Page 1

US1075

7.5A LOW DROPOUT POSITIVE

ADJUSTABLE REGULATOR

FEATURESFEATURES

1V Dropout at Full Load Current

Fast Transient Response

1% Voltage Reference Initial Accuracy

Output Current Limiting

Built-in Thermal Shutdown

APPLICATIONSAPPLICATIONS

Low Voltage Processor Applications such as :

P54C,P55C,Cyrix M2,

POWER PC,AMD

GTL+ Termination

PENTIUM PRO, KLAMATH

Low Voltage Memory Termination Applications

Standard 3.3V Chip-Set and Logic Applications

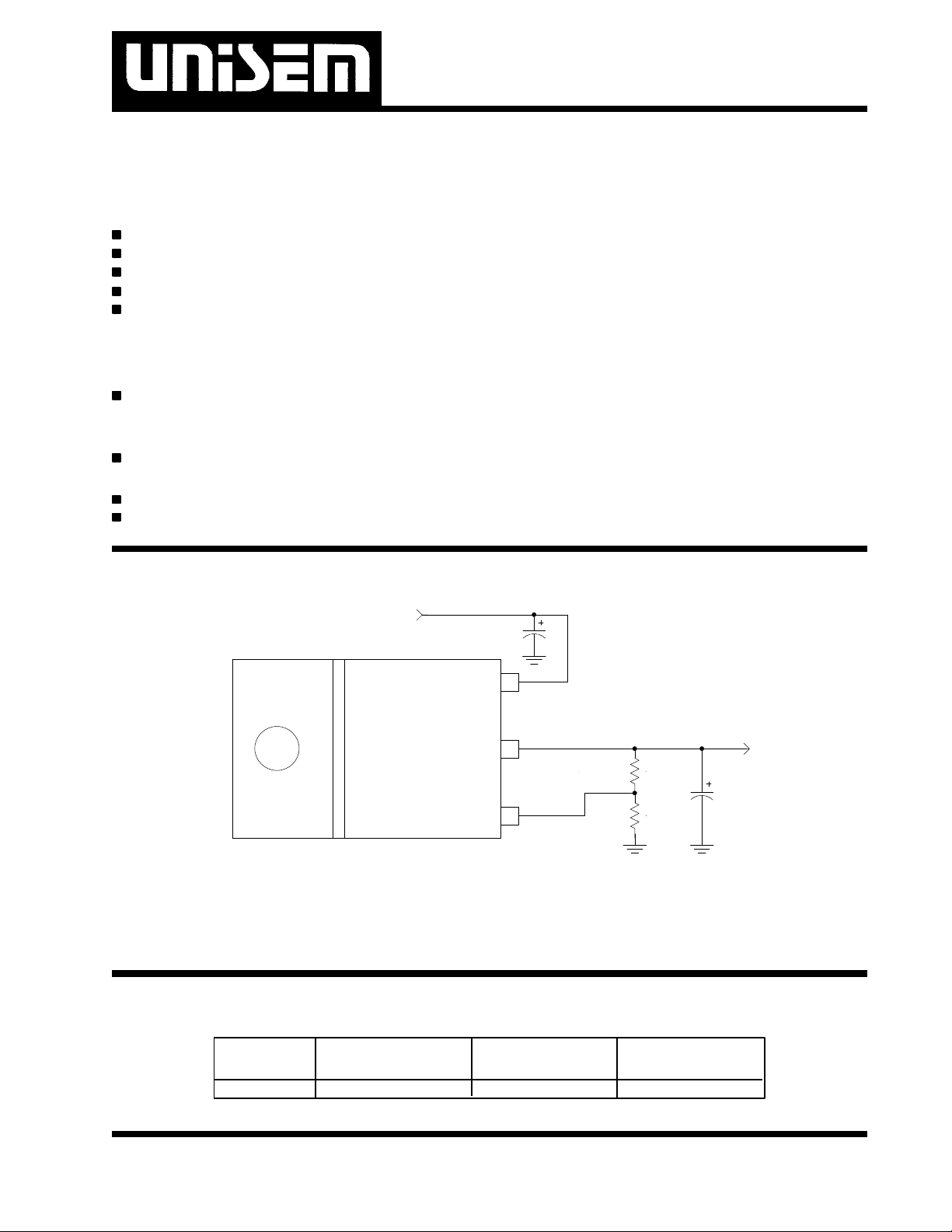

TYPICAL APPLICATIONTYPICAL APPLICATION

DESCRIPTIONDESCRIPTION

The US1075 product is a low dropout three terminal adjustable regulator with minimum of 7.5A output current

