Page 1

Flash Programmabl e System Dev i c es

with 8032 Microcontroller Core and 16Kbit SRAM

FEATURES SUMMARY

■ The uPSD321X Devices combine a Flash PSD

architecture with an 8032 microcontroller core.

The uPSD321X Devices of Flas h PSDs feat ure

dual banks of Flash memory, SRAM, general

purpose I/O and programmable logic, supervisory functions and access via I

PWM channels, and an on-board 8032 microcontroller core, with two UARTs, three 16-bit

Timer/Counters and two External Interrupts. As

with other Flash PSD families, the uPSD321X

Devices are also in-system programmable (ISP)

via a JTAG ISP interface.

■ Large 2KByte SRAM with battery back-up

option

■ Dual bank Flash memories

– 64KByte ma in Flash me mory

– 16KByte secondary Flash memory

■ Content Security

– Block access to Flash memory

■ Programmable Decode PLD for flexible address

mapping of all memories within 8032 space.

■ High-speed clock standard 8032 core (12-cycle)

2

■ I

C interface for peripheral connections

■ 5 Pulse Width Modulator (PWM) channels

■ Analog-to-Digital Converter (ADC)

■ Six I/O ports with up to 46 I/O pin s

■ 3000 gate PLD with 16 macrocells

■ Supervisor functions with Watchdog Timer

■ In-System Programming (ISP) via JTAG

■ Zero-Power Technology

■ Single Supply Voltage

– 4.5 to 5.5V

– 3.0 to 3.6V

2

C, ADC and

UPSD321 2C

UPSD3212C V

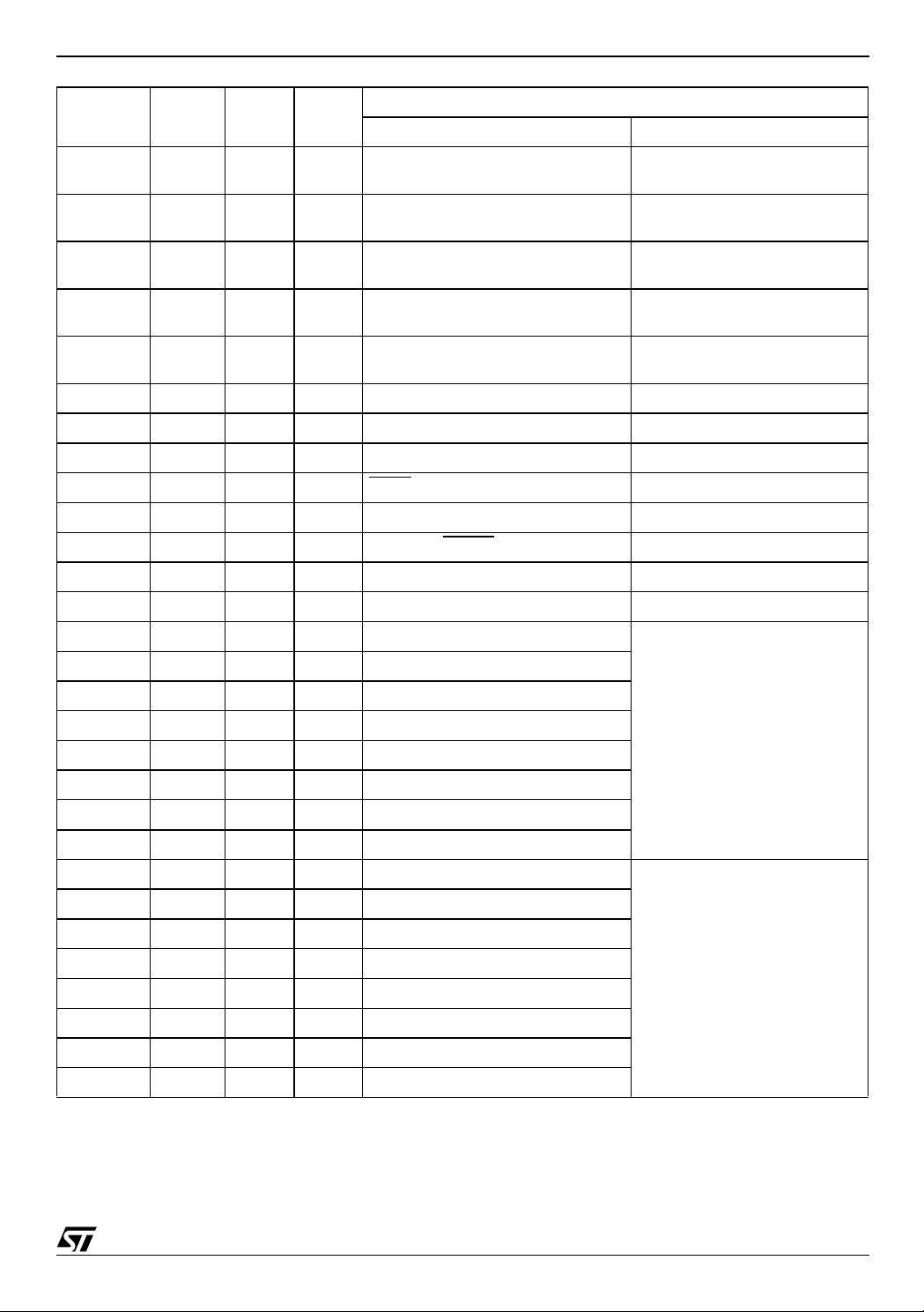

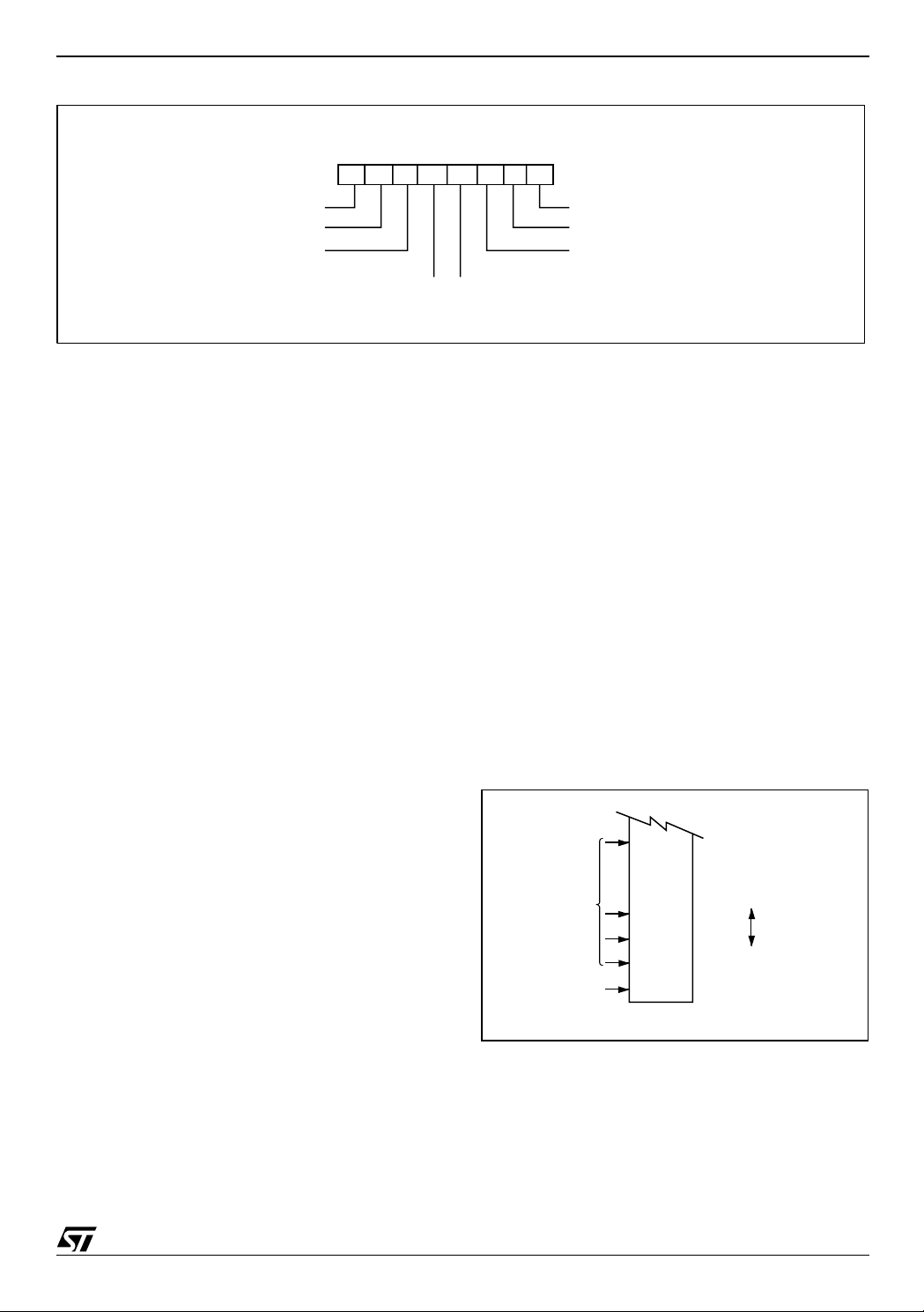

Figure 1. 52-lead, Thin, Quad, Flat Package

TQFP52 (T)

Figure 2. 80-lead, Thin, Quad, Flat Package

TQFP80 (U)

Rev. 1.2

1/152September 2003

Page 2

UPSD3212C, UPSD3212CV

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

uPSD321X Devices Product Matrix (Table 1.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TQFP52 Connections (Figure 3.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2

TQFP80 Connections (Figure 4.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3

80-Pin Package Pin Description (Table 2.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

52 PIN PACKAGE I/O PORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ARCHITECTURE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7

Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Memory Map and Address Space (Figure 5.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8032 MCU Registers (Figure 6.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuration of BA 16-bit Registers (Figure 7.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Stack Pointer (Figure 8.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PSW (Program Status Word) Register (Figure 9.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Data memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Interrupt Location of Program Memory (Figure 10.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

XRAM-PSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SFR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

RAM Address (Table 3.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Addressing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Direct Addressing (Figure 11.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 0

Indirect Addressing (Figure 12.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Indexed Addressing (Figure 13.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Arithmetic Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Arithmetic Instructions (Table 4.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Logical Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Logical Instructions (Table 5.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Data Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Data T r a nsfer In stru c ti ons th a t Acce ss Inter n al Da ta Memo ry Space (Tabl e 6.) . . . . . . . . . . . . . . 24

Shifting a BCD Number Two Digits to the Right (using direct MOVs: 14 bytes) (Table 7.). . . . . . . 25

Shifting a BCD Number Two Digits to the Right (using direct XCHs: 9 bytes) (Table 8.) . . . . . . . . 25

Shifting a BCD Number One Digit to the Right (Table 9.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Data T r a nsfer In stru c ti on tha t Acces s Exte rnal Da ta Memo ry Space (Table 10 .) . . . . . . . . . . . . . . 26

Lookup Table READ Instruction (Table 11.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/152

Page 3

UPSD3212C, UPSD3212CV

Boolean Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Boolean Instructions (Table 12.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Relative Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Jump Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Unconditional Jump Instructions (Table 13.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Machine Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Conditional Jump Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

State Sequence in uPSD321X Devices (Figure 14.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

uPSD3200 HARDWARE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

uPSD321X Devices Functional Modules (Figure 15.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MCU MODULE DISCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Special Function Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SFR Memory Map (Table 15.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

List of all SFR (Table 16.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

PSD Module Register Address Offset (Table 17.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

INTERRUPT SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

External Int0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Timer 0 and 1 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8

Timer 2 Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

I2C Interrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

External Int1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

USART Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Interrupt System (Figure 16.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 9

Interrupt Priority Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Interrupts Enable Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Priority Levels (Table 18.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SFR Register (Table 19.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Description of the IE Bits. (Table 20.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Description of the IEA Bits (Table 21.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Description of the IP Bits (Table 22.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Description of the IPA Bits (Table 23.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

How Interrupts are Handled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Vector Addresses (Table 24.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3/152

Page 4

UPSD3212C, UPSD3212CV

POWER-SAVING MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Power-Down Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power-Saving Mode Power Consumption (Table 25.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Control Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Pin Status During Idle and Power-down Mode (Table 26.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Description of the PCON Bits (Table 27.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

I/O PORTS (MCU Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

I/O Port Functions (Table 28.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

P1SFS (91H) (Table 29.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

P3SFS (93H) (Table 30.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

P4SFS (94H) (Table 31.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

PORT Type and Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

PORT Type and Description (Part 1) (Figure 17.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

PORT Type and Description (Part 2) (Figure 18.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

OSCILLATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Oscillat o r (Figu re 19 . ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SUPERVISORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

RESET Configuration (Figure 20.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 8

External Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Low VDD Voltage Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Watchdog Timer Overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

WATCHDOG TIMER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Watchdog Timer Key Register (WDKEY: 0AEH) (Table 32.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Description of the WDKEY Bits (Table 33.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

RESET Pulse Width (Figure 21.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Watchdog Timer Clear Register (WDRST: 0A6H) (Table 34.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Description of the WDRST Bits (Table 35.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

TIMER/COUNTERS (TIMER 0, TIMER 1 AND TIMER 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Timer 0 and Timer 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1

Control Register (TCON) (Table 36.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Description of the TCON Bits (Table 37.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

TMOD Register (TMOD) (Table 38.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Description of the TMOD Bits (Table 39.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Timer/Counter Mode 0: 13-bit Counter (Figure 22.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4/152

Page 5

UPSD3212C, UPSD3212CV

Timer 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Timer/Counter Mode 2: 8-bit Auto-reload (Figure 23.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Timer/Counter 2 Control Register (T2CON) (Table 40.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Timer/Counter 2 Operating Modes (Table 41.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Description of the T2CON Bits (Table 42.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Timer 2 in Capture Mode (Figure 24.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Timer 2 in Auto-Reload Mode (Figure 25.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Timer/Counter Mode 3: Two 8-bit Counters (Figure 26.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

