120Vac 94 96 94 96 %

Efficiency, 240Vac 96 98 96 98 %

Output voltage 200 375 200 375 Vdc 90-264Vac

Parameter Min Typ Max Unit Notes

Agency approvals

UL 1950, CSA 22.2 No.950,

TÜV, VDE, EN60950, CE Marked

Isolation voltage (in to out) None Isolation provided by DC-DC converter(s)

Isolation voltage (I/O to baseplate) 1500 Volts, rms

Leakage current 100 µA No filter

Page 3

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 3 of 12

Set your site on VICOR at www.vicorpower.com

Electrical Characteristics, continued

MODULE CONTROL SPECIFICATIONS

MODULE GENERAL SPECIFICATIONS

Parameter Min Typ Max Unit Notes

AC Bus OK (B OK)

On-state resistance (low) 15 Ω To negative output - bus normal

On-state current (low) -50 mA Bus normal

Off-state voltage 14.8 15.0 15.2 Vdc Bus abnormal, 27K internal pull up to 15Vdc (Fig. 10)

On-state threshold 235 240 245 Vdc Output bus voltage

Off-state threshold 200 205 210 Vdc Output bus voltage

Module Enable (EN)

On-state resistance (low) 15 Ω To negative output - converters are disabled

On-state current (low) 50 mA

Off-state voltage 14.8 15.0 15.2 Vdc 150K internal pull up to 15Vdc (Fig. 9)

On-state threshold 235 240 245 Vdc Output bus voltage

Off-state threshold 200 205 210 Vdc Output bus voltage

Over voltage shutdown 380 390 400 Vdc

AC Bus OK - module enable, differential error* 15 17 20 Vdc AC Bus OK and module enable thresholds track

Parameter Min Typ Max Unit Notes

MTBF >1,000,000 hours 25˚C, ground benign

Baseplate material Aluminum

Cover Polyetherimide

Pin material Copper, tin/lead solder dipped

Weight 2.1 (60) ounces (grams)

Size

2.28 x 1.45 x 0.5 inches

(57,9 x 36,8 x 12,7) (mm)