capability. This product is specifically designed to provide well regulated supply for low voltage IC applications

such as Pentium P54C,P55C as well as GTL+

termination for Pentium Pro and Klamath pro-

cessor applications . The US1075 is also well suited for

other processors such as Cyrix,AMD and Power

PCapplications. The US 1075 is guaranteed to have

<1.2V drop out at full load current making it ideal to

provide well regulated outputs such as 3.3V with input

supply voltage as low as 4.5V minimum.

5V

C1

1500uF

Vin

3

Vout

Adj

2

R1

121

1

R2

200

US1075

1075app1-1.0

Typical Application of US1075 in a 5V to 3.3V regulator

Notes: Pentium P54C,P55C ,Klamath,Pentium Pro,VRE,are trade marks of Intel Corp.Cyrix M2 is trade mark of Cyrix Corp.

Power PC is trade mark of IBM Corp.

3.3V

C2

2x 1500uF

PACKAGE ORDER INFORMATIONPACKAGE ORDER INFORMATION

Tj (°C) 3 PIN PLASTIC 3 PIN PLASTIC 3 PIN PLASTIC

TO220 (T) TO263 (M) POWER FLEX (P)

0 TO 150 US1075CT US1075CM US1075CP

Rev. 1.0

9/14/99

2-33

Page 2

US1075

ABSOLUTE MAXIMUM RATINGSABSOLUTE MAXIMUM RATINGS

Input Voltage (Vin) .................................................................. 7V

Power Dissipation ............................................ Internally Limited

