Datasheet V9MLN41206WT, V9MLN41206WH, V9MLN41206WA, V5.5MLN41206WT, V5.5MLN41206WH Datasheet (LITTELFUSE)

...Page 1

3

SURFACE MOUNT

VARISTORS

Surface Mount Varistors

151

www.littelfuse.com

Multiline Transient Voltage Surge Suppressor

MLN SurgeArray™Suppressor

The MLN SurgeArray™Suppressor is designed to help protect components from transient voltages that exist at the circuit board level. This

device provides four independent suppressors in a single “1206” leadless

chip in order to reduce part count and placement time as well as save

space on printed circuit boards.

SurgeArray™devices are intended to suppress ESD, EFT and other

transients in order to protect integrated circuits or other sensitive

components operating at any voltage up to 18VDC. SurgeArray devices

are rated to the IEC 61000-4-2 human body model ESD to help products

attain EMC compliance. The array offers excellent isolation and low

crosstalk between sections.

The inherent capacitance of the SurgeArray Suppressor permits it to

function as a filter/suppressor, thereby replacing separate zener/

capacitor combinations.

The MLN array is manufactured using the Littelfuse Multilayer technology

process and is similar to the Littelfuse ML and MLE Series of discrete

leadless chips.

The MLN can also be provided in a Dual version. Contact Littelfuse

for information.

Features

• Four Individual Devices in One 1206 Chip

• ESD Rated to IEC 61000-4-2 (Level 4)

• AC Characterized for Impedance and Capacitance

• Low Adjacent Channel Crosstalk, -55dB at 10MHz (Typ)

• Low Leakage (6nA at 5.5V, 30nA at 15V)

• Operating Voltage up to 18V

M(DC)

• -55

o

C to 125oC Operating Temperature Range

• Low-Profile, PCMCIA Compatible

Applications

• Data, Diagnostic I/O Ports

• Analog Signal/Sensor Lines

• Portable/Hand-Held Products

• Mobile Communications/Cellular Phones

• Computer/DSP Products

• Industrial Instruments Including Medical

Page 2

Multiline Transient Voltage Surge Suppressor

MLN SurgeArray™Suppressor

Surface Mount Varistors

152

www.littelfuse.com

Absolute Maximum Ratings

For ratings of individual members of a series, see device ratings and specifications table.

Continuous:

Steady State Applied Voltage: DC Voltage Range (V

M(DC)

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 V

Operating Ambient Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55 to 125

O

C

Storage Temperature Range (T

STG

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55 to 150

O

C

Device Ratings and Specifications Any Single Section

Temperature Derating

For applications exceeding 125oC ambient temperature, the peak surge

current and energy ratings must be reduced as shown in Figure 1.

MLN ARRAY UNITS

PA RT

NUMBER

MAX RATINGS (125

o

C) PERFORMANCE SPECIFICATIONS (25oC)

MAXIMUM

CONTINUOUS

WORKING

VO LTAGE

MAXIMUM

NON-

REPETITIVE

SURGE

CURRENT

(8/20µs)

MAXIMUM

CLAMPING

VO LTAGE

(AT NOTED

CURRENT

8/20µs)

MAXIMUM

NON-

REPETITIVE

SURGE

ENERGY

(10/1000µs)

TYPICAL

ESD SUPPRESSION

VOLTAGE (NOTE 1)

NOMINAL

VO LTAGE AT

1mA DC

CURRENT

CAPACITANCE

AT

1MHz (1V p-p)

V

M(DC)

I

TM

V

C

W

TM

(V) (A) (V) (J) (V) (V) (pF)

V5.5MLN41206

V9MLN41206

V14MLN41206

V18MLN41206

V18MLN41206L

430 520

250 300

140 175

100 125

NOTES:

1. Tested to IEC61000-4-2 Human Body Model (HBM) discharge test circuit. See explanation of Terms on page 7.

2. Direct discharge to device terminals (IEC preffered test method). See figure 2.

3. Corona discharge through air (represents actual ESD event)

4. Capacitance may be customized, contact Sales.

(See Fig. 3)

Peak

(NOTE 2)

8kV CONTACT

(NOTE 3)

15kV AIR

Clamp

(V)

Peak

(V)

(V)

VN(DC)

MIN

V

N(DC)

MAX

(NOTE 4)

C

TYP MAX

(pF)

45 75

5.5

9

14

18

18

30

30

30

30

20

7.1

11.0

15.9

22.0

25.0

9.3

16.0

20.3

28.0

35.0

60

95

110

165

200

35

50

55

60

95

45

75

85

100

130

0.1

0.1

0.1

0.1

0.05

15.5 at 2A

23 at 2A

30 at 2A

40 at 2A

50 at 1A

100

90

80

70

60

50

40

30

20

10

0

-55 50 60 70 80 90 100 110 120 130 140 150

PERCENT OF RATED VALUE

AMBIENT TEMPERATURE (oC)