STANDARD SERIAL INTERFACE (UART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Multiprocessor Comm u nications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Serial Port Control Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Serial Port Mode 0, Block Diagram (Figure 27.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Serial Port Control Register (SCON) (Table 43.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Description of the SCON Bits (Table 44.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Timer 1-Generated Commonly Used Baud Rates (Table 45.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Serial Port Mode 0, Waveforms (Figure 28.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Serial Port Mode 1, Block Diagram (Figure 29.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Serial Port Mode 1, Waveforms (Figure 30.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Serial Port Mode 2, Block Diagram (Figure 31.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Serial Port Mode 2, Waveforms (Figure 32.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Serial Port Mode 3, Block Diagram (Figure 33.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Serial Port Mode 3, Waveforms (Figure 34.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

ANALOG-TO-DIGITAL CONVERTOR (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

ADC Interrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

A/D Block Diagram (Figure 35.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 8

ADC SFR Memory Map (Table 46.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Description of the ACON Bits (Table 47.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

ADC Clock Input (Table 48.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 9

PULSE WIDTH MODULATION (PWM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4-channel PWM Unit (PWM 0-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Four-Channel 8-bit PWM Block Diagram (Figure 36.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

PWM SFR Memory Map (Table 49.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Programmable Period 8-bit PWM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Programmable PWM 4 Channel Block Diagram (Figure 37.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PWM 4 Channel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 4

PWM 4 With Programmable Pulse Width and Frequency (Figure 38.) . . . . . . . . . . . . . . . . . . . . . . 74

5/152

Page 6

UPSD3212C, UPSD3212CV

I2C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Block Diagram of the I2C Bus Serial I/O (Figure 39.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Serial Control Register (S2CON) (Table 50.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Description of the S2CON Bits (Table 51.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Selection of the Serial Clock Frequency SCL in Master Mode (Table 52.) . . . . . . . . . . . . . . . . . . . 76

Serial Status Register (S2STA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Data Shift Register (S2DAT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Serial Status Register (S2STA) (Table 53.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Description of the S2STA Bits (Table 54.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Data Shift Register (S2DAT) (Table 55.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Address Register (S2ADR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 8

Address Register (S2ADR) (Table 56.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Start /Stop Hold Time Detection Register (S2SETUP) (Table 57.). . . . . . . . . . . . . . . . . . . . . . . . .78

System Cock of 40MHz (Table 58.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

System Clock Setup Examples (Table 59.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

PSD MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Functional Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

PSD MODULE Block Diagram (Figure 40.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

In-System Programming (ISP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Methods of Programming Different Functional Blocks of the PSD MODULE (Table 60.). . . . . . . . 81

DEVELOPMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

PSDsoft Express Development Tool (Figure 41.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

PSD MODULE REGISTER DESCRIPTION AND ADDRESS OFFSET . . . . . . . . . . . . . . . . . . . . . . . . 83

Register Address Offset (Table 61.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

PSD MODULE DETAILED OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

MEMORY BLOCKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Primary Flash Memory and Second ary Flash memo ry Descr ip tion . . . . . . . . . . . . . . . . . . . . . 84

Memory Block Select Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Instructions (Table 62.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Power-down Instruction and Power-up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

READ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 7

Status Bit (Table 63.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Programming Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Data Polling Flowchart (Figure 42.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 9

Data Toggle Flowchart (Figure 43.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6/152

Page 7

UPSD3212C, UPSD3212CV

Erasing Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Specific Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Sector Protection/Security Bit Definition – Flash Protection Register (Table 64.). . . . . . . . . . . . . .92

Sector Protection/Security Bit Definition – Secondary Flash Protection Register (Table 65.). . . . . 92

SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Sector Select and SRAM Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Priority Level of Memory and I/O Components in the PSD MODULE (Figure 44.) . . . . . . . . . . . . . 93

VM Register (Table 66.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Separate Space Mode (Figure 45.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Combined Space Mode (Figure 46.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Page Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Page Register (Figure 47.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

PLDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

DPLD and CPLD Inputs (Table 67.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

The Turbo Bit in PSD MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

PLD Diagram (Figure 48.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Decode PLD (DPLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

DPLD Logic Array (Figure 49.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Complex PLD (CPLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 0

Macrocell and I/O Port (Figure 50.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Output Macrocell Port and Data Bit Assignments (Table 68.). . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Product Term Allocator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0 2

CPLD Output Macrocell (Figure 51.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Input Macrocells (IMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Input Macrocell (Figure 52.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

I/O PORTS (PSD MODULE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

General Port Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0 4

General I/O Port Architecture (Figure 53.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Port Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

MCU I/O Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PLD I/O Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Address Out Mod e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Peripheral I/O Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7/152

Page 8

UPSD3212C, UPSD3212CV

JTAG In-System Programming (ISP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Peripheral I/O Mode (Figure 54.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Port Operating Modes (Table 69.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Port Operating Mode Settings (Table 70.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

I/O Port Latched Address Output Assignments (Table 71.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Port Configuration Registers (PCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Port Configuration Registers (PCR) (Table 72.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Port Pin Direction Control, Output Enable P.T. Not Defined (Table 73.). . . . . . . . . . . . . . . . . . . . 107

Port Pin Direction Control, Output Enable P.T. Defined (Table 74.) . . . . . . . . . . . . . . . . . . . . . . . 107

Port Direction Assignment Example (Table 75.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Port Data Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Drive Register Pin Assignment (Table 76.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Ports A and B – Functionality and Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Port A and Port B Structure (Figure 55.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Port C – Functionality and Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Port C Structure (Figure 56.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Port D – Functionality and Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Port D Structure (Figure 57.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

External Chip Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Port D External Chip Select Signals (Figure 58.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

POWER MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1 3

APD Unit (Figure 59.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Enable Power-down Flow Chart (Figure 60.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Power-down Mode’s Effect on Ports (Table 78.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

PLD Power Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

PSD Chip Select Input (CSI, PD2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Input Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1 5

Input Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Power Management Mode Registers PMMR0 (Table 79.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Power Management Mode Registers PMMR2 (Table 80.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

APD Counter Operation (Table 81.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

RESET TIMING AND DEVICE STATUS AT RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Warm RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

I/O Pin, Register and PLD Status at RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Reset (RESET) Timing (Figure 61.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Status During Power-on RESET, Warm RESET and Power-down Mode (Table 82.). . . . . . . . . .117

8/152

Page 9

UPSD3212C, UPSD3212CV

PROGRAMMING IN-CIRCUIT USING THE JTAG SERIAL INTERFACE . . . . . . . . . . . . . . . . . . . . . 118

Standard JTAG Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

JTAG Port Signals (Table 83.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

JTAG Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Security and Flash memory Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

INITIAL DELIVERY STATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

AC/DC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

PLD ICC /Frequency Consumption (5V range) (Figure 62.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

PLD ICC /Frequency Consumption (3V range) (Figure 63.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

PSD MODULE Example, Typ. Power Calculation at V

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Absolute Maximum Ratings (Table 85.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Operating Conditions (5V Devices) (Table 86.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Operating Conditions (3V Devices) (Table 87.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

AC Symbols for Timing (Table 88.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Switching Waveforms – Key (Figure 64.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

DC Characteristics (5V Devices) (Table 89.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

DC Characteristics (3V Devices) (Table 90.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

External Program Memory READ Cycle (Figure 65.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

External Program Memory AC Characteristics (with the 5V MCU Module) (Table 91.) . . . . . . . . 128

External Program Memory AC Characteristics (with the 3V MCU Module) (Table 92.) . . . . . . . . 129

External Clock Drive (with the 5V MCU Module) (Table 93.) . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

External Clock Drive (with the 3V MCU Module) (Table 94.) . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

External Data Memory READ Cycle (Figure 66.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

External Data Memory WRITE Cycle (Figure 67.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

External Data Memory AC Characteristics (with the 5V MCU Module) (Table 95.). . . . . . . . . . . . 131

External Data Memory AC Characteristics (with the 3V MCU Module) (Table 96.). . . . . . . . . . . . 132

A/D Analog Specification (Table 97.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Input to Output Disable / Enable (Figure 68.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

CPLD Combinatorial Timing (5V Devices) (Table 98.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

CPLD Combinatorial Timing (3V Devices) (Table 99.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Synchronous Clock Mode Timing – PLD (Figure 69.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

CPLD Macrocell Synchronous Clock Mode Timing (5V Devices) (Table 100.). . . . . . . . . . . . . . . 134

CPLD Macrocell Synchronous Clock Mode Timing (3V Devices) (Table 101.). . . . . . . . . . . . . . . 135

Asynchronous RESET / Preset (Figure 70.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Asynchronous Clock Mode Timing (product term clock) (Figure 71.) . . . . . . . . . . . . . . . . . . . . . . 136

CPLD Macrocell Asynchronous Clock Mode Timin g (5V Devices) (Table 102.). . . . . . . . . . . . . . 136

CPLD Macrocell Asynchronous Clock Mode Timin g (3V Devices) (Table 103.). . . . . . . . . . . . . . 137

= 5.0V (Turbo Mode Off) (Table 84.). . 120

CC

9/152

Page 10

UPSD3212C, UPSD3212CV

Input Macrocell Timing (product term clock) (Figure 72.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Input Macrocell Timing (5V Devices) (Table 104.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Input Macrocell Timing (3V Devices) (Table 105.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Program, WRITE and Erase Times (5V Devices) (Table 106.). . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Program, WRITE and Erase Times (3V Devices) (Table 107.). . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Peripheral I/O READ Timing (Figure 73.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Port A Peripheral Data Mode READ Timing (5V Devices) (Table 108.) . . . . . . . . . . . . . . . . . . . . 140

Port A Peripheral Data Mode READ Timing (3V Devices) (Table 109.) . . . . . . . . . . . . . . . . . . . . 140

Peripheral I/O WRITE Timing (Figure 74.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Port A Peripheral Data Mode WRITE Timing (5V Devices) (Table 110.) . . . . . . . . . . . . . . . . . . . 141

Port A Peripheral Data Mode WRITE Timing (3V Devices) (Table 111.) . . . . . . . . . . . . . . . . . . . 141

Reset (RESET) Timing (5V Devices) (Table 112.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Reset (RESET) Timing (3V Devices) (Table 113.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

V

STBYON

V

STBYON

ISC Timing (Figure 76.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

ISC Timing (5V Devices) (Table 116.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

ISC Timing (3V Devices) (Table 117.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

MCU Module AC Measurement I/O Waveform (Figure 77.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

PSD MODULE AC Float I/O Waveform (Figure 78.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

External Clock Cycle (Figure 79.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Recommended Oscillator Circuits (Figure 80.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

PSD MODULE AC Measurement I/O Waveform (Figure 81.). . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

PSD MODULEAC Measurem ent Load Circuit (Figure 82.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Capacitance (Table 118.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 4 5

Definitions Timing (5V Devices) (Table 114.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Timing (3V Devices) (Table 115.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

PACKAGE MECHANICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10/152

Page 11

SUMMARY DESCRIPTION

■ Dual bank Flash memories

– Concurrent operation, read from memory

while erasing and writing the other. In-Application Programming (IAP) for remote updates

– Large 64KByte main Flash memory for appli-

cation code, operating systems, or bit maps

for graphic user interfaces

– Large 16KByte secondary Flash m emory di-

vided in small sectors. Eliminate external EEPROM with software EEPROM emulation

– Secondary Flash memory is large enough for

sophisticated communicat ion protoc ol du ring

IAP while continuing critical system tasks

■ Large SRAM with battery back-up option

– 2KByte SRAM for RTOS, high-level languag-

es, communication buffers, and stacks

■ Programmable Decode PLD for flexible address

mapping of all memories

– Place individual Flash an d SRAM sectors on

any address boundary

– Built-in page regist er breaks restrictive 8032

limit of 64KByte address space

– Special register swaps Flash memory seg-

ments between 8032 “program” space and

“data” space for efficient In-Application Programming

■ High-speed clock standard 8032 core (12-cycle)

– 40MHz operation at 5V, 24MHz at 3.3V

– 2 UARTs with independent baud rat e, three

16-bit Timer/Counters and two External Interrupts

2

■ I

C interface for peripheral connections

– Capable of master or slave operation

■ 5 Pulse Width Modulator (PWM) channels

– Four 8-bi t PWM un its

– One 8-bit PWM unit with prog ramm abl e peri-

od

UPSD3212C, UPSD3212CV

■ 4-channel, 8-bit Analog-to-Digital Converter

(ADC) with analog supply voltage (V

■ Six I/O ports with up to 46 I/O pins

2

– Multifunction I/O: GPI O, I

C, PWM, PLD I/O,

supervisor, and JTAG

– Eliminates need for external latches and logic

■ 3000 gate PLD with 16 macrocells

– Create glue logic, state machines, delays,

etc.