Storage Temperature Range .............................. -65°C TO 150°C

Operating Junction Temperature Range .................. 0°C TO 150°C

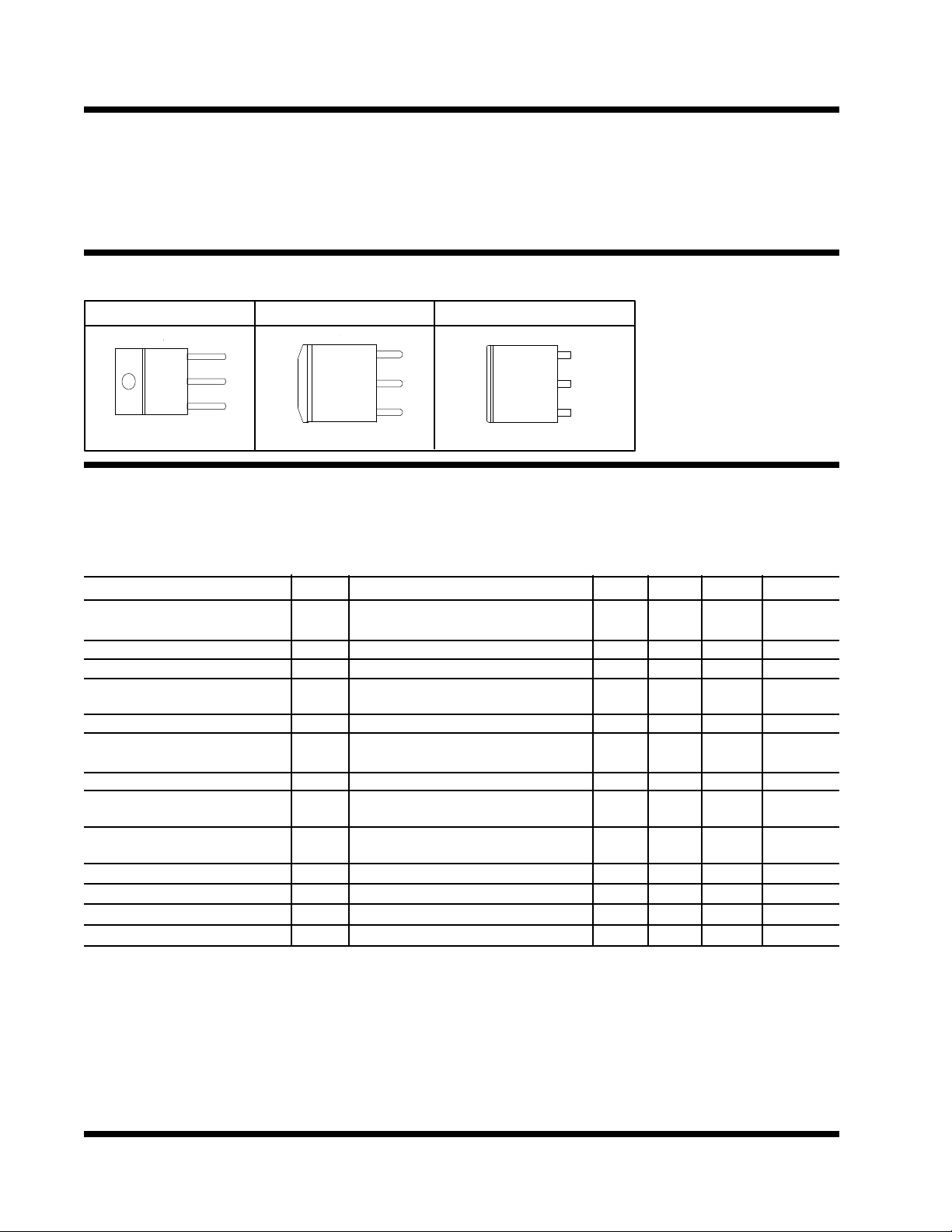

PACKAGE INFORMATIONPACKAGE INFORMATION

3 PIN PLASTIC TO220 ( T ) 3 PIN PLASTIC TO263 ( M ) 3 PIN PLASTIC POWER FLEX ( P )

Tab is

Vout

FRONT VIEW

3

2

1

Vin

Vout

Adj

Tab is

Vout

FRONT VIEW

3

Vin

2

Vout

1

Adj

θJT=2.7°C/W θJA=60°C/W θJA=35°C/W for 1" Square pad θJA=35°C/W for 1" Square pad

ELECTRICAL SPECIFICATIONSELECTRICAL SPECIFICATIONS

Unless otherwise specified ,these specifications apply over ,Cin=1uF,Cout=10uF,and Tj=0 to 150°C.Typical

values refer to Tj=25°C.

Tab is

Vout

FRONT VIEW

3

Vin

2

Vout

1

Adj

PARAMETER SYM TEST CONDITION MIN TYP MAX UNITS

Reference Voltage VREF Io=10mA,Tj=25°C,(Vin-Vo)=1.5V 1.238 1.250 1.262 V

Io=10mA, (Vin-Vo)=1.5V 1.225 1.250 1.275

Line Regulation Io=10mA,1.3V<(Vin-Vo)<7V 0.2 %

Load Regulation (note 1) Vin=3.3V,Vadj=0,10mA<Io<7.5A 0.4 %

Dropout Voltage Io=7.5A 1.0 1.2 V

(note 2) ∆VO Io=4A 0.92 1.1

Current Limit Vin=3.3V,dVo=100mV 7.6 9 A

Minimum Load Current Vin=3.3V,Vadj=0V 5 10 mA

(note 3)

Thermal Regulation 30 mS PULSE,Vin-Vo=3V,Io=7.5A 0.02 %/W

Ripple Rejection f=120HZ ,Co=25uF Tan

Io=7.5A,Vin-Vo=3V 60 70 dB

Adjust Pin Current IADJ Io=10mA,Vin-Vo=1.5V,Tj=25

Io=10mA,Vin-Vo=1.5V 55 120 uA

Adjust Pin Current Change Io=10mA,Vin-Vo=1.5V,Tj=25 0.2 5 uA

Temperature Stability Vin=3.3V,Vadj=0V,Io=10mA 0.5 %

Long Term Stability Tj=125°C,1000 Hrs 0.3 %

RMS Output Noise Tj=25°C 10hz<f<10khz 0.003 %Vo

Note 1 : Low duty cycle pulse testing with Kelvin connections are required in order to maintain accurate data.