* Tracking error between BUS OK and Enable thresholds

Page 4

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 4 of 12

Set your site on VICOR at www.vicorpower.com

Operating Characteristics

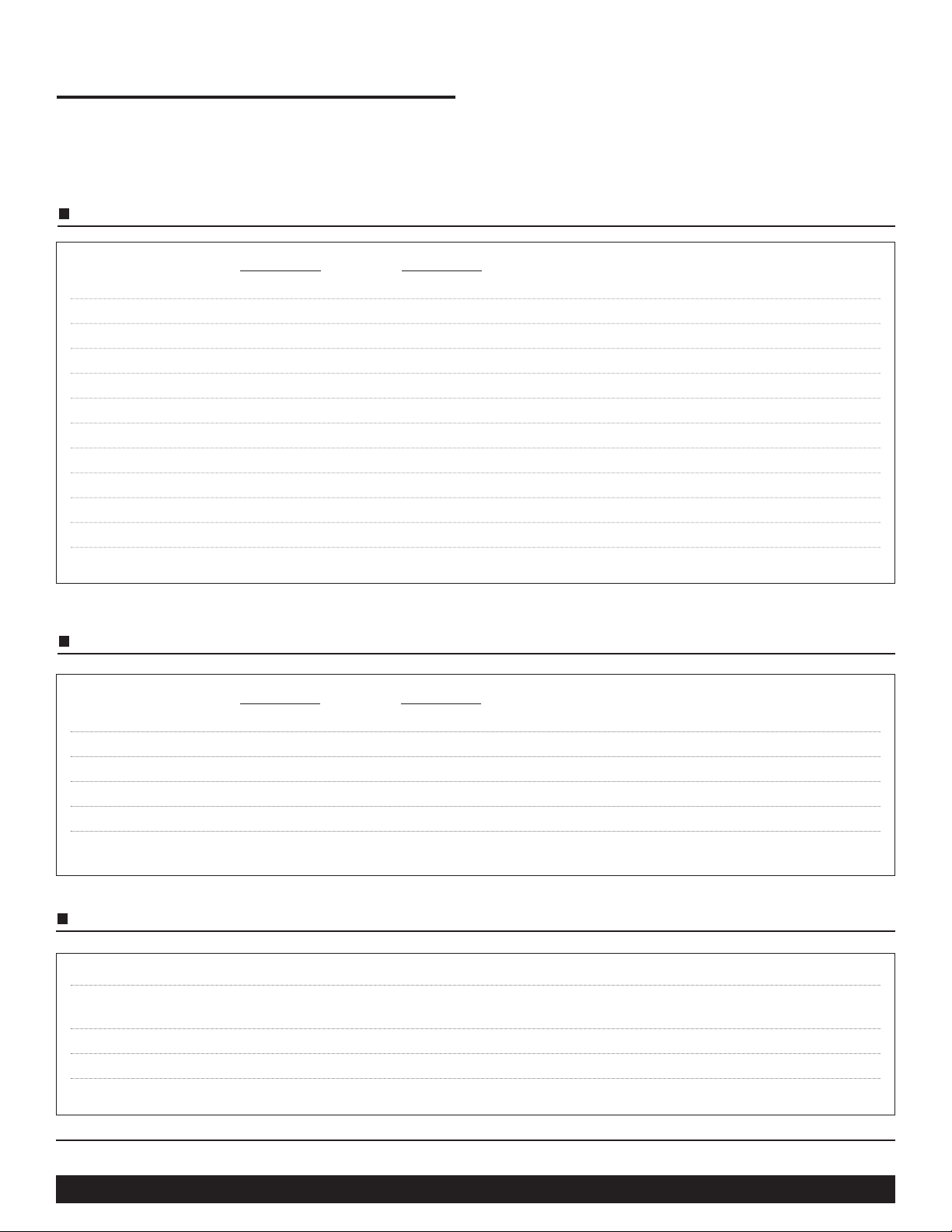

Figure 1—Start-up at 120Vac input

Figure 3—Power down, from 120Vac Figure 4—Power down, from 240Vac

Figure 2—Start-up at 240Vac input

Vdc output

Strap

Engaged

Iac input @2A / mV

Iac input @2A / mV

Enable

Enable

B OK

Vdc output

Enable

B OK

Vdc output

Enable

B OK

Vdc output

Enable

B OK

Figure 5—Output overvoltage protection 240Vac range

Vdc output

Enable

B OK

➞

Page 5

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 5 of 12

Set your site on VICOR at www.vicorpower.com

The VI-ARM Autoranging Rectifier Module (ARM) provides

an effective solution for the AC front end of a power supply

built with Vicor DC-DC converters. This high performance

power system building block satisfies a broad spectrum of

requirements and agency standards.

The ARM contains all of the power switching and control

circuitry necessary for autoranging rectification, inrush current

limiting, and overvoltage protection. This module also provides

converter enable and status functions for orderly power

up/down control or sequencing. To complete the AC front end

configuration, the user needs only to add holdup capacitors and

a suitable input filter with transient protection.

