Page 1

DATA SHEET

MOS INTEGRATED CIRCUIT

µµµµ

PD77113A, 77114

16-BIT FIXED-POINT DIGITAL SIGNAL PROCESSORS

DESCRIPTION

The µPD77113A and 77114 are 16-bit fixed-point digital signal processors (DSPs).

Compared with the µPD77016 family, these DSPs have improved power consumption and are ideal for battery-

powered mobile terminals such as PDAs and cellular phones.

Both mask ROM and RAM models are available.

For details of the functions of these DSPs, refer to the following User’s Manuals:

PD77111 Family User’s Manual : U14623E

µ

PD77016 Family User’s Manual - Instructions: U13116E

µ

FEATURES

Instruction cycle (operating clock)

z

PD77113A : 13.3 ns MIN (75 MHz MAX)

µ

PD77114 : 13.3 ns MIN (75 MHz MAX)

µ

Memory

z

• Internal instruction memory

PD77113A : RAM 3.5K words × 32 bits

µ

Mask ROM 48K words × 32 bits

PD77114 : RAM 3.5K words × 32 bits

µ

Mask ROM 48K words × 32 bits

• Data memory

PD77113A : RAM 16K words × 16 bits × 2 banks

µ

Mask ROM 32K words × 16 bits × 2 banks

PD77114 : RAM 16K words × 16 bits × 2 banks

µ

Mask ROM 32K words × 16 bits × 2 banks

External memory space 8K words × 16 bits × 2 banks

ORDERING INFORMATION

Part Number Package

PD77113AF1-xxx-CN1 80-pin plastic fine-pitch BGA (9 × 9)

µ

PD77114GC-xxx-9EU 100-pin plastic TQFP (fine pitch) (14 × 14)

µ

Remark

Document No. U14373EJ3V0DS00 (3rd edition)

Date Published February 2001 N CP(K)

Printed in Japan

xxx indicates ROM code suffix.

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

The mark shows major revised points.

©

1999

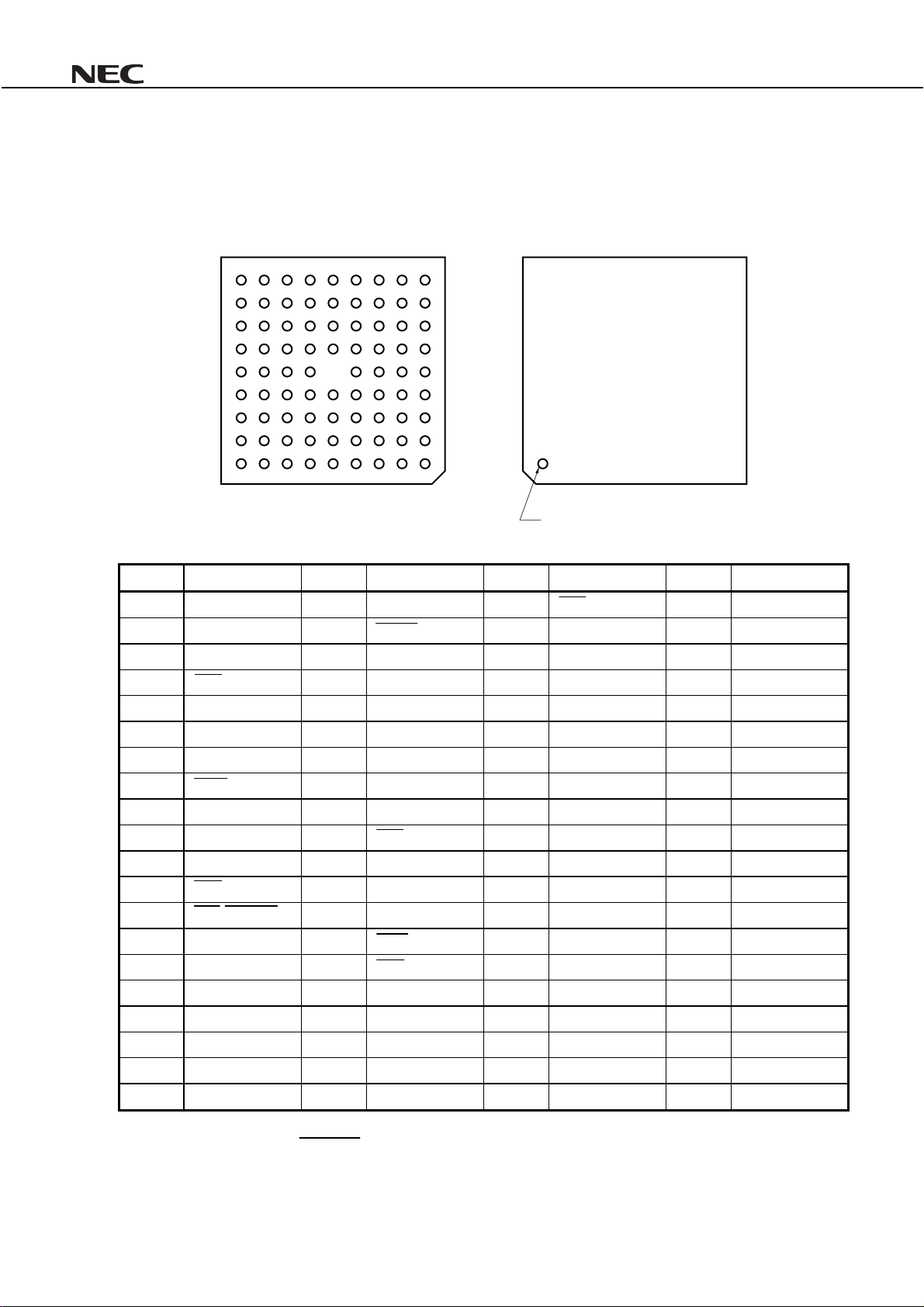

Page 2

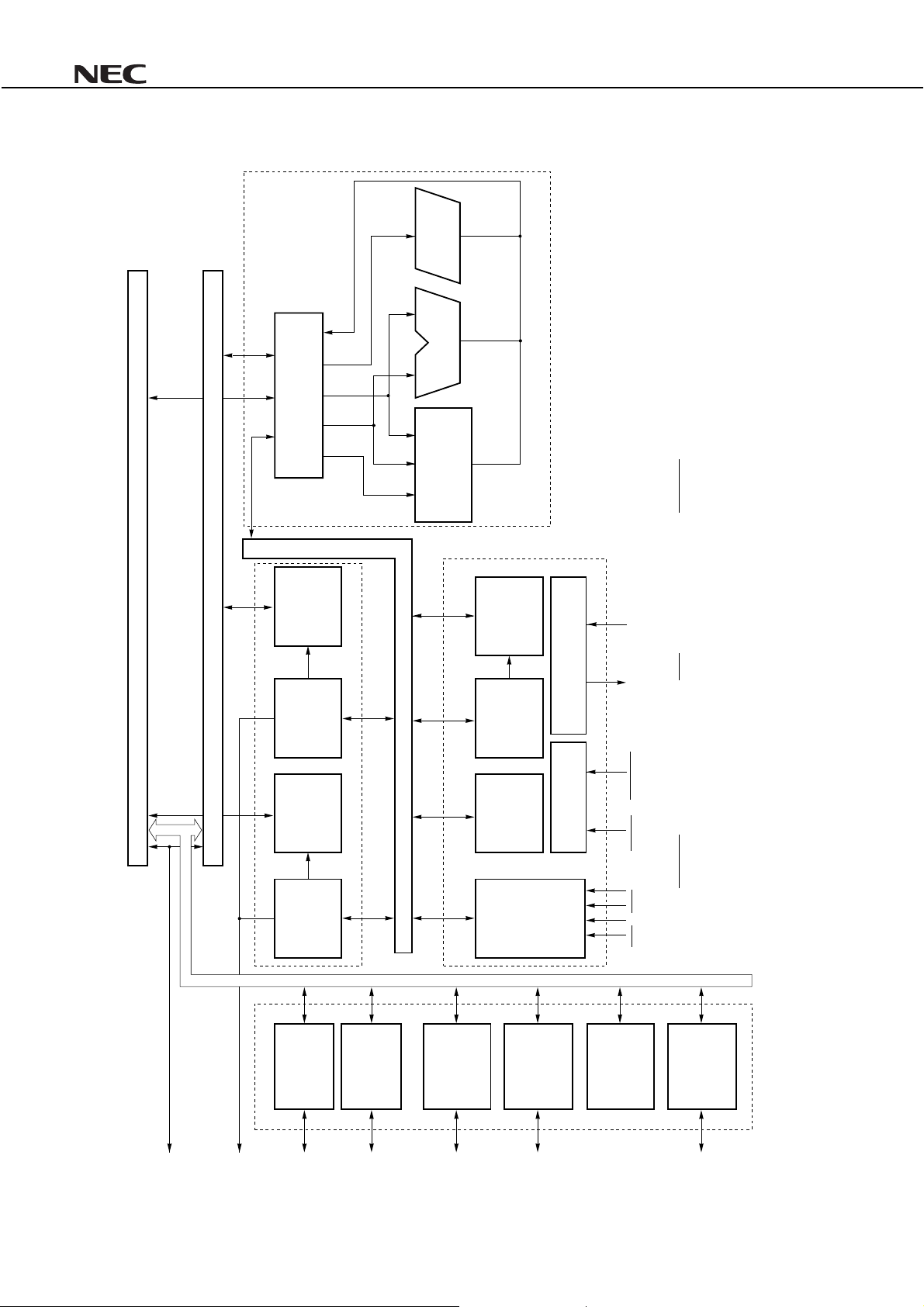

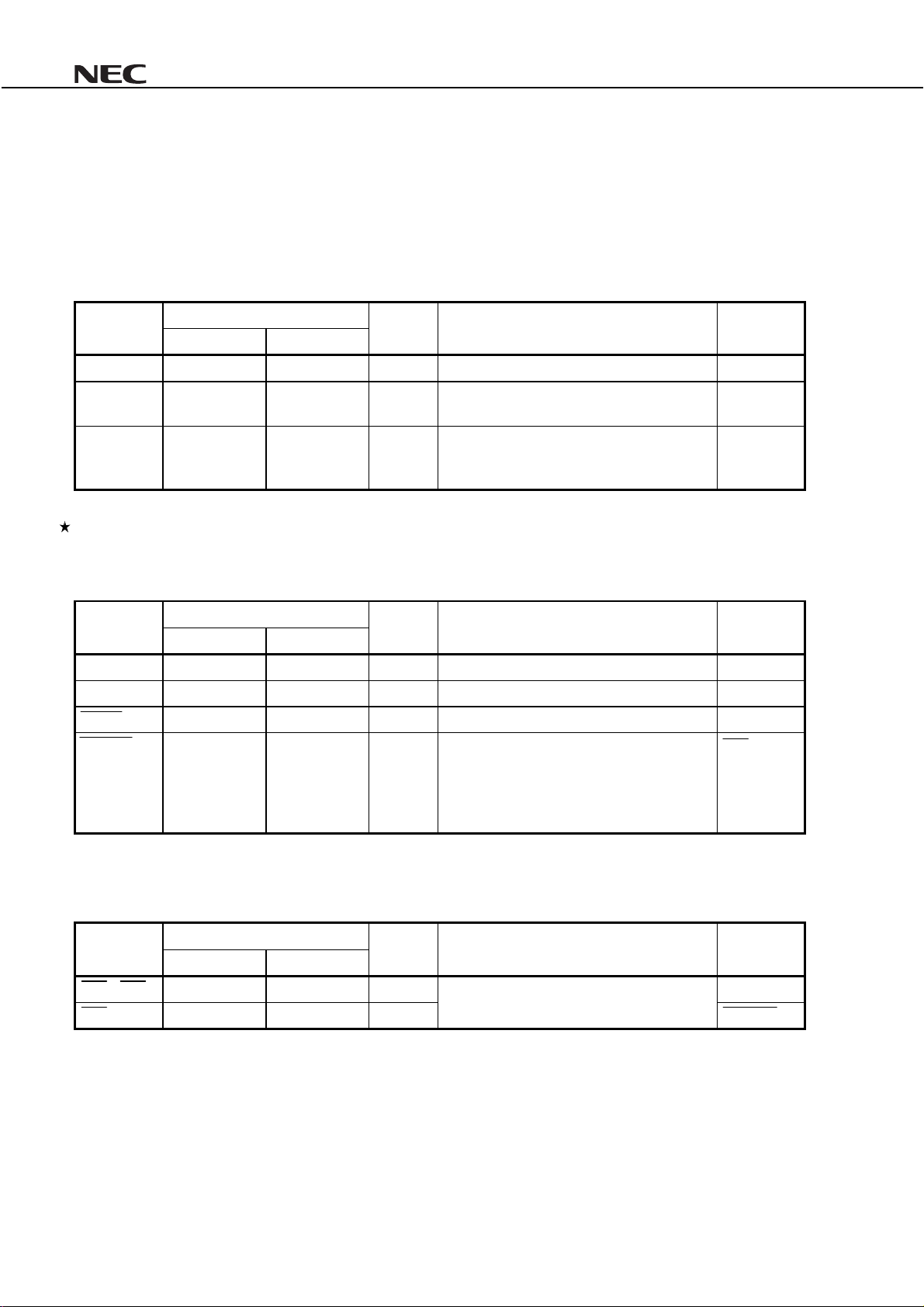

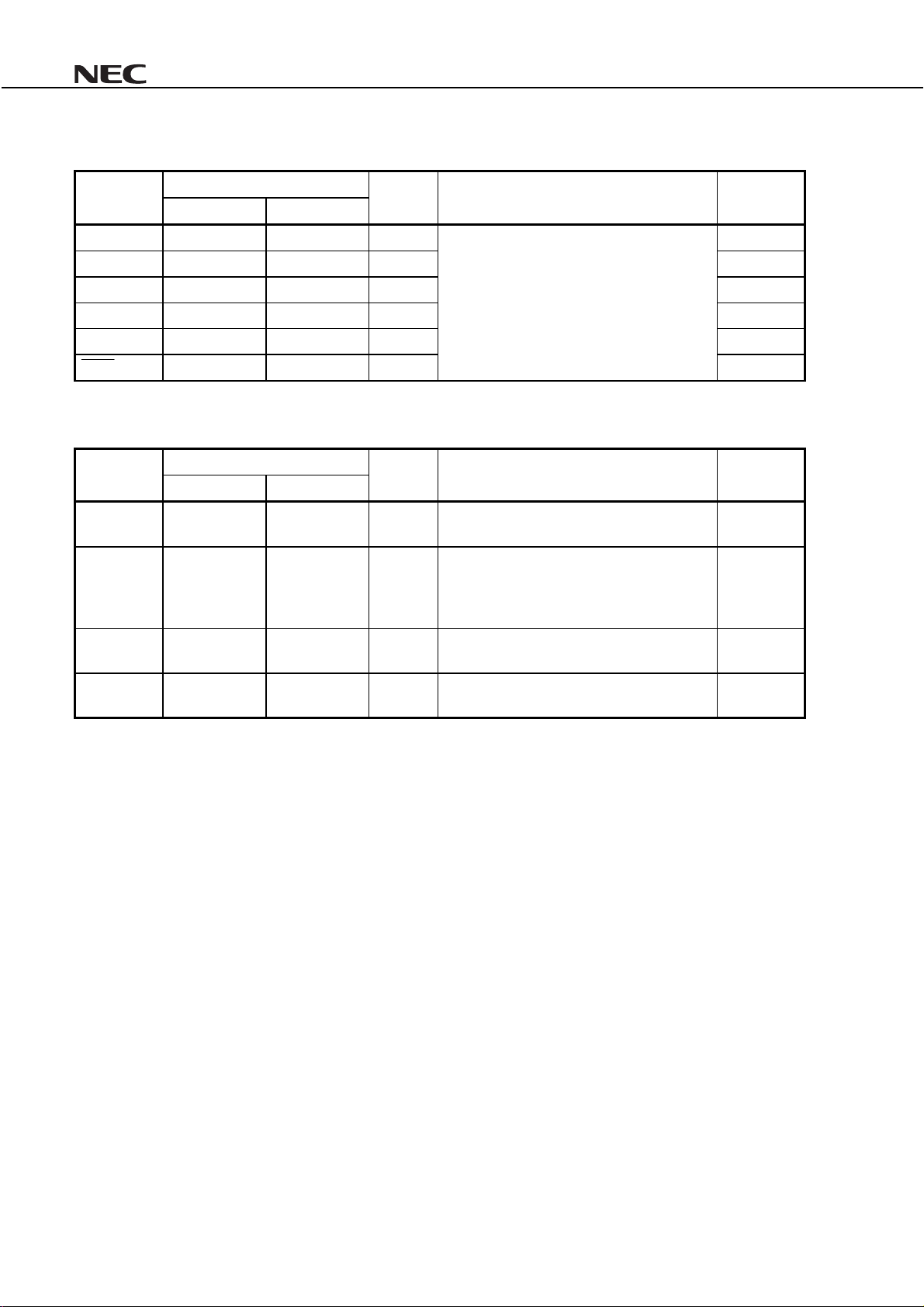

BLOCK DIAGRAM

BSFT

µµµµ

PD77113A, 77114

X bus

Y bus

R0 - R7

Y memory

data

addressing

unit

Main bus

ALU (40)

MAC

16 × 16 + 40 → 40

Program

control unit

Operation unit

Instruction

memory

PC stack

PLL

CLKOUT CLKIN

Note

WAKEUP

Interrupt

control

Host I/O

CPU control

Wait

RESET

Note

INT1 - INT4

controller

option.