Note 2 : Drop-out voltage is defined as the minimum

differential voltage between Vin and Vout required to maintain regulation at Vout. It is measured when the output

Note 3 : Minimum load current is defined as the minimum current required at the output in order for the output voltage to maintain regulation. Typically the resistor

dividers are selected such that it automatically maintains this current.

voltage drops 1% below its nominal value.

2-34

Rev. 1.0

9/14/99

Page 3

US1075

PIN DESCRIPTIONSPIN DESCRIPTIONS

PIN # PIN SYMBOL PIN DESCRIPTION

1 Adj A resistor divider from this pin to the Vout pin and ground sets the output voltage.

2 Vout The output of the regulator. A minimum of 10uF capacitor must be connected

from this pin to ground to insure stability.

3 Vin The input pin of the regulator. Typically a large storage capacitor is connected

from this pin to ground to insure that the input voltage does not sag below the

minimum drop out voltage during the load transient response. This pin must

always be 1.3V higher than Vout in order for the device to regulate properly.

BLOCK DIAGRAMBLOCK DIAGRAM

Vin 3

+

CURRENT

LIMIT

THERMAL

SHUTDOWN

Figure 1 - Simplified block diagram of the US1050

APPLICATION INFORMATIONAPPLICATION INFORMATION

Introduction

The US1075 adjustable Low Dropout (LDO) regulator is

a 3 terminal device which can easily be programmed

with the addition of two external resistors to any voltages within the range of 1.25 to 5.5 V.This regulator

unlike the first generation of the 3T regulators such as

LM117 that required 3V differential between the input

and the regulated output,only needs 1.3V differential to

maintain output regulation. This is a key requirement for

today’s microprocessors that need typically 3.3V supply and are often generated from the 5V supply. Another

major requirement of these microprocessors such as

the Intel P54C is the need to switch the load current

from zero to several amps in tens of nanoseconds at

2 Vout

1.25V

1075blk1-1.0

the processor pins ,which translates to an approximately

300 to 500 nS current step at the regulator . In addition,

the output voltage tolerances are also extremely tight

and they include the transient response as part of the

specification.For example Intel VRE specification calls

for a total of ±100mV including initial tolerance,load regu-

lation and 0 to 4.6A load step.

The US1075 is specifically designed to meet the fast

current transient needs as well as providing an accurate

initial voltage , reducing the overall system cost with the

need for fewer output capacitors.

+

1 Adj

Rev. 1.0

9/14/99

2-35

Page 4

US1075

Output Voltage Setting

The US1075 can be programmed to any voltages in the

range of 1.25V to 5.5V with the addition of R1 and R2

external resistors according to the following formula:

R

2

V V

OUT REF ADJ

Where : V Typically

I lly

ADJ

= uA Typica

R in figure

1 2

& R as shown

Vin

= +

REF

V = .

50

+ ×1

R

1

125

US1075

Adj

I R

VoutVin

IAdj = 50uA

2

2

Vout

R1

Vref

R2

1075app2-1.0

regulation is achieved when the bottom side of R2 is

connected to the load and the top side of R1 resistor is

connected directly to the case or the Vout pin of the

regulator and not to the load. In fact , if R1 is connected

to the load side, the effective resistance between the

regulator and the load is gained up by the factor of (1+R2/

R1) ,or the effective resistance will be ,Rp(eff)=Rp*(1+R2/

R1).It is important to note that for high current applications, this can represent a significant percentage of the

overall load regulation and one must keep the path from

the regulator to the load as short as possible to minimize this effect.

PARASITIC LINE

RESISTANCE

Vin

VoutVin

US1075

Adj

Rp

R1

R2

R

L

Figure 2 - Typical application of the US1075

for programming the output voltage.