FIGURE 1. PEAK CURRENT AND ENERGY DERATING CURVE

t

t

1

t

2

100

90

50

10

O

1 TIME

PERCENT OF PEAK VALUE

O1 = VIRTUAL ORIGIN OF WAVE

t

1

= VIRTUAL FRONT TIME = 1.25 x t

(IMPULSE DURATION)

t = TIME FROM 10% TO 90% OF PEAK

t

2

= VIRTUAL TIME TO HALF VALUE

EXAMPLE:

FOR AN 8/20µs CURRENT

WAVEFORM:

8µs = t

1

= VIRTUAL FRONT

20µs = t

2

= VIRTUAL TIME TO

HALF VALUE

TIME

FIGURE 2. PEAK PULSE CURRENT TEST WAVEFORM FOR CLAMPING VOLTAGE

Page 3

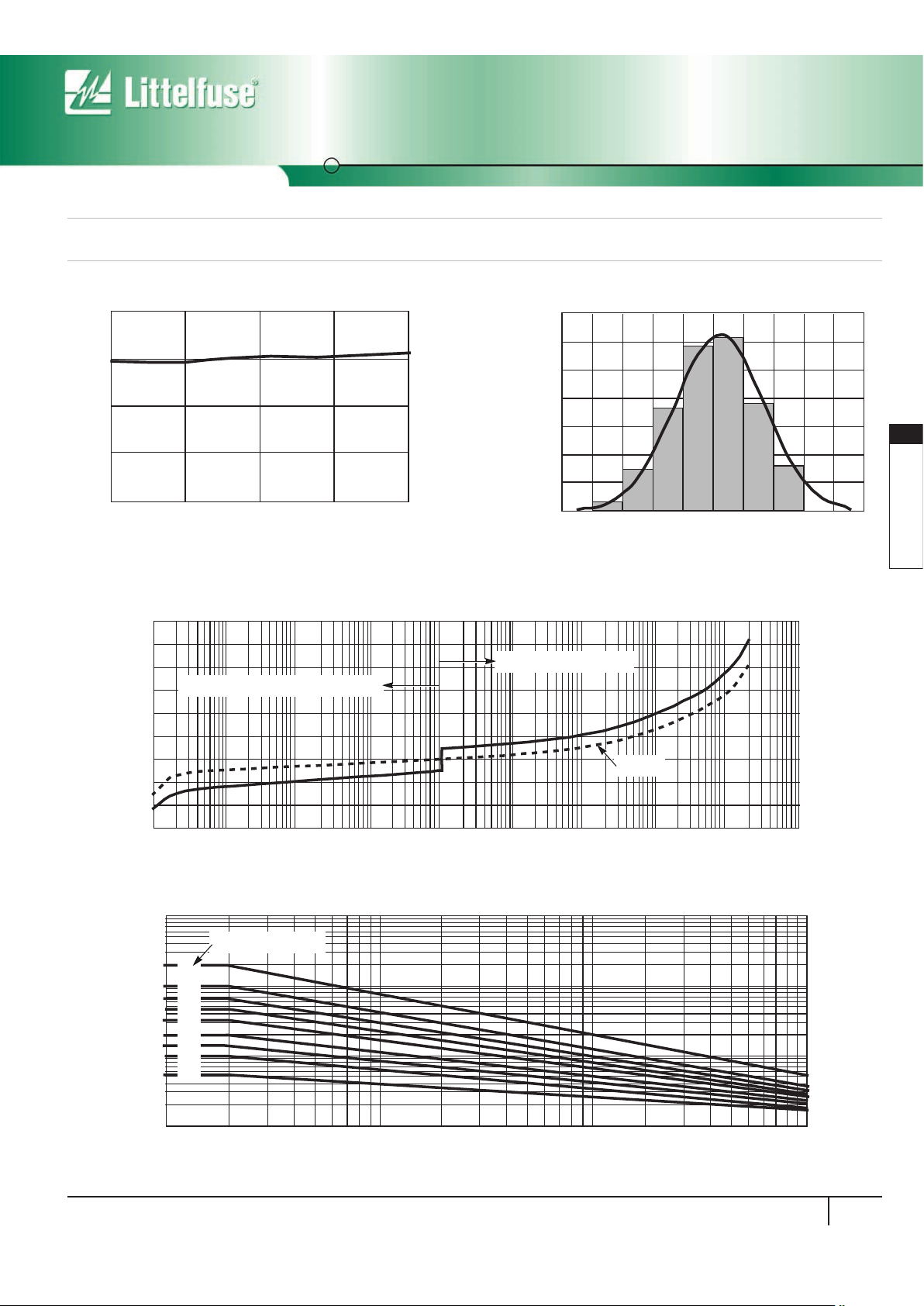

Typical Performance Curves Any Single Section

40

30

20

10

0

1 10 100 1000

NUMBER OF DISCHARGES

V

NOM

10,000

FIGURE 4. PRODUCT DISTRIBUTION OF CAPACITANCE (1MHz)