Note The WAKEUP pin is multiplexed with the INT4 pin. The function of the WAKEUP pin can be activated or deactivated by mask

IE

I/O

X memory Y memory

Data memory unit

X memory

data

addressing

unit

Serial

I/O #1

Peripheral units

External memory

2

Serial

I/O #2

Data Sheet U14373EJ3V0DS

Port

Loop control

stack

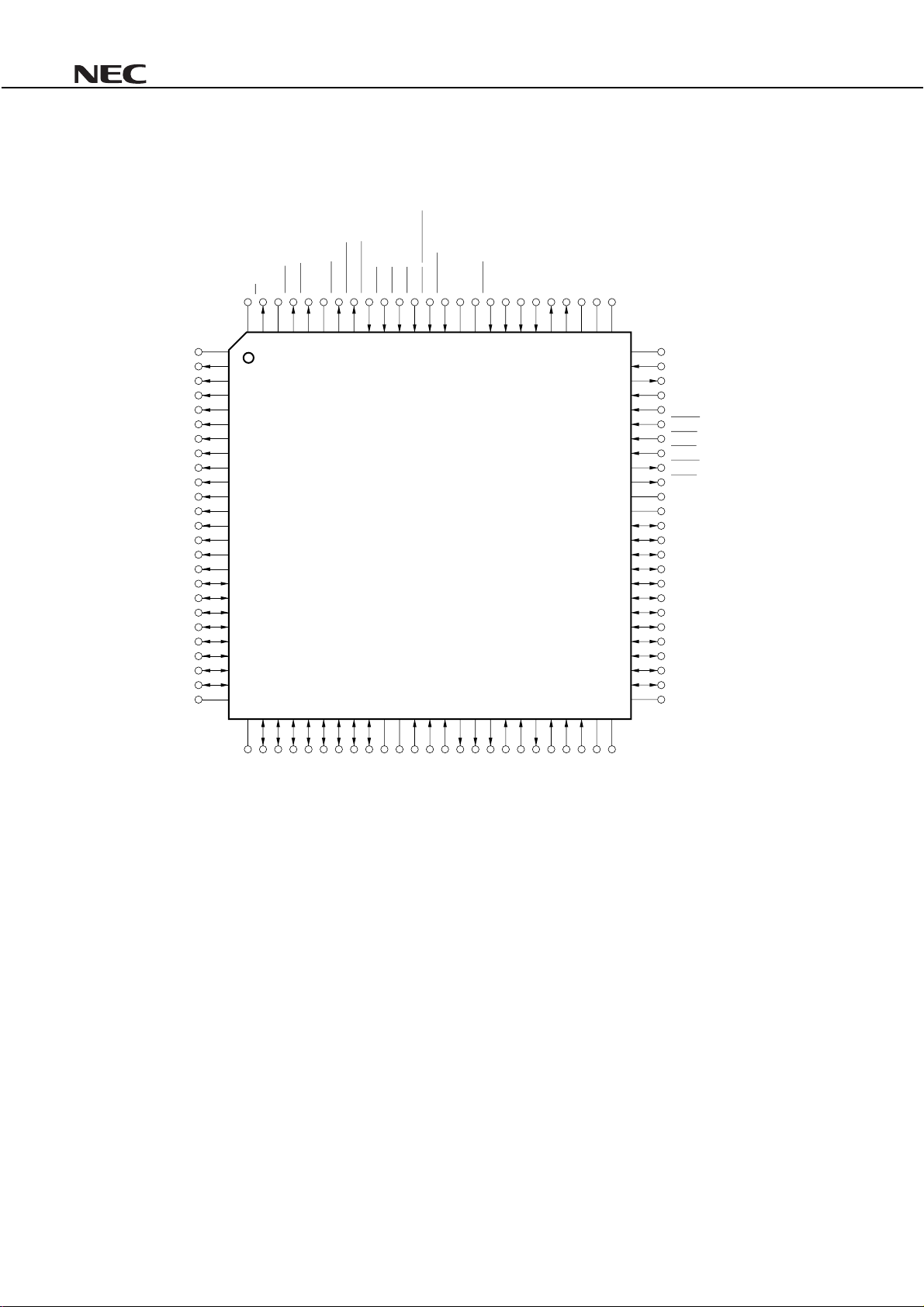

Page 3

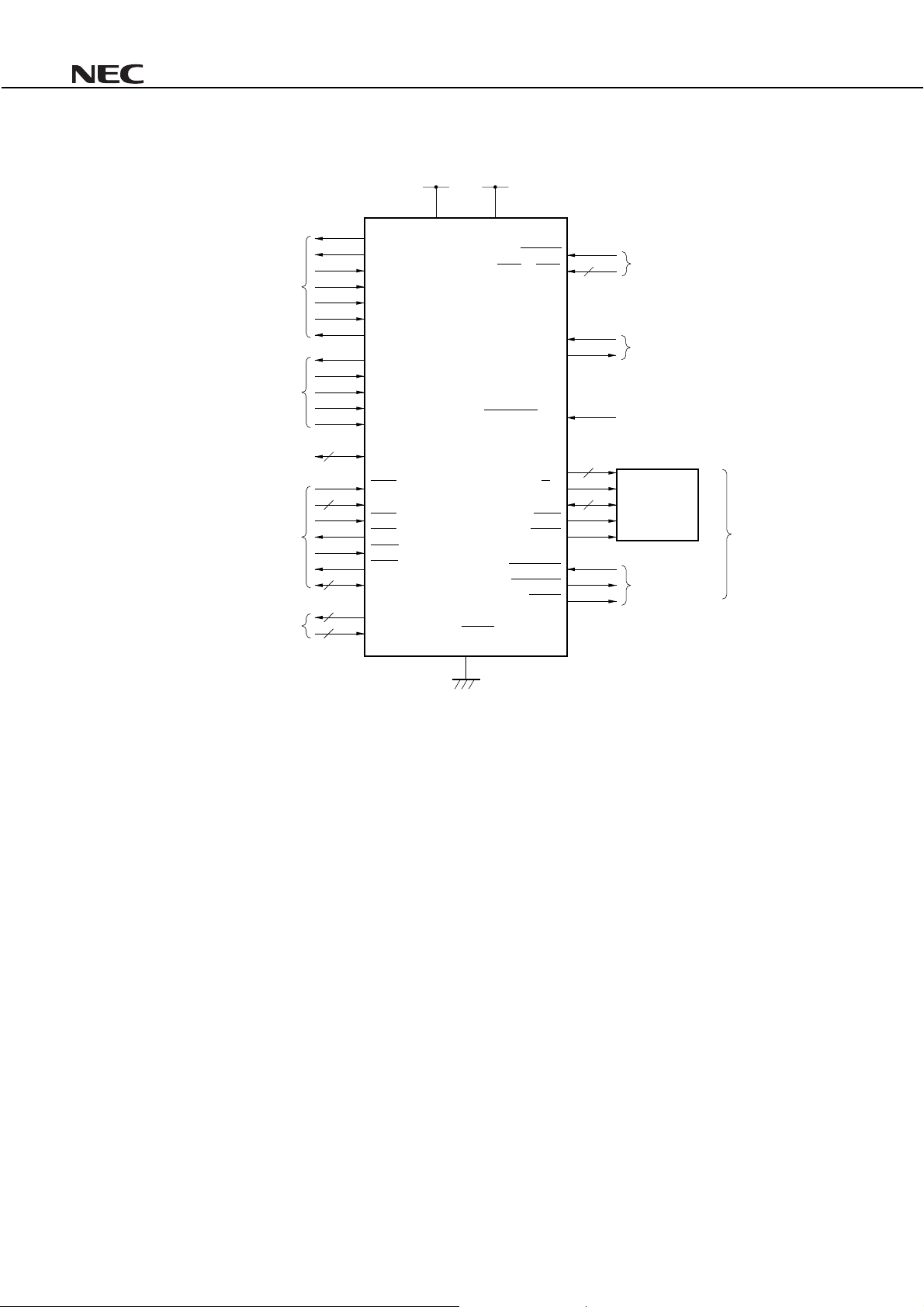

PIN CONFIGURATION

Serial interface #1

Serial interface #2

SO1

SORQ1

SOEN1

SCK1

SI1

SIEN1

SIAK1

SO2

SOEN2

SCK2

SI2

SIEN2

+2.5 V +3 V

IV

DD

EV

WAKEUP

DD

RESET

INT1 - INT4

CLKIN

CLKOUT

Note 1

(4)

µµµµ

PD77113A, 77114

Reset, interrupt

Clock

System control

Notes 1.

Port

Host interface

For debugging

P0 - P3

(4)

HCS

HA0, HA1

(2)

HRD

HRE

HWR

HWE

HD0 - HD7

(8)

TDO, TICE

(2)

TCK, TDI, TMS, TRST

(4)

GND

DA0 - DA12

X/Y

D0 - D15

MRD

MWR

HOLDRQ

HOLDAK

BSTB

(13)

(16)

The function of this pin can be activated or deactivated by mask option.

An external data memory interface is not provided on the

2.

PD77113A.