Functional Description

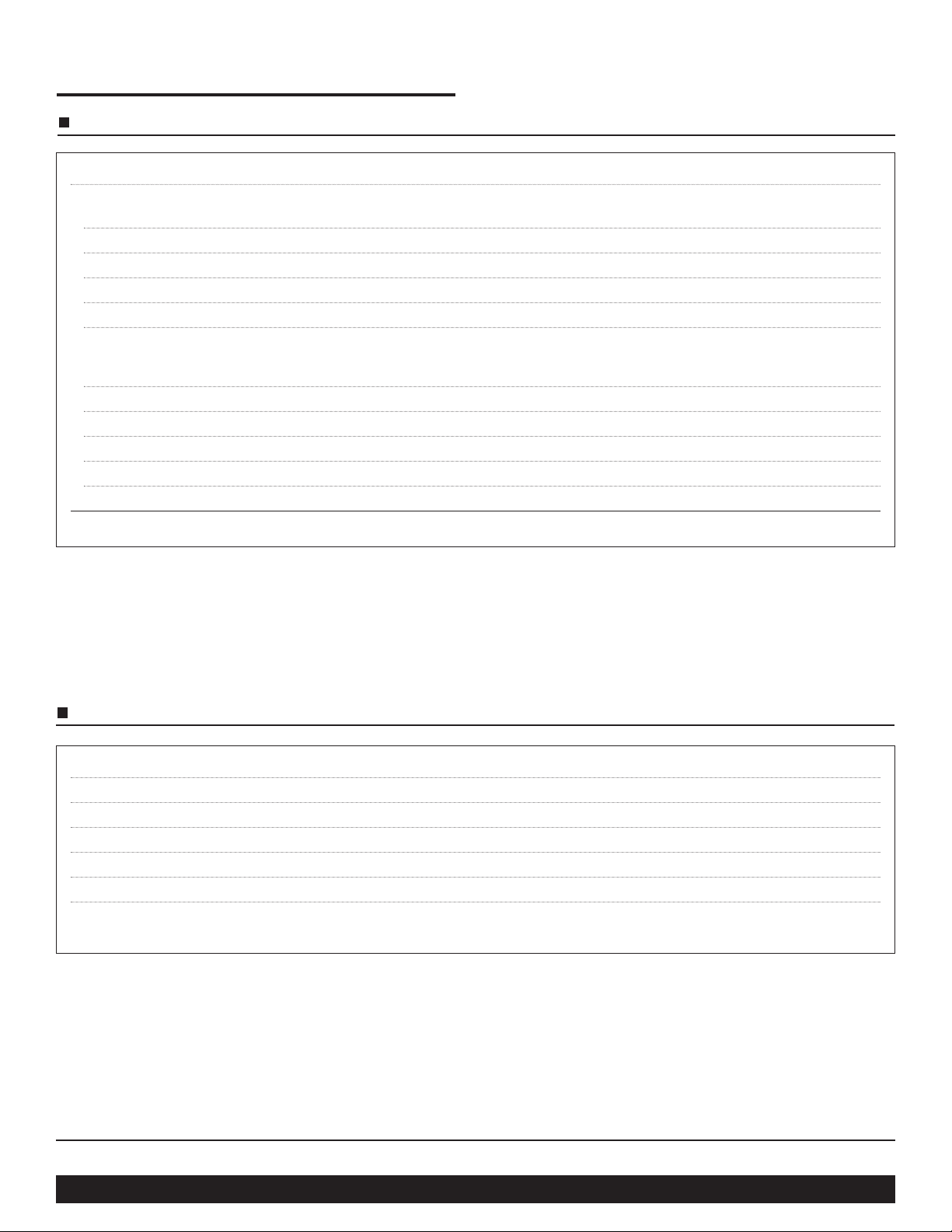

The switch that bypasses the inrush limiting PTC (positive

temperature coefficient) thermistor is open when power is

applied, as is the switch that engages the strap for voltage

doubling. (

See Fig. 6). In addition, the converter modules are

disabled via the Enable (EN) line, and Bus-OK (B OK) is high.

Power-Up Sequence. (See Fig. 7).:

Upon application of input power, the output bus capacitors

begin to charge. The thermistor limits the charge current,

and the exponential time constant is determined by the

holdup capacitor value and the thermistor cold resistance.

The slope (dv/dt) of the capacitor voltage approaches

zero as the capacitors become charged to the peak of the

AC line voltage.

If the bus voltage is less than 200V as the slope nears

zero, the voltage doubler is activated, and the bus voltage

climbs exponentially to twice the peak line voltage.

If the bus voltage is greater than 200V, the doubler is

not activated.

If the bus voltage is greater than 235V as the slope

approaches zero, the inrush limiting thermistor is

bypassed. Below 235V, the thermistor is not bypassed.

The converters are enabled 50 milliseconds after the

thermistor bypass switch is closed.

Bus-OK is asserted after an additional 50 millisecond

delay to allow the converter outputs to settle within

specification.

Power-Down Sequence. (See Fig. 7). When input power is

turned off or fails, the following sequence occurs as the bus

voltage decays:

Bus-OK is deasserted when the bus voltage falls below

205Vdc (Typ.).

The converters are disabled when the bus voltage falls

below 200Vdc. If power is reapplied after the converters

are disabled, the entire power-up sequence is repeated. If

a momentary power interruption occurs and power is

reestablished before the bus reaches the disable threshold,

the power-up sequence is not repeated.