70

60

50

40

30

20

10

0

SAMPLES

CAPACITANCE (pF)

7060504030 35 45 55 65

Typical Performance Curves Any Single Section

FIGURE 5. V-I CHARACTERISTICS

FIGURE 6. PULSE RATING FOR LONG DURATION SURGES (ANY SINGLE SECTION)

90

80

70

60

50

40

30

20

10

0

VARISTOR VOLTAGE (V)

1.0E

-07

CURRENT (A)

1.0E

-06

1.0E

-05

1.0E

-04

1.0E

-03

1.0E

-02

1.0E

-01

1.0E

+00

1.0E

+01

1.0E

+02

MAXIMUM STANDBY CURRENT (LEAKAGE)

MAXIMUM CLAMP VOLTAGE

TYPICAL

1

2

10

100

10

3

10

4

10

5

10

6

∞

100

10

1

0.1

10 100 1000 10000

SQUARE WAVE PULSE DURATION ( µs)

SURGE CURRENT (A)

NUMBER OF SURGES

MLN SurgeArray™Suppressor

Surface Mount Varistors

Multiline Transient Voltage Surge Suppressor

153

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Page 4

Multiline Transient Voltage Surge Suppressor

MLN SurgeArray™Suppressor

Surface Mount Varistors

154

www.littelfuse.com

Typical Performance Curves Any Single Section (Continued)

FIGURE 7. STANDBY CURRENT AT NORMALIZED VARISTOR VOLTAGE AND TEMPERATURE (ANY SINGLE SECTION)

FIGURE 8. CAPACITANCE vs FREQUENCY

FIGURE 9. EQUIVALENT SERIES RESISTANCE

100

10

0.1µA1µA10µA 100µA1mA

CURRENT (A)

NORMALIZED VARISTOR VOLTAGE (%)

-40oC

25

o

C

85

o

C

125

o

C

70

65

60

55

50

45

40

1GHz

100MHz

10MHz

1MHz

FREQUENCY

CAPACITANCE (pF)

1000

1MHz

FREQUENCY

OHMS

100

10

1

0.1

10MHz 100MHz 1GHz 10GHz

Page 5

Soldering Recommendations

The principal techniques used for the soldering of components in surface

mount technology are Infrared (IR) Reflow, Vapour Phase Reflow, and

Wave Soldering. Typical profiles are shown in Figures 12, 13 and 14.

When wave soldering, the MLN suppressor is attached to the circuit

board by means of an adhesive. The assembly is then placed on a conveyor and run through the soldering process to contact the wave. With IR

and Vapour Phase Reflow, the device is placed in a solder paste on the

substrate. As the solder paste is heated, it reflows and solders the unit to

the board.

The recommended solder for the MLN suppressor is a 62/36/2

(Sn/Pb/Ag), 60/40 (Sn/Pb), or 63/37 (Sn/Pb). Littelfuse also

recommends an RMA solder flux.

Wave soldering is the most strenuous of the processes. To avoid the

possibility of generating stresses due to thermal shock, a preheat stage

in the soldering process is recommended, and the peak temperature of

the solder process should be rigidly controlled.

Typical Performance Curves Any Single Section (Continued)

FIGURE 10. IMPEDANCE vs FREQUENCY

FIGURE 11. ADJACENT CHANNEL CROSSTALK

10000

1000

100

10

1

0.1

1MHz

10MHz

100MHz

1GHz

10GHz

FREQUENCY

IMPEDANCE (Z)

0

-20

-40

-60

-80

-100

-120

1kHz 100kHz10kHz 1MHz 10MHz 100MHz 1GHz

FREQUENCY

CROSSTALK (dB)

VIN = 1V

RMS

Z = 50Ω

When using a reflow process, care should be taken to ensure that the

MLN chip is not subjected to a thermal gradient steeper than 4 degrees

per second; the ideal gradient being 2 degrees per second. During the

soldering process, preheating to within 100 degrees of the solders peak

temperature is essential to minimize thermal shock. Examples of the soldering conditions for the MLN array of suppressors are given in the

tables below.

Once the soldering process has been completed, it is still necessary to

ensure that any further thermal shocks are avoided. One possible cause of

thermal shock is hot printed circuit boards being removed from the solder

process and subjected to cleaning solvents at room temperature. The

boards must be allowed to gradually cool to less than 50oC before cleaning.