– Eliminate external PALs, PLDs, and 74HCxx

– Simple PSDsoft Express software... Free

■ Supervisor functions

– Generates reset upon low voltage or watch-

dog time-out. Eliminate external supervisor

device

– RESET

■ In-System Programming (ISP) via JTAG

Input pin; Reset output via PLD

– Program entire chip in 10 - 25 seconds with

no involvement of 8032

– Allows efficient manu facturing, easy product

testing, and Just-In-Time inventory

– Eliminate sockets and pre-programmed parts

TM

– Program with FlashLINK

■ Content Security

cable and any PC

– Programmable Security Bit blocks access of

device programmers and readers

■ Zero-Power Technology

– Memories and PLD automatically reach

standby current between input changes

■ Packages

– 52-pin TQFP

– 80-pin TQFP: allows access to 8032 address/

data/control signals for connecting to external

peripherals

REF

)

11/152

Page 12

UPSD3212C, UPSD3212CV

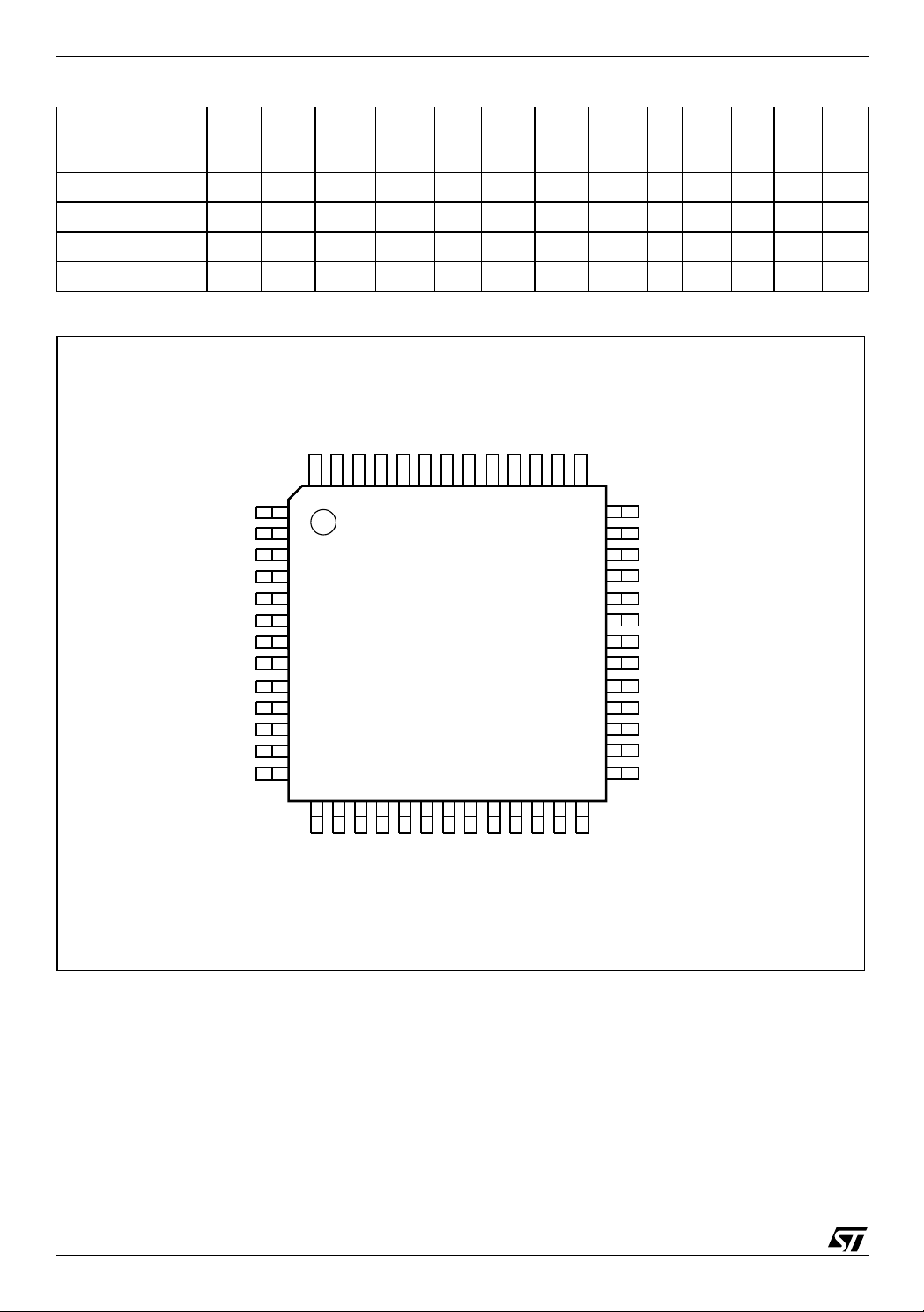

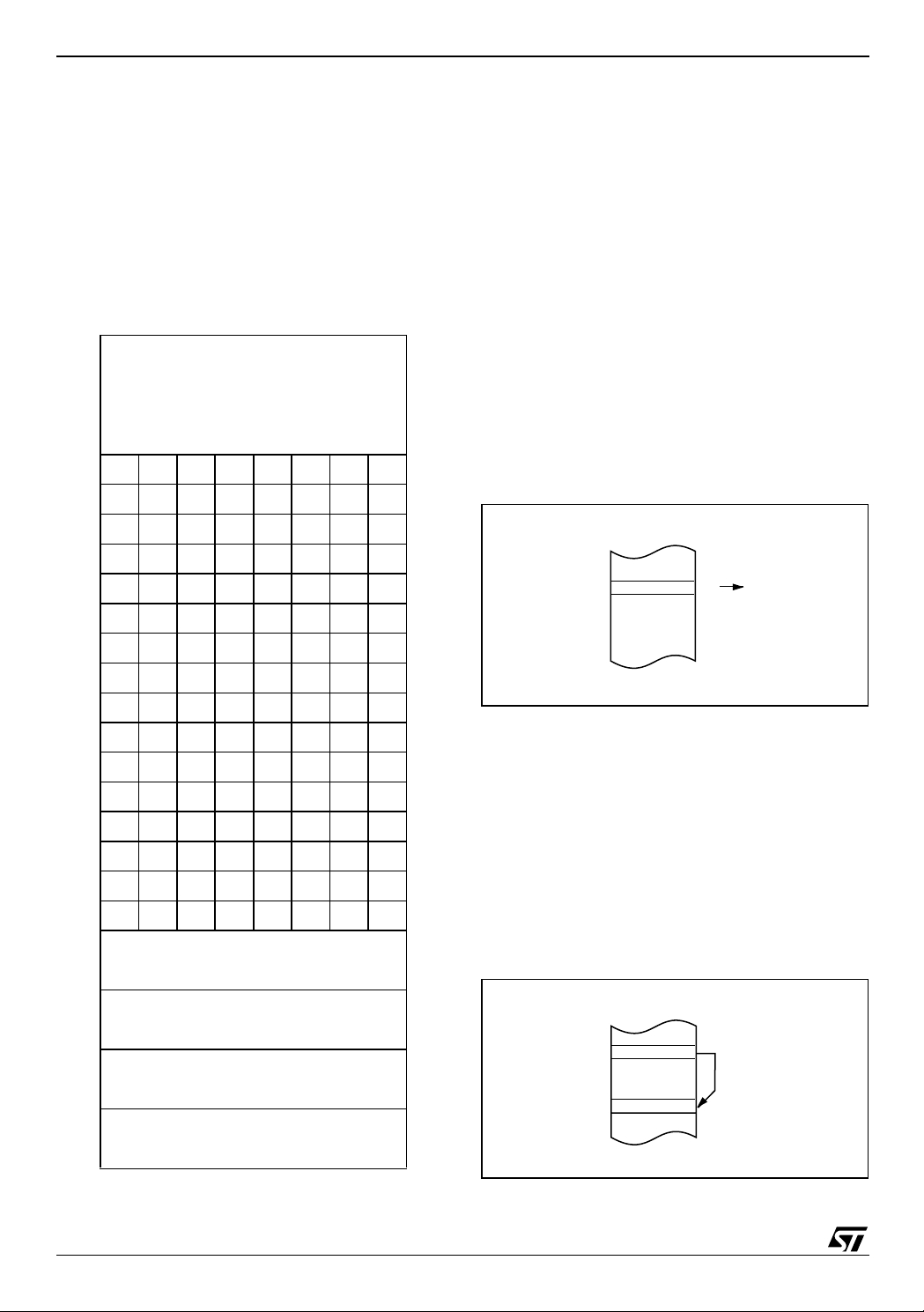

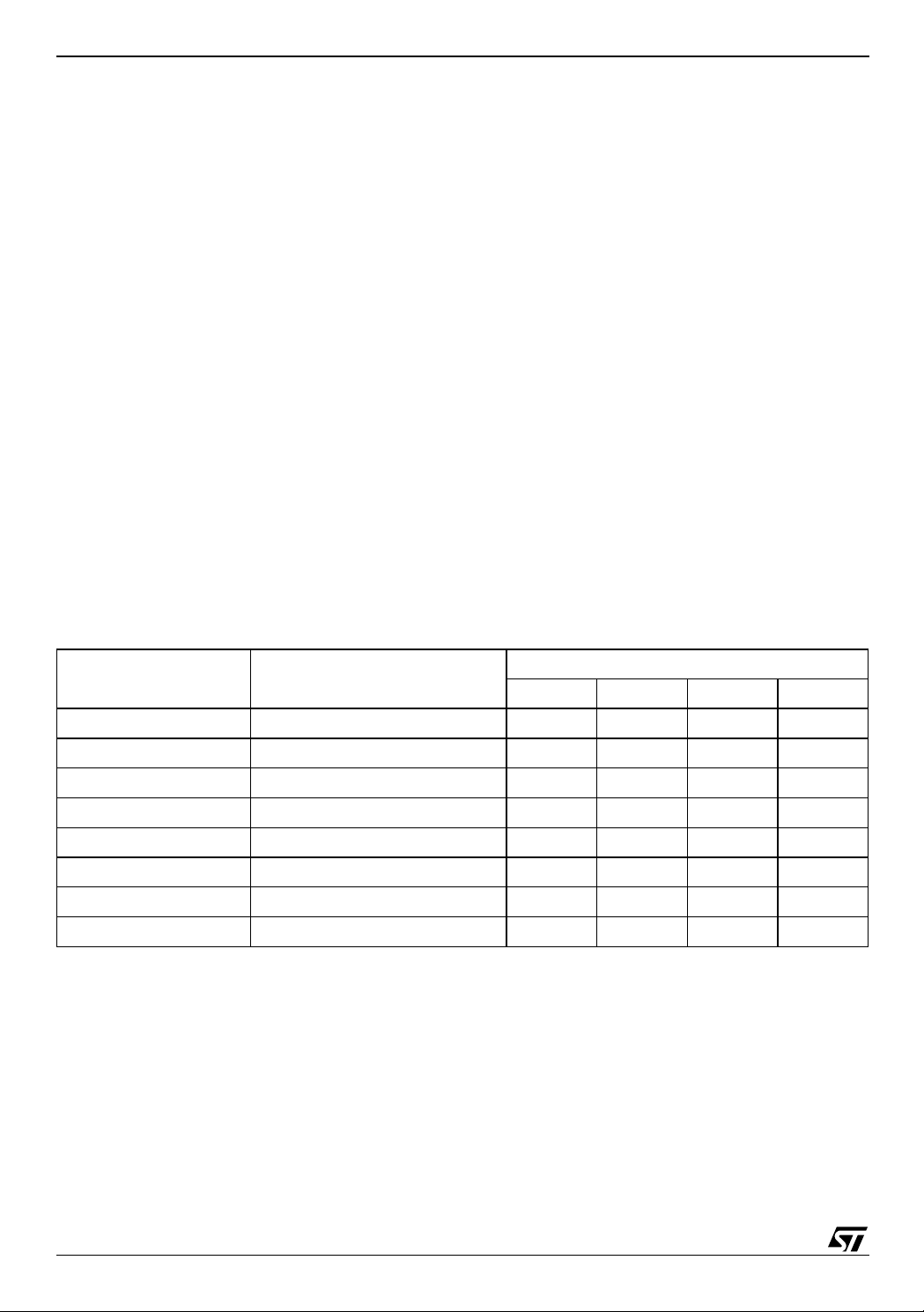

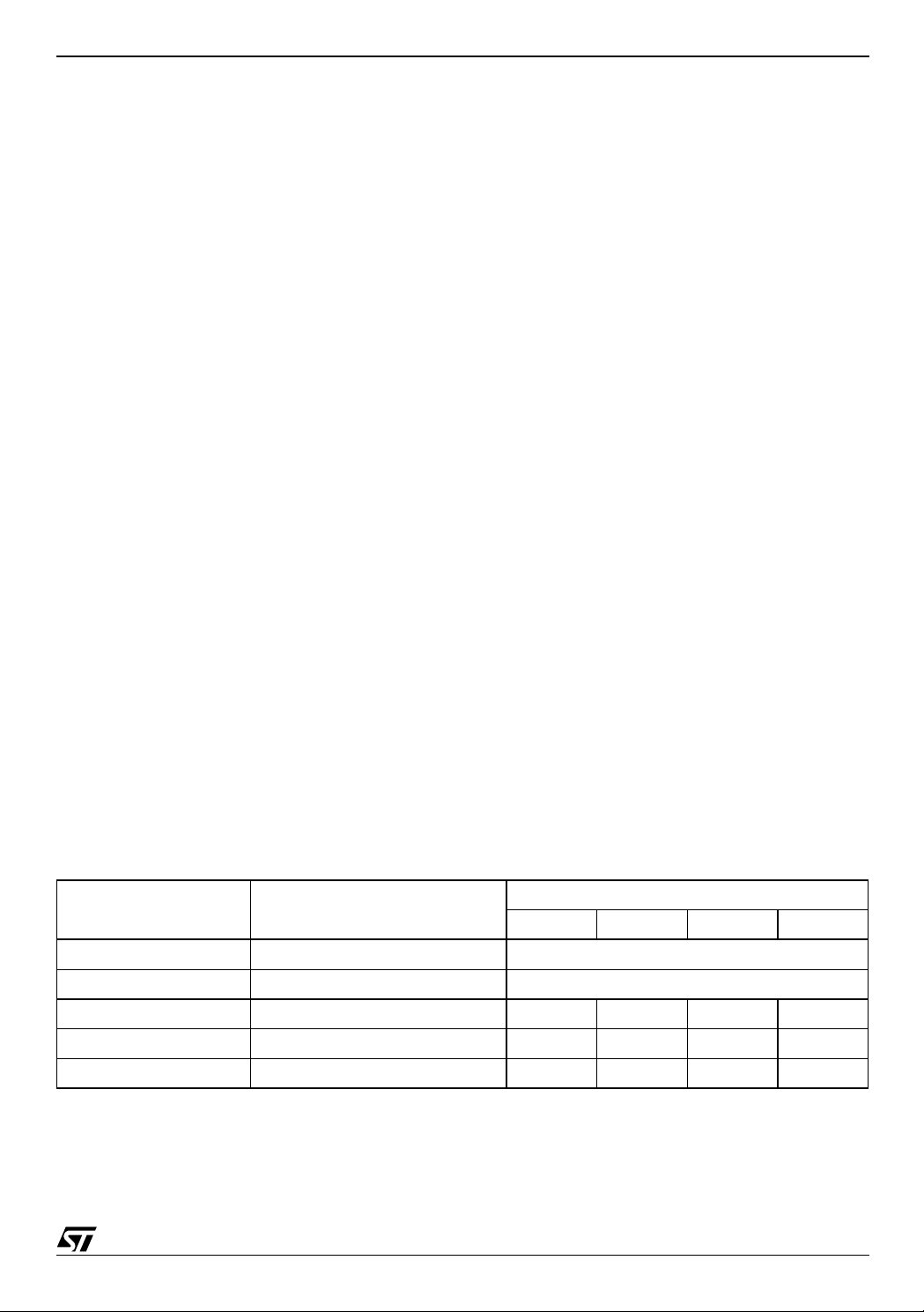

Table 1. uPSD321X Devices Product Matrix

Main

Part No.