Application Note

Figure 6—Functional block diagram

Figure 7—Timing diagram: power up/down sequence

1.1

2.1

3.1

4.1

5.1

1.2

2.2

Power

400

300

200

100

Up

1. 1

0

2.1

3.1

50ms

4.1

5.1

50ms

+Out

PTC

L

Thermistor

N

Microcontroller

Strap

Strap

–Out

EN

BOK

90–132V

AC Line

Output

Bus

(Vdc)

Strap

PTC

Thermistor

Bypass

Converter

Enable

Bus OK

Power

Down

2.2

1.2

Page 6

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 6 of 12

Set your site on VICOR at www.vicorpower.com

Figure 8—Converter connections

Application Note, continued

Off-Line Power Supply Configuration

The ARM maintains the DC output bus voltage between 200

and 375Vdc over the entire universal input range, which is

compatible with Vicor VI-260 series and VI-J60 series DC-DC

converters, as well as next-generation 300V input Vicor

converters. The ARM automatically switches to the proper

rectification mode (doubled or undoubled) depending on the

input voltage, eliminating the possibility of damage due to

improper line connection. The ARM–1 is rated at 500W in the

low range (90-132Vac input), and 750W in the high range

(180-264Vac input). The ARM–2 is rated for 1000W and

1500W for the low and high input ranges respectively. Either

of these modules can serve as the AC front end for any number

and combination of compatible converters as long as the

maximum power rating is not exceeded.

Strap (ST) Pin. In addition to input and output power pin

connections, it is necessary to connect the Strap pin to the

junction of the series holdup capacitors (

C1, C2, Fig. 8)

for proper (autoranging) operation. Gas tubes across the

capacitors provide input transient protection. The bleeder

resistors (

R1, R2, Fig. 8) discharge the holdup capacitors when

power is switched off.

Enable (EN) Pin. (See Fig. 9). The Enable pin must be

connected to the Gate-In or PC pin of all converter modules to

disable the converters during power-up. Otherwise, the

converters would attempt to start while the holdup capacitors

were being charged through an unbypassed thermistor,

preventing the bus voltage from reaching the thermistor

bypass threshold thus disabling the power supply. The Enable

output (the drain of an N channel MOSFET) is internally

pulled up to 15V through a 150kΩ resistor.

A signal diode should be placed close to and in series with the

Gate-In pin of each converter to eliminate the possibility of

control interference between converters. The Enable pin

switches to the high state (15V) with respect to the negative

output power pin to turn on the converters after the power-up

inrush is over. The Enable function also provides input

overvoltage protection for the converters by turning off the

converters if the DC bus voltage exceeds 400Vdc. The

thermistor bypass switch opens if this condition occurs,

placing the thermistor in series with the input voltage, which

reduces the bus voltage to a safe level while limiting input

current in case the gas tubes fire. The thermistor bypass switch

also opens if a fault or overload reduces the bus voltage to less

than 180Vdc.

Holdup Box (HUB)

820µF HUB820-S, 2200µF HUB2200-S

1200µF HUB1200-S, 2700µF HUB2700-S

1800µF HUB1800-S, 3300µF HUB3300-S

N

Filter

Z1

Part

C1,2

C3–6

R1,2

V1,2

F1,2

D1,2

*

C7,8

Z1

D3,D4

C10,C11

R3

Sizing PCB traces:

All traces shown in bold carry significant

current and should be sized accordingly.

VI-ARM- _12

N/ST/L

+/– In

*

VI-ARM- _22

N/ST/L

+/– In

Required if C1 & C2 are located more than

6 inches from output of VI-ARM.

ST

L

Description

Holdup capacitors

4700pF

150kΩ, 0.5W

220V MOV

3A, PC Tron

Diode

Film Cap., 0.8µf

MOV

1N5817

0.001µF

500Ω

10A rms at 90Vac and 500W

4A DC at 190Vdc and 750W

20A rms at 90Vac and 1000W

8A DC at 190Vdc and 1500W

VI-ARM

Vicor

Part Number

see text

01000

00127-1503

13755

02178

00670

03040

26108

+V

BOK

EN

–V

R1R2C1

V1

C7*

C8*

V2

R3

D1

D2

To additional modules

C2

D4

C3

F1

D3

F2

C10

C11

C4

C5

C6

+In

Gate In (PC)

Gate Out (PR)

–In

+In

Gate In (PC)

Gate Out (PR)

–In

Vicor DC-DC

Converter

Vicor DC-DC

Converter

Page 7

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 7 of 12

Set your site on VICOR at www.vicorpower.com

Application Note, continued

o

D

r

Figure 9—Enable (EN) function; See Fig.8 for details

D

o

Figure 10—Bus OK (B OK) isolated power status indicator

Figure 11—Filter connections

Bus-OK (B OK) Pin. (See Fig. 10). The Bus-OK pin is

intended to provide early-warning power fail information

and is also referenced to the negative output pin.