MLN SurgeArray™Suppressor

Surface Mount Varistors

Multiline Transient Voltage Surge Suppressor

155

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Page 6

Multiline Transient Voltage Surge Suppressor

MLN SurgeArray™Suppressor

Surface Mount Varistors

156

www.littelfuse.com

FIGURE 12. IR REFLOW SOLDER PROFILE

TEMPERATURE (

o

C)

TIME (MINUTES)

250

200

150

100

50

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

MAXIMUM

PREHEAT DWELL

PREHEAT ZONE

TEMPERATURE 222

o

C

RAMP RATE

<2

o

C/s

40-80

SECONDS

ABOVE 183

o

C

FIGURE 14. VAPOR PHASE SOLDER PROFILE

TEMPERATURE (

o

C)

TIME (MINUTES)

250

200

150

100

50

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

RAMP RATE

PREHEAT ZONE

>50

o

C/s

MAXIMUM

TEMPERATURE 222

o

C

40-80

SECONDS

ABOVE 183

o

C

FIGURE 13. WAVE SOLDER PROFILE

TEMPERATURE (

o

C)

TIME (MINUTES)

300

250

200

150

100

50

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

MAXIMUM WAVE 260oC

SECOND PREHEAT

FIRST PREHEAT

Recommended Pad Outline

E

D

A

B

C

DIMENSION ABCDE

Millimeters 0.89 1.65 2.54 0.46 0.79

Inches 0.035 0.065 0.100 0.018 0.030

P

L

T

S

X

BL

BW

W

LWTBWBL PXS

Inch 0.126 ±0.008 0.063 ±0.008 0.053 Max 0.016 ±0.004 0.007 +0.01/- 0.002 0.030 Ref 0.045 ±0.004 0.015 ±0.004

Millimeter 3.2 ±0.2 1.6 ±0.2 1.35 Max 0.41 ±0.1 0.18 +0.25/-0.05 0.76 Ref 1.14 ±0.1 0.38 ±0.1

Mechanical Dimensions

TABLE 1. PAD LAYOUT DIMENSIONS

Page 7

Ordering Information

VXXMLN TYPES

V 18 1206

PACKING OPTIONS

A: 2500 Piece Bulk Pack

H: 7in (178mm) Diameter Reel (Note)

T: 13in (330mm) Diameter Reel (Note)

NOTE: See Standard Shipping Quantities table.

DEVICE SIZE:

i.e., 120 mil x 60 mil

DEVICE FAMILY

TVSS Device

MAXIMUM DC

WORKING VOLTAGE

ML N

SERIES DESIGNATOR

N: Array

W T

END TERMINATION OPTION

W: Ag/Pd/P

t

MULTILAYER DESIGNATOR

4

NUMBER OF SECTIONS

Tape and Reel Specifications

• Conforms to EIA - 481, Revision A

• Can be Supplied to IEC Publication 286 - 3

SYMBOL DESCRIPTION MILLIMETERS

A

0

Width of Cavity Dependent on Chip Size to Minimize Rotation.

B

0

Length of Cavity Dependent on Chip Size to Minimize Rotation.

K

0

Depth of Cavity Dependent on Chip Size to Minimize Rotation.

W Width of Tape 8 ±0.2

F Distance Between Drive Hole Centers and Cavity Centers 3.5 ±0.5

E Distance Between Drive Hole Centers and Tape Edge 1.75 ±0.1

P

1

Distance Between Cavity Center 4 ±0.1

P

2

Axial Distance Between Drive Hole Centers and Cavity Centers 2 ±0.1

P

0

Axial Distance Between Drive Hole Centers 4 ±0.1

D

0

Drive Hole Diameter 1.55 ±0.05

D

1

Diameter of Cavity Piercing 1.05 ±0.05

t

1

Embossed Tape Thickness 0.3 Max

t

2

Top Tape Thickness 0.1 Max

NOTE: Dimensions in millimeters.

Standard Shipping Quantities

K

0

t

1

t

2

D

0

P

0

D

1

P

1

A

0

P

2

B

0

F

E

W

PLASTIC CARRIER TAPE

EMBOSSMENT

TOP TAPE

8mm

NOMINAL

PRODUCT

IDENTIFYING

LABEL

178mm

OR 330mm

DIA. REEL

DEVICE SIZE “13” INCH REEL (“T” OPTION) “7” INCH REEL (“H” OPTION) BULK PACK (“A” OPTION)

1206 10,000 2,500 2,500

MLN SurgeArray™Suppressor

Surface Mount Varistors

Multiline Transient Voltage Surge Suppressor

157

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Loading...

Loading...