Flash

uPSD3212C-40T6 512K 128K 16K 16 37 5 3 2 1 4 5V 40 52

uPSD3212CV-24T6 512K 128K 16K 16 37 5 3 2 1 4 3V 24 52

uPSD3212C-40U6 512K 128K 16K 16 46 5 3 2 1 4 5V 40 80

uPSD3212CV-24U6 512K 128K 16K 16 46 5 3 2 1 4 3V 24 80

Figure 3. TQ FP 52 Connection s

(bit)

Sec.

Flash

SRAM

(bit)

PB0

52515049484746454443424140

(bit)

PB1

PB2

Macro

-Cells

PB3

PB4

Pins

PB5

I/O

VREF

GND

PWM

Ch.

RESET

PB6

Timer

/ Ctr

PB7

P1.7/ADC3

UART

Ch.

P1.6/ADC2

ADC

2

C

I

Ch.

V

CC

MHz Pins

PD1

1

PC7

2

PC6

3

PC5

4

See note

Note: 1. Pull-up resis tor requ i r ed on pin 5 (2kΩ for 3V devices, 7.5kΩ for 5V dev i ces).

2. NC = Not Connected.

(1)

PC4

NC

V

CC

GND

PC3

PC2

PC1

PC0

5

6

7

8

9

10

11

12

13

14151617181920212223242526

GND

P4.2

P4.1

P4.0

P3.1 / TXD

P4.7 / PWM4

P4.6 / PWM3

P4.5 / PWM2

P4.4 / PWM1

P4.3 / PWM0

P3.0 / RXD

P3.2 / EXINT0

P3.3 / EXINT1

39 P1.5 / ADC1

38 P1.4 / ADC0

37 P1.3 / TXD1

36 P1.2 / RXD1

35 P1.1 / T2X

34 P1.0 / T2

33 V

CC

32 XTAL2

31 XTAL1

30 P3.7 / SCL1

29 P3.6 / SDA1

28 P3.5 / T1

27 P3.4 / T0

AI07423

12/152

Page 13

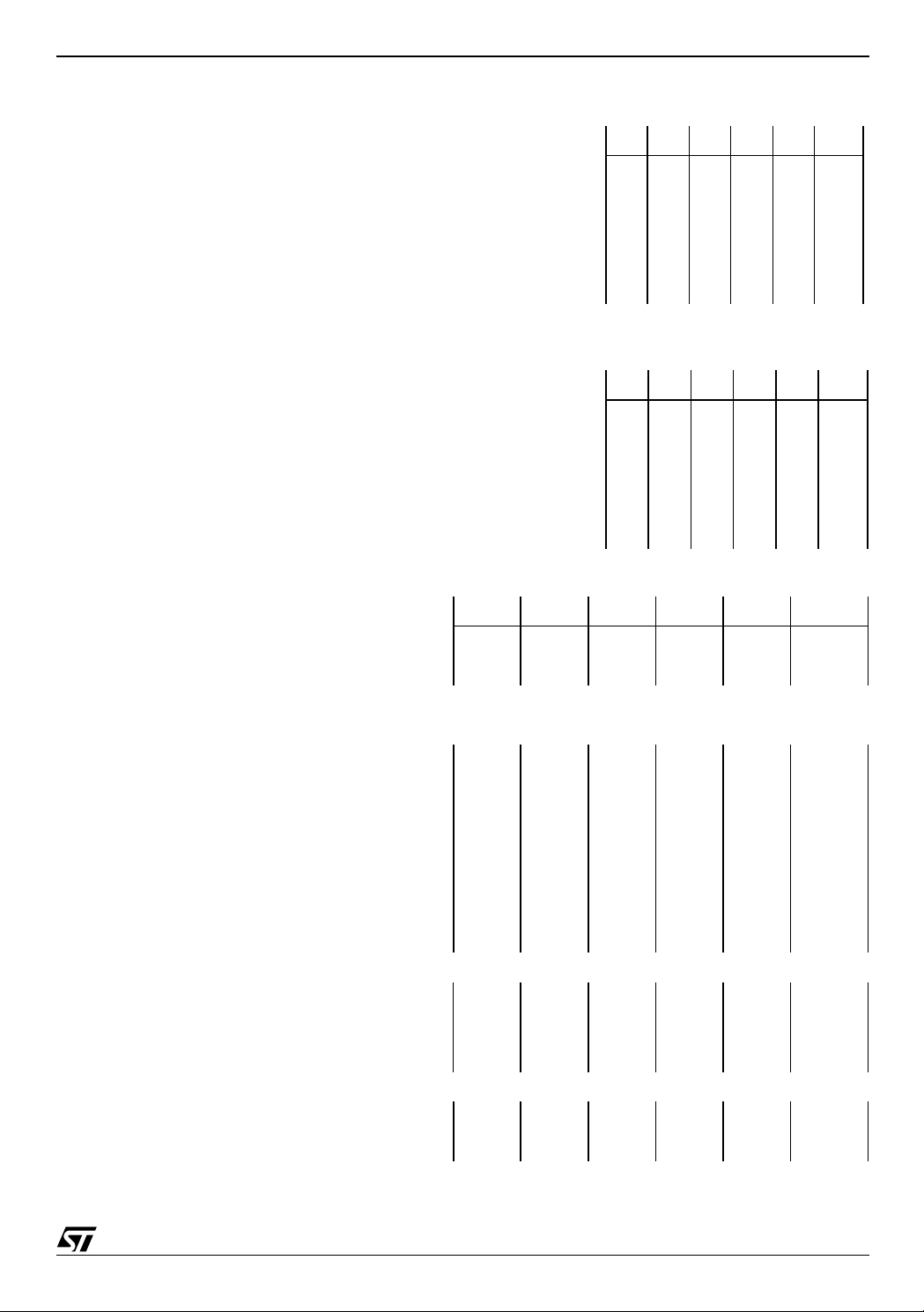

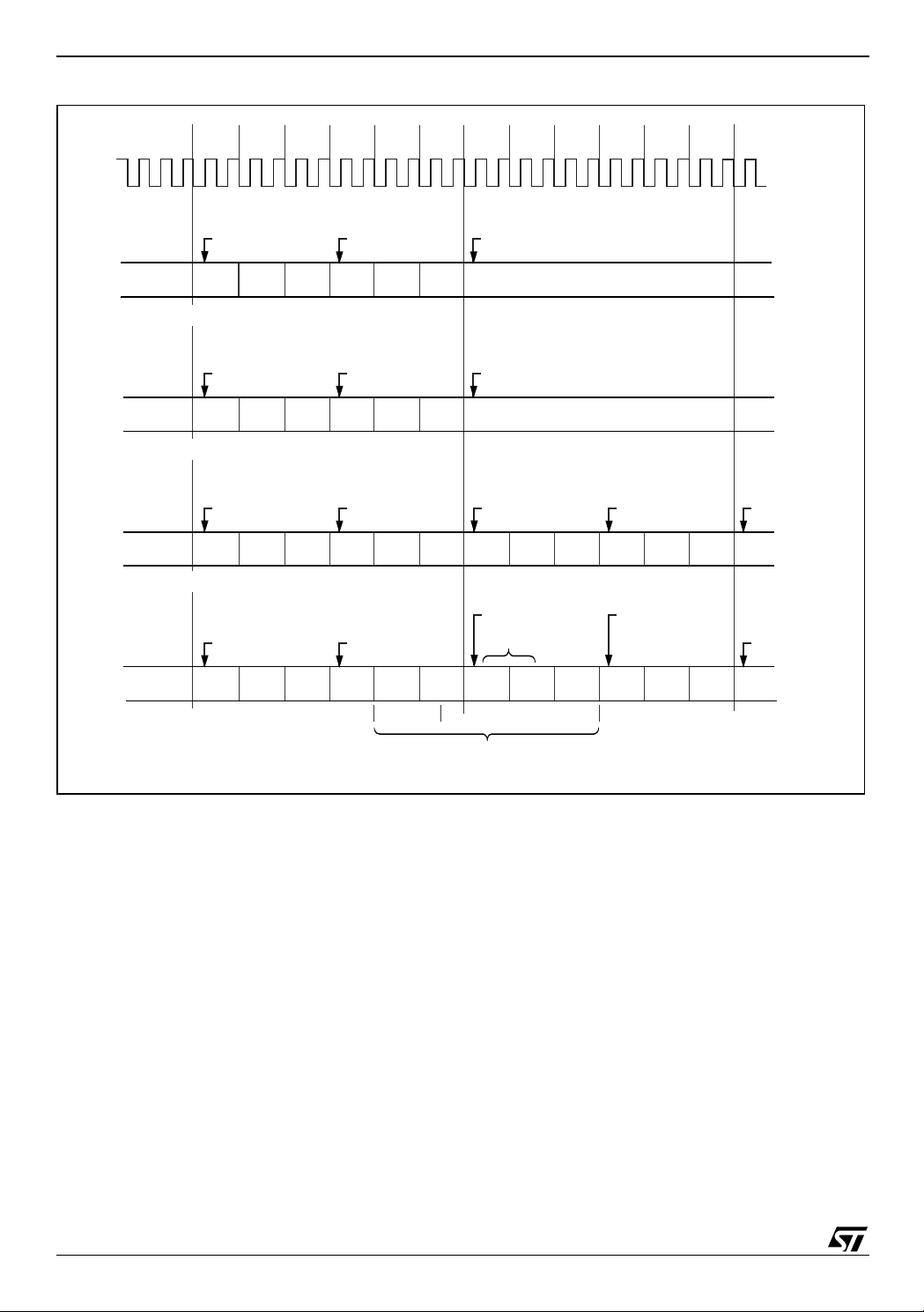

Figure 4. TQ FP 80 Connection s

PB0

P3.2 / EXINT0

80797877767574737271706968676665646362

PB1

P3.1 / TXD

PB2

P3.0 / RXD

PB3

PB4

PB5NCVREF

GND

RESET

PB6

UPSD3212C, UPSD3212CV

PB7

RD, CNTL1

P1.7 / ADC3

PSEN, CNTL2

WR, CNTL0

P1.6 / ADC2

61

PD2

P3.3 /EXINT1

PD1

PD0, ALE

PC7

PC6

PC5

See note

P4.7 / PWM4

P4.6 / PWM3

(1)

PC4

NC

NC

V

CC

GND

PC3

PC2

PC1

NC

PC0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21222324252627282930313233343536373839

40

60 P1.5 / ADC1

59 P1.4 / ADC0

58 P1.3 / TXD1

57 P2.3, A11

56 P1.2 / RXD1

55 P2.2, A10

54 P1.1 / T2X

53 P2.1, A9

52 P1.0 / T2

51 P2.0, A8

50 V

CC

49 XTAL2

48 XTAL1

47 P0.7, AD7

46 P3.7 / SCL1

45 P0.6, AD6

44 P3.6 / SDA1

43 P0.5, AD5

42 P3.5 / T1

41 P0.4, AD4

PA7

PA6

PA5

PA4

PA3

GND

P4.5 / PWM2

P4.4 / PWM1

P4.3 / PWM0

Note: 1. Pull-up resis tor requ i r ed on pin 8 (2kΩ for 3V devices, 7.5kΩ for 5V dev i ces).