Caution: There is no input to output isolation in the ARM.

It is necessary to monitor Bus-OK via an optoisolator if it is to

be used on the secondary (output) side of the converters. Aline

isolation transformer should be used when performing scope

measurements. Scope probes should never be applied

simultaneously to the input and output as this will destroy the unit.

Filter. Two input filter recommendations are shown for low

power VI-ARM-1 and high power VI-ARM-2 (

See Fig. 11).

Both filter configurations provide sufficient common mode and

differential mode insertion loss in the frequency range between

100kHz and 30MHz to comply with the Level B conducted

emissions limit.

Hold-up Capacitors. Hold-up capacitor values should be

determined according to output bus voltage ripple, power fail

hold-up time, and ride-through time. (See Fig. 12). Many

applications require the power supply to maintain output

regulation during a momentary power failure of specified

duration, i.e., the converters must hold-up or ride-through such

an event while maintaining undisturbed output voltage

regulation. Similarly, many of these same systems require

notification of an impending power failure in order to allow time

to perform an orderly shutdown.

The energy stored on a capacitor which has been charged to

voltage V is:

ε = 1/2(CV

2

) (1)

Where: ε = stored energy

C = capacitance

V= voltage across the capacitor

Energy is given up by the capacitors as they are discharged by

the converters. The energy expended (the power-time product)

is:

ε = P∆t = C(V

1

2

–V

2

2

) / 2 (2)

Where: P = operating power

∆t = discharge interval

V

1

= capacitor voltage at the beginning of ∆t

V

2

= capacitor voltage at the end of ∆t

Rearranging equation 2 to solve for the required capacitance:

C = 2P∆t / (V

1

2

–V

2

2

) (3)

High power filter connections

Low power filter connections

Vicor

DC-DC

Converter

Vicor

DC-DC

Converter

+In

N

ST

L

150kΩ

Micro-

controller

15Vdc

+V

BOK

EN

–V

To additional modules

Gate In (PC)

Gate Out (PR)

–In

+In

Gate In (PC)

Gate Out (PR)

–In

N

ST

L

Micro-

controller

27kΩ

15Vdc

+V

BOK

EN

–V

+5 Vdc

Secondary

referenced

To additional modules

Vic

DC-

Conve

C

R1

L2/N

L1

GND

Z1

F1

L2

R2

L1

C1

L3

R3

Vicor

Description

1.0µF

4700pF

0.15µF

12A fuse

27µH

1.3mH

10Ω

150kΩ, 0.5W

2.2Ω

MOV

Part Number

02573

01000

03269

05147

14563

15016

00127-1503

03040

C2

R4

C3

C4

Part

C1

N

C2, C3

ST

C4

F1

L

L1, L2

L3

R1, R2

R3

R4

Z1

R2

10

L2/N

GND

C1

390K

Z1

L1

F1

R1

1/2W

1/2W

L3

L1

L2

4700pF

4700pF

N

C6

.22µF

ST

(X2)

L

Vicor

Part Number

02134

11479

02573

03285

04068

L4

C4

4700pF

C5

4700pF

Description

1000µH 12A/6.5MΩ

22µH

.68µf (x type)

4700pf

.22µf (x type)