µ

External data

memory

Note 2

Data bus

control

Data Sheet U14373EJ3V0DS

3

Page 4

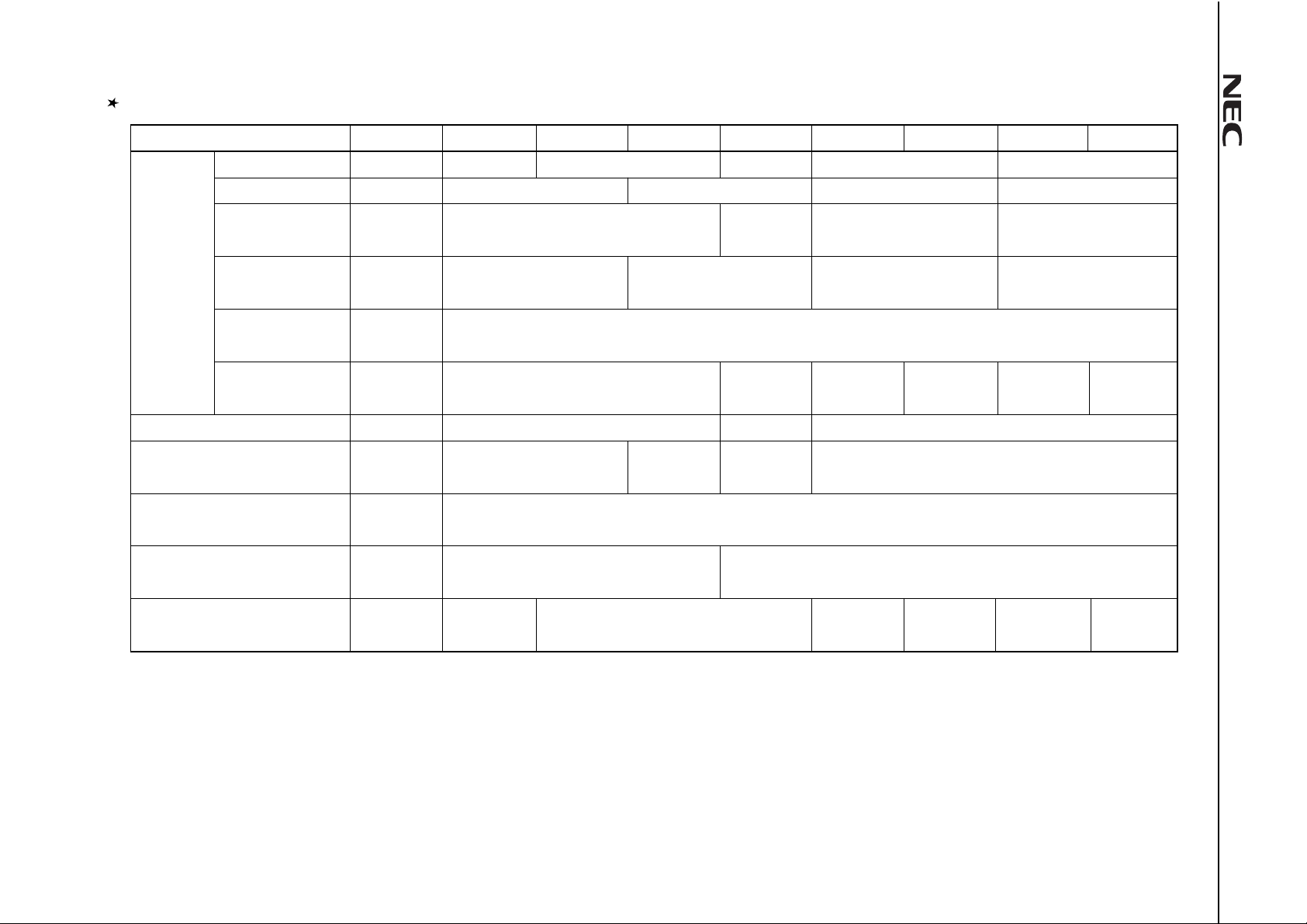

4

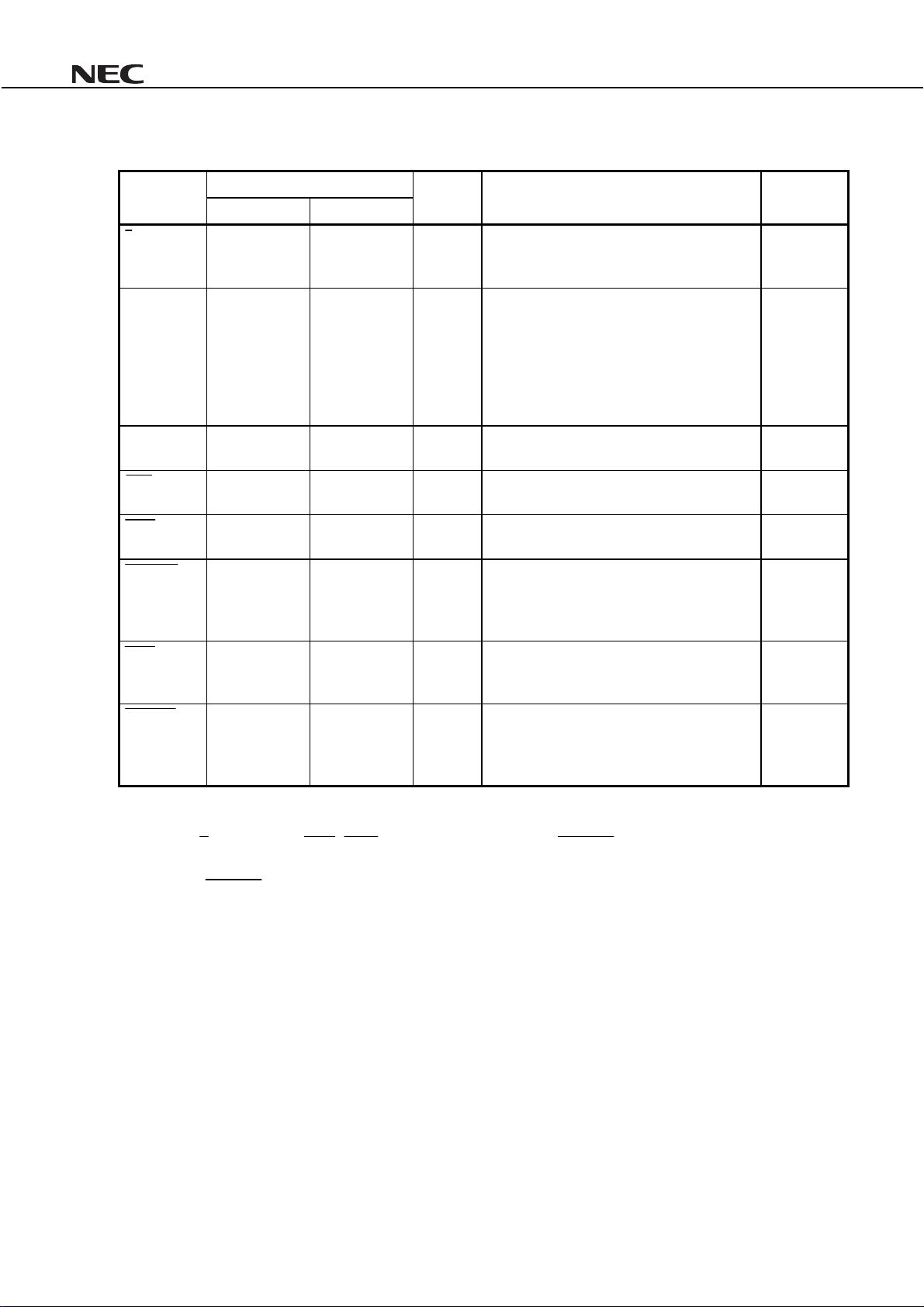

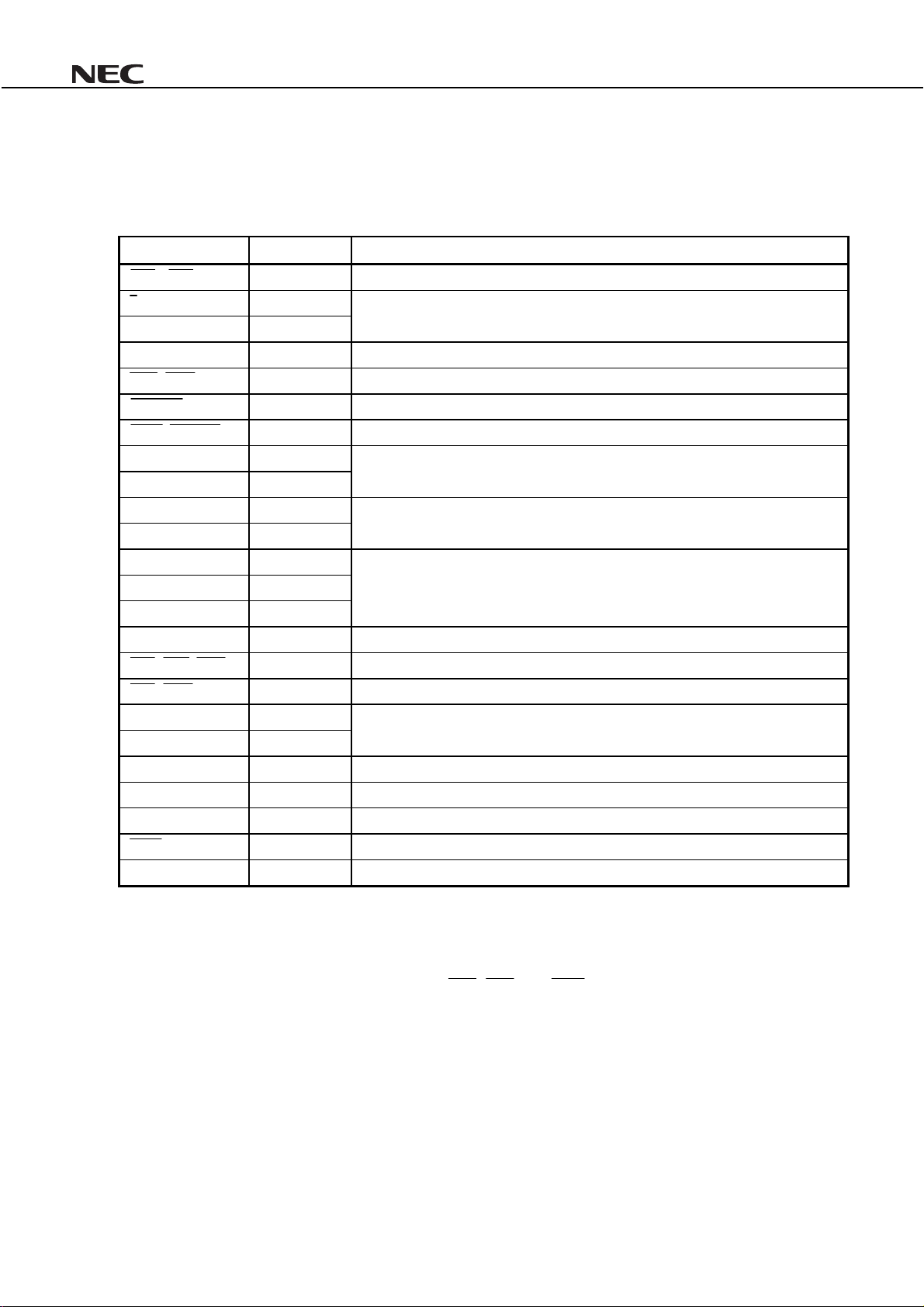

DSP FUNCTION LIST

Item PD77016

Memory space

(words × bits)

Data Sheet U14373EJ3V0DS

Instruction cycle (at maximum speed)

Multiple

Serial interface (two channels)

Supply voltage

Internal instruction RAM

Internal instruction ROM

Data RAM

(X/Y memory)

Data ROM

(X/Y memory)

External instruction

memory

External data memory

(X/Y memory)

µµµµµ µ µ

1.5K × 32 256 × 32 4K × 32 1K × 32

None

2K × 16 each 3K × 16 each 3K × 16 each

None 12K × 16 each 16K × 16 each

48K × 32

48K × 16 each 16K × 16 each None 16K × 16 each

30 ns (33 MHz)

–

Channels 1 and 2

have same function.

5 V 3 V DSP core: 2.5 V

×1, 2, 3, 4, 8 (mask option) Fixed to ×4 Integer of ×1 to 16 (mask option)

Channel 1 has same function as PD77016. Channel 2 does not have SORQ2 and SIAK2 pins (for connection of codec).

PD77019 PD77018A PD77019-013 PD77111 PD77112

24K × 32 None

16.6 ns (60 MHz) 13.3 ns (75 MHz)

µ

PD77110

35.5K × 32

24K × 16 each

None

32K × 16 each

15.3 ns (65 MHz)

Integer of ×1 to 8

(external pin)

31.75K × 32

None

I/O pins : 3 V

µµ

PD77113A PD77114

3.5K × 32

48K × 32

16K × 16 each

32K × 16 each

None 8K × 16 each

Package

160-pin QFP

116-pin BGA

100-pin TQFP 80-pin TQFP

80-pin FBGA

100-pin TQFP100-pin TQFP

80-pin FBGA 100-pin TQFP

µµ

µ

µ

PD77113A, 77114

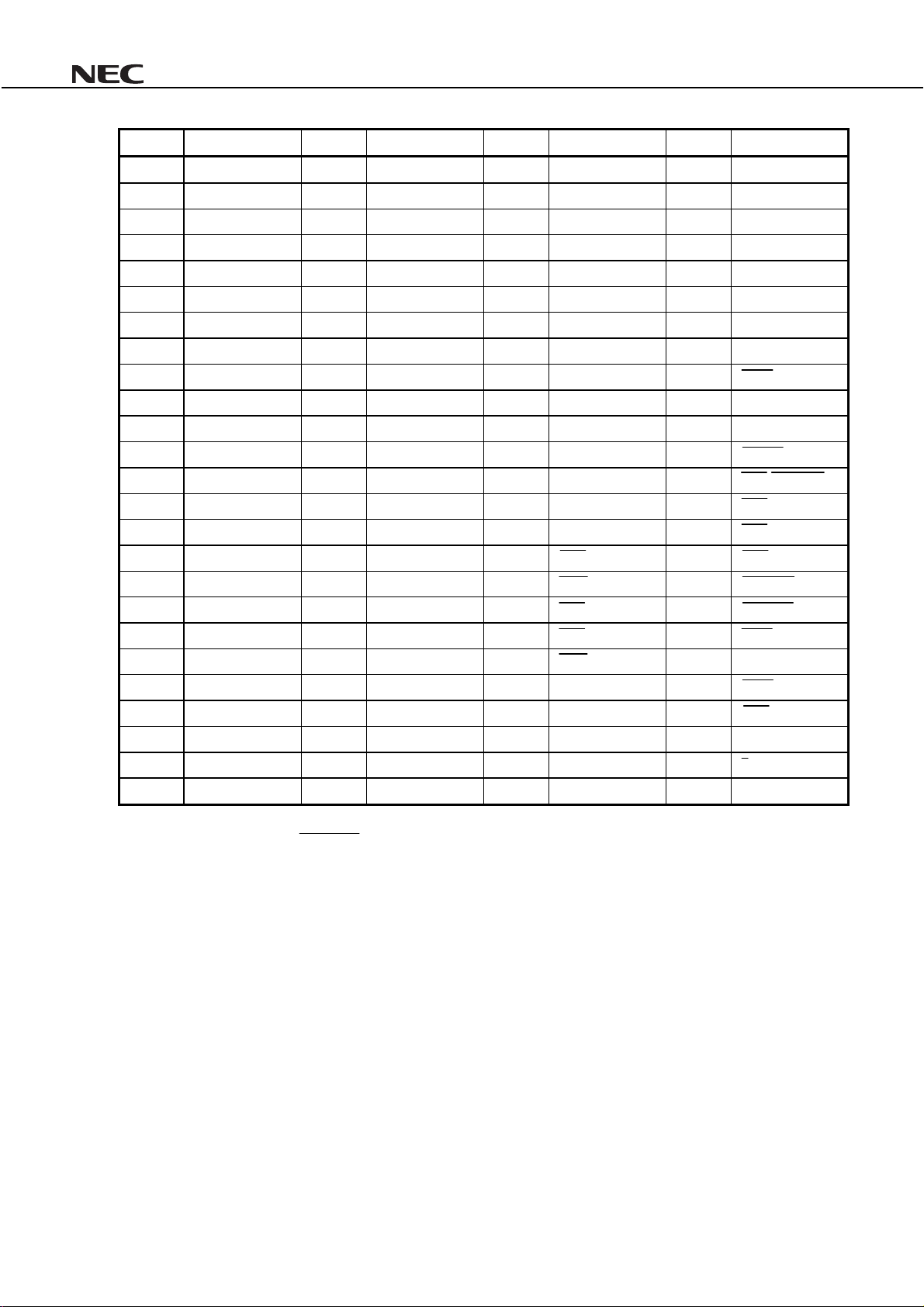

Page 5

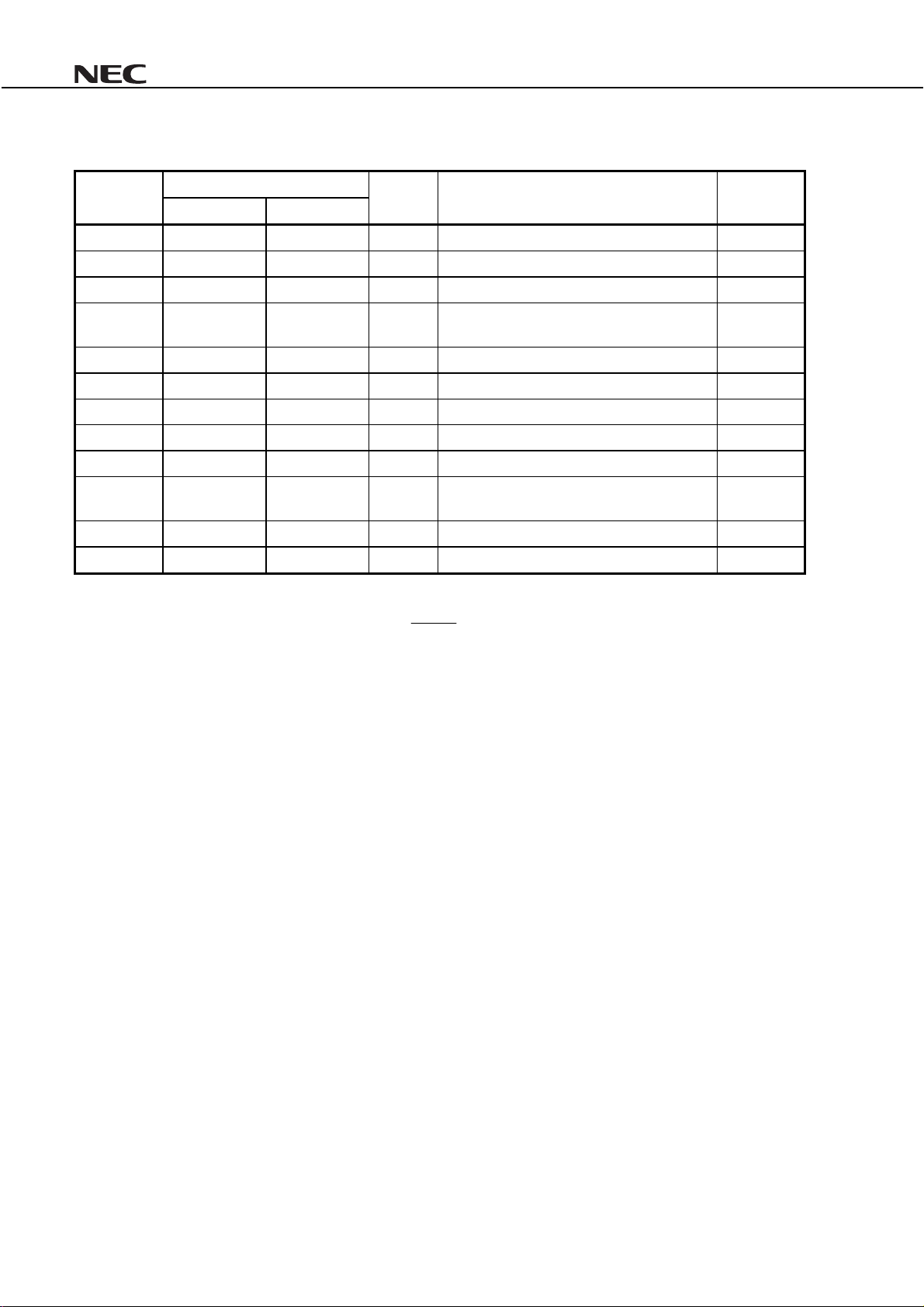

PIN CONFIGURATION

µµµµ

PD77113A, 77114

80-pin plastic fine-pitch BGA (9

PD77113AF1-xxx-CN1

µµµµ

9)