2. NC = Not Connected.

P4.2

P4.1

PA2

P4.0

PA1

PA0

AD0, P0.0

AD1, P0.1

AD2, P0.2

AD3, P0.3

P3.4 / T0

AI07424

13/152

Page 14

UPSD3212C, UPSD3212CV

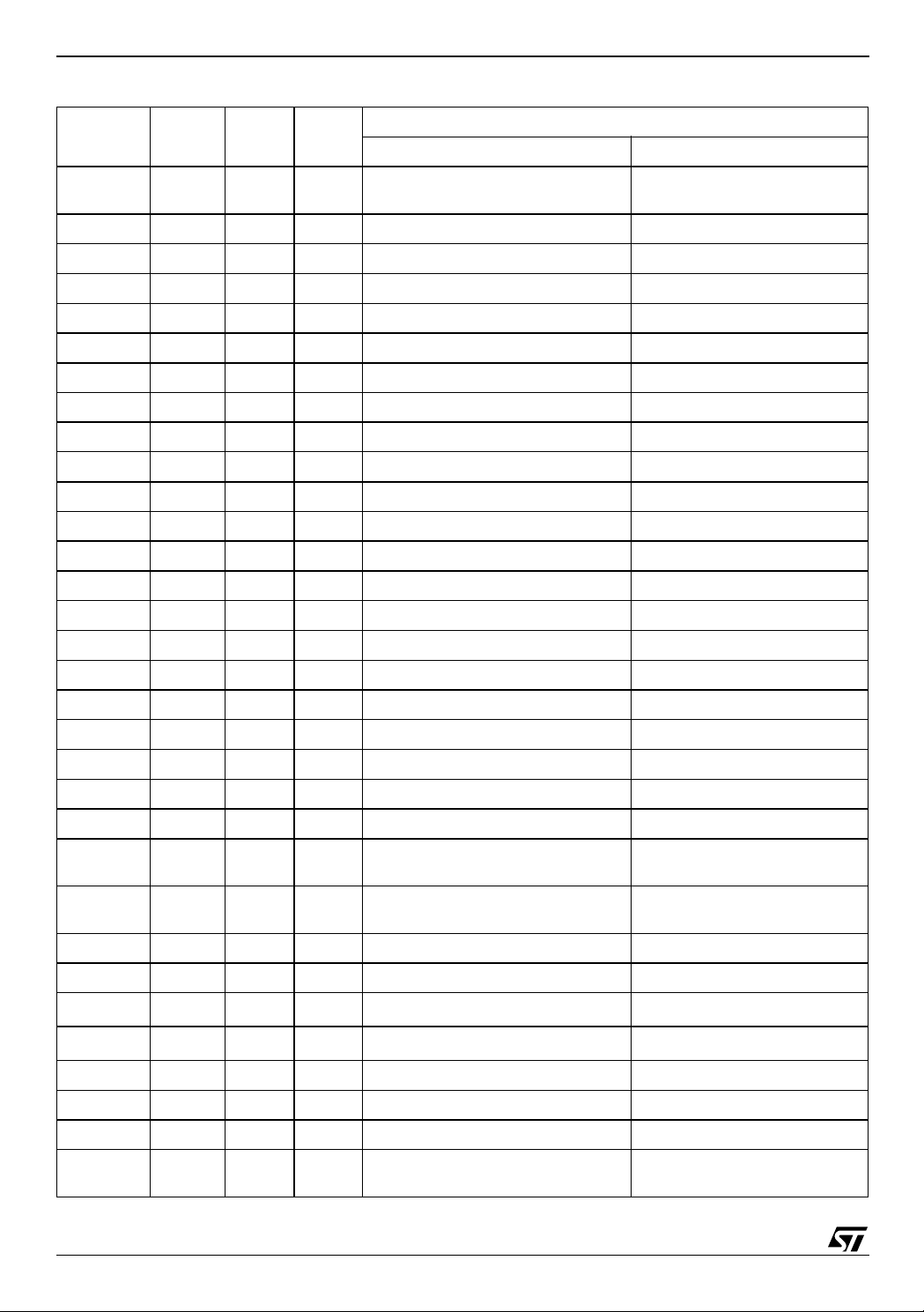

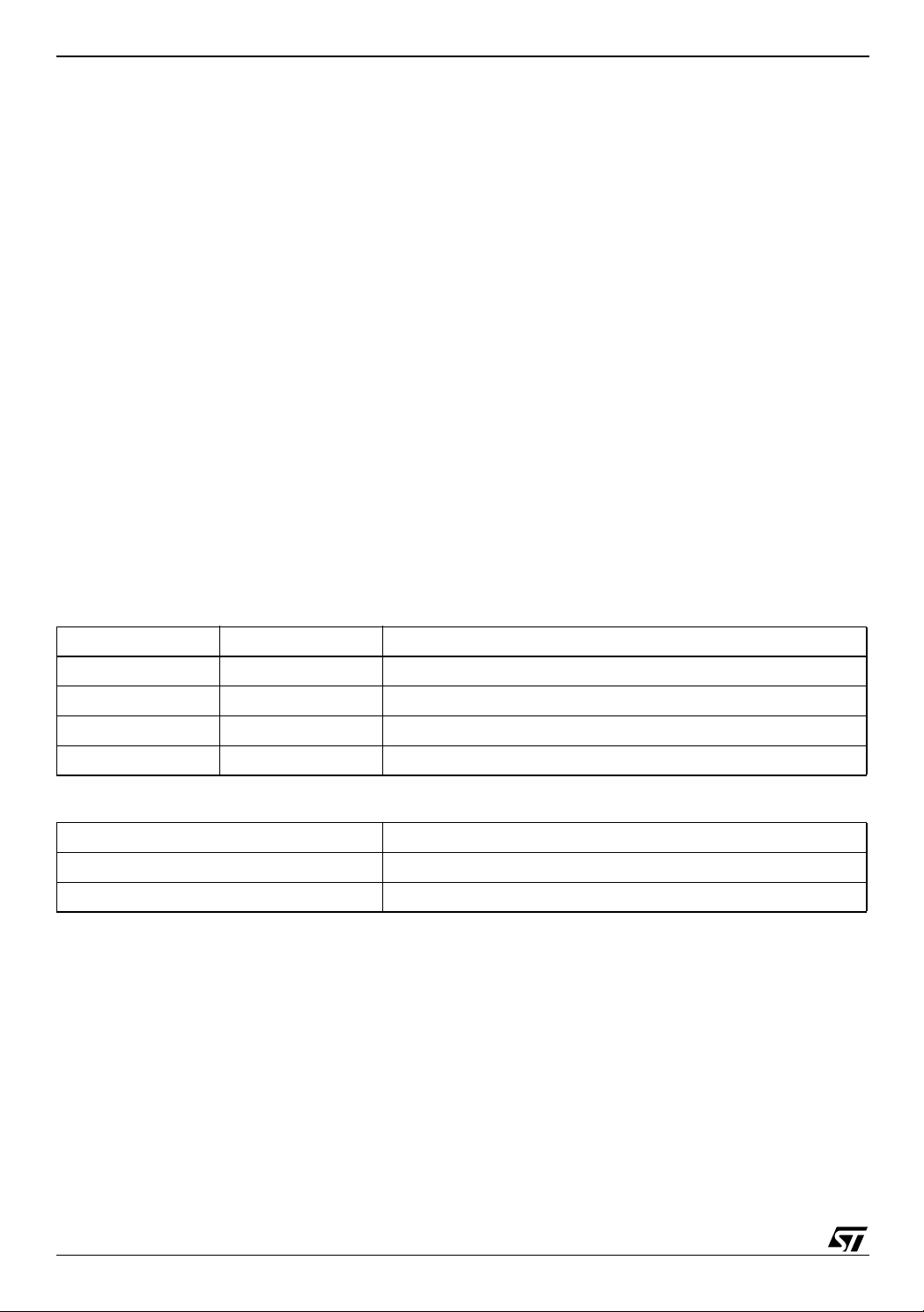

Table 2. 80-Pin Package Pin Description

Port Pin

P0.0 AD0 36 I/O

P0.1 AD1 37 I/O Multiplexed Address/Data bus A0/D0

P0.2 AD2 38 I/O Multiplexed Address/Data bus A2/D2

P0.3 AD3 39 I/O Multiplexed Address/Data bus A3/D3

P0.4 AD4 41 I/O Multiplexed Address/Data bus A4/D4

P0.5 AD5 43 I/O Multiplexed Address/Data bus A5/D5

P0.6 AD6 45 I/O Multiplexed Address/Data bus A6/D6

P0.7 AD7 47 I/O Multiplexed Address/Data bus A7/D7

P1.0 T2 52 I/O General I/O port pin Timer 2 Count input

P1.1 T2EX 54 I/O General I/O port pin Timer 2 Trigger input

P1.2 RxD2 56 I/O General I/O port pin 2nd UART Receive

P1.3 TxD2 58 I/O General I/O port pin 2nd UART Transmit

P1.4 ADC0 59 I/O General I/O port pin ADC Channel 0 input

P1.5 ADC1 60 I/O General I/O port pin ADC Channel 1 input

P1.6 ADC2 61 I/O General I/O port pin ADC Channel 2 input

P1.7 ADC3 64 I/O General I/O port pin ADC Channel 3 input

Signal

Name

Pin No. In/Out

Basic Alternate

External Bus

Multiplexed Address/Data bus A1/D1

Function

P2.0 A8 51 O External Bus, Address A8

P2.1 A9 53 O External Bus, Address A9

P2.2 A10 55 O External Bus, Address A10

P2.3 A11 57 O External Bus, Address A11

P3.0 RxD1 75 I/O General I/O port pin UART Receive

P3.1 TxD1 77 I/O General I/O port pin UART Transmit

P3.2 INTO 79 I/O General I/O port pin

P3.3 INT1 2 I/O General I/O port pin

P3.4 T0 40 I/O General I/O port pin Counter 0 input

P3.5 T1 42 I/O General I/O port pin Counter 1 input

P3.6 SDA1 44 I/O General I/O port pin

P3.7 SCL1 46 I/O General I/O port pin

P4.0 33 I/O General I/O port pin

P4.1 31 I/O General I/O port pin

P4.2 30 I/O General I/O port pin

P4.3 PWM0 27 I/O General I/O port pin

Interrupt 0 input / Timer 0 gate

control

Interrupt 1 input / Timer 1 gate

control

2

I

C Bus serial data I/O

2

I

C Bus clock I/O

8-bit Pulse Width Modulation

output 0

14/152

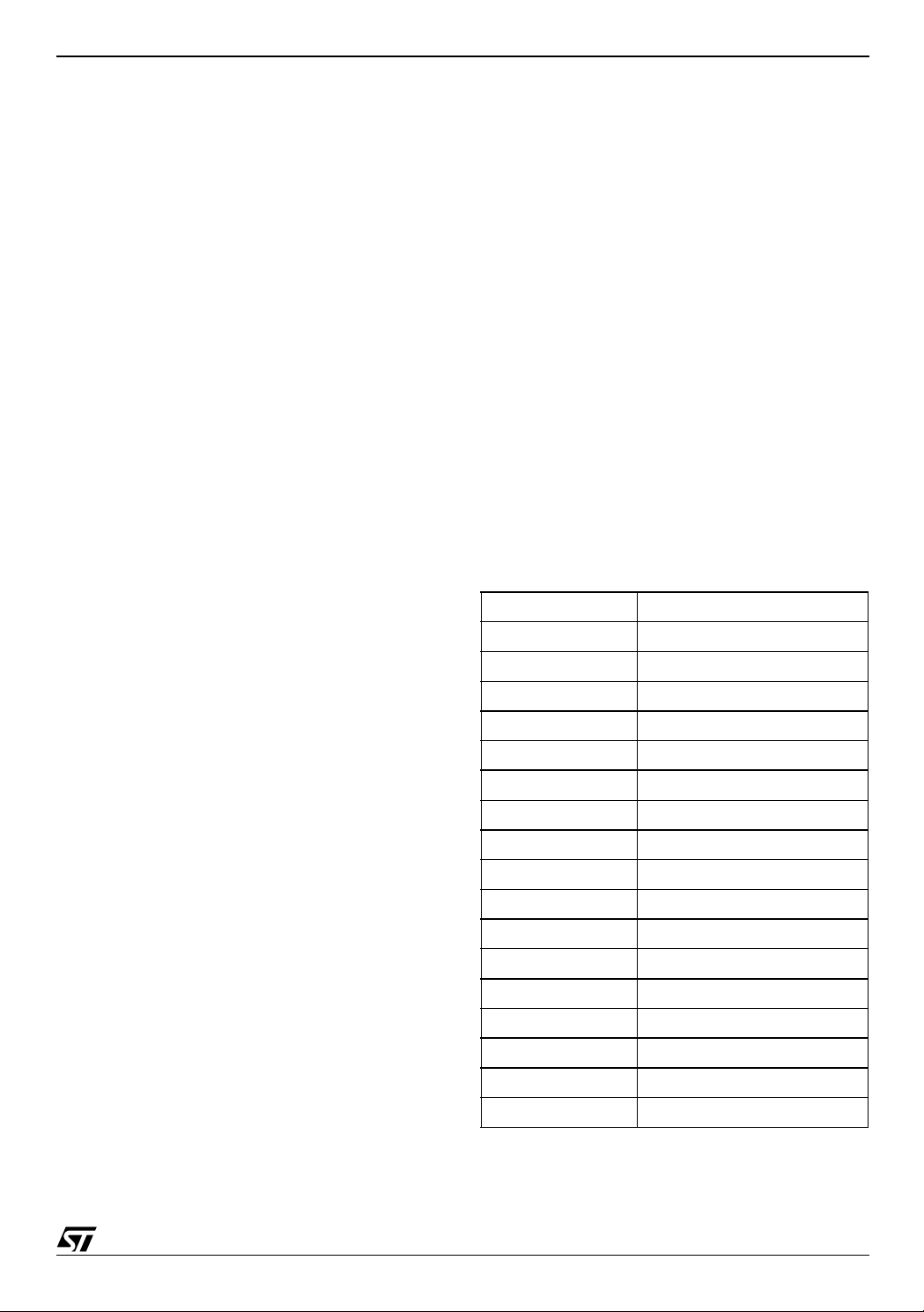

Page 15

UPSD3212C, UPSD3212CV

Port Pin

P4.4 PWM1 25 I/O General I/O port pin

P4.5 PWM2 23 I/O General I/O port pin

P4.6 PWM3 19 I/O General I/O port pin

P4.7 PWM4 18 I/O General I/O port pin

Signal

Name

PUP 8 I/O

AVREF 70 O Reference Voltage input for ADC

RD_ 65 O READ signal, external bus

WR_ 62 O WRITE signal, external bus

PSEN_ 63 O PSEN

ALE 4 O Address Latch signal, external bus

RESET_ 68 I Active low RESET

XTAL1 48 I Oscillator input pin for system clock

XTAL2 49 O Oscillator output pin for system clock

Pin No. In/Out

Pull-up resistor required (2kΩ for 3V

devices, 7.5kΩ for 5V devices)

signal, external bus

Function

Basic Alternate

8-bit Pulse Width Modulation

output 1

8-bit Pulse Width Modulation

output 2

8-bit Pulse Width Modulation

output 3

Programmable 8-bit Pulse Width

modulation output 4

input

PA0 35 I/O General I/O port pin

PA1 34 I/O General I/O port pin

PA2 32 I/O General I/O port pin

PA3 28 I/O General I/O port pin

PA4 26 I/O General I/O port pin

PA5 24 I/O General I/O port pin

PA6 22 I/O General I/O port pin

PA7 21 I/O General I/O port pin

PB0 80 I/O General I/O port pin

PB1 78 I/O General I/O port pin

PB2 76 I/O General I/O port pin

PB3 74 I/O General I/O port pin

PB4 73 I/O General I/O port pin

PB5 72 I/O General I/O port pin

PB6 67 I/O General I/O port pin

PB7 66 I/O General I/O port pin

1. PLD Macro-cell outputs

2. PLD inputs

3. Latched Address Out (A0-A7)

4. Peripheral I/O Mode

1. PLD Macro-cell outputs

2. PLD inputs

3. Latched Address Out (A0-A7)

15/152

Page 16

UPSD3212C, UPSD3212CV

Port Pin

PC0 TMS 20 I JTAG pin

PC1 TCK 16 I JTAG pin

PC2

PC3 TSTAT 14 I/O General I/O port pin

PC4 TERR 9 I/O General I/O port pin

PC5 TDI 7 I JTAG pin

PC6 TDO 6 O JTAG pin

PC7 5 I/O General I/O port pin

PD1 CLKIN 3 I/O General I/O port pin

PD2 CSI 1 I/O General I/O port pin

Vcc 12

Vcc 50

GND 13

GND 29

GND 69

NC 10

Signal

Name

V

STBY

Pin No. In/Out

15 I/O General I/O port pin

Function

Basic Alternate

1. PLD Macro-cell outputs

2. PLD inputs

3. SRA M stand by voltage input

4. SRAM battery-on indicator

5. JTAG pins are dedicated pins

1. PLD I/O

2. Clock input to PLD and APD

1. PLD I/O

2. Chip select to PSD Module

(V

STBY

(PC4)