1

/

W

390k

2

10Ω 1/

W

2

17A/250V

MOV 03040

C3

C2

Part

L1,L4

L2, L3

C1

C2,C3,C4,C5

C6

R1

R2

F1

Z1

Page 8

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 8 of 12

Set your site on VICOR at www.vicorpower.com

Application Note, continued

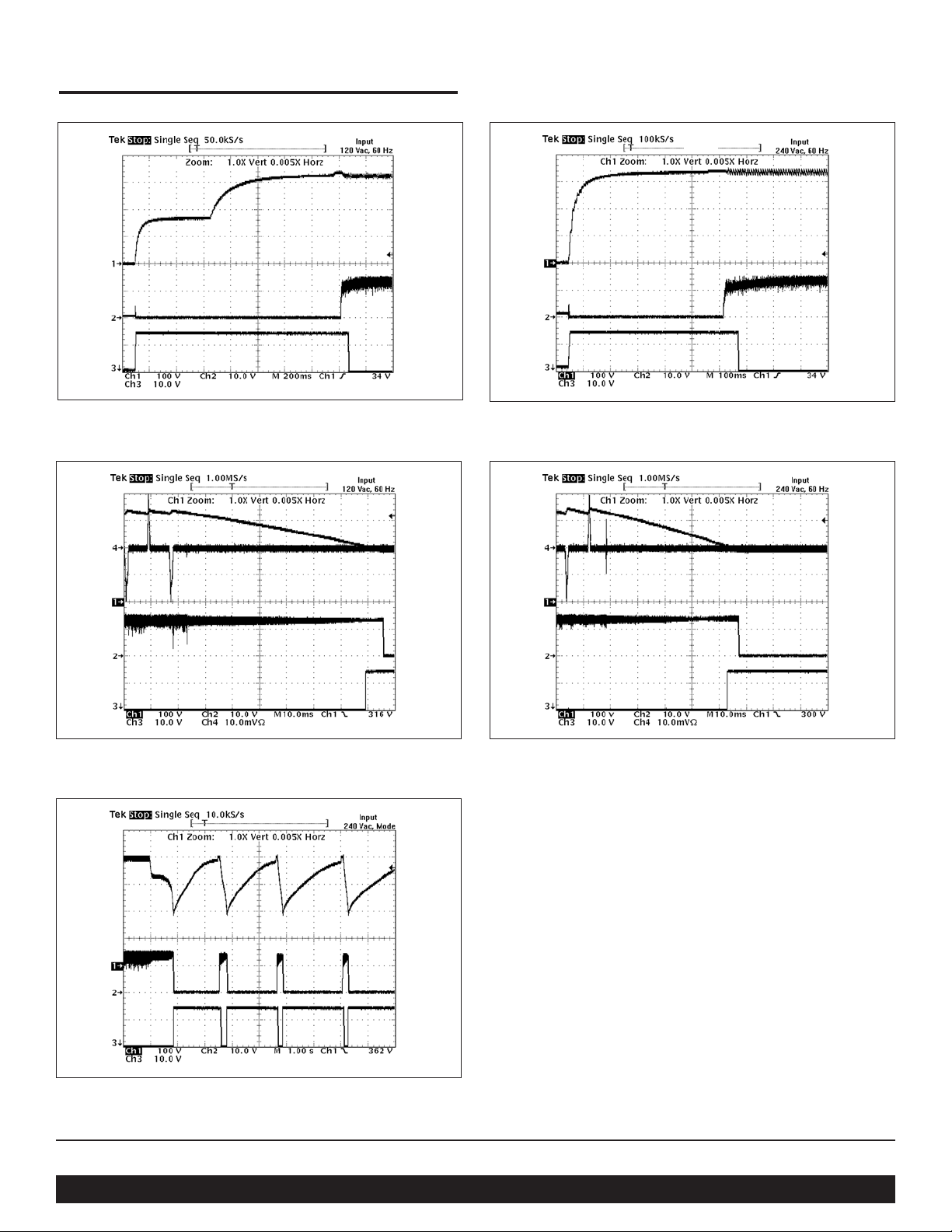

Figure 13—Hold-up time vs. operating power and total bus

capacitance, series combination of C1, C2 (Fig. 8)

Figure 15—Ripple voltage vs. operating power and bus

capacitance, series combination of C1, C2 (see Fig. 8)

Figure 14—Ride-through time vs. operating power

Figure 12—Hold-up time

The holdup time (∆t) is defined as the interval between power

fail warning (B OK) and converter shutdown (EN) as illustrated

in Fig. 12. The Bus-OK and Enable thresholds are 205V and

185V, respectively. A simplified relationship between hold-up

time, operating power, and bus capacitance is obtained by

inserting these constants:

C = 2P∆t / (205

2

– 1852)

C = 2P∆t / (7,800)

It should be noted that the series combination (

C1, C2, Fig. 8)

requires each capacitor to be twice the calculated value,

but the required voltage rating is reduced to 200V.