××××

(Bottom View) (Top View)

9

8

7

6

5

4

3

2

1

JHGFEDCBA ABCDEFGHJ

Index mark

Pin No. Pin Name Pin No. Pin Nam e Pin No. Pin Name Pin No. Pin Nam e

A1

−

C3 NU E6 HCS G8 P1

A2 NU C4 RESET E7 GND G9 GND

A3 EV

DD

C5 TDI E8 HD1 H1 NU

A4 INT3 C6 TDO E9 HD2 H2 NU

A5 GND C7 CLKIN F1 NU H3 SCK1

A6 TMS C8 HA0 F2 NU H4 SOEN2

A7 GND C9 EV

A8 TRST D1 EV

A9

−

D2 NU F5 HD0 H7 P0

DD

DD

F3 SOEN1 H5 SIEN2

F4 GND H6 P3

B1 NU D3 INT2 F6 SI2 H8 HD7

B2 NU D4 NU F7 HD3 H9 NU

B3 INT1 D5 TCK F8 HD6 J1

B4

B5 IV

INT4/WAKEUP

DD

Note

D6 GND F9 HD5 J2 NU

D7 HWR G1 EV

DD

J3 SI1

−

B6 TICE D8 HRD G2 GND J4 SORQ1

B7 IV

DD

D9 EV

DD

G3 SIEN1 J5 SO2

B8 HA1 E1 NU G4 SO1 J6 SCK2

B9 CLKOUT E2 GND G5 IV

DD

J7 EV

DD

C1 GND E3 SIAK1 G6 HD4 J8 NU

C2 NU E4 NU G7 P2 J9

−

The function of the WAKEUP pin can be activated or deactivated by a mask option.

Note

Data Sheet U14373EJ3V0DS

5

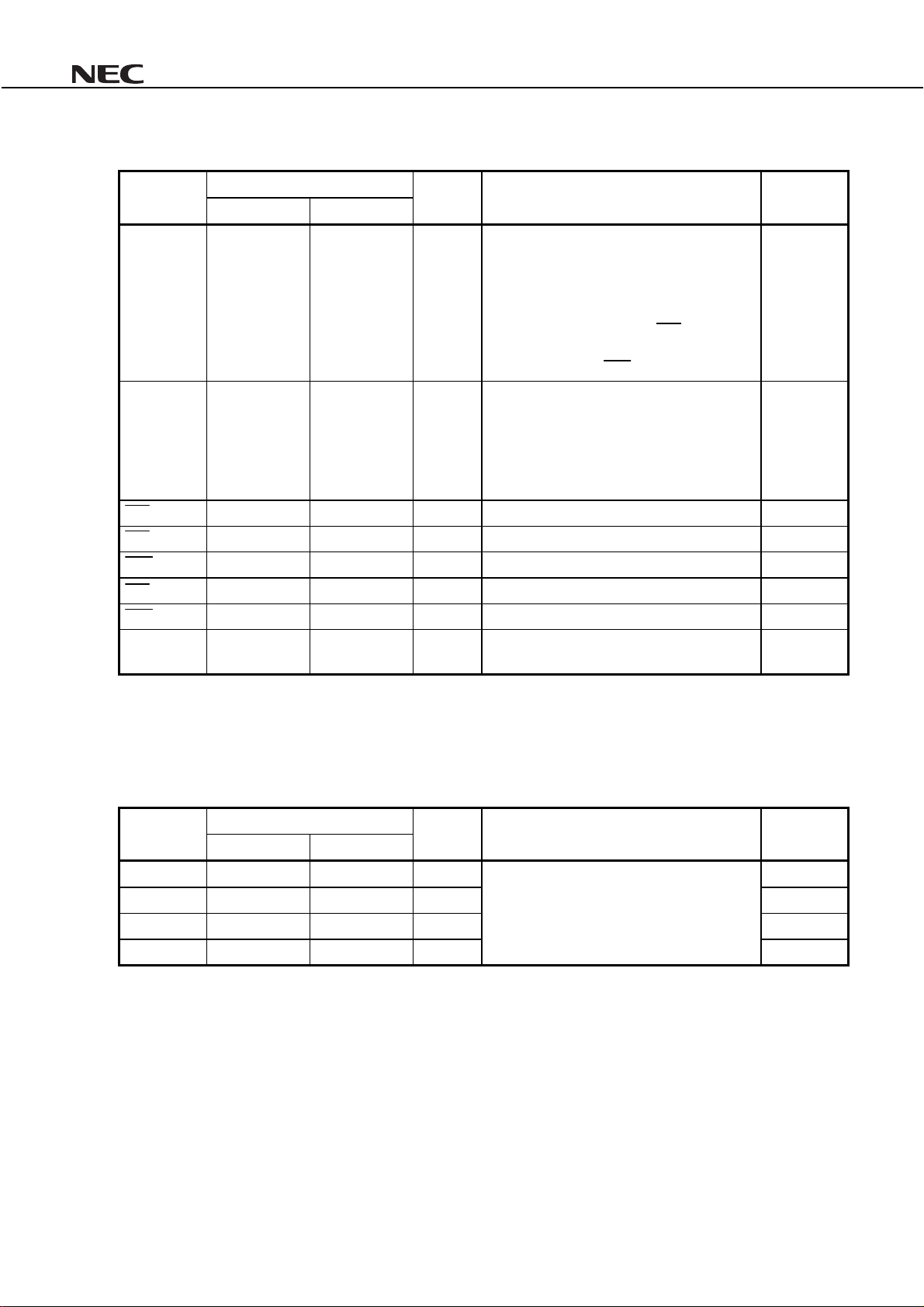

Page 6

µµµµ

PD77113A, 77114

100-pin plastic TQFP (fine-pitch) (14

PD77114GC-xxx-9EU

µµµµ

EVDDX/Y

I.C.

MRD

100

999897969594939291908988878685848382818079787776

GND

NC

NC

DA12

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

D15

D14

D13

D12

D11

D10

D9

D8

EV

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26272829303132333435363738394041424344454647484950

14) (Top View)

××××

MWRNCBSTB

HOLDAK

HOLDRQ

INT1

INT2

Note

INT3

INT4/WAKEUP

RESET

GND

IVDDTRST

TMS

TDI

TCK

TICE

TDO

GND

IVDDGND

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

EV

DD

CLKIN

CLKOUT

HA1

HA0

HWR

HRD

HCS

HWE

HRE

GND

DD

EV

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

P0

P1

P2

P3

GND

D7D6D5D4D3D2D1

GND

The functions can be activated or deactivated by a mask option.

Note

D0

DD

SI1

IV

GND

SIEN1

SCK1

SIAK1

SO1

SOEN1

SOEN2

SORQ1

SO2

SCK2

SIEN2

SI2

NC

DD

EV

6

Data Sheet U14373EJ3V0DS

Page 7

µµµµ

PD77113A, 77114

Pin No. Pin Name Pin No. Pin Nam e Pin No. Pin Name Pin No. Pin Nam e

1 GND 26 GND 51 GND 76 GND

2 NC 27D7 52P3 77IV

DD

3 NC 28D6 53P2 78GND

4 DA12 29D5 54P1 79TDO

5 DA11 30D4 55P0 80TICE

6 DA10 31D3 56HD7 81TCK

7 DA9 32 D2 57 HD6 82 TD1

8 DA8 33 D1 58 HD5 83 TMS

9 DA7 34 D0 59 HD4 84 TRST

10 DA6 35 I V

DD

60 HD3 85 IV

DD

11 DA5 36 GND 61 HD2 86 GND

12 DA4 37 SI1 62 HD1 87 RESET

13 DA3 38 S IEN1 63 HD0 88

14 DA2 39 S CK1 64 EV

DD

89 INT3

INT4/WAKEUP

15 DA1 40 SIAK1 65 GND 90 INT2

16 DA0 41 SO1 66 HRE 91 INT1

17 D15 42 S ORQ1 67 HWE 92 HOLDRQ

18 D14 43 S OEN1 68 HCS 93 HOLDAK

19 D13 44 S OEN2 69 HRD 94 BSTB

20 D12 45 S O2 70 HWR 95 NC

21 D11 46 S CK2 71 HA0 96 MWR

22 D10 47 S IEN2 72 HA1 97 MRD

23 D9 48 SI2 73 CLKOUT 98 I.C.

24 D8 49 NC 74 CLKIN 99 X/Y

25 EV

DD

50 E V

DD

75 E V

DD

100 EV

DD

Note

The function of the WAKEUP pin can be activated or deactivated by a mask option.

Note

Data Sheet U14373EJ3V0DS

7

Page 8

PIN NAME

BSTB : Bus Strobe

CLKIN : Clock Input

CLKOUT : Clock Output

D0 - D15 : 16-bit Data Bu s

DA0 - DA12 : External Data Memory Address Bus

DD

EV

GND : Ground

HA0, HA1 : Host Data Access

HCS : Host Chip Select

HD0 - HD7 : Host Data Bus

HOLDAK : Hold Acknowledge

HOLDRQ : Hold Request

HRD : Host Read

HRE : Host Read Enable

HWE : Host Write Enable

HWR : Host Write

I.C. : Internally Connected

INT1 - INT4 : Interrupt

DD

IV

MRD : Memory Read Output

MWR : Memory Wri te Output

NC : Non-Connection

NU : Not Used

P0 - P3 : Port

RESET : Reset

SCK1, SCK2 : Serial Clock Input

SI1, SI2 : Serial Data Input

SIAK1 : Serial Input Acknowledge

SIEN1, SIEN2 : Serial Input Enable

SO1, SO2 : Serial Data Output

SOEN1, SOEN2: Serial Output Enable

SORQ1 : Serial Output Request

TCK : Test Clock Input

TDI : Test Data Input

TDO : Test Data Output

TICE : Test In-Circuit Emulator

TMS : Test Mode Select

TRST : Test Reset

WAKEUP : Wakeup from STOP Mode

X/Y : X/Y Memory Select

: Power Supply for I/O Pins

: Power Supply for DSP Core

µµµµ

PD77113A, 77114

8

Data Sheet U14373EJ3V0DS

Page 9

µµµµ

PD77113A, 77114

CONTENTS

1. PIN FUNCTION................................................................................................................................. 10

1.1 Pin Function Description.......................................................................................................... 10

1.2 Connection of Unused Pins ..................................................................................................... 15

2. FUNCTION OUTLINE....................................................................................................................... 17

2.1 Program Control Unit................................................................................................................ 17

2.2 Arithmetic Unit........................................................................................................................... 18

2.3 Data Memory Unit...................................................................................................................... 19

2.4 Peripheral Units......................................................................................................................... 19

3. CLOCK GENERATOR...................................................................................................................... 20

4. RESET FUNCTION........................................................................................................................... 20

4.1 Hardware Reset ......................................................................................................................... 20

4.2 Initializing PLL........................................................................................................................... 21

5. FUNCTIONS OF BOOT-UP ROM...................................................................................................21

5.1 Boot at Reset ............................................................................................................................. 21

5.2 Reboot ........................................................................................................................................ 22

5.3 Signature Operation.................................................................................................................. 23

5.4 Instruction ROM Modification.................................................................................................. 23

6. STANDBY MODES........................................................................................................................... 24

6.1 HALT Mode................................................................................................................................. 24

6.2 STOP Mode ................................................................................................................................ 24

7. MEMORY MAP.................................................................................................................................. 25

7.1 Instruction Memory ................................................................................................................... 25

7.2 Data Memory.............................................................................................................................. 27

8. MASK OPTION ................................................................................................................................. 28

8.1 Clock Control Options.............................................................................................................. 28

8.2 WAKEUP Function .................................................................................................................... 29

9. INSTRUCTIONS................................................................................................................................. 30

9.1 Outline of Instructions.............................................................................................................. 30

9.2 Instruction Set and Operation.................................................................................................. 31

10. ELECTRICAL SPECIFICATIONS..................................................................................................... 37

11. PACKAGE DRAWINGS.................................................................................................................... 56

12. RECOMMENDED SOLDERING CONDITIONS............................................................................... 58

Data Sheet U14373EJ3V0DS

9

Page 10

µµµµ

PD77113A, 77114

1. PIN FUNCTION

Because the pin numbers differ depending on the package, refer to the diagram of the package to be used.

1.1 Pin Function Description

• Power supply

Pin Name

DD

IV

DD

EV

GND 1, 26, 36, 51,

Remark

100-pin TQFP 80-pin BGA

35, 77, 85 B5, B7, G5

25, 50, 64, 75,

100

65, 76, 78, 86

Please supply voltage to the IV

Pin No.

A3, C9, D1, D9,

G1, J7

A5, A7, C1, D6,

E2, E7, F4, G2,

G9

I/O Function Shared by:

Power to DSP core (+2.5 V)

−

Power to I/O pins (+3 V)

−

Ground

−

DD

and EVDD pins simultaneously.

• System control

Pin Name

100-pin TQFP 80-pin BGA

CLKIN 74 C7 Input System clock i nput

CLKOUT 73 B9 Output Internal system clock output

RESET 87 C4 Input Internal system reset signal input

WAKEUP 88 B4 Input St op mode releas e signal input.

Pin No.

I/O Function Shared by:

• When this pin is asserted active, the stop

mode is released. The functi on of this pin

can be activated or deacti vated by a mask

option.

−

−

−

−

−

INT4

• Interrupt

Pin Name

100-pin TQFP 80-pin BGA

INT1 - INT3 91 - 89 B3, D3, A4 Input

INT4 88 B4 Input

10

Pin No.

Data Sheet U14373EJ3V0DS

I/O Function Shared by:

External maskable int errupt input.

• Detected at the fall i ng edge.

−

WAKEUP

Page 11

µµµµ

PD77113A, 77114

• External data memory interface (

Pin No.

Pin Name

100-pin TQFP 80-pin BGA

X/Y 99

DA0 - DA12 16 - 4

D0 - D15 34 - 27, 24 - 17

MRD 97

MWR 96

HOLDRQ 92

BSTB 94

HOLDAK 93

PD77114 only)

µµµµ

−

−

−

−

−

−

−

−

I/O Function Shared by:

Output

(3S)

Output

(3S)

I/O

(3S)

Output

(3S)

Output

(3S)

Input Hold request signal

Output Bus strobe si gnal

Output Hold acknowledge signal

Memory select signal output.