)

NC 11

NC 17

NC 71

52 PIN PACKAGE I/O PORT

The 52-pin package members of the uPSD321X

Devices have the same port pins as those of the

80-pin package except:

■ Port 0 (P0.0-P0.7, external address/data bus

AD0-AD7)

■ Port 2 (P2.0-P2.3, external address bus A8-

A11)

■ Port A (PA0-PA7)

■ Port D (PD2)

■ Bus control signal (RD,WR,PSEN,ALE)

Pin 5 requires a pull-up resistor (2kΩ for 3V devices, 7.5kΩ for 5V devices) for all devices.

16/152

Page 17

ARCHITECTURE OVERVIEW

Memory Organization

The uPSD321X Devices’s standard 8032 Core

has separate 64KB address spac es for Program

memory and Data Memory. Program memory is

where the 8032 executes in structions from. Data

memory is used to hold data variables. Flash

memory can be mapped in either program or data

space. The Flash memory consists of two flash

memory blocks: the main Flash (512Kbit) and the

Secondary Flash (128Kbit). Except during flash

memory programming or update, Flash memory

can only be read, not written to. A Page Register

is used to access memory beyond t he 64K bytes

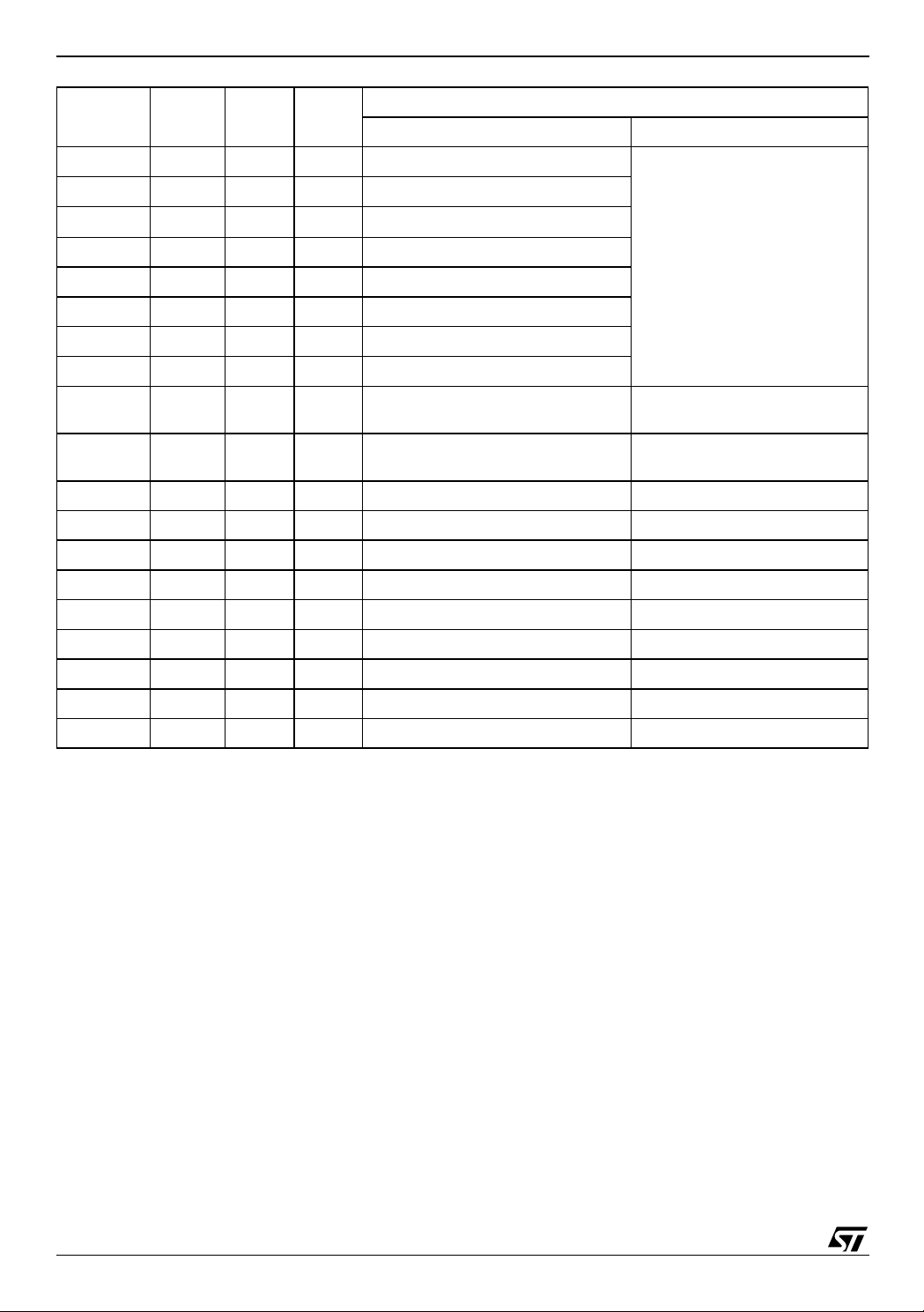

Figure 5. Memory Map and Address Space

MAIN

FLASH

UPSD3212C, UPSD3212CV

address space. Refer to the PSD Module for details on mapping of the Flash memory.

The 8032 core h as t wo ty pes of data m em ory (internal and external) that can be read and written.

The internal SRAM cons ists of 256 byte s, and includes the stack area.

The SFR (Special Function Registers) occupies

the upper 128 bytes of the internal SRAM, the registers can be accessed by Direct addressing only.

Another 2K bytes resides in the PSD Modul e that

can be mapped to any address space defined by

the user.

EXT. RAM

SECONDARY

FLASH

16KB

Flash Memory Space

64KB

INT. RAM

FF

Indirect

Addressing

7F

Indirect

Direct

Addressing

0

Internal RAM Space

(256 Bytes)

SFR

Direct

Addressing

or

2KB

External RAM Space

(MOVX)

AI07425

17/152

Page 18

UPSD3212C, UPSD3212CV

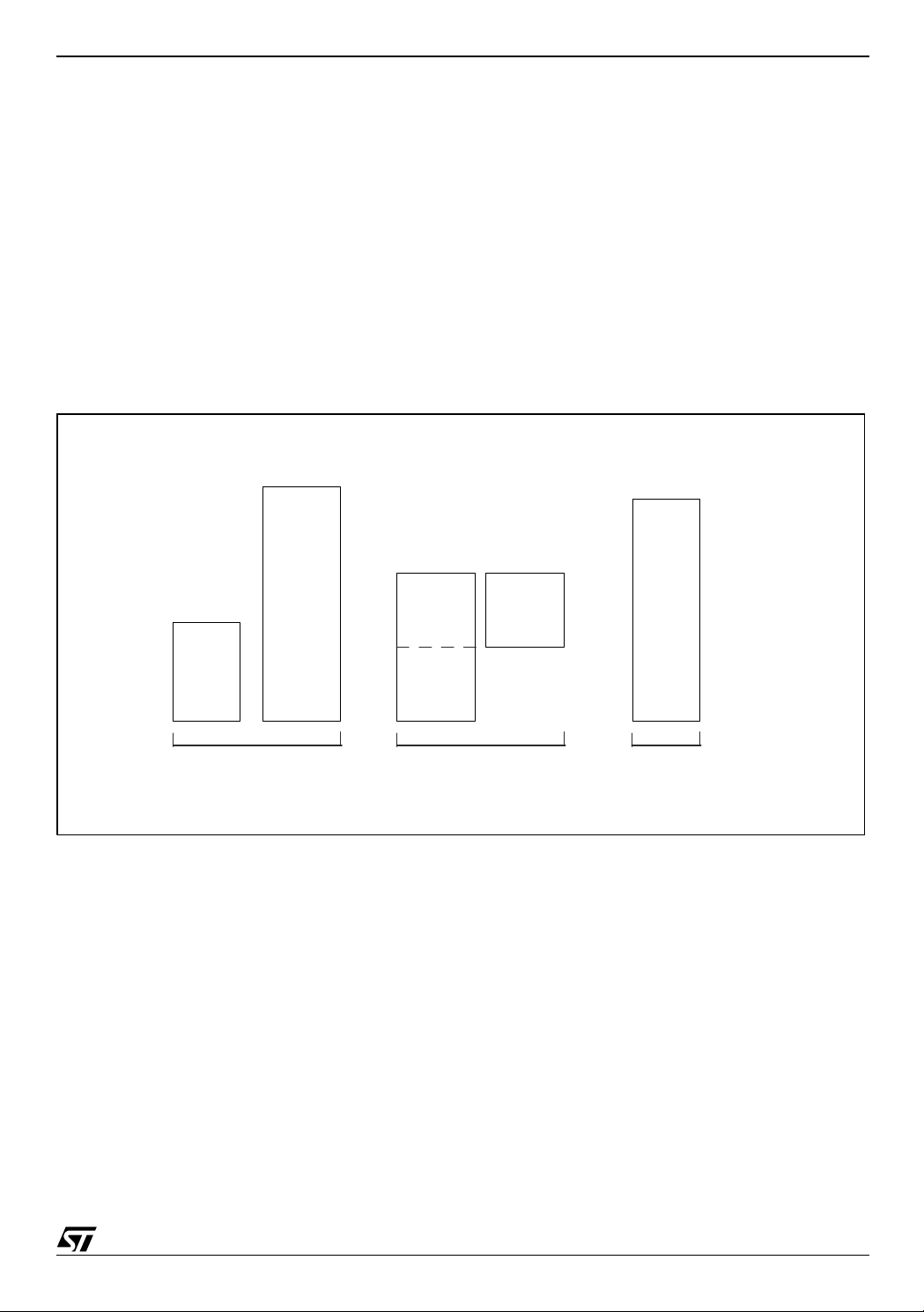

Registers

The 8032 has several registers; these are the Program Counter (PC), Accumulator (A), B Register

(B), the Stack Pointer (SP), the Program Status

Word (PSW), General purpose registers (R0 to

R7), and DPTR (Data Pointer register).

Accumulator. The Ac cumulator is the 8-bit general purpose register, used for data operation such

as transfer, temporary saving, and conditional

tests. The Accumulator can be used as a 16-bit

register with B Register as shown in Figure 6.

B Register. The B Register is the 8-bit general

purpose register, used f or an arithmetic operation

such as multiply, division with the Accumulator

(see Figure 7).

Stack Pointer. The Stack Pointer Register is 8

bits wide. It is incremented before data is stored

during PUSH and CALL executions. While the

stack may reside anywhere in on-chip RAM, the

Stack Po inter is initi alize d to 07h af ter reset. Th is

causes the stack to begin at location 08h (see Figure 8).

Program Counter. The Program Counter is a 16bit wide which consists of two 8-bit registers, PCH

and PCL. This counter indicates the address of the

next instruction to be executed. In RESET

the program counter has reset routine address

(PCH:00h, PCL:00h).

Program Status Word. The Program Status

Word (PSW) contains several bits that reflect the

current state of the CPU and select Internal RAM

(00h to 1Fh: Bank0 to Bank3). The PSW is described in Figure 9, page 19. It contains the Carry

Flag, the Auxiliary Carry Flag, the Half Carry (for

BCD operation), the general purpose flag, the

Register Bank Select Flags, the Overflow Flag,

and Parity Flag.

[Carry Flag, CY]. This flag stores any carry or not

borrow from the ALU of CPU after an arithmetic

operation and is also changed by the Shift Instruction or Rotate Instruction.

[Auxiliary Carry Flag, AC]. After operation, this is

set when there is a carry from Bit 3 of ALU or there

is no borrow from Bit 4 of ALU.

[Register Bank Select Flags, RS0, RS1]. This flags

select one of four bank(00~07H:bank0,

08~0Fh:bank1, 10~17h: bank2, 17~1Fh:bank3) in

Internal RAM.

[Overflow Flag, OV]. This flag is set to '1' when an

overflow occurs as the result of an arithmetic operation involving signs. An overflow occurs when the

result of an addition or subtraction exceeds +127

(7Fh) or -128 (80h). The CLRV instruction clears

the overflow flag. There is no set instruction. When

state,

the BIT instruction is executed, Bit 6 of memory is

copied to this flag.

[Parity Flag, P]. This flag reflects on number of Accumulator’s “1.” If the number of Accumulator’s 1

is odd, P=0. otherwise, P=1. The sum of adding

Accumulator’s 1 to P is always even.