Allowable ripple voltage on the bus (or ripple current in the

capacitors) may define the capacitance requirement.

Consideration should be given to converter ripple rejection and

resulting output ripple voltage. The ripple rejection (R) of many

Vicor converters is specified as a function of the input/output

voltage ratio:

R = 30 + 20log(Vin / Vout) (4)

For example, a converter whose output is 15V and nominal

input is 300V will provide 56dB ripple rejection, i.e., 10V p-p

of input ripple will produce 15mVp-p of output ripple. (

See

Fig. 16) Equation 3 is again used to determine the required

capacitance. In this case, V

1

and V2are the instantaneous

values of bus voltage at the peaks and valleys (see Fig. 12) of

the ripple, respectively. The capacitors must hold up the bus

voltage for the time interval (∆t) between peaks of the rectified

line as given by:

∆t = (π – θ) / 2πf (5)

Where: f = line frequency

θ = rectifier conduction angle

The approximate conduction angle is given by:

θ = Cos-1V2/V

1

(6)

Ripple (V p-p)

π –θθ

Power

Fail

Hold-up Time

Ride-Thru Time

B OK

Power Fail

Warning

Converter

Shutdown

254V

205V

185V

40

35

30

25

20

15

10

AC Fail Warning Time (ms)

5

0

1100µF

*

Operating Power (W)

820µF

*

*

2200µF1600µF1300µF

680µF

(Arm-2)

(Arm-1)

150012501000750500250

100

90

80

70

60

50

40

30

Hold up Time (ms)

20

10

0

Operating Power (W)

Total

capacitance

820µF

90Vac 115Vac

150012501000750500250

30

25

20

*

*

15

10

P-P Ripple Volts (V)

5

0

1100µF

Operating Power (W)

820µF

*

680µF

2200µF1600µF1300µF

(Ver. 12)

(Ver. 22)

150012501000750500250

Page 9

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 9 of 12

Set your site on VICOR at www.vicorpower.com

Application Note, continued

Figure 16—Converter ripple rejection vs. output voltage

Determining Ripple Voltage on the Hold-up Capacitors.

Fig. 15 is used to determine ripple voltage as a function of

operating power and bus capacitance, and shows that the ripple

voltage across the hold-up capacitors will be 12Vac.

Determining the Ripple on the Output of the

DC-DC Converter. Fig. 16 is used to determine the ripple

rejection of the DC-DC converter and indicates a ripple

rejection of approximately 60 dB for a 12 Volt output. If the

ripple on the bus voltage is 12Vac and the ripple rejection of

the converter is 60 dB, the output ripple of the converter due to

ripple on its input (primarily 120Hz) will be 12 mV p-p.

Note that 2nd Generation converters have greater ripple

rejection then either VI-200s or VI-J00s.

For more information about designing an autoranging AC

input power supply using the ARM and Vicor DC-DC

converter modules, contact Vicor Applications Engineering at

the nearest Vicor Technical Support Center (see back cover),

or send an E-mail to apps@vicr.com.

• • •

Another consideration in hold-up capacitor selection is their

ripple current rating. The capacitors’rating must be higher than

the maximum operating ripple current. The approximate

operating ripple current (rms) is given by:

Irms = 2P/Vac (7)

Where: P = operating power level

Vac = operating line voltage

Calculated values of bus capacitance for various hold-up time,

ride-through time, and ripple voltage requirements are given as

a function of operating power level in Figures 13, 14, and 15,

respectively.

Example

In this example, the output required at the point of load is 12Vdc

at 320 Watts. Therefore, the output power from the ARM would

be 375 Watts (assuming a converter efficiency of 85%). The

desired hold-up time is 9 ms over an input range of 90 to 264Vac.

Determining Required Hold-up Capacitance. Fig. 13 is used

to determine hold-up capacitance for a given hold-up time and

power level, and shows that the total bus capacitance must be

at least 820µF. Since two capacitors are used in series, each

capacitor must be at least 1,640µF. Note that hold-up time is

not dependent on line voltage.

Determining Ride-through Time. Figure 14 illustrates ridethrough time as a function of line voltage and output power,

and shows that at a nominal line of 115Vac, ride-through would

be 68 ms. Ride-through time is a function of line voltage.