0: Uses X memory.

1: Uses Y memory.

Address bus of external data memory.

• Accesses the external memory.

• Continuously outputs the external memory

address accessed las t when the external

memory is not being accessed. Kept low

(0x000) if the external memory is never

accessed after reset.

16-bit data bus.

• Accesses the external memory.

Read output

• External memory read

Write output

• External memory write

• Input a low level to t hi s pin when the external

device uses the external data memory bus of

the

PD77114.

µ

• This pin goes l ow when the

the external data memory bus .

• This pin goes low when the ex t ernal device

is enabled to use the external data memory

bus of the

PD77114.

µ

PD77114 uses

µ

−

−

−

−

−

−

−

−

Remark

Pins marked “3S” under the heading “I/O” go into a high-impedance state in the following conditions:

X/Y, DA0-DA12, MRD, MWR: When the bus is released (HOLDAK = low level)

D0-D15: When the external data memory is not being accessed and when the bus is released

(HOLDAK = low level)

Data Sheet U14373EJ3V0DS

11

Page 12

• Serial interface

µµµµ

PD77113A, 77114

Pin Name

SCK1 39 H3 Input Serial 1 cloc k input

SORQ1 42 J4 Output Serial output 1 request

SOEN1 43 F3 Input Serial output 1 enable

SO1 41 G4 Output

SIEN1 38 G3 Input Serial input 1 enable

SI1 37 J3 Input Serial data input 1

SIAK1 40 E3 Output Serial i nput 1 acknowledge

SCK2 46 J6 Input Serial 2 clock input

SOEN2 44 H4 Input Serial output 2 enable

SO2 45 J5 Output

SIEN2 47 H5 Input Serial input 2 enable

SI2 48 F6 Input Serial data input 2

Remark

100-pin TQFP 80-pin BGA

The pins marked “3S” under the heading “I/O” go into a high-impedance state on completion of data

Pin No.

I/O Function Shared by:

Serial data output 1

(3S)

Serial data output 2

(3S)

transfer and input of the hardware reset (RESET) signal.

−

−

−

−

−

−

−

−

−

−

−

−

12

Data Sheet U14373EJ3V0DS

Page 13

• Host interface

µµµµ

PD77113A, 77114

Pin Name

100-pin TQFP 80-pin BGA

HA1 72 B8 Input Spec i fies the register to be accessed by HD7

HA0 71 C8 Input Spec i fies the register to be accessed by HD7

HCS 68 E6 Input Chip select input

HRD 69 D8 Input Host read input

HWR 70 D7 Input Host write input

HRE 66

HWE 67

HD0 - HD7 63 - 56 F5, E8, E9, F7,

Pin No.

G6, F9, F8, H8

I/O Function Shared by:

through HD0.

• 1: Accesses the hos t i nterface status

register (HST).

• 0: Accesses the hos t transmit data register

(HDT (out)) when read (HRD = 0), and

host receive data regist er (HDT (i n))

when written (HWR = 0).

through HD0.

• 1: Accesses bits 15 through 8 of HST, HDT

(in), and HDT (out).

• 0: Accesses bits 7 through 0 of HST, HDT

(in), and HDT (out).

−

−

Output Host read enable output

Output Host write enable output

I/O

(3S)

8-bit host data bus

−

−

−

−

−

−

−

−

Remark

The pins marked “3S” under the heading “I/O” go into a high-impedance state when the host interface is

not being accessed.

• I/O ports

Pin Name

100-pin TQFP 80-pin BGA

P0 55 H7 I/O

P1 54 G8 I/O

P2 53 G7 I/O

P3 52 H6 I/O

Pin No.

I/O Function Shared by:

General-purpose I/O port

−

−

−

−

Data Sheet U14373EJ3V0DS

13

Page 14

• Debugging interface

µµµµ

PD77113A, 77114

Pin Name

100-pin TQFP 80-pin BGA

TDO 79 C6 Output

TICE 80 B6 Output

TCK 81 D5 Input

TDI 82 C5 Input

TMS 83 A6 Input

TRST 84 A8 Input

Pin No.

I/O Function Shared by:

• Others

Pin Name

100-pin TQFP 80-pin BGA

I.C. 98

NU

NC 2, 3, 49, 95

−−

Pin No.

−−

−

A2, B1, B2, C2,

C3, D2, D4, E1,

E4, F1, F2, H1,

H2, H9, J2, J8

−−

A1, A9, J1, J9

I/O Function Shared by:

For debugging

Internally connected. Leave this pin

unconnected.

No function pins. Connect to EV

−

resistor, or connect to GND via pull-down

resistor.

No-connect pins. Leave these pins

unconnected.

Pins to strengthen sol deri ng. Connect these

−

pins to the board as necessary.

DD

via pull-up

−

−

−

−

−

−

−

−

−

−

Caution If any signal is input to these pins or if an attempt is made to read these pins, the normal

operation of the

PD77113A and 77114 is not guaranteed.

µµµµ

14

Data Sheet U14373EJ3V0DS

Page 15

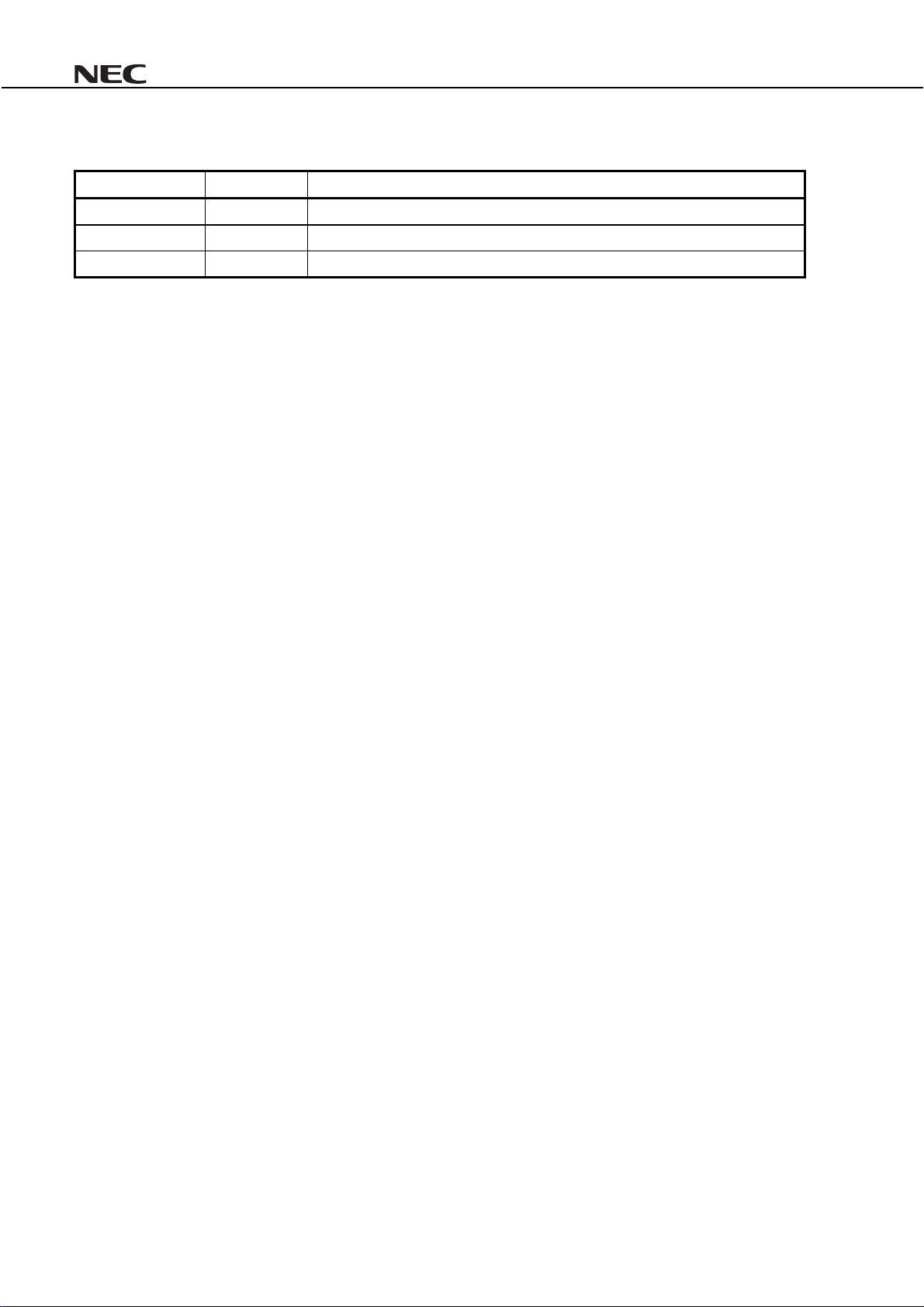

1.2 Connection of Unused Pins

1.2.1 Connection of Function Pins

When mounting, connect unused pins as follows:

Pin I/O Recommended Connection

INT1 - INT4 Input Connect to EVDD.

X/Y Output

DA0 - DA12 Output

D0 - D15

MRD, MWR Output Leave unconnected.

HOLDRQ Input Leave unconnected. (i nternally pulled up).

BSTB, HOLDAK Output Leave unconnected.

SCK1, SCK2 Input

SI1, SI2 Input

SIEN1, SIEN2 Input

SOEN1, SOEN2 Input

SORQ1 Output

SO1, SO2 Output

SIAK1 Output

HA0, HA1 Input Connect to EVDD or GND.

HCS, HRD, HWR Input Connec t to EVDD.

HRE, HWE Output Leave unconnected.

HD0 - HD7

P0 - P3 I/O

TCK Input Connect to GND via pull-down resistor.

TDO, TICE Out put Leave unconnected.

TMS, TDI Input Leave unconnected. (internally pulled up).

TRST Input Leave unconnected. (internal l y pul l ed down).

CLKOUT Output Leave unconnected.

Note 1

Note 2

I/O Connect to E VDD via pull-up resistor, or c onnect to GND via pull-down resistor.

I/O

Leave unconnected.

DD

Connect to EV

Connect to GND.

Leave unconnected.

Connect to EV

or GND.

DD

via pull-up resistor, or c onnect to GND via pull-down resistor.

µµµµ

PD77113A, 77114

Notes 1.

These pins may be left unconnected if the external data memory is not accessed in the program.

However, connect these pins as recommended in the halt and stop modes when the power

consumption must be lowered.

These pins may be left unconnected if HCS, HRD, and HWR are fixed to the high level.

2.

However, connect these pins as recommended in the halt and stop modes when the power

consumption must be lowered.

Data Sheet U14373EJ3V0DS

15

Page 16

1.2.2 Connection of no-function pins

Pin I/O Recommended Connection

µµµµ

PD77113A, 77114

I.C.

NU

NC

−

−

−

Leave unconnected.

Connect to EVDD via pull-up resistor, or c onnect to GND via pull-down resistor.

Leave unconnected.

16

Data Sheet U14373EJ3V0DS

Page 17

µµµµ

PD77113A, 77114

2. FUNCTION OUTLINE

2.1 Program Control Unit

This unit is used to execute instructions, and control branching, loops, interrupts, the clock, and the standby mode

of the DSP.

2.1.1 CPU control

A three-stage pipeline architecture is employed and almost all the instructions, except some instructions such as

branch instructions, are executed in one system clock.

2.1.2 Interrupt control

Interrupt requests input from external pins (INT1 through INT4) or generated by the internal peripherals (serial

interface and host interface) are serviced. The interrupt of each interrupt source can be enabled or disabled.

Multiple interrupts are also supported.

2.1.3 Loop control task

A loop function without any hardware overhead is provided. A loop stack with four levels is provided to support

multiple loops.

2.1.4 PC stack

A 15-level PC stack that stores the program counter supports multiple interrupts and subroutine calls.

2.1.5 PLL

A PLL is provided as a clock generator that can multiply or divide an external clock input to supply an operating

clock to the DSP. A multiple of ×1 to ×16 or a division ratio of 1/1 to 1/16 can be set by a mask option.

Two standby modes are available for lowering the power consumption while the DSP is not in use.

• HALT mode : Set by execution of the HALT instruction. The current consumption drops to several mA. The

normal operation mode is recovered by an interrupt or hardware reset.

• STOP mode: Set by execution of the STOP instruction. The current consumption drops to several 10 µA. The

normal operation mode is recovered by hardware reset or WAKEUP pin

If the WAKEUP function is activated by mask option

Note

2.1.6 Instruction memory

The capacity and type of the memory differ depending on the model of the DSP.

64 words of the instruction RAM are allocated to interrupt vectors.

A boot-up ROM that boots up the instruction RAM is provided, and the instruction RAM can be initialized or

rewritten by self boot (boot from the internal data ROM or external data space) or host boot (boot via host interface).

The µPD77113A and 77114 have 3.5K-word instruction RAM and 48K-word instruction ROM.

Note

.

Data Sheet U14373EJ3V0DS

17

Page 18

µµµµ

PD77113A, 77114

2.2 Arithmetic Unit

This unit performs multiplication, addition, logical operations, and shift, and consists of a 40-bit multiply

accumulator, 40-bit data ALU, 40-bit barrel shifter, and eight 40-bit general-purpose registers.

2.2.1 General-purpose registers (R0 through R7)

These eight 40-bit registers are used to input/output data for arithmetic operations, and load or store data from/to

data memory.

A general-purpose register (R0 to R7) is made up of three parts: R0L through R7L (bits 15 through 0), R0H

through R7H (bits 31 through 16), and R0E through R7E (bits 39 through 32). Depending on the type of operation,

RnL, RnH, and RnE are used as one register or in different combinations.

2.2.2 Multiply accumulator (MAC)

The MAC multiplies two 16-bit values, and adds or subtracts the multiplication result from one 40-bit value, and

outputs a 40-bit value.

The MAC is provided with a shifter (MSFT: MAC ShiFTer) at the stage preceding the input stage. This shifter can

arithmetically shift the 40-bit value to be added to or subtracted from the multiplication result 1 or 16 bits to the right .

2.2.3 Arithmetic logic unit (ALU)

This unit inputs one or two 40-bit values, executes an arithmetic or logical operation, and outputs a 40-bit value.

2.2.4 Barrel shifter (BSFT: Barrel ShiFTer)

The barrel shifter inputs a 40-bit value, shifts it to the left or right by any number of bits, and outputs a 40-bit value.

The data may be arithmetically shifted to the right shifted to the right, in which case the data is sign-extended, or

logically shifted to the right, in which case 0 is inserted from the MSB.

18

Data Sheet U14373EJ3V0DS

Page 19

µµµµ

PD77113A, 77114

2.3 Data Memory Unit

The data memory unit consists of two banks of data memory and two data addressing units.

2.3.1 Data memory

The capacity and type of the memory differ depending on the model of the DSP. All DSPs have two banks of data

memory (X data memory and Y data memory). A 64-word peripheral area is assigned in the data memory space.

The µPD77113A and 77114 have 16K words × 2 banks data RAM and 32K words × 2 banks data ROM.

In addition, the µPD77114 has an external data memory interface so that the external memory can be expanded

to 8K words × 2 banks.

2.3.2 Data addressing unit

An independent data addressing unit is provided for each of the X data memory and Y data memory spaces.

Each data addressing unit has four data pointers (DPn), four index registers (DNn), one modulo register (DMX or

DMY), and an address ALU.