R0~R7. General purpose 8-bit registers that are

locked in the lower portion of internal data area.

Data Pointer Register. Data Pointer Register is

16-bit wide which consists of two-8bit registers,

DPH and DPL. This register is used as a data

pointer for the data transmission with external data

memory in the PSD Module.

Figure 6. 8032 MCU Registers

Accumulator

B Register

Stack Pointer

Program Counter

Program Status Word

General Purpose

Register (Bank0-3)

Data Pointer Register

AI06636

PCH

DPTR(DPH)

A

B

SP

PCL

PSW

R0-R7

DPTR(DPL)

Figure 7. Configuration of BA 16-bit Registers

B

AB

A

Two 8-bit Registers can be used as a "BA" 16-bit Registers

AI06637

Figure 8. Stack Pointer

Stack Area (30h-FFh)

Bit 15 Bit 0Bit 8 Bit 7

Hardware Fixed

SP (Stack Pointer) could be in 00h-FFh

SP00h

00h-FFh

AI06638

18/152

Page 19

Figure 9. PSW (Program Status Word) Registe r

UPSD3212C, UPSD3212CV

MSB

CY

PSW

Carry Flag

Auxillary Carry Flag

General Purpose Flag

AC FO RS1 RS0 OV P

Register Bank Select Flags

(to select Bank0-3)

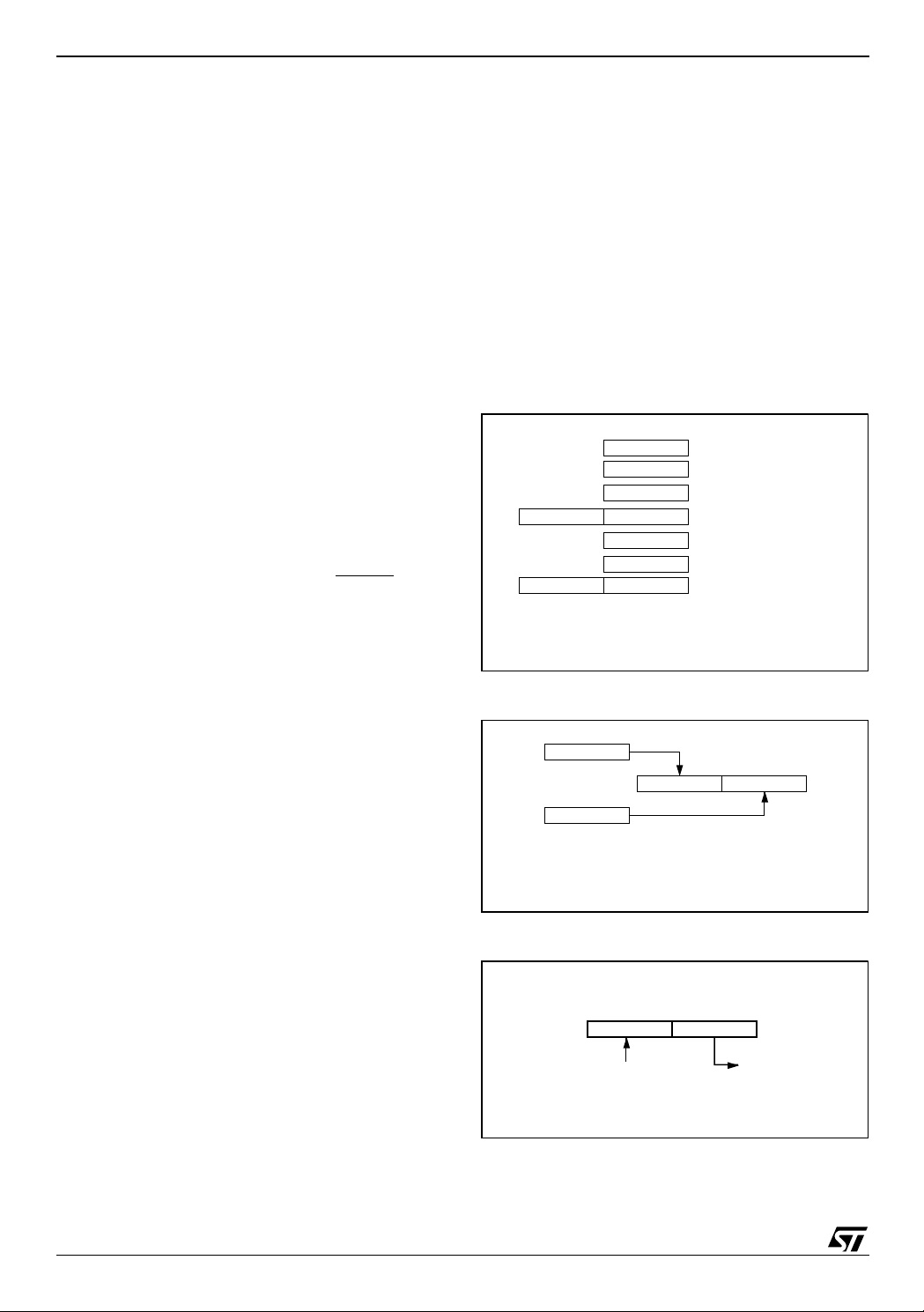

Program Memory

The program memory consists of two Flash memory: 64KByte Main Flash and 16KByte of Secondary Flash. The Flash mem ory can be mapped to

any address space as define d by the user in the

PSDsoft Tool. It can also be mapped to Data

memory space during Flash memory update or

programming.

After reset, the CPU begins execution from location 0000h. As shown in Figure 10, each interrupt

is assigned a fixed location in Program Memory.

The interrupt causes the CPU to jump to t hat location, where it commences execution of the service

routine. External Interrupt 0, for example, is assigned to location 0003h. If External Interrupt 0 is

going to be used, its service routine must begin at

location 0003h. If the interrupt is not going to be

used, its service location is available as gen eral

purpose Program Memory.

The interrupt service locations are spaced at 8byte intervals: 0003h for External Interrupt 0,

000Bh for Timer 0, 0013 h for E xternal I nterrupt 1,

001Bh for Timer 1 and so forth. If an interrupt service routine is short enough (as is often the c ase

in control applications), it can reside entirely within

that 8-byte interval (see Figure 10). Longer service

routines can use a jump instruction to s kip over

subsequent interrupt locat ions, if other interrupts

are in use.

Data memory

The internal data memory is divided into four physically separate d blocks: 256 bytes of internal RAM,

128 bytes of Special Function Registers (SFRs)

areas and 2K bytes (XRAM-PSD) in the PSD Module.

LSB

Reset Value 00h

Parity Flag

Bit not assigned

Overflow Flag

AI06639

RAM

Four register banks, each 8 registers wide, occupy

locations 0 through 31 in the lower RAM area.

Only one of these banks may be enabled at a time.

The next 16 bytes, locations 32 through 47, contain 128 directly addressable bit locations. The

stack depth is only limited by the available internal

RAM space of 256 bytes.

XRAM-PSD

The 2K bytes of XRAM-P SD resides in the PSD

Module and can be mapped to any address space

through the DPLD (Decoding PLD) as defined by

the user in PSDsoft Development tool. The XRAMPSD has a battery backup feature that allow the

data to be retained in t he event of a power lost.

The battery is connected t o the Port C PC2 pin.

This pin must be configured in PSDSoft to be battery back-up.

Figure 10. Inte rru pt Lo c atio n of P rog ra m Memory

008Bh

•

•

•

•

0013h

000Bh

0003h

0000hReset

8 Bytes

AI06640

Interrupt

Location

•

•

•

•

•

19/152

Page 20

UPSD3212C, UPSD3212CV

SFR

The SFRs can only be addressed directly in the

address range from 80h to FFh. Table 15, page 32

gives an overview of the Speci al Function Registers. Sixteen address in the SFRs space are bothbyte and bit-addressable. The bit-addressable

SFRs are those whose address ends in 0h and 8h.

The bit addresses in this area are 80h to FFh.

Table 3. RAM Address

Byte Address

(in Hexadecimal)

↓↓

FFh 255

30h 48

Byte Address

(in Decimal)

Addressing Modes

The addressing modes in uPSD321 X Devices instruction set are as follows

■ Direct addressing

■ Indirect addressing

■ Register addressing

■ Register-specific addressing

■ Immediate constants addressing

■ Indexed addressing

(1) Direct addressing. I n a direct addressing t he

operand is specified by an 8-bit address field in the

instruction. Only internal Data RAM and SFRs

(80~FFH RAM) can be directly addressed.

Example:

msb Bit Address (Hex) lsb

2Fh 7F 7E 7D 7C 7B 7A 79 78 47

2Eh 77 76 75 74 73 72 71 70 46

2Dh 6F 6E 6D 6C 6B 6A 69 68 45

2Ch 67 66 65 64 63 62 61 60 44

2Bh 5F 5E 5D 5C 5B 5A 59 58 43

mov A, 3EH ;A <----- RAM[3E]

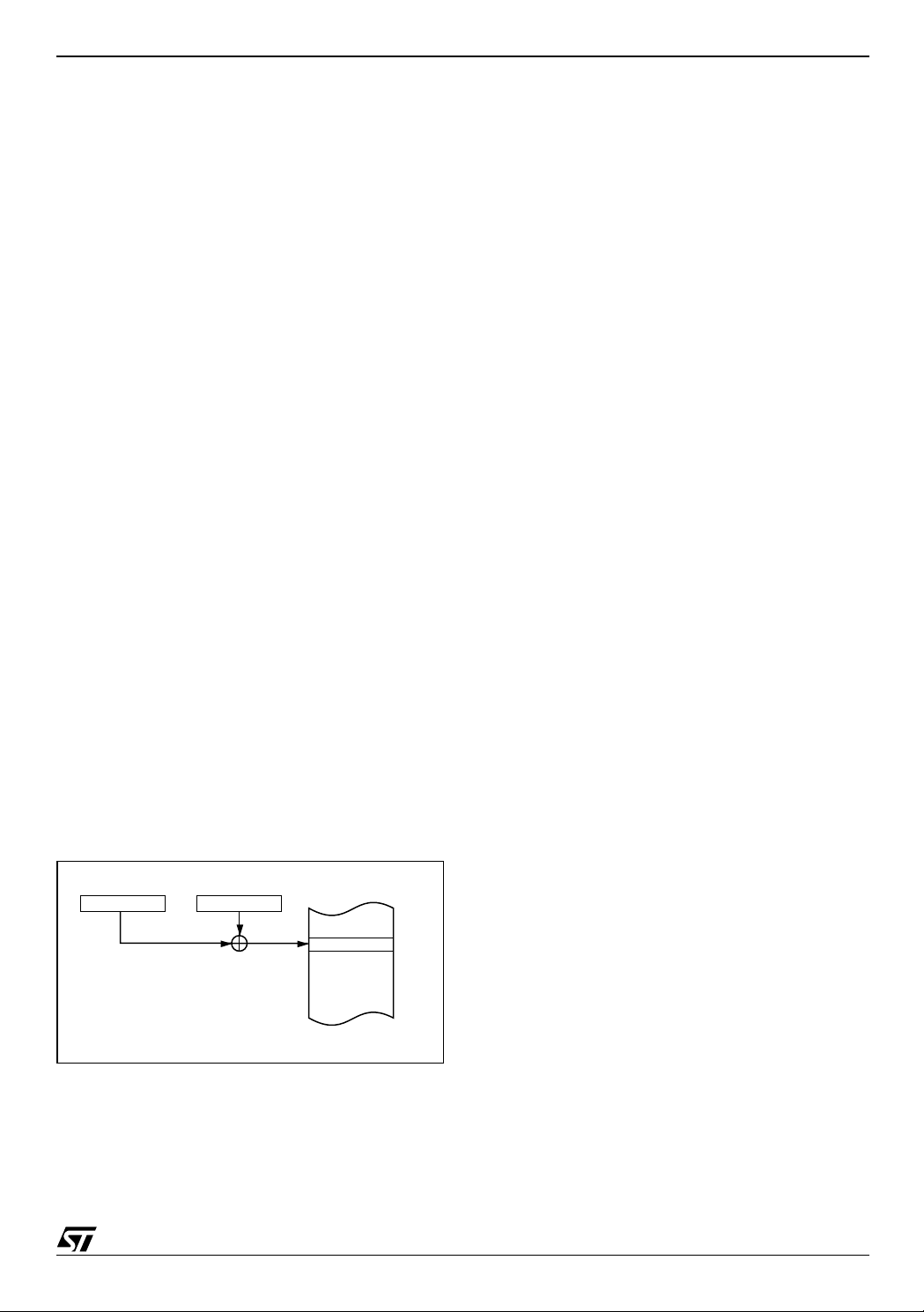

Figure 11. Direct Addressing

Program Memory

3Eh

04

A

2Ah 57 56 55 54 53 52 51 50 42

29h 4F 4E 4D 4C 4B 4A 49 48 41

28h 47 46 45 44 43 42 41 40 40

27h 3F 3E 3D 3C 3B 3A 39 38 39

26h 37 36 35 34 33 32 31 30 38

25h 2F 2E 2D 2C 2B 2A 29 28 37

24h 27 26 25 24 23 22 21 20 36

23h 1F 1E 1D 1C 1B 1A 19 18 35

22h 17 16 15 14 13 12 11 10 34

21h 0F 0E 0D 0C 0B 0A 09 08 33

20h 07 06 05 04 03 02 01 00 32

1Fh

Register Bank 3

18h 24

17h

Register Bank 2

10h 16

0Fh

Register Bank 1

08h 8

07h

Register Bank 0

00h 0

31

23

15

AI06641

(2) Indirect addressing. In indirect addressing

the instruction specifies a register which contains

the address of the operand. Both internal and external RAM can be indirectly addressed. The address register for 8-bit addresses can be R0 or R1

of the selected register bank, or the Stack Pointer.

The address register for 16-bit addresses can only

be the 16-bit “data pointer” register, DPTR.