80

75

70

65

60

55

50

Ripple Rejection (dB)

45

40

Output Voltage

50301552

Page 10

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 10 of 12

Set your site on VICOR at www.vicorpower.com

Converter Pins

No. Function Label

1 –Out –V

2 Enable EN

3 Bus OK B OK

4+Out+V

5 Neutral N

6 Strap ST

7 Line L

Mechanical Drawings

PCB MOUNTING SPECIFICATIONS

23

617

4

5

PLATED

THRU HOLE

DIA

±0,08

*DENOTES TOL = ±0.003

0.133

3,38

1.734**

44,04

.400*

10,16

1.140**

28,96

0.170*

4,32

0.800*

20,32

0.525*

13,34

0.275*

6,99

2.000*

50,80

0.06

1,5

R (4X)

INBOARD

SOLDER

MOUNT

PIN STYLE 1&S

0.094 ±0.003

2,39 ±0,08

0.43

10,9

(7X)

**PCB WINDOW

PCB THICKNESS

0.062 ±0.010

1,57 ±0,25

0.53

13,5

ONBOARD

SOLDER

MOUNT

PIN STYLE 2&N

0.094 ±0.003

2,39 ±0,08

PINS STYLES

STYLE 1 & 2: TIN/LEAD

HOT SOLDER DIPPED

STYLE S & N: GOLD PLATED COPPER

ALUMINUM

BASEPLATE

ALL MARKINGS

THIS SURFACE

MODULE OUTLINE

Unless otherwise specified,

dimensions are in inches

mm

Decimals Tol. Angles

0.XX ±0.01

±0,25 ±1°

0.XXX ±0.005

±0,127

0.50 ±0.02

12,7 ±0,5

Slotted (Style 1)

Slotted (Style 1)

or

or

Threaded (Style 2)

4-40 UNC-2B (6X)

or

Thru Hole (Style 3)

#30 Drill Thru (6X)

(0.1285)

0.235±.015

5,97±0,38

(REF)

0.350±.015

8,89±0,38

(REF)

(REF)

0.21

5,2

0.525

13,34

0.275

6,99

(ALL MARKINGS THIS SURFACE)

0.400

10,16

0.800

20,32

1.04

26,4

1.45

36,8

style 2 & 3

baseplates only

(4X)***

4321

2.000

50,80

567

* Style 1 baseplate only

** Style 2 & 3 baseplates

*** Reserved for Vicor accessories

Not for mounting

0.490 ±.015

12,45 ±0,38

0.080

DIA. (7X)

2,03

0.12*

3,1

(REF)

0.20**

5,08

0.01

0.27

(2X)

6,9

ALUMINUM

BASEPLATE

0.43

10,9

0.54

(7X)

13,7

0.62

(7X)

15,7

2.28

57,9

Pin Style 1&S

(Short Pin)

Pin Style 2&N

(Long Pin)

0.49

12,4

0.65

16,5

1.30

33,0

0.06

R (3X)

1,5

1.27

32,3

1.45

36,8

(REF.)

0.09

2,3

0.10

X 45˚

2,5

CHAMFER

FULL R (6X)

0.13

3,3

Use a

4-40 Screw (6x)

Torque to:

5 in-lbs

0.57 N-m

(6X)

Page 11

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module Rev. 2.4 Page 11 of 12

Set your site on VICOR at www.vicorpower.com

Notes

Page 12

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 ARM, Autoranging Rectifier Module P/N 23498 Rev. 2.4 4/03/10M

Set your site on VICOR at www.vicorpower.com

Vicor’s comprehensive line of power solutions includes modular, high

density DC-DC converters and accessory components, configurable power

supplies, and custom power systems.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is

assumed by Vicor for its use. No license is granted by implication or otherwise under any patent or patent

rights of Vicor. Vicor components are not designed to be used in applications, such as life support systems,

wherein a failure or malfunction could result in injury or death. All sales are subject to Vicor’s Terms and

Conditions of Sale, which are available upon request.

Specifications are subject to change without notice.

Vicor Corporation

25 Frontage Road

Andover, MA, USA01810

Tel: 800-735-6200

Fax: 978-475-6715

Email

Vicor Express: vicorexp@vicr.com

Technical Support: apps@vicr.com

Component Solutions

for Your Power System

45

Loading...

Loading...