2.4 Peripheral Units

A serial interface, host interface, general-purpose I/O port, and wait cycle register are provided. All these internal

peripherals are mapped to the X data memory and Y data memory spaces, and are accessed from program as

memory-mapped I/Os.

2.4.1 Serial interface (SIO)

Two serial interfaces are provided. These serial interfaces have the following features:

• Serial clock : Supplied from external source to each interface. The same clock is used for input and output

on the interface.

• Frame length: 8 or 16 bits, and MSB or LSB first selectable for each interface and input or output

• Handshake : Handshaking with external devices is implemented with a dedicated status signal. With the

internal units, polling, wait, or interrupt are used.

2.4.2 Host interface (HIO)

This is an 8-bit parallel port that inputs data from or outputs data to an external host CPU or DMA controller. In

the DSP, a 16-bit register is mapped to memory for input data, output data, and status. Handshaking with an external

device is implemented by using a dedicated status signal. Handshaking with internal units is achieved by means of

polling, wait, or interrupts.

2.4.3 General-purpose I/O port (PIO)

This is a 4-bit I/O port that can be set in the input or output mode in 1-bit units.

2.4.4 Wait cycle register

The number of wait cycles to be inserted when the external data memory area is accessed can be specified in

advance by using a register (DWTR)

This function is not available on the µPD77113A because this DSP does not have an external data area.

Note

Note

. The number of wait cycles that can be set is 1, 3, or 7.

Data Sheet U14373EJ3V0DS

19

Page 20

µµµµ

PD77113A, 77114

3. CLOCK GENERATOR

The clock generator generates an internal system clock based on the external clock input from the CLKIN pin and

supplies the generated clock to the internal units of the DSP.

For details of how to set the PLL multiple, refer to

4.2 Initializing PLL

, and

8.1 Clock Control Options

.

Halt mode

CLKIN

CLKOUT

Stop mode

PLL control circuit

×m

Output divider Halt divider

÷n ÷l

4. RESET FUNCTION

When a low level of a specified width is input to the RESET pin, the device is initialized.

4.1 Hardware Reset

Internal

system clock

If the RESET pin is asserted active (low level) for a specified period, the internal circuitry of the DSP is initialized.

If the RESET pin is then deasserted inactive (high level), boot processing of the instruction RAM is performed

according to the status of the port pins (P0 and P1). After boot processing, processing is executed starting from the

instruction at address 0x200 of instruction memory (reset entry). In addition, a self-check is performed by the internal

data RAM at the same time as the boot processing. This check takes about 20 ms (at 50 MHz operation, the length

of this period is in inverse proportion to the operating frequency.)

On power application, the RESET pin must be asserted active (low level) after 4 input clocks have been input with

the RESET pin in the inactive status (high level), after the supply voltage has reached the level of the operating

voltage. In other words, no power-ON reset function is available. On power application, the PLL must be initialized.

20

Data Sheet U14373EJ3V0DS

Page 21

µµµµ

PD77113A, 77114

4.2 Initializing PLL

Initializing the PLL starts from the 1024th input clock after the RESET pin has been asserted active (low level).

Initialization takes 1024 clocks and it takes the PLL 100 µs to be locked.

After that, the DSP operates with the set value of the PLL specified by a mask option when the RESET pin is

deasserted inactive (high level).

After initializing the PLL, be sure to execute boot-up processing to re-initialize the internal RAM. To initialize the

PLL, the internal memory contents and register status of the DSP are not retained.

If the RESET pin is deasserted inactive before the PLL initialization mode is set, the DSP is normally reset (the

PLL is not initialized).

CLKIN

10241 2048

RESET

PLL initialization

(internal status)

Approx. 100 s

PLL lock time

PLL initialization

mode

µ

Caution Do not deassert the RESET signal inactive in the PLL initialization mode and during PLL lock

period.

5. FUNCTIONS OF BOOT-UP ROM

To rewrite the contents of the instruction memory on power application or from program, boot up the instruction

RAM by using the internal boot-up ROM.

The µPD77113A and 77114 have a function to verify the contents of the internal instruction RAM and a function to

modify the instruction ROM in the boot-up ROM.

5.1 Boot at Reset

After hardware reset has been cleared, the boot program first reads the general-purpose I/O ports P0 and P1 and,

depending on their bit pattern, determines the boot mode (self boot or host boot). After boot processing, processing

is executed starting from the instruction at address 0x200 (reset entry) of the instruction memory.

The pins (P0 and P1) that specify the boot mode must be kept stable for the duration of 3 clocks before and for

the duration of 12 clocks after reset has been cleared (the clock is input from CLKIN).

If host boot or self boot is specified, a self-check of the internal data RAM is performed at the same time as boot

processing.

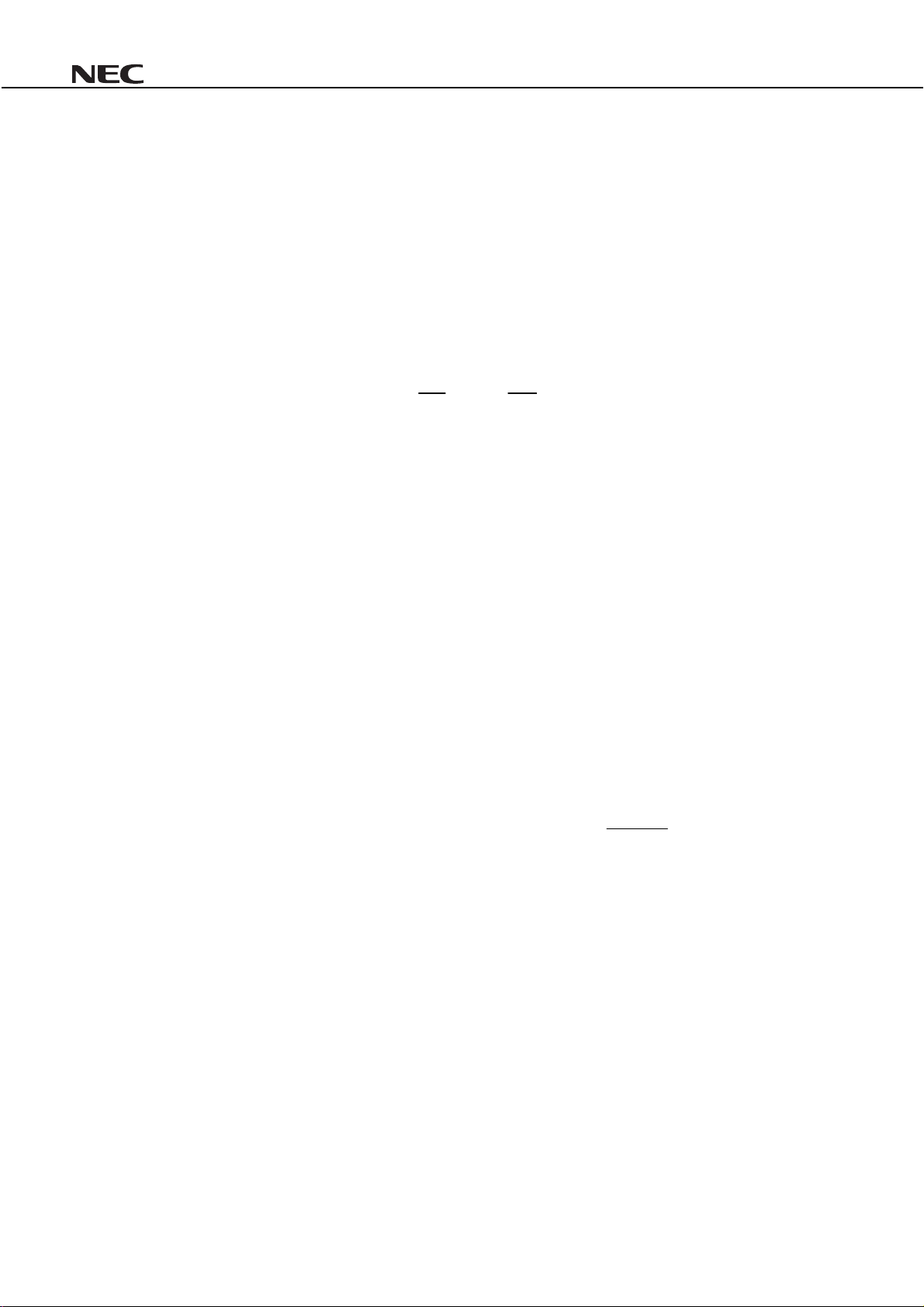

P1 P0 Boot Mode

Note

00

0 1 Ex ecutes host boot and then branches to address 0x200.

1 1 Ex ecutes self boot and then branches to address 0x200.

1 0 Set ting prohibited

Does not execute boot but branc hes to address 0x200

.

This setting is used when the DSP must be reset to recover from the standby mode after reset boot has

Note

been executed once.

Data Sheet U14373EJ3V0DS

21

Page 22

µµµµ

PD77113A, 77114

5.1.1 Self boot

The boot-up ROM transfers the instruction code stored in the data memory space to the instruction RAM, based

on the boot parameter written to address 0x4000 of the Y data memory. Generally, with a mask ROM model, this

function is implemented by storing the instructions to be booted in the data ROM.

In addition, the instructions to be booted can be also stored in an external data area in the form of flash ROM, and

self boot can be executed from this external data area.

5.1.2 Host boot

In this boot mode, a boot parameter and instruction code are obtained via the host interface, and transferred to the

instruction RAM.

5.2 Reboot

By calling the next reboot entry from the program, the contents of the instruction RAM can be rewritten.

Reboot Mode Entry Address

Self boot

Y memory

Host boot Host reboot 0x5

5.2.1 Self reboot

The instruction codes stored in the data memory are transferred to the instruction RAM.

Set the following parameters and call the entry address of the corresponding reboot mode to execute self reboot.

• R7L: Number of instruction steps for rebooting

• DP3: First address of X memory in which instruction codes are stored (in the case of reboot from X memory),

or first address of the instruction memory to be loaded (in the case of reboot from Y memory)

• DP7: First address of instruction memory to be loaded (in the case of reboot from X memory), or first address

of X memory in which instruction codes are stored (in the case of reboot from Y memory)

5.2.2 Host reboot

An instruction code is obtained via the host interface and transferred to the instruction RAM.

The entry address of is 0x5. Host reboot is executed by calling this address after setting the following parameter:

Word reboot 0x2X memory

Byte reboot 0x4

Word reboot 0x1

Byte reboot 0x3

• R7L: Number of instruction steps for rebooting

• DP3: First address of instruction memory to be loaded

22

Data Sheet U14373EJ3V0DS

Page 23

µµµµ

PD77113A, 77114

5.3 Signature Operation

The µPD77113A and 77114 have a signature operation function so that the contents of the internal instruction

RAM can be verified. The signature operation performs a specific arithmetic operation on the data in the instruction

RAM booted up, and returns the result to a register. Perform the signature operation in advance on the device when

it is operating normally, and repeat the signature operation later to check whether the data in RAM is correct by

comparing the operation result with the previous result. If the results are identical, there is no problem.

The entry address is 0x9. Execute the operation by calling this address after setting the following parameter. The

operation result is stored in register R7.

• R7L: Number of instruction steps for operation

• DP3: First address of instruction memory for operation

5.4 Instruction ROM Modification

The µPD77113A and 77114 have a function to modify the contents of the internal instruction mask ROM.

Instructions at up to four addresses can be modified.

The entry address is 0x10D. By calling this address with the following parameters, modification is performed.

R7L : Address of instruction ROM to be modified

R6H, R6L : Instruction code (32 bits)

Data Sheet U14373EJ3V0DS

23

Page 24

µµµµ

PD77113A, 77114

6. STANDBY MODES

Two standby modes are available. By executing the corresponding instruction, each mode is set and the power

consumption can be reduced.

6.1 HALT Mode

To set this mode, execute the HALT instruction. In this mode, functions other than clock circuit and PLL are

stopped to reduce the current consumption.

To release the HALT mode, use an interrupt or hardware reset. When releasing the HALT mode using an

interrupt, the contents of the internal registers and memory are retained. It takes several 10 system clocks to release

the HALT mode when the HALT mode is released using an interrupt.

In the HALT Mode, the clock circuit of the µPD77111 family supplies the following clock as the internal system

clock. The clock output from the CLKOUT pin is also as follows.

The clock output from the CLKOUT pin, however, has a high-level width that is equivalent to 1 cycle of the normal

operation (i.e., the duty factor is not 50%).

PD77113A, 77114: 1/l of internal system clock (l = integer from 1 to 16, specified by mask option)

•

µ

6.2 STOP Mode

To set this mode, execute the STOP instruction. In this mode, all the functions, including the clock circuit and

PLL, are stopped and the power consumption is minimized with only leakage current flowing.

To release the STOP mode, use hardware reset or WAKEUP pin.

When releasing the STOP mode by using the WAKEUP pin, the contents of the internal registers and memory are

retained, but it takes several 100 µs to release the mode.

The WAKEUP pin is multiplexed with the INT4 pin. Usually, this pin functions as an interrupt pin, but functions as

the WAKEUP pin when it is asserted active in the STOP mode. Whether the WAKEUP pin is used to release the

STOP mode is selected by mask option. For details, refer to

8.2 WAKEUP Function

.

24

Data Sheet U14373EJ3V0DS

Page 25

µµµµ

PD77113A, 77114

7. MEMORY MAP

A Harvard architecture, in which the instruction memory space and data memory space are separated is

employed.

7.1 Instruction Memory

7.1.1 Instruction memory map

The instruction memory space consists of 64K words × 32 bits, and the capacity and type of the memory differ

depending on the product.

µ

PD77113A, 77114

0x FFFF

Internal instruction

ROM

(48K words)

00xx430

0F0

F

F

00xx100F0F0

F

00xx0022430

F

00xx00210F0

F

00xx00100F0

F

0x0000

System

Internal instruction RAM

(3.5K words)

Vector area (64 words)

System

Boot-up ROM

(256 words)

Caution Programs and data cannot be placed at addresses reserved for the system, nor can these

addresses be accessed. If these addresses are accessed, the normal operation of the device

cannot be guaranteed.

Data Sheet U14373EJ3V0DS

25

Page 26

µµµµ

PD77113A, 77114

7.1.2 Interrupt vector table

Addresses 0x200 through 0x23F of the instruction memory are entry points (vectors) of interrupts. Four

instruction addresses are assigned to each interrupt source.

Vector Interrupt Source

0x200 Reset

0x204

0x208

0x20C

0x210 INT1

0x214 INT2

0x218 INT3

0x21C INT4

0x220 SI1 input

0x224 SO1 output

0x228 SI2 input

0x22C SO2 output

0x230 HI input

0x234 HO output

0x238

0x23C

Reserved

Reserved

Cautions 1. Although reset is not an interrupt, it is handled like an interrupt as an entry to a vector.

2. It is recommended that unused interrupt source vectors be used to branch an error

processing routine.

3. Because a vector area also exists in the internal RAM area of the mask ROM model, this

area must be booted up. In addition, because the entry address after reset is 0x200,

address 0x200 must be booted up even when the internal instruction RAM and interrupts are

not used.

26

Data Sheet U14373EJ3V0DS

Page 27

µµµµ

PD77113A, 77114

7.2 Data Memory

7.2.1 Data memory map

The data memory space consists of an X memory space and a Y memory space of 64K words × 16 bits each, and

the memory capacity and memory type differ depending on the product.