Example:

mov @R1, #40 H ;[R1] <-----40H

Figure 12. Indirect Addressing

Program Memory

55h

7

R1

40h

55

AI06642

20/152

Page 21

UPSD3212C, UPSD3212CV

(3) Register addressing. The register banks,

containing registers R0 through R7, can be accessed by certain instructions which carry a 3-bit

register specification within the opc ode of the instruction. Instructions that access the registers

this way are code efficient, since t his mode eliminates an address byte. When the instruction is executed, one of four banks is selected at execution

time by the two bank select bits in the PSW.

Example:

mov PSW, #0001000B ; select Bank0

mov A, #30H

mov R1, A

(4) Register-specific addressing. Some instructions are specific to a certain register. For example, some instructions always operate on the

Accumulator, or Data Pointer, etc., so no address

byte is needed to point it. The opcode it self does

that.

(5) Immediate constants addressing. The value of a constant can follow the opcode in Program

memory.

Example:

mov A, #10H.

(6) Indexed addressing. Only Program memory

can be accessed with indexed addressing, a nd it

can only be read. This addressing mode is intended for reading look-up tables in Program memory.

A 16-bit base register (either DPTR or PC) points

to the base of the table, and the Accumulator is set

up with the table entry number. The address of the

table entry in Program memory is formed by adding the Accumulator data to the bas e p ointer (see

Figure 13).

Example:

movc A, @A+DPTR

Figure 13. Indexed Addressing

Arithmetic Instructions

The arithmetic instructions is listed in Table 4,

page 22. The table indicates the addressing

modes that can be used with each ins truction to

access the <byte> operand. For example, the

ADD A, <byte> instruction can be written as:

ADD a, 7FH (direct addressing)

ADD A, @R0 (indirect addressing)

ADD a, R7 (register addressing)

ADD A, #127 (immediate constant)

Note: Any byte in the internal Data Memory space

can be incremented without going through the Accumulator.

One of the INC instructions operates on the 16-bit

Data Pointer. The Data Pointer is used to generate

16-bit addresses for external memory, so being

able to increment it in one 16-bit operations is

a useful feature.

The MUL A B instruc tion mul tiplies the Accum ula-

tor by the data in the B register and puts the 16-bit

product into the concatenated B and Accumulator

registers.

The DIV AB instruction divides the Accumulator by

the data in the B register and leaves the 8-bit quotient in the Accumulator, and the 8-bit remainder in

the B regi s ter.

In shift operations, dividing a num ber by 2n s hifts

its “n” bits to the right. Using DIV AB t o perform the

division completes the shift in 4?s and leaves the

B register holding the b its that were shifted out.

The DAA instruction is for BCD arithmetic operations. In BCD arithmetic, ADD and ADDC instructions should always be followed by a DAA

operation, to ensure that the result is also in BCD.

Note: DAA will not convert a binary number to

BCD. The DAA operation produces a meaningful

result only as the second step in the addition of

two BCD bytes.

ACC DPTR

3Ah 1E73h

Program Memory

3Eh

AI06643

21/152

Page 22

UPSD3212C, UPSD3212CV

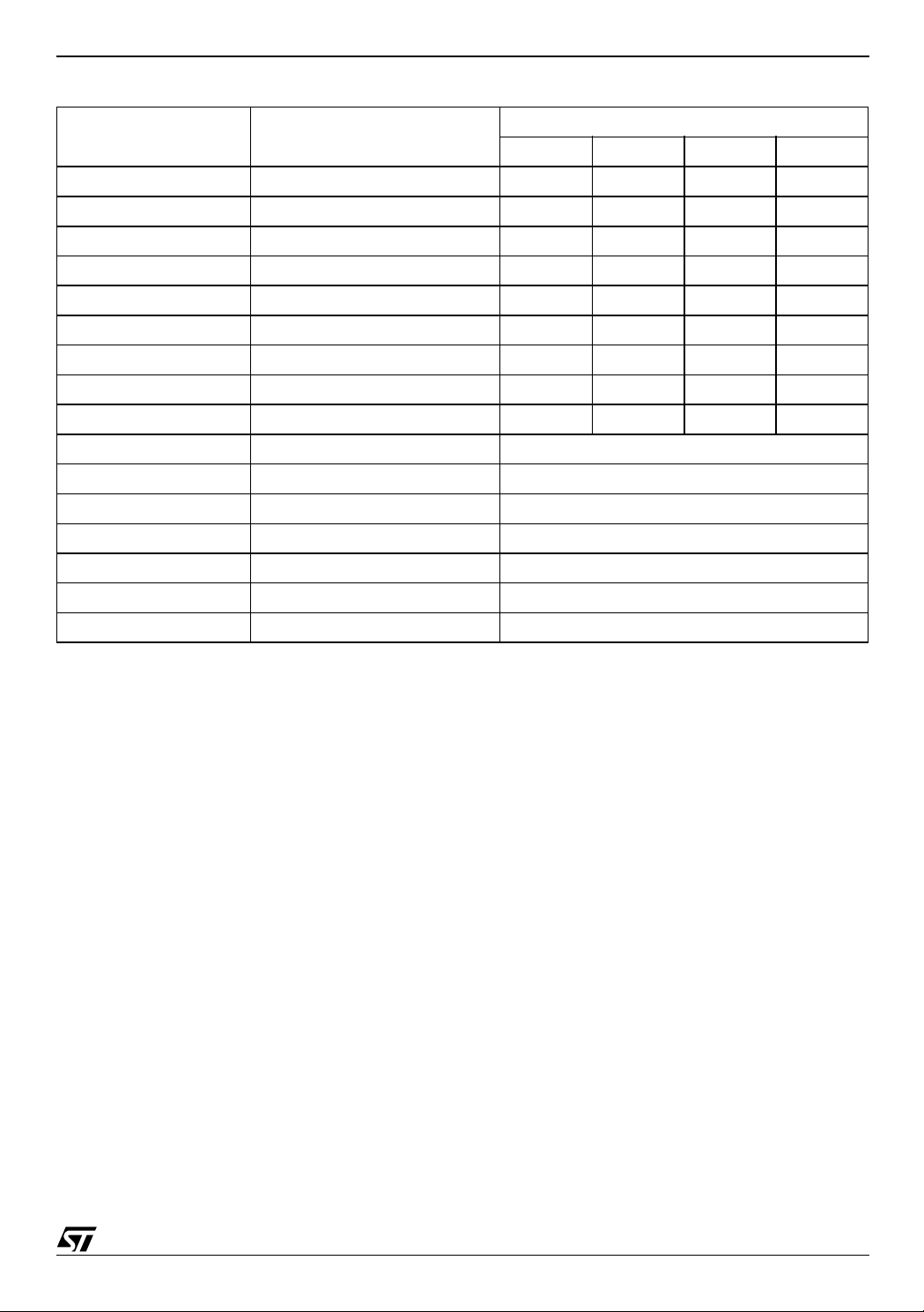

Table 4. Arithmetic Instructions

Mnemonic Operation

ADD A,<byte> A = A + <byte> X X X X

ADDC A,<byte> A = A + <byte> + C X X X X

SUBB A,<byte> A = A – <byte> – C X X X X

INC A = A + 1 Accumulator only

INC <byte> <byte> = <byte> + 1 X X X

INC DPTR DPTR = DPTR + 1 Data Pointer only

DEC A = A – 1 Accumulator only

DEC <byte> <byte> = <byte> – 1 X X X

MUL AB B:A = B x A Accumulator and B only

DIV AB

DA A Decimal Adjust Accumulator only

A = Int[ A / B ]

B = Mod[ A / B ]

Dir. Ind. Reg. Imm

Logical Instructions

Table 5, page 23 shows list of uPSD321X Devices

logical instructions. The instructions that perform

Boolean operations (AND, OR, Exclusive OR,

NOT) on bytes perform the operation on a bit-bybit basis. That is, if the Accumulator contains

00110101B and byte contains 01010011B, then:

ANL A, <byte>

will leave the Accumulat or holding 00010001B.

The addressing modes that can be used to access

the <byte> operand are listed in Table 5.

The ANL A, <byte> instruction may take any of the

forms:

ANL A,7FH(direct addressing)

ANL A, @R1 (indirect addressing)

ANL A,R6 (register addressing)

ANL A,#53H (immediate constant)

Note: Boolean operations can be performed on

any byte in the internal Data Mem ory space without going through the Accumulator. The XRL

<byte>, #data instruction, for example, offers a

quick and easy way to invert port bits, as in

If the operation is in response to an interrupt, not

using the Accumulator saves the time and effort to

push it onto the stack in the service routine.

The Rotate instructions (RL A , RLC A, etc.) shift

the Accumulator 1 bit to the left or right. For a left

rotation, the MSB rolls into the LSB position. For a

right rotation, the LSB rolls into the MSB position.

The SWAP A instruction interchanges the high

and low nibbles within the Accumulator. This is a

useful operation in BCD manipulations. For example, if the Accumulator contains a b inary number

which is known to be less than 100, it can be quickly converted to BCD by the following code:

MOVE B,#10

DIV AB

SWAP A

ADD A,B

Dividing the number by 10 leaves the tens digit in

the low nibble of the Acc umulator, and the ones

digit in the B register. The SWAP and ADD instructions move the tens digit to the high nibble of the

Accumulator, and the ones digit to the low nibble.

XRL P1, #0FFH.

Addressing Modes

Accumulator and B only

22/152

Page 23

UPSD3212C, UPSD3212CV

Table 5. Logical Instructions

Mnemonic Operation

Dir. Ind. Reg. Imm

ANL A,<byte> A = A .AND. <byte> X X X X

ANL <byte>,A A = <byte> .AND. A X

ANL <byte>,#data A = <byte> .AND. #data X

ORL A,<byte> A = A .OR. <byte> X X X X

ORL <byte>,A A = <byte> .OR. A X

ORL <byte>,#data A = <byte> .OR. #data X

XRL A,<byte> A = A .XOR. <byte> X X X X

XRL <byte>,A A = <byte> .XOR. A X

XRL <byte>,#data A = <byte> .XOR. #data X

CRL A A = 00h Accumulator only

CPL A A = .NOT. A Accumulator only

RL A Rotate A Left 1 bit Accumulator only

RLC A Rotate A Left through Carry Accumulator only

RR A Rotate A Right 1 bit Accumulator only

Addressing Modes

RRC A Rotate A Right through Carry Accumulator only

SWAP A Swap Nibbles in A Accumulator only

23/152

Page 24

UPSD3212C, UPSD3212CV

Data Transfers

Internal RAM. Table 6 shows the menu of in-

structions that are available for moving data

around within the internal memory spaces, and the

addressing modes that can be used with each

one. The MOV <dest>, <src> instruction allows

data to be transferred between any two internal

RAM or SFR locations without going through t he

Accumulator. Remember, the Uppe r 128 b ytes of

data RAM can be access ed only by indirect addressing, and SFR space only by di rect addressing.

Note: In uPSD321X Devices, the stack resides in

on-chip RAM, and grows upwards . The PUSH instruction first increments the St ack Pointer (SP),

then copies the byte into the stack. PUSH and

POP use only direct addressing to identify the byte

being saved or restored, but the stack itself is accessed by indirect addressing us ing the S P register. This means the stack can go into the Upper

128 bytes of RAM, if they are implemented, but not

into SFR space.

The Data Transfer instructions include a 16-bit

MOV that can be used to initialize the Data Pointer

(DPTR) for look-up tables in Program Memory.

The XCH A, <byte> instruction causes the Accumulator and ad-dressed byte to exchange data.

The XCHD A, @Ri instruction is similar, but only

the low nibbles are involved in the exchange. To

see how XCH and XCHD can be used to facilitate

data manipulations, cons ider first the problem of

shifting and 8-digit BCD number two digits to the

right. Table 8 shows how this can be done using

XCH instructions. To aid in understanding how the

code works, the contents of the regist ers that are

holding the BCD number and t he content of the

Accumulator are shown alongside each instruction

to indicate their status after the instruction has

been executed.

After the routine has been executed, the Accumulator contains the two digits that were shifted out

on the right. Doing the routine with direct MOVs

uses 14 code bytes. The same operation with

XCHs uses only 9 bytes and executes almost

twice as fast. To right-shift by an odd number of

digits, a one-digit must be executed. Table 9

shows a sample of code that will right-shift a BCD

number one digit, using the XCHD instruction.

Again, the contents of the registers holding the

number and of the accumulator are shown alongside each instruction.

Table 6. Data Transfer Instructions that Access Internal Data Memory Space

Mnemonic Operation

Dir. Ind. Reg. Imm

MOV A,<src> A = <src> XXXX

MOV <dest>,A <dest> = A X X X

MOV <dest>,<src> <dest> = <src> XXXX

MOV DPTR,#data16 DPTR = 16-bit immediate constant X

PUSH <src> INC SP; MOV “@SP”,<src> X

POP <dest> MOV <dest>,”@SP”; DEC SP X

XCH A,<byte> Exchange contents of A and <byte> X X X

XCHD A,@Ri Exchange low nibbles of A and @Ri X

Addressing Modes

24/152

Page 25

UPSD3212C, UPSD3212CV

First, pointers R1 and R0 are set up to point to the

two bytes containing the last four BCD digits. Then

Table 7. Shifting a BCD Number Two Digits to the Right (using direct MOVs: 14 bytes)

a loop is executed which leaves the last byte, location 2EH, holding the l ast two dig its of the shi fted

number. The pointers are decremented, and the

loop is repeated for location 2DH. The CJNE instruction (Compare and Jump if Not equal) is a

loop control that will be described later. The l oop

MOV A,2Eh 00 12 34 56 78 78

MOV 2Eh,2 Dh 00 12 34 56 56 78

MOV 2Dh,2 Ch 00 12 34 34 56 78

executed from LOOP to CJNE for R1 = 2EH, 2DH,

2CH, and 2BH. At that point the digit that was originally shifted out on the right has propagated to location 2AH. Since that location should be left with

MOV 2Ch,2 Bh 00 12 12 34 56 78