The US1075 keeps a constant 1.25V between the output pin and the adjust pin. By placing a resistor R1 across

these two pins a constant current flows through R1, adding to the Iadj current and into the R2 resistor producing

a voltage equal to the (1.25/R1)*R2 + Iadj*R2 which will

be added to the 1.25V to set the output voltage. This is

summarized in the above equation. Since the minimum

load current requirement of the US1075 is 10 mA , R1 is

typically selected to be 121Ω resistor so that it automatically satisfies the minimum current requirement.

Notice that since Iadj is typically in the range of 50uA it

only adds a small error to the output voltage and should

only be considered when a very precise output voltage

setting is required. For example, in a typical 3.3V application where R1=121Ω and R2=200Ω the error due to

Iadj is only 0.3% of the nominal set point.

Load Regulation

Since the US1075 is only a 3 terminal device , it is not

possible to provide true remote sensing of the output

voltage at the load.Figure 3 shows that the best load

1075app3-1.0

Figure 3 - Schematic showing connection for best load

regulation

Stability

The US1075 requires the use of an output capacitor as

part of the frequency compensation in order to make the

regulator stable. Typical designs for microprocessor applications use standard electrolytic capacitors with a

typical ESR in the range of 50 to 100 mΩ and an output

capacitance of 500 to 1000uF. Fortunately as the capacitance increases, the ESR decreases resulting in a

fixed RC time constant. The US1075 takes advantage of

this phenomena in making the overall regulator loop

stable.For most applications a minimum of 100uF aluminum electrolytic capacitor such as Sanyo MVGX series ,Panasonic FA series as well as the Nichicon PL

series insures both stability and good transient response.

2-36

Rev. 1.0

9/14/99

Page 5

US1075

=

(

)

(

)

∆

TTC=−=−=°

1163581

6

9

Thermal Design

The US1075 incorporates an internal thermal shutdown

that protects the device when the junction temperature

exceeds the maximum allowable junction temperature.

Although this device can operate with junction tempera-

tures in the range of 150°C ,it is recommended that the

selected heat sink be chosen such that during maximum continuous load operation the junction temperature is kept below this number. The example below

shows the steps in selecting the proper Regulator heat

sink for the worst case current consumption using Intel

200MHz microprocessor as the load .

Assuming the following specifications :

V V

IN

5

V V

O

=

35

.

I A

OUT

MAX

=

46

.

T C

A

= °

35

The steps for selecting a proper heat sink to keep the

junction temperature below 135°C is given as :

∆T=Temperature Rise Above Ambient

T

∆

θ

SA

=

D

P

81

θ

SA

= = °

C W

117.. /

5) Next , a heat sink with lower θsa than the one calculated in step 4 must be selected. One way to do this is

to simply look at the graphs of the “Heat Sink Temp

Rise Above the Ambient” vs. the “Power Dissipation” and

select a heat sink that results in lower temperature rise

than the one calculated in previous step. The following

heat sinks from AAVID and Thermaloy meet this criteria.

Air Flow (LFM)

0 100 200 300 400

Thermalloy 6021PB 6021PB 6073PB 6109PB 7141D

AAVID 534202B 534202B 507302 575002 576802B

1) Calculate the maximum power dissipation using :

P I V V

D O UT IN O UT

= × −

P . . . W

D

= × − =46 5 3 5 69

( )

2) Select a package from the Regulator data sheet

and record its junction to case (or Tab) thermal

resistance.

Selecting TO220 package gives us :

θJC C W= °27. /

3) Assuming that the heat sink is Black Anodized, cal-

culate the maximum Heat sink temperature allowed :

Assume , θcs=0.05°C/W (Heat sink to Case thermal

resistance for Black Anodized)

T T P

S J D= − × +

= − × + = °

ST C135 6 9 27 0 05 116

θ θJC CS

. . .

( )

4) With the maximum heat sink temperature calcu-

lated in the previous step, the Heat Sink to Air thermal

resistance (θsa) is calculated by first calculating the

temperature rise above the ambient as follows :

T S A

Rev. 1.0

9/14/99

2-37

Loading...

Loading...