µ

0x FFFF

00xxED0

0F0

F

00xxCB0F0F0

F

F

PD77113A

Data RAM

(8K words)

System

µ

PD77114

Data RAM

(8K words)

External data

memory

(8K words)

00xx430F0F0

00xx3388430

00xx33870F0

00xx320F0F0

00xx210F0F0

00xx100F0F0

0x0000

F

F

F

F

F

F

Data ROM

(32K words)

System

Peripheral

(64 words)

System

Data RAM

(4K words)

System

Data RAM

(4K words)

Data ROM

(32K words)

System

Peripheral

(64 words)

System

Data RAM

(4K words)

System

Data RAM

(4K words)

Caution Programs and data cannot be placed at addresses reserved for the system, nor can these

addresses be accessed. If these addresses are accessed, the normal operation of the device

cannot be guaranteed.

Data Sheet U14373EJ3V0DS

27

Page 28

µµµµ

PD77113A, 77114

7.2.2 Internal peripherals

The internal peripherals are mapped to the internal data memory space.

X/Y Memory Address Register Name Function Peripheral Name

0x3800 SDT1 First serial data register

0x3801 SST1 Firs t serial status register

0x3802 SDT2 Second serial data regist er

0x3803 SST2 Sec ond serial status register

0x3804 PDT Port data register

0x3805 PCD Port command regis ter

0x3806 HDT Host data register

0x3807 HST Host status register

0x3808 DWTR Data memory wait cycle register WTR

0x3809 - 0x383F Reserved area

Caution Do not access this area.

SIO

PIO

HIO

−

Cautions 1. The register names listed in this table are not reserved words of the assembler or the C

language. Therefore, when using these names in assembler or C, the user must define

them.

2. The same register is accessed, as long as the address is the same, regardless of whether

the X memory space or Y memory space is accessed.

3. Even different registers cannot be accessed at the same time from both the X and Y memory

spaces.

8. MASK OPTION

The µPD77113A and 77114 have mask options that must be specified when an order for a ROM is placed. This

section explains these mask options. The mask options are specified in the Workbench (WB77016) development

tool. To order a mask ROM, output a mask ROM ordering file format (.msk file) using WB77016.

8.1 Clock Control Options

The following four clock related options must be specified.

• PLL multiple

• Output division ratio

• HALT division ratio

• Validity of CLKOUT pin

28

Data Sheet U14373EJ3V0DS

Page 29

µµµµ

PD77113A, 77114

When the PLL multiple is m, output division ratio is n, and halt division ratio is l, the relationship between each

operation mode and operating clock is as follows:

Operation Mode Clock S uppl i ed Inside DSP

Normal operation mode m/n times external input cl ock

HALT mode m/n/l times ex t ernal i nput clock

STOP mode S topped

The PLL control circuit multiplies the input clock by an integer from 1 to 16. Specify the mask option of the PLL

multiple so that the multiplied frequency falls within the specified PLL lock frequency range.

The output divider divides the clock multiplied by the PLL by an integer from 1 to 16. Specify the mask option of

the output division ratio so that the frequency m/n times the external input clock supplied to the DSP falls within the

specified operating frequency range of the DSP.

The HALT divider functions only in the HALT mode. It divides the clock of the output divider by an integer from 1

to 16 and supplies the divided clock to the internal circuitry. Specify the mask option of the HALT division ratio so

that necessary division can be performed.

Whether the clock supplied to the internal circuitry of the DSP (internal system clock) is “output” or “not output”

from the CLKOUT pin can be specified. Specify the mask option as necessary.

If an odd value (other than 1) is specified as the output division ratio, the high-level width of the clock output from

the CLKOUT pin is equal to one cycle during normal operation (i.e., the clock does not have a duty factor of 50%).

8.2 WAKEUP Function

The WAKEUP pin can be used to release the STOP mode as well as a hardware reset.

If the STOP mode is released by means of a hardware reset, the status before the STOP mode was set cannot be

restored after the STOP mode has been released. If the WAKEUP pin is used, however, the status before the STOP

mode is set can be retained and program execution can be resumed starting from the instruction after the STOP

instruction.

Whether the WAKEUP pin is used to release the STOP mode can be specified by a mask option.

When the WAKEUP function is specified valid, the WAKEUP pin is multiplexed with the INT4 pin and it usually

functions as an interrupt pin. The pin functions as the WAKEUP pin only in the STOP mode (if this pin is asserted

active in the STOP mode, it is used only to release the STOP mode, and execution does not branch to an interrupt

vector).

Data Sheet U14373EJ3V0DS

29

Page 30

µµµµ

PD77113A, 77114

9. INSTRUCTIONS

9.1 Outline of Instructions

An instruction consists of 32 bits. Almost all the instructions, except some such as branch instructions, are

executed with one system clock. The maximum instruction cycle of the µPD77113A and 77114 is 13.3 ns. The

following nine types of instructions are available:

(1) Trinomial operation instructions

These instructions specify an operation by the MAC. As the operands, three general-purpose registers can be

specified.

(2) Binomial operation instructions

These instructions specify an operation by the MAC, ALU, or BSFT. As the operands, two general-purpose

registers can be specified. An immediate value can be specified for some of these instructions, instead of a

general-purpose register, for one input.

(3) Uninominal operation instructions

These instructions specify an operation by the ALU. As the operands, one general-purpose register can be

specified.

(4) Load/store instructions

These instructions transfer 16-bit values between memory and a general-purpose register. Any general-purpose

register can be specified as the transfer source or destination.

(5) Register-to-register transfer instructions

These instructions transfer data from one general-purpose register to another.

(6) Immediate value setting instructions

These instructions write an immediate value to a general-purpose register and the registers of the address

operation unit.

(7) Branch instructions

These instruction specify branching of program execution.

(8) Hardware loop instructions

These instruction specify repetitive execution of an instruction.

(9) Control instructions

These instructions are used to control the program.

30

Data Sheet U14373EJ3V0DS

Page 31

µµµµ

PD77113A, 77114

9.2 Instruction Set and Operation

An operation is written in the operation field for each instruction in accordance with the operation representation

format of that instruction. If two or more parameters can be written, select one of them.

(a) Representation formats and selectable registers

The following table shows the representation formats and selectable registers.

Representation Format Selectable Register

r0, r0′, r0

rI, rI

rh, rh

re R0E - R7E

reh R0EH - R7EH

dp DP0 - DP7

dn DN0 - DN7

dm DMX, DMY

dpx DP0 - DP3

dpy DP4 - DP7

dpx_mod DPn, DPn++, DPn−−, DPn##, DPn%%, !DPn## (n = 0 - 3)

dpy_mod DPn, DPn++, DPn−−, DPn##, DPn%%, !DPn## (n = 4 - 7)

dp_imm DPn##imm (n = 0 - 7)

*xxx Contents of memory with address xxx

″

′

′

R0 - R7

R0L - R7L

R0H - R7H

<Example> I f the contents of the DP0 register are 1000, *DP 0 i ndi c ates the contents of

address 1000 of the memory.

Data Sheet U14373EJ3V0DS

31

Page 32

µµµµ

PD77113A, 77114

(b) Modifying data pointer

The data pointer is modified after the memory has been accessed. The result of modification becomes valid

starting from the instruction that immediately follows. The data pointer cannot be modified.

Example Operation

DPn Nothing is done (value of DPn is not changed.)

DPn++ DPn ← DPn + 1

DPn

−−

DPn## DPn ← DPn + DNn

DPn%%

!DPn## Reverses bits of DPn and t hen ac cesses memory.

DPn##imm DPn ← DPn + imm

DPn ← DPn − 1

(Adds value of correspondi ng DN0 to DN7 to DP0 to DP7.)

Example: DP0 ← DP0 + DN0

(n = 0 - 3) DPn = ((DPL + DNn) mod (DMX + 1)) + DP

(n = 4 - 7) DPn = ((DP

After memory access, DPn ← DPn + DNn

L

+ DNn) mod (DMY + 1)) + DP

H

H

(c) Instructions that can be simultaneously written

Instructions that can be simultaneously written are indicated by √.

(d) Status of overflow flag (OV)

The status of the overflow flag is indicated by the following symbol:

: Not affected

z

: Set to 1 when overflow occurs

Caution If an overflow does not occur as a result of an operation, the overflow flag is not reset but

retains the status before the operation.

32

Data Sheet U14373EJ3V0DS

Page 33

Instruction Set

Instruction

Instruction

Name

Mnemonic Operation

µµµµ

PD77113A, 77114

Instructions Si m ul taneously Written Flag

Trinomial

Binomial

Uninominal

Load/

store

Transfer

Immediatevalue

Branch

Loop

Control

OV

Trinomial

operation

Binomial

operation

Multiply add ro = ro + rh * rh

Multiply sub ro = ro − rh * rh

Sign unsign

multiply add

ro = ro + rh * rl

(rl is in positive integer

′

′

ro ← ro + rh * rh

ro ← ro − rh * rh

ro ← ro + rh * rl

format.)

Unsign unsign

multiply add

ro = ro + rl * rl

′

(rl and rl’ are in positive

ro ← ro + rl * rl

integer format.)

ro

+ rh * rh

1-bit shift

ro = (ro>>1) + rh * rh

ro ←

′

2

multiply add

ro

+ rh * rh

ro ←

16-bit shift

ro = (ro>>16) + rh * rh

′

16

2

multiply add

Multiply ro = rh * rh

Add ro″ = ro + ro

′

′

ro ← rh * rh

ro″ ← ro + ro

′√

Immediate add ro′ = ro + imm ro′ ← ro + imm

(where imm ≠ 1)

Sub ro″ = ro − ro

′

ro″ ← ro − ro

Immediate sub ro′ = ro − imm ro ← ro − imm

(where imm ≠ 1)

Arithmetic right

ro′ = ro SRA rl ro′ ← ro >> rl

shift

Immediate

ro′ = ro SRA imm ro′ ← ro >> imm

arithmetic right

shift

Logical right

ro′ = ro SRL rl ro′ ← ro >> rl

shift

Immediate

ro′ = ro SRL imm ro′ ← ro >> imm

logical right

shift

Logical left shift ro′ = ro SLL rl ro′ ← ro << rl

Immediate

ro′ = ro SLL imm ro′ ← ro << imm

logical left shift

AND ro″ = ro & ro

Immediate

ro′ = ro & imm ro′ ← ro & imm

′

ro″ ← ro & ro

AND

OR ro″ = ro ro

′

ro″ ← ro ro

Immediate OR ro′ = ro imm ro′ ← ro imm

Exclusive OR ro″ = ro ∧ ro

Immediate

ro′ = ro ∧ imm ro′ ← ro ∧ imm

′

ro″ ← ro ∧ ro

exclusive OR

′√

′√

√

′√

′

′

√

√

′√

′√

√

√

√

′√

′√

′√

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Data Sheet U14373EJ3V0DS

33

Page 34

Instruction

Binomial

operation

Uninominal

operation

Instruction

Name

Less than ro″ = LT (ro, ro′)

Clear CLR (ro)

Mnemonic Operation

if (ro < ro′)

″ ←

{ro

0x0000000001}

″ ←

else {ro

0x0000000000}

ro ← 0x0000000000

Increment ro′ = ro + 1 ro′ ← ro + 1

Decrement ro′ = ro − 1ro

′ ←

ro − 1

Absolute value ro′ = ABS (ro) if (ro < 0)

{ro′ ← −ro}

else {ro′ ← ro}

1’s

ro′ = ~ro ro′ ← ~ro

complement

2’s

ro′ = −ro ro′ ← −ro

complement

Clip ro′ = CLIP (ro)

if ( ro > 0x007FFFFFFF)

′ ←

{ro

0x007FFFFFFF}

elseif {ro < 0xFF80000000}

{ro′ ← 0xFF80000000}

′ ←

else {ro

ro}

µµµµ

PD77113A, 77114

Instructions Si m ul taneously Written Flag

Trinomial

Binomial

Uninominal

Load/

store

Transfer

Immediatevalue

Branch

√

√√

√√

√√

√√

√√

√√

√√

Loop

Control

OV

z

z

z

z

Round ro′ = ROUND (ro)

if (ro > 0x007FFF0000)

′ ←

{ro

0x007FFF0000}

elseif {ro < 0xFF80000000}

{ro′ ← 0xFF80000000}

′ ←

else {ro

& 0xFFFFFF0000}

Exponent ro′ = EXP (ro)

ro′ ← log

Substitution ro′ = ro ro′ ← ro

Accumulated

ro′ + = ro ro′ ← ro′ + ro

addition

Accumulated

ro′ − = ro ro′ ← ro′ − ro

subtraction

Division ro′ / = ro

if (sign (ro′) == sign (ro))

′ ←

{ro

(ro′ − ro) << 1}

else

′ ←

{ro

(ro′ + ro)<<1}

if (sign (ro

′ ←

{ro

ro′ + 1}

(ro + 0x8000)

1

2

(

)

ro

′

)==0)

√√

√√

√√

z

z

z

√√

√√

√√

34

Data Sheet U14373EJ3V0DS

Page 35

Instruction

Load/

store

Registerto-register

transfer

Immediate

value

setting

Instruction

Name

Parallel

load/store

Partial load/

store

addressing

load/store

Notes 1, 2

Notes 1, 2, 3

Note 4

Immediate

value index

load/store

Note 5

Register-toregister

Note 6

transfer

Immediate

value setting

Mnemonic Operation

ro = *dpx_mod ro′ =

ro ← *dpx, ro′ ← *dpy

*dpy_mod

ro = *dpx_mod

ro ← *dpx, *dpy ←rh

*dpy_mod = rh

*dpx_mod = rh ro =

*dpx ← rh, ro ← *dpy

*dpy_mod

*dpx_mod = rh

*dpy_mod = rh

′

dest = *dpx_mod

dest′ = *dpy_mod

dest = *dpx_mod

*dpy_mod = source

*dpx_mod = source

dest = *dpy_mod

*dpx_mod = source

*dpy_mod = source

*dpx ← rh, *dpy ← rh

dest ← *dpx,

dest′ ← *dpy

dest ← *dpx,

*dpy ← source

*dpx ← source,

dest ← *dpy

*dpx ← source,

*dpy ← source

′

dest = *addr dest ← *addrDirect

*addr = source *addr ← source

dest = *dp_imm dest ← *dp

*dp_imm = source *dp ← source

dest = rl dest ← rl

rl = source rl ← source

rl = imm

rl ← imm

(where imm = 0 to 0xFFFF)

dp = imm

dp ← imm

(where imm = 0 to 0xFFFF)

dn = imm

dn ← imm

(where imm = 0 to 0xFFFF)

dm = imm

dm ← imm

(where imm = 1 to 0xFFFF)

µµµµ

PD77113A, 77114

Instructions Si m ul taneously Written Flag

Trino-

Bino-

Unino-

mial

mial

minal

√√√

Load/

store

Transfer

Immediatevalue

Branch

Loop

Control

OV

z

′

z

′

z

z

√

z

z

Notes 1.

Of the two mnemonics, either one of them or both can be written.

After transfer, modification specified by mod is performed.

2.

Select any of dest, dest’ = {ro, reh, re, rh, rl}, source, source’ = {re, rh, rl}.

3.

Select any of dest = {ro, reh, re, rh, rl}, source = {re, rh, rl},

4.

Select any of dest = {ro, reh, re, rh, rl}, source = {re, rh, rl}.

5.

Select any register other than general-purpose registers as dest and source.

6.

Data Sheet U14373EJ3V0DS

addr =

0: X-0xFFF

0: Y-0xFFFF

: X (X memory)

: Y (Y memory)

.

35

Page 36

Instruction

Instruction

Name

Mnemonic Operation

µµµµ

PD77113A, 77114

Instructions Si m ul taneously Written Flag

Trinomial

Binomial

Uninominal

Load/

store

Transfer

Immediatevalue

Branch

Loop

Control

OV

Branch

Hardware

loop

Jump JMP imm PC ← imm

Register

JMP dp PC ← dp

indirect jump

Subroutine call CALL imm SP ← SP + 1

STK ← PC + 1

PC ← imm

Register

indirect

subroutine call

CALL dp SP ← SP + 1

STK ← PC + 1

PC ← dp

Return RET PC ← STK

SP ← SP − 1

Interrupt return RETI PC ← STK

STK ← SP − 1

Recovery of interrupt

enable flag

Repeat REP count

Start RC ← count

During repeat PC

End PC

Loop LOOP count

Start RC ← count

(instruction of two or

more lines)

During repeat PC

End PC

RF

RC

RF

RF

RC

RF

←

←

←

←

←

←

←

←

←

←

0

PC

RC − 1

PC + 1

1

0

PC

RC − 1

PC + 1

1

√

z

√

z

√

z

√

z

√

z

√

z

z

z

Control

36

Loop hop LPOP LC ← LSR3

LE ← LSR2

LS ← LSR1

LSP ← LSP − 1

No operation NOP PC ← PC + 1

Halt HALT CPU stops.

Stop STOP CPU, PLL, and

OSC stop.

Condition IF (ro cond) Condition test

Forget interrupt FINT Discard interrupt

request

Data Sheet U14373EJ3V0DS

√√√

z

z

z

z

z

z

Page 37

10. ELECTRICAL SPECIFICATIONS

µµµµ

PD77113A, 77114

Absolute Maximum Ratings (TA = +25

C)

°°°°

Parameter Symbol Condition Rating Unit

DD

IV

EV

Input voltage V

Output voltage V

Storage temperature T

Operating temperature T

O

stg

A

DD

I

For DSP core

For I/O pins

VI < EVDD + 0.5 V

0.5 to +3.6 VSupply voltage

−

0.5 to +4.6 V

−

0.5 to +4.1 V

−

0.5 to +4.1 V

−

65 to +150

−

40 to +85

−

Caution Product quality may suffer if the absolute maximum rating is exceeded even momentarily for any

parameter. That is, the absolute maximum ratings are rated values at which the product is on

the verge of suffering physical damage, and therefore the product must be used unber

conditions that ensure that the absolute maximum ratings are not exceeded.

Recommended Operating Conditions

Parameter Symbol Condition MIN. TYP. MAX. Unit

DD

Operating voltage

IV

EV

Input voltage V

For DSP core 1.8 2.7 V

DD

For I/O

pins

I

IVDD = 1.8 to 2.7 V 3.3

DD

IV

= 2.3 to 2.7 V

2.7

0EV

3.6

DD

C

°

C

°

V

V

Capacitance (TA = +25

C, IVDD = 0 V, EVDD = 0 V)

°°°°

Parameter Symbol Condition MIN. TYP. MAX. Unit

Input capacitance C

Output capacitance C

I/O capacitance C

I

f = 1 MHz,

Pins other than those

O

IO

tested: 0 V

10 pF

10 pF

10 pF

Data Sheet U14373EJ3V0DS

37

Page 38

µµµµ

PD77113A, 77114

DC Characteristics (Unless otherwise specified, TA =

operating condition range)

Parameter Symbol Condition MIN. TYP. MAX. Unit

IHN

High-level input voltage

Low-level output voltage V

High-level input leakage

current

Low-level input leakage

current

Pull-up pin current I

Pull-down pin current I

Internal supply current

IHN

[V

IHS

= V

= EVDD, VIL = 0 V,

I

no load]

V

V

V

DD

I

I

V

V

I

I

DDH

DDS

LH

PUI

PDI

Pins other than below 0.7 EV

IHS

CLKIN, RESET,

INT1 - INT4, SCK1, SIEN1,

SOEN1, SCK2, SIEN2, SOEN2

IHC

CLKIN 0.5 EV

IL

Pins other than below 0 0.2 EV

IC

CLKIN 0 0.5 EV

OH

IOH = −2.0 mA 0.7 EV

IOH = −100 µA 0.8 EV

OL

IOL = 2.0 mA 0.2 EV

Other than TDI, TMS, and TRST

I

DD

V

= EV

LL

Other than TDI, TMS, and TRST

I

V

= 0 V

TDI, TMS, 0 V ≤ VI ≤ EV

TRST, 0 V ≤ VI ≤ EV

Note

During operating, 30 ns, IVDD =

2.7 V

In halt mode, tcC = 30 ns,

divided by eight, IV

In stop mode, 0°C < TA < 60°C 100

40 to +85

−−−−

DD

DD

DD

= 2.7 V

C, with IVDD and EVDD within recommended

°°°°

0.8 EV

DD

DD

DD

EV

EV

EV

DD

DD

DD

V

V

V

+0.25

DD

DD

VLow-level input voltage

V

–0.25

DD

DD

DD

010

10 0

−

250 0

−

0 250

VHigh-level output voltage V

V

V

A

µ

A

µ

A

µ

A

µ

TBD 75 mA

TBD 10 mA

A

µ

38

The TYP. values are when an ordinary program is executed.

Note

The MAX. values are when a special program that brings about frequent switching inside the device is

executed.

Data Sheet U14373EJ3V0DS

Page 39

Common Test Criteria of Switching Characteristics

CLKIN, RESET, INT1 - INT4,

SCK1, SIEN1, SOEN1, SCK2,

SIEN2, SOEN2

Input

(other than above)

0.8 EV

0.5 EV

0.2 EV

0.7 EV

0.5 EV

0.2 EV

0.5 EV

µµµµ

PD77113A, 77114

DD

DD

DD

DD

DD

DD

DD

Test points

Test points

Test pointsOutput

0.8 EV

0.5 EV

0.2 EV

0.7 EV

0.5 EV

0.2 EV

0.5 EV

DD

DD

DD

DD

DD

DD

DD

Data Sheet U14373EJ3V0DS

39

Page 40

µ

PD77113A, 77114

A

=

AC Characteristics (T

40 to +85

−−−−

Clock

Timing requirements

Parameter Symbol Condition MIN. TYP. MAX. Unit

CLKIN cycle time

CLKIN high-level width t

CLKIN low-level width t

CLKIN rise/fall time t

requirements

Note 1

Note 3

µµµµ

PD77113A, 77114

C, with IVDD and EVDD within recommended operating condition range)

°°°°

cCX

t

Note 2

IVDD = 1.8

to 2.7 V

PLL lock

range

IVDD = 2.3

25 ns

25 × m 50 × mns

10 × m 50 × mns

to 2.7 V

wCXH

wCXL

rfCX

cC (R)

t

IVDD = 1.8 to 2.7 V 25 nsInternal clock cycle time

12.5 ns

12.5 ns

5ns

IVDD = 2.3 to 2.7 V 13.3 ns

Notes 1.

m: Multiple, n: Division ratio

This is the range in which the PLL is locked (stably oscillates). Input t

2.

cCX

3.

Input t

so that the value of (t

Switching characteristics

Parameter Symbol Condition MIN. TYP. MAX. Unit

Internal clock cycle

CLKOUT cycle time t

CLKOUT width t

CLKOUT rise/fall time t

m: Multiple, n: Division ratio, l: HALT division ratio

Note

Note

cC

t

cCO

wCO

rfCO

dCO

cCX

within this range.

cCX

÷ m × n) satisfies this condition.

During normal operation t

In HALT mode

During

normal

operation

n = 1, or even number

n = odd number

(other than 1)

In HALT mode

tcC ÷ 2 − 3ns

cC

÷ n ÷ 2 − 3

t

tcC ÷ n ÷ 2 − 3

cCX

× n ÷ mns

cCX

t

× n ÷ m × l

cC

t

5ns

IVDD = 1.8 to 2.7 V 20 nsCLK OUT del ay time t

IVDD = 2.3 to 2.7 V 15 ns

ns

ns

ns

ns

40

Data Sheet U14373EJ3V0DS

Page 41

µ

Clock I/O timing

CLKIN

Internal clock

µµµµ

PD77113A, 77114

PD77113A, 77114

t

cCX

t

t

wCXH

t

dCO

t

wCO

t

cC, tcC(R)

t

cCO

t

wCXL

t

wCO

rfCX

t

rfCO

t

rfCX

t

rfCO

CLKOUT

Data Sheet U14373EJ3V0DS

41

Page 42

µ

PD77113A, 77114

Reset, Interrupt

Timing requirements

Parameter Symbol Condition MIN. TYP. MAX. Unit

WAKEUP low-level width t

INT1 - INT4 low-level width t

INT1 - INT4 recovery time t

Notes 1.

The value on power application is the time from when the supply voltages have reached IV

and EVDD = 2.7 V. A stable clock input is also required.

Note that tcC is I (I = integer of 1 to 16) times that during normal operation in the HALT mode.

2.

If the low-level width of RESET is greater than 1024tcC, the PLL initialization mode is triggered. If there

3.

is no need to use the PLL initialization mode, set the width to less than 1024tcC.

When the power is turned on, a recovery period of 4t

4.

w (RL)

rec (R)

w (WAKEUPL)

w (INTL)

rec (INT)

On power application

Note 1

in STOP mode

During normal operation,

in HALT mode

On power application

Note 4

µµµµ

PD77113A, 77114

,

100 +

2048t

cC

4t

4t

cC

4t

cCX

Note 2

Note 2

cCX

Note 3

100

Note 2

cC

3t

cC

3t

cCX

is necessary before inputting RESET.

µ

ns

nsRESET recovery time t

ns

µ

ns

ns

DD

= 1.8 V

sRESET low-level width t

s

Reset timing

RESET

WAKEUP timing

WAKEUP

Interrupt timing

INT1 - INT4

t

w(RL)

t

w (WAKEUPL)

t

w(INTL)

t

rec(R)

t

rec(INT)

42

Data Sheet U14373EJ3V0DS

Page 43

µµµµ

µ

PD77113A, 77114

PD77113A, 77114

External Data Memory Access (

Timing requirements

Parameter Symbol Condition MIN. TYP. MAX. Unit

Read data setup time t

Read data hold time t

Switching characteristics

Parameter Symbol Condition MIN. TYP. MAX. Unit

Address cycle time t

Address output hold time t

MRD output delay time t

Write data output valid ti m e t

Write data output hold time t

MWR output delay time t

MWR output hold time t

MWR low-level width t

MWR high-level width t

PD77114 only)

µµµµ

suDDRD

hDDRD

rcDA

hDA

dDR

vDDWD

hDDWD

dDW

hDA

wDWL

wDWH

18 ns

0ns

Note

cDW

tcC + (tcC × t

)

ns

0ns

5ns

5ns

0ns

0 0.5 t

cC

ns

0ns

cDW

tcC × t

− 3

ns

0.5 tcC − 3ns

Note

cDW

: Number of data wait cycles

t

Data Sheet U14373EJ3V0DS

43

Page 44

µ

PD77113A, 77114

External data memory access timing (read)

DA0 - DA12

X/Y

t

dDR

MRD

D0 - D15

External data memory access timing (write)

DA0 - DA12

t

rcDA

t

suDDRD

µµµµ

PD77113A, 77114

t

dDR

t

hDDRD

X/Y

MWR

D0 - D15

t

t

t

vDDWD

dDW

t

wDWL

rcDA

t

wDWH

t

dDW

t

vDDWD

t

hDA

t

hDDWD

Hi-Z Hi-Z

44

Data Sheet U14373EJ3V0DS

Page 45

µµµµ

µ

PD77113A, 77114

PD77113A, 77114

Bus Arbitration (

PD77114 only)

µµµµ

Timing requirements

Parameter Symbol Condition MIN. TYP. MAX. Unit

HOLDRQ setup time t

HOLDRQ hold time t

Switching characteristics

Parameter Symbol Condition MIN. TYP. MAX. Unit

BSTB hold time t

BSTB output delay ti m e t

HOLDAK output delay time t

Data hold time during bus

arbitration

Data valid time during bus

arbitration

suHRQ

hHRQ

hBS

dBS

dHAK

h (BS-D)

t

v (BS-D)

t

0ns

0ns

0ns

20 ns

18 ns

25 ns

25 ns

Data Sheet U14373EJ3V0DS

45

Page 46

µ

PD77113A, 77114

Bus arbitration timing (when bus is idle)

CLKIN

µµµµ

PD77113A, 77114

(Bus busy) Bus idle

t

hBS

BSTB

suHRQ

t

HOLDRQ

HOLDAK

X/Y, DA0 - DA12,

MRD, MWR

Bus arbitration timing (when bus is busy)

CLKIN

(Bus busy) Bus busy

Bus release Bus idle (Bus busy)

dBS

t

t

t

dHAK

t

h (BS-D)

hHRQ

t

suHRQ

Hi-Z

Bus idle Bus idle (Bus busy)

t

hBS

Bus release

t

dBS

t

dHAK

t

v (BS-D)

t

hHRQ

BSTB

HOLDRQ

HOLDAK

X/Y, DA0 - DA12,

MRD, MWR

t

suHRQ

t

hHRQ

t

dHAK

t

h (BS-D)

Hi-Z

t

suHRQ

t

dHAK

t

v (BS-D)

t

hHRQ

46

Data Sheet U14373EJ3V0DS

Page 47

µ

Serial Interface

Timing requirements

Parameter Symbol Condition MIN. TYP. MAX. Unit

µµµµ

PD77113A, 77114

PD77113A, 77114

SCK cycle time t

SCK high-/low-level widt h t

SCK rise/fall time t

Switching characteristics

cSC

wSC

rfSC

suSOE

hSOE

suSIE

hSIE

suSI

hSI

60 ns

25 ns

20 ns

IVDD = 1.8 to 2.7 V

10

nsSOEN setup time t

IVDD = 2.3 to 2.7 V 5 ns

IVDD = 1.8 to 2.7 V 15 nsSOEN hold time t

IVDD = 2.3 to 2.7 V 10 ns

IVDD = 1.8 to 2.7 V 10 nsSIEN setup time t

IVDD = 2.3 to 2.7 V 5 ns

IVDD = 1.8 to 2.7 V 15 nsSIEN hold time t

IVDD = 2.3 to 2.7 V 10 ns

IVDD = 1.8 to 2.7 V 10 nsSI setup time t

IVDD = 2.3 to 2.7 V 5 ns

IVDD = 1.8 to 2.7 V 15 nsSI hold time t

IVDD = 2.3 to 2.7 V 10 ns

Parameter Symbol Condition MIN. TYP. MAX. Unit

SORQ hold time t

SO hold time t

SIAK hold time t

dSOR

hSOR

dSO

hSO

dSIA

hSIA

IVDD = 1.8 to 2.7 V 30 nsS ORQ output delay time t

IVDD = 2.3 to 2.7 V 25 ns

0ns

IVDD = 1.8 to 2.7 V 30 nsS O output delay time t

IVDD = 2.3 to 2.7 V 25 ns

0ns

IVDD = 1.8 to 2.7 V 30 nsS I AK output delay time t

IVDD = 2.3 to 2.7 V 25 ns

0ns

Data Sheet U14373EJ3V0DS

47

Page 48

µµµµ

µ

PD77113A, 77114

PD77113A, 77114

Caution If noise is superimposed on the serial clock, the serial interface may be deadlocked. Bear in

mind the following points when designing your system: